Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about "Conductive material electric discharge removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

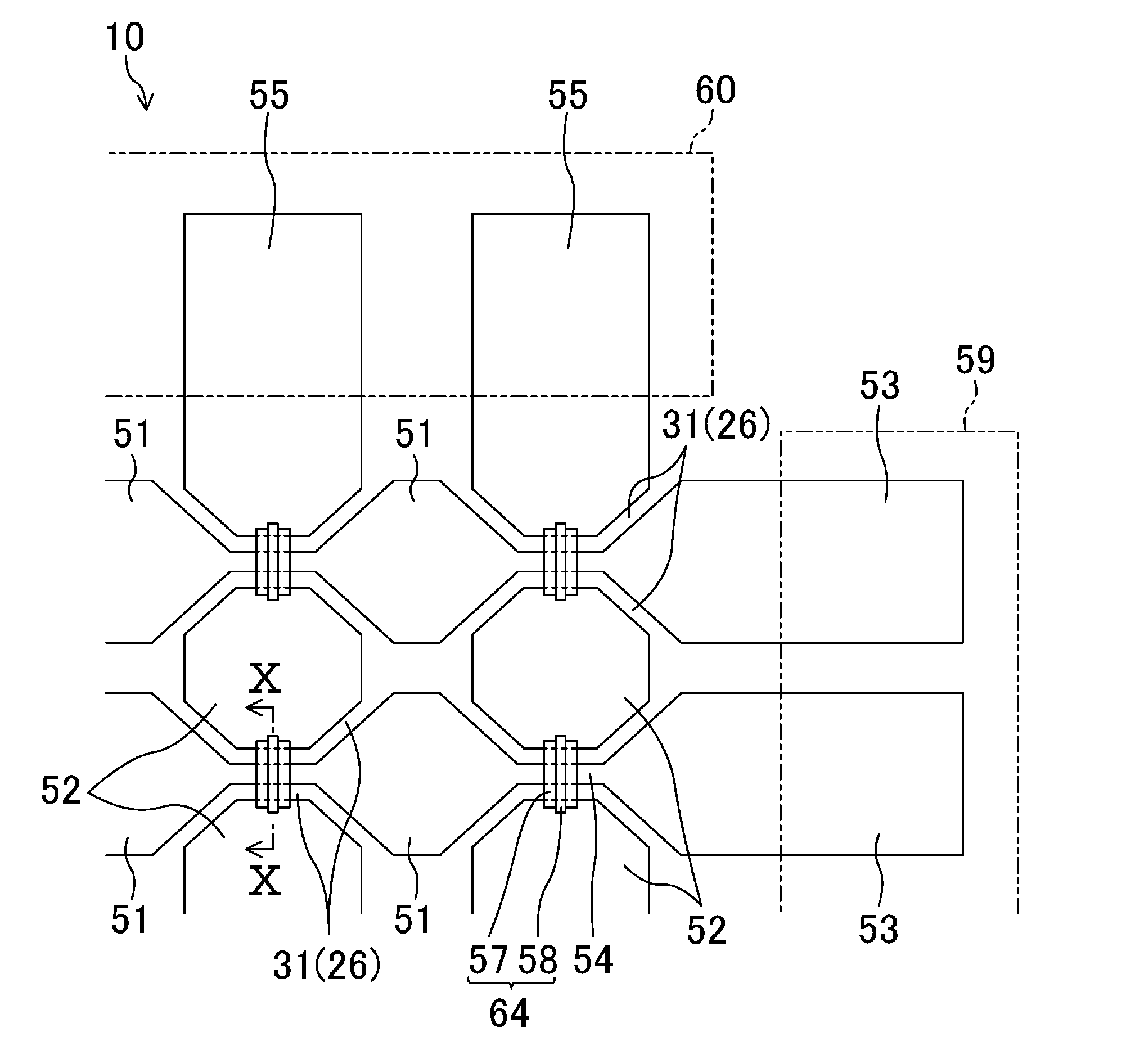

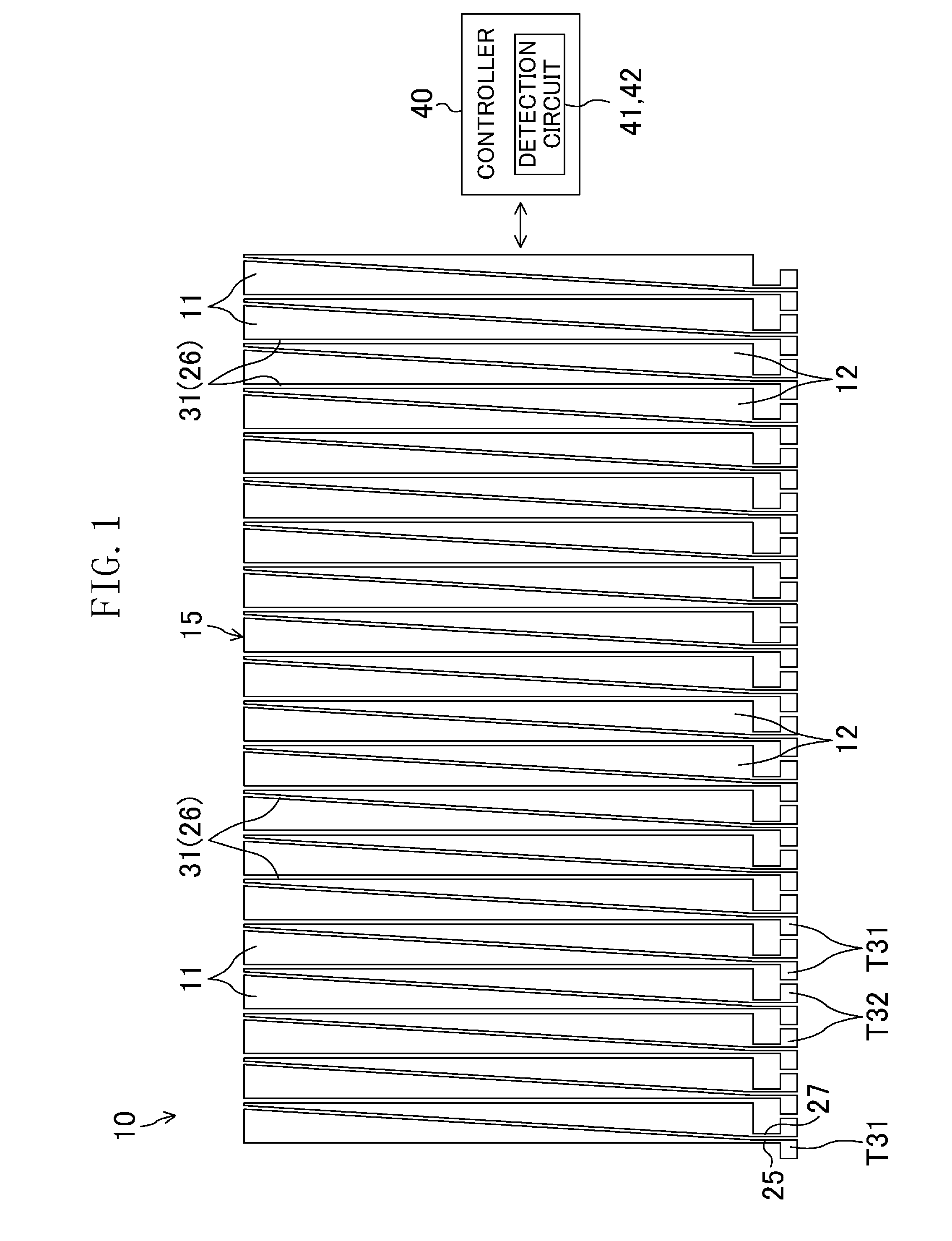

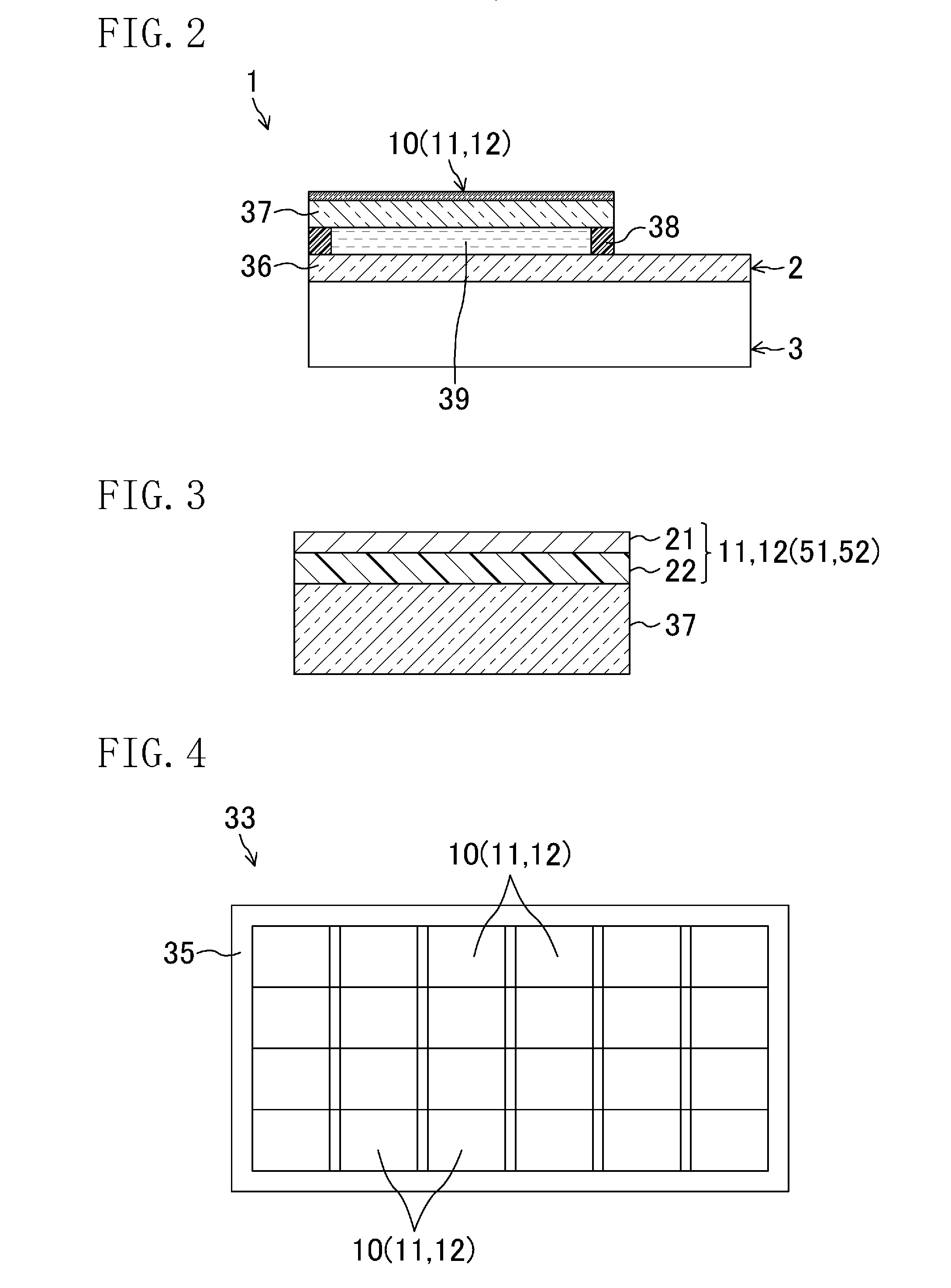

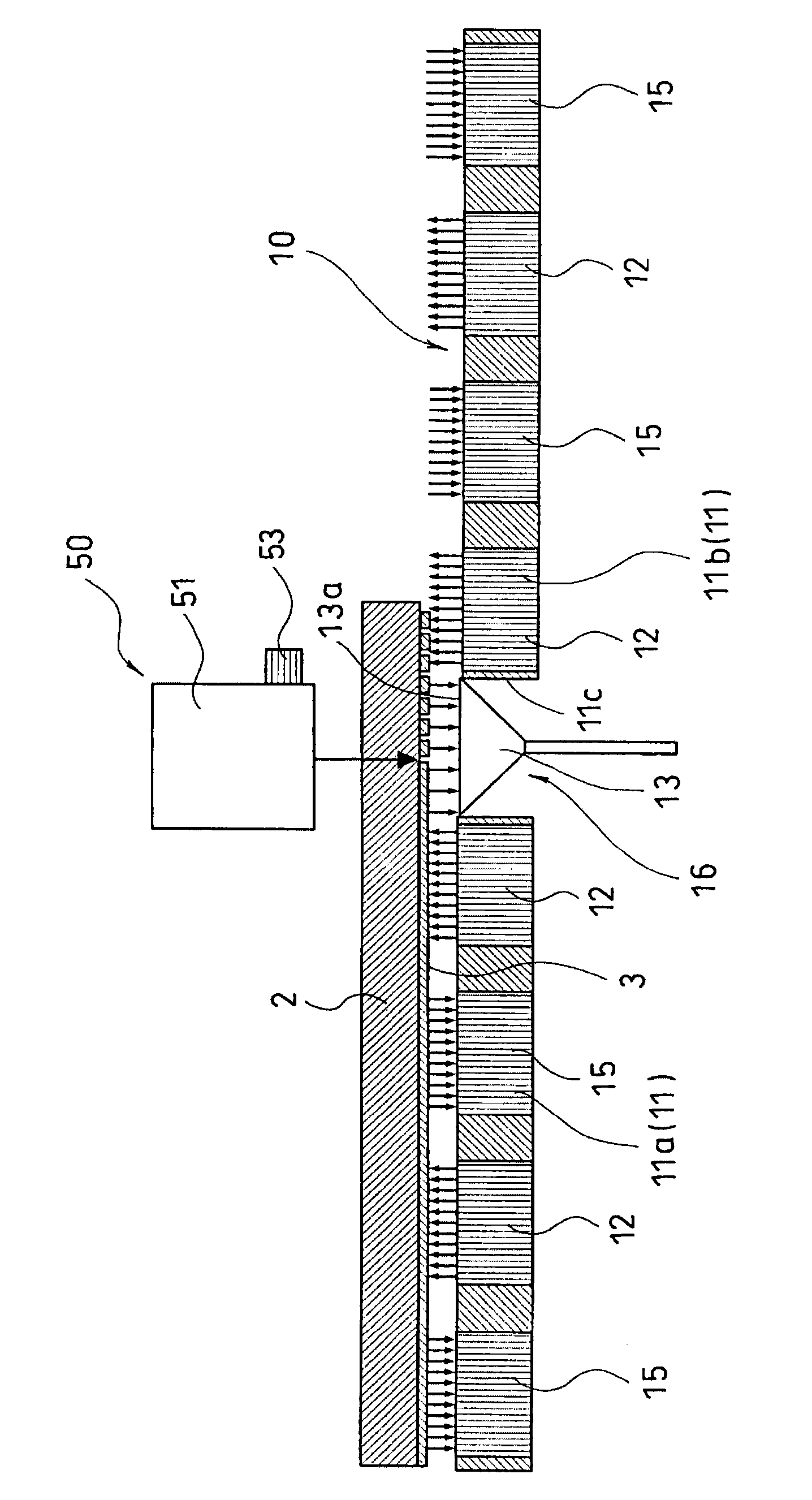

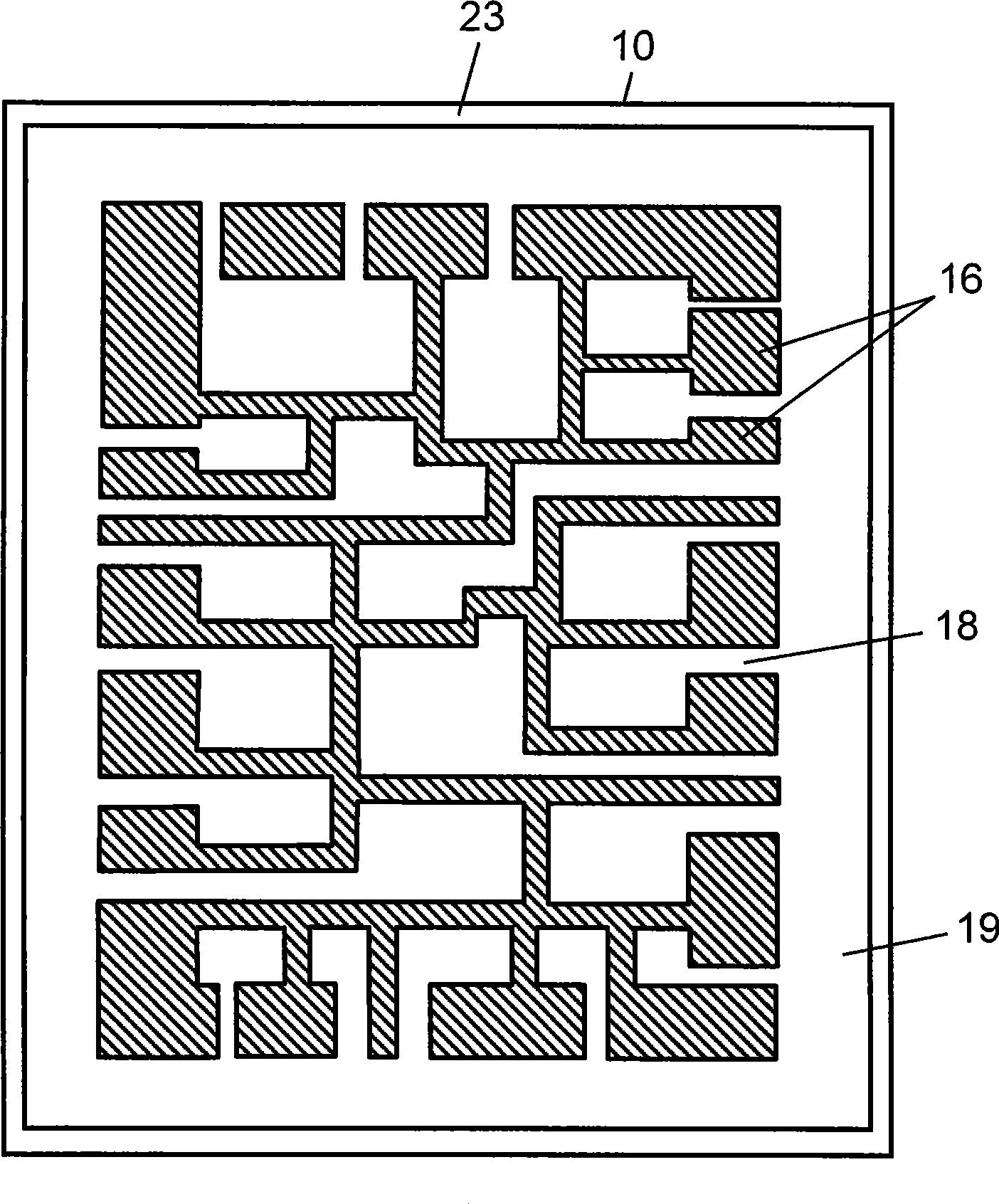

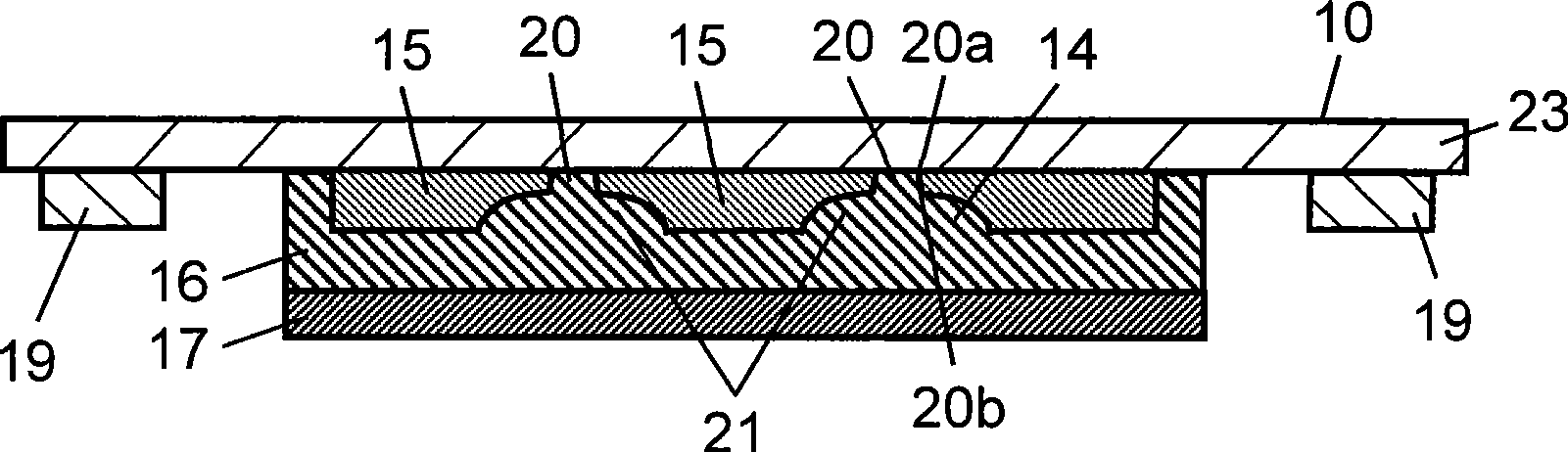

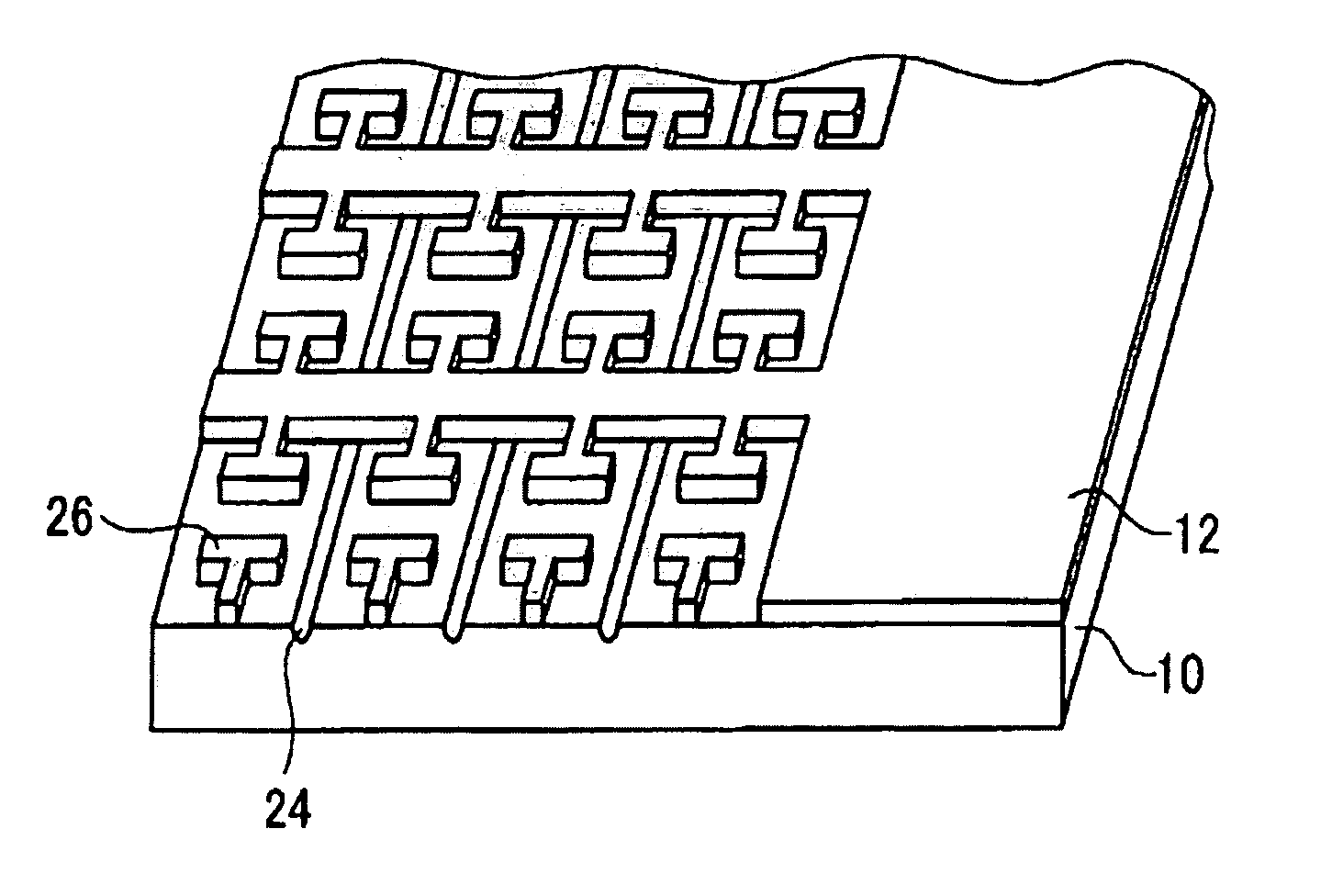

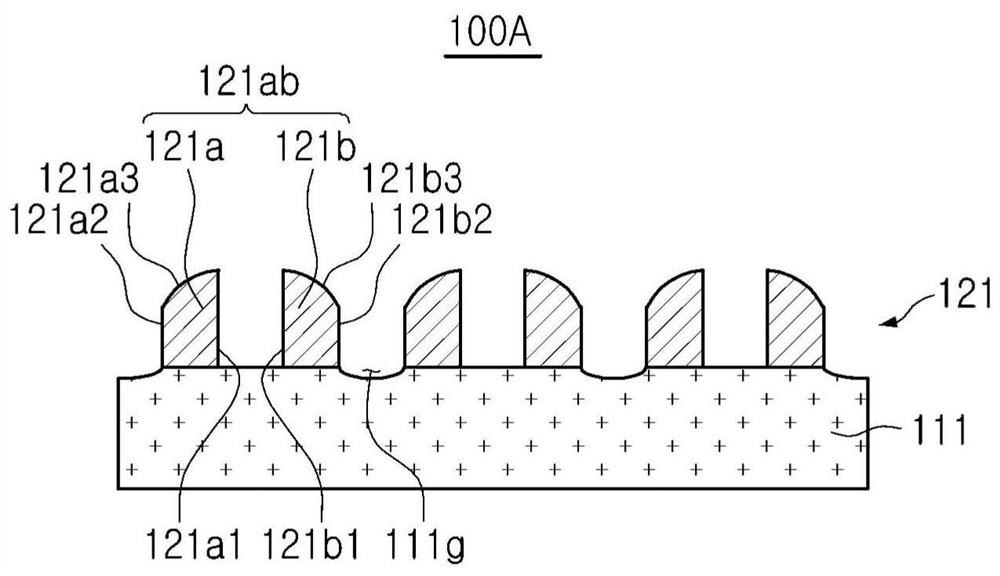

Touch panels, method for fabricating touch panels, display devices, and method for fabricating display devices

InactiveUS20120098791A1Less visibleLess distinguishableConductive material electric discharge removalConductive pattern formationLocation detectionCapacitance

A touch panel includes a touch region for detecting a location of a touch by an object, and a plurality of touch location detection electrodes arranged in the touch region. The touch panel is configured to detect the location of the touch based on a capacitance formed between the touch location detection electrodes and the object. An optical characteristic of a gap between the touch location detection electrodes adjacent to each other is substantially equal to an optical characteristic of the touch location detection electrodes.

