Circuit board and method for manufacturing the same

A circuit substrate and circuit technology, applied in printed circuit manufacturing, printed circuits, printed circuits, etc., can solve problems such as damage to the conductivity of electrical wiring, and achieve the effect of preventing corrosion and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

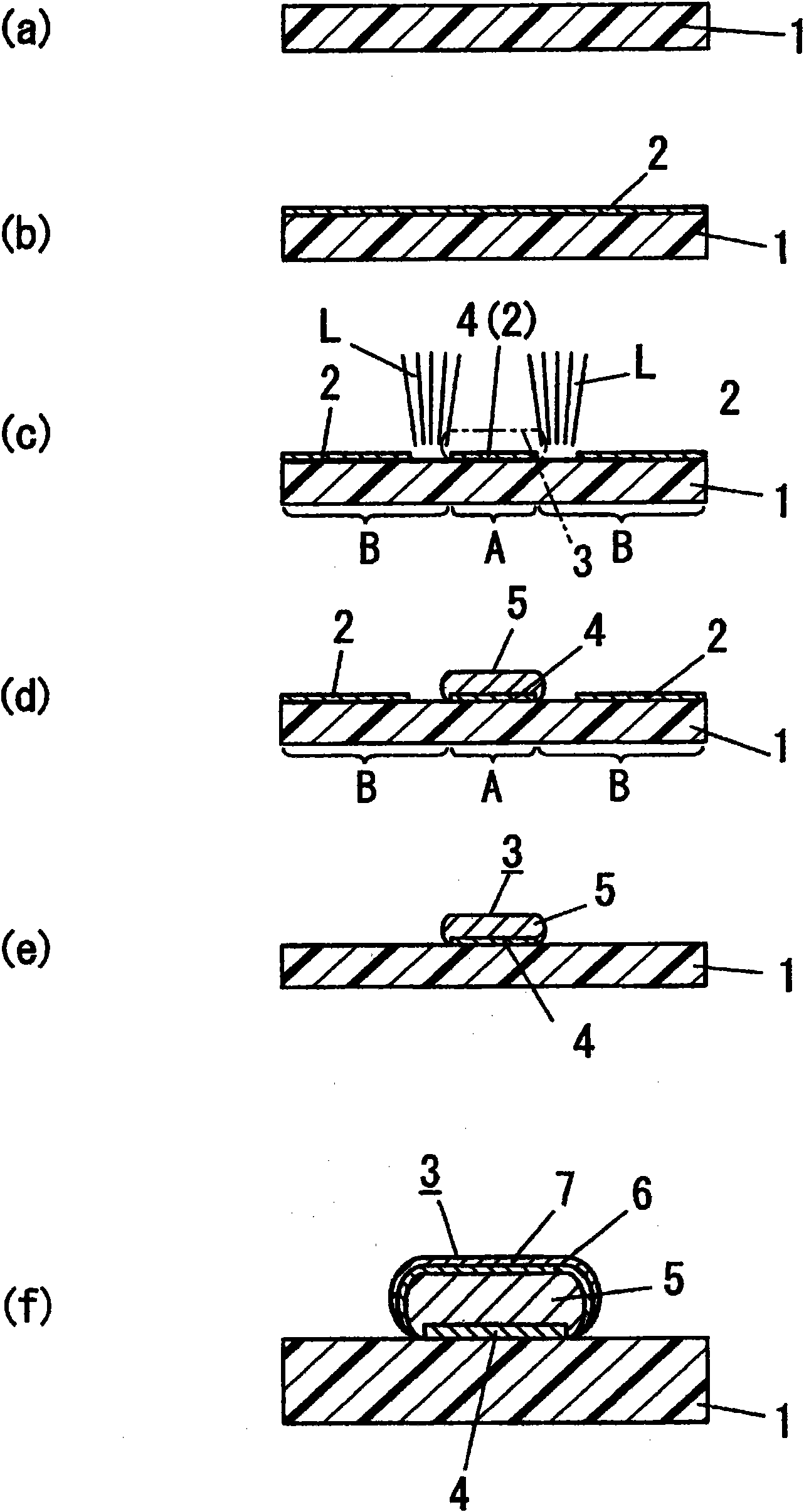

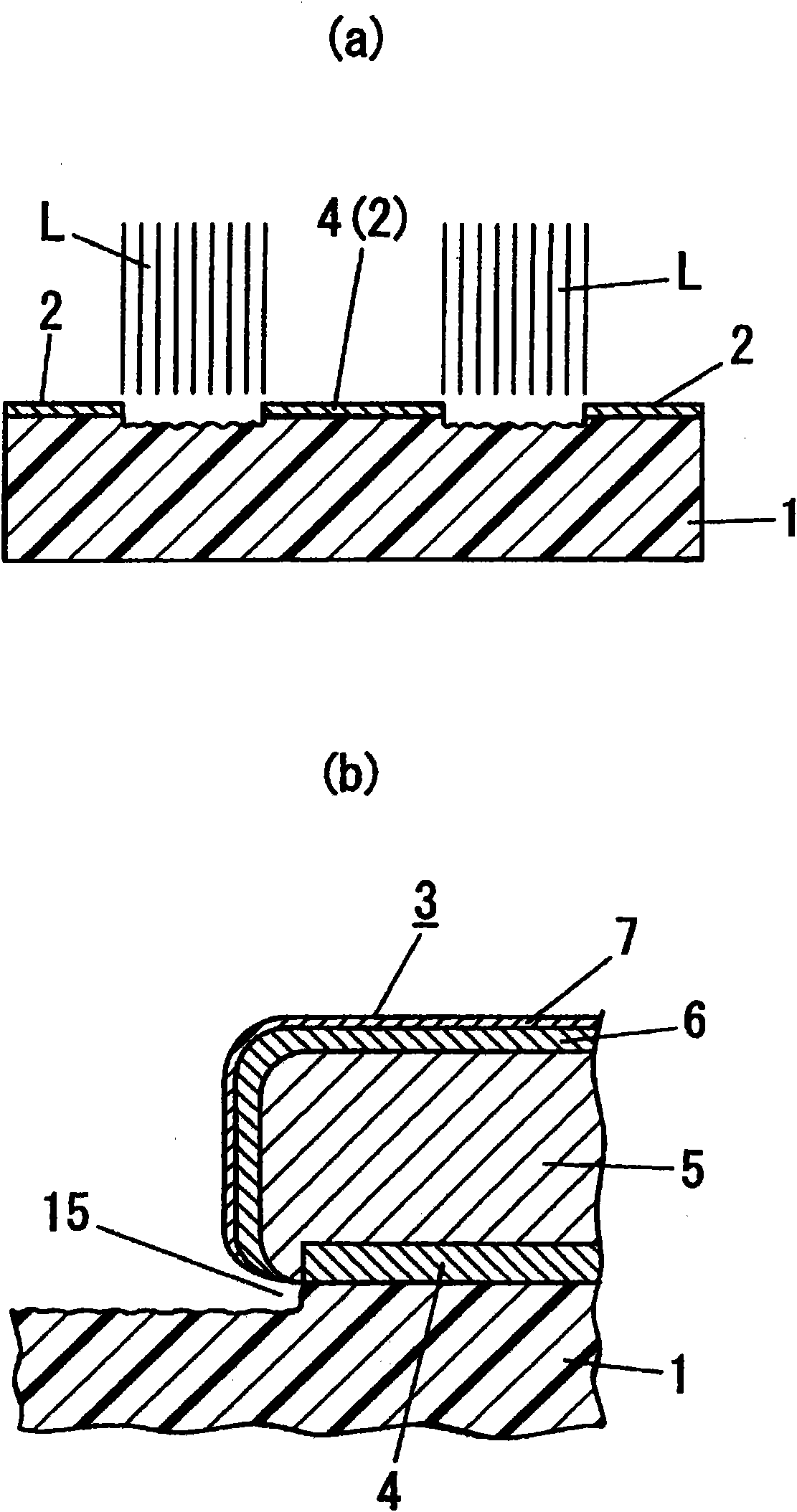

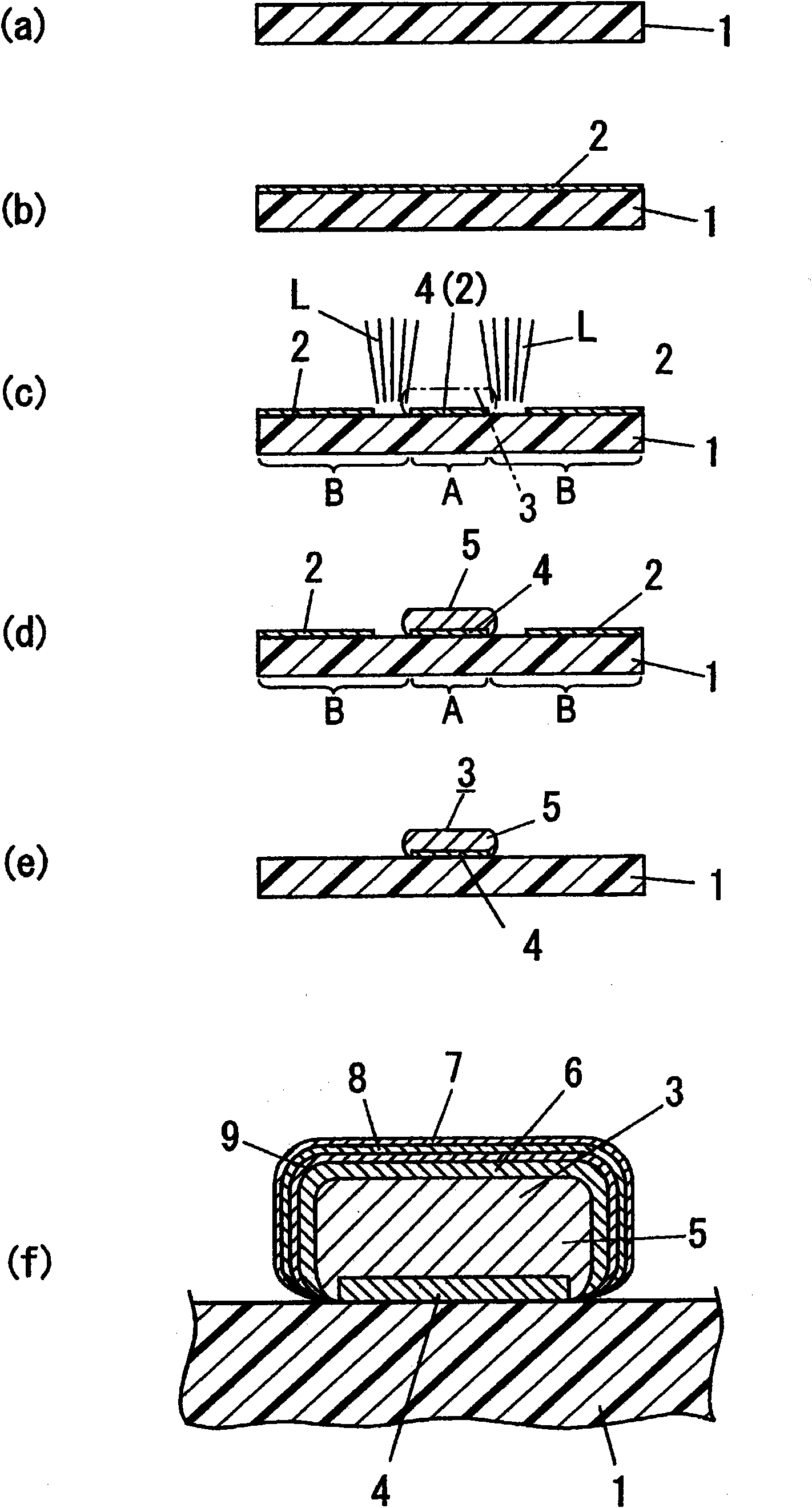

[0066] The insulating substrate 1 was molded using "BT1500" manufactured by Kurashiki Polyester Co., Ltd., a molding material (Kurabo Polyester Co., Ltd.) whose base resin was colored black polyphthalamide ( image 3 (a)). Then, after performing plasma treatment on the surface of the insulating substrate 1, copper was sputtered on the surface of the insulating substrate 1 to form a metal thin film 2 with a film thickness of 0.3 μm ( image 3 (b)).

