Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Inhibit corrosion reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel and production method thereof

ActiveCN103695773AImprove or reduce staffImprove or reduce property damageTemperature control deviceProof constructionRoom temperature

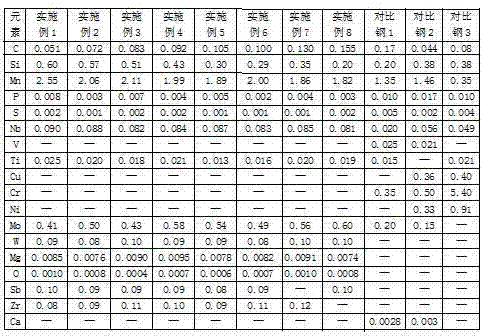

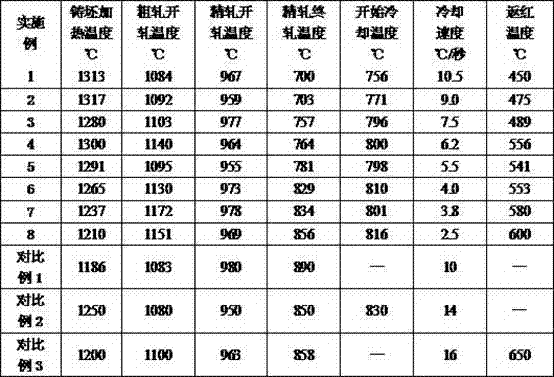

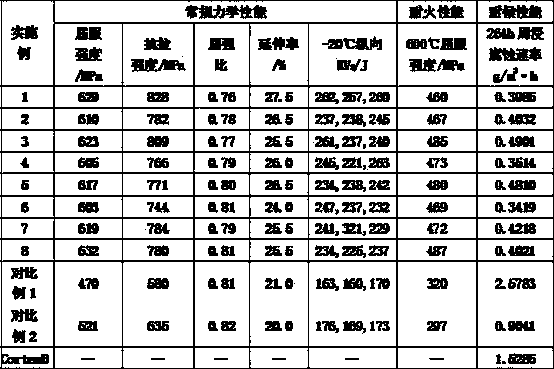

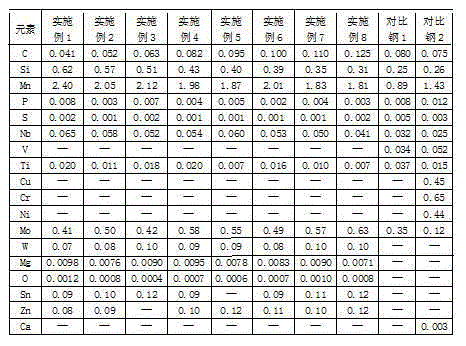

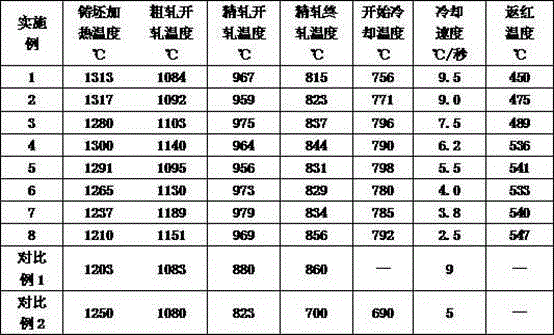

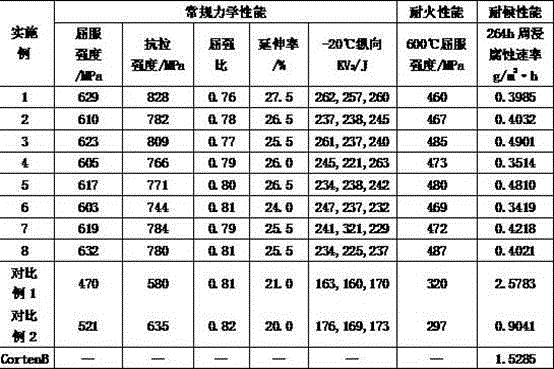

The invention relates to a 690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel which comprises the following components in percentage by weight: 0.051-0.155% of C, 0.20-0.60% of Si, 1.82-2.55% of Mn, at most 0.008% of P, at most 0.002% of S, 0.081-0.090% of Nb, 0.010-0.025% of Ti, 0.41-0.60% of Mo, 0.08-0.10% of W, 0.0071-0.0095% of Mg and at most 0.0010% of O. The production method comprises the following steps: desulfurizing molten iron; smelting in a converter; carrying out vacuum treatment, and adding the Mg element; carrying out conventional continuous casting, and heating the casting blank; carrying out sectional rolling; and carrying out finish rolling, and cooling for later use. The steel has the following advantages: the chemical components and technique are simple, the yield strength of the steel plate is 690-850MPa, the earthquake-proof property is good (the yield-tensile ratio is at most 0.83), the fire resistance is favorable (the yield strength at 600 DEG C is not lower than 2 / 3 of that at room temperature), and the corrosion resistance is better than CortenB. Besides, the steel grade has excellent impact toughness and weldability.

Owner:武汉钢铁有限公司

550MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel and production method thereof

ActiveCN103695772AImprove or reduce staffImprove or reduce property damageTemperature control deviceProof constructionRoom temperature

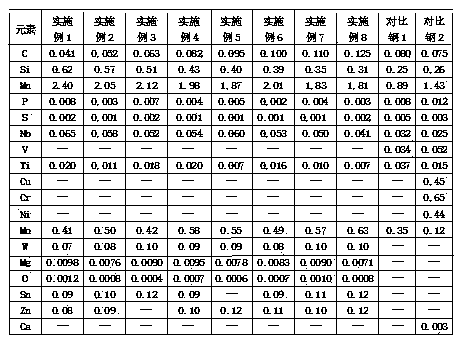

The invention relates to a 550MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel which comprises the following components in percentage by weight: 0.041-0.125% of C, 0.31-0.62% of Si, 1.81-2.40% of Mn, at most 0.008% of P, at most 0.002% of S, 0.041-0.065% of Nb, 0.007-0.020% of Ti, 0.41-0.63% of Mo, 0.07-0.10% of W, 0.0071-0.0098% of Mg and at most 0.0012% of O. The production method comprises the following steps: desulfurizing molten iron; smelting in a converter; carrying out vacuum treatment, and adding the Mg element; carrying out conventional continuous casting, and heating the casting blank; carrying out sectional rolling; and carrying out finish rolling, and cooling for later use. The steel has the following advantages: the chemical components and technique are simple, the yield strength of the steel plate is 550-700MPa, the earthquake-proof property is good (the yield-tensile ratio is at most 0.83), the fire resistance is favorable (the yield strength at 600 DEG C is not lower than 2 / 3 of that at room temperature), and the corrosion resistance is better than CortenB. Besides, the steel grade has excellent impact toughness and weldability.

Owner:武汉钢铁有限公司

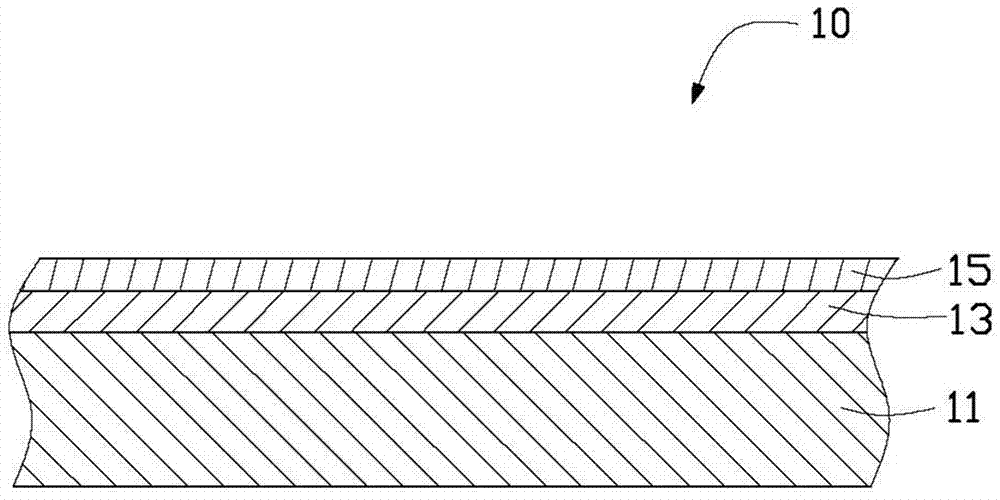

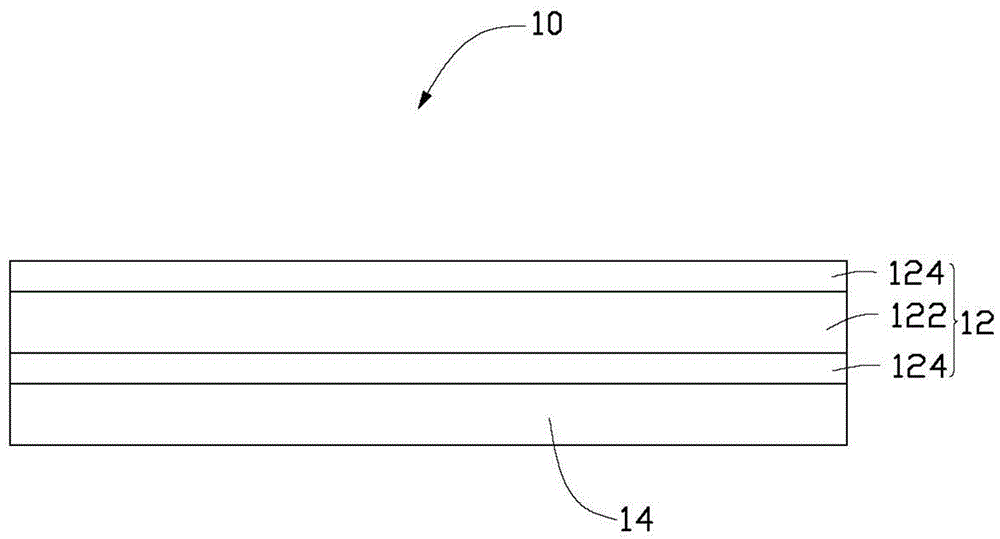

Current collector, electrochemical battery electrode and electrochemical battery

ActiveCN103187576AInhibit corrosion reactionReduce contact resistanceElectrode carriers/collectorsLi-accumulatorsMetal foilGraphite

The invention relates to a current collector. The current collector comprises a metal foil and a graphene film covered on at least one surface of the metal foil. The invention further relates to an electrochemical battery electrode using the current collector and an electrochemical battery using the electrochemical battery electrode.

Owner:TSINGHUA UNIV +1

Application of 1-myristyl-3-methylimidazolium chloride ionic liquid serving as steel corrosion inhibitor

InactiveCN101818349AMake up for the lack of toxic side effectsInhibit corrosion reactionCorrosion reactionVolatile corrosion inhibitor

The invention discloses application of 1-myristyl-3-methylimidazolium chloride ionic liquid serving as a steel corrosion inhibitor. The method of the application comprises the step of: immersing steel in acid liquor containing the corrosion inhibitor of the 1-myristyl-3-methylimidazolium chloride ionic liquid to clean the steel. The invention has the advantages that the ionic liquid is used as the corrosion inhibitor and is extremely easy to dissolve in common solutions in production, such as water and the like, which is beneficial to the penetration in the use of the corrosion inhibitor; compared with common inorganic corrosion inhibitors, the corrosion inhibitor of the invention does not have toxic action on the environment and organisms and makes up the defect of big toxic and side effects on the traditional corrosion inhibitors. The corrosion inhibitor can effectively restrain the corrosion reaction of steel materials in acid media and has good corrosion inhibition efficiency.

