Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Excellent releasability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

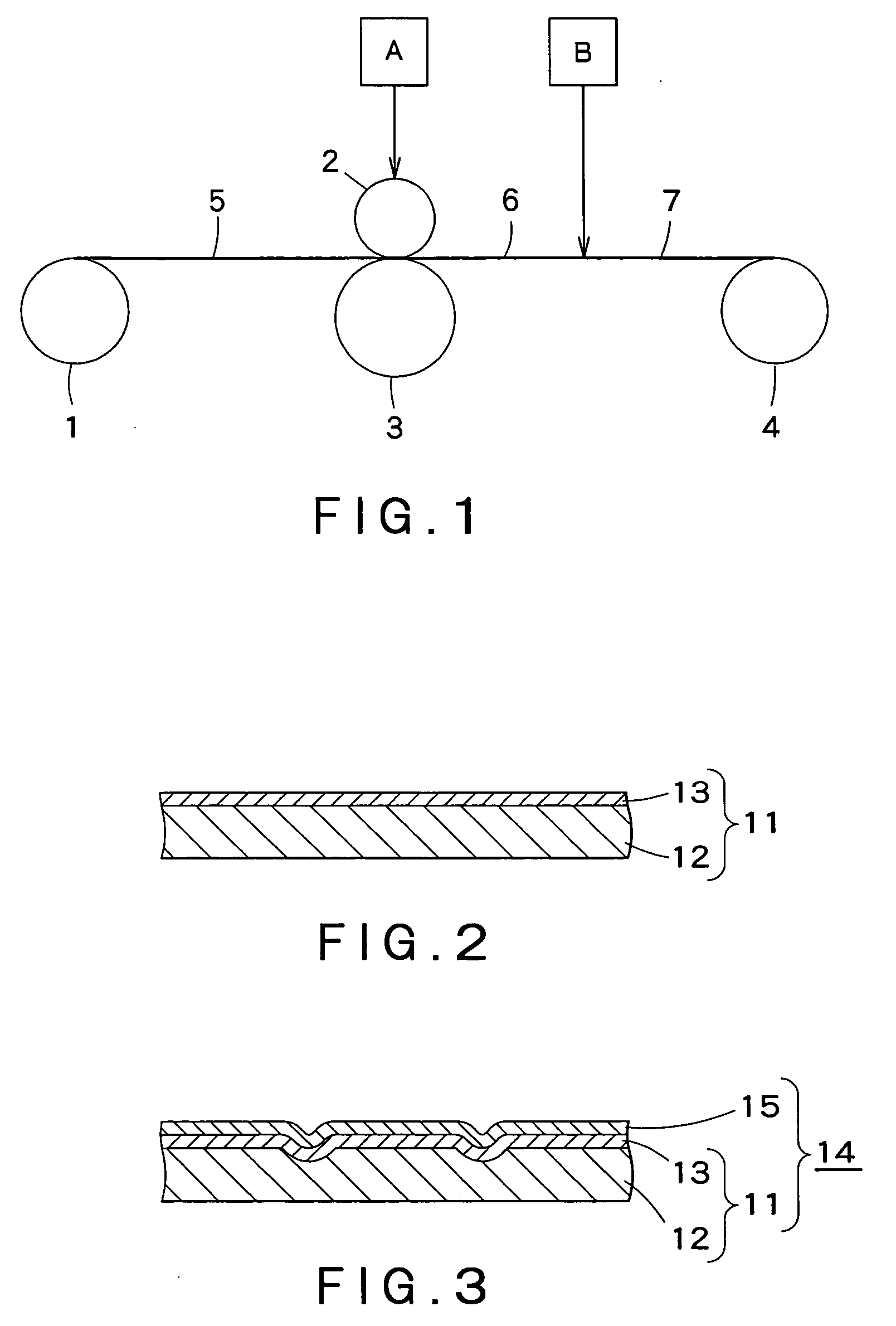

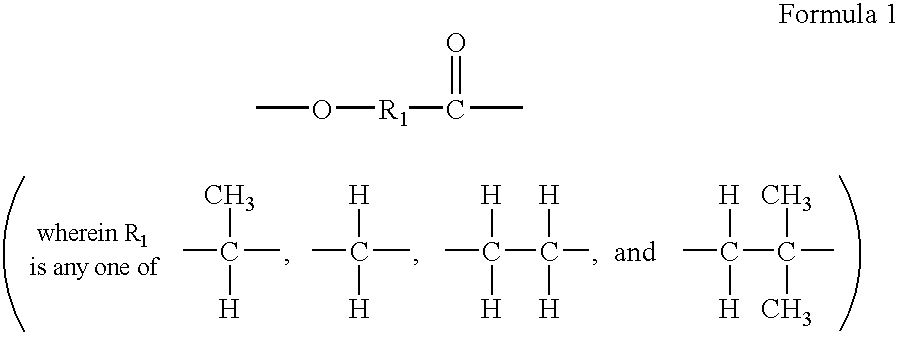

Cellulose acylate laminate film, method for producing same, polarizer and liquid crystal display device

InactiveUS20100055356A1High degree of substitutionExcellent releasabilityLiquid crystal compositionsCellulosic plastic layered productsPolarizerLiquid-crystal display

A stretched cellulose acylate laminate film having a skin layer containing a cellulose acylate with a total degree of acyl substitution of more than 2.7 and a core layer containing a cellulose acylate with a total degree of acyl substitution of 2.0-2.7 wherein the core layer is thicker than the skin B layer and at least one of these layers contains a retardation-controlling agent, is excellent in high expressibility, little optical unevenness and good releasability from a support.

Owner:FUJIFILM CORP

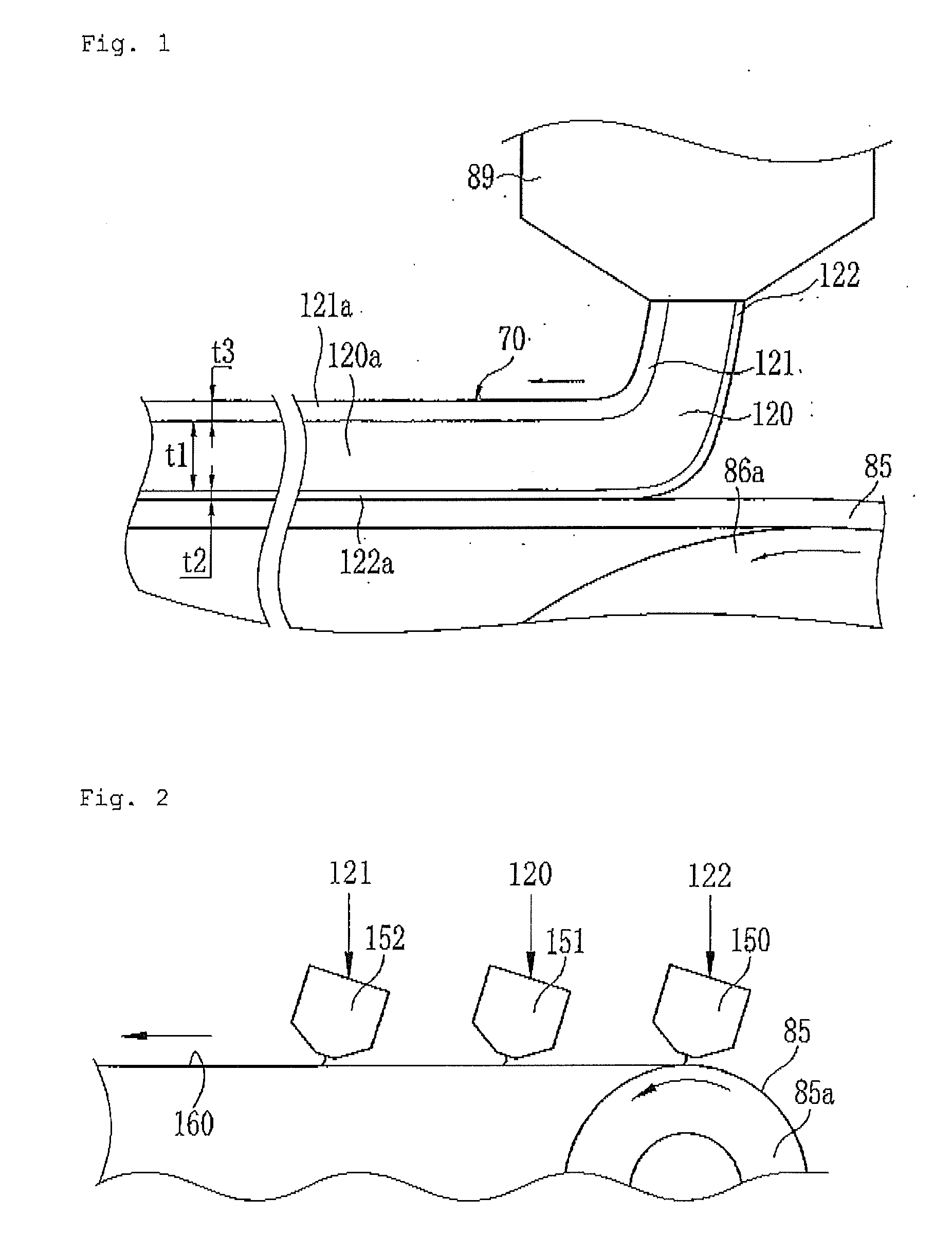

Embossed release paper for synthetic leather production and support therefor, and synthetic leather using the release paper and process for producing the synthetic leather

InactiveUS20070116929A1Excellent embossabilityExcellent releasabilityPaper coatingPaper/cardboardAdhesiveHeat resistance

This invention provides an embossed release paper for synthetic leather production, which has embossability, heat resistance and durability and, at the same time, has excellent separability from a two-pack curing type PU adhesive and can be used in all of synthetic leathers such as PU, PVC, and semisynthetic leathers, and a process for producing the same. The embossed release paper for synthetic leather production comprises at least paper as a support and an ionizing radiation cured film provided on the paper. The upper part of the cured film has been embossed. The ionizing radiation cured film has been formed by applying an ionizing radiation to a coating liquid having a specific composition to cure the coating liquid.

Owner:DAI NIPPON PRINTING CO LTD

Thermoplastic cellulose derivative composition and fiber comprising the same

InactiveUS6984631B2Good fluidityIncrease resistanceOrganic active ingredientsBiocidePolyesterSide chain

A thermoplastic cellulose derivative composition of the present invention contains, as a main component, a cellulose ester having an aliphatic polyester side chain having a repeat unit having 2 to 5 carbon atoms, wherein a rate of heating loss at 200° C. is 5 wt % or less, a melt viscosity at 200° C. and 1000 sec−1 is 50 to 300 Pa·sec, and a melt tension at the time of take-up at 200° C. and 100 m / min is 0.1 to 40 mN. The present invention can provide excellent fiber products by melt spinning of the composition.

