Water control agent for oil well and preparation method thereof

A water control agent and oil well technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of strong sensitivity, short water control period, high injection pressure, etc., and achieve easy control of reaction conditions, adsorption and Effect of low friction and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

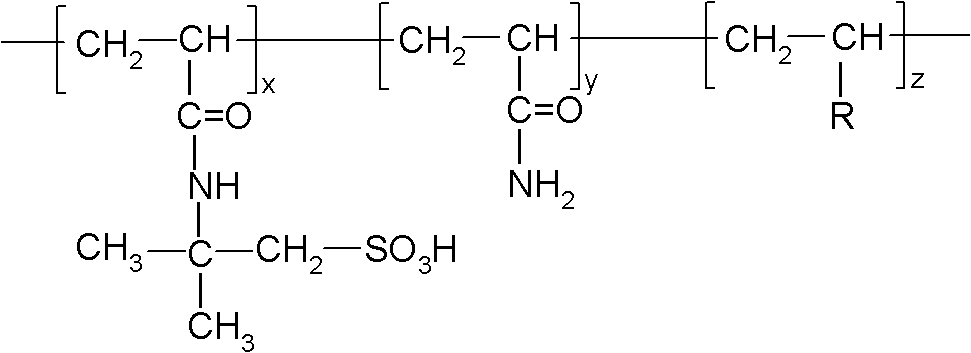

Method used

Image

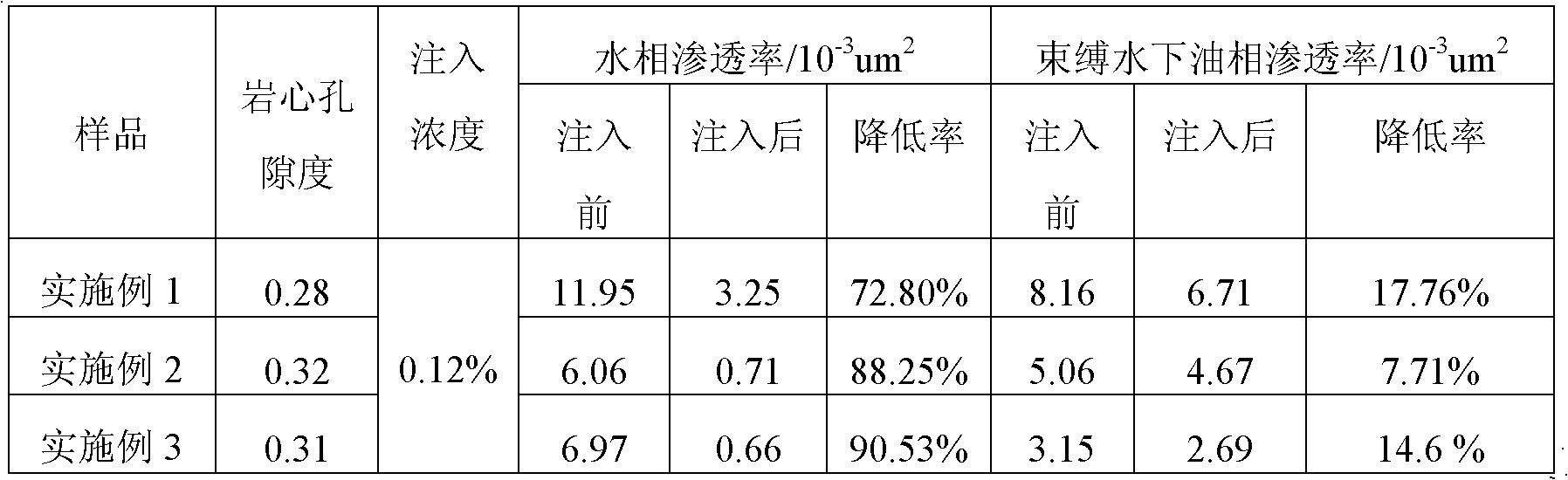

Examples

Embodiment 1

[0032] Add 40ml of kerosene, 3.2g of Span80 and 0.6g of methyl acrylate into a 250ml four-neck flask equipped with a stirrer, dropping funnel, nitrogen pipe, and thermometer. After the dissolution is complete, nitrogen is used to remove oxygen for 5 hours to prepare a continuous phase.

[0033] Put the beaker in the ice-water mixture, measure 60ml of deionized water and pour it into the beaker, weigh 0.3g of 2-acrylamido-2-methylpropanesulfonic acid into the beaker, stir until it is completely dissolved, and adjust the pH value 7-9, then weigh 11.1g of acrylamide and add it to the beaker and stir until it is completely dissolved, measure 0.9ml of 2% ammonium persulfate solution and add it to the beaker, stir to make it evenly mixed, and deoxygenate with nitrogen for 5 hours to prepare a dispersion Mutually.

[0034] Under the condition that the stirring speed is 1000-1200r / min, the dispersed phase is added dropwise to the continuous phase, and the dropwise addition is complete...

Embodiment 2

[0040]As described in Example 1, the difference is that 1.2ml of 2% ammonium persulfate solution was added, and 6ml of 0.1% sodium bisulfite solution was added to obtain a product yield of 72%, and the intrinsic viscosity of the product was 343ml / g. Elemental analysis shows that the mass percentages of hydrophobic groups and hydrophilic groups in the product are 3.0% and 7..2%, respectively.

Embodiment 3

[0042] As described in Example 1, the difference is that the reaction temperature is 50°C. The yield of the final product was 80%, and the intrinsic viscosity of the product was 843ml / g. Elemental analysis showed that the mass percentages of hydrophobic groups and hydrophilic groups in the product were 3.4% and 7.6%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com