Owner:UNIV OF JINAN

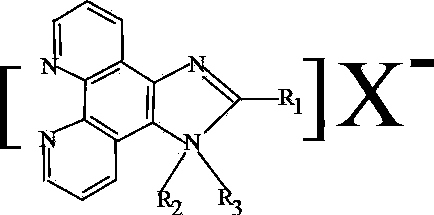

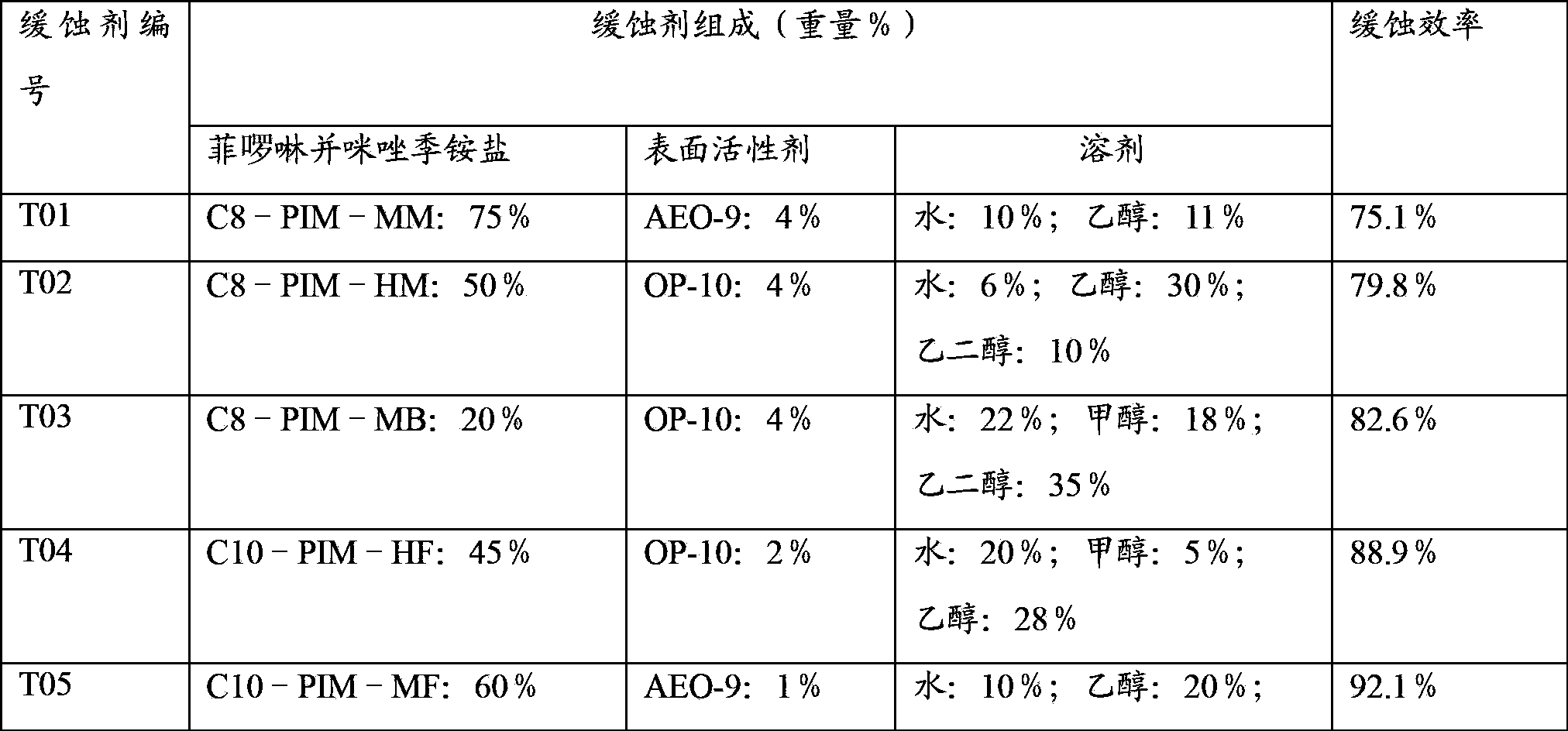

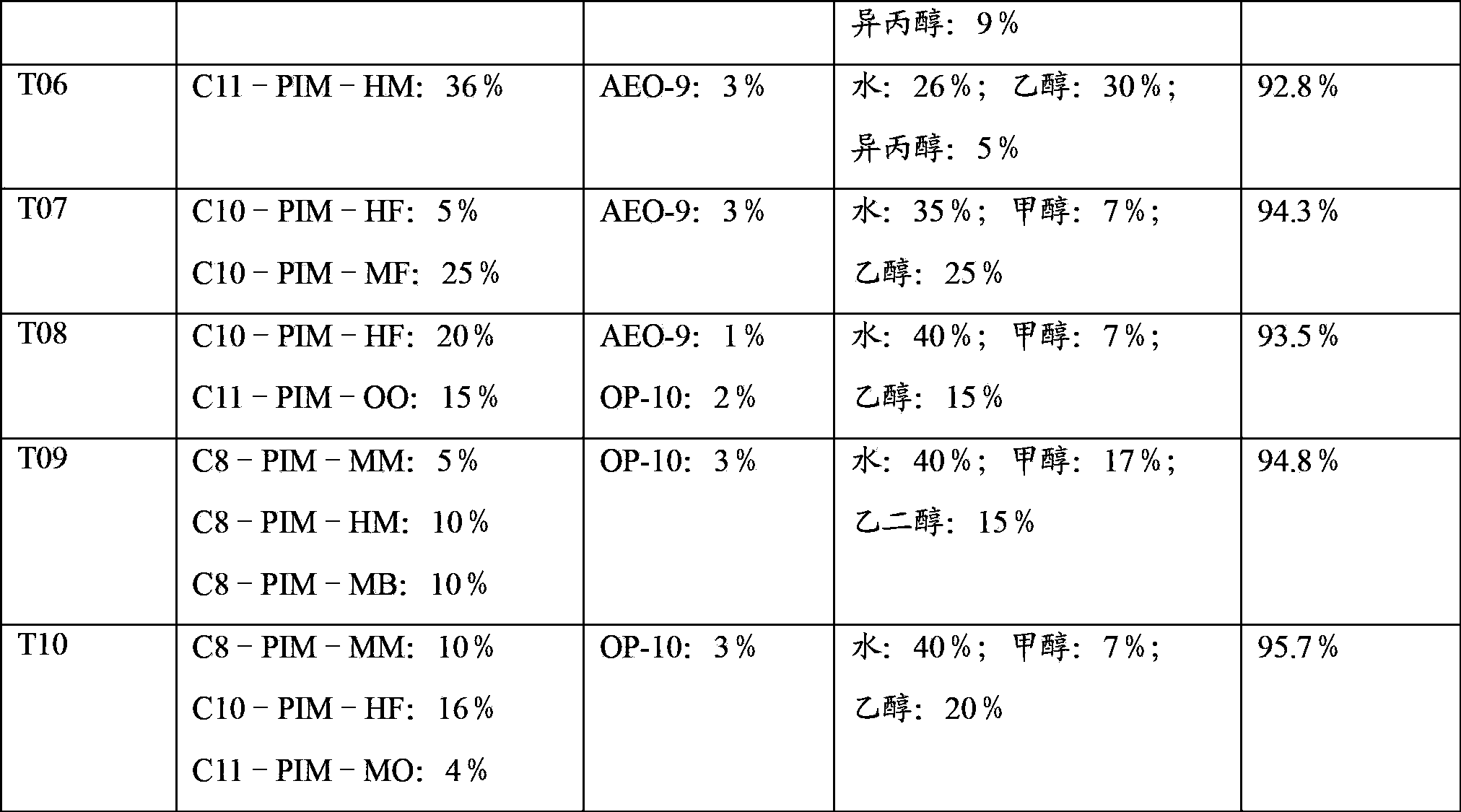

Corrosion inhibitor for gas field and preparation method thereof

ActiveCN103897681AGood stabilityGood film formationDrilling compositionBorehole/well accessoriesSolventSolubility

The invention discloses a corrosion inhibitor for a gas field and a preparation method thereof, belonging to the fields of corrosion and protection. The corrosion inhibitor is composed of the following components in percentage by weight: 20-75% of phenanthrolinoimidazole quaternary ammonium salt, 1-5% of nonionic surfactant and 20-75 of solvent. By using the phenanthrolinoimidazole quaternary ammonium salt as the main component of the corrosion inhibitor, the corrosion inhibitor has favorable stability and can well form a film on the metal surface. The phenanthrolinoimidazole is quaterized to different degrees, thereby improving the solubility of the phenanthrolinoimidazole in the water solution and changing the solubility and distribution ratio of the corrosion inhibitor molecules in an oil-gas-water multiphase flow.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

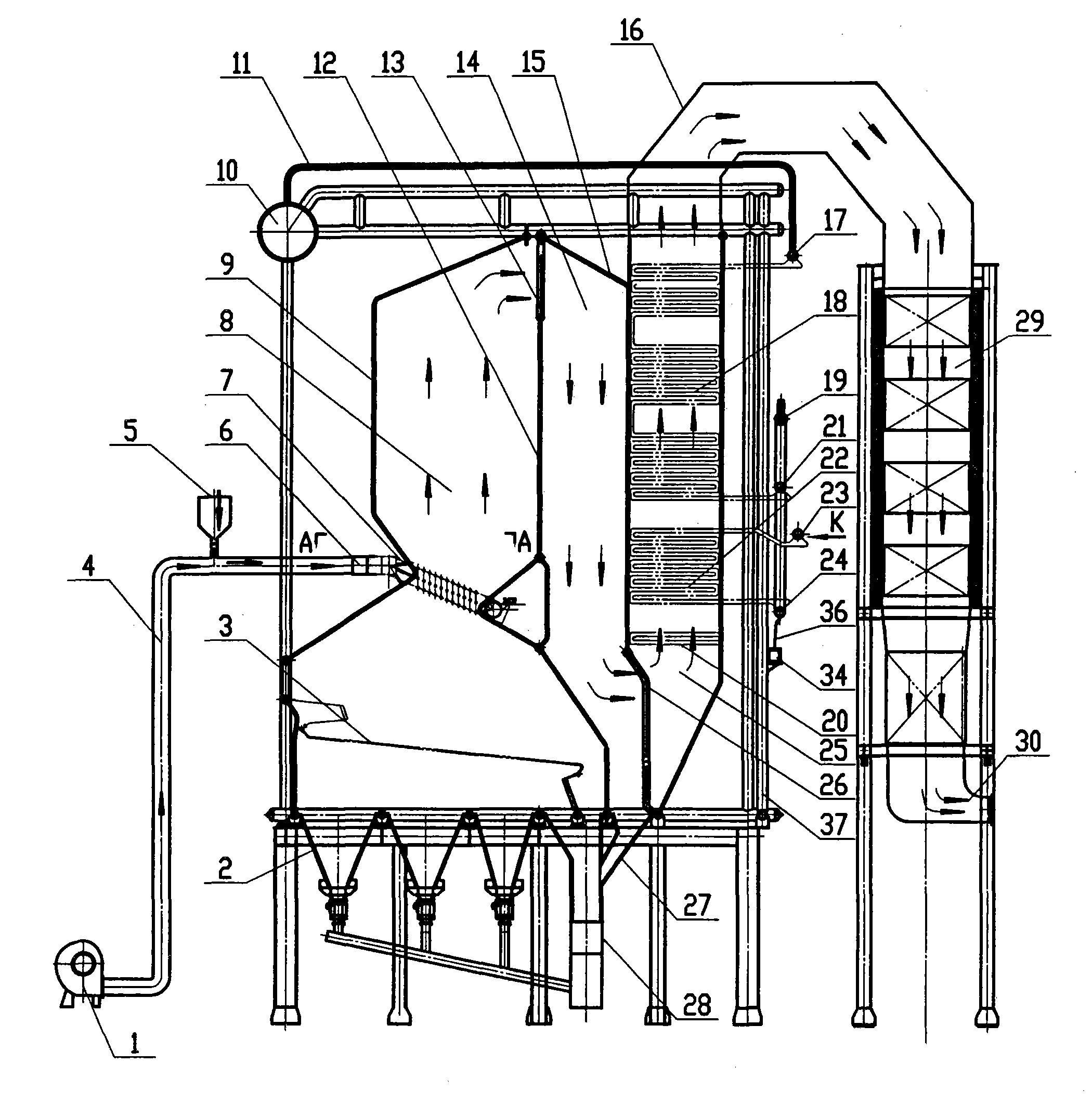

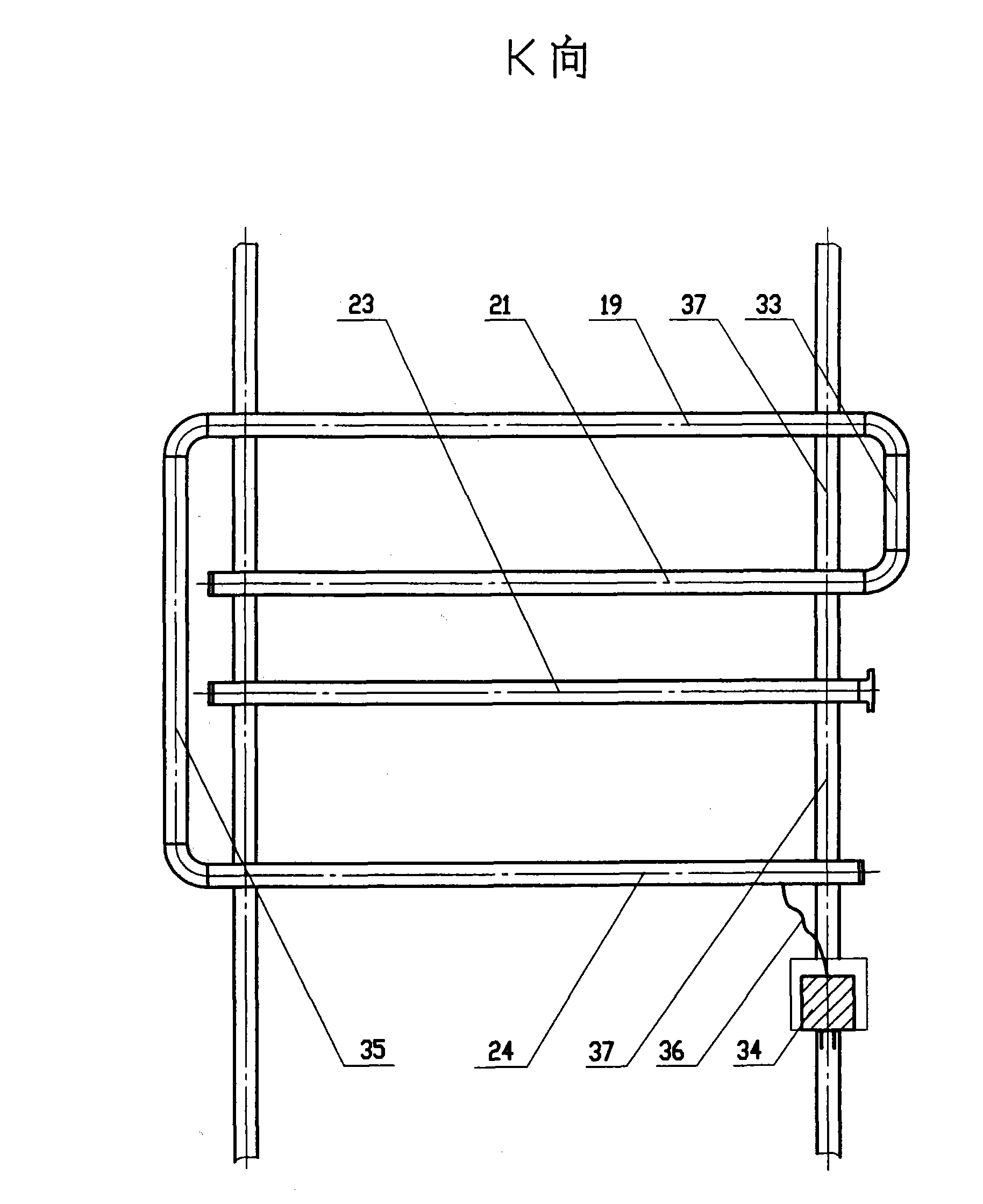

Biomass preventing corrosion of superheater and garbage power generation boiler

The invention discloses a biomass preventing the corrosion of superheater and a garbage power generation boiler, belonging to power generation equipment using renewable sources as fuel. The garbage power generation boiler comprises a boiler body, characterized in that: a circular secondary air box is arranged around a furnace arc part of a hearth and the spacing between a front arc and a rear arc is appropriately shortened; a limestone powder funnel is arranged at a secondary air main, limestone powder is fully mixed with smoke gas under the driving of secondary air so as to reduce the content of chlorine in the smoke gas; a shaft flue I, a shaft flue II and a shaft flue III are arranged sequentially at a high-temperature smoke gas outlet of the hearth, a superheater pipe is arranged inside the shaft flue II and controlled within 800 DEG C; a box body for fixing a zinc spelter is arranged at a descending pipe wall which is adjacent to a high-temperature superheater inlet header and a low-temperature superheater outlet header, and the zinc spelter is connected with the high-temperature superheater inlet header or the low-temperature superheater outlet header via conducting wires; the garbage power generation boiler has obvious effect in preventing the corrosion of the superheater, prolongs the service life of the superheater and includes low cost, simple and convenient construction and maintenance.

Owner:朴显泽 +2

Passivating anticorrosion treatment method for surface of stainless steel sieving plate

InactiveCN107815678AInhibit corrosion reactionImprove corrosion resistanceMetallic material coating processesMetallurgyCorrosion resistant

The invention discloses a passivation and anticorrosion treatment method for the surface of stainless steel sieve plate, which relates to the technical field of stainless steel sieve plate, including: (1) cleaning; (2) vacuum impregnation; (3) surface irradiation treatment; (4) passivation: The surface passivation anticorrosion treatment method of the stainless steel sieve plate of the present invention can not only form a corrosion-resistant passivation film on the surface of the stainless steel sieve plate, but also make the surface of the passivation film smoother, and effectively improve the contact angle of the surface of the passivation film , thereby significantly improving the fouling resistance of the passivation film surface.