Owner:TORAY IND INC

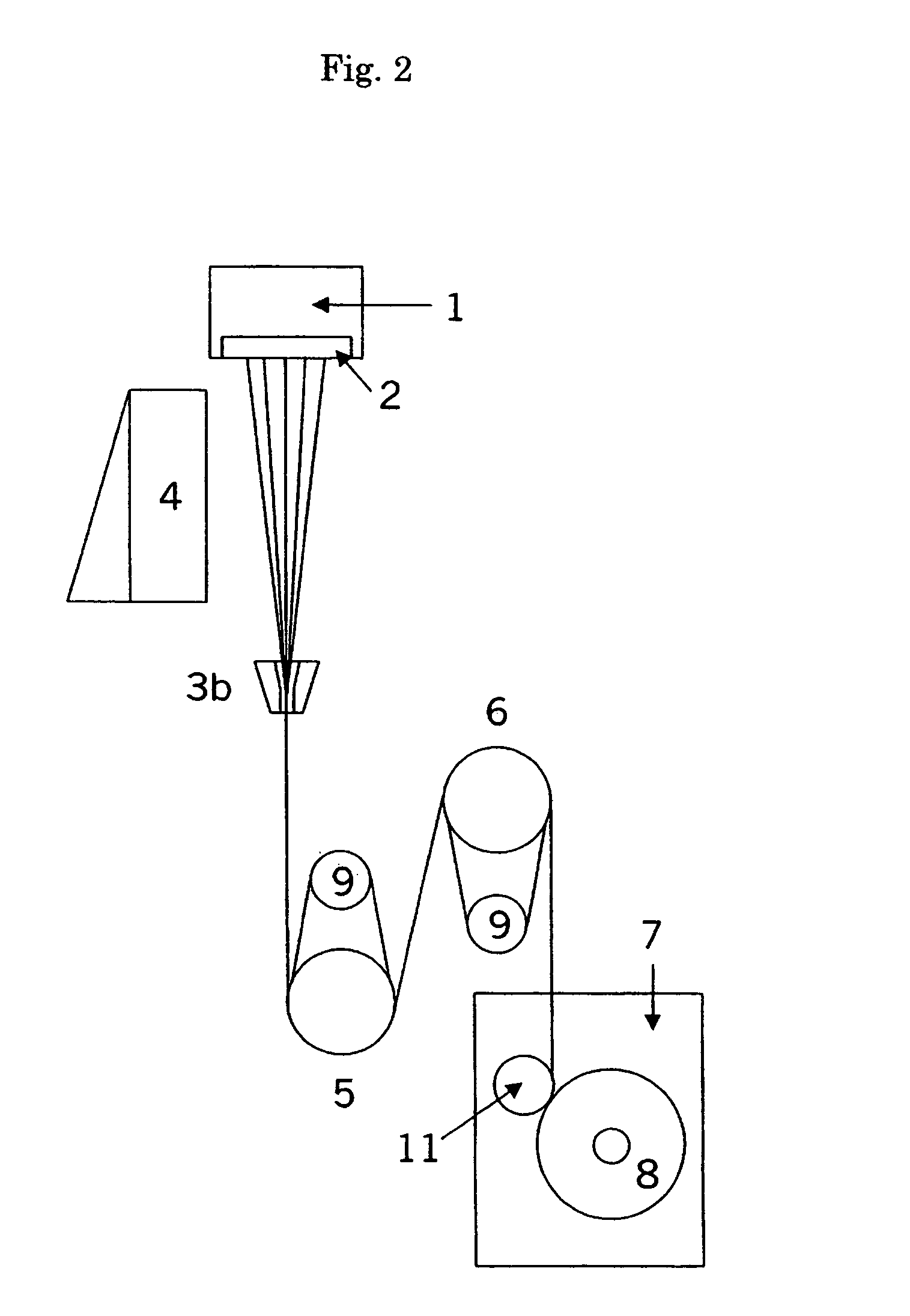

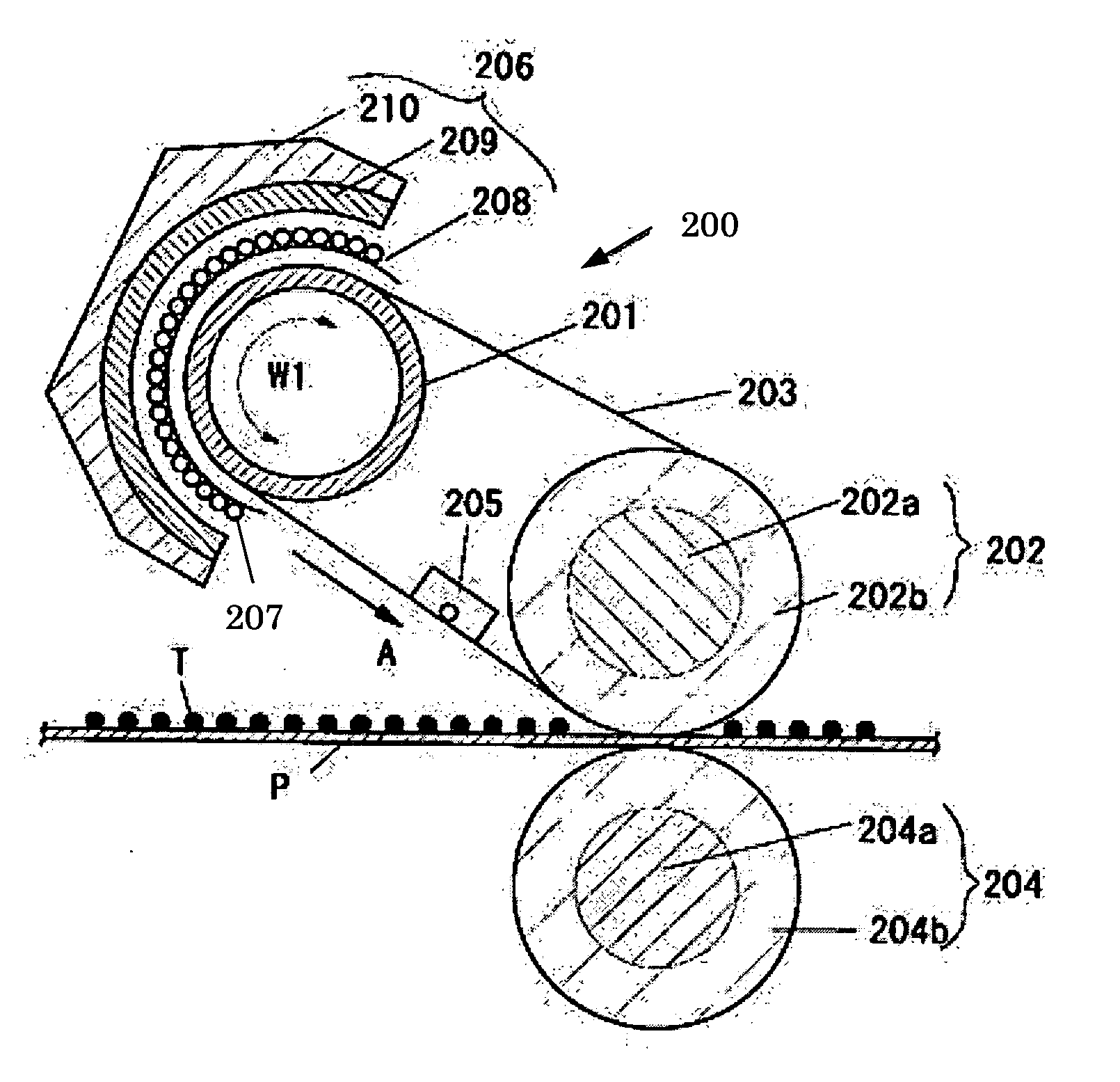

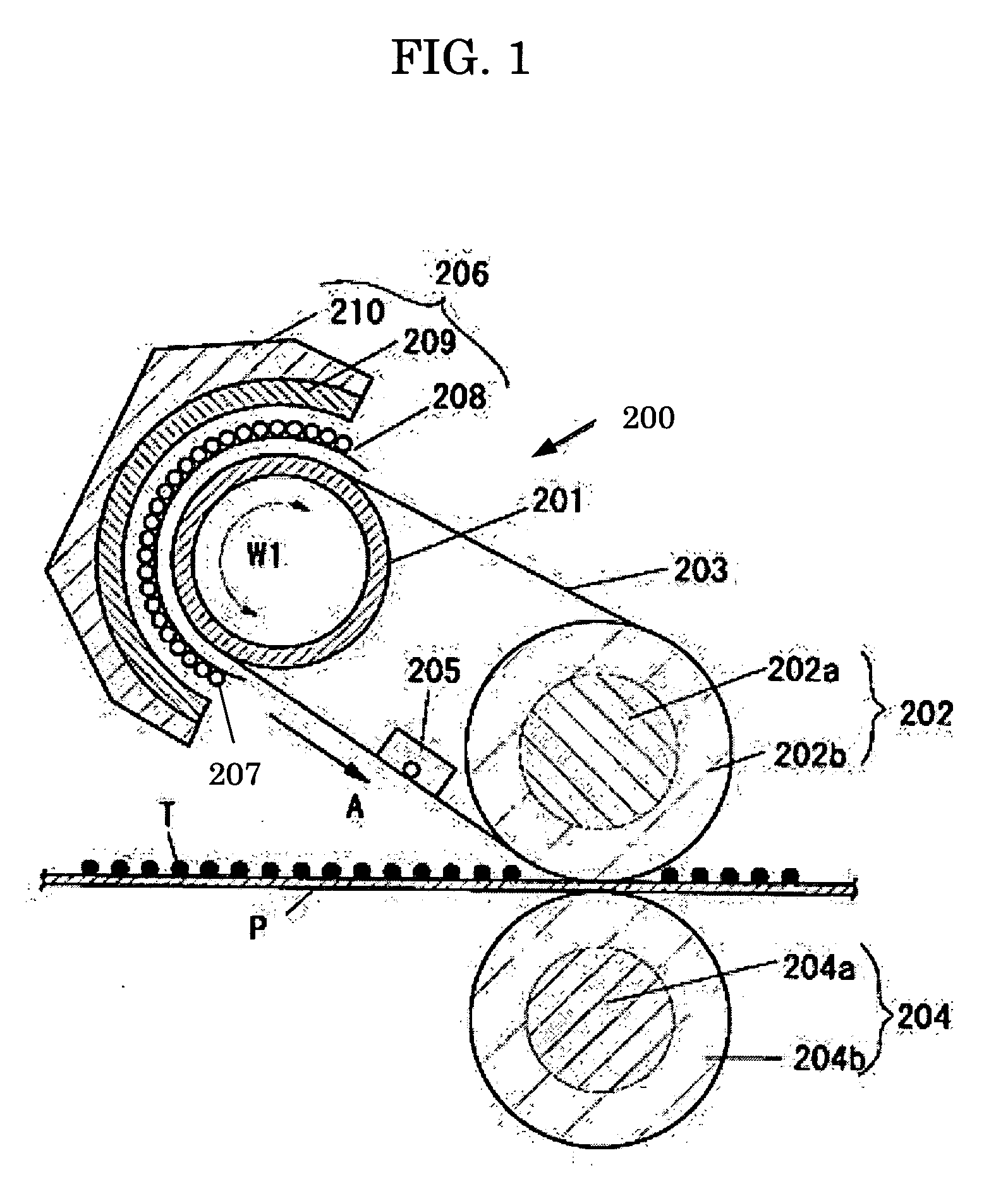

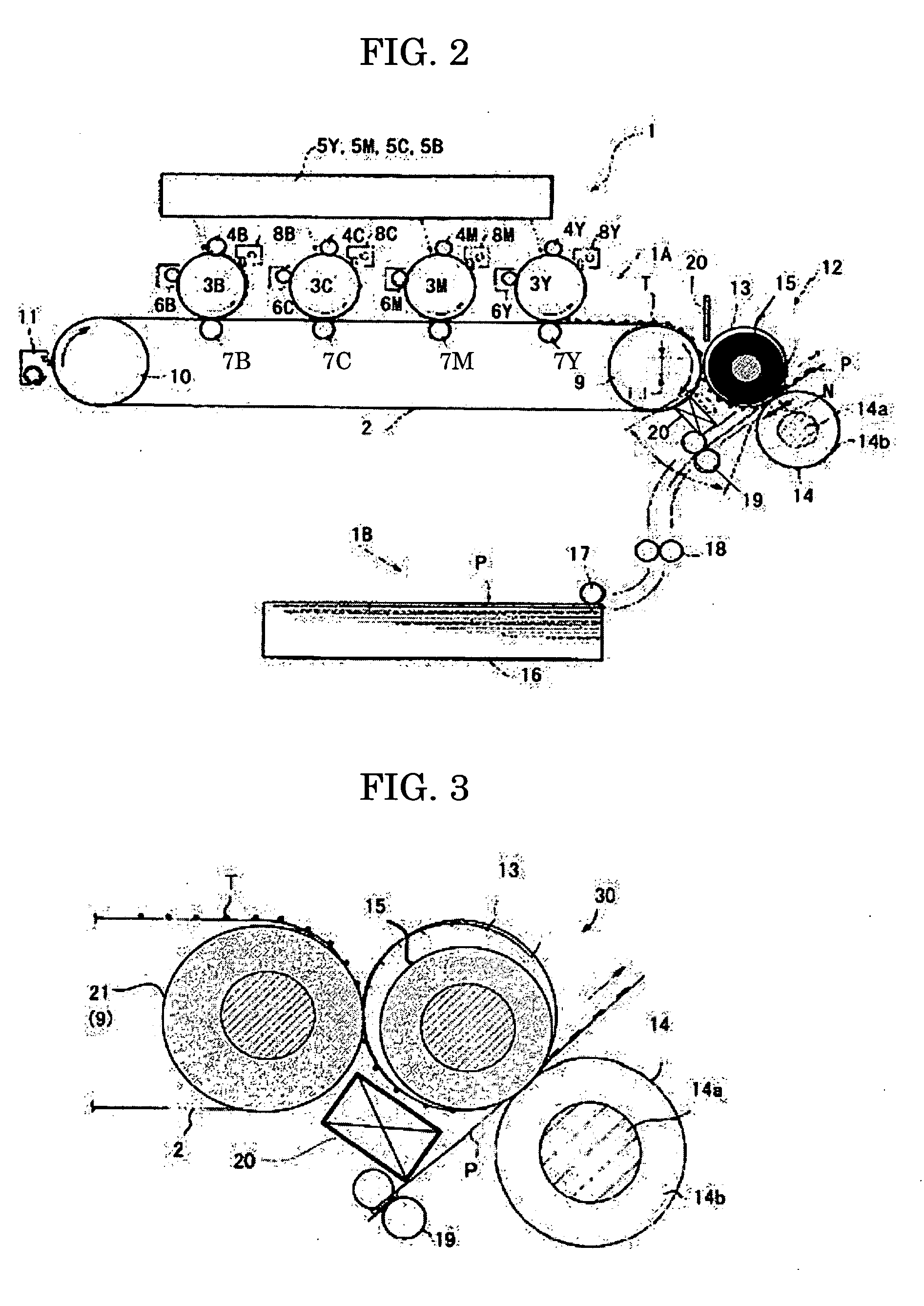

Image-fixing apparatus, and, image-forming apparatus

InactiveUS20060013624A1Excellent releasabilityHigh qualityElectrographic process apparatusElastic modulusEngineering

An image-fixing apparatus including a fixing belt; a fixing member; a pressure member; and a heating source, wherein the fixing belt is heated by the heating source, wherein the fixing member is brought into pressure contact with the pressure member via the fixing belt to form a nip and a paper carrying an unfixed toner is allowed to pass through the nip, thereby fixing the unfixed toner on the paper, and wherein the toner to be used includes a binder resin, a colorant, and a releasing agent, and wherein the toner has a ½ flown-out temperature of 115° C. to 145° C. and has a storage elastic modulus (G′) at 190° C. of 200 Pa or more.

Owner:RICOH KK

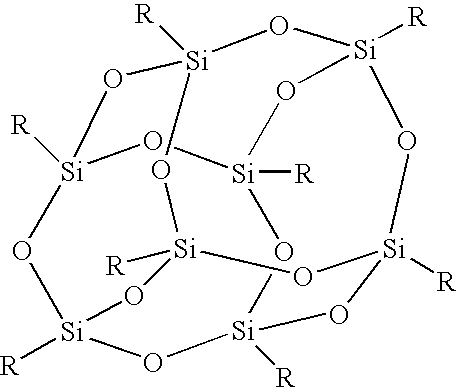

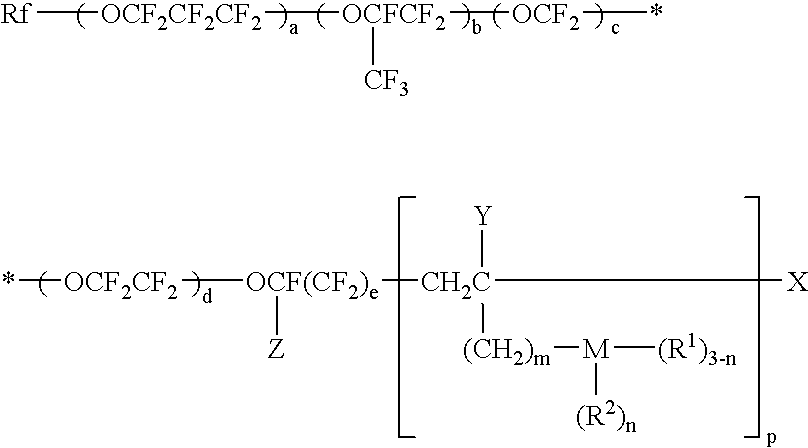

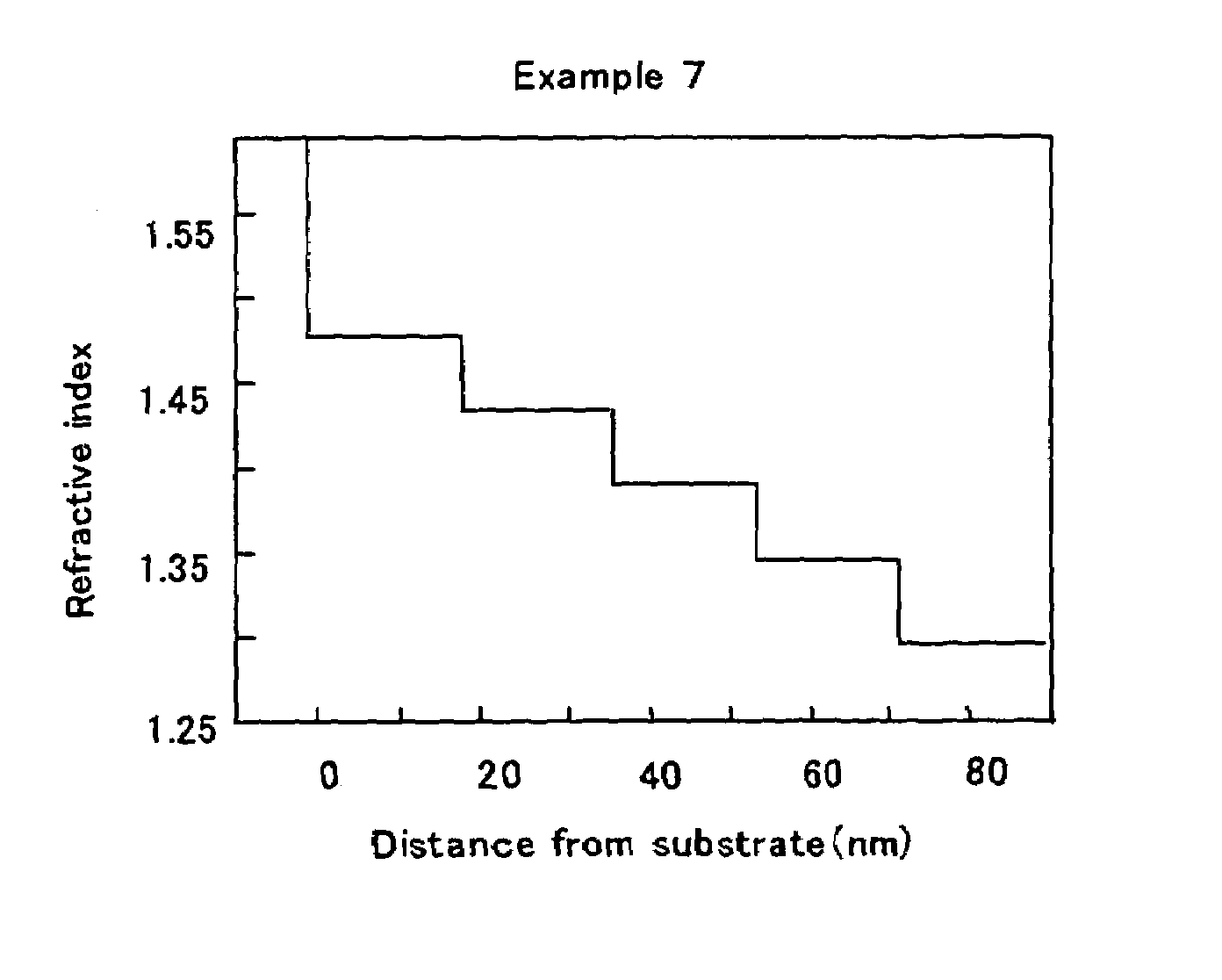

Surface-treating agent comprising inorganic/organic composite material

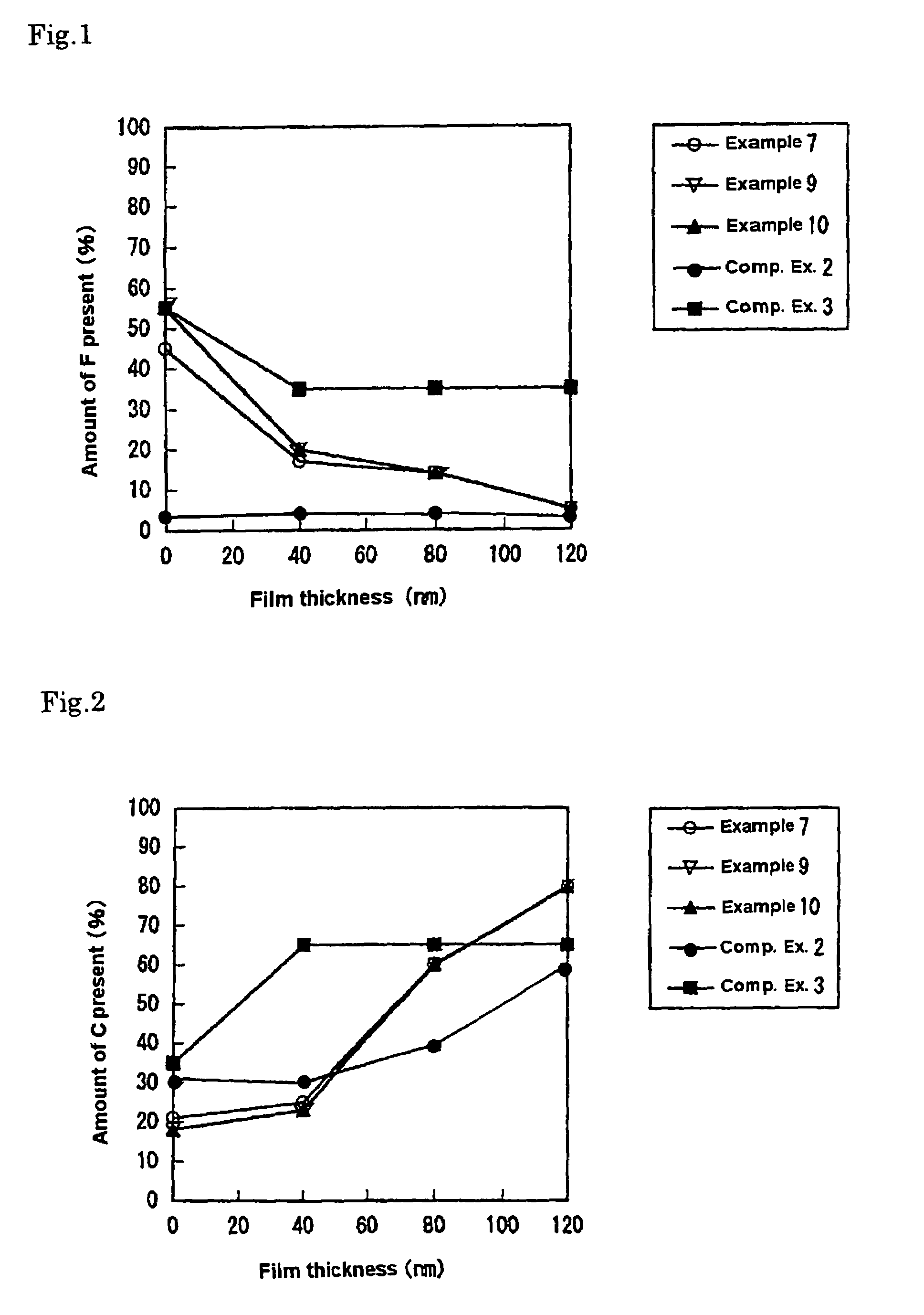

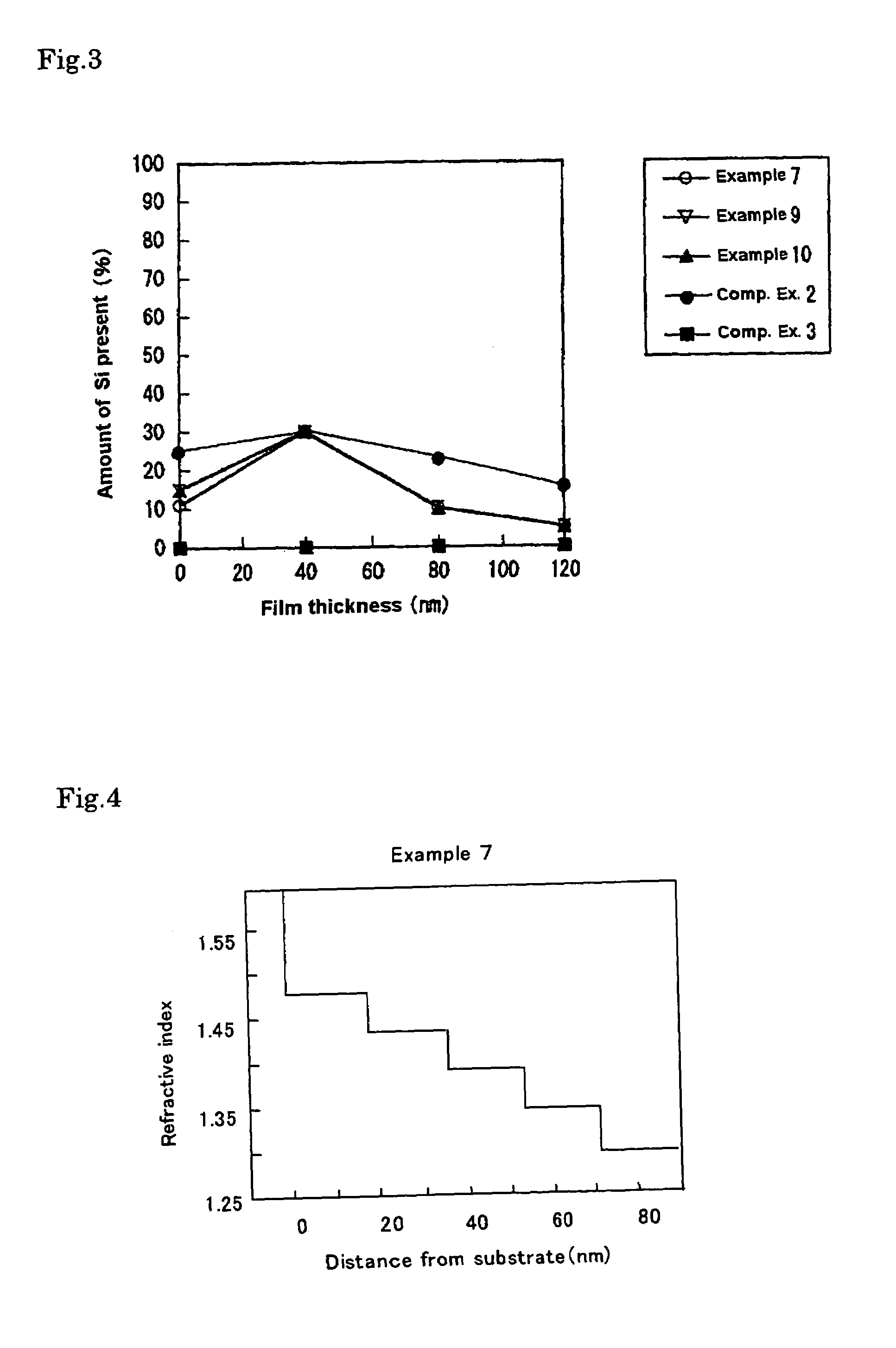

InactiveUS20040186216A1Excellent releasabilityHigh transparencySynthetic resin layered productsOrganic dyesRefractive indexOrganic chemistry

A surface treatment agent, which contains: (A) a hydrolyzable metal alkoxide or a hydrolyzate thereof, (B) a fluorocompound containing a perfluoroalkyl group and a functional group reactive with the hydrolyzable metal alkoxide (A), and (C) an adhesion improvement agent, can provide a film having transparency and durability while maintaining excellent soil releasability and low refractive index.

Owner:DAIKIN IND LTD

Surface treatment agent comprising inorganic-organic hybrid material

InactiveUS7125926B2Excellent releasabilityHigh transparencySynthetic resin layered productsOrganic dyesRefractive indexHybrid material

A surface treatment agent, which contains:(A) a hydrolyzable metal alkoxide or a hydrolyzate thereof,(B) a fluorocompound containing a perfluoroalkyl group and a functional group reactive with the hydrolyzable metal alkoxide (A), and(C) an adhesion improvement agent,can provide a film having transparency and durability while maintaining excellent soil releasability and low refractive index.

Owner:DAIKIN IND LTD

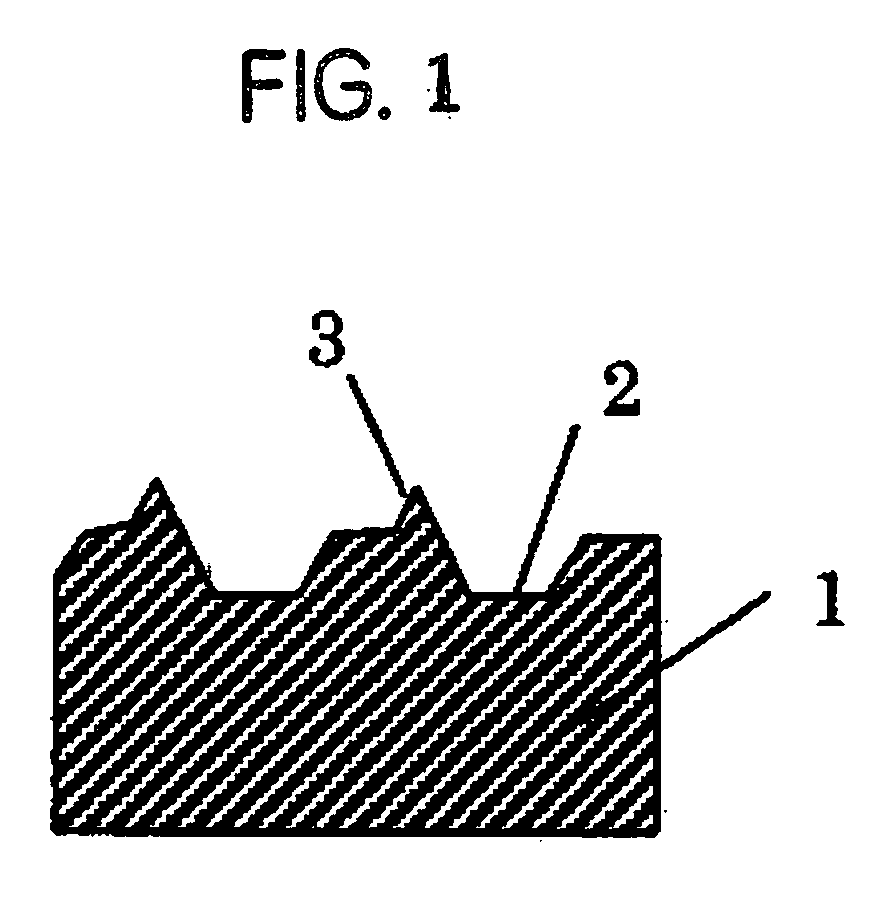

Shaping sheet, resin decorative material and method of producing the same

ActiveUS20070231583A1Easy to controlHigh-grade feelingDecorative surface effectsRecord information storageEngineeringContamination

The present invention provides a shaping sheet that includes a base material having at least an ink layer provided on the whole surface thereof and a surface shaping layer that is present on the ink layer, contacts the ink layer, and covers the whole surface of the ink layer, in which the surface shaping layer is a crosslinked and cured product of a curable resin composition and the surface shaping layer has a concavoconvex pattern on a surface thereof. There can be obtained: a shaping sheet that has a fine concavoconvex pattern, allows elaborated shaping with a high-grade feeling, and has excellent releasability; a shaping sheet having excellent design properties and releasability that can readily control a lustrous portion and a matted portion; and further a shaping sheet whose surface is free of contamination by impurities separated out of the base material even when it is repeatedly used.

