Self-emulsifier and use thereof in tertiary oil recovery

A self-emulsifier and emulsifier technology, which is applied in drilling compositions, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of serious emulsification of strong alkali produced liquid, corrosion and scaling, and production capacity decline. , to achieve the effect of easy operation of process conditions, stable emulsification system and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

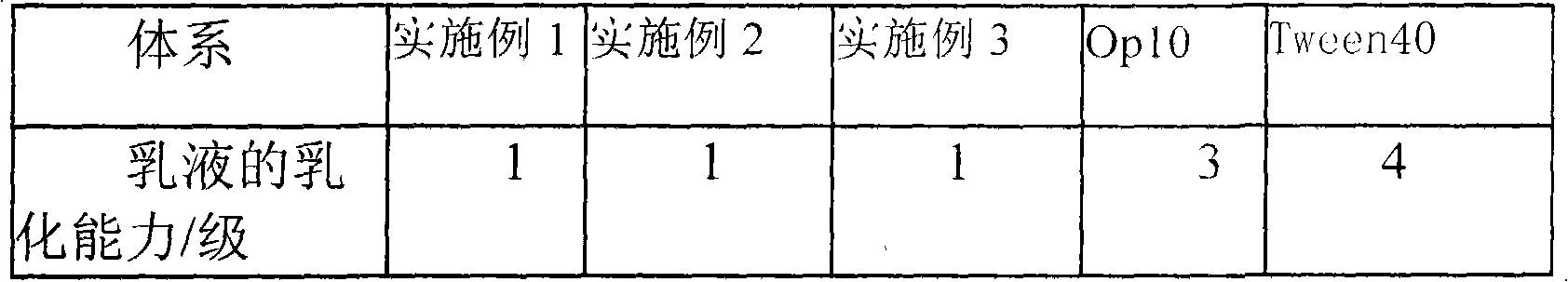

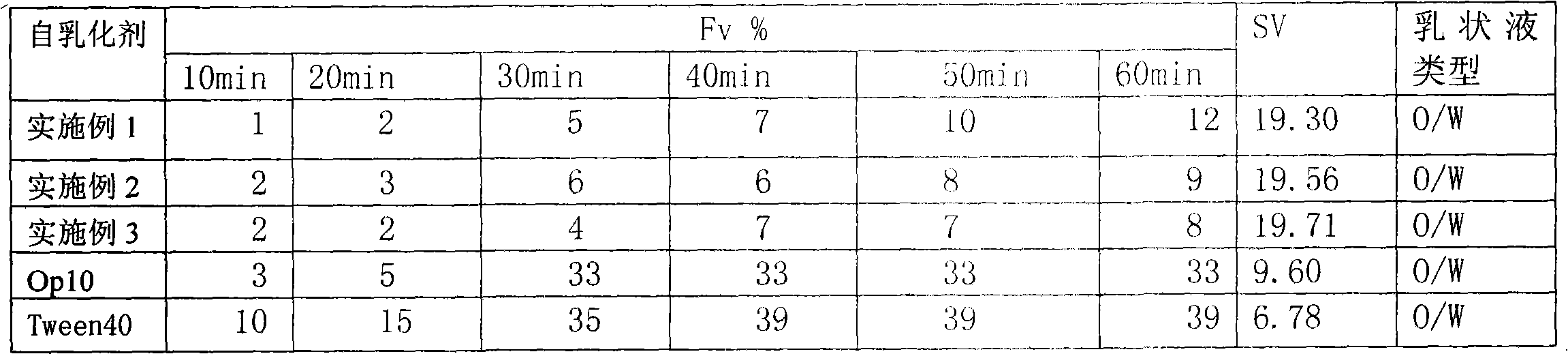

Embodiment 1

[0011] Embodiment 1: Alkylamide betaine 25%, carboxylic acid type amino acid type zwitterionic surfactant 13.5%, amine oxide surfactant 13.5%, fatty alcohol polyoxyethylene ether 5%, polyoxyethylene sorbitan Monooleate 3.7%, nonylphenol polyoxyethylene ether 2.3%, fatty acid methyl ester ethoxylate 1.5%, C 6 -C 18 The self-emulsifier was obtained under the conditions of 1.7% fatty alcohol, 0.8% triethanolamine, 0.5% glyceride, 32.5% water, heating temperature 65°C and stirring time 30min.

Embodiment 2

[0012] Embodiment 2: 30% of alkylamide betaine, 24% of carboxylic acid type amino acid type zwitterionic surfactant, 14% of amine oxide surfactant, 1% of fatty alcohol polyoxyethylene ether, polyoxyethylene sorbitan Monooleate 0.7%, nonylphenol polyoxyethylene ether 1.3%, fatty acid methyl ester ethoxylate 0.5%, C 6 -C 18 A self-emulsifier was obtained under the conditions of 3.7% fatty alcohol, 2.3% triethanolamine, 0.5% glyceride, 22% water, heating temperature 65°C and stirring time 30min.

Embodiment 3

[0013] Embodiment 3: Alkylamide betaine 24%, carboxylic acid type amino acid type zwitterionic surfactant 9%, amine oxide surfactant 5%, fatty alcohol polyoxyethylene ether 2%, polyoxyethylene sorbitan Monooleate 3%, Nonylphenol Polyoxyethylene Ether 1%, Fatty Acid Methyl Ethoxylate 1%, C 6 -C 18 The self-emulsifier was obtained under the conditions of 0.6% fatty alcohol, 0.4% triethanolamine, 0.5% glyceride, 53.5% water, heating temperature 65°C and stirring time 30min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com