Owner:安徽屹翔滤材有限公司

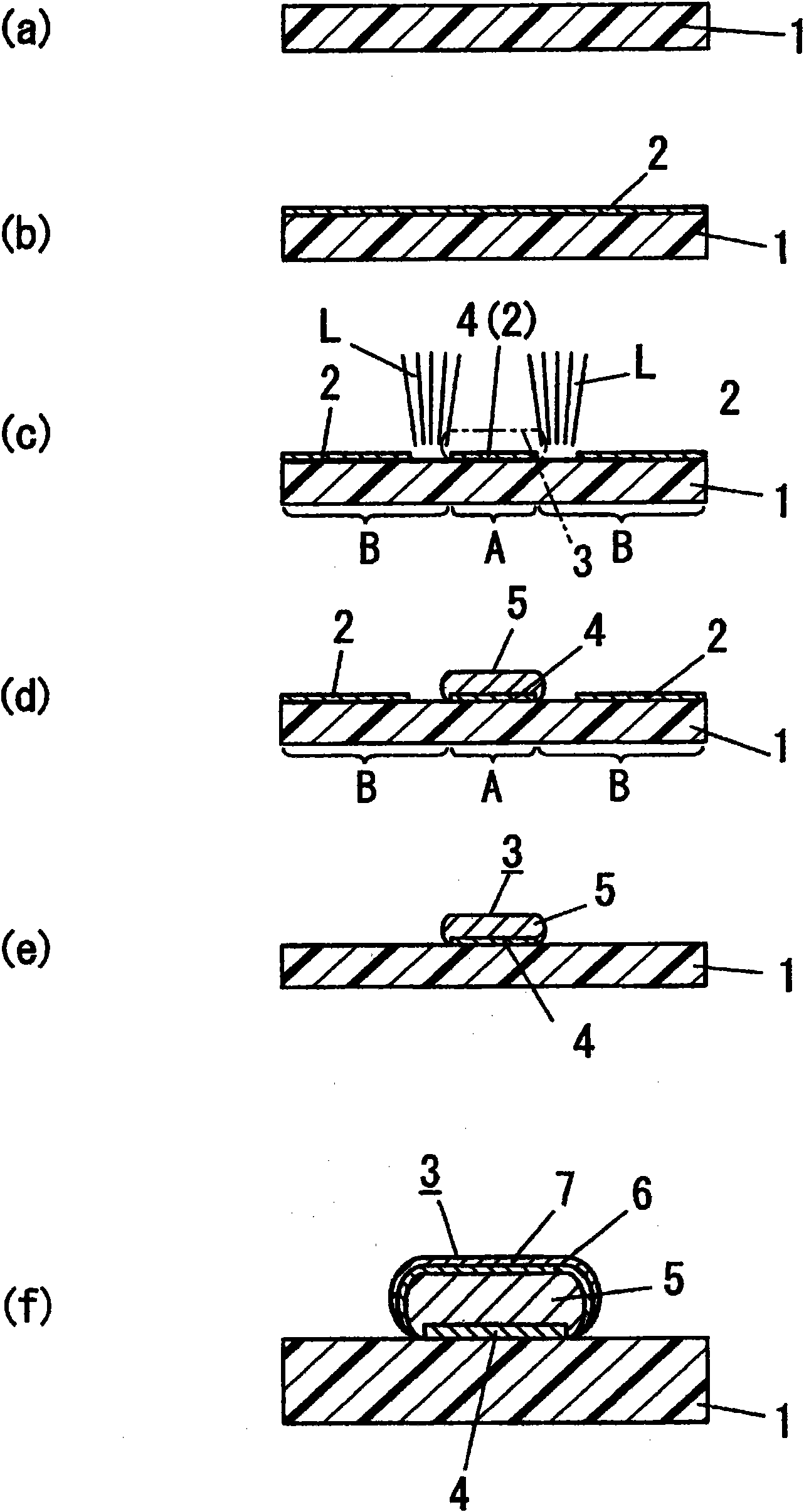

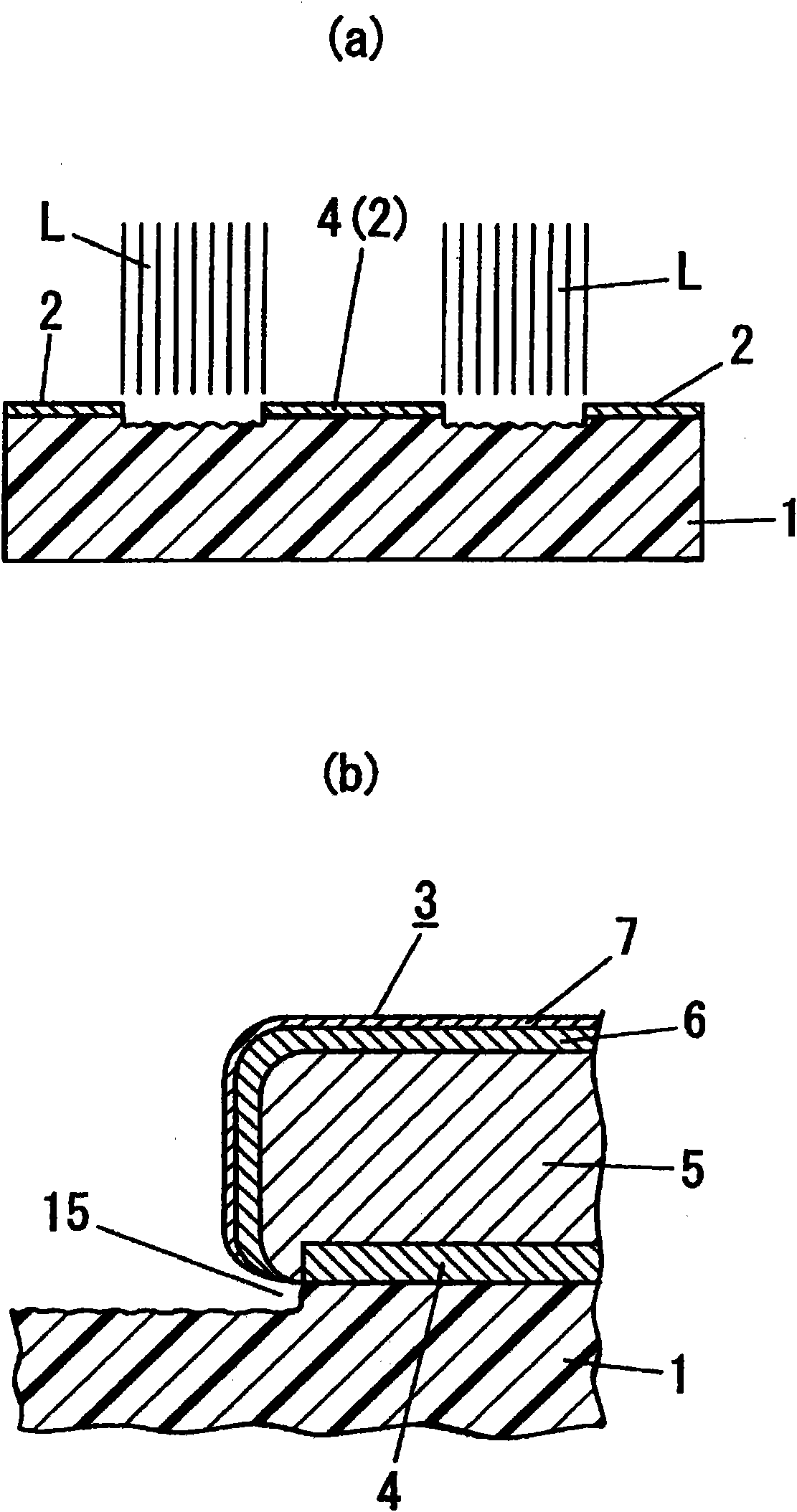

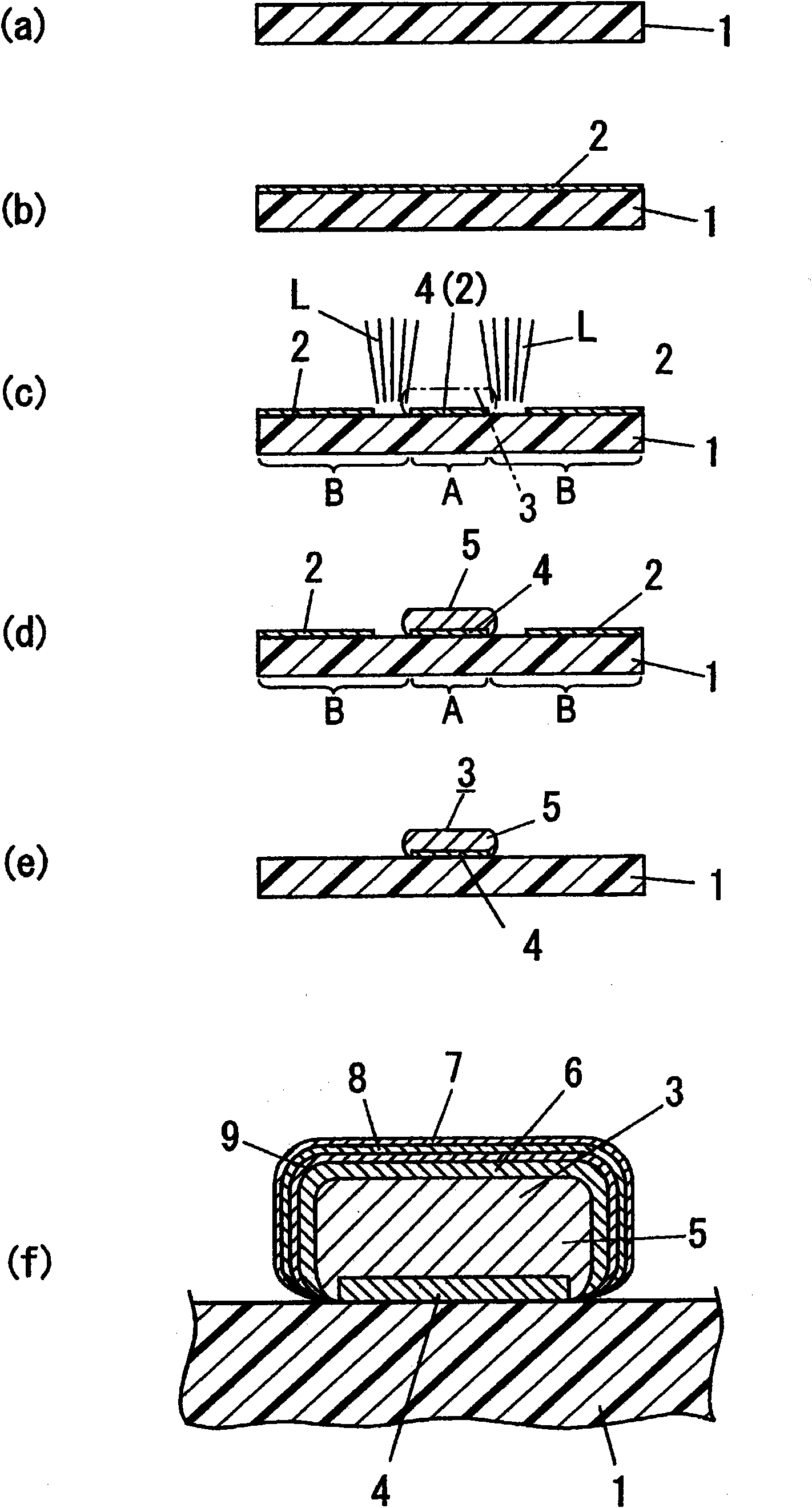

Circuit board and method for manufacturing the same

InactiveCN101849447AInhibit corrosion reactionAvoid corrosionPrinted circuit aspectsConductive material electric discharge removalEngineeringLaser beams

A circuit board is provided with an insulating substrate (1) and a circuit (3) formed on the insulating substrate (1). The circuit is provided with a plated base layer (4) whereupon a pattern is formed by irradiating a metal thin film (2) applied on a surface of the insulating substrate (1) with a laser beam (L) along the profile of the circuit (3) and partially removing the metal thin film (2) from the profile of the circuit (3). The circuit is also provided with a Cu-plated layer (5), an Ni-plated layer (6) and an Au-plated layer (7), which are formed by metal plating, on a surface of the plated base layer (4) in this order from the side of the plated base layer. Between the Ni-plated layer (6) and the Au-plated layer (7), a first intermediate plated layer (8) having a less noble metal than Au with respect to reference electrode potential is formed in contact with the Au-plated layer, and a second intermediate plated layer (9) having a more noble metal than the metal in the first intermediate plated layer with respect to the reference electrode potential is formed in contact with the first intermediate plated layer (8).

