Water-based porcelain film coating and preparation method thereof

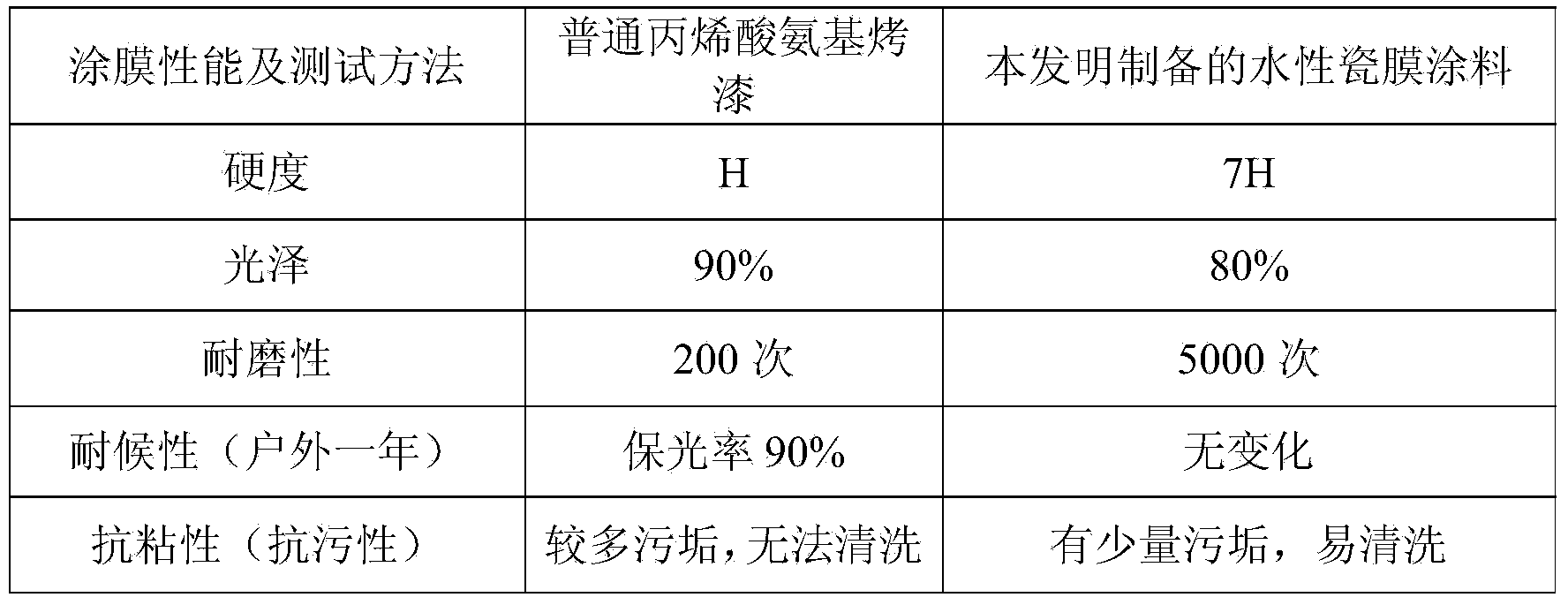

A technology of water-based porcelain film coating and formulation, applied in the direction of coating, etc., can solve the problems of inorganic coatings such as lack of waterproof and anti-adhesive properties, lack of decoration, etc., and achieve good outdoor durability and anti-pollution, good anti-sticking, good The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example is a preparation example of water-based inorganic porcelain film coating, which is prepared as follows:

[0034] 1) Weigh each component according to the following formula:

[0035] 30g large particle size silica sol with a particle size distribution of 40-50nm, 20g small particle size silica sol with a particle size distribution of 10-15nm, 24g methyltrimethoxysilane, 13g methyltriethoxysilane, 6.5g iron Manganese black, 3.2g of nano-alumina with a particle size of 500nm, 0.6g of polyether modified organosilane, 1.1g of polydimethyl hydroxy-containing silicone oil; 1g of a mixture of formic acid and acetic acid at a mass ratio of 1:1;

[0036] The large particle size silica sol and the small particle size silica sol used in this example can be specifically GRACE PM50 and GRACE AM, and the iron manganese black used can be specifically BLACK430;

[0037] 2) Mix the large particle size silica sol with the small particle size silica sol, and disperse for 3-5 min at 30...

Embodiment 2

[0039] This example is a preparation example of water-based inorganic porcelain film coating, which is prepared as follows:

[0040] 1) Weigh each component according to the following formula:

[0041] 35g large particle size silica sol with a particle size distribution of 40-50nm, 16g small particle size silica sol with a particle size distribution of 10-15nm, 22g methyltrimethoxysilane, 20g methyltriethoxysilane, 7.5g iron Manganese black, 2.5g nano-alumina with a particle size of 800nm, 0.8g polyether modified organosilane, 1.3g polydimethyl hydroxy-containing silicone oil; 1.5g of a mixture of formic acid and acetic acid in a 2:1 mass ratio;

[0042] The large particle size silica sol and the small particle size silica sol used in this example can be GRACE PM50 and GRACE AM respectively, and the iron manganese black can be BLACK430;

[0043] 2) Mix the large particle size silica sol with the small particle size silica sol, and disperse for 3-5 min at 300-500RPM; add iron manganese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com