Owner:DAI NIPPON PRINTING CO LTD

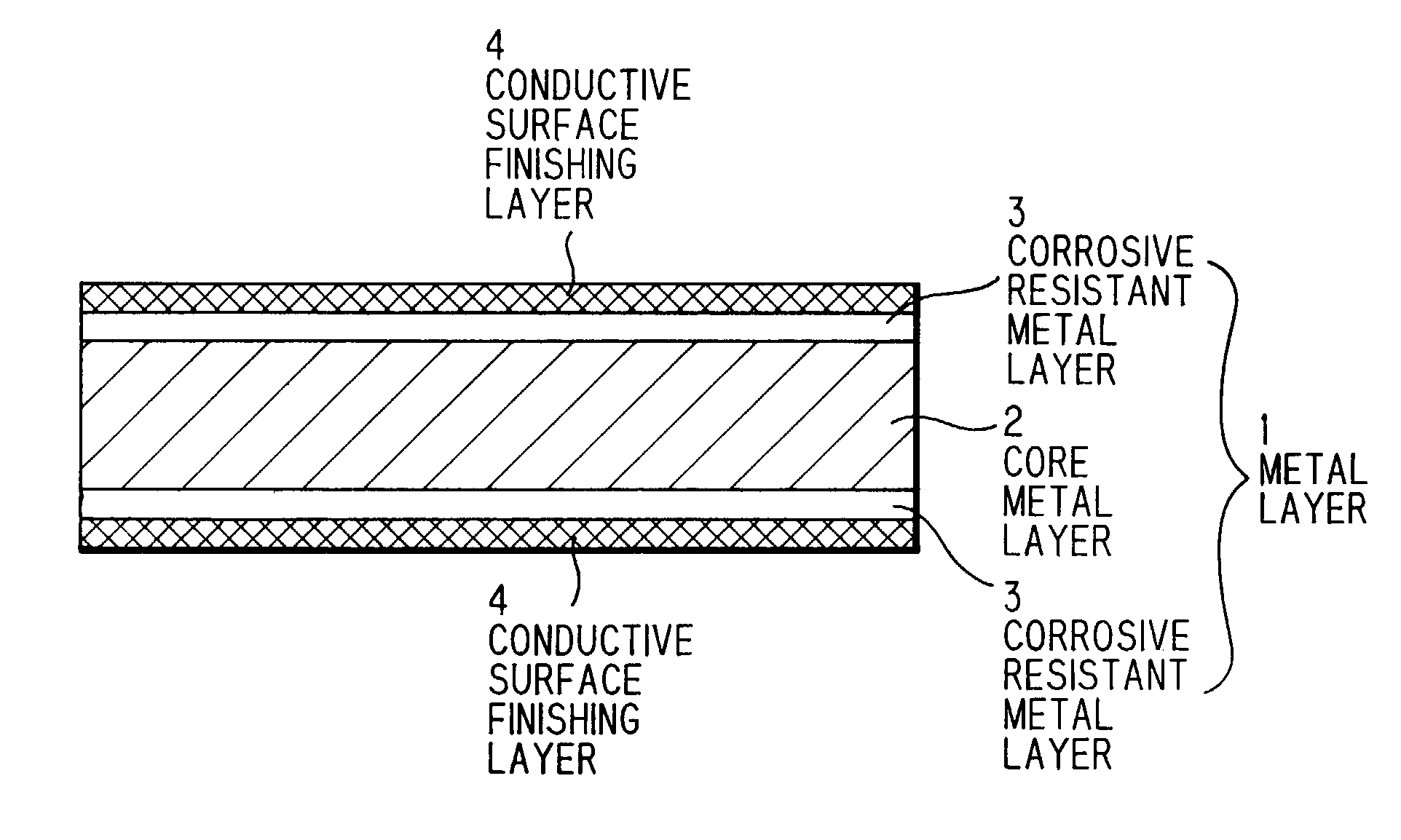

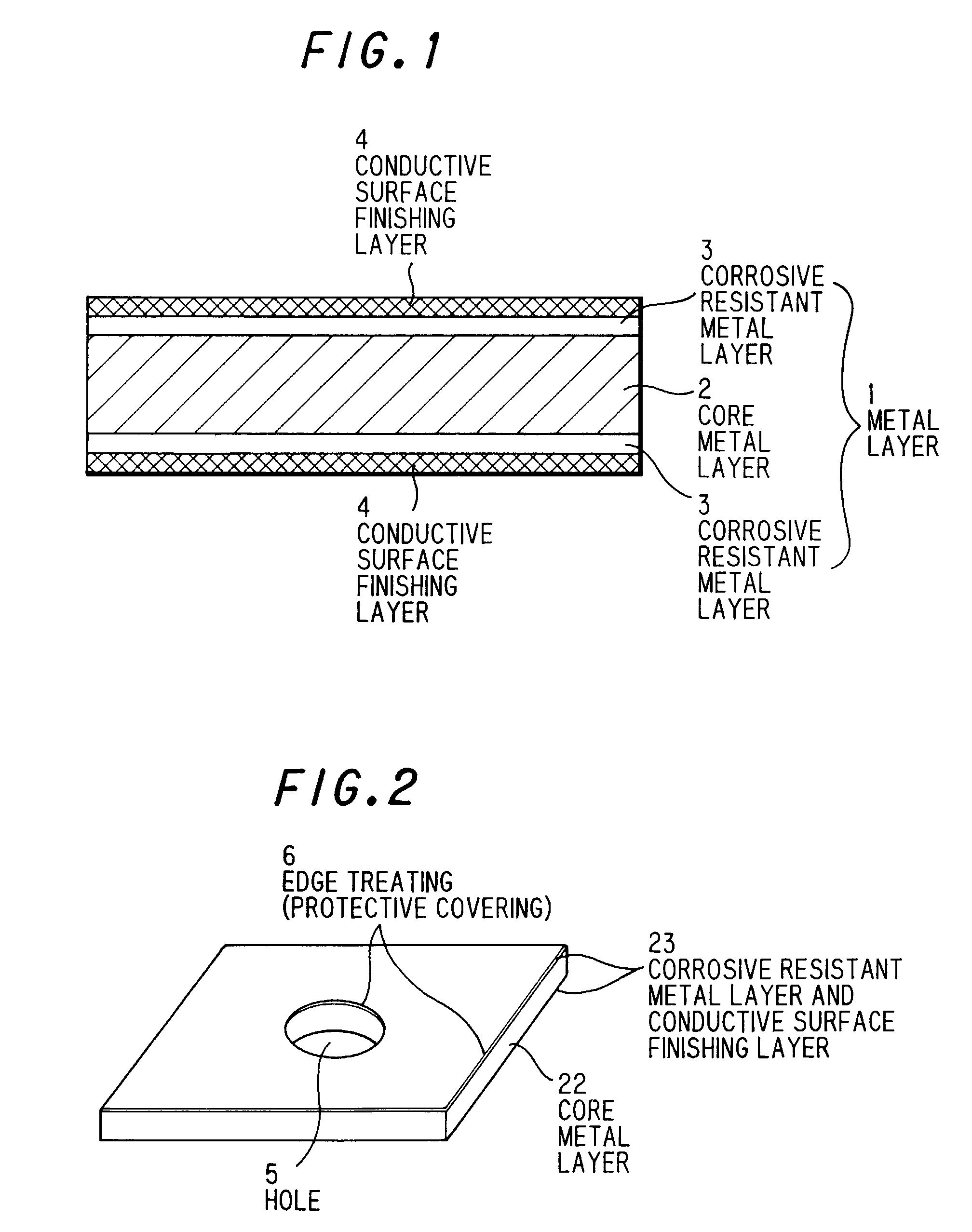

Corrosive resistant metal material covered with conductive substance

InactiveUS7399532B2Improve conductivityExcellent mold releasabilitySolid electrolyte fuel cellsFuel cell detailsNiobiumConductive materials

A corrosive resistant metal material covered with a conductive substance suitable for use in a component material requiring conductivity and corrosion resistance like electrical conductive material, electrical contact, electromagnetic wave shield, electrochemical electrode or antistatic material, specifically for component material requiring conductivity in sever condition of corrosive environment is provided. A corrosive resistant metal material covered with a conductive substance is formed by cladding a corrosive resistant metal selected from the group consisting of titanium, zirconium, tantalum, niobium and alloy thereof on a conductive metal selected from the group consisting of iron, aluminum, copper, titanium, magnesium, zirconium, tantalum, niobium, tungsten, nickel, chrome and alloy thereof, and covering a conductive surface finishing layer over surface of a corrosive resistant metal layer with a mixture of conductive substance and resinous binder.

Owner:HITACHI CABLE +1

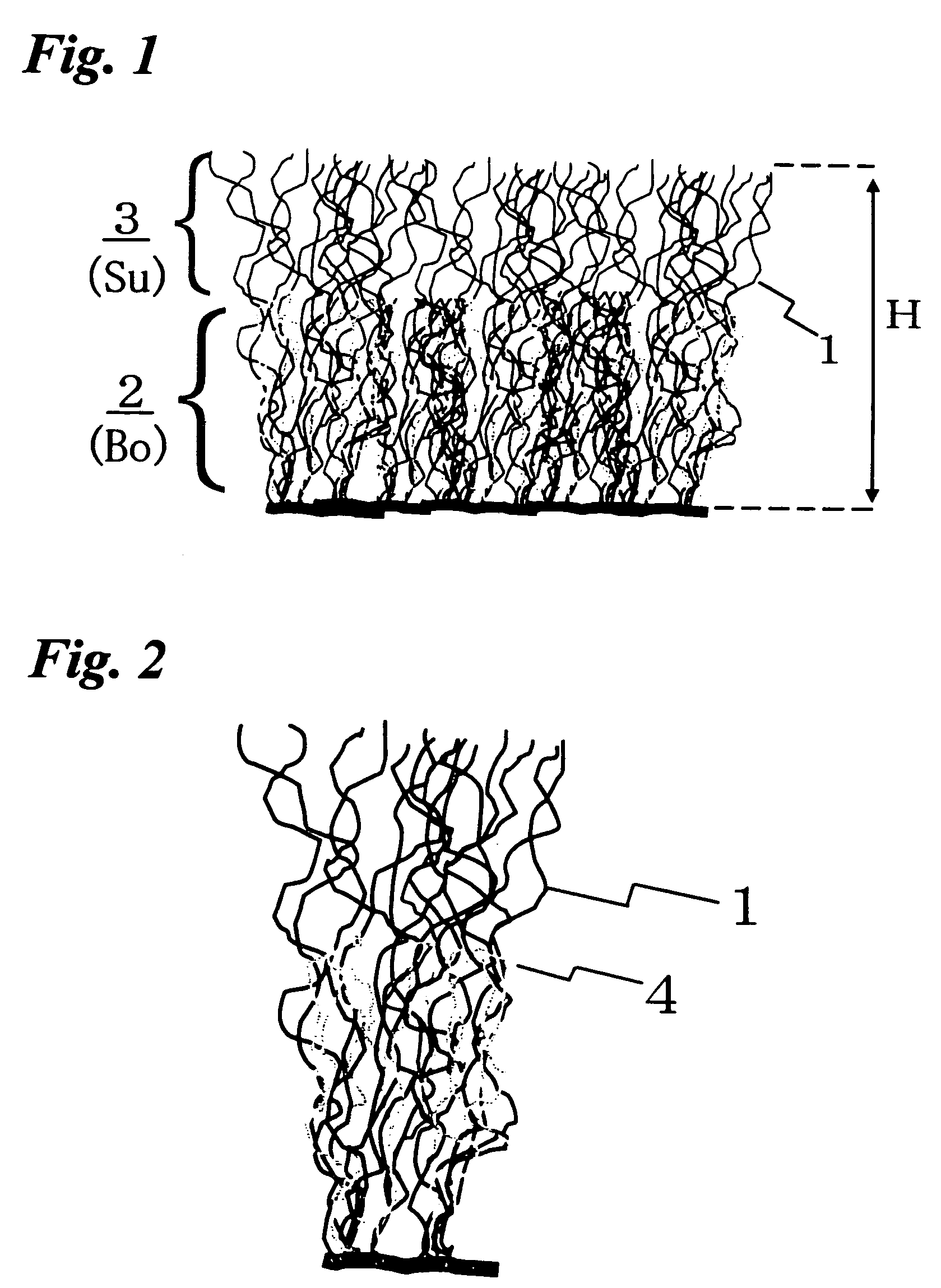

Silver-knit material

InactiveUS6993941B2Less deformationReduce fatigueLiquid surface applicatorsCircular knitting machinesFiberComposite material

A sliver-knit material causing less buckling fatigue or deformation during compression and improved with shedding, in which a pile thread contains 30% or more of staple fibers having steric crimps, and a dense layer (Bo) and a bulky layer (Su) on the side of the upper layer in contact with the dense layer (Bo) are formed, where the ratio of height between the dense layer (Bo) and the bulky layer (Su) in the sliver-knit material is from 2:5 to 1:1, and at least a portion of fibers present in the dense layer (Bo) are folded back.

Owner:KURARAY CO LTD

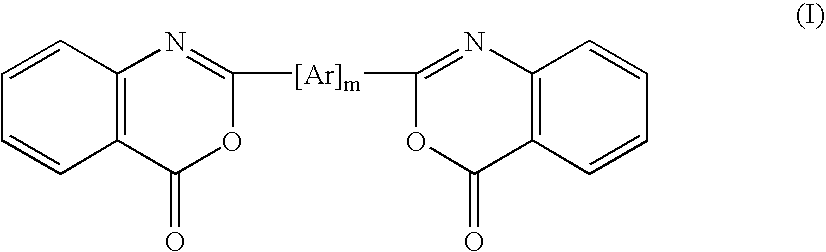

Polycarbonate resin composition and molded articles thereof

ActiveUS7148313B2Good colorIncrease resistanceCeramic shaping apparatusUltraviolet lightsCarboxylic acid

A polycarbonate resin composition comprising 100 parts by weight of a polycarbonate resin (component A), 0.01 to 10 parts by weight of at least one ultraviolet light absorber (component B) selected from the group of a specific cyclic imino ester, and 0.01 to 1 part by weight of a fatty acid ester compound (component C) which is an ester of a polyhydric alcohol and an aliphatic carboxylic acid and has a molecular weight of 500 to 2,000 g / mol, as well as molded articles thereof.The polycarbonate resin composition provides molded articles having excellent transparency, color and resistance to ultraviolet radiation, is excellent in heat stability at the time of molding and releasability and fully suppresses the production of a deposit on a metal mold.