Owner:PANASONIC CORP

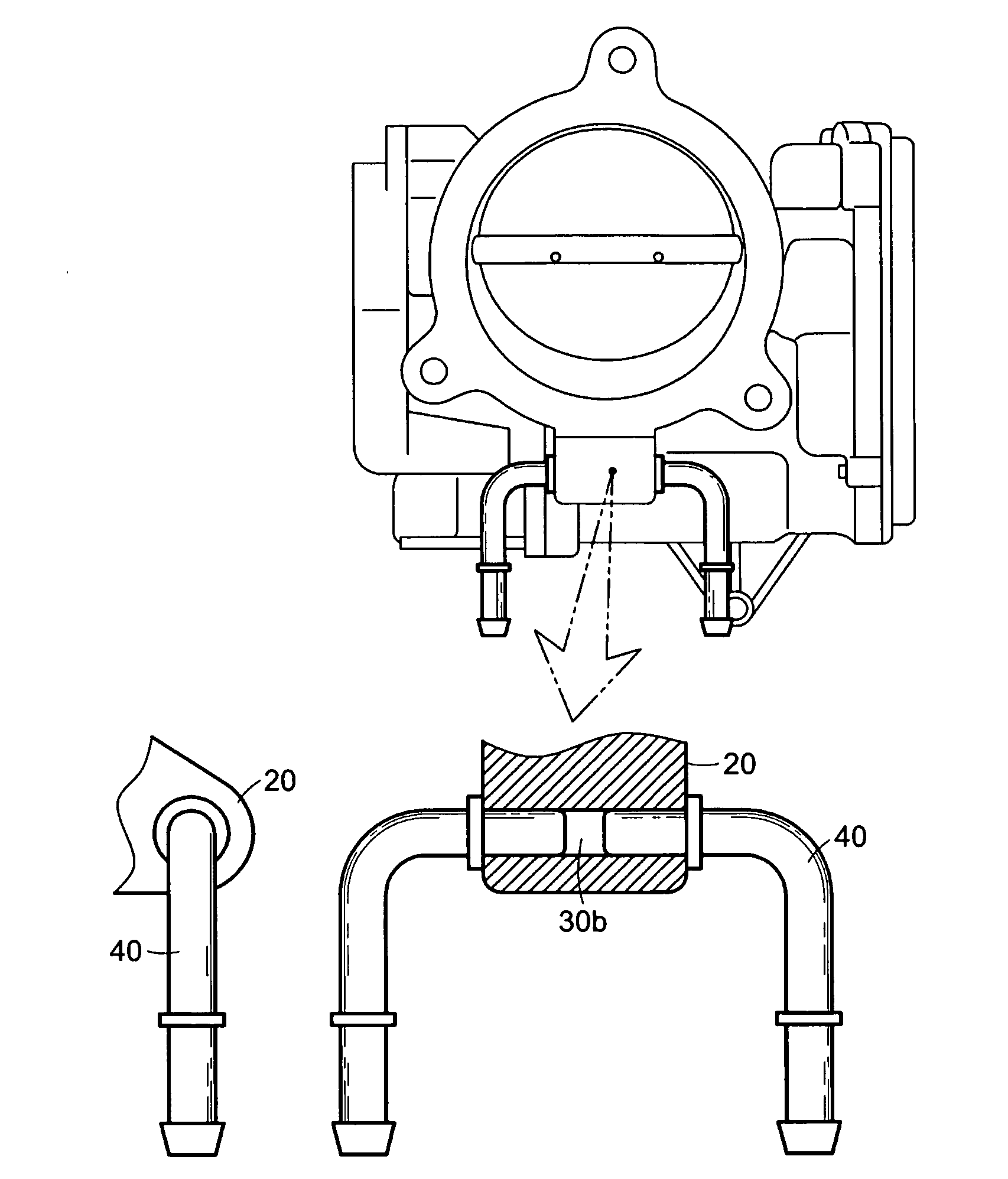

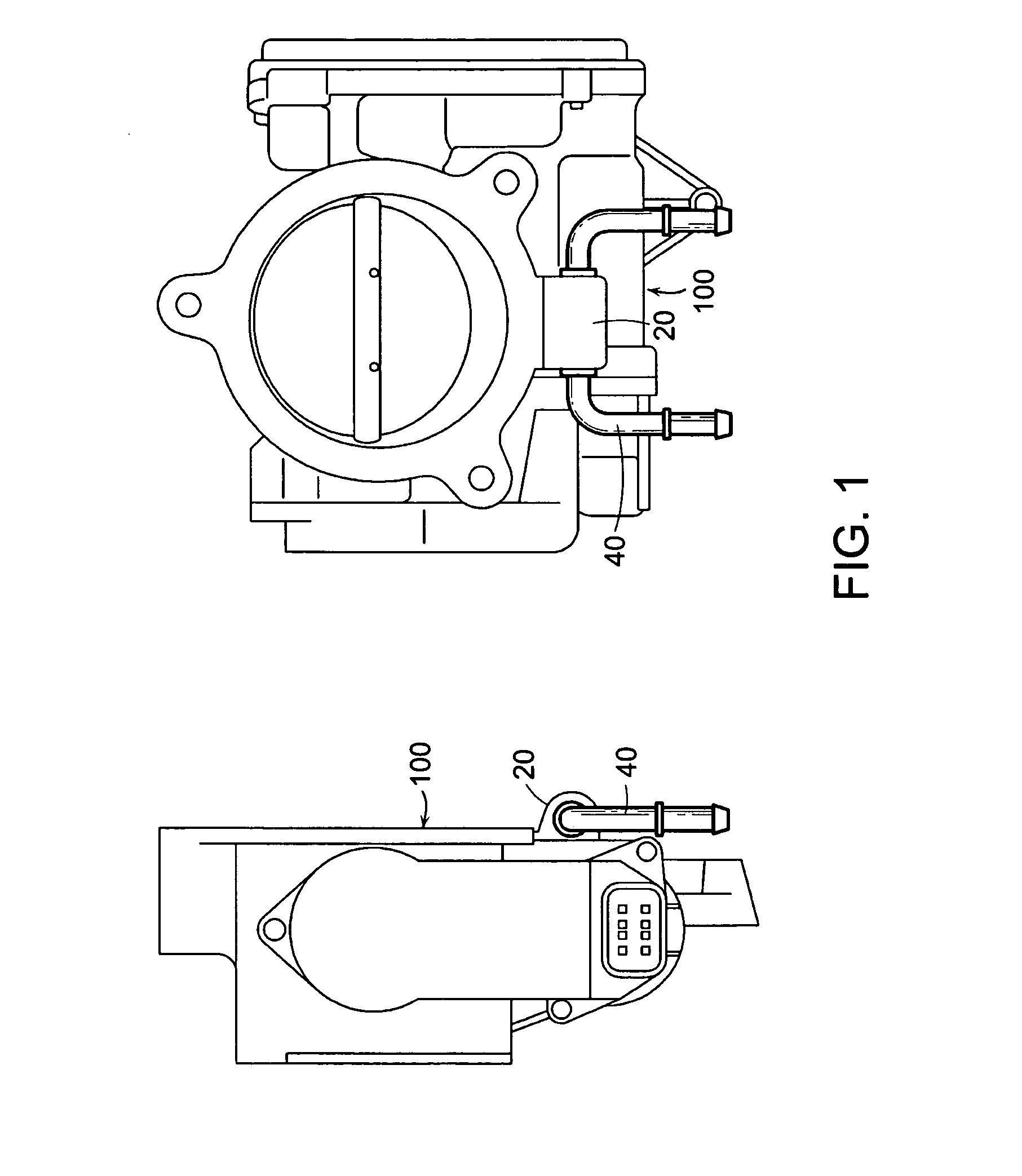

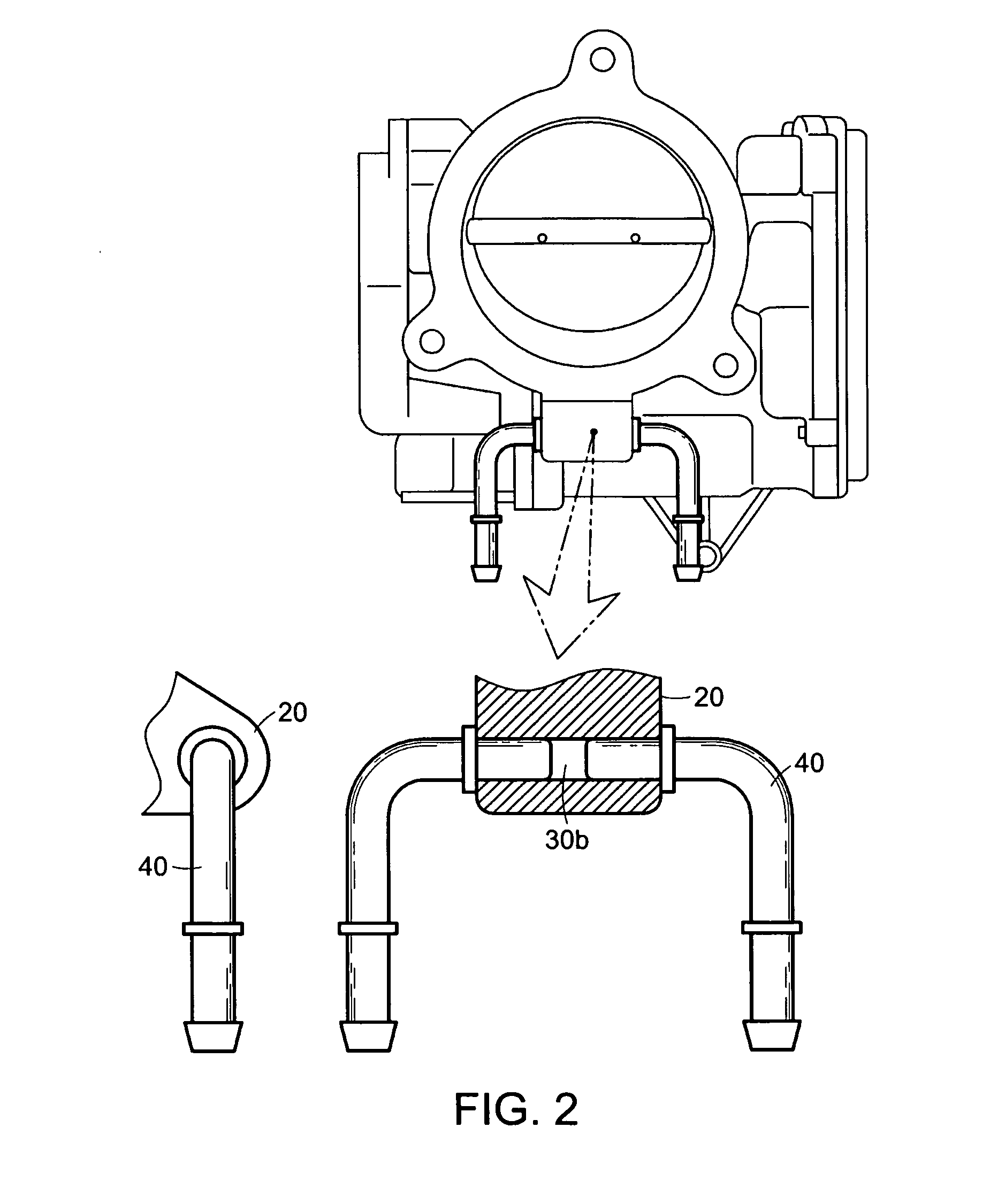

Magnesium throttle body and method of manufacturing the same

InactiveUS20080313898A1Inhibit corrosion reactionAvoid reactionValve arrangementsInternal combustion piston enginesEngineeringThrottle

A magnesium-based throttle body is disclosed. The throttle body is manufactured by using a mold for manufacture of a throttle body. The throttle body includes a cooling water tube fixing portion into which a cooling water tube is press-inserted, the cooling water tube fixing portion being formed integrally with the throttle body.

Owner:KIA MOTORS CORP

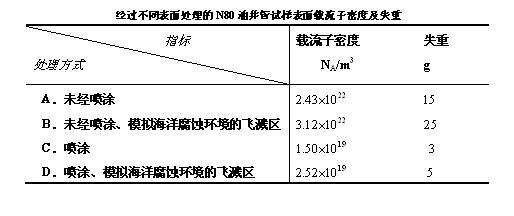

Method for preparing anticorrosive paint for surface of ocean oil well pipe and coating treatment method of anticorrosive paint on pipe surface

ActiveCN102108238AImprove marine corrosion resistanceImprove wear resistancePretreated surfacesAnti-corrosive paintsEpoxyPolymer science

The invention relates to a method for preparing an anticorrosive paint for the surface of an ocean oil well pipe and a coating treatment method of the anticorrosive paint on a pipe surface and belongs to the technical field of steel pipe anticorrosive surface treatment. Epoxy resin serves as a paint substrate, and various additives are added into the epoxy resin to optimize the corrosion resistance of the paint. At the same time, the comprehensive mechanical performance of the epoxy resin is enhanced, namely the wear resistance, heat resistance, rigidity, strength and the like are further improved through the additives. A potential-capacitance test and a Mott-Schottky analysis on the oil well pipe subjected to coating treatment show that carrier density on the pipe surface is much less than that of the pipe surface which is not subjected to coating treatment; and in a weightlessness test, the weightlessness of the oil well pipe subjected to the coating treatment is the minimum. Therefore, the oil well pipe subjected to the treatment has high corrosion resistance.

Owner:SHANGHAI UNIV +1

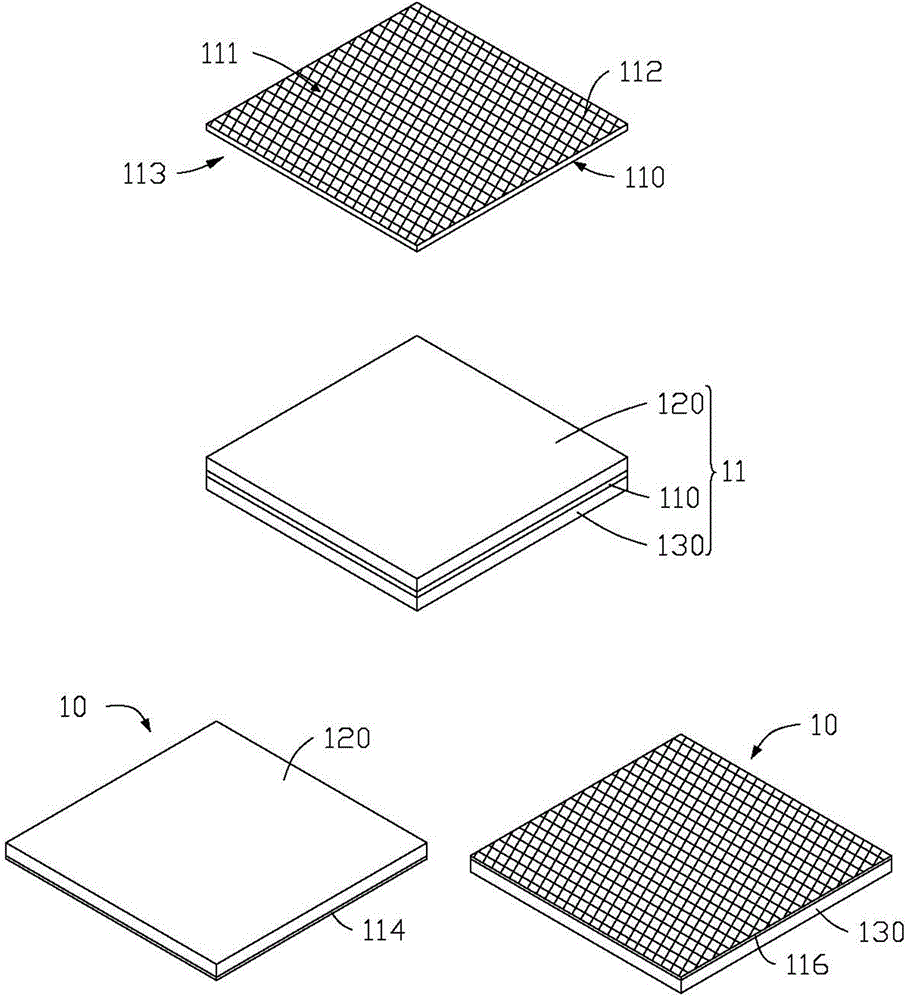

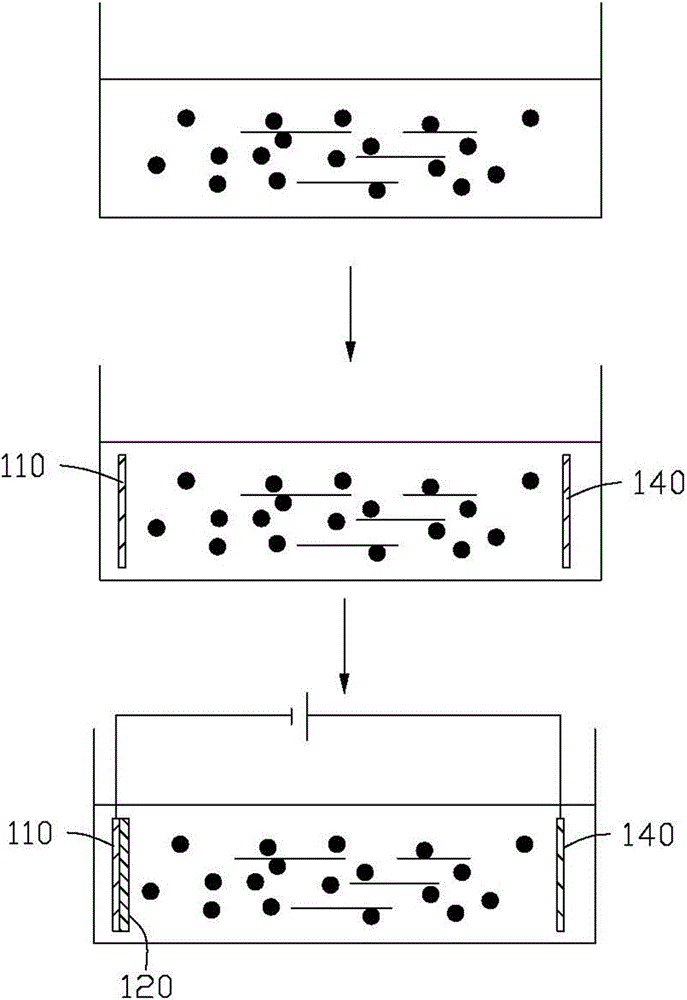

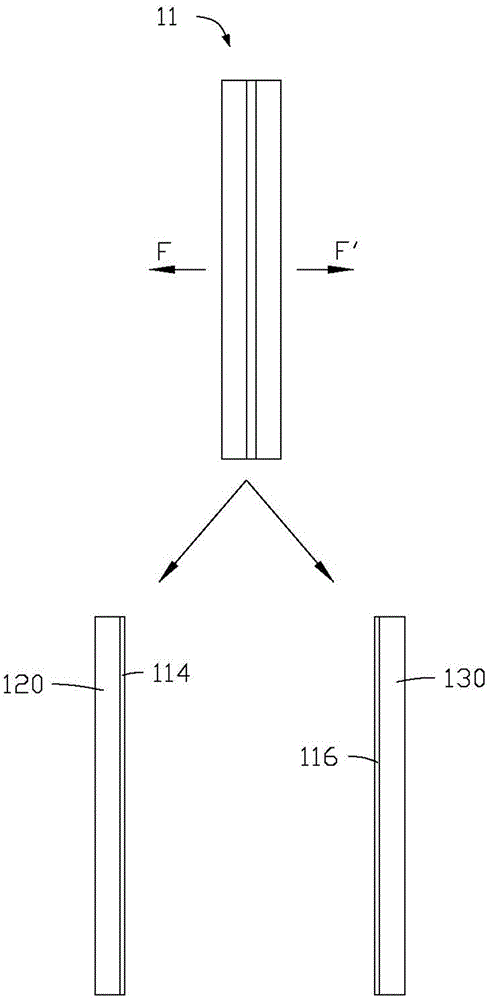

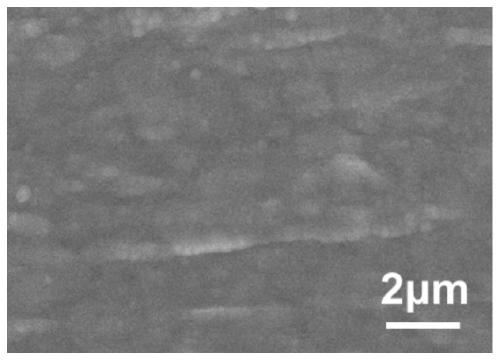

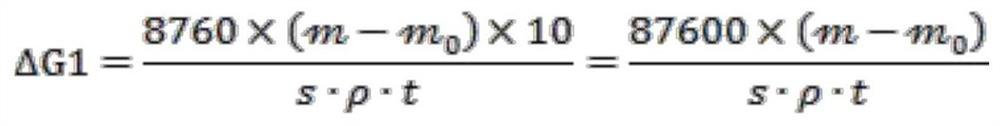

Current collector preparation method

ActiveCN105449221AInhibit corrosion reactionReduce the effect of contact resistanceElectrode carriers/collectorsNanotubeElectroplating

