Water-based paint and preparation method thereof

A technology of water-based paint and ammonia water, which is applied in polyester paint, epoxy resin paint, polyurea/polyurethane paint, etc., to achieve the effects of excellent burst resistance, less environmental pollution, and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

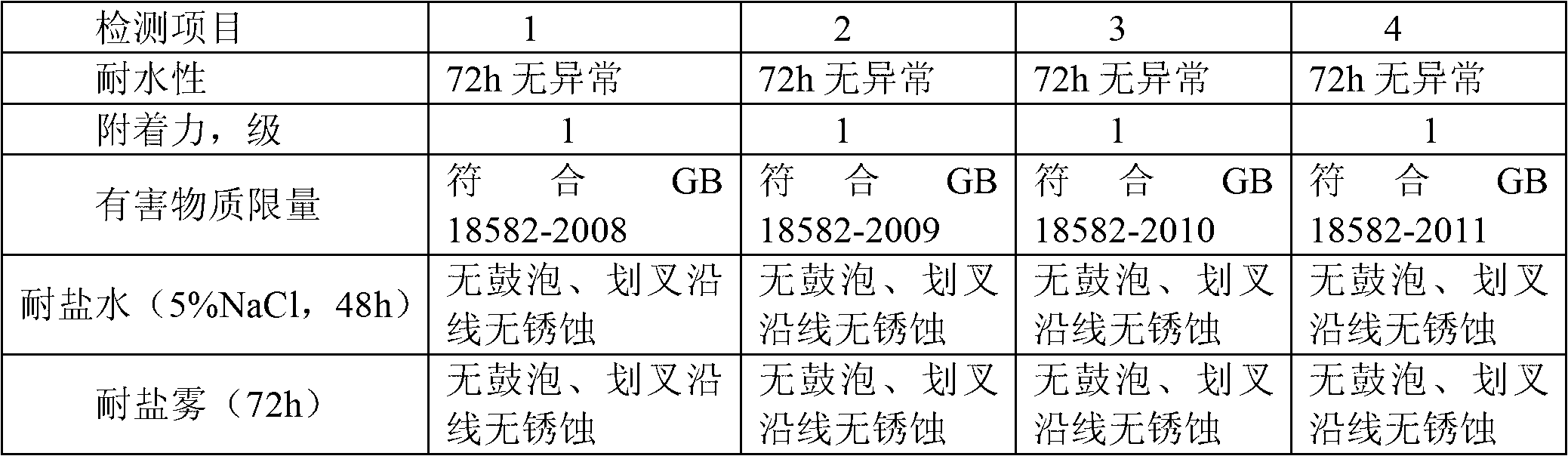

Examples

Embodiment 1

[0029] The coating made of the following raw materials by weight: 52 parts of water, 0.5 part of sodium dodecylsulfonate, 30 parts of emulsion or water dispersion resin, 0.8 part of ammonia, 0.2 part of defoamer (the brand produced in Germany is TEGO Tego, defoamer model TEGOFoamex 825), 0.1 part of sodium acetate, 0.5 part of fungicide (sulfadimethoxine), 0.5 part of corrosion inhibitor, 0.1 part of potassium persulfate.

[0030] Follow the steps below to prepare water-based coatings:

[0031] (1) Water, sodium lauryl sulfonate, emulsion or water dispersion resin, ammoniacal liquor, defoamer are equipped by embodiment 1; In the present embodiment, defoamer, sodium acetate, bactericide, corrosion inhibitor, Potassium persulfate; the equipped water is divided into three parts, the first part of water is used for step (2), the second part of water is used for step (3), the third part of water is used for step (4), and the first part of water accounts for the equipped 45% of the...

Embodiment 2

[0038] The coating made of the following raw materials by weight: 55 parts of water, 0.7 part of sodium dodecylsulfonate, 70 parts of emulsion or water dispersion resin, 1 part of ammonia, 0.1 part of defoamer (the brand produced in Germany is TEGO Tego, defoamer model TEGFOamex 825), 0.05 parts of sodium acetate, 2.5 parts of fungicide (sulfamethazine), 1 part of corrosion inhibitor, 0.2 parts of potassium persulfate.

[0039] Prepare the water-based paint according to the following steps successively:

[0040] Water, sodium lauryl sulfonate, emulsion or water dispersion resin, ammoniacal liquor, defoamer are equipped by embodiment 2; In the present embodiment, defoamer, sodium acetate, bactericide, corrosion inhibitor, potassium persulfate The equipped water is divided into three parts, the first part of water is used for step (2), the second part of water is used for step (3), and the third part of water is used for step (4), and the first part of water accounts for 30% of ...

Embodiment 3

[0047] A coating made of the following raw materials by weight: 53 parts of water, 0.6 part of sodium dodecylsulfonate, 50 parts of emulsion or water dispersion resin, 0.9 part of ammonia, 0.15 part of defoamer (using mineral oil to defoam agent), 0.07 parts of sodium acetate, 5 parts of fungicide (trimethoprim), 0.1 part of corrosion inhibitor, and 0.15 parts of potassium persulfate.

[0048] Prepare the water-based paint according to the following steps successively:

[0049] Water, sodium laurylsulfonate, emulsion or water dispersion resin, ammoniacal liquor, defoamer are equipped by embodiment 3; In the present embodiment, defoamer, sodium acetate, bactericide, corrosion inhibitor, potassium persulfate The equipped water is divided into three parts, the first part of water is used for step (2), the second part of water is used for step (3), and the third part of water is used for step (4), and the first part of water accounts for 30% of the equipped water 50%, the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com