Owner:TEIJIN KASEK KK

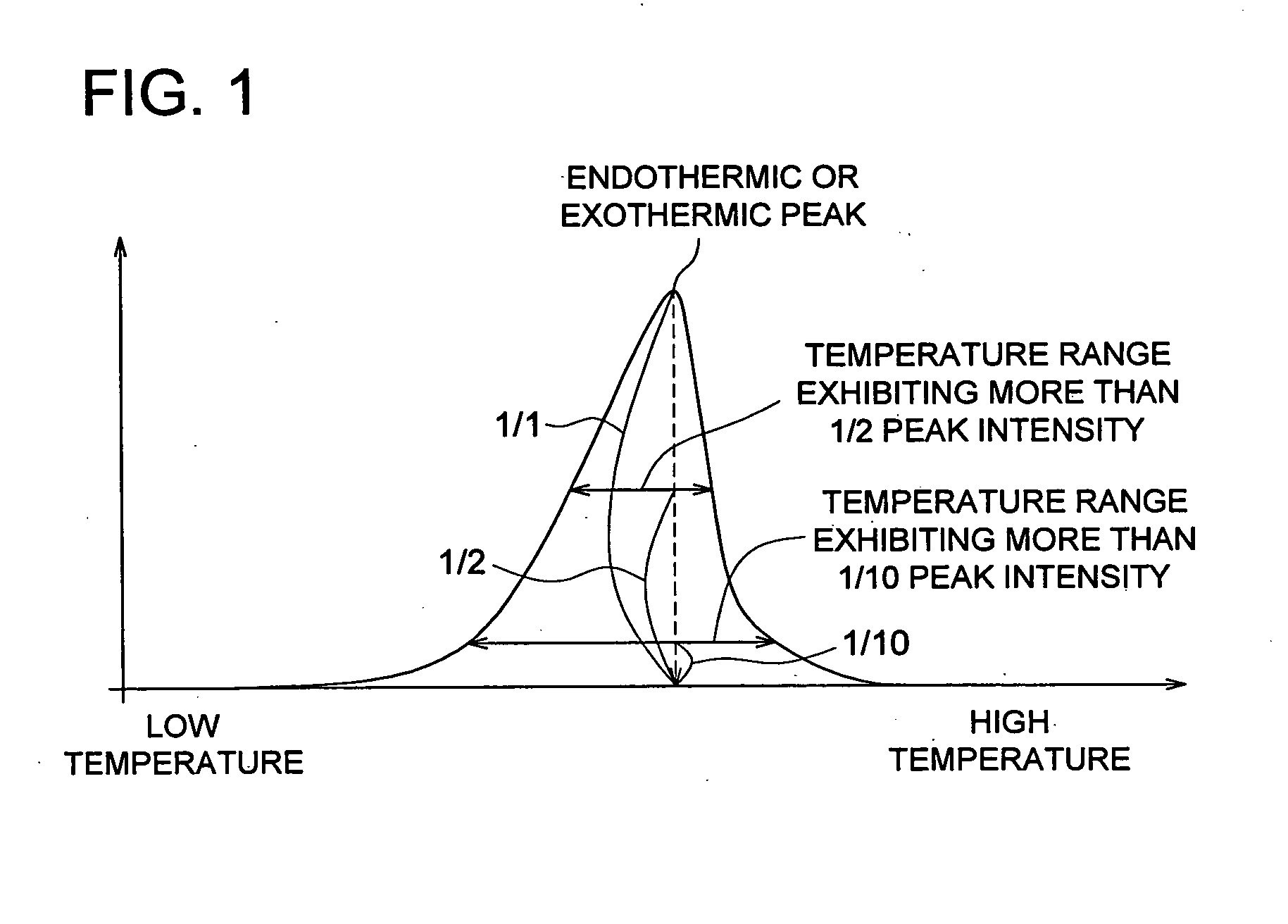

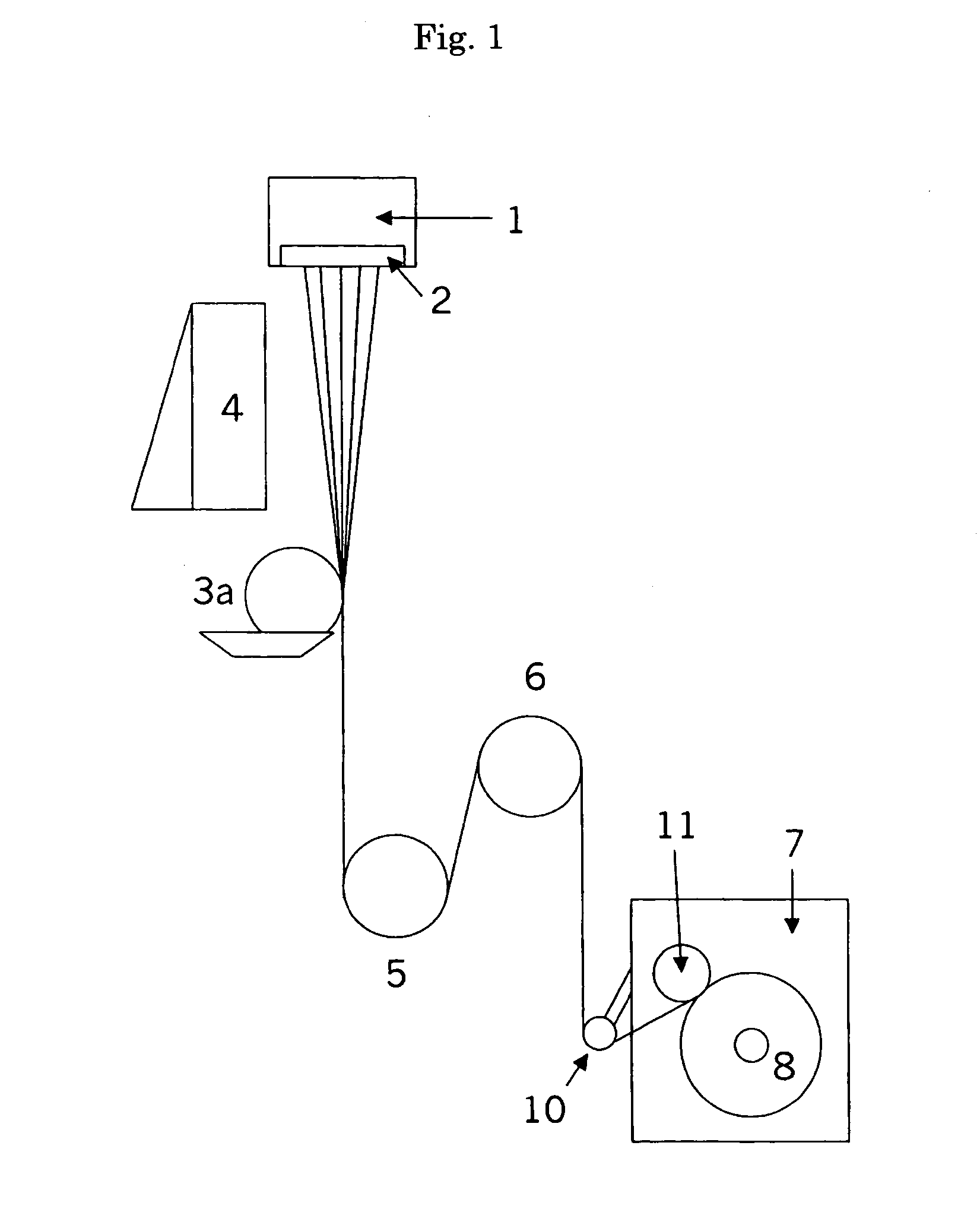

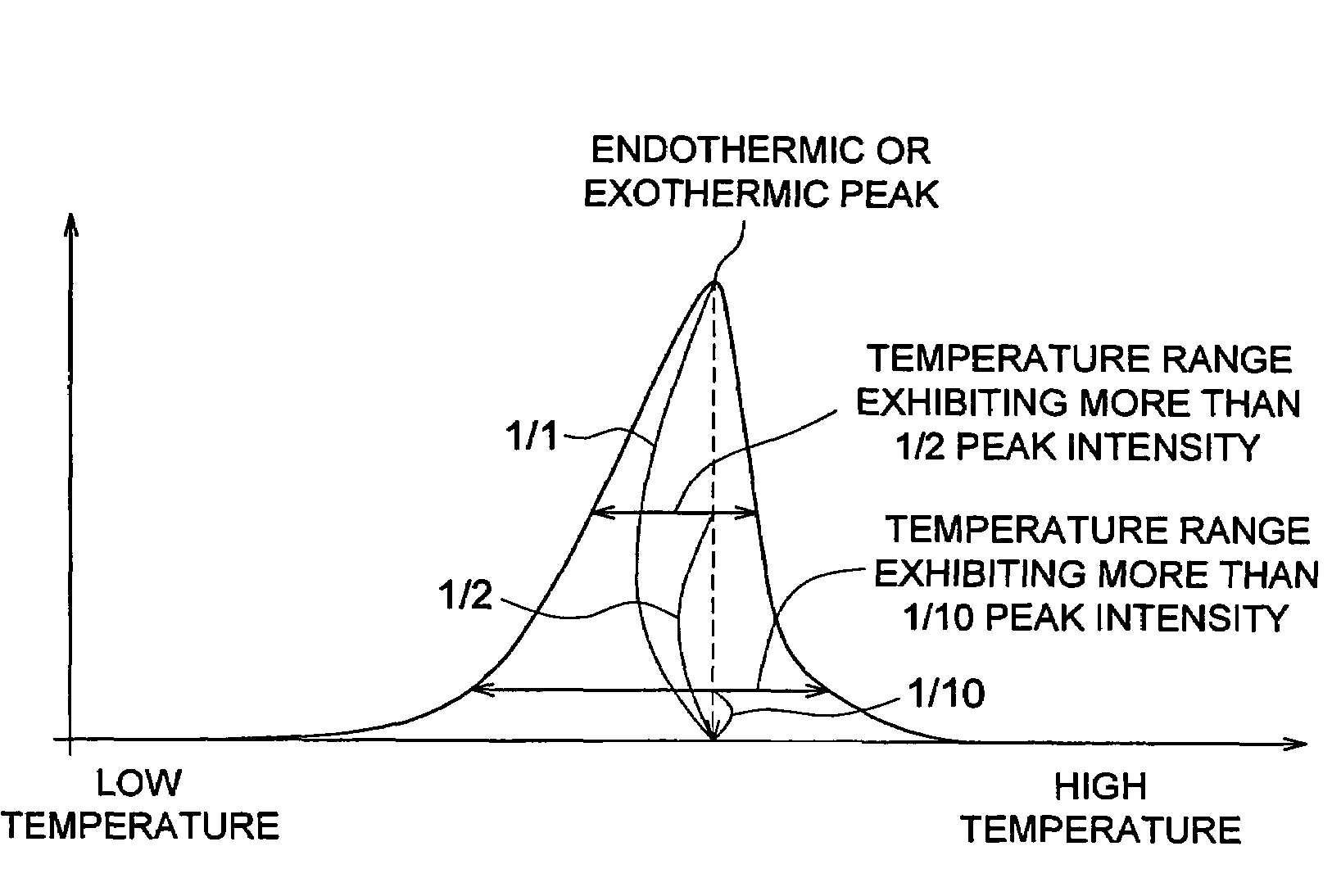

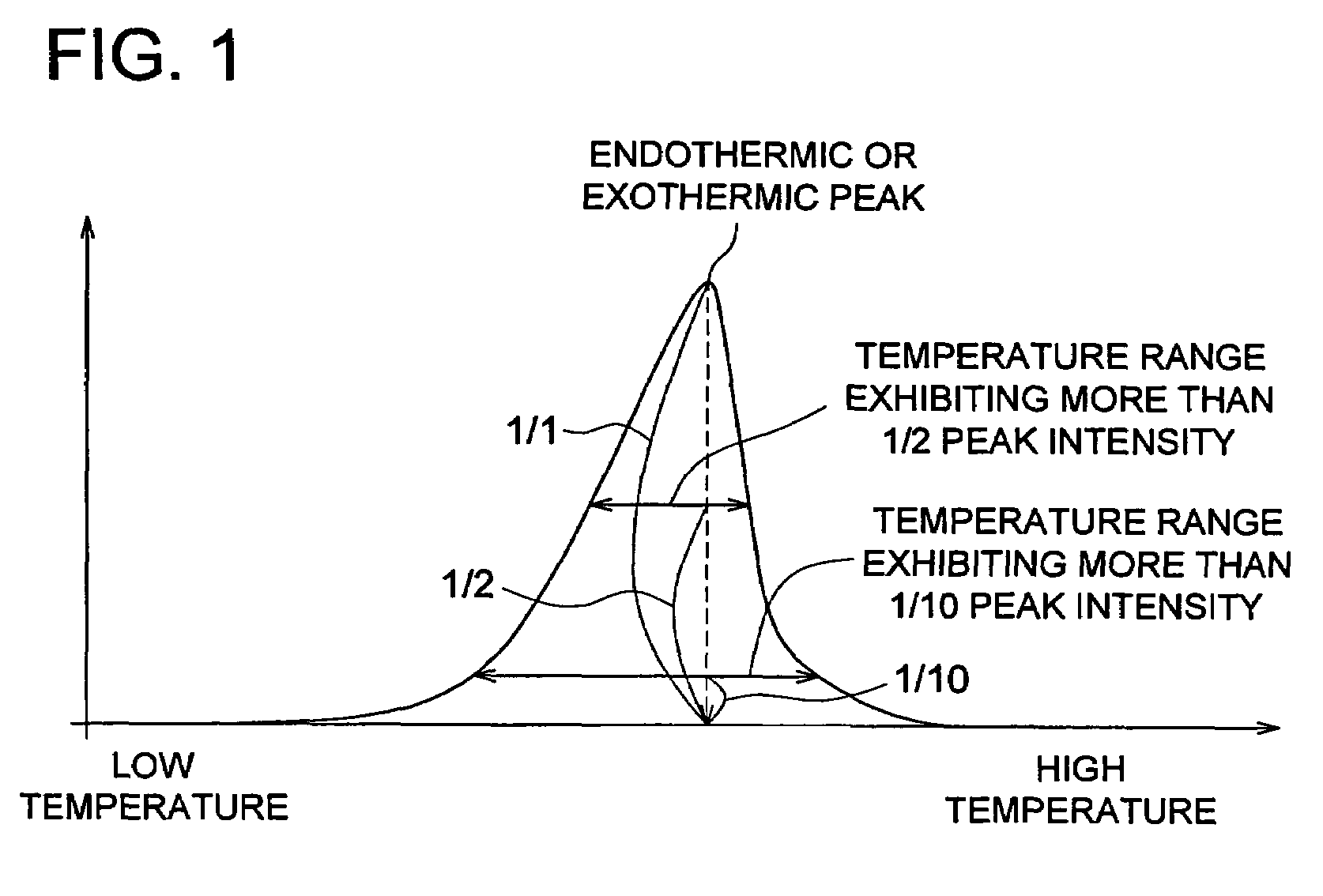

Electrophotographic toner

An electrophotographic toner comprising a resin, a colorant and a release agent which comprises a first wax and a second wax, wherein: (i) the first wax exhibits: an endothermic peak appearing in the range 75-100° C., a peak width at half height of the endothermic peak of 10-40° C., an exothermic peak appearing in the range 70-100° C. and a peak width at half height of the exothermic peak of 10-40° C., in a DSC measurement; (ii) the second wax exhibits: an endothermic peak appearing in the range 60-90° C., a peak width at half height of the endothermic peak of 5° C. or less, an exothermic peak appearing in the range 55-80° C. and a peak width at half height of the exothermic peak of 5° C. or less, in the DSC measurement; (iii) a weight ratio of the first wax to the second wax is between 9:1 and 2:8; and (iv) the resin contains a polar group.

Owner:KONICA MINOLTA BUSINESS TECH INC

Thermoplastic Acrylonitrile-Butadiene-Styrene Resin Composition With Excellent Releasability And Colorability

ActiveUS20100048798A1Excellent colorability and releasabilityImprove colorabilityThermoplasticPolymer chemistry

A thermoplastic acrylonitrile-butadiene-styrene (ABS) resin composition of the present invention comprises (a) a bimodal graft copolymer of a conjugated diene rubbery polymer whose average particle diameter of 800 to 1,500 Å and a conjugated diene rubbery polymer whose average particle diameter of 2,500 to 3,500 Å, the conjugated diene rubbery polymers being grafted with an aromatic vinyl compound and a vinyl cyanide compound, (b) an acrylic resin of a methacrylic or acrylic acid alkyl ester compound, an aromatic vinyl compound and a vinyl cyanide compound, (c) a copolymer of an aromatic vinyl compound and a vinyl cyanide compound, and (d) polysiloxane masterbatches. The ABS resin composition has excellent colorability and releasability while maintaining the inherent physical properties (e.g., impact strength and tensile strength) of the base resin.

Owner:LG CHEM LTD

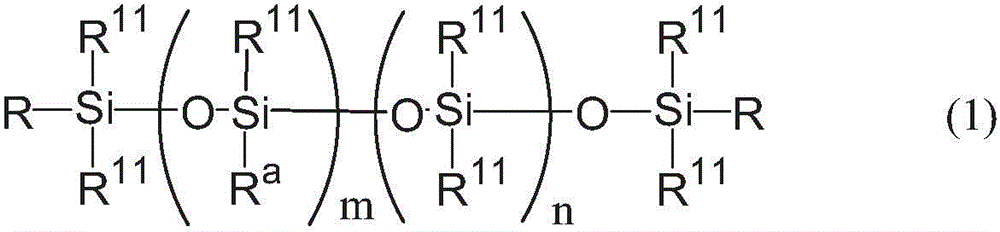

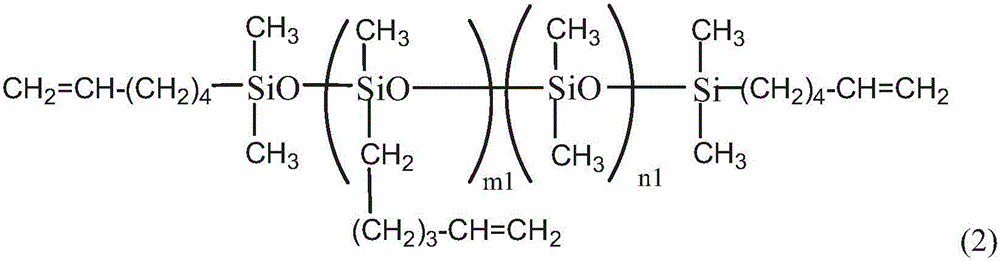

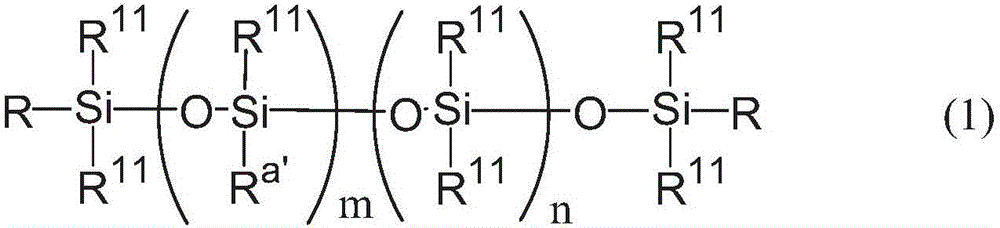

Curable organopolysiloxane composition and release film for use with dielectric ceramic layer-forming material using same

ActiveCN105899616AExcellent releasabilityExcellent easeFilm/foil adhesivesSynthetic resin layered productsOrganic solventHydrogen atom

A curable organopolysiloxane composition comprising: (A) an organopolysiloxane having a form of anywhere from a liquid having a viscosity of 20 mPa.s or greater to a gum that exhibits plasticity,containing the following components a1) and a2) at a mass ratio of 100:0 to 50:50: a1) organopolysiloxane comprising an alkenyl group having 4 to 12 carbon atoms, the alkenyl group having a vinyl moiety content of 0.5 to 3.0 mass%, and a2) organopolysiloxane with an alkenyl group having 2 to 3 carbon atoms, the alkenyl group having a vinyl moiety content of 0.5 to 3.0 mass%; (B) an organopolysiloxane having a form from a liquid having a viscosity of 1,000,000 mPas or greater to a gum that exhibits plasticity, the organopolysiloxane optionally comprising an alkenyl group having 2 to 12 carbon atoms, the alkenyl group having a vinyl moiety content of less than 0.100 mass%; (C) an organohydrogen polysiloxane comprising at least two silicon-bonded hydrogen atoms within its molecule; (D) a hydrosilylation catalyst; and (E) as desired, an organic solvent; the mass ratio of components (A) and (B) being in a range from 90:10 to 99:1.

Owner:DOW TORAY CO LTD

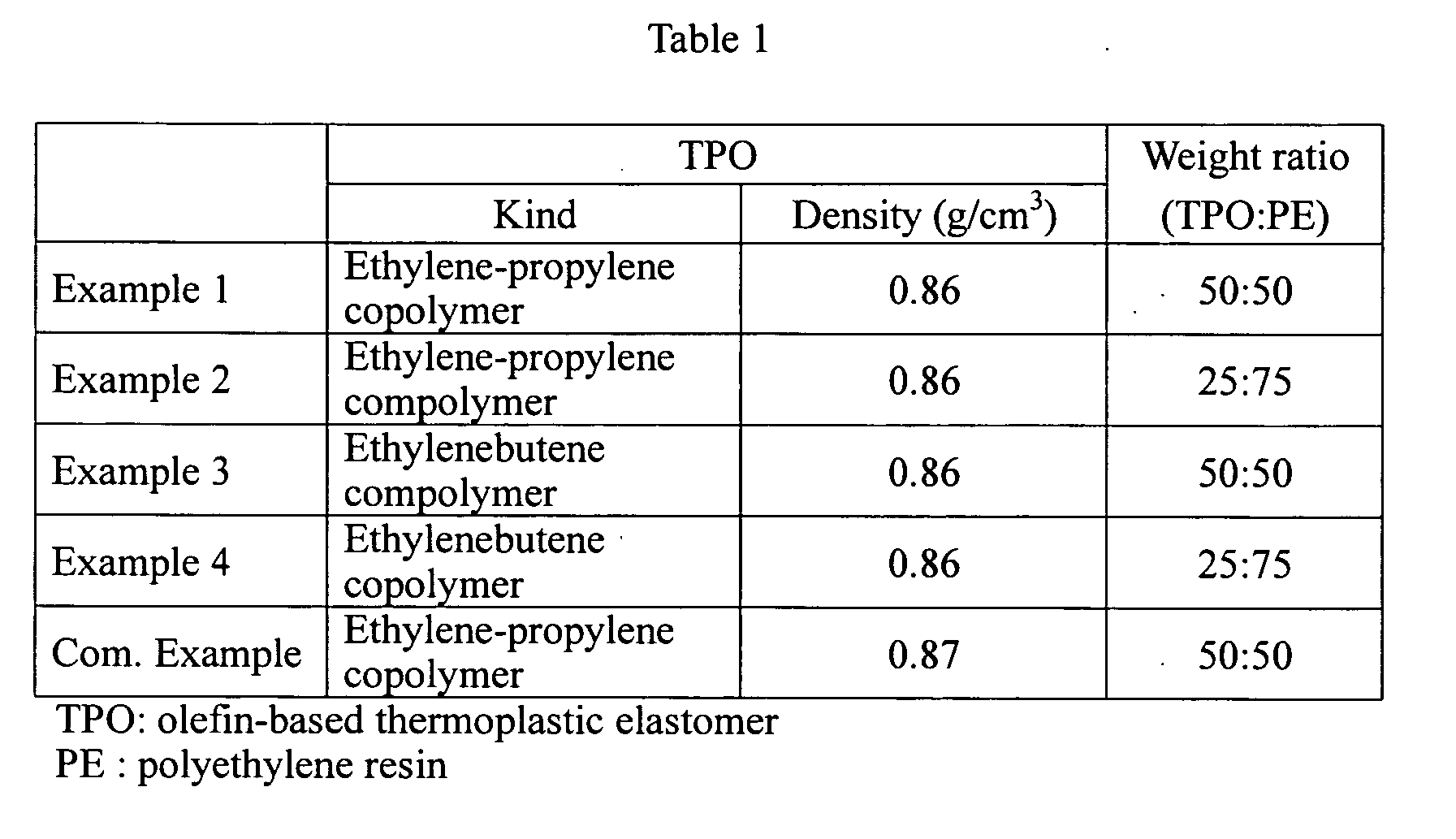

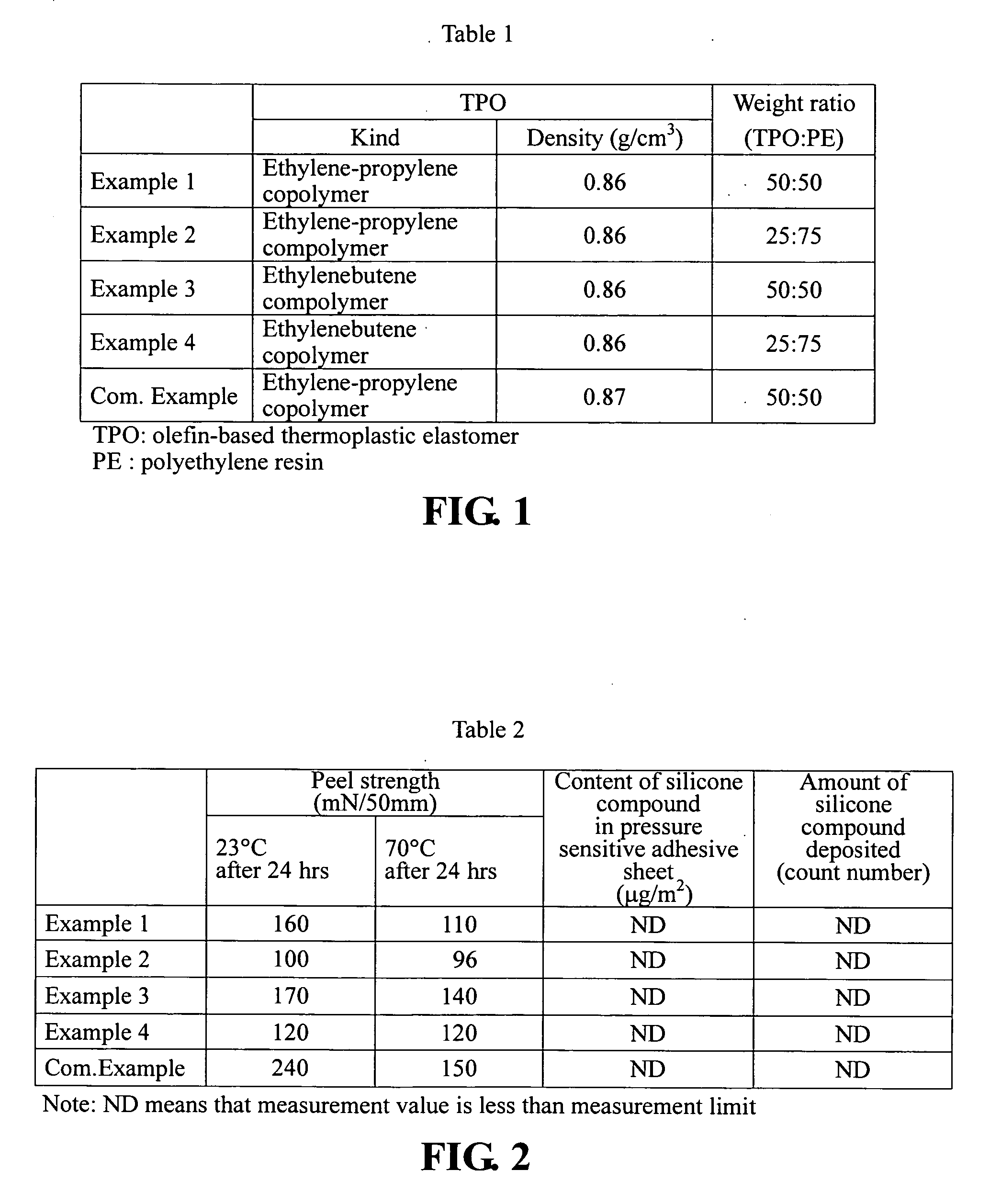

Releasing sheet and pressure-sensitive adhesive article

InactiveUS20050048302A1Excellent releasabilityPrevent generation of particleFilm/foil adhesivesSynthetic resin layered productsPressure sensitivePolyolefin

Disclosed herein are a release sheet and a pressure sensitive adhesive sheet with release sheet. The release sheet and the pressure sensitive adhesive sheet with release sheet of the present invention are hard to give adverse effects to hard disk drives or the like, when a pressure sensitive adhesive sheet peeled off from the release sheet is attached to the hard disk drives or the like. The pressure sensitive adhesive sheet with release sheet has a structure in which a pressure sensitive adhesive sheet comprised from a pressure sensitive adhesive layer and a pressure sensitive adhesive sheet base is adhered to a release sheet comprised from a releasing agent layer and a release sheet base, wherein the pressure sensitive adhesive layer is in contact with the releasing agent layer. The release sheet includes a releasing agent layer comprised of an olefin-based thermoplastic elastomer and a polyolefin resin, and a release sheet base. The density of the olefin-based thermoplastic elastomer is less than 0.87 g / cm3. The weight ratio of the olefin-based thermoplastic elastomer to the polyolefin resin is preferably in the range of 15:85 to 85:15.