Owner:SHARP KK

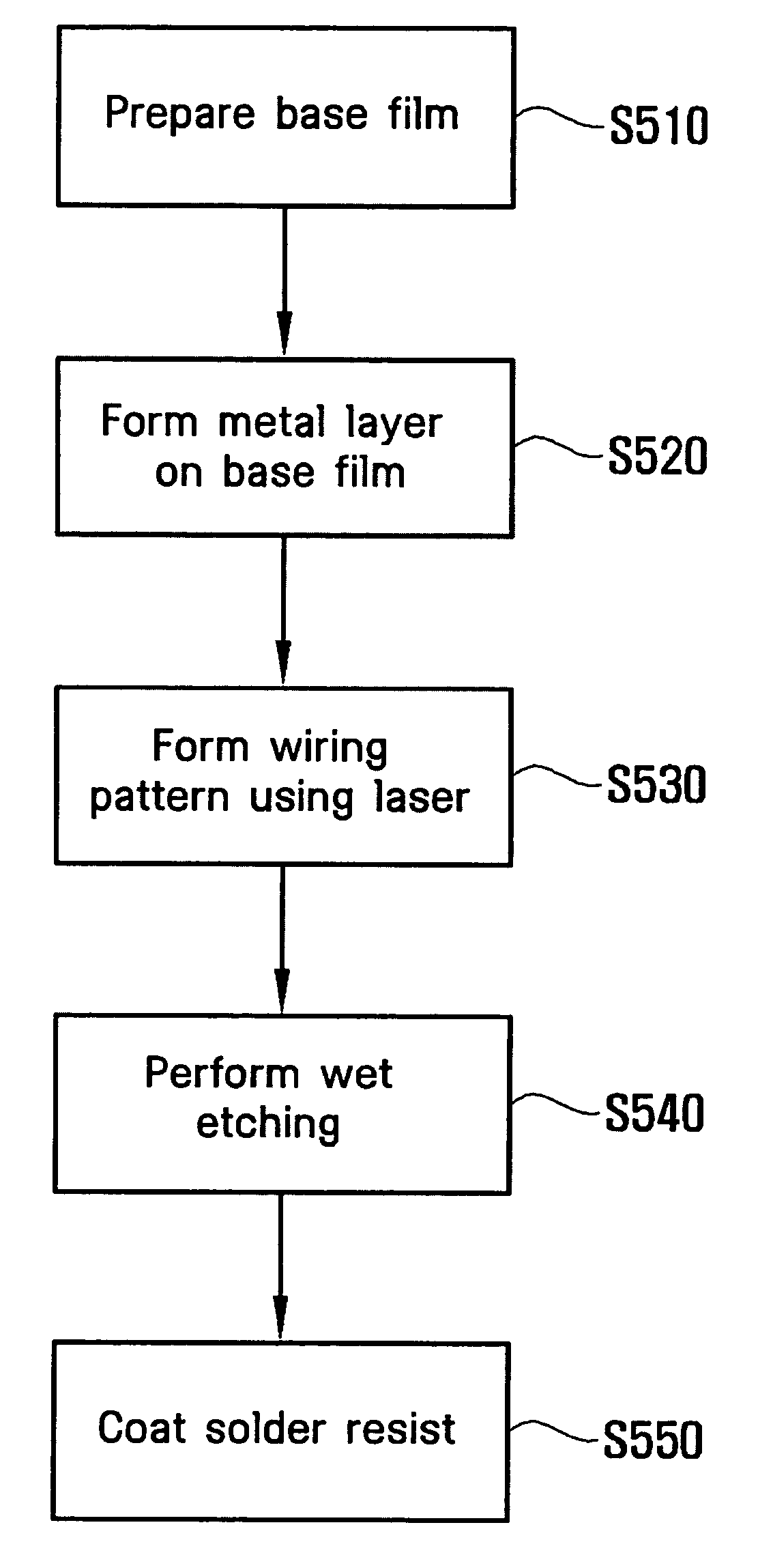

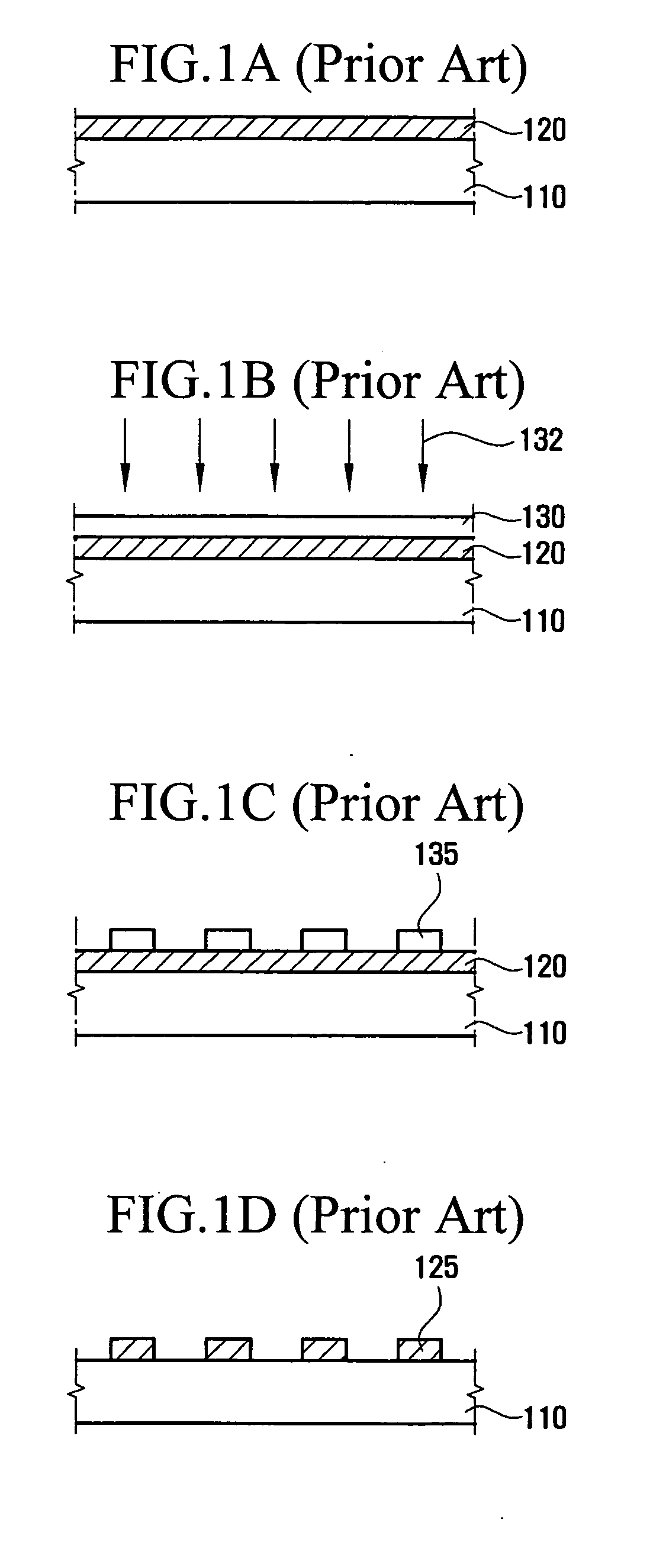

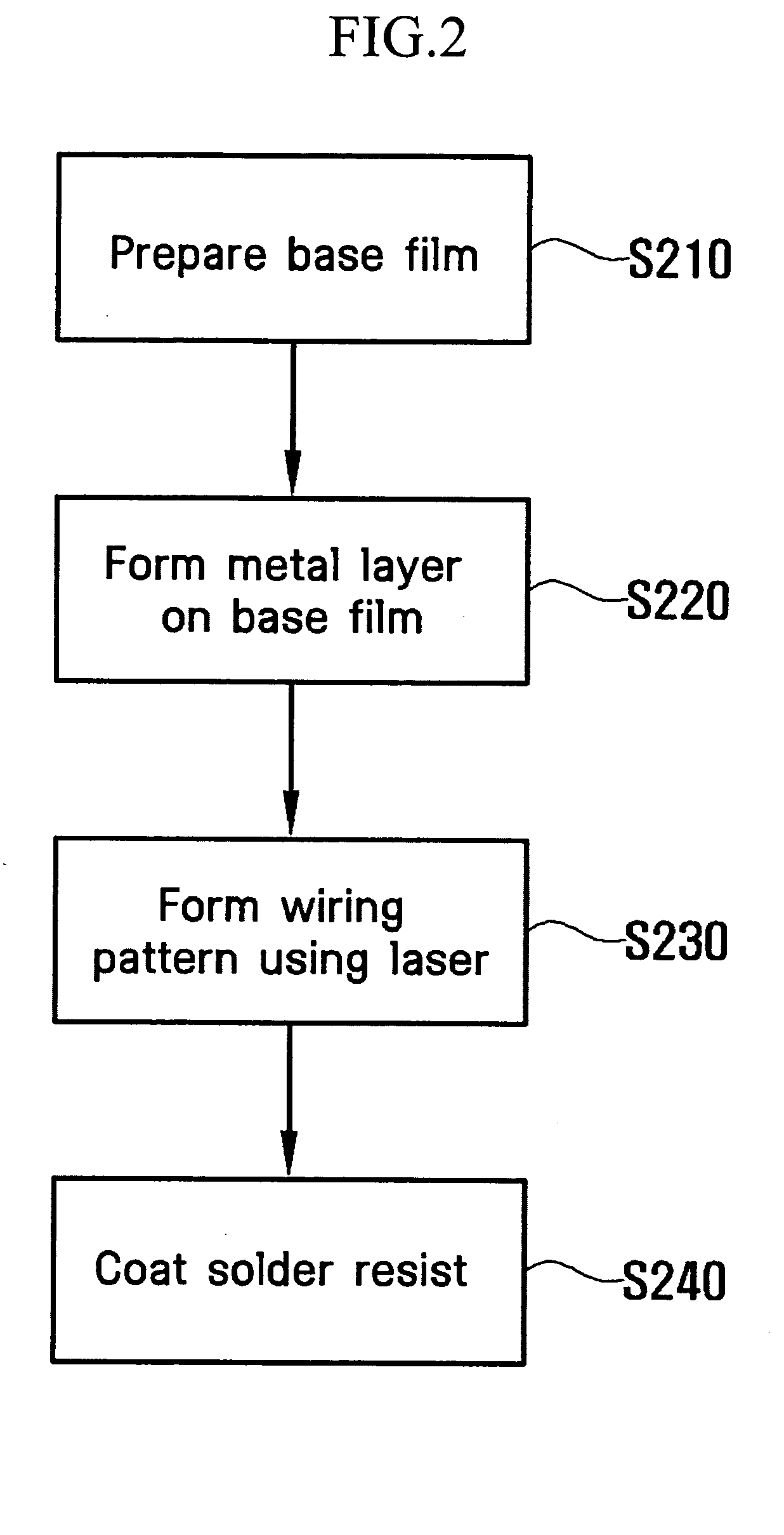

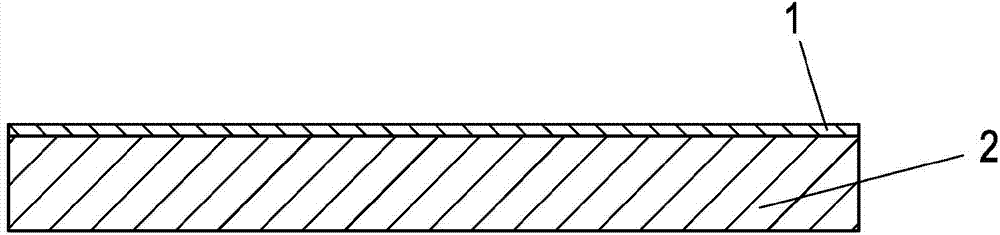

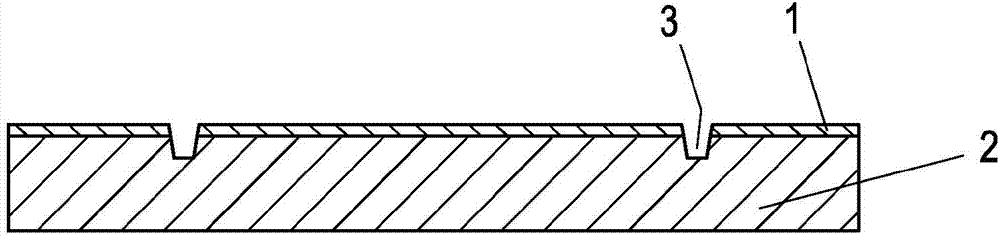

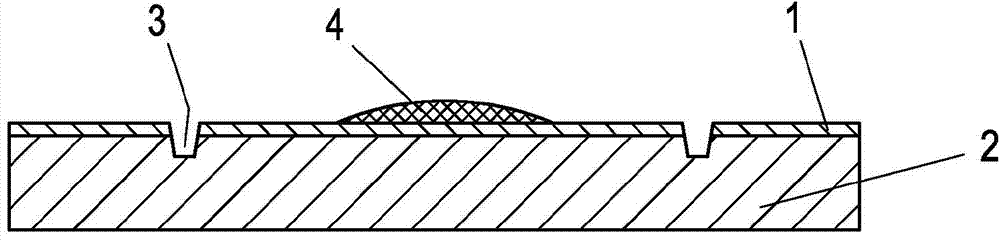

Method of manufacturing tape wiring substrate

InactiveCN1671270AReduce manufacturing costReduce the numberSemiconductor/solid-state device manufacturingConductive material electric discharge removalEtchingEngineering

A method of manufacturing a tape wiring substrate, by which the production cost can be reduced by a simplified manufacturing process. A fine wiring pattern having fine pitches can be formed. The method of manufacturing a tape wiring substrate includes preparing a base film, forming a metal layer on the base film, and processing the metal layer into a wiring pattern using a laser. In addition, the metal layer is partially removed using the laser, and a wiring pattern is formed by a subsequent wet etching.

Owner:SAMSUNG ELECTRONICS CO LTD

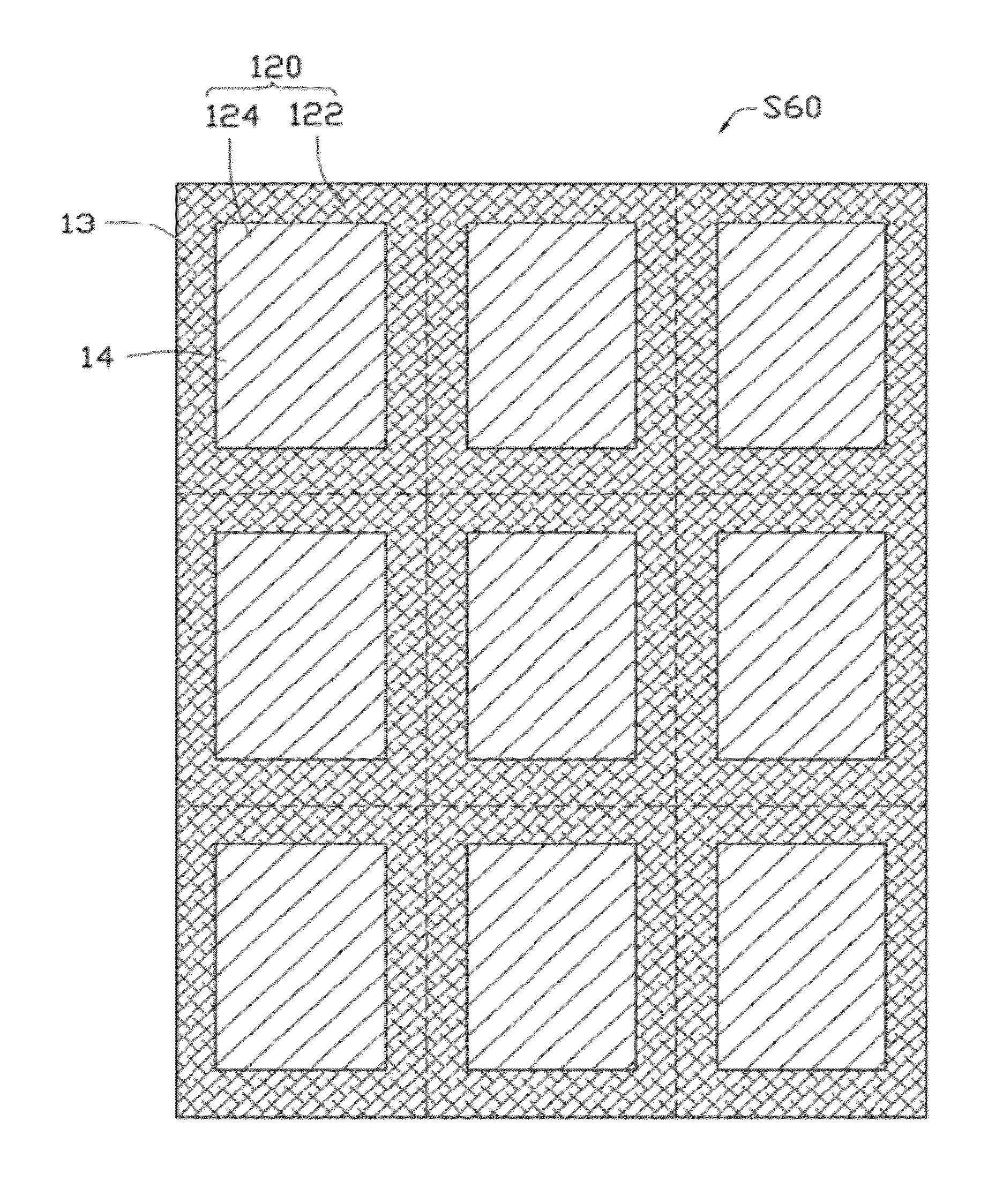

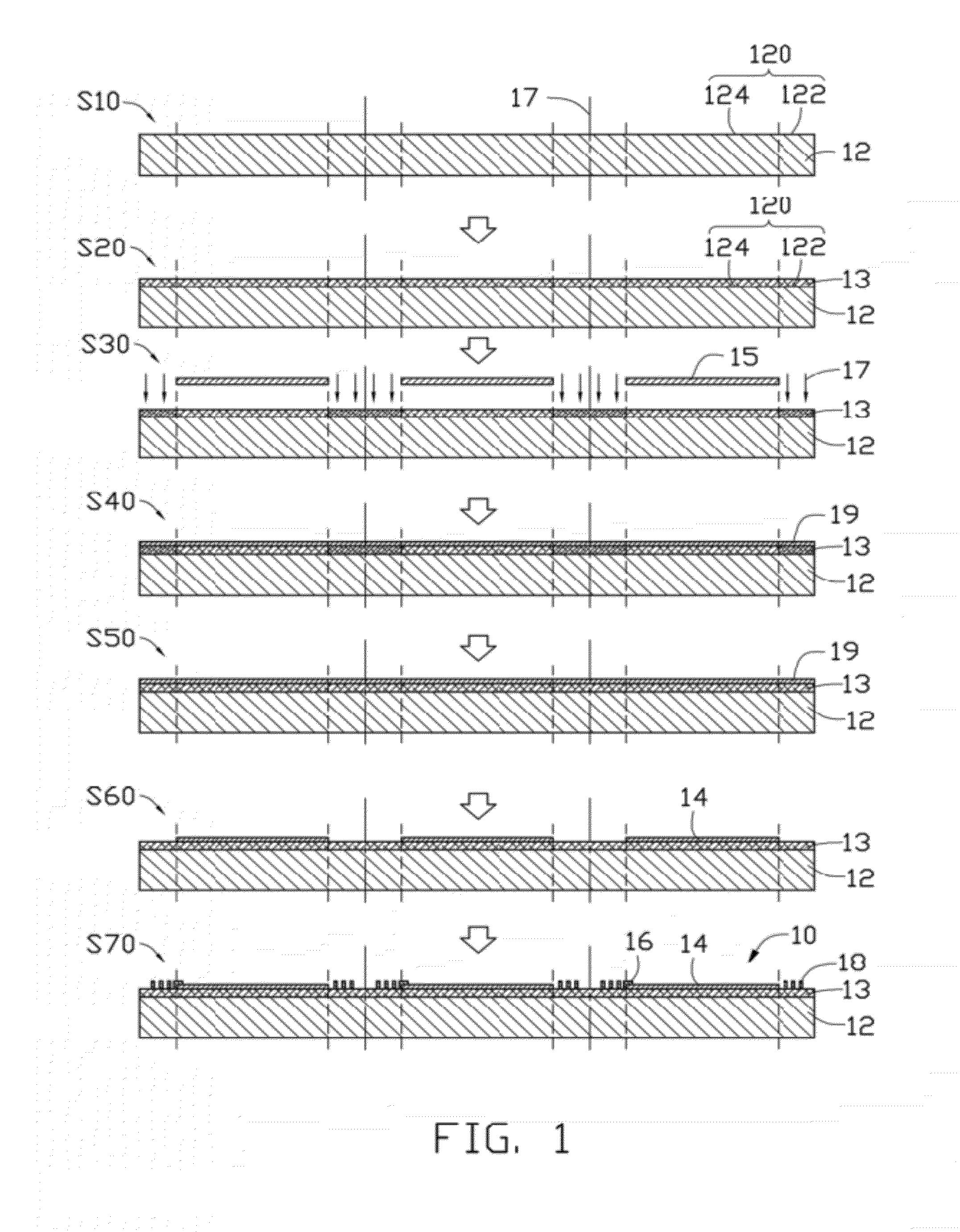

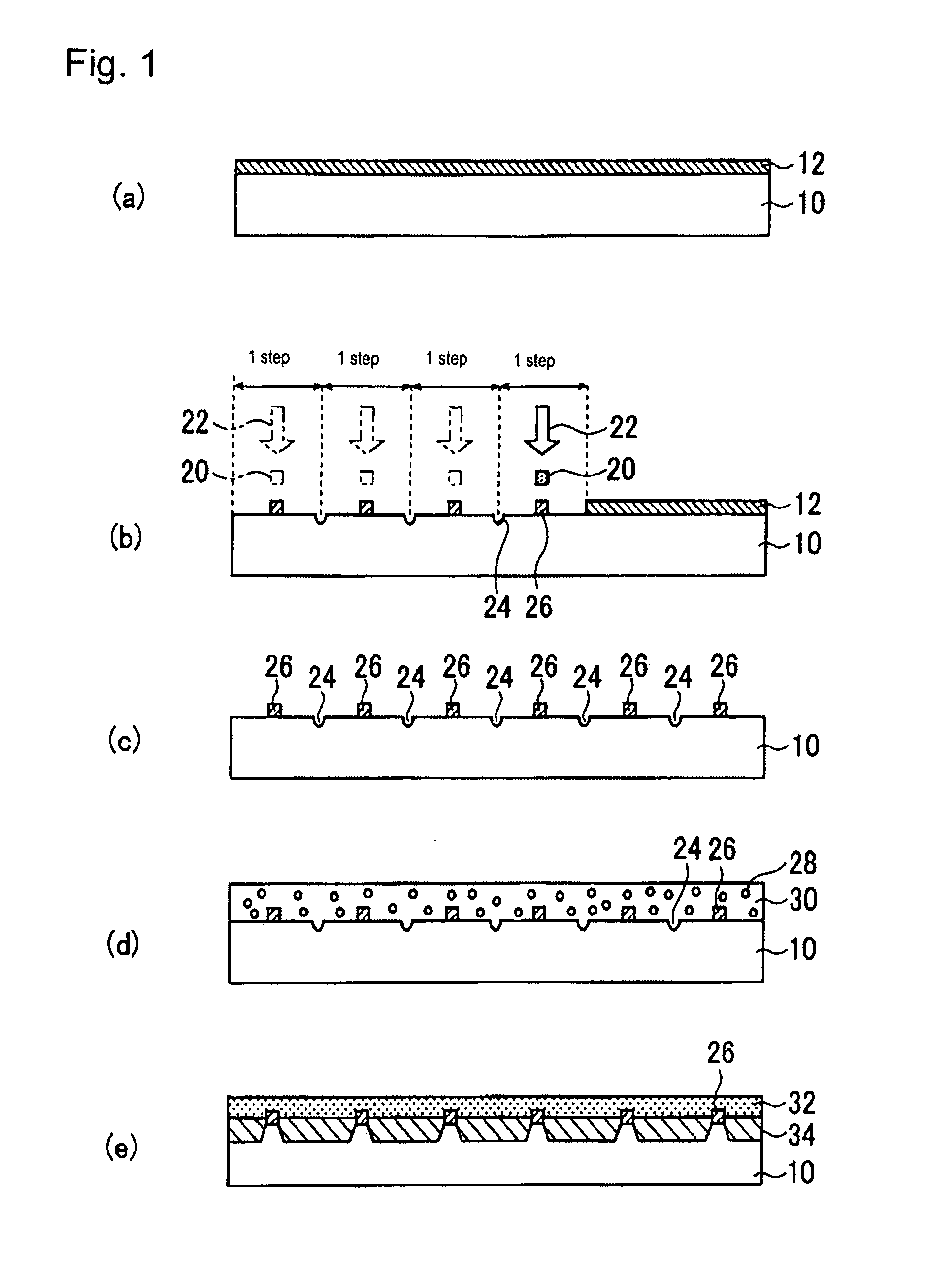

Method for making touch panel

InactiveUS20120312776A1Material nanotechnologyLamination ancillary operationsCarbon nanotubeTouch panel

