Preparation method for super-hydrophobic coating

A super-hydrophobic coating and coating technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of resin curing, long time, troublesome operation, etc., and achieve convenient construction and easy repair. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

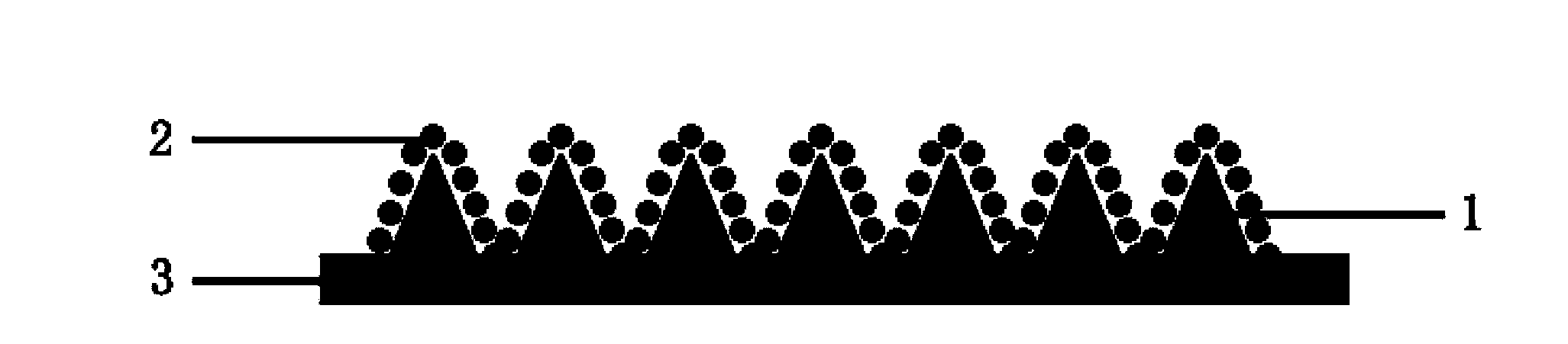

Image

Examples

Embodiment 1

[0026] Step 1. Mix 9g of hydrophobic resin moisture-curable polyurethane with 3g of 500-mesh modified talcum powder particles, dissolve them in 6g of ethyl acetate as a solvent, and prepare coating solution I;

[0027] Step 2. Add 6g of methyltrimethoxysilane and 1g of ethyl orthosilicate to 100g of ethanol to form a mixed solution, add 30g of water to the mixed solution, and then add 10g to a concentration of 1×10 -3 mol / L oxalic acid aqueous solution was stirred for 10 minutes, and after standing for 3 hours, 10 g of 25% ammonia water was added, stirred for 10 minutes, and a superhydrophobic gel was obtained after standing for 15 hours. Take 10 g of the above-mentioned superhydrophobic gel, add 20 g of industrial pure ethanol, and ultrasonically treat it for 4 minutes, set the parameters of ultrasonic dispersion as frequency 20KHz, power 360W, and prepare coating solution II;