Owner:LINTEC CORP

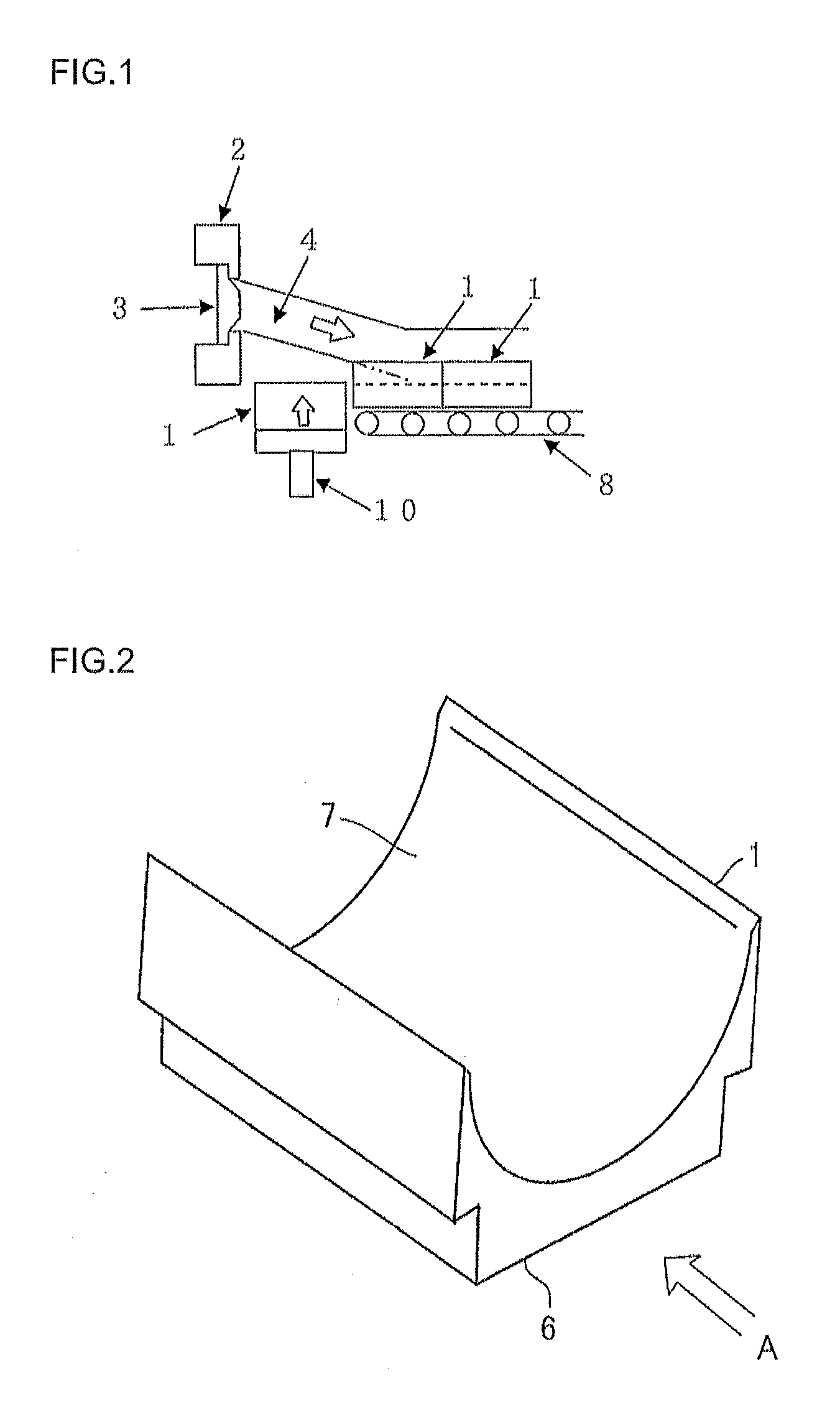

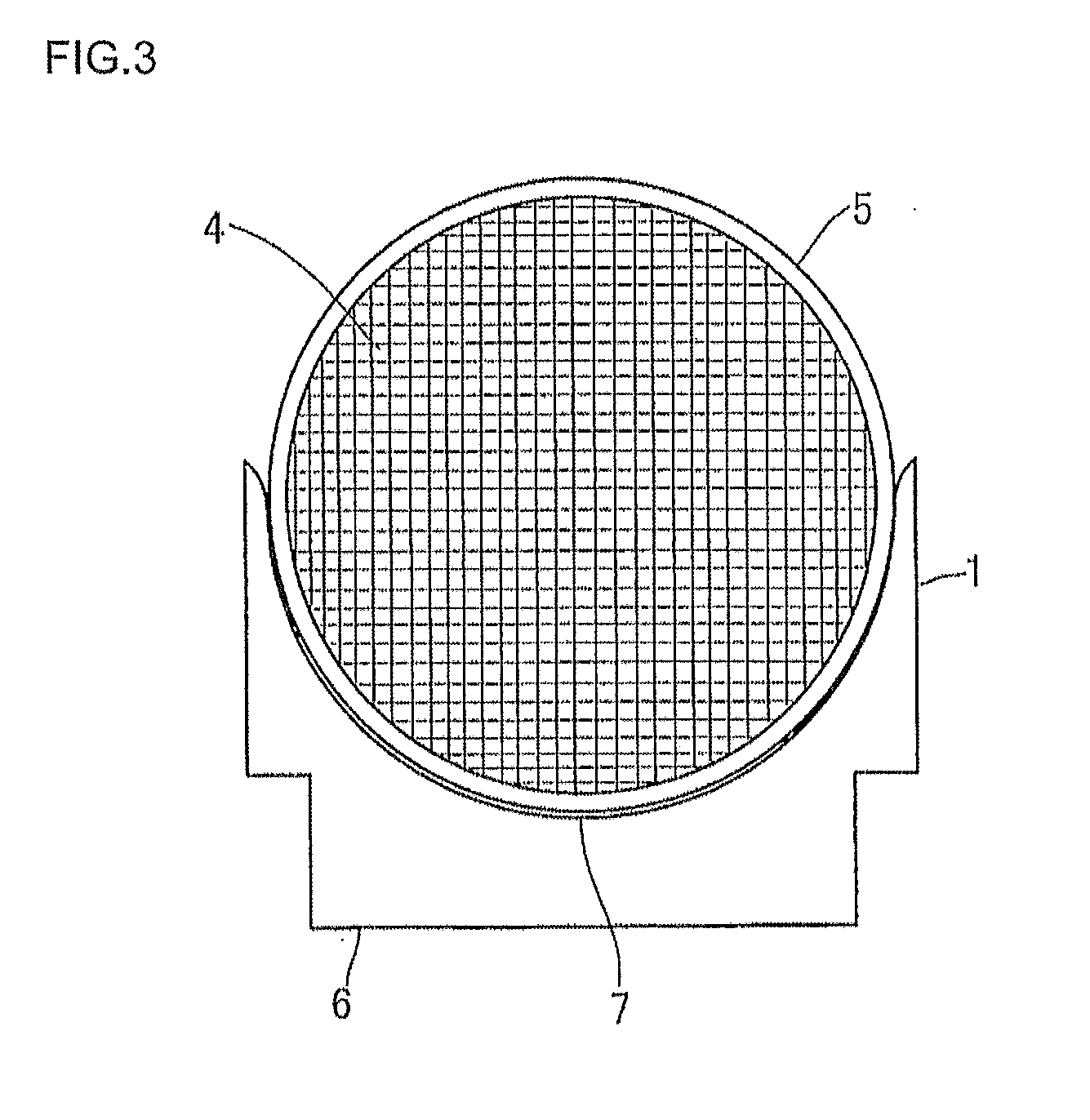

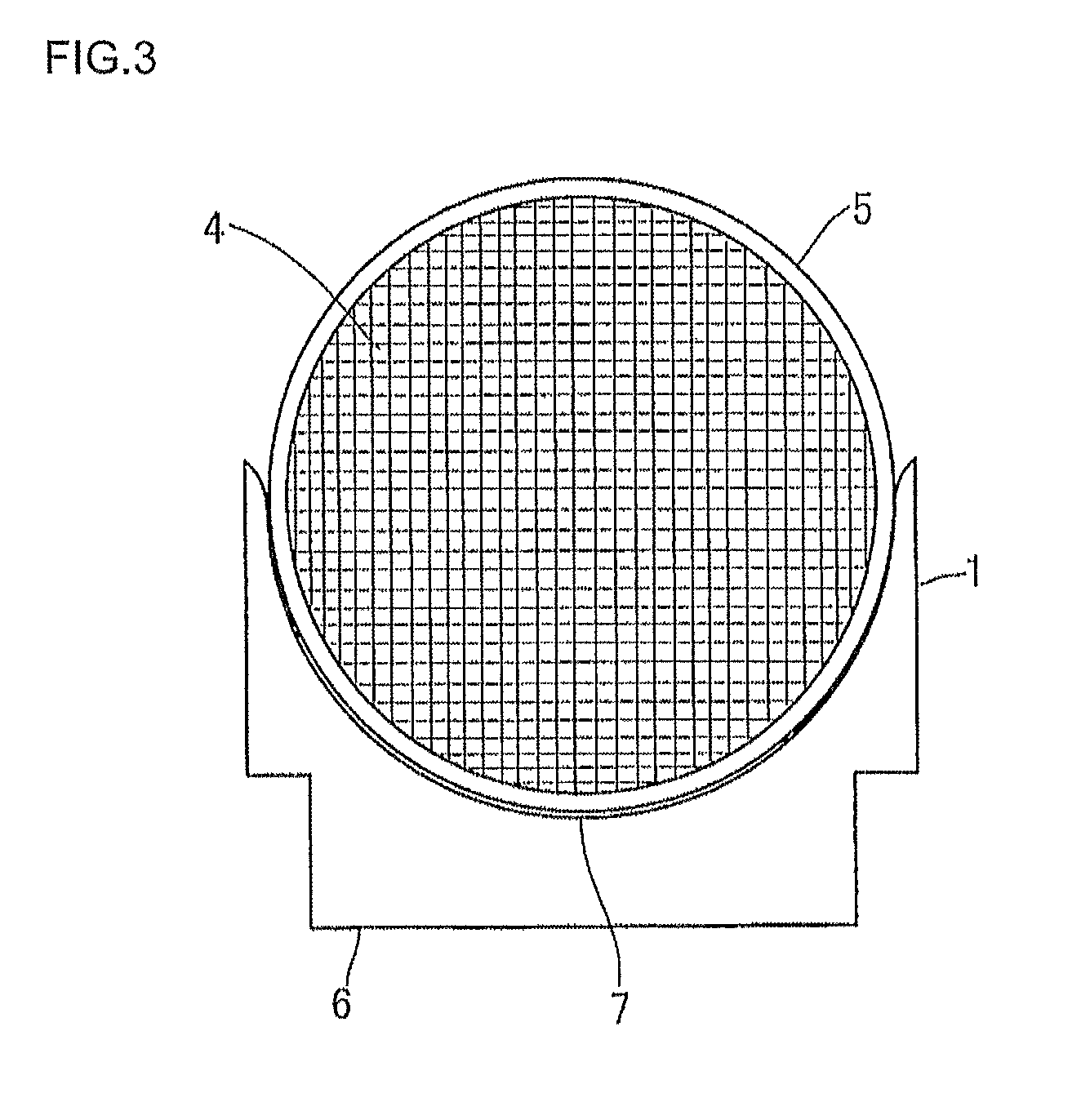

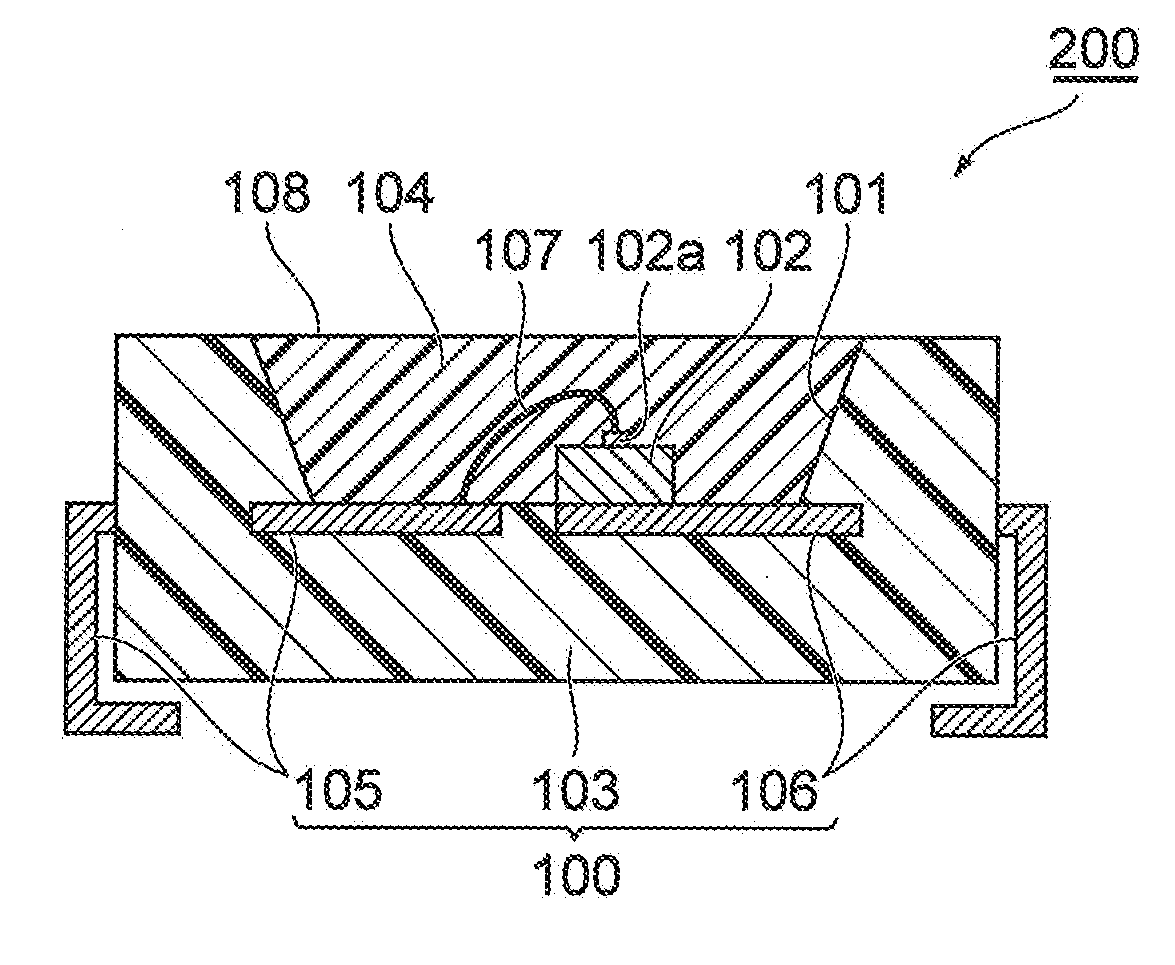

Conveyance receiver for honeycomb formed article, and conveyance apparatus and conveyance method using the conveyance receiver

ActiveUS20110083942A1Reduce morbidityGood hygroscopicityDischarging arrangementCharge manipulationHoneycombHardness

There is provided a conveyance receiver 1 having a bottom face 6 formed in parallel with the conveyance path to abut against the conveyance path and a support face 7 formed to match a shape of an outer periphery 5 of the honeycomb formed article 4. The support face 7 is made of a cured porous polyurethane resin material having a Shore D hardness Hs of 40≦Hs≦70.

Owner:NGK INSULATORS LTD

Thermoplastic cellulose derivative composition and fiber comprising the same

InactiveUS20040030043A1Improve heat resistanceExcellent spinabilityBiocideOrganic active ingredientsPolyesterSide chain

A thermoplastic cellulose derivative composition of the present invention contains, as a main component, a cellulose ester having an aliphatic polyester side chain having a repeat unit having 2 to 5 carbon atoms, wherein a rate of heating loss at 200° C. is 5 wt % or less, a melt viscosity at 200° C. and 1000 sec<-1 >is 50 to 300 Pa.sec, and a melt tension at the time of take-up at 200° C. and 100 m / min is 0.1 to 40 mN. The present invention can provide excellent fiber products by melt spinning of the composition.

Owner:TORAY IND INC

4-methyl-1-pentene polymer, resin composition containing 4-methyl-1-pentene polymer, masterbatch thereof, and formed product thereof

ActiveUS20110165416A1Excellent mold releasabilityExcellent blocking resistanceFilm/foil adhesivesSynthetic resin layered productsMasterbatchSolvent

[Object] To provide a resin composition with excellent mold releasability and blocking resistance.[Solution] A resin composition containing a 4-methyl-1-pentene polymer includes 0.01 to 10 parts by mass of a 4-methyl-1-pentene polymer (B) per 100 parts by mass of at least one resin (A) selected from the group consisting of thermoplastic resins and thermosetting resins, wherein the 4-methyl-1-pentene polymer (B) has (B1) an intrinsic viscosity [η] of 0.01 or more but less than 0.50 dl / g measured at 135° C. in a decalin solvent.

Owner:MITSUI CHEM INC

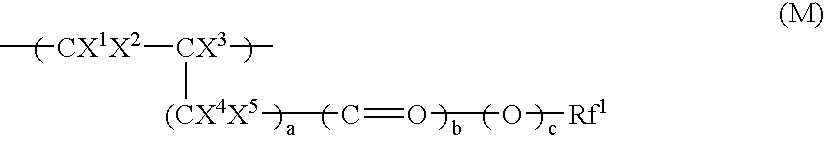

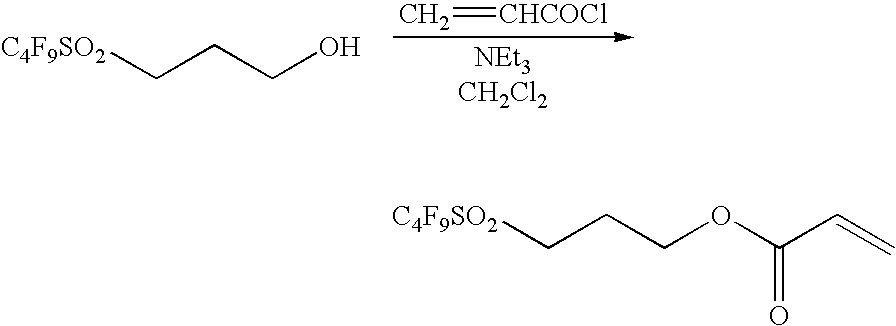

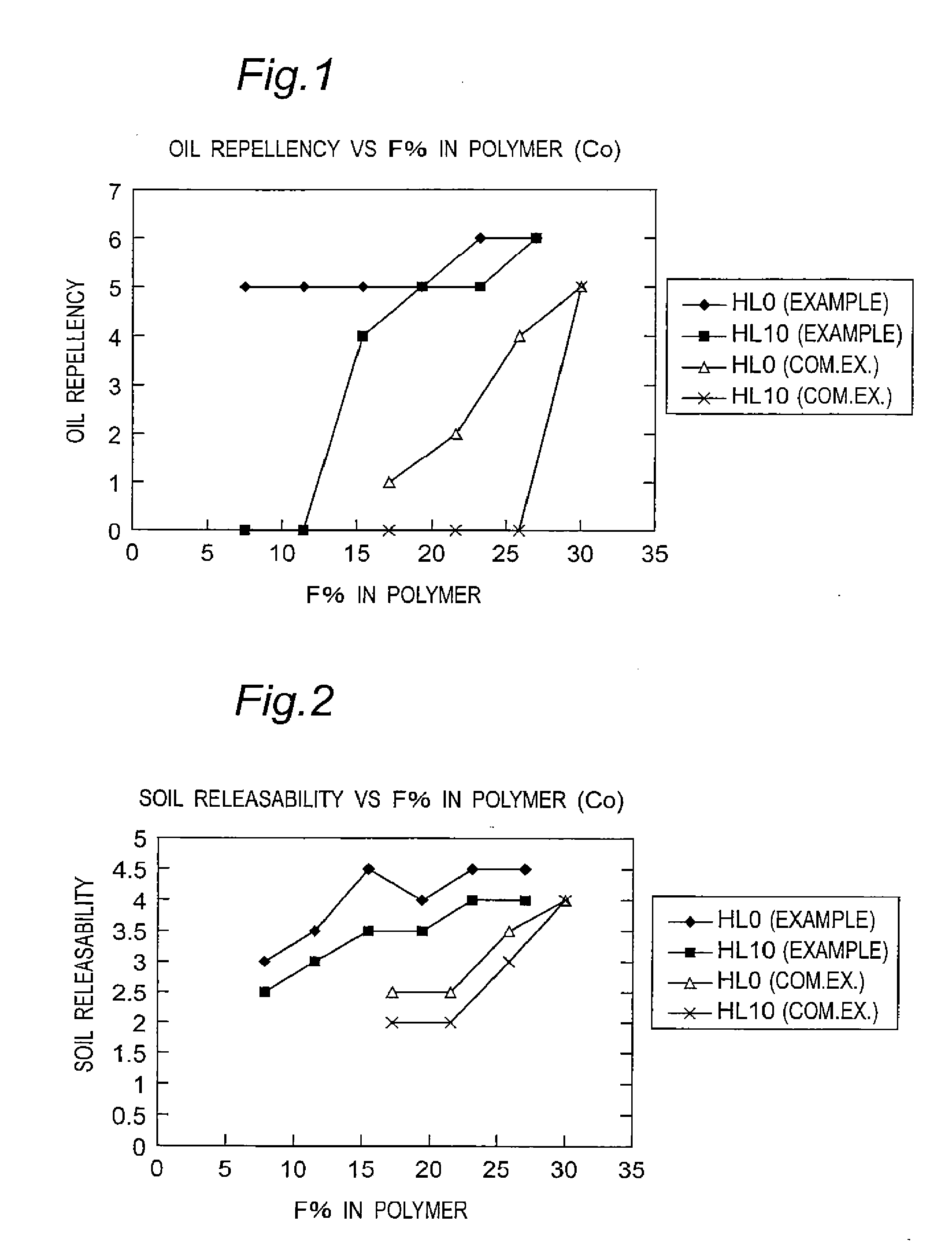

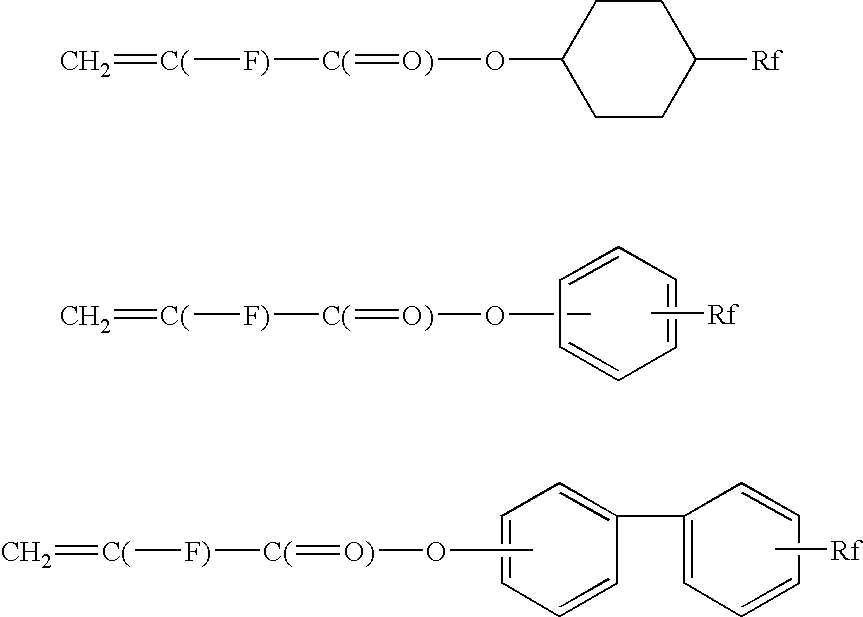

Fluorine-containing copolymer having excellent washing resistance and soil release agent