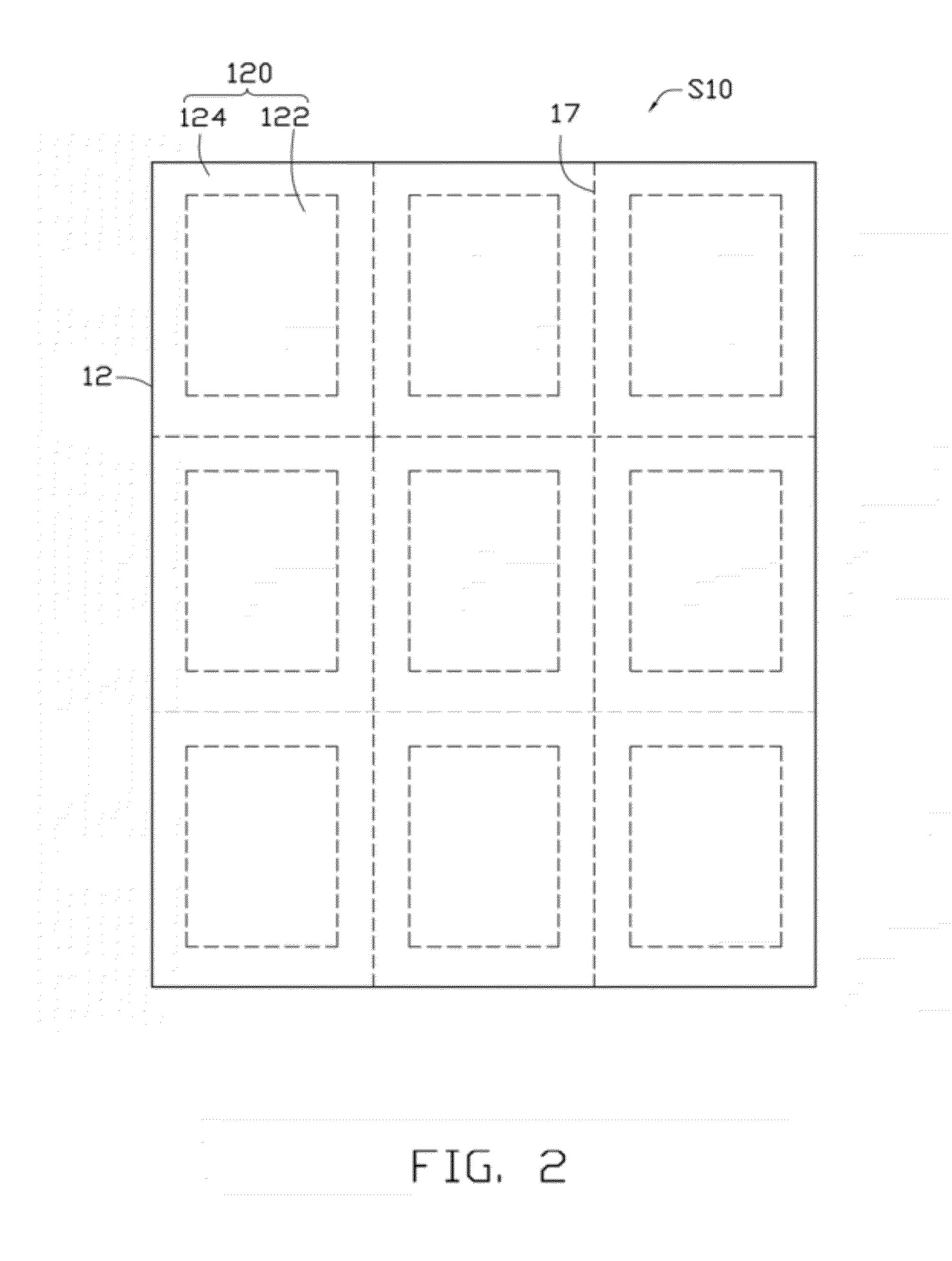

A method for making a plurality of touch panels one time which includes the following steps. A substrate is provided. The substrate has a surface defining a plurality of target areas with each including a touch-view area and a trace area. An adhesive layer is formed on the surface of the substrate. The adhesive layer on the trace areas is solidified. A carbon nanotube layer is formed on the adhesive layer. The adhesive layer on the touch-view area is solidified. The carbon nanotube layer on the trace areas is removed to obtain a plurality of transparent conductive layers spaced from each other. An electrode and a conductive trace are formed on each target area. A plurality of touch panels is obtained by cutting the substrate.

Owner:SHIH HUA TECH LTD

Flexible printed circuit

ActiveUS20190029116A1Easy to foldShow cabinetsPrinted circuit aspectsConductive materialsEngineering

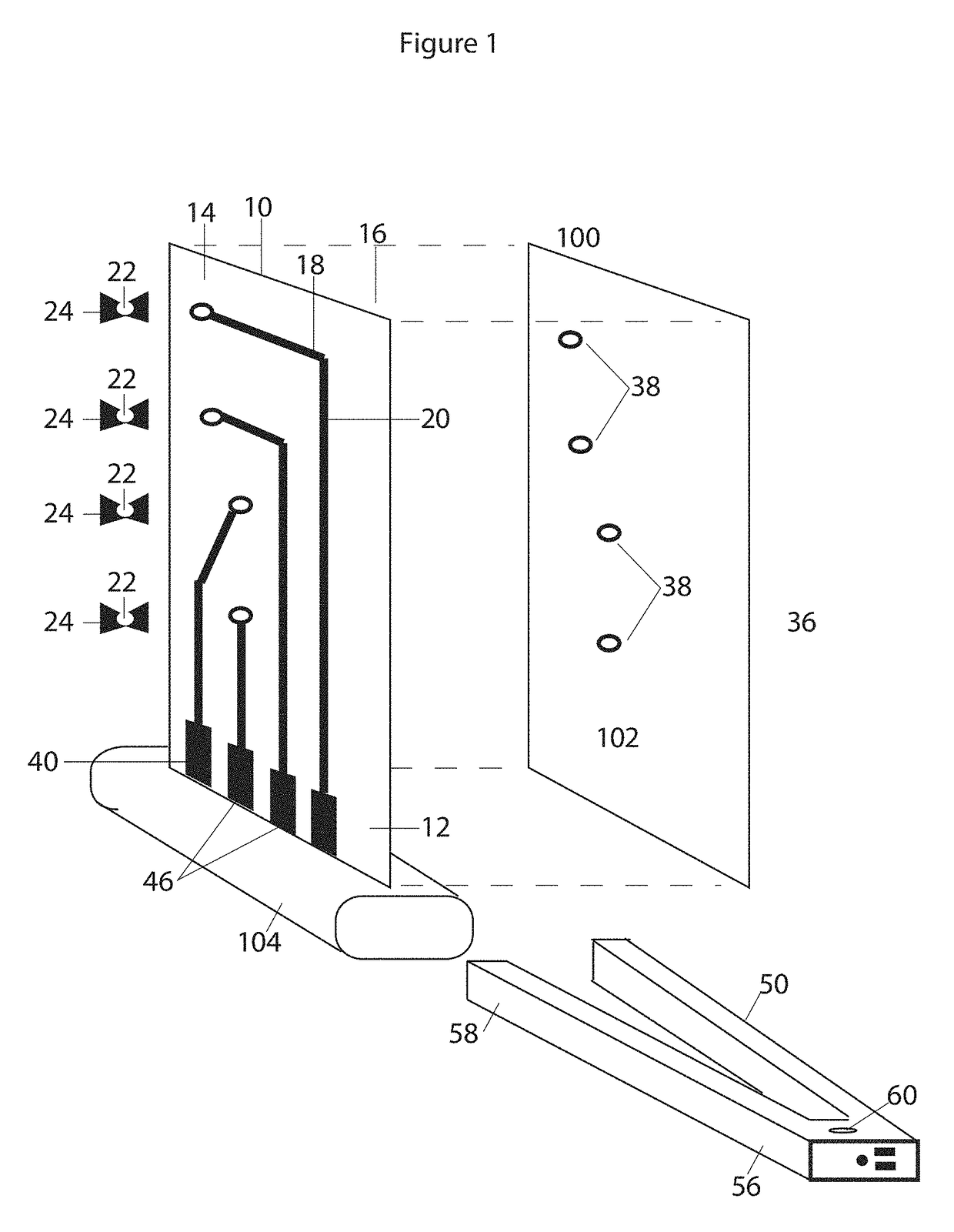

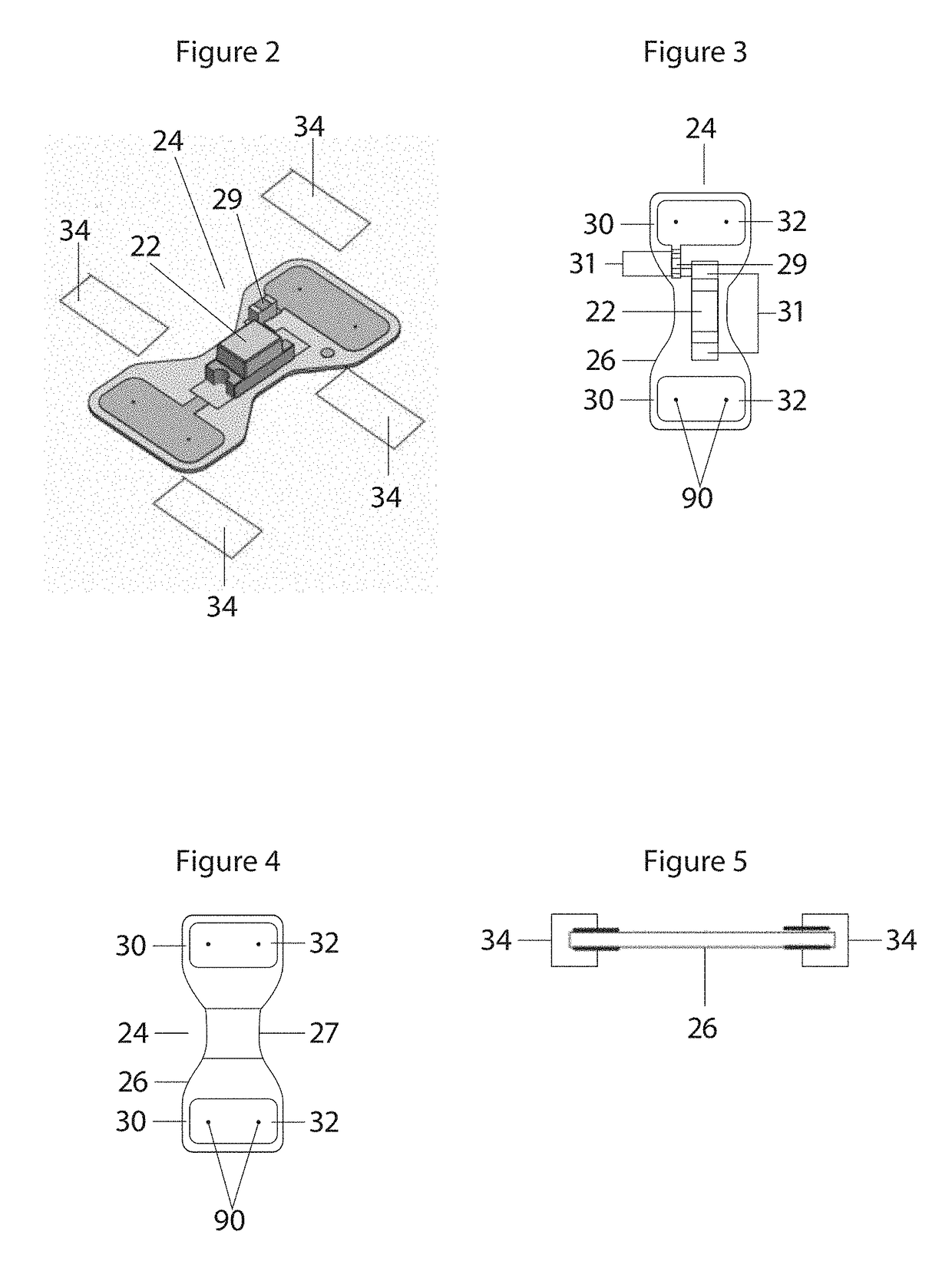

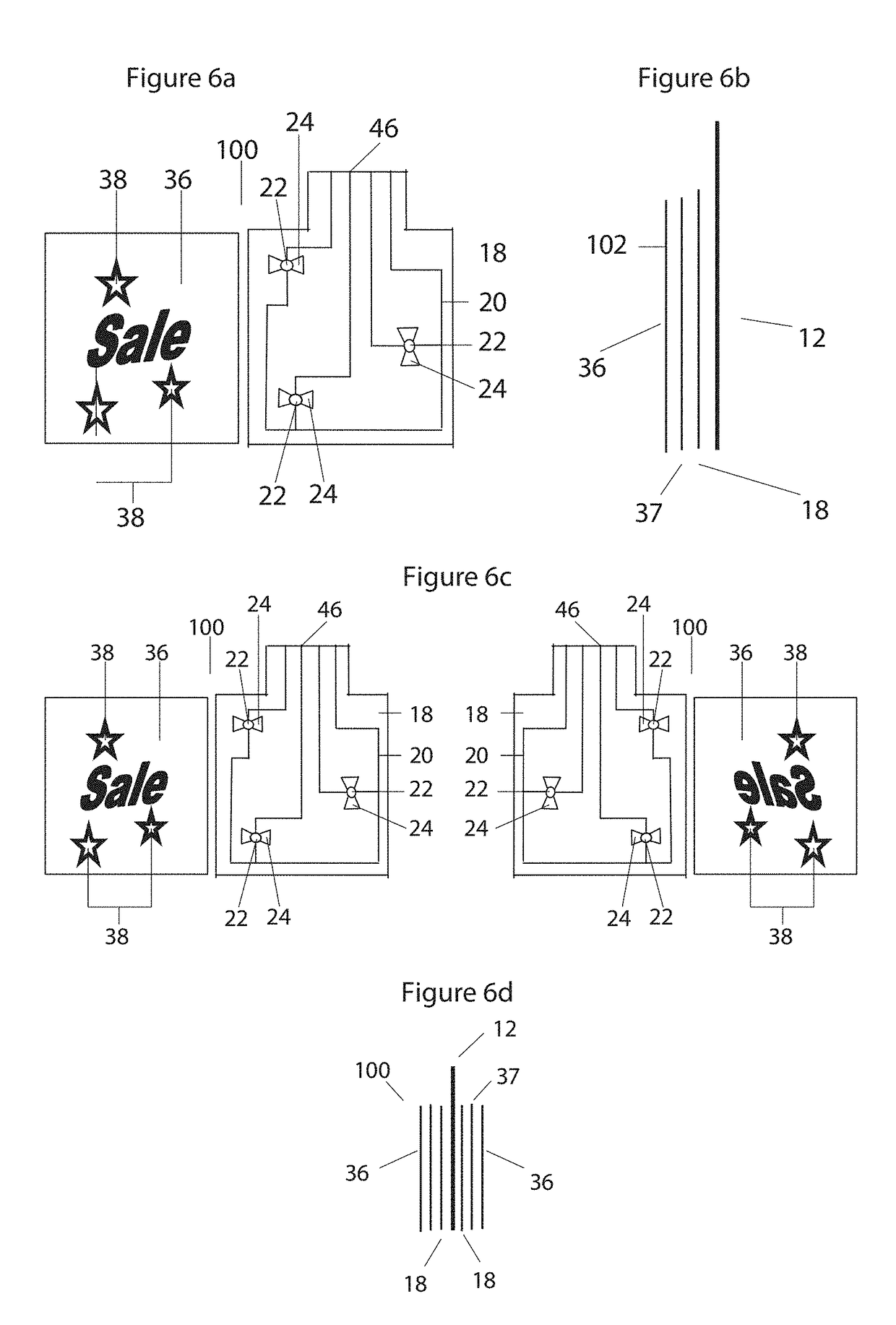

A flexible printed circuit is described that includes a flexible supporting substrate having a first face and a second face. A conductive material is deposited by vacuum deposition on at least one of the first face or the second face of the flexible supporting substrate. A flexible conductive circuit is formed on the conductive material by electrical discharge machining. The flexible conductive circuit defines a plurality of electrical component placement circuits to which electrical components may be attached. The flexible printed circuit can be rolled or folded. The flexible printed circuit can also be made in sizes much larger than is currently possible with other competing technologies.