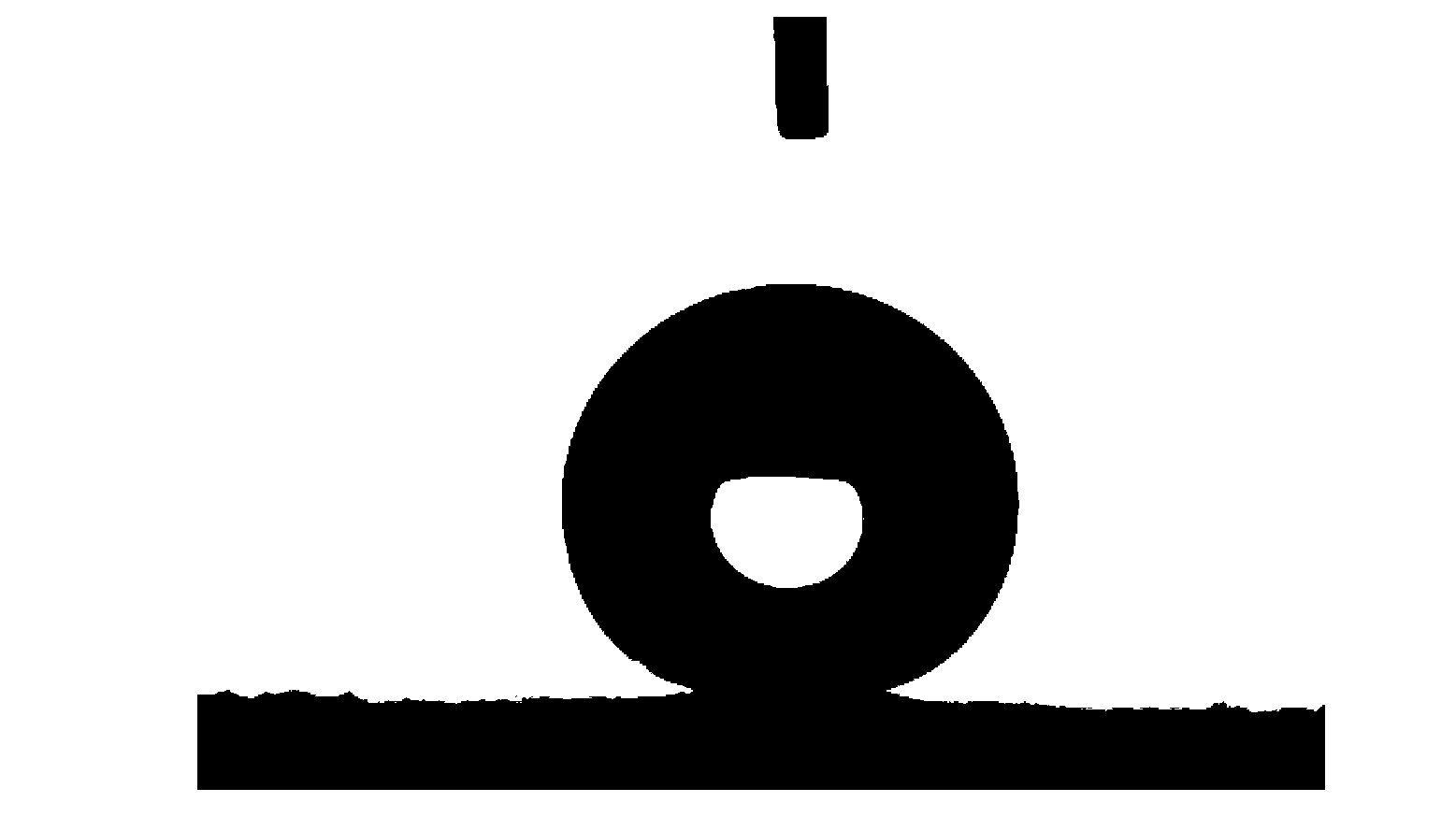

[0028] Step 3. Roll coating solution I on a 1×5 cm substrate glass slide. After 24 hours, coating...

Embodiment 2

[0030] Step 1. Mix 7.2g of hydrophobic resin fluorocarbon resin with 3g of 1000 mesh modified calcium carbonate particles, dissolve in 5.4g of butyl acetate as a solvent, and prepare coating solution I;

[0031] Step 2. Add 9g of methyltrimethoxysilane and 0.9g of ethyl orthosilicate to 98g of ethanol to form a mixed solution, add 30g of water to the mixed solution, and then add 9g to a concentration of 1×10 -3 mol / L oxalic acid aqueous solution was stirred for 10 minutes, and after standing for 3 hours, 9 g of ammonia water with a concentration of 26% was added, stirred for 10 minutes, and stood for 24 hours to obtain a superhydrophobic gel. Take 10g of the above-mentioned superhydrophobic gel, add 20g of industrial pure ethanol, and ultrasonicate for 4 minutes, set the parameters of ultrasonic dispersion as frequency 20KHz, power 360W, and prepare coating solution II;

[0032] Step 3. Roll coating the coating solution Ⅰ on a 1×5 cm substrate glass slide. After 24 hours, the ...