InactiveUS20100093919A1Excellent releasabilityIncrease resistanceOther chemical processesLiquid repellent fibresFiberMeth-

Disclosed is a soil release agent composition essentially containing a fluorine-containing copolymer, which is essentially composed of (a) a fluorine-containing monomer having a fluoroalkyl group, (b) a polyalkyleneglycol (meth)acrylate, (c) a monomer having an acetoacetyl group and (d) a monomer having a cation-donating group, and a crosslinking agent. This soil release agent composition imparts a base material such as a fiber fabric with excellent oil repellency, antifouling property and soil releasing property, while maintaining washing resistance of the base material. The monomer (a) is preferably represented by the following formula (1).CH2═C(—X)—C(═O)—Y-Z-Rf (1)(In the formula, X represents a hydrogen atom, a linear or branched alkyl group having 1-21 carbon atoms, a fluorine atom, a chlorine atom or the like; Y represents —O— or —NH—; Z represents an aliphatic group having 1-10 carbon atoms, an aromatic group having 6-18 carbon atoms, an alicyclic group or the like; and Rf represents a linear or branched fluoroalkyl group having 1-21 carbon atoms.)

Owner:DAIKIN IND LTD

Fluoropolymer and soil remover

InactiveUS20090256102A1Excellent washing durabilityHigh flip-flop propertyFibre treatmentBromineChemistry

A fluorocopolymer formed from, as essential ingredients,(a) a fluoromonomer represented by the general formula:CH2═C(—X)—C(—O)—Y—[—(CH2)m-Z-]p-(CH2)n—Rf (1)[wherein X is hydrogen, C1-21 linear or branched alkyl, fluorine, chlorine, bromine, iodine, —CFX1X2 (wherein X1 and X2 each is hydrogen, fluorine, chlorine, bromine, or iodine), cyano, C1-21 linear or branched fluoroalkyl, (un)substituted benzyl, or (un)substituted phenyl; Y is —O— or —NH—; Z is —S— or —SO2—; Rf is C1-21 fluoroalkyl; m is 1-10; n is 0-10; and p is 0 or 1] and(b) a polyalkylene glycol (meth)acrylate. A soil remover containing this fluorocopolymer imparts to a woven fabric, etc. excellent oil repellency, unsusceptibility to fouling, and the property of releasing stains therefrom, while maintaining durability in washing.

Owner:DAIKIN IND LTD

Fluorine-containing polymer and soil release agent

InactiveUS20080194450A1Improve washabilityHigh flip-flop propertyOrganic detergent compounding agentsOrganic chemistryMeth-Macromonomer

Owner:DAIKIN IND LTD

Conveyance receiver for honeycomb formed article, and conveyance apparatus and conveyance method using the conveyance receiver

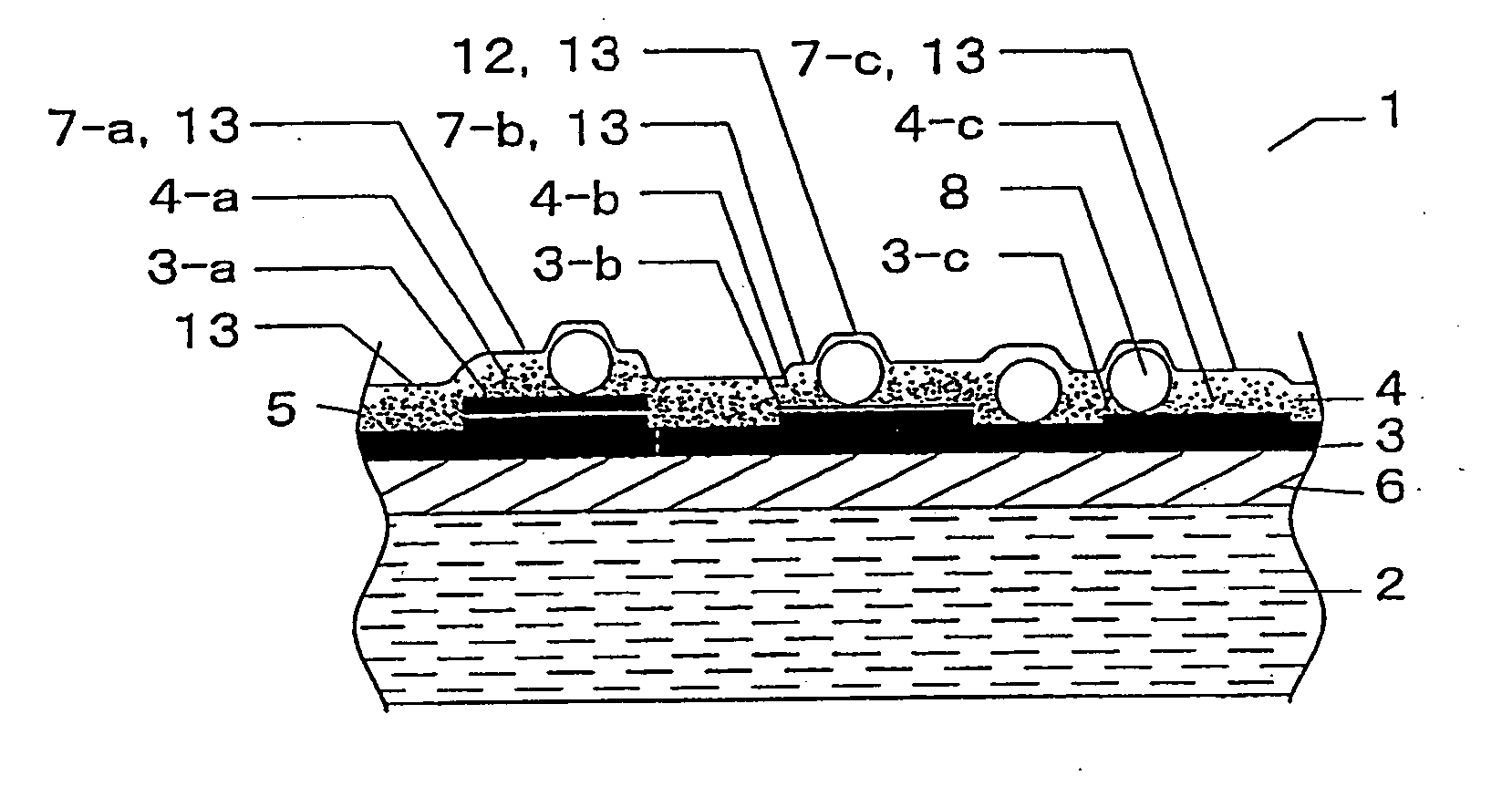

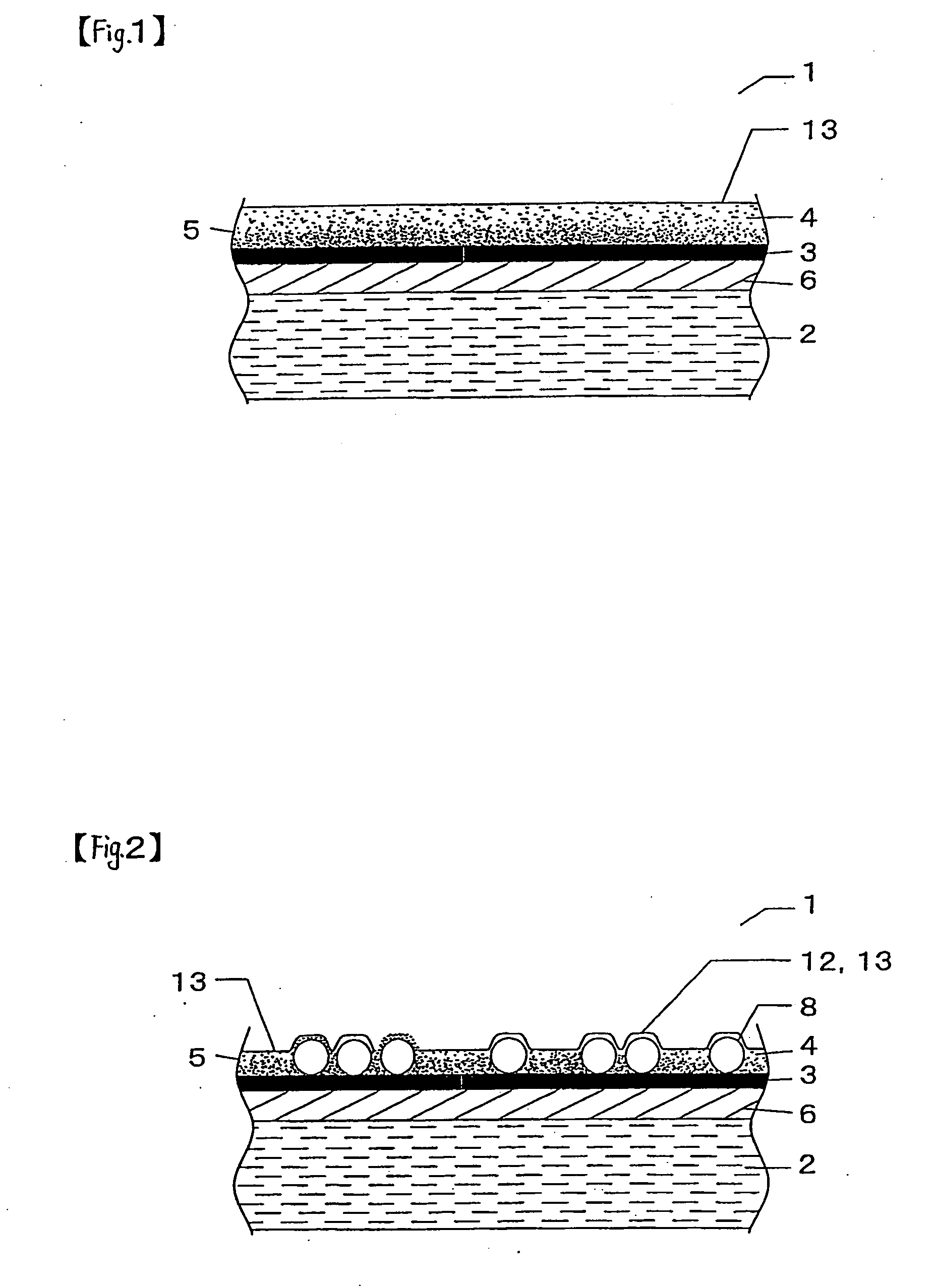

ActiveUS8245839B2Good hygroscopicityExcellent releasabilityDischarging arrangementCharge manipulationHoneycombHardness

There is provided a conveyance receiver 1 having a bottom face 6 formed in parallel with the conveyance path to abut against the conveyance path and a support face 7 formed to match a shape of an outer periphery 5 of the honeycomb formed article 4. The support face 7 is made of a cured porous polyurethane resin material having a Shore D hardness Hs of 40≦Hs≦70.

Owner:NGK INSULATORS LTD

Shaping sheet, resin decorative material and method of producing the same

ActiveUS8187695B2Good release effectMaintain good propertiesDecorative surface effectsRecord information storageEngineeringContamination

The present invention provides a shaping sheet that includes a base material having at least an ink layer provided on the whole surface thereof and a surface shaping layer that is present on the ink layer, contacts the ink layer, and covers the whole surface of the ink layer, in which the surface shaping layer is a crosslinked and cured product of a curable resin composition and the surface shaping layer has a concavoconvex pattern on a surface thereof. There can be obtained: a shaping sheet that has a fine concavoconvex pattern, allows elaborated shaping with a high-grade feeling, and has excellent releasability; a shaping sheet having excellent design properties and releasability that can readily control a lustrous portion and a matted portion; and further a shaping sheet whose surface is free of contamination by impurities separated out of the base material even when it is repeatedly used.

Owner:DAI NIPPON PRINTING CO LTD

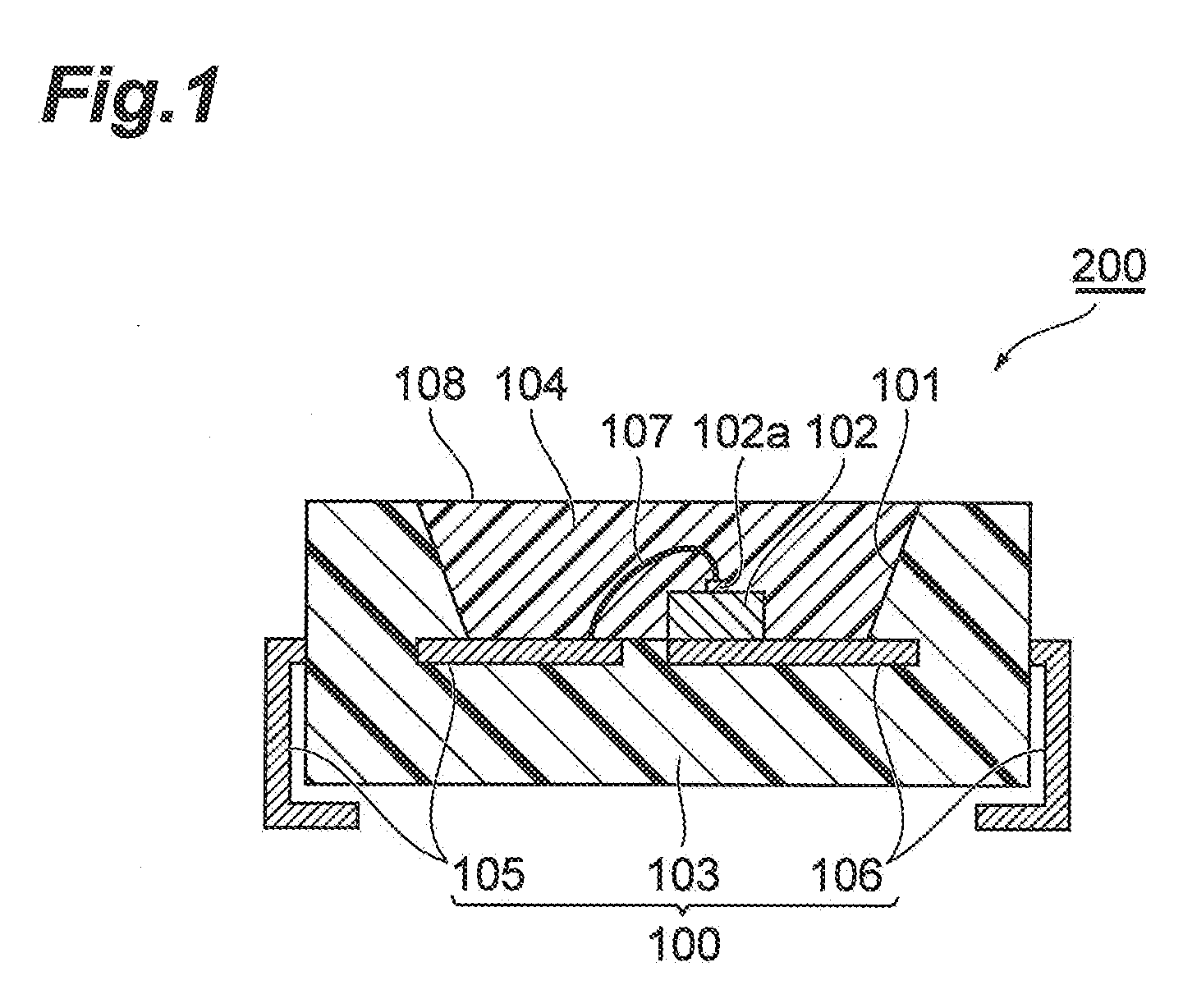

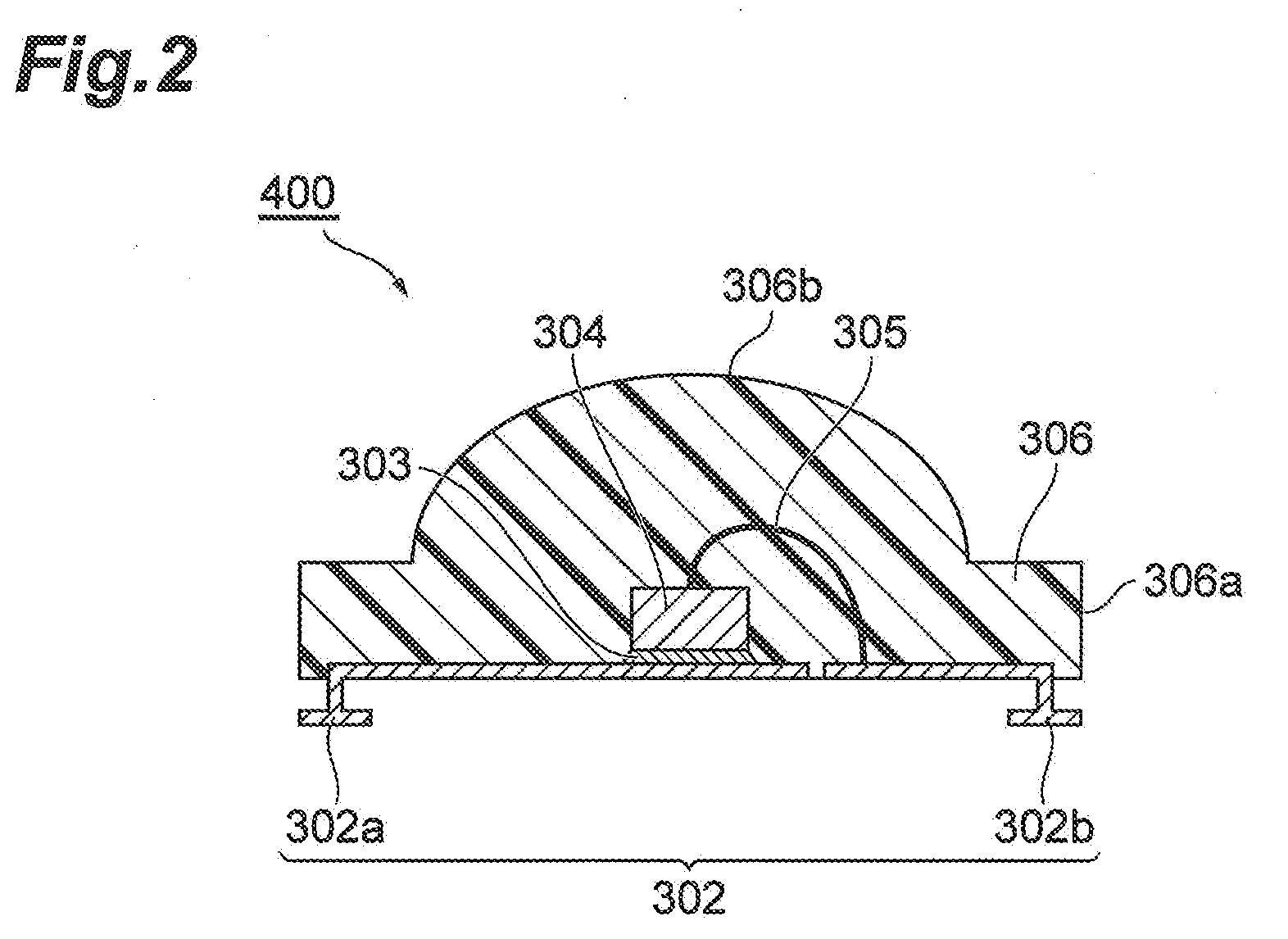

Urethane resin composition, cured object, and photosemiconductor device using cured object

InactiveUS20120196977A1Excellent curing acceleration effectLong application periodSemiconductor/solid-state device detailsSolid-state devicesPolyolAntioxidant

A urethane resin composition obtained by a method comprising the steps of:melt mixing an isocyanate (B), an antioxidant (C), a release agent (D) and a dispersing agent (E) to obtain a molten mixture, andmixing the molten mixture and a polyol (A):wherein the release agent (D) is a compound represented by the following formula (1):[Chemical Formula 1]R1—COOH (1)the dispersing agent (E) is a compound represented by the following formula (2) having a weight-average molecular weight Mw of no greater than 16000:and the content of the dispersing agent (E) in the urethane resin composition is 0.1 to 5.0 wt %.

