Electronic ink printing coating compound with pearl effect and preparation method of compound

A technology of electronic ink and pearlescent effect, which is applied in the direction of coating, etc., can solve the problems of complex process, insufficient adhesion of pearlescent varnish layer and electronic ink layer, and restrict the development of personalized electronic ink printing industry, so as to simplify the production process and solve the problem of The effect of poor fastness and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

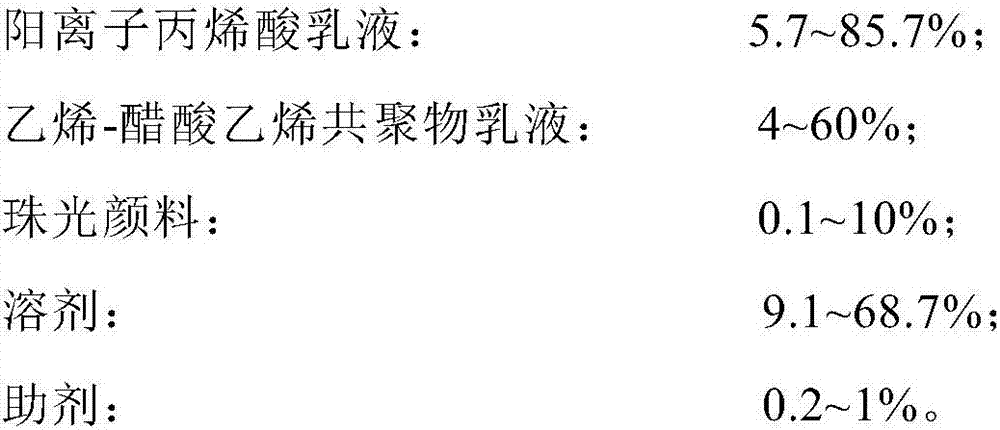

Method used

Image

Examples

Embodiment 1

[0024] Example 1 (following formula all is mass percentage wt%)

[0025] A method for preparing an electronic ink printing coating with pearlescent effect, the method comprises the following processing steps (in the following formula, the solid content of cationic acrylic acid emulsion in the electronic ink printing coating is 35%, and the solid content of VAE emulsion in the electronic ink printing coating is 50%):

[0026] (1) Add cationic acrylic emulsion 5.7 and VAE emulsion 60, stir at 200r / min for 3 minutes

[0027] (2) Add ethanol 5 and deionized water 28.6 in advance to the above emulsion, and stir at 200r / min for 3 minutes;

[0028] (3) Add silicone oil defoamer 0.2, stir at 800r / min for 20 minutes;

[0029] (4) Add pearlescent pigment 0.5 and stir at 1000r / min for 30 minutes.

Embodiment 2

[0030] Example 2 (following formula all is mass percentage wt%)

[0031] A method for preparing an electronic ink printing coating with pearlescent effect, the method comprises the following processing steps (in the following formula, the solid content of cationic acrylic acid emulsion in the electronic ink printing coating is 35%, and the solid content of VAE emulsion in the electronic ink printing coating is 50%):

[0032] (1) Add cationic acrylic emulsion 17.1 and VAE emulsion 12, stir at 200r / min for 3 minutes

[0033] (2) Ethanol 15 and deionized water 53.7 are pre-mixed and added to the above emulsion, and stirred at 200r / min for 3 minutes;

[0034] (3) Add silicone oil defoamer 0.2, stir at 800r / min for 20 minutes;

[0035] (4) Add Pearlescent Pigment 2 and stir at 1000r / min for 30 minutes.

Embodiment 3

[0036] Embodiment 3 ( The following formulas are all mass percent wt%)

[0037] A method for preparing an electronic ink printing coating with pearlescent effect, the method comprises the following processing steps (in the following formula, the solid content of cationic acrylic acid emulsion in the electronic ink printing coating is 35%, and the solid content of VAE emulsion in the electronic ink printing coating is 50%):

[0038] (1) Add cationic acrylic emulsion 85.7 and VAE emulsion 4, stir at 200r / min for 3 minutes

[0039] (2) Ethanol 2 and deionized water 7.1 are pre-mixed and added to the above emulsion, and stirred at 200r / min for 3 minutes;

[0040] (3) Add silicone oil defoamer 0.2, stir at 800r / min for 20 minutes;

[0041] (4) Add Pearlescent Pigment 10 and stir at 1000r / min for 30 minutes.

[0042] The performance of the electronic ink printing coating prepared in Examples 1-3 is evaluated, and the evaluation method is as follows:

[0043] Adhesion to electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com