Alcoholysis process for methyltrimethoxysilane

A technology of methyltrimethoxysilanol and methyltrichlorosilane, which is applied in the field of alcoholysis of methyltrimethoxysilane, can solve problems affecting the normal production of methyltrimethoxysilane, reactor clogging, etc., and achieve Avoid incomplete alcoholysis reaction, easy to operate, stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

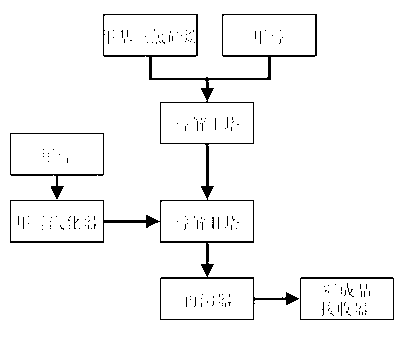

[0015] A methyltrimethoxysilane alcoholysis process, the main equipment of which includes alcoholysis I tower, alcoholysis II tower, methanol vaporizer, reboiler, crude product receiver;

[0016] Among them, the alcoholysis I tower and the alcoholysis II tower are filled with non-metallic fillers; the non-metallic fillers are: ceramics;

[0017] A methyltrimethoxysilane alcoholysis process, comprising the following components by weight: 150 parts of methyltrichlorosilane, 100 parts of methanol;

[0018] The specific process is as follows:

[0019] 1) Incomplete alcoholysis reaction: Use a metering pump to drop 150 parts of methyltrichlorosilane and 65 parts of methanol into the alcoholysis I tower at a constant speed. The temperature in the tower is controlled at 28°C. Methyltrichlorosilane and methanol Disperse and mix under the action of fillers, carry out liquid-liquid phase alcoholysis reaction at room temperature, the by-product HCl overflows from the top of the alcoholy...

Embodiment 2

[0022] A methyltrimethoxysilane alcoholysis process, comprising the following components in weight ratio: 150 parts of methyltrichlorosilane, 90 parts of methanol;

[0023] The specific process is as follows:

[0024] 1) Incomplete alcoholysis reaction: Use a metering pump to drop 150 parts of methyltrichlorosilane and 60 parts of methanol into the alcoholysis I tower at a constant speed. The temperature in the tower is controlled at 15°C. Methyltrichlorosilane and methanol Disperse and mix under the action of fillers, carry out liquid-liquid phase alcoholysis reaction at room temperature, the by-product HCl overflows from the top of the alcoholysis I tower, and the incomplete alcoholysis generated by the reaction flows into the top of the alcoholysis II tower;

[0025] 2) Complete alcoholysis reaction: 30 parts of methanol is vaporized by the methanol vaporizer and then enters the alcoholysis II tower, and continues alcoholysis with the incomplete alcoholyzate flowing into th...

Embodiment 3

[0029] A methyltrimethoxysilane alcoholysis process, comprising the following components by weight: 150 parts of methyltrichlorosilane, 95 parts of methanol;

[0030] The specific process is as follows:

[0031] 1) Incomplete alcoholysis reaction: Use a metering pump to drop 150 parts of methyltrichlorosilane and 75 parts of methanol into the alcoholysis I tower at a constant speed. The temperature in the tower is controlled at 35 ° C. Methyltrichlorosilane and methanol Disperse and mix under the action of fillers, carry out liquid-liquid phase alcoholysis reaction at room temperature, the by-product HCl overflows from the top of the alcoholysis I tower, and the incomplete alcoholysis generated by the reaction flows into the top of the alcoholysis II tower;

[0032] 2) Complete alcoholysis reaction: 20 parts of methanol is vaporized by the methanol vaporizer and then enters the alcoholysis II tower, and continues alcoholysis with the incomplete alcoholyzate flowing into the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com