Owner:TF MASSIF TECH LTD

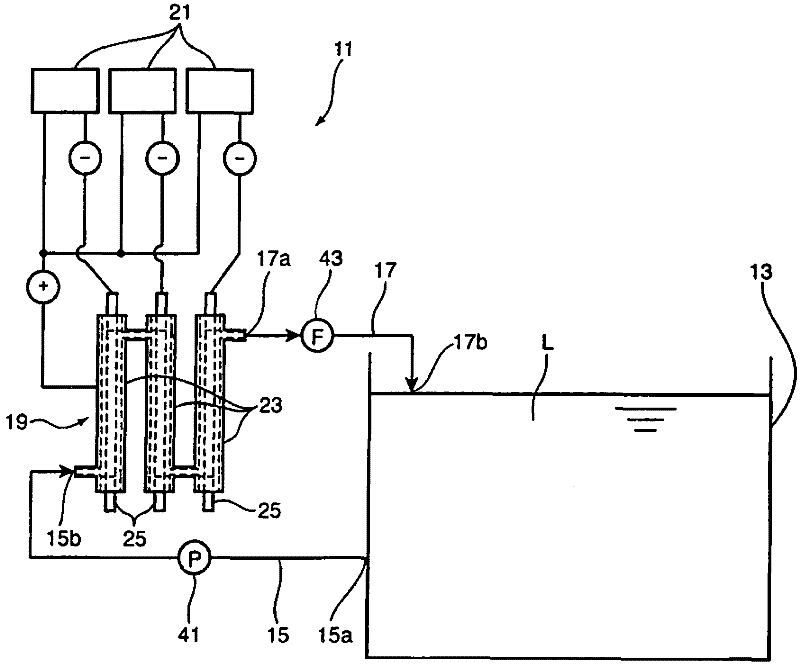

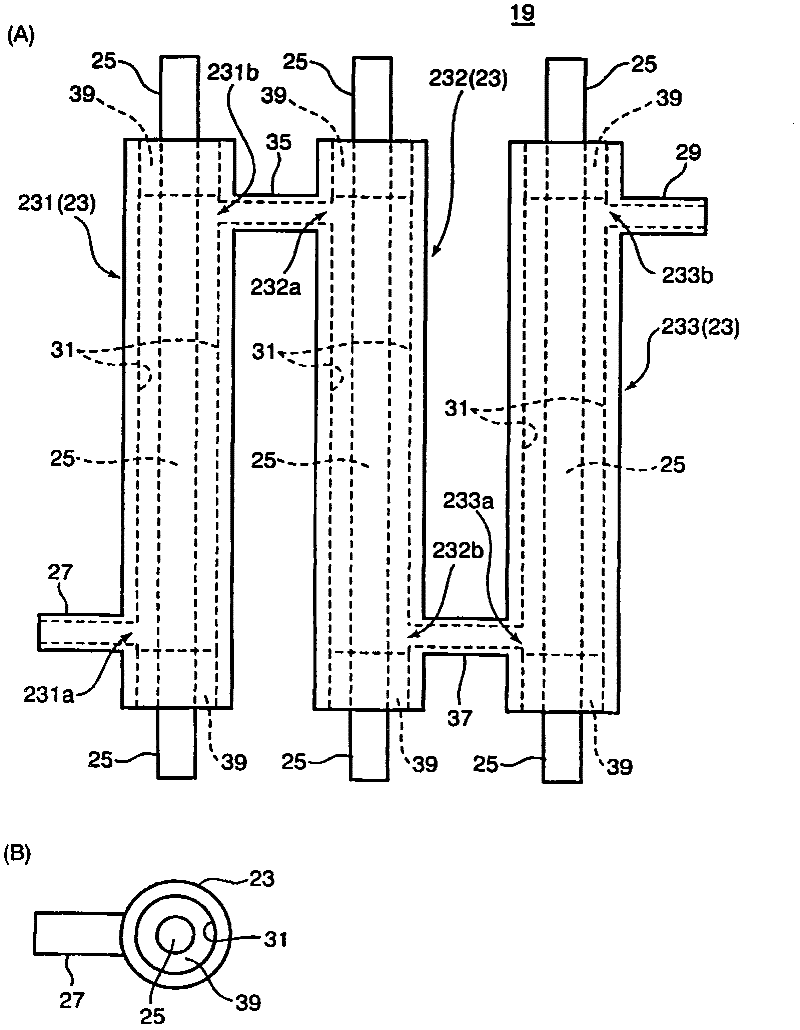

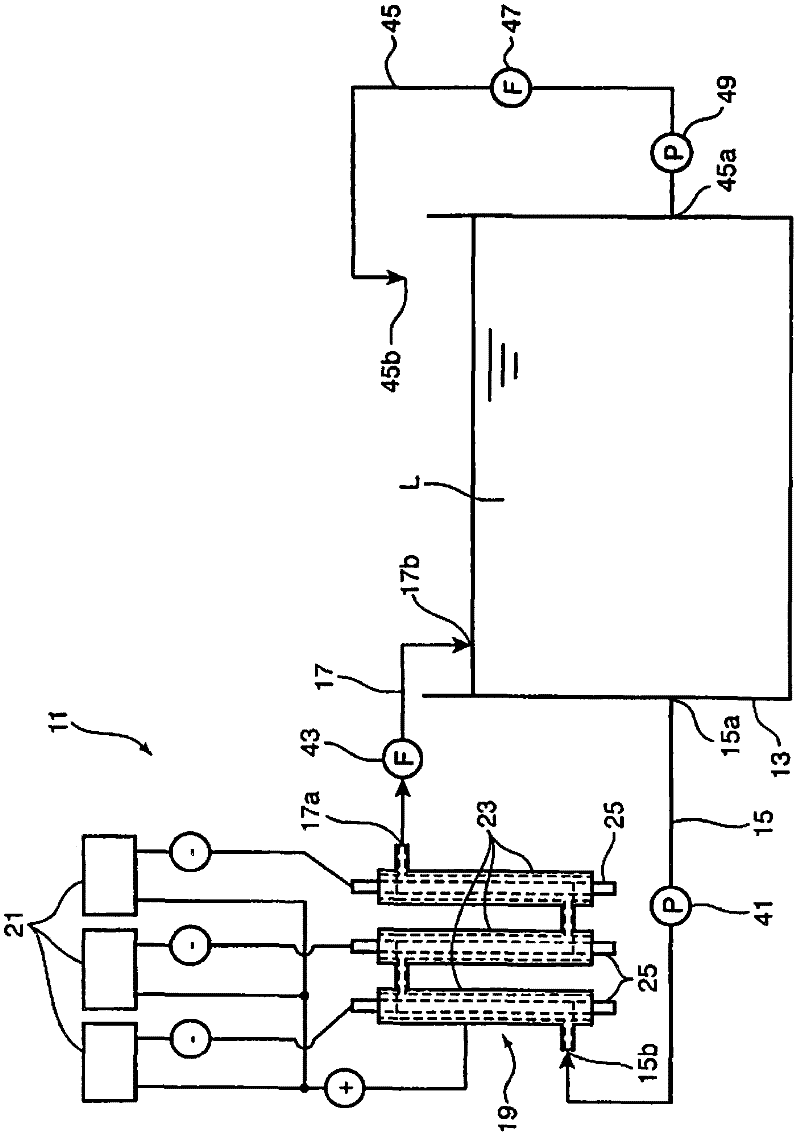

Electrolytic regeneration device

ActiveCN102383139AReduce fluid volumeCellsInsulating layers/substrates workingMiniaturizationEngineering

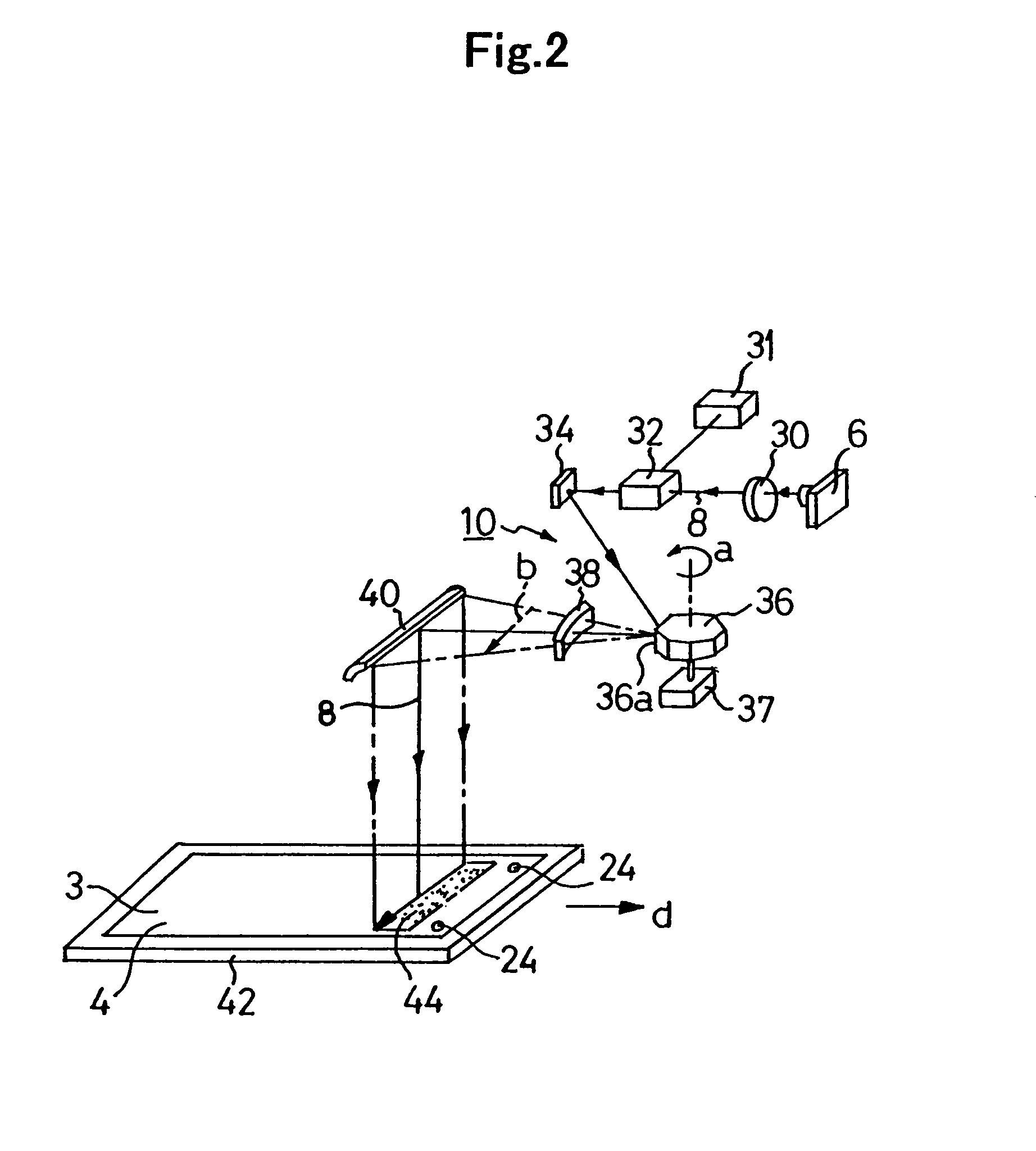

The invention provides an electrolytic regeneration device, wherein, a regeneration unit (19) includes a tubular portion (23) having the inner circumferential surface (31) functioning as an anode, and a cathode (25) provided inside the tubular portion and extending along the extension direction of the tubular portion in a state of separation from the inner circumferential surface. The treatment liquid used for desmearing treatment is fed through a gap between the inner circumferential surface (31) of the tubular portion (23) and the cathode (25). A feed-side conduit (15) is connected by a downstream end portion (15b) thereof to the tubular portion (23) and guides the treatment liquid discharged from a desmearing treatment tank (13) into a regeneration unit (19). A return-side conduit (17) is connected by an upstream end portion (17a) thereof to the tubular portion (23) and guides the treatment liquid discharged from the regeneration unit (19) into the desmearing treatment tank (13). Via the above way, the electrolytic regeneration device is capable of realizing miniaturization and reducing total liquid amount.

