Preparation technique of methyl trimethoxysilane

A technology of methyltrimethoxysilane and methyltrichlorosilane is applied in the field of preparation technology of methyltrimethoxysilane, and can solve the problem that methyltrimethoxysilane is difficult to realize continuous production, the reaction process is difficult to control, and the efficiency is low. problems, to achieve the effect of DCS computer control, high effective content of products, and few operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through examples.

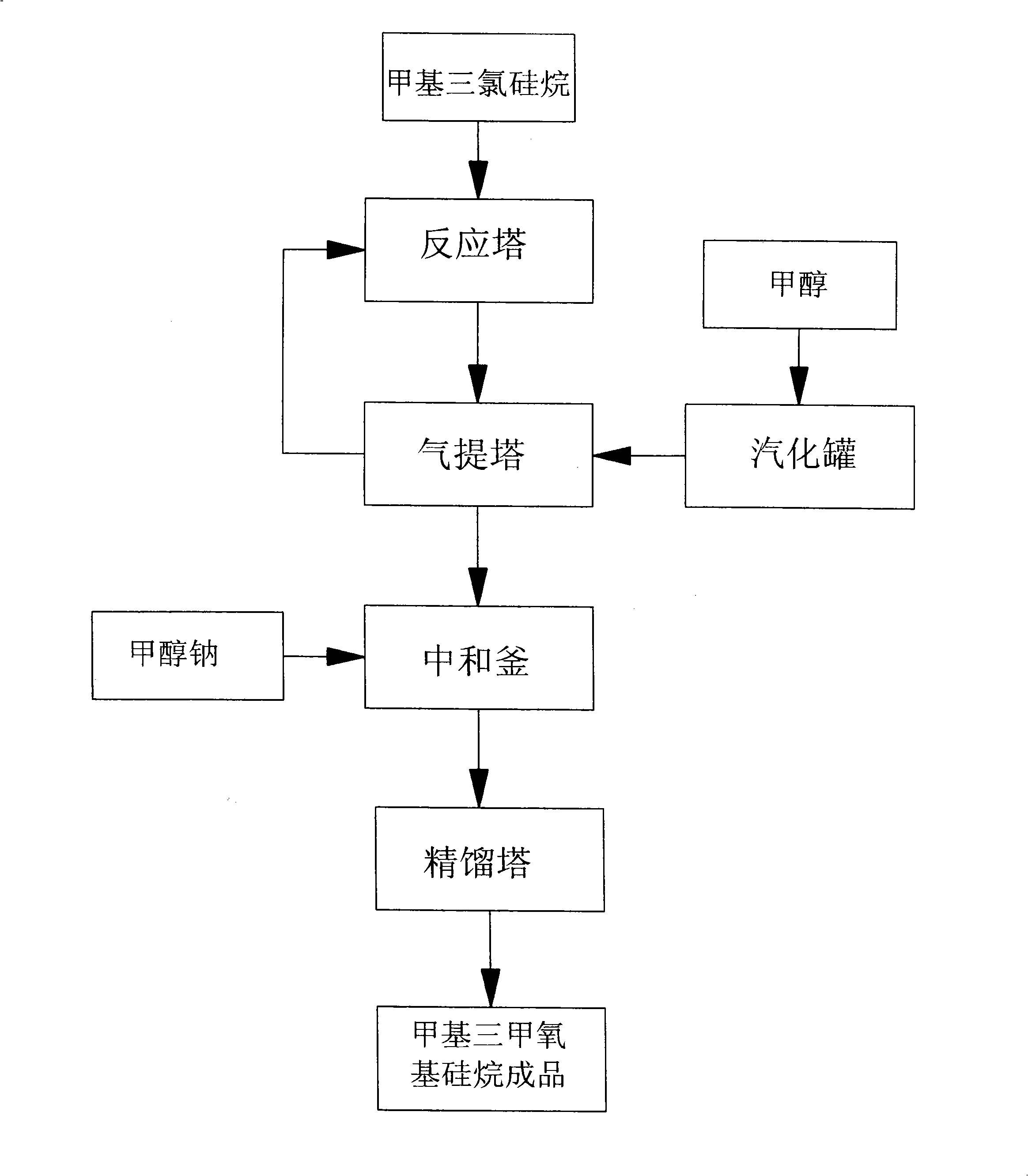

[0017] The preparation of methyltrimethoxysilane: adopt measuring pump to measure methyltrichlorosilane and methanol respectively, the mass ratio of described methyltrichlorosilane and methanol is 1.5: 1, methanol enters vaporization tank, and the temperature of vaporization tank is controlled at Any value between 70-80°C, because methanol only has a boiling point of 64.7°C, after being vaporized rapidly, it passes through another device from bottom to top—a stripper, and the temperature inside the stripper is 90°C. Then methanol gas enters the bottom of the reaction tower, and methyltrichlorosilane enters and sprays down from the top of the reaction tower. The two react through countercurrent contact. The main product produced during the reaction falls to the bottom of the reactor, and the by-product HCl gas Overflow from the gas overflow hole at the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com