The present invention relates to a current collector preparation method which is as follows: providing a carbon nanotube layer including a plurality of micropores and opposing first and second surfaces; electroplating a first metal layer on a first surface of the carbon nanotube layer; electroplating a second metal layer on a second surface of the carbon nanotube layer and forming a carbon nanotube composite layer; and tearing the carbon nanotube composite layer to divide the carbon nanotube composite layer into a first sub carbon nanotube layer and a second sub carbon nanotube layer, wherein the first sub carbon nanotube layer is attached to the surface of the first metal layer, and the second sub carbon nanotube layer is attached to the surface of the second metal layer.

Owner:TSINGHUA UNIV +1

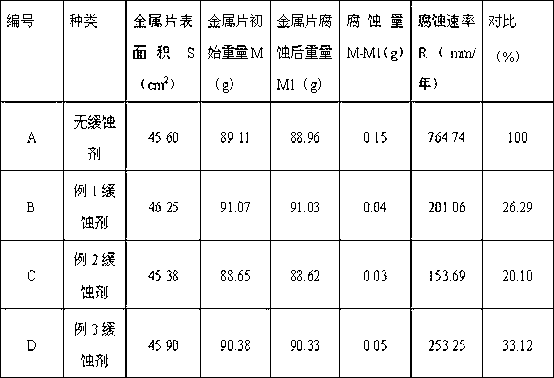

Compound corrosion inhibitor for chlorine salt-type snow-melting agent and application of compound corrosion inhibitor

InactiveCN103254871AGood slow releaseIncreased anodic polarizationOther chemical processesThioureaPhosphate

The invention discloses a compound corrosion inhibitor for a chlorine salt-type snow-melting agent and an application of the compound corrosion inhibitor. The compound corrosion inhibitor comprises the following materials in parts by mass: 12-35 parts of sodium hexametaphosphate, 8-20 parts of sodium silicate, 5-20 parts of zinc dihydrogen phosphate, 5-12 parts of sodium dodecyl benzene sulfonate, 5-20 parts of sodium tartrate, 4-12 parts of hexamethylene tetramine, and 6-13 parts of allyl thiourea, wherein the compound corrosion inhibitor is obtained by uniformly mixing the materials in the proportioning ratio. The prepared compound corrosion inhibitor can be bagged and sold by being uniformly mixed with chlorine salt in a ratio of (0.5 to 8): 100 of parts by mass. The compound corrosion inhibitor disclosed by the invention is a special corrosion inhibitor aiming at the chlorine salt-type snow-melting agent, has an obvious slow-release effect on the metals, such as roads, bridges and ancillary facilities and then achieves a good slow-release effect via the co-action of the seven materials.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Sintering resisting type burnt-on sand coating and preparation method thereof

InactiveCN108526389APrevent infiltrationPrevent corrosionFoundry mouldsFoundry coresAluminum silicateSuspending Agents

The invention relates to the field of casting technical materials, and particularly relates to a sintering resisting type burnt-on sand coating and a preparation method thereof. The coating comprisesa refractory aggregate, a carrier, a suspending agent and an adhering agent, wherein the refractory aggregate comprises the following materials in parts by mass: 30-50 parts of kieselguhr, 30-50 partsof asbestos powder, 5-15 parts of talcum powder, 5-15 parts of mica powder, 5-15 parts of aluminum silicate, and 5-10 parts of kaolin; the mass of the carrier is 100-150% of the mass of the refractory aggregate; the mass of the suspending agent is 3-10% of the mass of the refractory aggregate; and the mass of the adhering agent is 5-15% of the mass of the refractory aggregate. The coating is highin high temperature strength and stability, and low in gas evolution; when coating a sand core with the coating, the refractory material in the coating is capable of insulating heat, so that the heating time of the sand core can be delayed, and the sand core is prevented from overheating sintering, and as a result, a casting product quality is obviously improved; the sintering preventing effect is obvious; and the problem of sintering burnt-on sand produced by pouring a jacket core of an engine cylinder body, a water channel core and air channel core of a cylinder cover, or a small core, a thin hole, a narrow hole and a blind of a hydraulic valve part, and the like can be effectively solved.

Owner:SHIYAN CHANGJIANG RIVER MOLDING MATERIAL

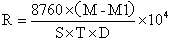

Preparation method of lubricating rust-preventive oil

InactiveCN108587737AImprove stabilityGood lubrication and anti-rust effectOrganic-compounds/hydrides/coordination-complexes catalystsAdditivesRosinFatty alcohol

The invention belongs to the technical field of lubricating oil processing, and concretely relates to a preparation method of lubricating rust-preventive oil. The preparation method comprises the following steps: phospho-tungstic acid and benzothiazoles ionic liquid are grafted to prepare an immobilized ionic liquid catalyst which is used for catalyzing a catalytic reaction of rosin borate, the lubrication anticorrosion performance of the cutting fluid is effectively increased, tallol is used as a raw material, liquid SO3 is taken as the catalyst, the material and monoethanolamine are subjected to a reaction to generate tall oil acid monoethanolamine, finally, rosin borate, tall oil acid monoethanolamine, butyl stearate, white oil, tung oil, sodium hexametaphosphate, phenoxy-1-propanol , fatty alcohol polyoxyethylene ether, sodium dodecyl benzene sulfonate, an anti-oxidant, and a bactericide are used as the raw materials to prepare the lubricating rust-preventive oil.

Owner:周文辽

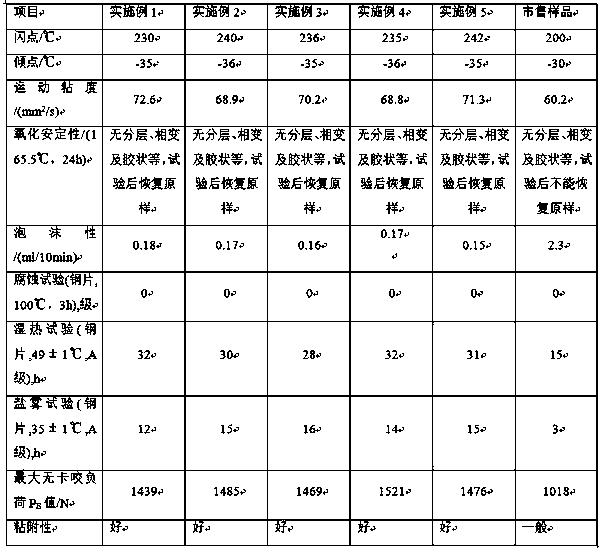

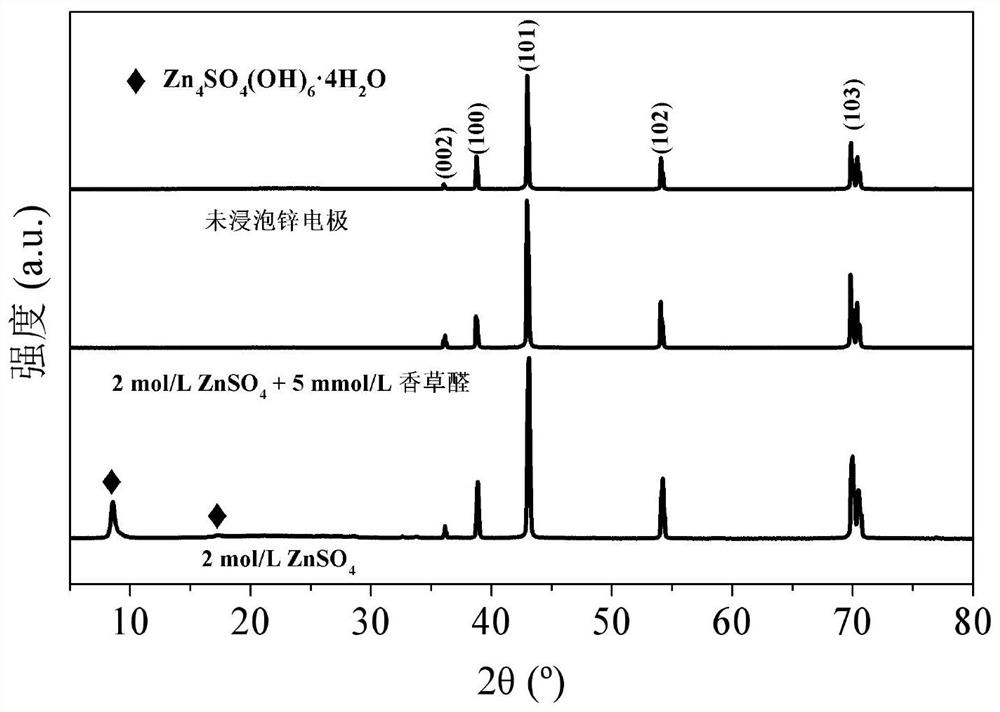

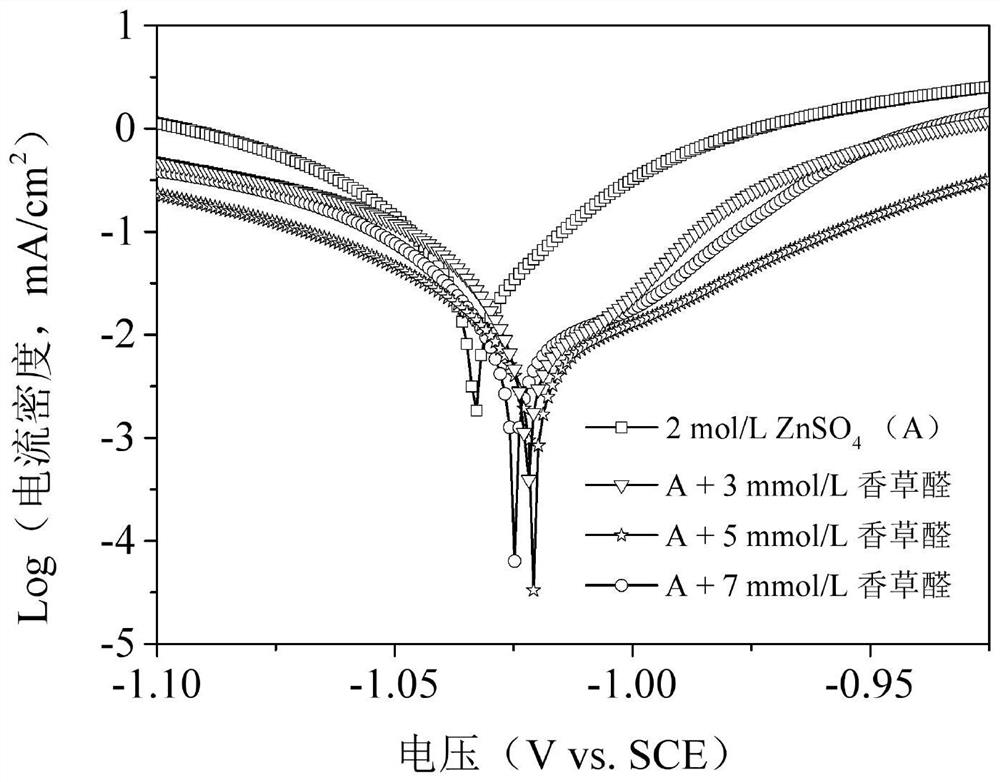

Weakly acidic electrolyte additive for aqueous rechargeable zinc battery and application of weakly acidic electrolyte additive

PendingCN113363603AAvoid direct contactInhibit corrosion reactionSecondary cells servicing/maintenanceAcid electrolytesElectrolytic agentElectrical battery

The invention discloses a weakly acidic electrolyte additive for a water-based rechargeable zinc battery and application of the weakly acidic electrolyte additive, and belongs to the technical field of zinc battery electrolyte. The electrolyte additive is vanillin (C8H8O3) small organic molecules, and the use amount of the vanillin additive is 1-60 mmol / L. The vanillin additive has a zinc-loving characteristic, can be adsorbed on the surface of a zinc negative electrode and guide zinc ion deposition at a zinc negative electrode / electrolyte interface, can effectively inhibit zinc dendrite growth, corrosion and other side reactions, improves the deposition / stripping efficiency of zinc, and further improves the cycle life and coulombic efficiency of the water-based rechargeable zinc battery. The vanillin additive has the advantages of being low in cost, environmentally friendly, free of toxicity and the like, the electrolyte formula and the preparation process are simple, and the vanillin additive has very wide application prospects in the field of water system rechargeable zinc batteries.

Owner:NANKAI UNIV

Circulating water corrosion and scale inhibitor and preparation method thereof

ActiveCN105645610AInhibit corrosion reactionGood anti-scaling effectSpecific water treatment objectivesScale removal and water softeningChemistryCorrosion

The invention relates to a circulating water corrosion and scale inhibitor and a preparation method thereof. The circulating water corrosion and scale inhibitor mainly comprises polyacrylamide, 2-hydroxyphosphonoacetic acid, polyepoxysuccinic acid, anthocyanidins, tea polyphenol, melamine, isophorondiamine, ethylene glycol and water. The circulating water corrosion and scale inhibitor is suitable for industrial circulating cooling water systems to realize pre-film corrosion, scale prevention and corrosion inhibition of high-salinity wastewater in the circulating cooling water.