Owner:C UYEMURA & CO LTD

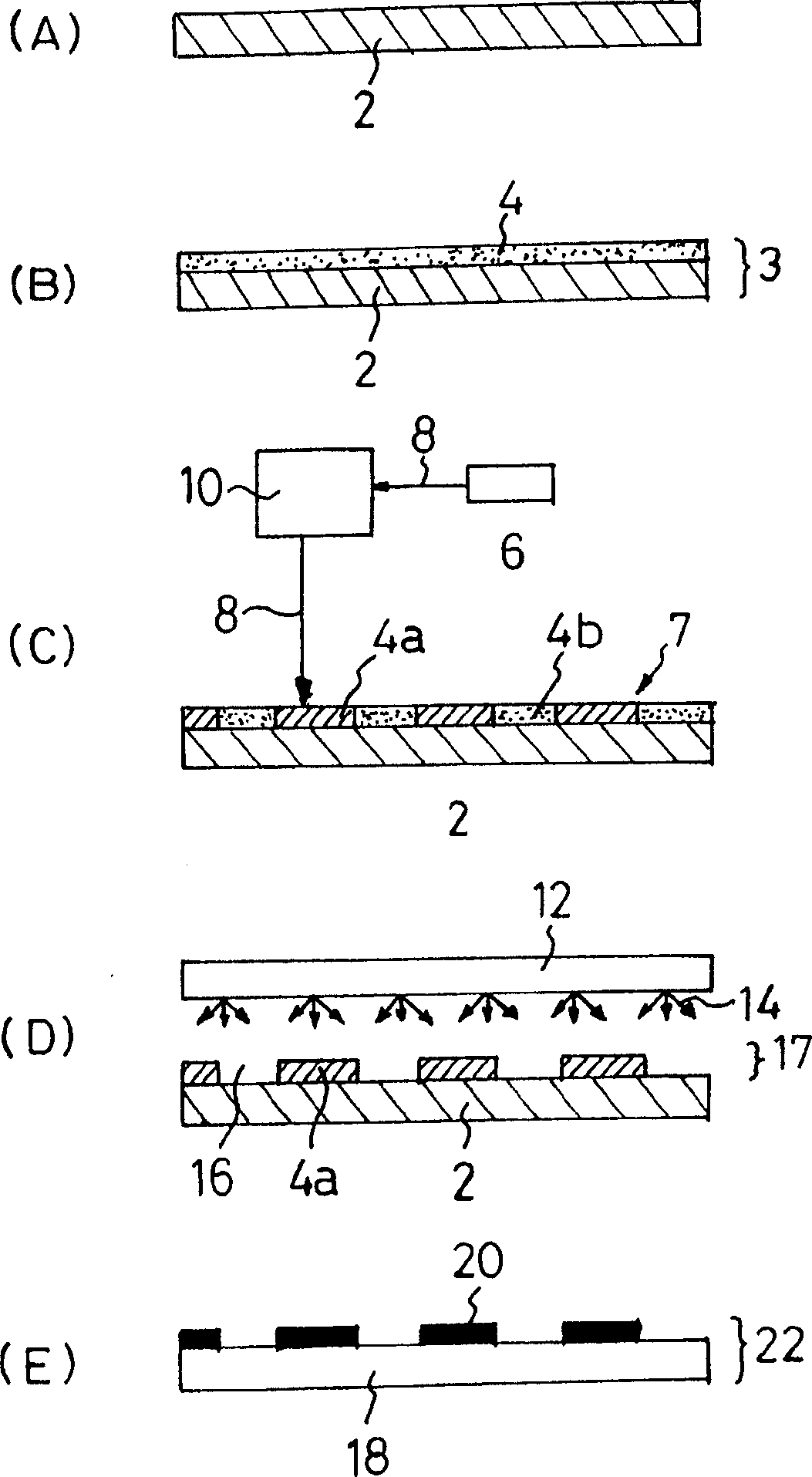

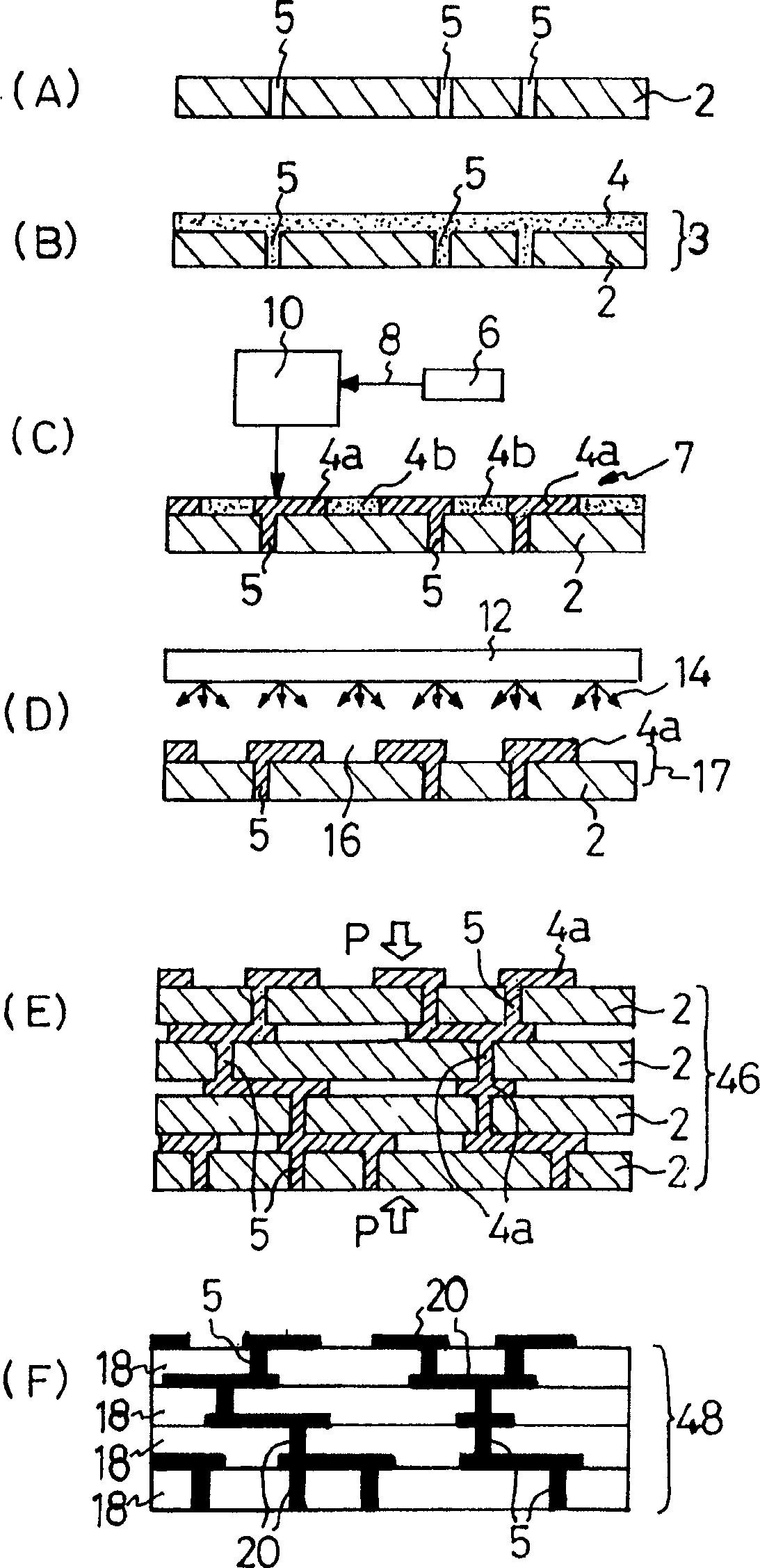

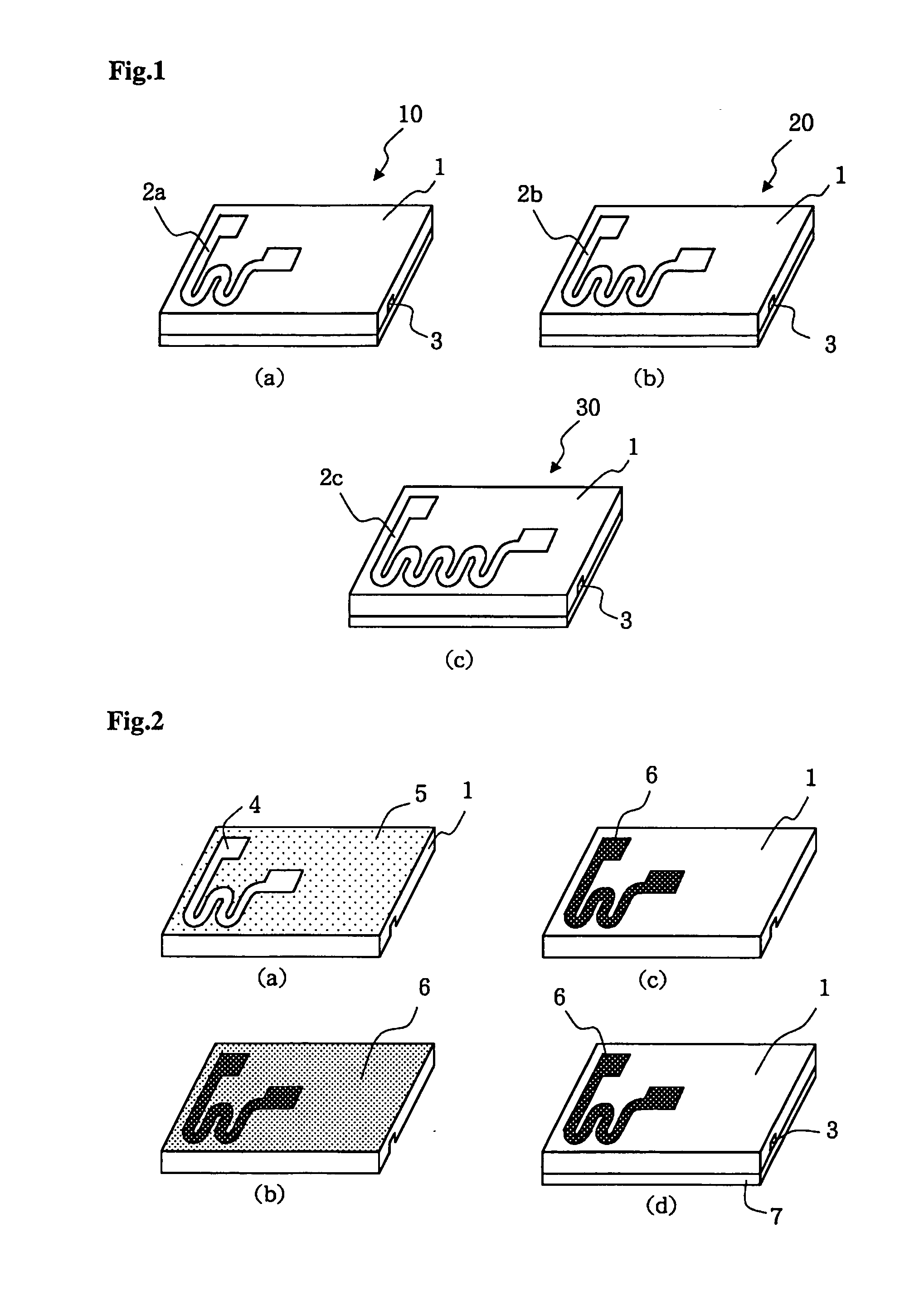

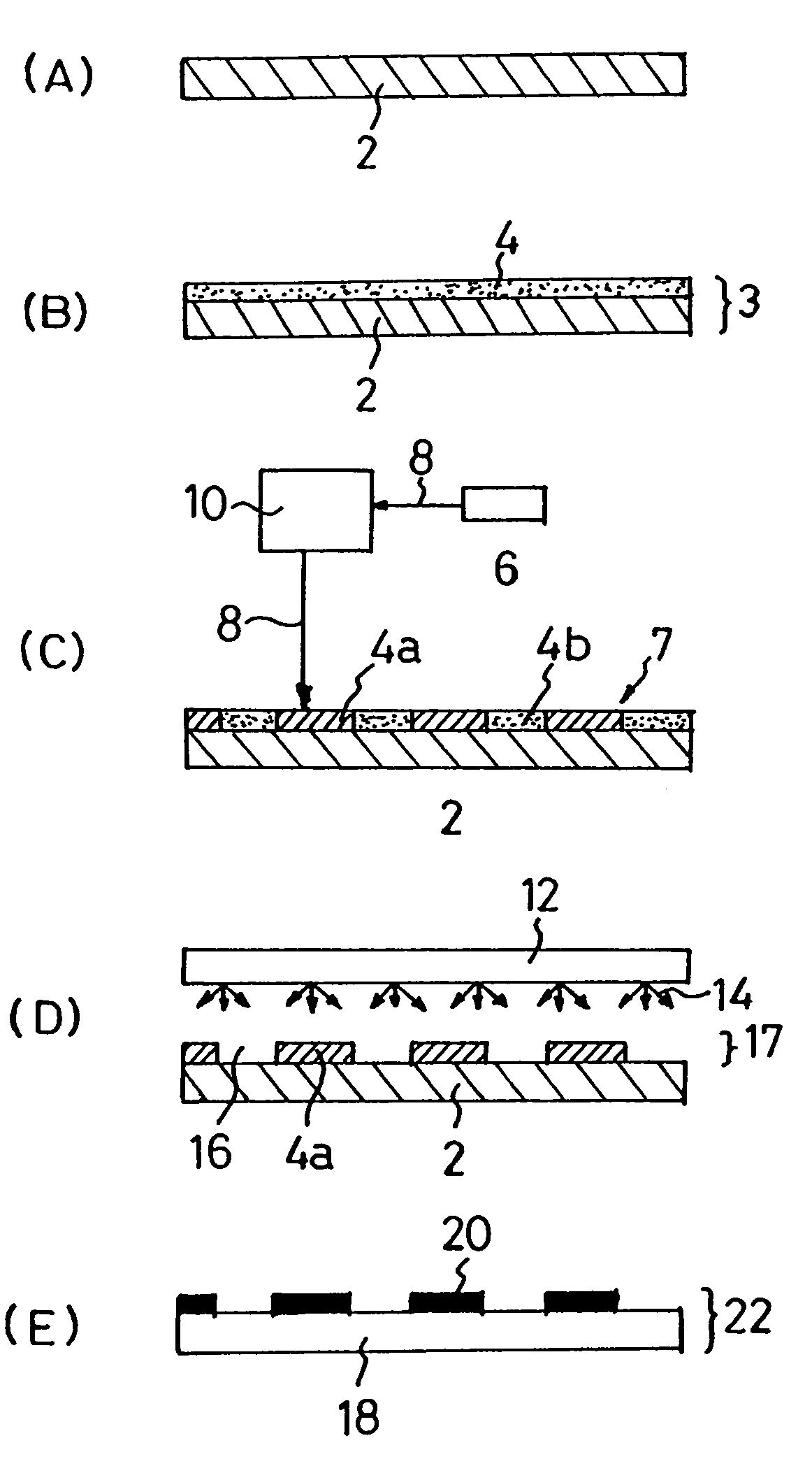

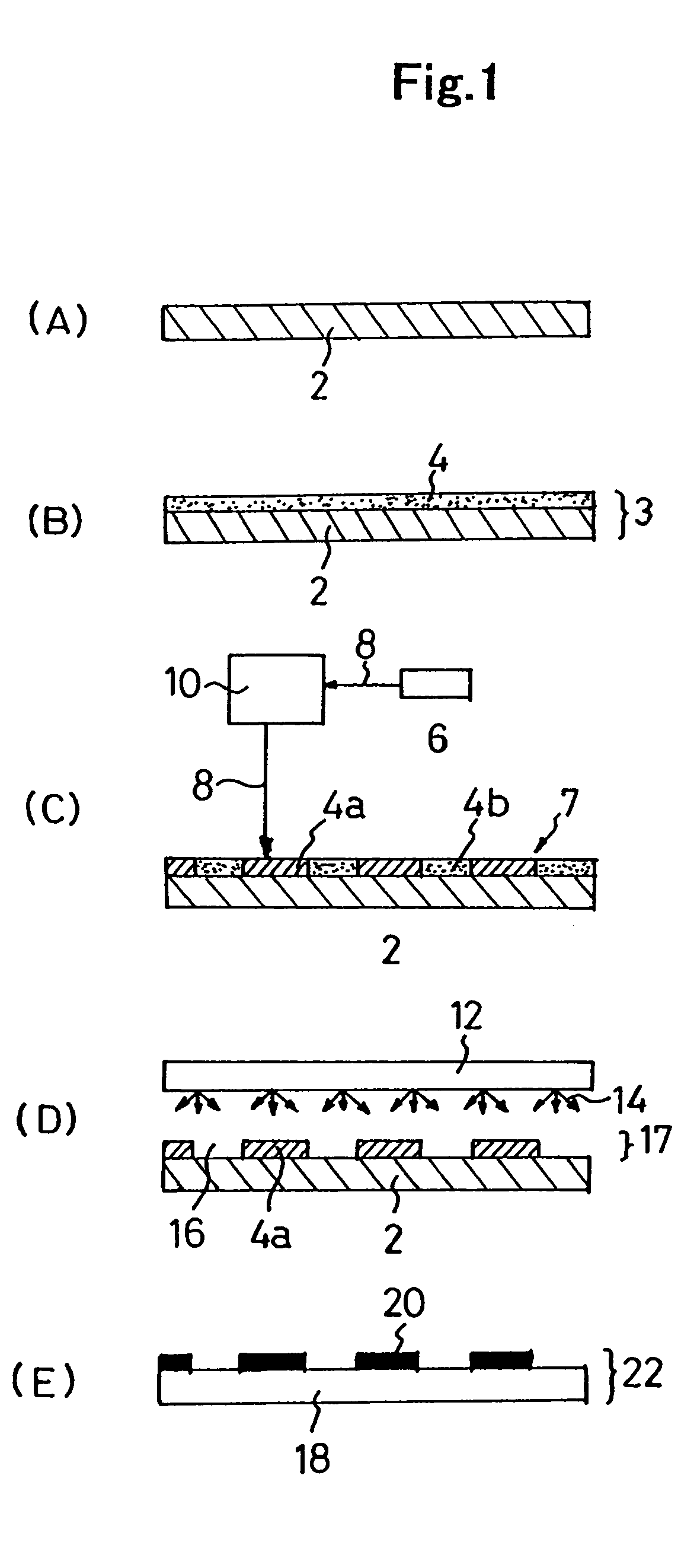

Method for forming image on object surface including circuit substrate

By using a novel method, the exposure time of the photosensitive paste layer is reduced and the exposure fineness of the layer is improved, thereby developing a highly fine circuit substrate of high density having a thermal resistance at a reasonable cost. A circuit substrate is manufactured as follows. A photosensitive paste containing photoresist and a circuit material is applied onto a substrate surface so as to form a photosensitive paste layer (4). This photosensitive paste layer (4) is plotted by a laser beam (8) so as to form a plotted area (7). The photosensitive paste layer (4) is developed and an exposed area (4a) or an unexposed area (4b) is removed so as to form a circuit pattern (17). This circuit pattern (17) is sintered to form a circuit pattern (20) composed of the circuit material. It is possible to form a highly fine circuit pattern of high density by laser beam plotting. Moreover, when a greensheet (2) is used as the substrate, it is possible to form a ceramic substrate (18) having a thermal resistance by sintering. Furthermore, by using this method, it is possible to form an arbitrary image on an arbitrary object.

Owner:DAIKEN CHEM

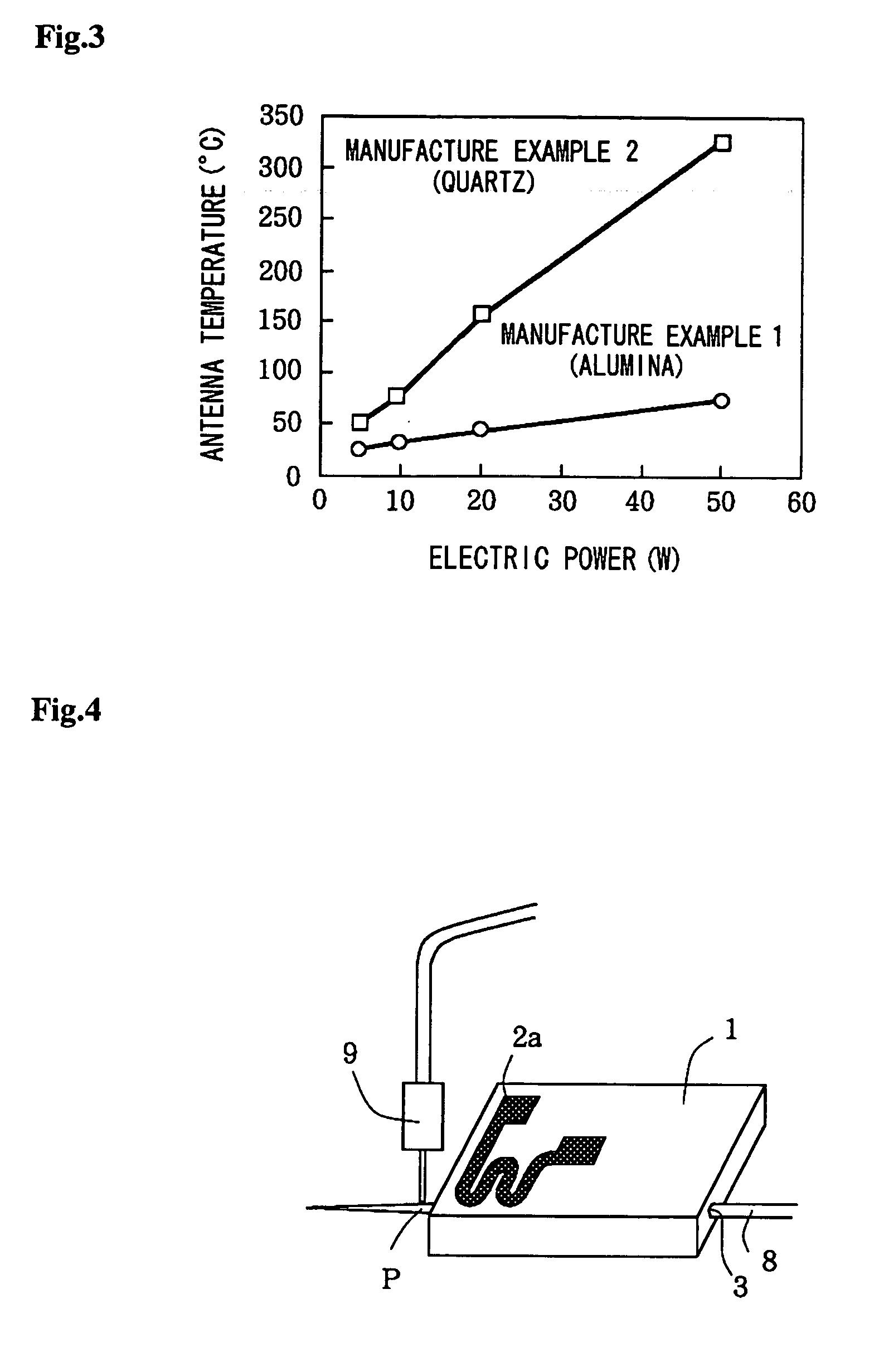

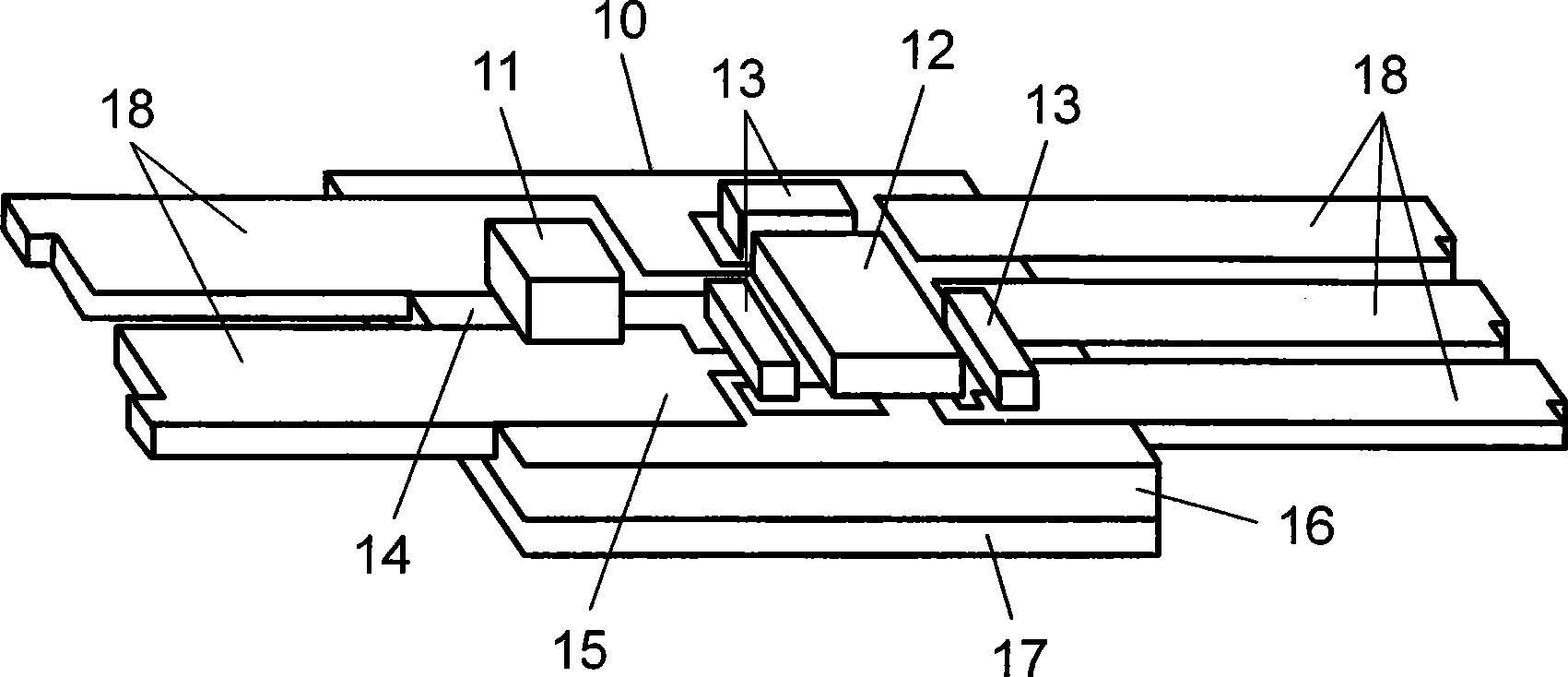

Micro Plasma Jet Generator

ActiveUS20080063576A1High densityStable generationDecorative surface effectsMaterial analysis by electric/magnetic meansPlasma jetAtmospheric pressure