Owner:HITACHI CHEM CO LTD

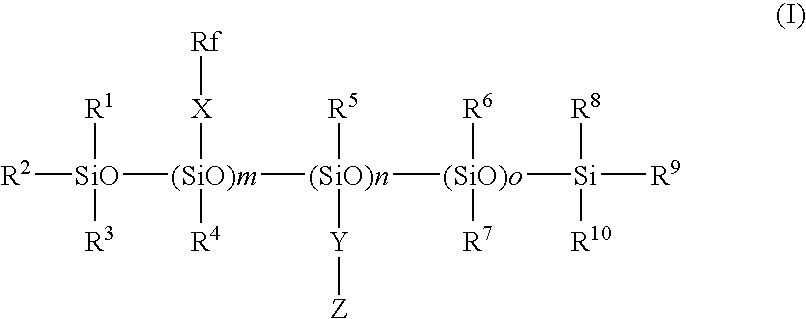

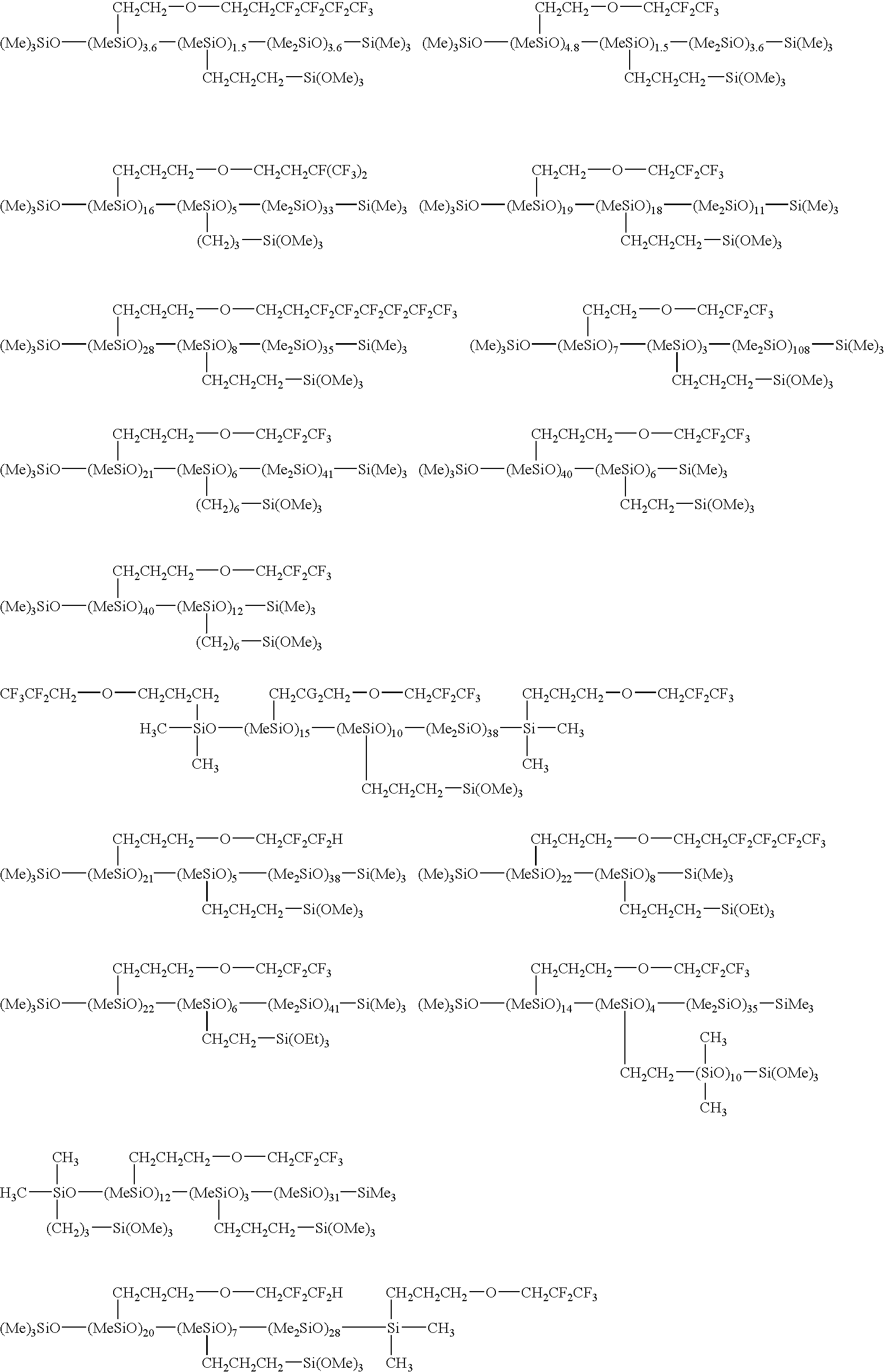

Fluorosilicone mold release composition

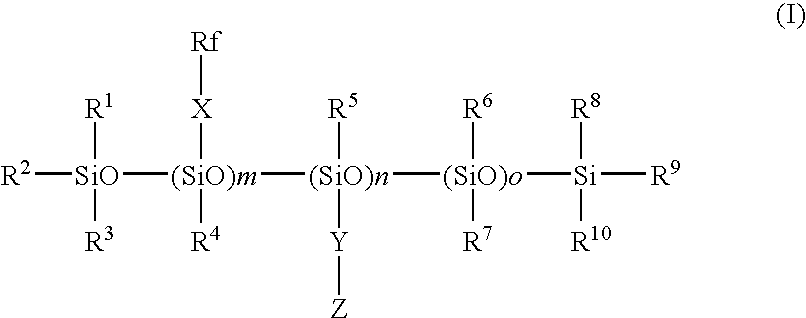

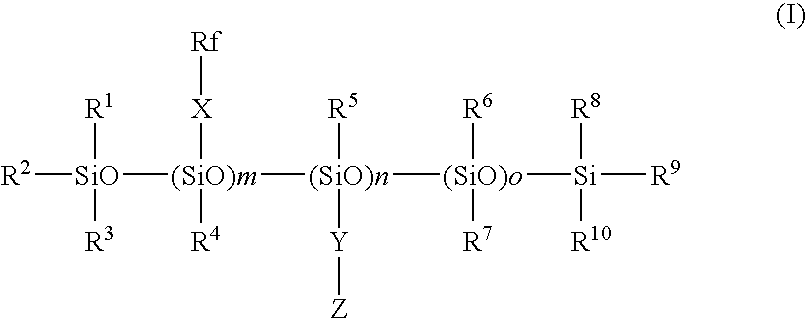

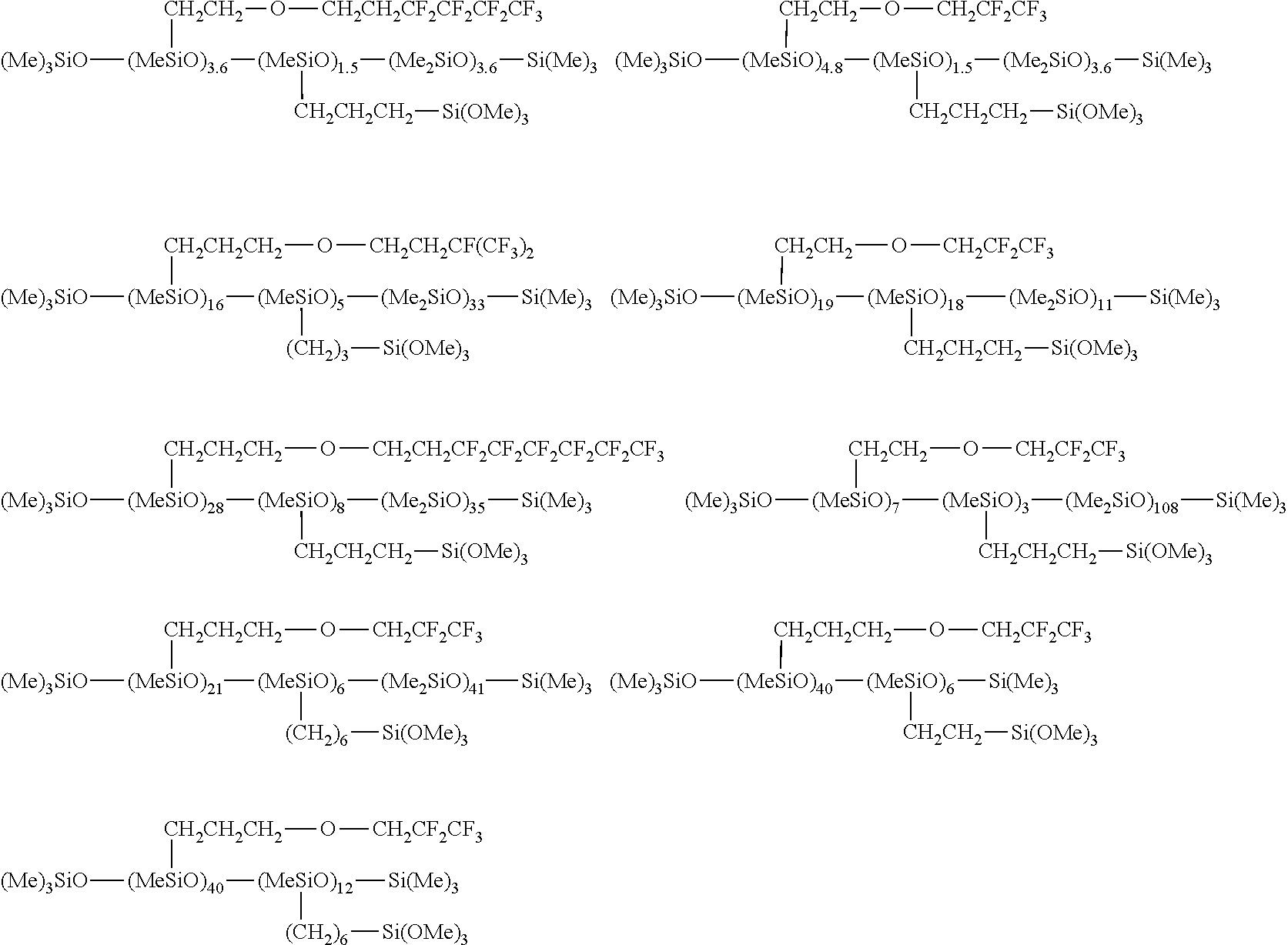

ActiveUS20100126380A1Increased durabilityExcellent releasabilityGroup 4/14 element organic compoundsCoatingsArylSilylene

Disclosed in a mold release composition comprising a fluorosilicone compound of the formula (I): (I) wherein R1, R2, R4, R5, R6, R7, R8 and R9 each is, the same or different, a substituted or unsubstituted alkyl group, or a substituted or unsubstituted aryl group, R3 and R10 each is; the same or different, a substituted or unsubstituted alkyl group, or a substituted or unsubstituted aryl group, or Rf-X—, or Z—Y— in which X and Y each is; the same or different, a divalent organic group, Rf is a C1-6 fluoroalkyl group, Z is a silyl group containing a hydrolyzable site, m is 1-100, n is 1-50, and o is 0-200. The mold release composition can give excellent mold releasability and durability of mold releasability (repeated mold releasability).

Owner:DAIKIN IND LTD

Fluorosilicone mold release composition

ActiveUS8497340B2Increased durabilityExcellent releasabilityGroup 4/14 element organic compoundsCoatingsArylSilylene

Disclosed in a mold release composition comprising a fluorosilicone compound of the formula (I): (I) wherein R1, R2, R4, R5, R6, R7, R8 and R9 each is, the same or different, a substituted or unsubstituted alkyl group, or a substituted or unsubstituted aryl group, R3 and R10 each is; the same or different, a substituted or unsubstituted alkyl group, or a substituted or unsubstituted aryl group, or Rf—X—, or Z—Y— in which X and Y each is; the same or different, a divalent organic group, Rf is a C1-6 fluoroalkyl group, Z is a silyl group containing a hydrolyzable site, m is 1-100, n is 1-50, and o is 0-200. The mold release composition can give excellent mold releasability and durability of mold releasability (repeated mold releasability).

Owner:DAIKIN IND LTD

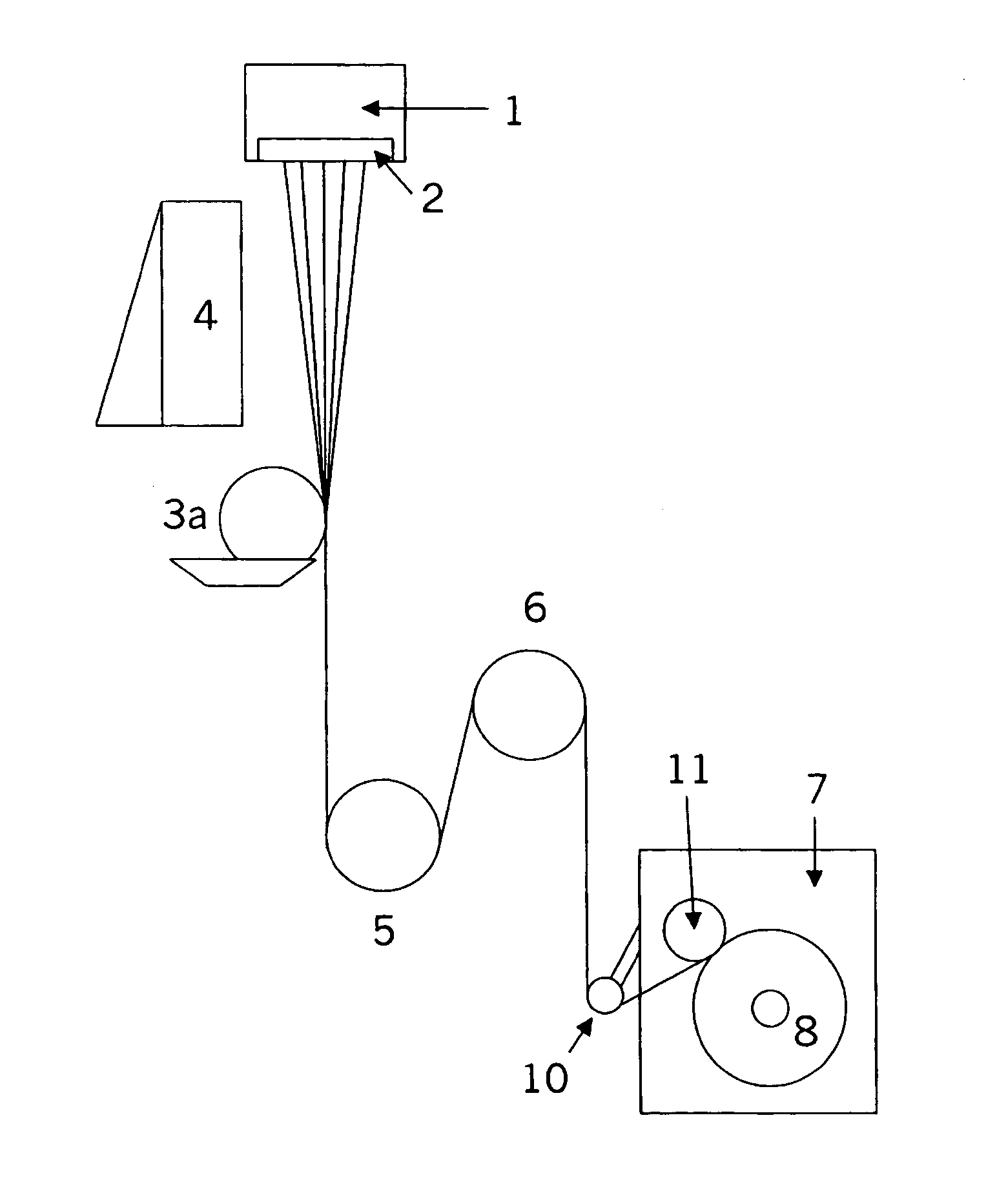

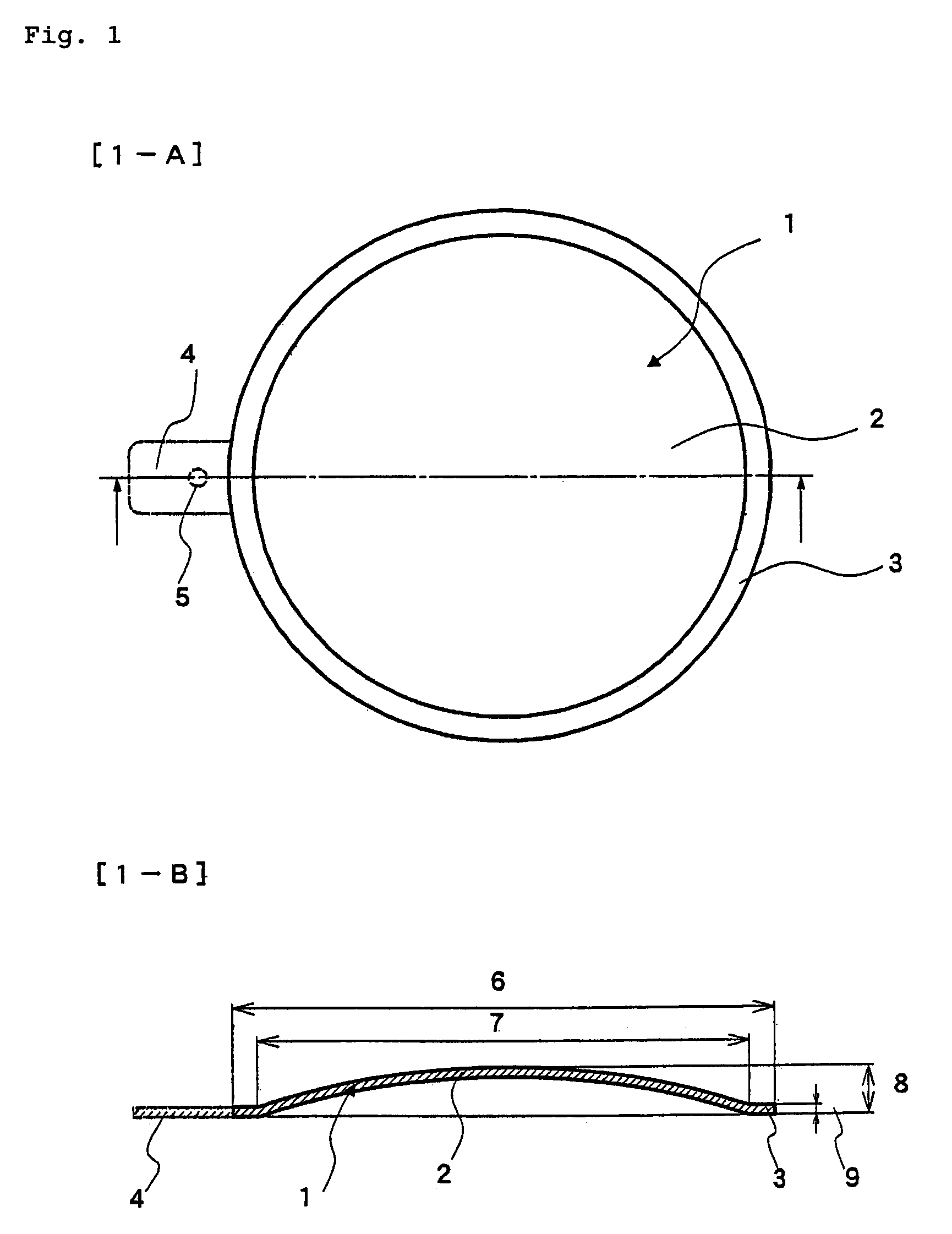

Fixing belt

InactiveUS20040180167A1Good fixabilityImprove the lubrication effectMusical toysDollsImideHeat resistance

A high-strength polyimide belt, specifically, a fixing belt which, for example, has the given strength, heat resistance, rigidity, and flexibility necessary for conveying a receiving material while pressing and heating unfixed toner images, and which is excellent in functions such as belt lubricity, toner fixability, and toner releasability. The fixing belt comprises a tubular object made of a polyimide resin and at least one functional layer superposed thereon, wherein the tubular object is molded by applying a polyimide precursor to a tubular mold, defoaming the precursor by centrifugal force, and then converting the precursor into an imide. In this belt, the thickness of the tubular polyimide resin object and functional layer or the buckling strength and tear strength of the belt preferably are within respective given ranges.