Owner:内蒙古润嘉节能环保科技有限公司

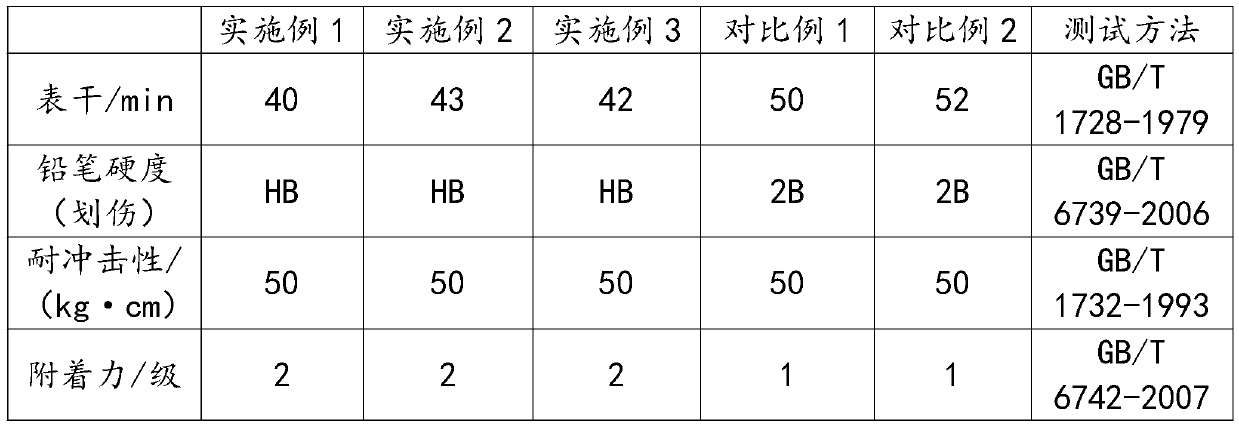

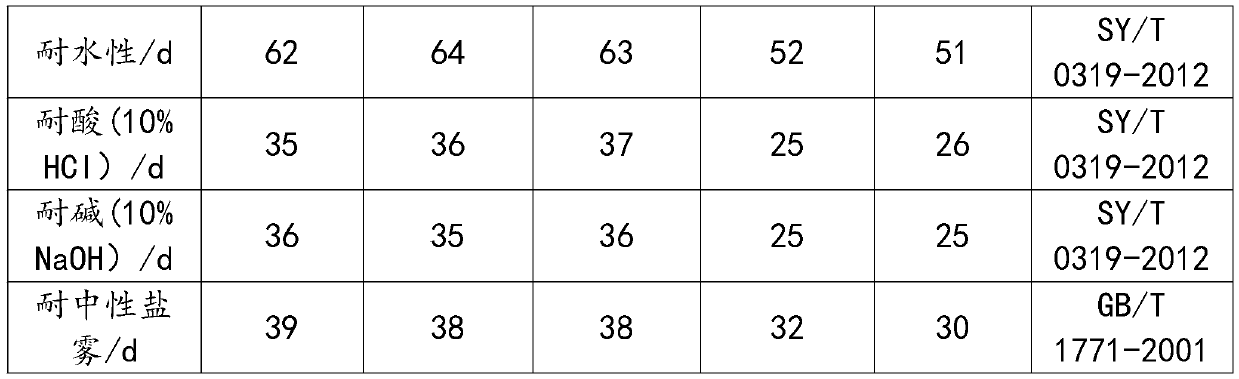

Rust-proof coating for ship deck and preparation process of coating

InactiveCN110054945AImprove stabilityGood redox propertiesLiquid surface applicatorsAnti-corrosive paintsDefoaming AgentsMaterials science

The invention discloses a rust-proof coating for a ship deck. The rust-proof coating is prepared from, by weight, 30-40 parts of silicone acrylic emulsion, 50-60 parts of acrylic emulsion, 2.5-3 partsof polyethylene wax emulsion, 28-34 parts of fluoro-silicon emulsion, 12-16 parts of anti-rust pigments, 3-5 parts of fillers, 2-3 parts of nano-silicon dioxide, 3-4 parts of corrosion inhibitors, 2-3 parts of dispersing agents, 2-3 parts of defoaming agents, 1.5-2 parts of waterborne leveling agents, 1.5-2 parts of waterborne wetting agents and 8-10 parts of ethanol water. The invention furtherdiscloses a preparation process of the rust-proof coating for the ship deck. According to the coating, the corrosion inhibitors and the anti-rust pigments are added, a bottom layer, a middle layer anda surface layer have different structures are matched each other, so that the prepared coating has good hydrophobicity, water resistance can reach 62d, acid and alkali resistance can reach 35d, saltfog performance can reach 38d, and the coating has good corrosion resistance.

Owner:谭运学

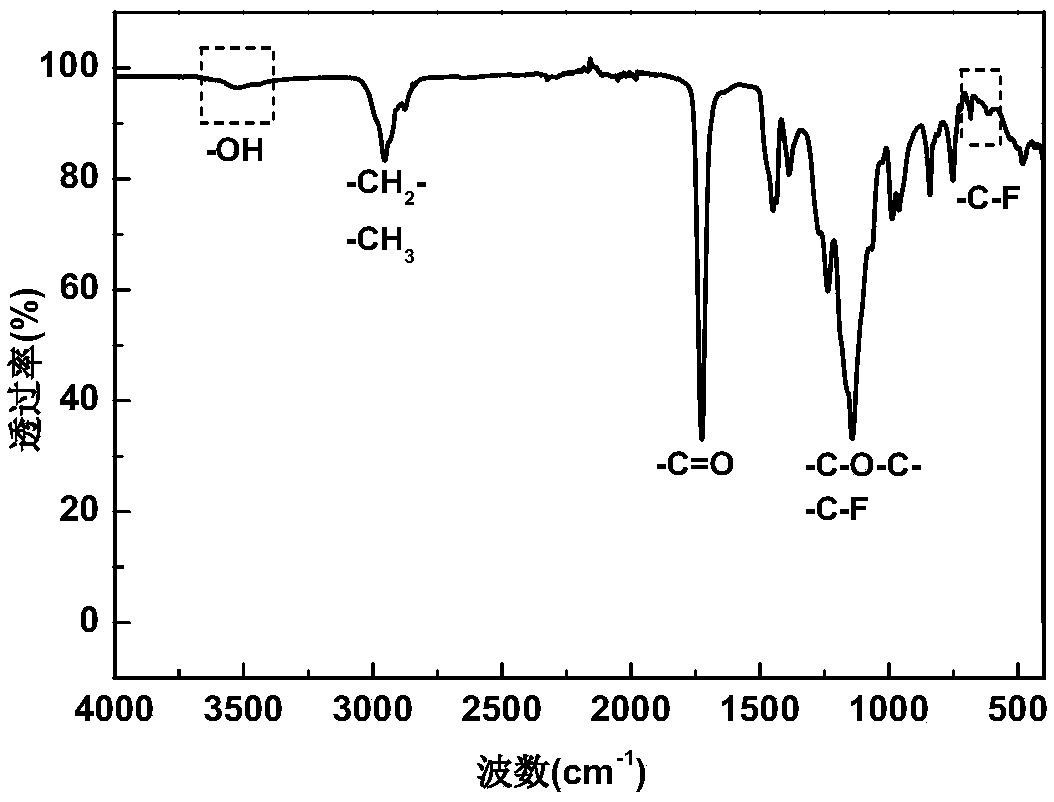

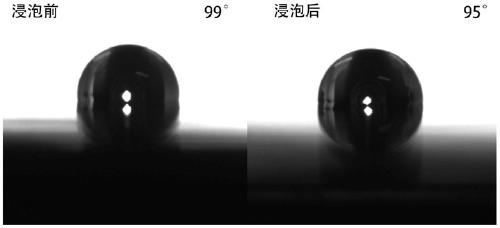

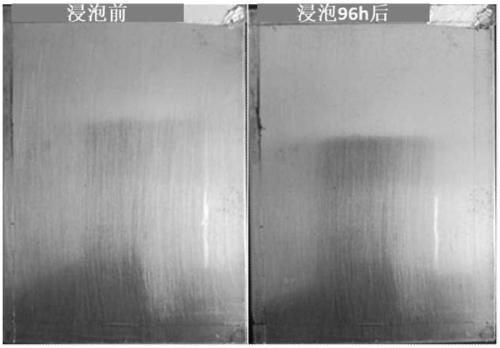

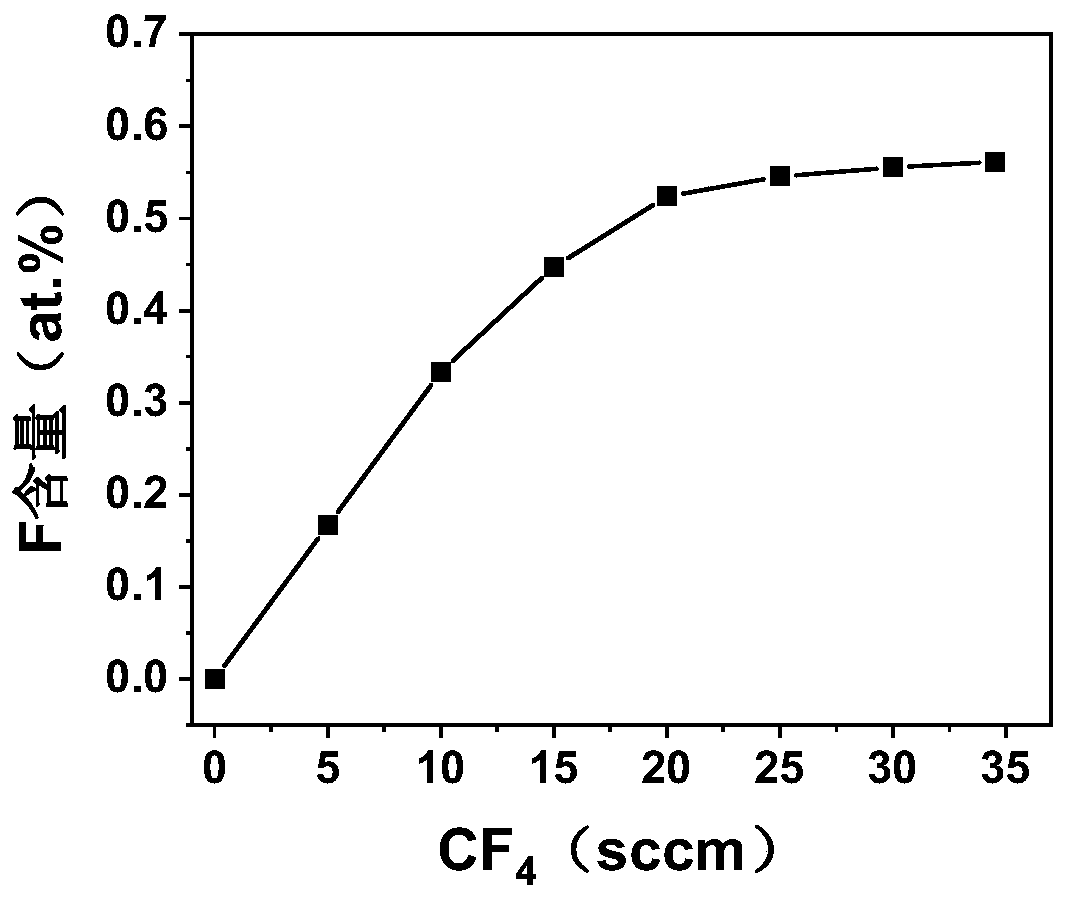

Fluorine and silicone copolymerization modification amphiphilic acrylate polymer anti-corrosive paint and preparation method thereof

InactiveCN109135485AImproves corrosion protectionLong-lasting corrosion protectionAnti-corrosive paintsPolymer scienceSolvent

The invention belongs to the technical field of fluoride and siloxane modified acrylate polymer anti-corrosive paint preparation, and particularly relates to fluorine and silicone copolymerization modification amphiphilic acrylate polymer anti-corrosive paint and a preparation method thereof. A catalyst-containing solvent is added in mixed liquid of acrylic comonomer, an organic fluorine modifierand an organic silicone modifier and subjected to polymerization to obtain the fluorine and silicone copolymerization modification amphiphilic acrylate polymer anti-corrosive paint; 40.0-52.0 parts bymass of acrylic comonomer, 2.0-15.0 parts by mass of organic fluorine modifier, 1.0-3.0 parts by mass of organic silicone modifier, 0.05-1.0 part by mass of catalyst and 45.0-50.0 parts by mass of solvent are applied. Accordingly, a fluorine and silicone copolymerization modification amphiphilic acrylate polymer can improve the corrosion protection property of coating.

Owner:南通中国科学院海洋研究所海洋科学与技术研究发展中心

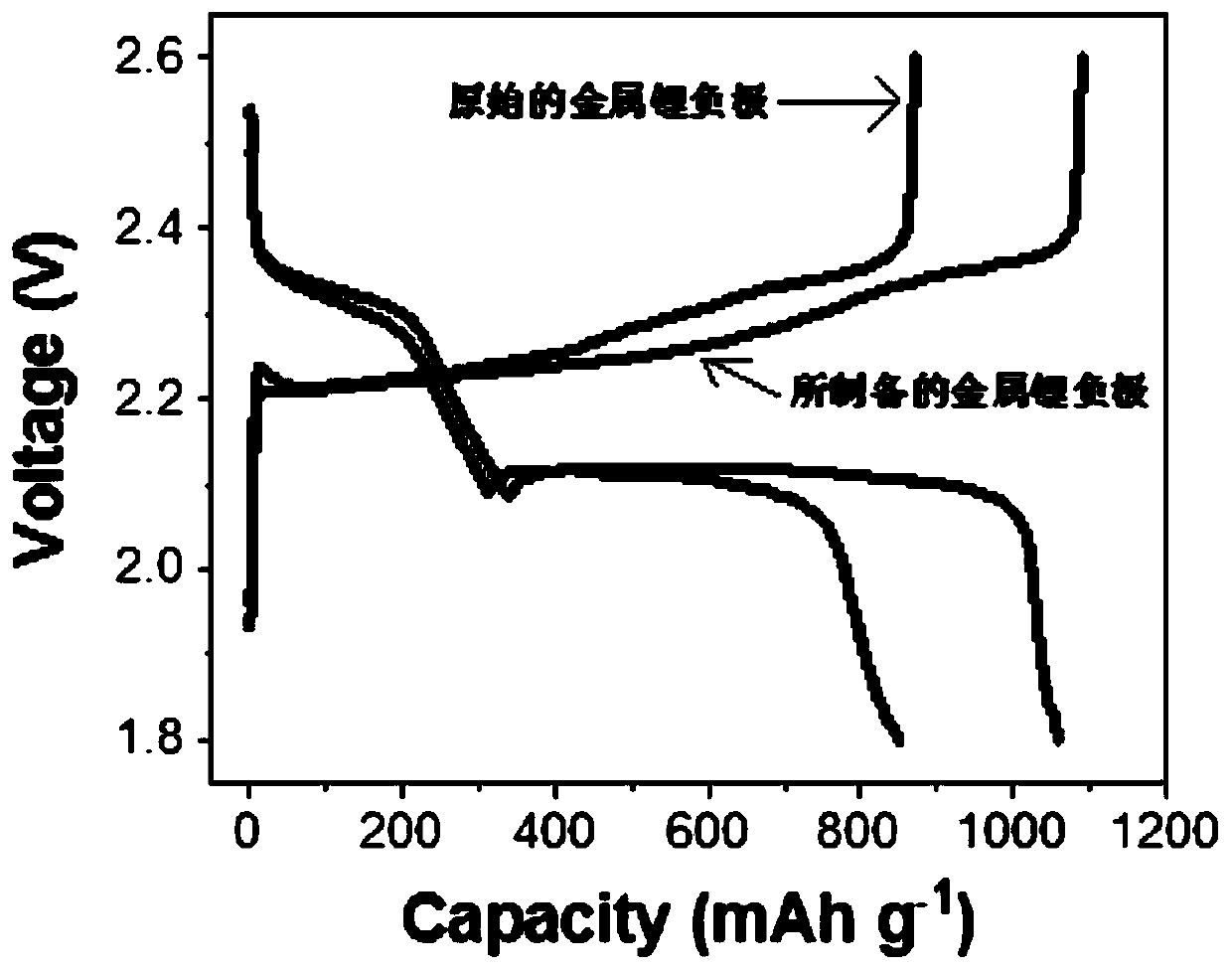

Preparation method of metal lithium negative electrode, metal lithium negative electrode, battery and application

