Washing agent for wash oil for well cementation and preparation method thereof

A flushing agent and oil-washing technology, applied in the field of oil-washing flushing agent and its preparation, can solve problems such as contact pollution between cement slurry and oil-based drilling fluid, and achieve the effects of good flushing effect, easy availability of materials, and strong degreasing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

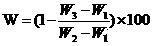

Method used

Image

Examples

Embodiment 1

[0025] Add 1200 kg of water into the reaction kettle, raise the temperature to 45°C, weigh 375 kg of fatty alcohol polyoxyethylene ether sodium sulfate (n=3), 105 kg of fatty alcohol polyoxyethylene ether (n=9), octylphenol Add 180 kg of polyoxyethylene ether (n=10) and 75 kg of sorbitan monooleate into the reaction kettle respectively, add a small amount of silicone defoamer while stirring, after stirring for 30 minutes, cool to room temperature and discharge , to obtain a translucent liquid, that is, sample 1 of the oil washing and rinsing agent of the present invention.

Embodiment 2

[0027] Add 1100 kg of water into the reaction kettle, raise the temperature to 45°C, weigh 100 kg of liquid soap, 300 kg of fatty alcohol polyoxyethylene ether sodium sulfate (n=3), 95 kg of fatty alcohol polyoxyethylene ether (n=9) kg, 175 kg of octylphenol polyoxyethylene ether (n=10), and 70 kg of sorbitan monooleate were added to the reaction kettle respectively, and a small amount of silicone defoamer was added while stirring, and after stirring for 30 minutes, Cool to room temperature and discharge to obtain a translucent liquid, which is sample 2 of the oil washing and rinsing agent of the present invention.

Embodiment 3

[0029] Add 1100 kg of water into the reaction kettle, raise the temperature to 45°C, weigh 150 kg of liquid soap, 280 kg of fatty alcohol polyoxyethylene ether sodium sulfate (n=3), 90 kg of fatty alcohol polyoxyethylene ether (n=9) kg, 170 kg of octylphenol polyoxyethylene ether (n=10), and 70 kg of sorbitan monooleate were added to the reaction kettle, stirred evenly, and after stirring for 30 minutes, cooled to room temperature and discharged to obtain half Transparent liquid, which is the sample 3 of the oil washing and rinsing agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com