The present invention provides a microplasma jet generator capable of stably generating a microplasma jet in a microspace at atmospheric pressure with low electric power.The microplasma jet generator is driven with a VHF power supply to generate an inductively coupled microplasma jet and includes a substrate, a micro-antenna disposed on the substrate, and a discharge tube located close to the micro-antenna. The micro-antenna has a flat meandering shape with plural turns.

Owner:JAPAN SCI & TECH CORP

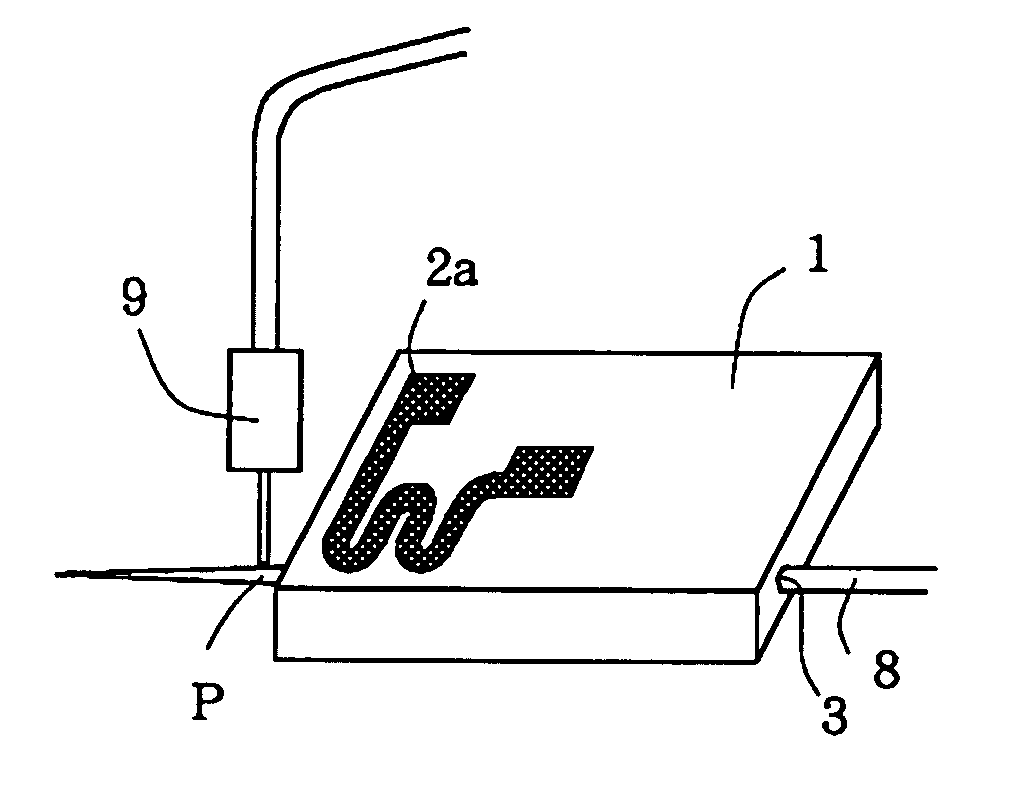

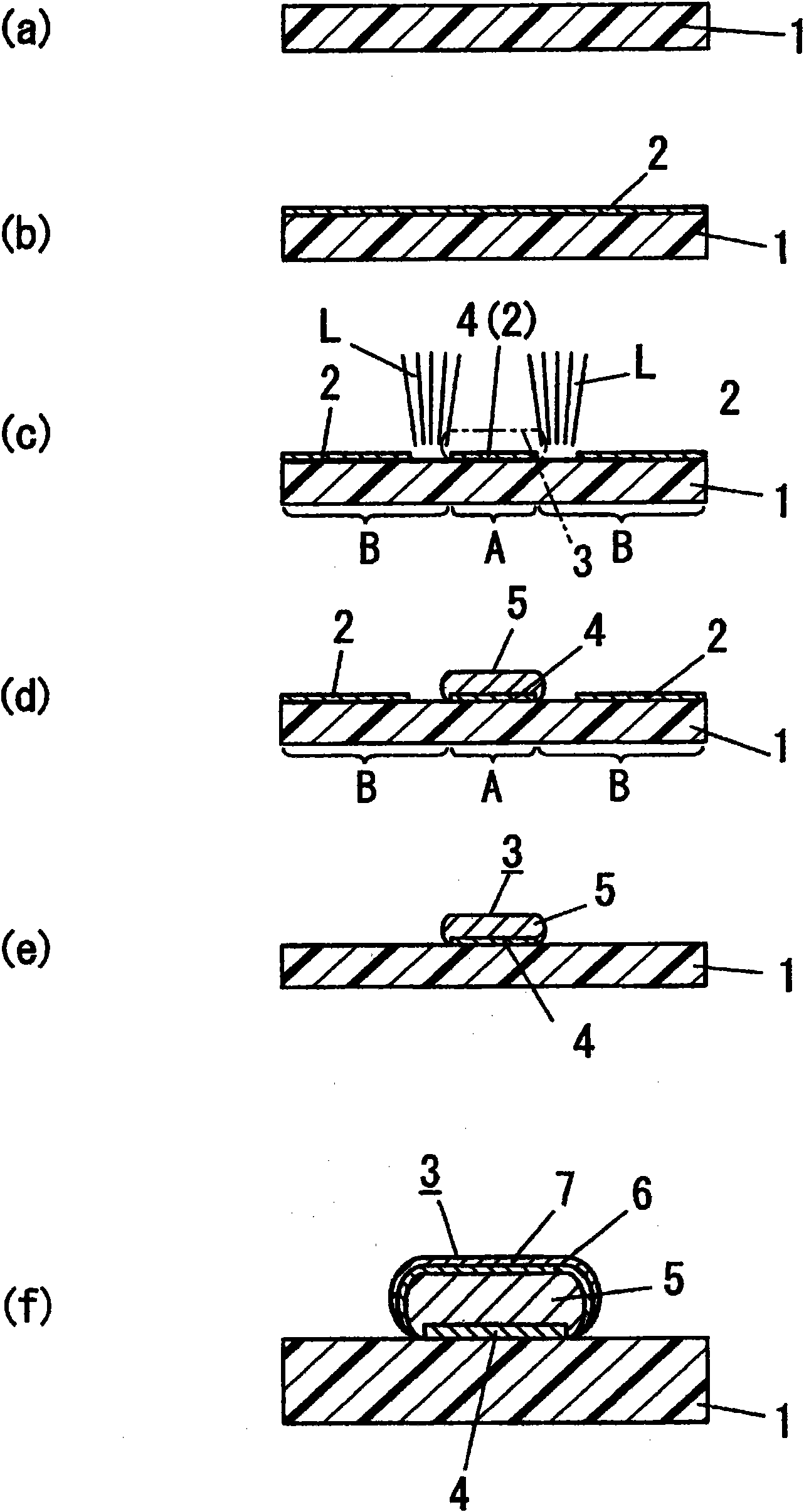

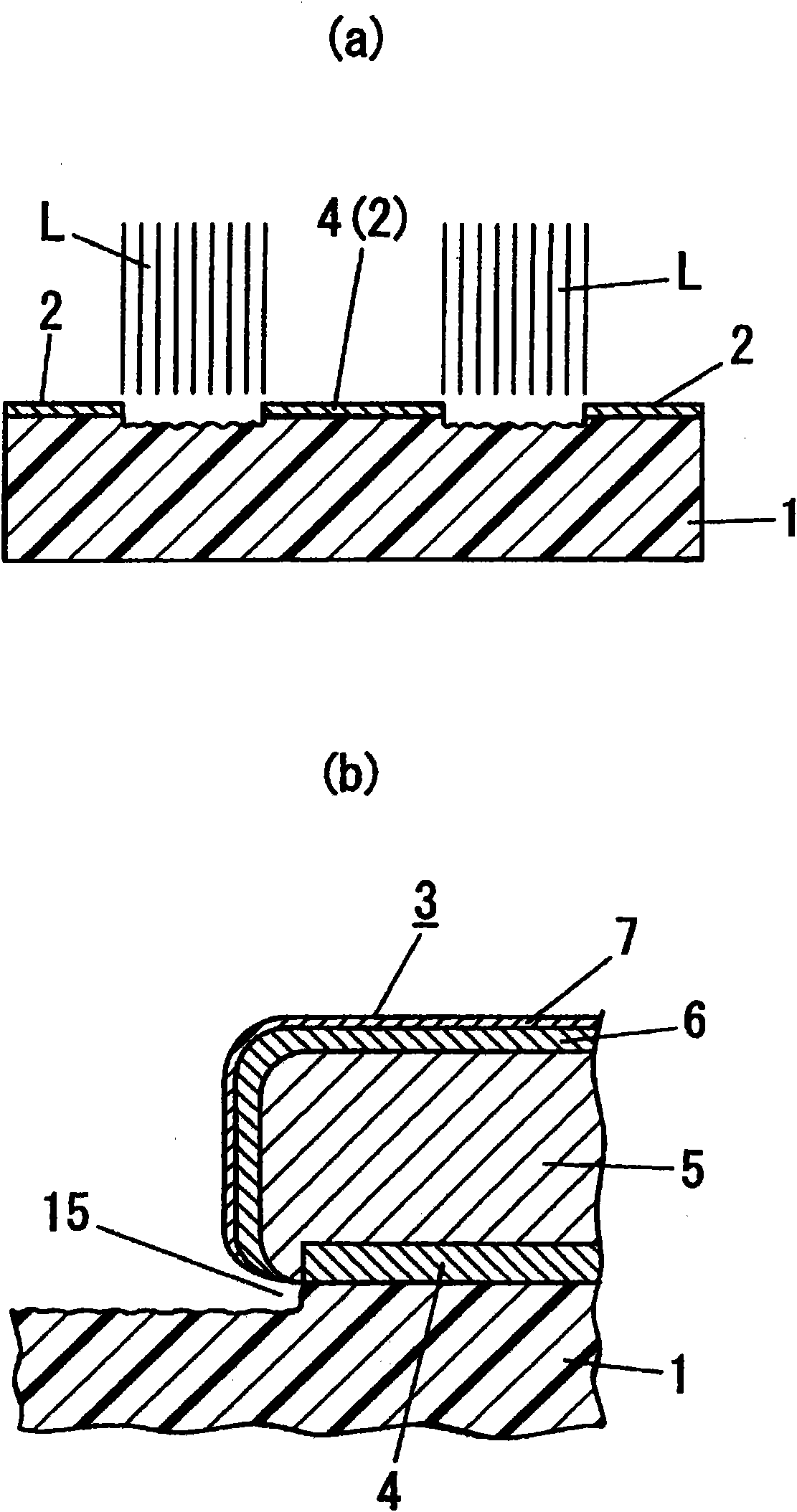

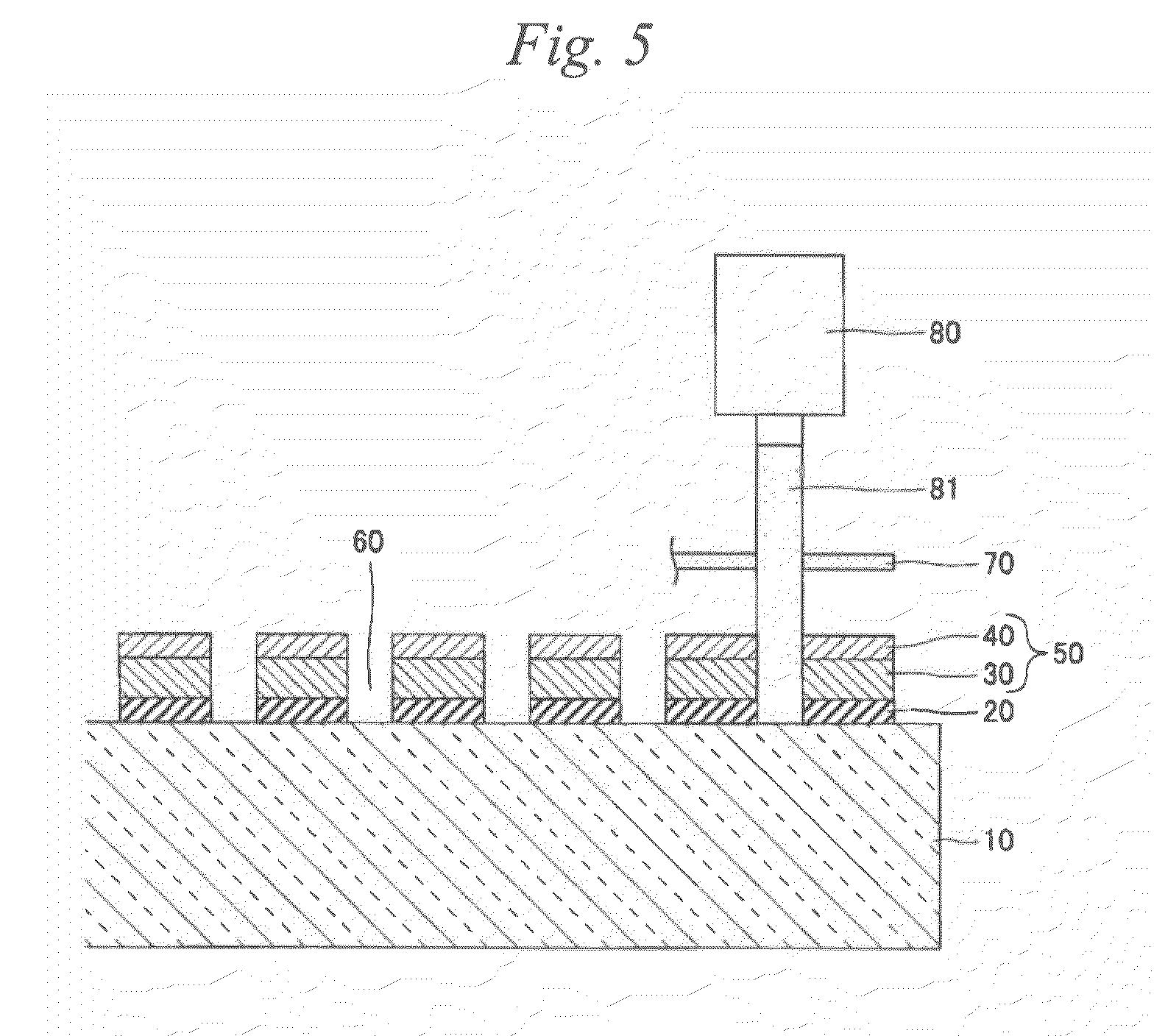

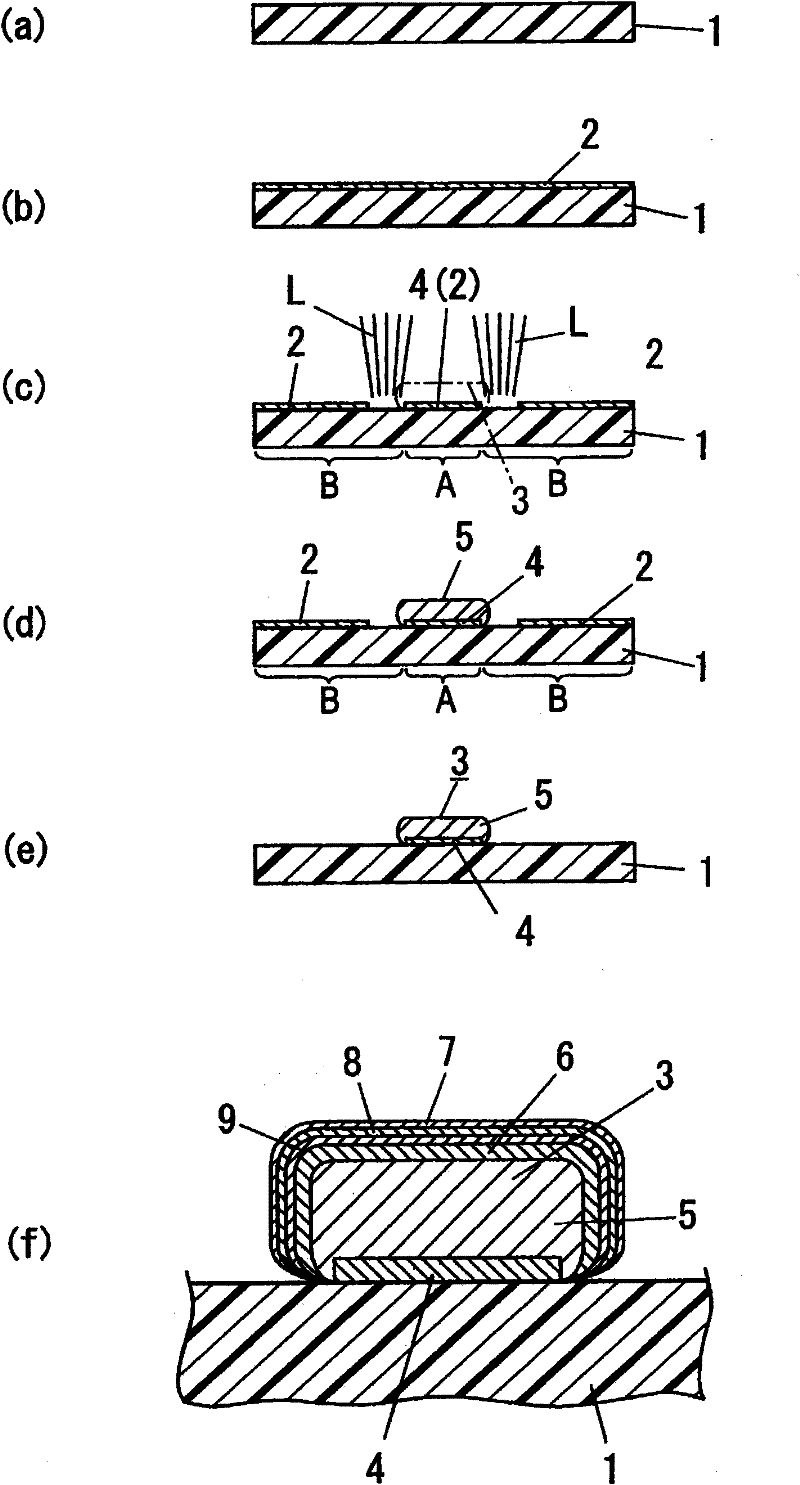

Circuit board and method for manufacturing the same

InactiveCN101849447AInhibit corrosion reactionAvoid corrosionPrinted circuit aspectsConductive material electric discharge removalEngineeringLaser beams

A circuit board is provided with an insulating substrate (1) and a circuit (3) formed on the insulating substrate (1). The circuit is provided with a plated base layer (4) whereupon a pattern is formed by irradiating a metal thin film (2) applied on a surface of the insulating substrate (1) with a laser beam (L) along the profile of the circuit (3) and partially removing the metal thin film (2) from the profile of the circuit (3). The circuit is also provided with a Cu-plated layer (5), an Ni-plated layer (6) and an Au-plated layer (7), which are formed by metal plating, on a surface of the plated base layer (4) in this order from the side of the plated base layer. Between the Ni-plated layer (6) and the Au-plated layer (7), a first intermediate plated layer (8) having a less noble metal than Au with respect to reference electrode potential is formed in contact with the Au-plated layer, and a second intermediate plated layer (9) having a more noble metal than the metal in the first intermediate plated layer with respect to the reference electrode potential is formed in contact with the first intermediate plated layer (8).