Embodiment 3

[0034] Step 1. Mix 9g of hydrophobic resin fluorocarbon resin with 3g of 1500 mesh modified talcum powder particles, dissolve in 1.5g of tetrahydrofuran as a solvent, and prepare coating solution I;

[0035] Step 2. Add 8g of methyltrimethoxysilane and 0.8g of ethyl orthosilicate to 96g of ethanol to form a mixed solution, add 30g of water to the mixed solution, and then add 8g to a concentration of 1×10 -3 mol / L oxalic acid aqueous solution was stirred for 10 minutes, and after standing for 3 hours, 8 g of ammonia water with a concentration of 27% was added, stirred for 10 minutes, and stood for 24 hours to obtain a superhydrophobic gel. Take 10g of the above-mentioned superhydrophobic gel, add 20g of industrial pure ethanol, and ultrasonicate for 4 minutes, set the parameters of ultrasonic dispersion as frequency 20KHz, power 360W, and prepare coating solution II;

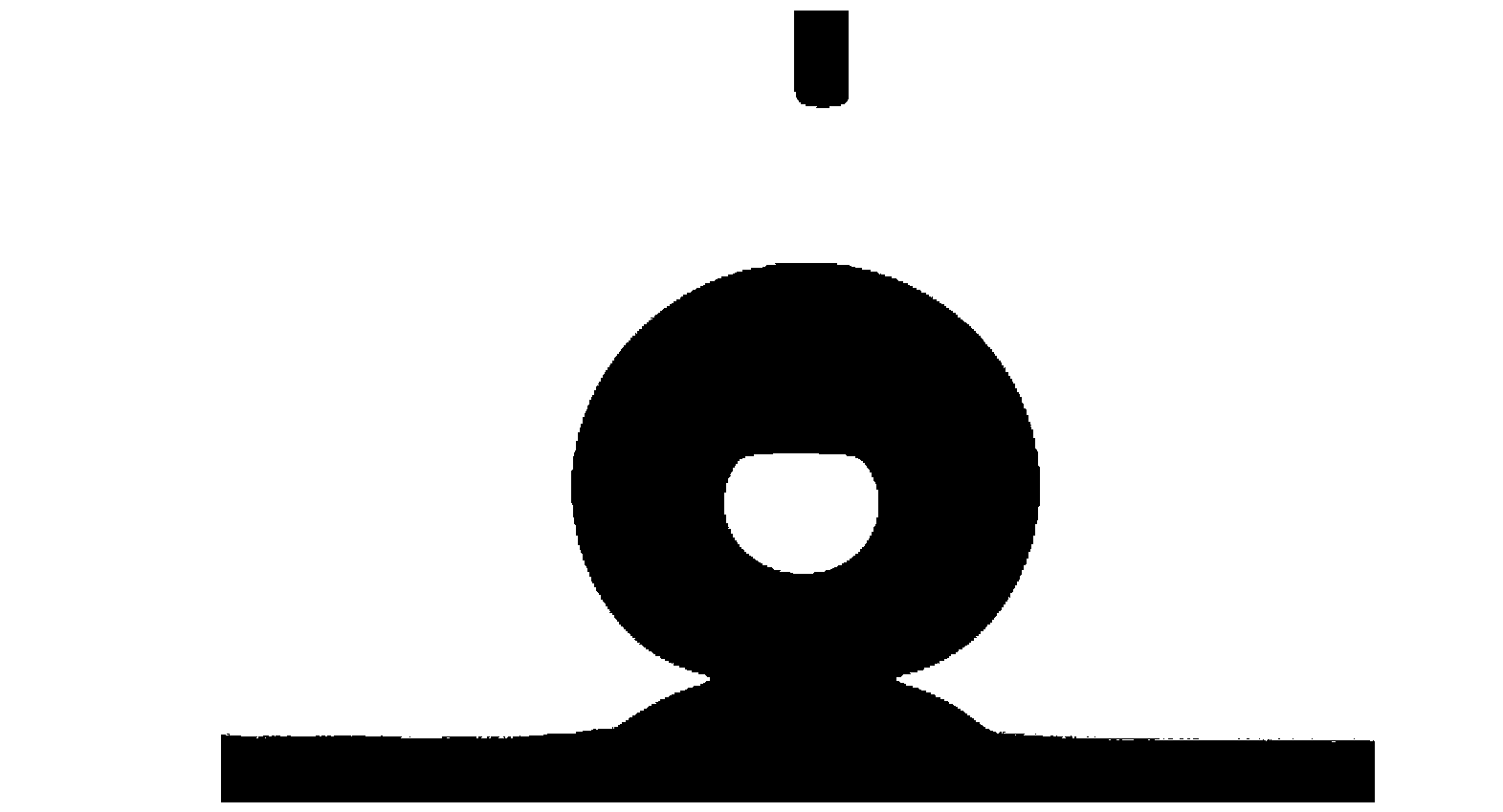

[0036] Step 3. Roll coating solution I on a 1×5 cm glass slide. Coating solution I was cured at 270°C for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com