Hot-dip aluminizing zinc chrome-free passivated steel-plate and technique thereof

A chromium-free passivation and passivation treatment technology, applied in metal material coating processes, chemical instruments and methods, devices for coating liquid on surfaces, etc., can solve the problem of reducing corrosion resistance and service life, easy breakdown, Poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

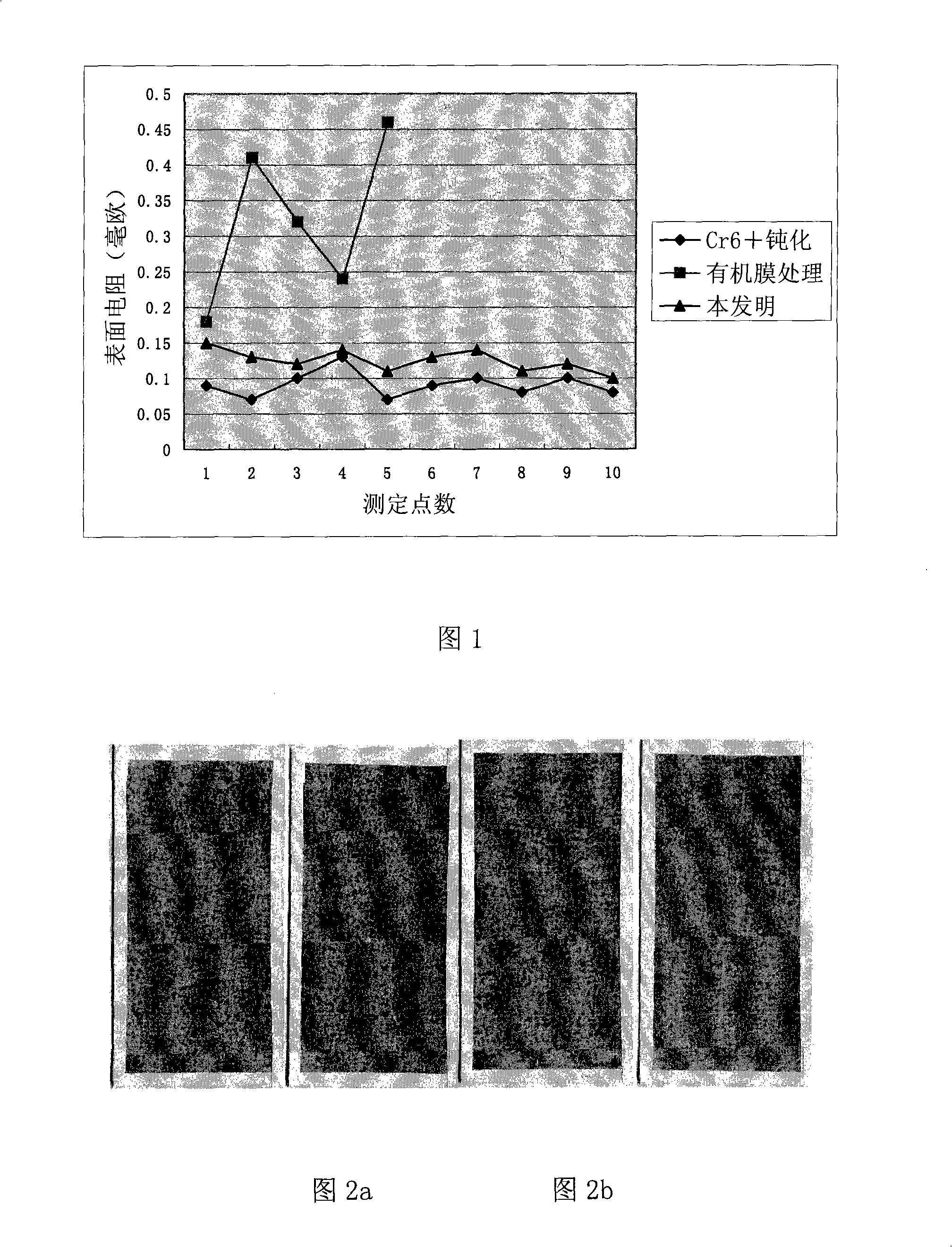

[0065] The present invention (embodiment 1~3) corrosion resistance:

[0066] table 3

[0067] Salt spray test 72h

(ASTM B117)

Cyclic corrosion test 3 cycles

(SST 8h+DWELL 16h is 1 cycle)

5% black rust and slight white rust

As shown in Figure 2a

<10% black rust and white rust

As shown in Figure 2b

[0068] Weldability:

[0069] Take the product of the present invention as an example of the welding performance of the explosion-proof strip steel in the display production plant, and the measured weldability is as shown in table 4:

[0070] Table 4

[0071] user

user 1

user 2

Steel plate specification

0.8*40mm*C

0.8*40*C

Welding process and joint form

Four point projection welding

single pulse current

Six-point lap, dispersion-enhanced

Upper electrode / lower plate electrode welding torch

Usage (e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com