Owner:NITTO DENKO CORP

Fluorine-containing fiber processing agent having alcohol repellency and soil release properties

InactiveUS20100216363A1Improve washabilityGood effectStain/soil resistant fibresSynthetic resin layered productsFiberSoil science

Disclosed is a fluorine-containing copolymer having, as an essential component, a repeating unit derived from (a) a monomer having a fluoroalkyl group or a fluoroalkenyl group, (b) a monomer having an alkylene oxide group, (c) a monomer having an acetoacetyl group, (d) a monomer having a —CH(OH)—CH2—Cl group, and (e) a monomer having a —CH(OH)—CH2—OH group. In this fluorine-containing copolymer, the amounts of the monomer (a), the monomer (b), the monomer (c), the monomer (d) and the monomer (e) are 30-80 parts by weight, 1-30 parts by weight, 0.5-20 parts by weight, 0.5-20 parts by weight and 0.5-20 parts by weight, respectively. This fluorine-containing copolymer provides a base material such as a fiber product with excellent alcohol repellency, oil repellency, antifouling properties and soil release properties, while maintaining washing durability. This fluorine-containing copolymer serves as an active ingredient for a fluorine-containing fiber processing agent having soil release properties.

Owner:DAIKIN IND LTD

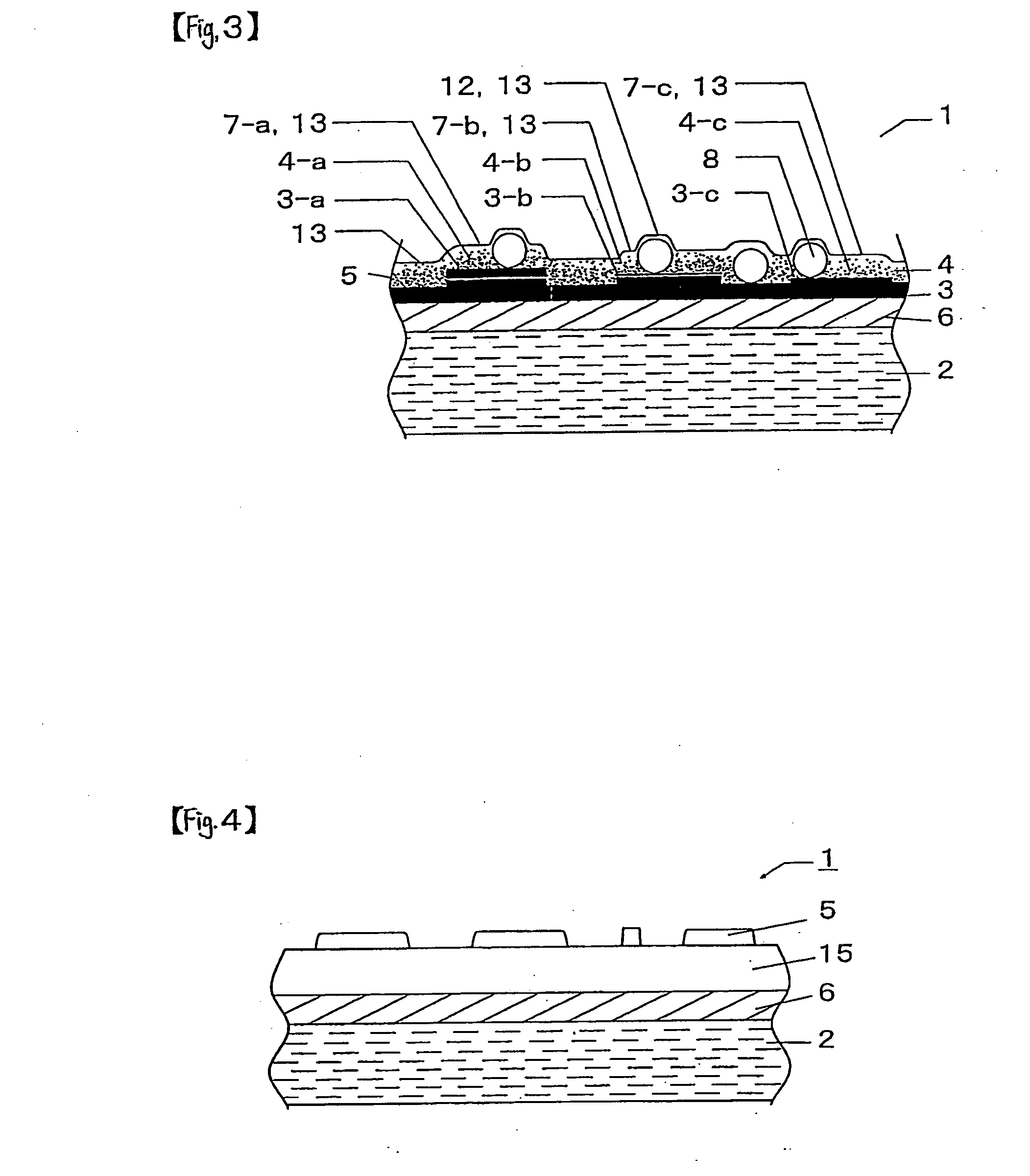

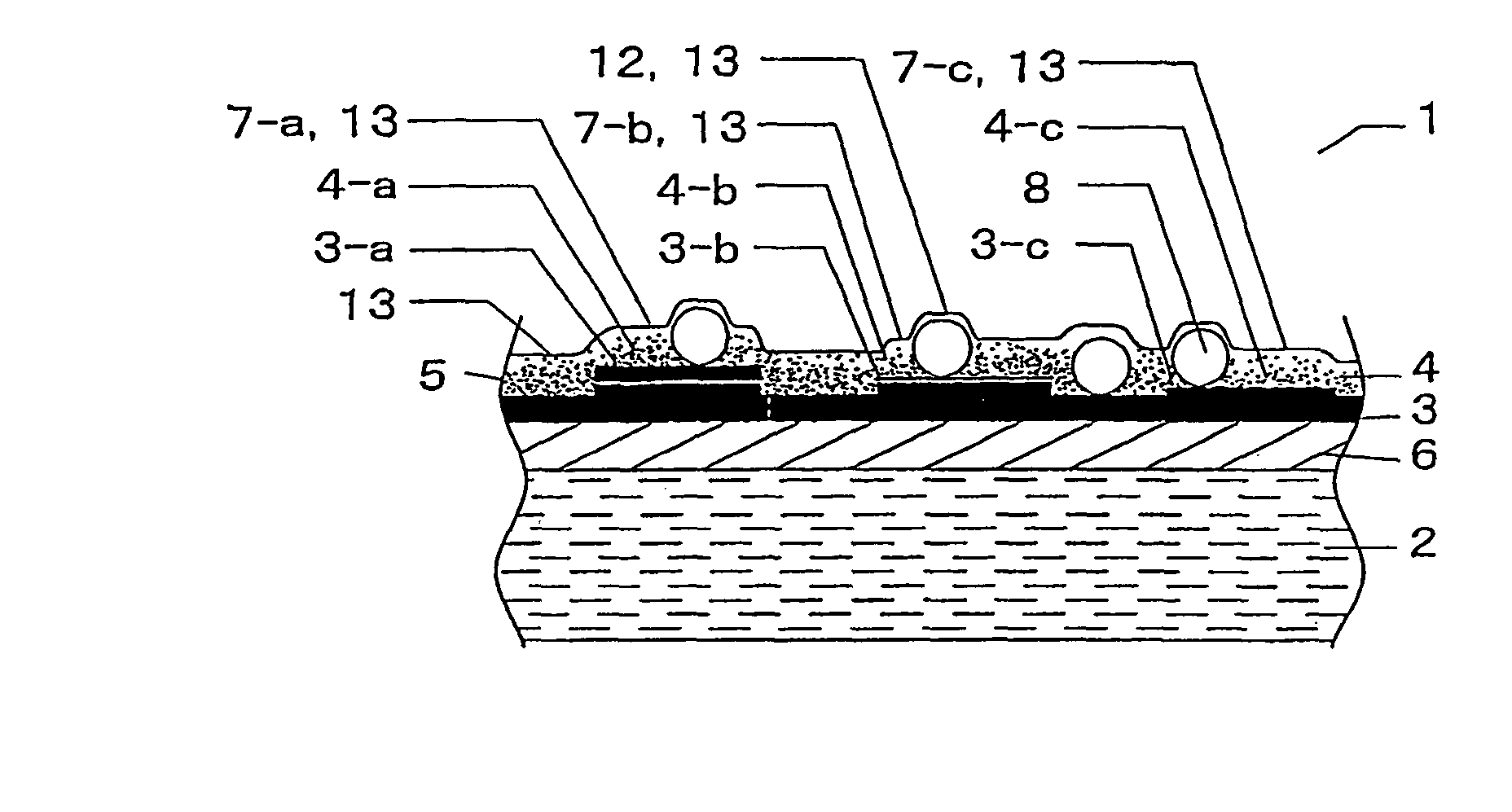

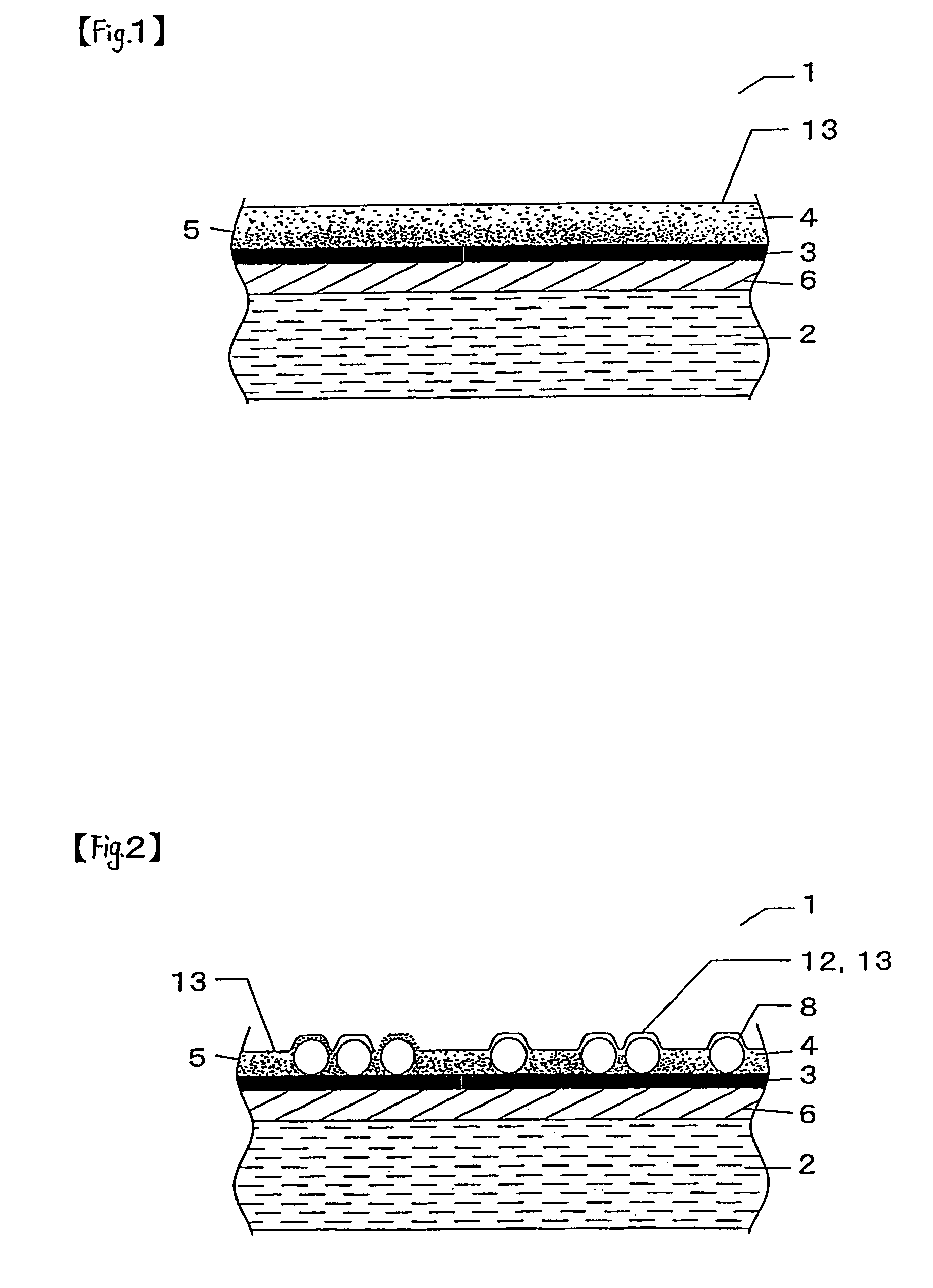

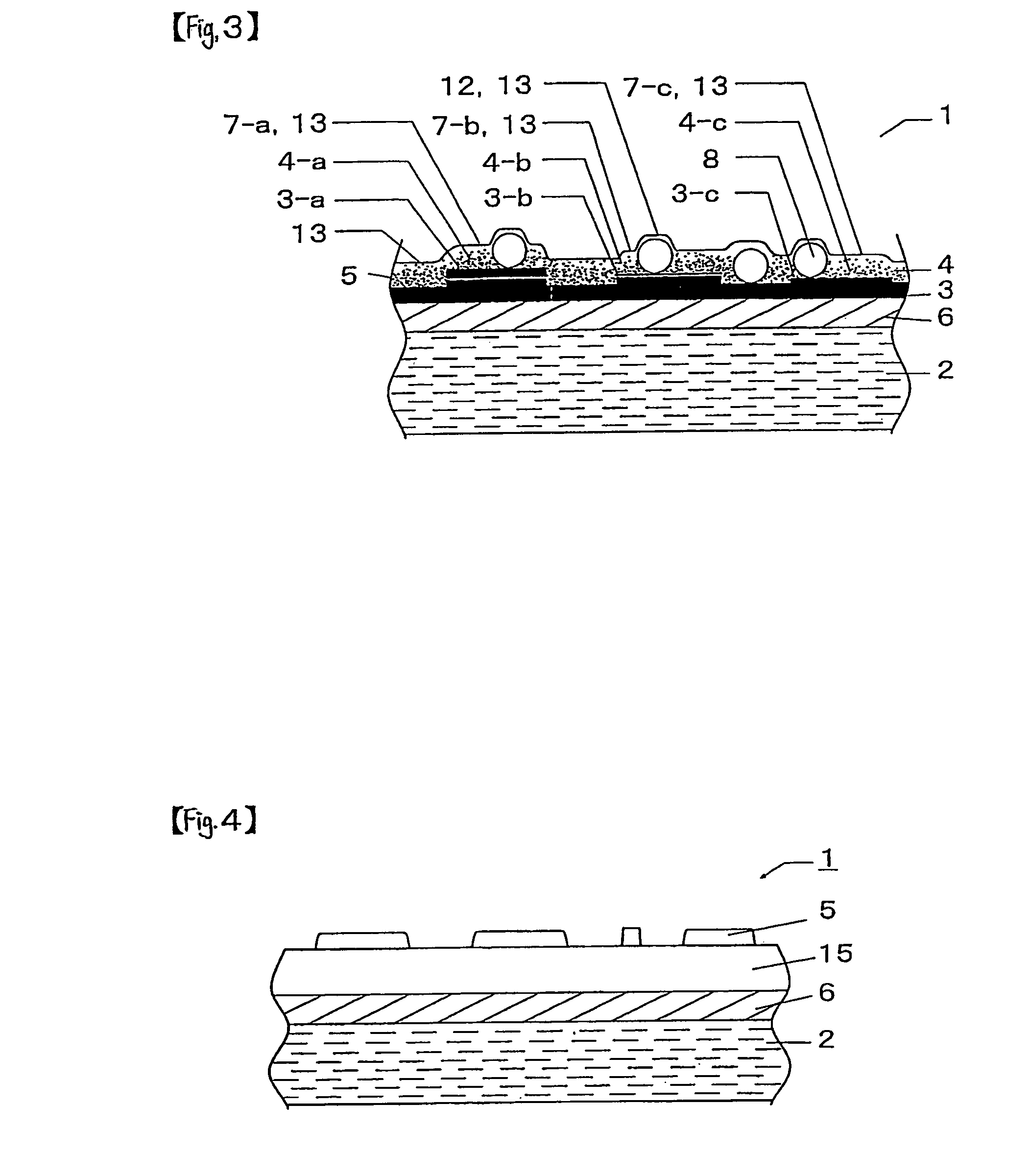

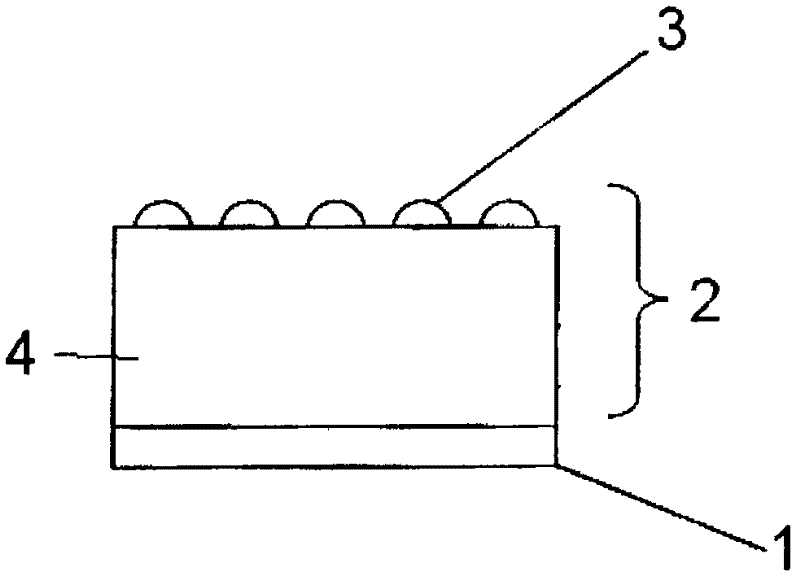

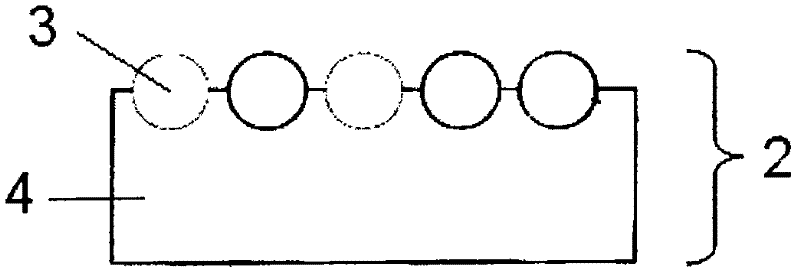

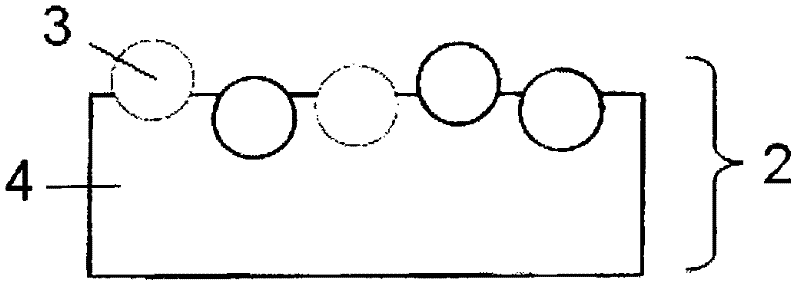

Intermediate transfer belt, image forming apparatus, and method for producing intermediate transfer belt

InactiveCN102636979AExcellent releasabilityEasy to cleanElectrographic process apparatusElastomerLatent image

An intermediate transfer belt configured to receive a toner image formed by developing, with a toner, a latent image on an image bearing member, the intermediate transfer belt including a base layer (1) and an elastic layer (2) laid on the base layer, wherein the elastic layer includes spherical resin particles (3) and a layer formed of an elastic body (4), and has a concavo-convex pattern in a surface of the elastic layer, wherein the spherical resin particles are arranged in a plane direction in the surface of the elastic layer, and wherein the intermediate transfer belt has glossiness of 35% or higher as determined based on reflected light at 85 DEG on the surface of the intermediate transfer belt.

Owner:RICOH KK

Electrophotographic toner

An electrophotographic toner comprising a resin, a colorant and a release agent which comprises a first wax and a second wax, wherein: (i) the first wax exhibits: an endothermic peak appearing in the range 75-100° C., a peak width at half height of the endothermic peak of 10-40° C., an exothermic peak appearing in the range 70-100° C. and a peak width at half height of the exothermic peak of 10-40° C., in a DSC measurement; (ii) the second wax exhibits: an endothermic peak appearing in the range 60-90° C., a peak width at half height of the endothermic peak of 5° C. or less, an exothermic peak appearing in the range 55-80° C. and a peak width at half height of the exothermic peak of 5° C. or less, in the DSC measurement; (iii) a weight ratio of the first wax to the second wax is between 9:1 and 2:8; and (iv) the resin contains a polar group.

Owner:KONICA MINOLTA BUSINESS TECH INC

Optical Disk

InactiveUS20070258351A1Inhibit productionGood optical performanceRecord carriersMechanical record carriersCompact discMonoglyceride

It is an object of the present invention to provide a process for manufacturing a high-density optical disk having excellent optical properties by suppressing the production of a cloud caused by a release failure and preventing the deterioration of hue and light transmittance. The present invention is a process for manufacturing a high-density optical disk, comprising the steps of: (1) preparing a resin composition comprising an aromatic polycarbonate resin and a predetermined amount of monoglyceride behenate; (2) injecting molding the resin composition to obtain a substrate; and (3) forming an information recording / reproduction layer on the substrate, wherein the aromatic polycarbonate resin has a sodium metal content of 0.0005 to 0.05 ppm and a viscosity average molecular weight of 10,000 to 20,000, and the monoglyceride behenate has a sodium metal content of 1 ppm or less.

Owner:TEIJIN KASEK KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com