[0067] Next, the metal thin film 2 is irradiated with a THG-YAG laser L with a wavelength of 355 nm and an output of 0.35 W along the outline of the circuit pattern to carry out laser patterning, thereby forming a plating base layer 4 ( image 3 (c)).

[0068] Next, carry out the copper plating treatment of energization to the base plating layer 4 that is formed by laser drawing, thereby form the copper plating layer 5 on the base plating layer 4 ( image 3 (d)). The copper plating treatment uses a copper sulfate bath composed ...

Embodiment 2

[0076] A circuit board was obtained in the same manner as in Example 1 except that the second intermediate plating layer 9 was formed by palladium plating and the first intermediate plating layer 8 was formed by rhodium plating.

[0077] Here, a palladium plating bath having a Pd concentration of 6 g / L and a pH of 0.8 was used for the palladium plating treatment of the second intermediate plating layer 9 . At a temperature of 55°C and a current density of 0.75A / dm 2 , under the plating conditions of 25 seconds, and the second intermediate plating layer 9 is formed of Pd with a film thickness of 0.1 μm.

[0078] In addition, the first intermediate plating layer 9 containing Rh was formed under the same conditions as in Example 1.

Embodiment 3

[0080] A circuit board was obtained in the same manner as in Example 1 except that the second intermediate plating layer 9 was formed by silver plating and the first intermediate plating layer 8 was formed by rhodium plating.

[0081] Here, the silver plating treatment of the second intermediate plating layer 9 uses a low cyano group bath composed of a bath with a silver concentration of 50 g / L, a free cyano group concentration of 1 g / L, and a Se concentration of 5 mg / L. / dm 2 , under the plating conditions of 15 seconds, and the second intermediate plating layer 9 was formed of Ag with a film thickness of 0.3 μm.

[0082] In addition, the first intermediate plating layer 8 containing Rh was formed under the same conditions as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com