InactiveCN111430713AUniform compositionInhibit corrosion reactionFinal product manufactureLi-accumulatorsMetallic lithiumElectrical battery

The invention provides a preparation method of a metal lithium negative electrode, the metal lithium negative electrode, a battery and an application, wherein the preparation method of the metal lithium negative electrode comprises the steps of depositing a carbon fluoride film layer on the surface of a metal lithium sheet by utilizing a direct-current pulse plasma vapor deposition method, etc. According to the preparation method of the metal lithium negative electrode, the protective layer is formed on the surface of the metal lithium sheet to form the stable metal lithium negative electrode,the lithium negative electrode does not easily generate dendrites in the charging and discharging process, the potential safety hazards are avoided, and the metal lithium negative electrode has the excellent cycle performance.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

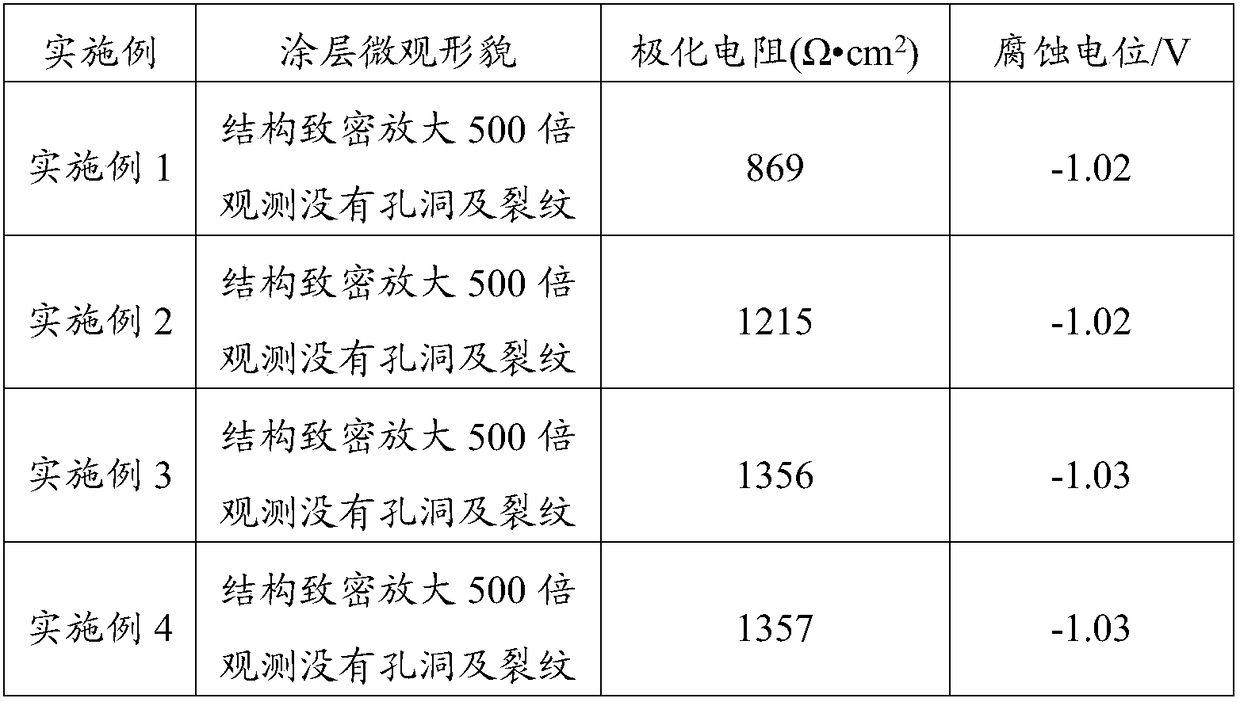

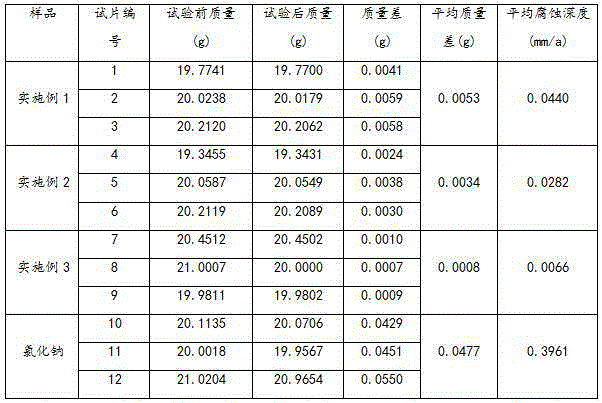

Plasma spraying zinc-aluminum high-strength steel as well as preparation method and application thereof

InactiveCN108265262AAvoid direct contactInhibit corrosion reactionMolten spray coatingElectrical resistance and conductanceRare earth

The invention provides a preparation method of plasma spraying zinc-aluminum high-strength steel. Zinc powder, aluminum powder and rare earth metal powder are subjected to ball grinding to obtain compound metal powder, wherein the mass ratio of the zinc powder to the aluminum powder to the rare earth metal powder is (84 to 87):(13 to 14.5):(0.2 to 0.6); the high-strength steel surface is sequentially subjected to pretreatment and shot blasting to obtain a high-strength steel substrate; the compound metal powder is sprayed and coated on the surface of the high-strength steel substrate by a plasma spraying method; a zinc-aluminum coating is formed at the surface of the high-strength steel substrate; the plasma spraying zinc-aluminum high-strength steel is obtained. The plasma spraying zinc-aluminum high-strength steel provided by the invention has good corrosion resistant performance and is applicable to severe conditions in marine environment. Experimental results of the embodiment showthat the polarization resistance of the plasma spraying zinc-aluminum high-strength steel provided by the invention reaches 1357 Omega.cm<2>, and the corrosion potential reaches -1.03V.

Owner:SHANGHAI UNIV

Method for prolonging playing time of snow melting function of environmental protection snow-melting agent

ActiveCN104927771AReduce contact speedReduce meltingOther chemical processesSnow meltingEnvironmental engineering

The invention discloses a method for prolonging playing time of snow melting function of an environmental-protection snow-melting agent. The environmental-protection snow-melting agent and solid-state polydimethylsiloxane are placed in the same airtight space, it is guaranteed that the environmental-protection snow-melting agent and solid-state polydimethylsiloxane are not in contact and inter-amalgamation, the airtight space is heated, the polydimethylsiloxane is evaporated and coated on the surface of the snow-melting agent, and therefore the environmental-protection snow melting agent coated with the polydimethylsiloxane is formed. A polydimethylsiloxane plated film is formed on the environmental-protection snow melting agent in a vapor plating mode, the direct contact of the environmental-protection snow melting agent and the ground is avoided, and therefore the corrosion on metal and concrete and the harm on surrounding vegetation and soil can be greatly lowered; due to the hydrophobicity of the polydimethylsiloxane, the speed of contact between water penetrating through a PDMS layer and the coated environmental-protection snow melting agent can be slowed down, water absorption of the PDMS layer is slow, melting of the coated environmental-protection snow melting agent is slow, and the reaction time of the environmental-protection snow melting agent is prolonged.

Owner:ANHUI UNION SAFE TECH

Water-based cleaning agent special for steel

InactiveCN109023405AReduce corrosion rateGood corrosion inhibition effectWater basedSodium metasilicate

The invention discloses a water-based cleaning agent special for steel. The water-based cleaning agent comprises a composite surface active agent, hydroxypropyl chitosan, amino acid, 2-ethylhexyl sulfate sodium, a compound containing an s-triazine structure, a plant extract, P-mercapto phenylboric acid, sodium metasilicate, sodium gluconate, molybdate intercalated zinc-aluminum-cerium hydrotalcite, furfuryl glycidyl ether, thiourea, polyorganosiloxane and water. The composite surface active agent is the mixture of lauryl sodium sulfate, hexadecylPyridinium chloride, polyethylene glycol octylphenol ether, sodium dodecyl sulfate and disodium lauroamphodiacetate. The water-based cleaning agent special for steel is high in cleaning efficiency, excellent in corrosion inhibition performance andcapable of meeting the steel cleaning requirement.

Owner:HEFEI LYUJIE ENVIRONMENTAL PROTECTION TECH

Plant type composite efficient corrosion inhibitor as well as preparation method and application thereof

ActiveCN112680190AWide range of raw materialsRaw materials are environmentally friendlyOther chemical processesSodium molybdateSulfate zinc

The invention provides a plant type composite efficient corrosion inhibitor. The plant type composite efficient corrosion inhibitor is prepared from the following raw materials in percentage by mass: 12 to 66.0 percent of plants, 5.0 to 16.0 percent of sodium molybdate, 1.5 to 12 percent of sodium gluconate, 3.5 to 25 percent of sodium tartrate, 0 to 23 percent of zinc sulfate and 4.0 to 23.0 percent of monopotassium phosphate. The corrosion inhibitor disclosed by the invention is high in corrosion inhibition capability and can achieve a corrosion inhibition effect on a chlorine salt type snow-melting agent. After the corrosion inhibitor is added, the corrosion of the chlorine salt type snow-melting agent to metal and concrete and the harm to vegetation can be reduced. The corrosion inhibitor is mainly prepared from plants, is non-toxic, and is a very efficient and environment-friendly corrosion inhibitor. The invention further provides a preparation method and application of the plant type composite efficient corrosion inhibitor.

Owner:新疆交通科学研究院有限责任公司

Shell and producing method thereof

InactiveCN102905495AImprove thermal stabilityAtomic diameter is largeVacuum evaporation coatingSputtering coatingCeriumAlloy substrate

The invention provides a shell. The shell comprises a substrate, an Al (aluminum) layer and an anti-corrosion layer, wherein the A1 layer and the anti-corrosion layer are sequentially formed on the surface of the substrate which is made of aluminum or aluminum alloy or magnesium alloy, and the anti-corrosion layer is an Al-Ce (aluminum-cerium) layer or an Al-Ce-O (aluminum-cerium- oxygen) layer. The invention further provides a producing method of the shell. The method includes the step of sequentially forming the Al layer and the anti-corrosion layer on the aluminum substrate or the aluminum alloy substrate or the magnesium alloy substrate. Corrosion resistance of the shell is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

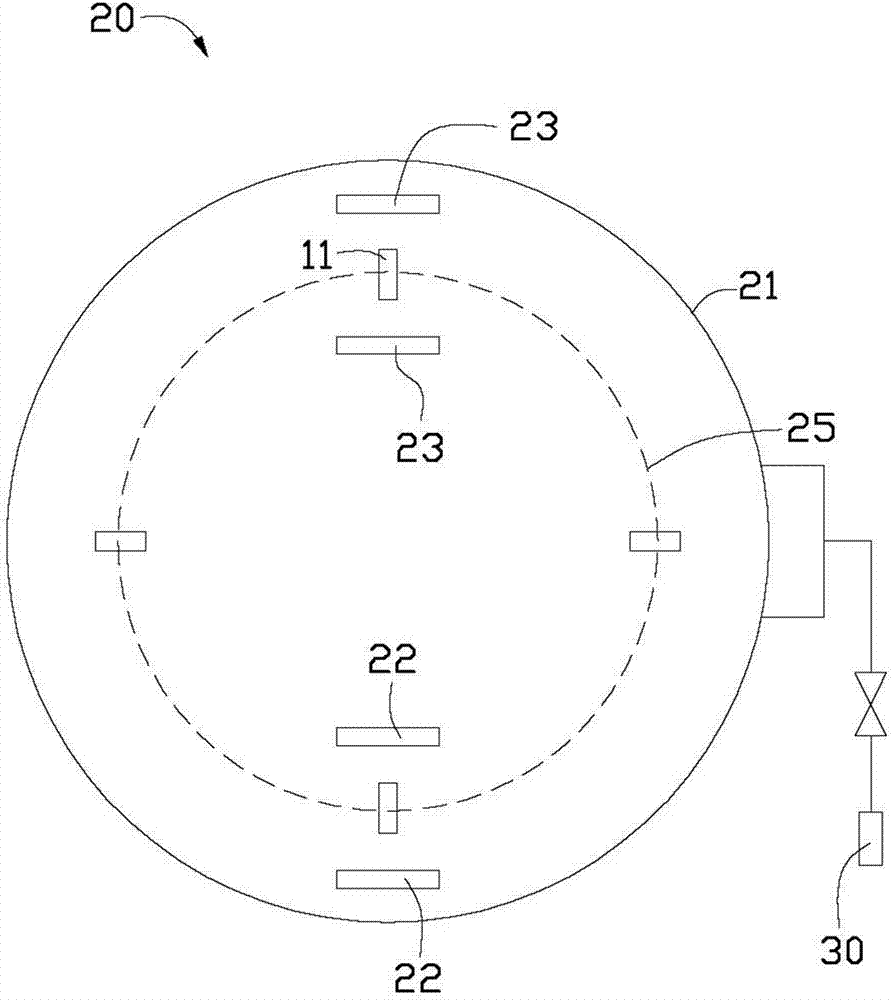

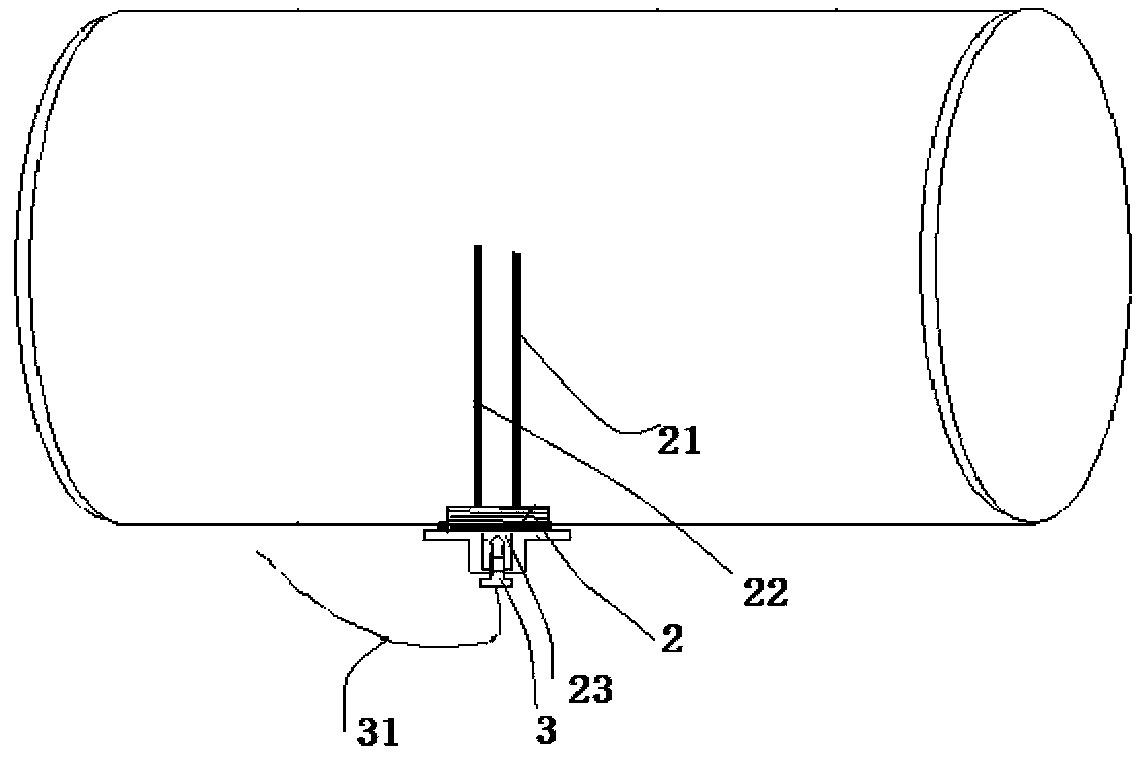

Electronic anti-corrosion inner container of electric water heater

InactiveCN103352229AWill not polluteInhibit corrosion reactionWater heatersDecompositionWater quality

The invention discloses an electronic anti-corrosion inner container of an electric water heater. The electronic anti-corrosion inner container of the electric water heater comprises an electric water heater inner container and is characterized in that an electronic anti-corrosion instrument integrated with the electric water heater inner container is arranged on the electric water heater inner container; the electronic anti-corrosion instrument mainly comprises an anode, a reference electrode and a threaded connection base; the anode is a bar body made of iridium titanium; the end parts on the same side of the anode and the reference electrode are connected with the threaded connection base; the threaded connection base is in bolted connection with the electric water heater inner container via external screw threads; the anode and the reference electrode extend into the electric water heater inner container. Since the anode of the electronic anti-corrosion instrument integrated with the electric water heater inner container is an insoluble titanium anode, a layer of electronic oxidation protective film can be formed on the inner wall of the electric water heater inner container during a corrosion prevention reaction, a corrosion reaction is directly prevented, and decomposition products are avoided, so that water is prevented from being polluted.

Owner:钱伟

Waterproof and antirust material for PC component

The invention belongs to the technical field of concrete building materials, and particularly relates to a waterproof and antirust material for a PC component. The waterproof and antirust material comprises the following components in parts by weight: 300-360 parts of cement, 500-610 parts of quartz sand, 900-1100 parts of gravels, 30-60 parts of fly ash, 30-50 parts of mineral powder, 150-180 parts of water, 12-20 parts of steel fibers, 8-15 parts of an antirust agent, 6-9 parts of a water reducing agent and 2-5 parts of a defoaming agent. The antirust agent is prepared from the following components in parts by weight: 3-5 parts of tetraamminecopper sulfate, 2-4 parts of modified silica sol, 1-2 parts of acrylate emulsion, 0.5-2 part of sodium fluosilicate and 0.5-1 part of coalescing agent. The antirust agent is matched with the steel fibers, a passive film is formed on the surface of a steel bar in concrete, external water and air are effectively prevented from entering to generatea corrosion reaction, and therefore the antirust performance of a PC component is improved, the preparation method is simple, the strength, water resistance and corrosion resistance of the concrete are improved, the service life of the PC component is prolonged, the production efficiency of the PC component is improved, and the production cost is reduced.

Owner:浙江波威新材料科技有限公司

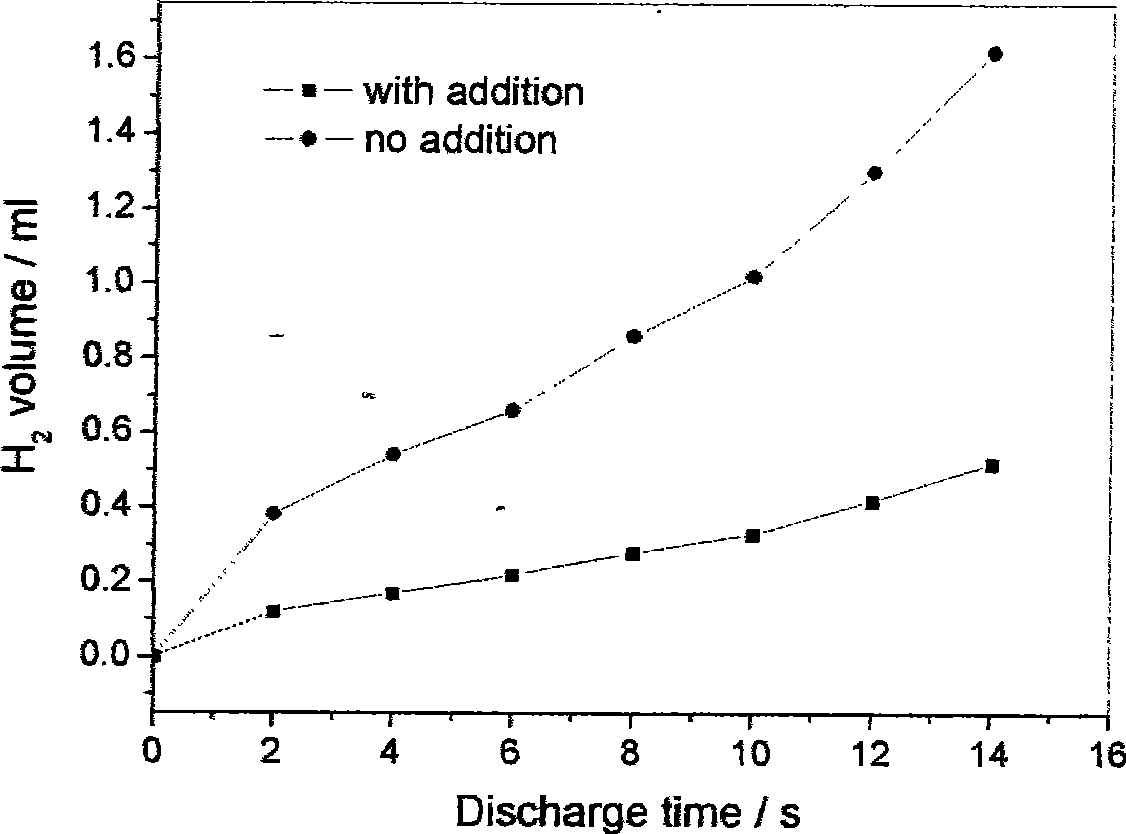

Water system lithium cell electrolyte solution

InactiveCN101483255AInhibit corrosion reactionImprove discharge efficiencySecondary cellsAqueous electrolyte cellsDischarge efficiencyCorrosion reaction

The invention relates to a water system lithium battery electrolyte comprising water, an alkalis and an additive agent characterized in that the additive agent is a RSiX3, wherein the R in the RSiX3 is selected from an amino group, a sulfhydryl, a vinyl, an epoxy radical, a cyano and a methacryloyloxyl or the like, the X is an alkoxyl group. The alkoxyl group in the additive agent is hydrolyzed in water solution and an alcohol is formed adsorbing on a lithium electrode surface; the part containing RSi- is adsorbed on the lithium electrode surface, which improves the discharging efficiency when the metal lithium is used as a battery cathode, inhibits a corrosion reaction between the metal lithium and the electrolyte, thereby reducing the generation of the hydrogen on the lithium electrode, improving the electrode utilization efficiency and the battery safety. The electrolyte containing the additive agent for the water lithium battery, any proper anode and the metal lithium cathode can be combined into the water system lithium battery.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

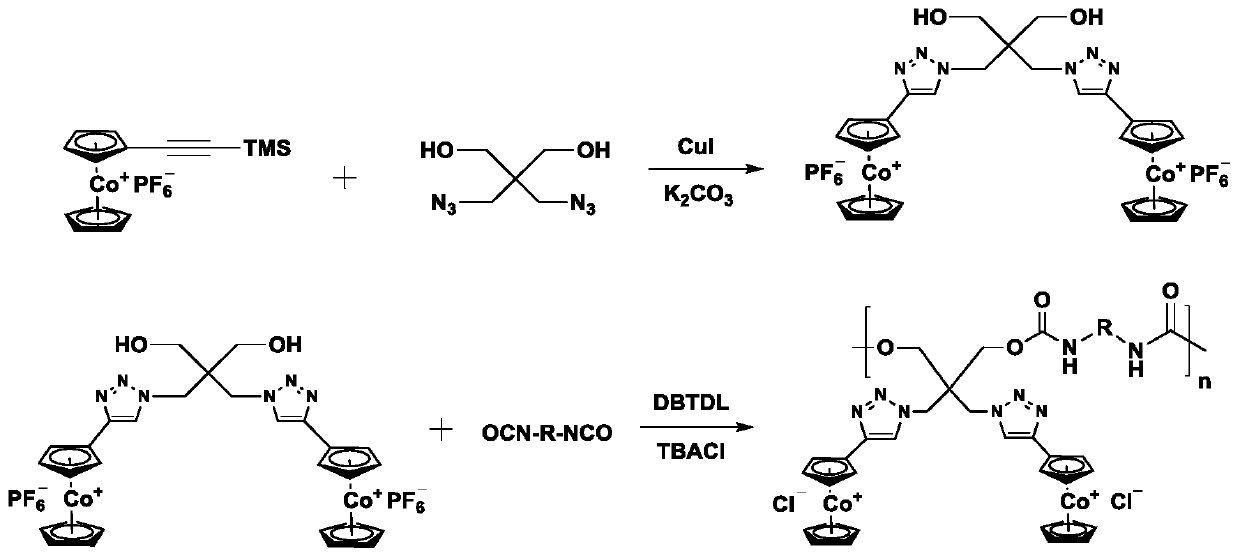

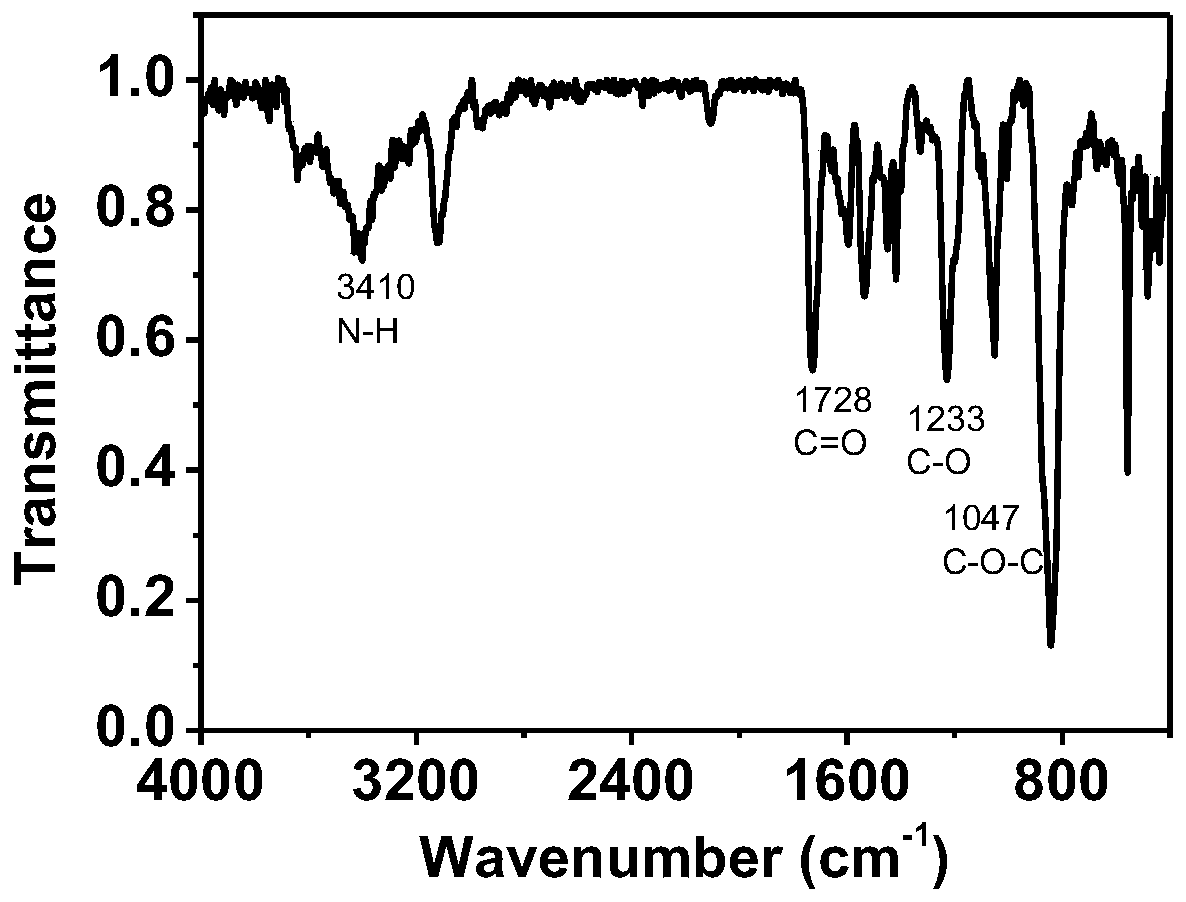

Cobaltocene cation-based waterborne polyurethane, corrosion inhibitor system and preparation method thereof

The invention relates to cobaltocene cation-based aqueous polyurethane, a corrosion inhibitor system and a preparation method thereof. An active functional group, namely alcohol hydroxyl, is introduced to cobaltocene cation by taking a triazole ring as a connecting group, and then the cobaltocene cation-based aqueous polyurethane is obtained through simple and convenient step-by-step addition polymerization reaction and ion exchange reaction, thereby realizing low-cost synthesis and high-efficiency polymerization. The structure of the target cobaltocene cation-based aqueous polyurethane has many advantages of inorganic, organic and polymer corrosion inhibitors compared with corrosion inhibitors commonly used at present. The product of the cobaltocene cation-based aqueous polyurethane can be used as a corrosion inhibitor to slow down the corrosion of hydrochloric acid to iron and steel products in practical applications such as pickling.

Owner:西北工业大学太仓长三角研究院 +1

Yield strength is 550mpa grade refractory and weather-resistant earthquake-resistant construction steel and its production method

ActiveCN103695772BSimple processHigh strengthTemperature control deviceProof constructionChemical composition

The invention relates to a 550MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel which comprises the following components in percentage by weight: 0.041-0.125% of C, 0.31-0.62% of Si, 1.81-2.40% of Mn, at most 0.008% of P, at most 0.002% of S, 0.041-0.065% of Nb, 0.007-0.020% of Ti, 0.41-0.63% of Mo, 0.07-0.10% of W, 0.0071-0.0098% of Mg and at most 0.0012% of O. The production method comprises the following steps: desulfurizing molten iron; smelting in a converter; carrying out vacuum treatment, and adding the Mg element; carrying out conventional continuous casting, and heating the casting blank; carrying out sectional rolling; and carrying out finish rolling, and cooling for later use. The steel has the following advantages: the chemical components and technique are simple, the yield strength of the steel plate is 550-700MPa, the earthquake-proof property is good (the yield-tensile ratio is at most 0.83), the fire resistance is favorable (the yield strength at 600 DEG C is not lower than 2 / 3 of that at room temperature), and the corrosion resistance is better than CortenB. Besides, the steel grade has excellent impact toughness and weldability.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com