Owner:PANASONIC CORP

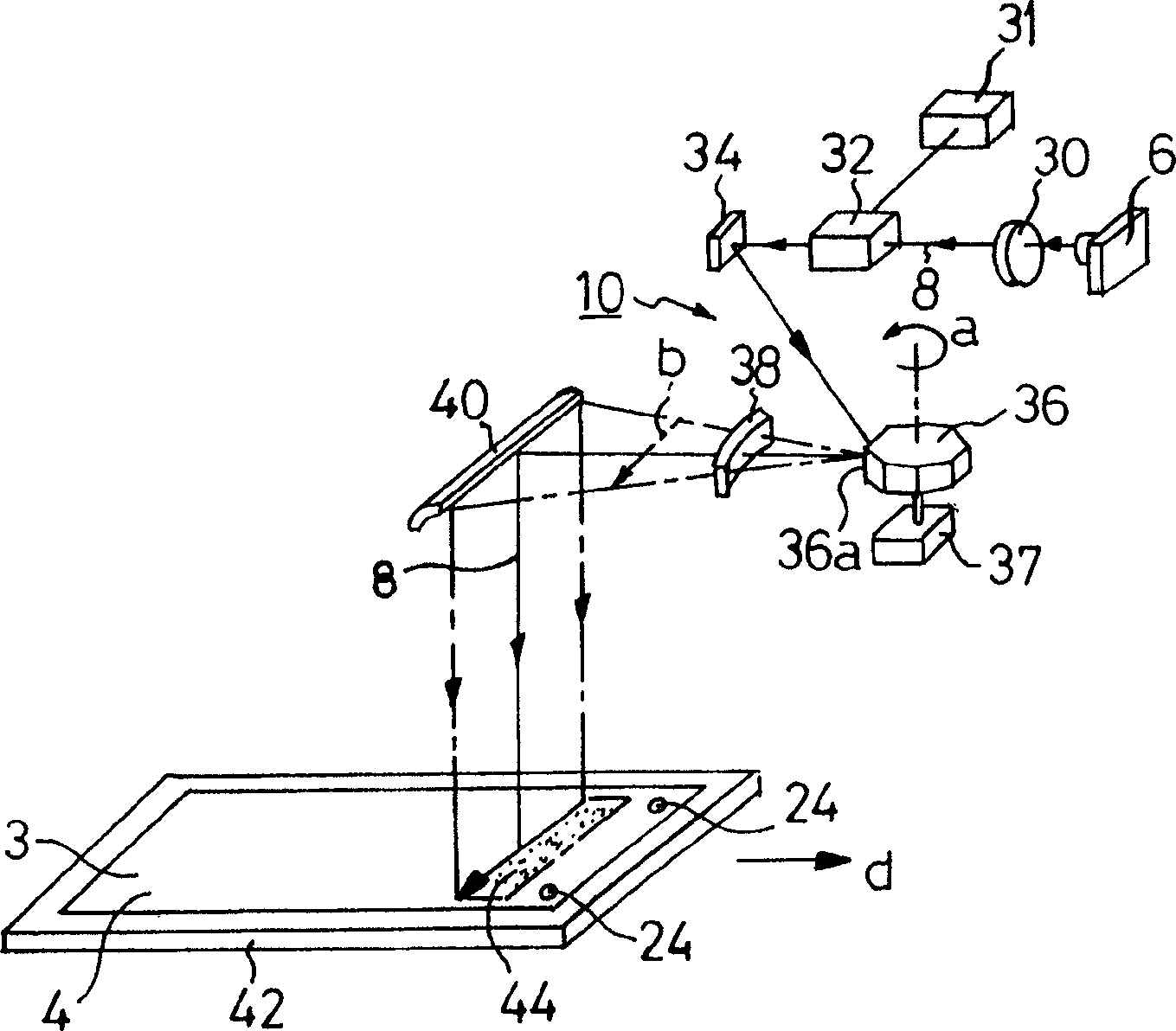

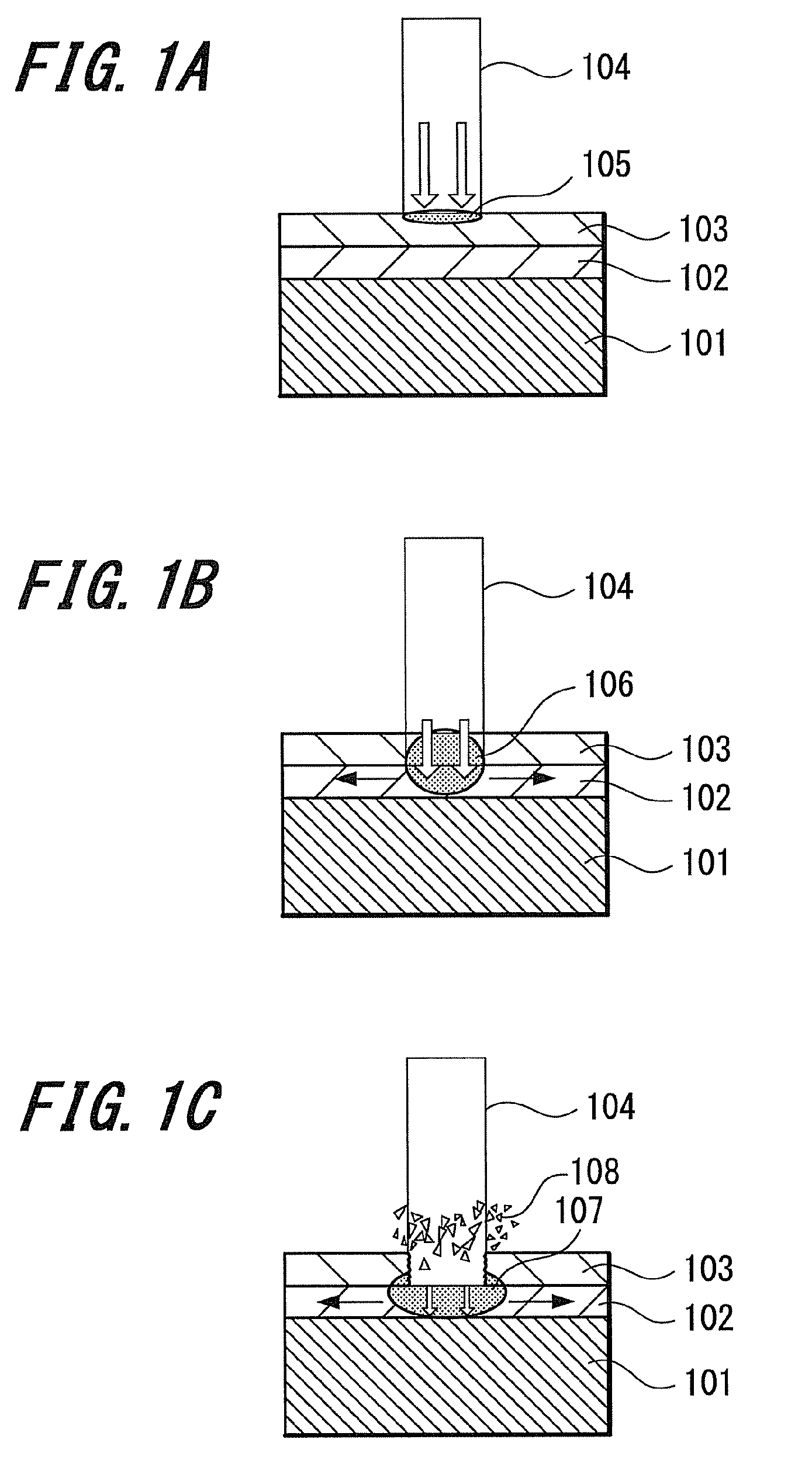

Laser processing apparatus and laser processing method as well as debris extraction mechanism and debris extraction method

InactiveUS8288681B2Low costReduce the environmentPhotosensitive materialsPhotomechanical apparatusLaser processingLaser light

Owner:JAPAN DISPLAY INC

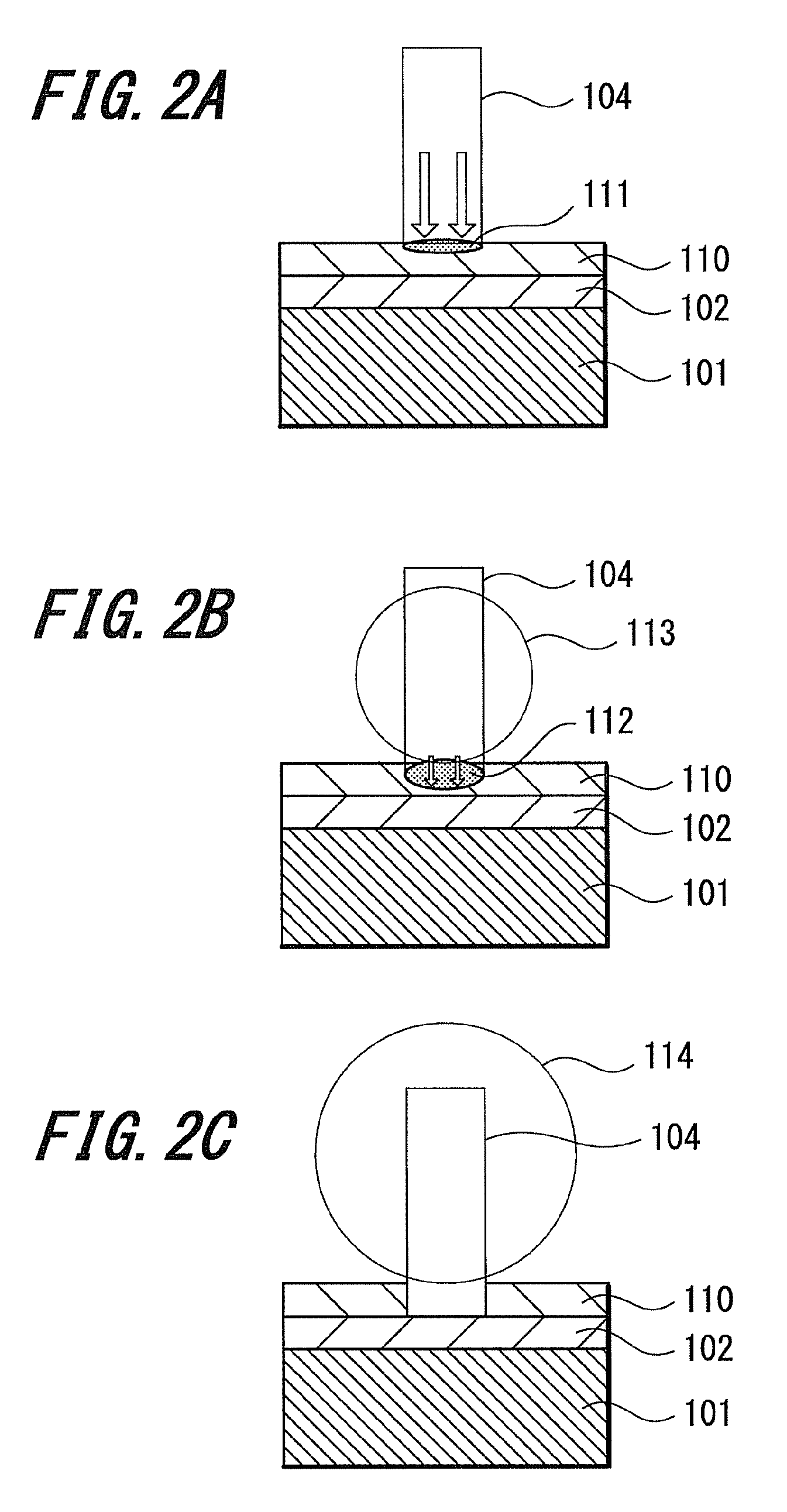

Beam processing apparatus, beam processing method, and beam processed substrate

InactiveCN101977723AAvoid bendingLow costSemiconductor/solid-state device manufacturingTransparent dielectricsLight beamAtomic physics

Owner:MARUBUN

Process for producing substrate provided with metal pattern and substrate provided with metal laminate

InactiveCN102214539AHigh precisionGas discharge electrodesGas discharge vessels/containersMetallic materialsOptoelectronics

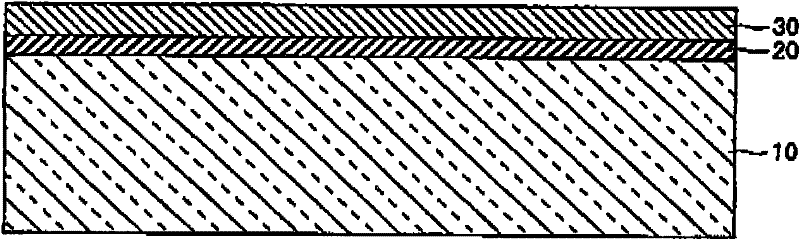

The present invention relates to a process for producing a substrate provided with a metal pattern by forming a pattern of a metal layer on a substrate using a laser light, the process including: a step of preparing a substrate in which the metal layer is formed on a surface thereof; a step of forming on the metal layer an assist layer which comprises a metal material different from that of the metal layer and which has a light absorptivity for the laser light different from that of the metal layer, thereby forming a metal laminate on the substrate; and a step of patterning the metal layer by irradiating the metal laminate with the laser light to remove a laser light-irradiated portion of the metal laminate, thereby forming a metal pattern on the substrate.

Owner:AGC INC

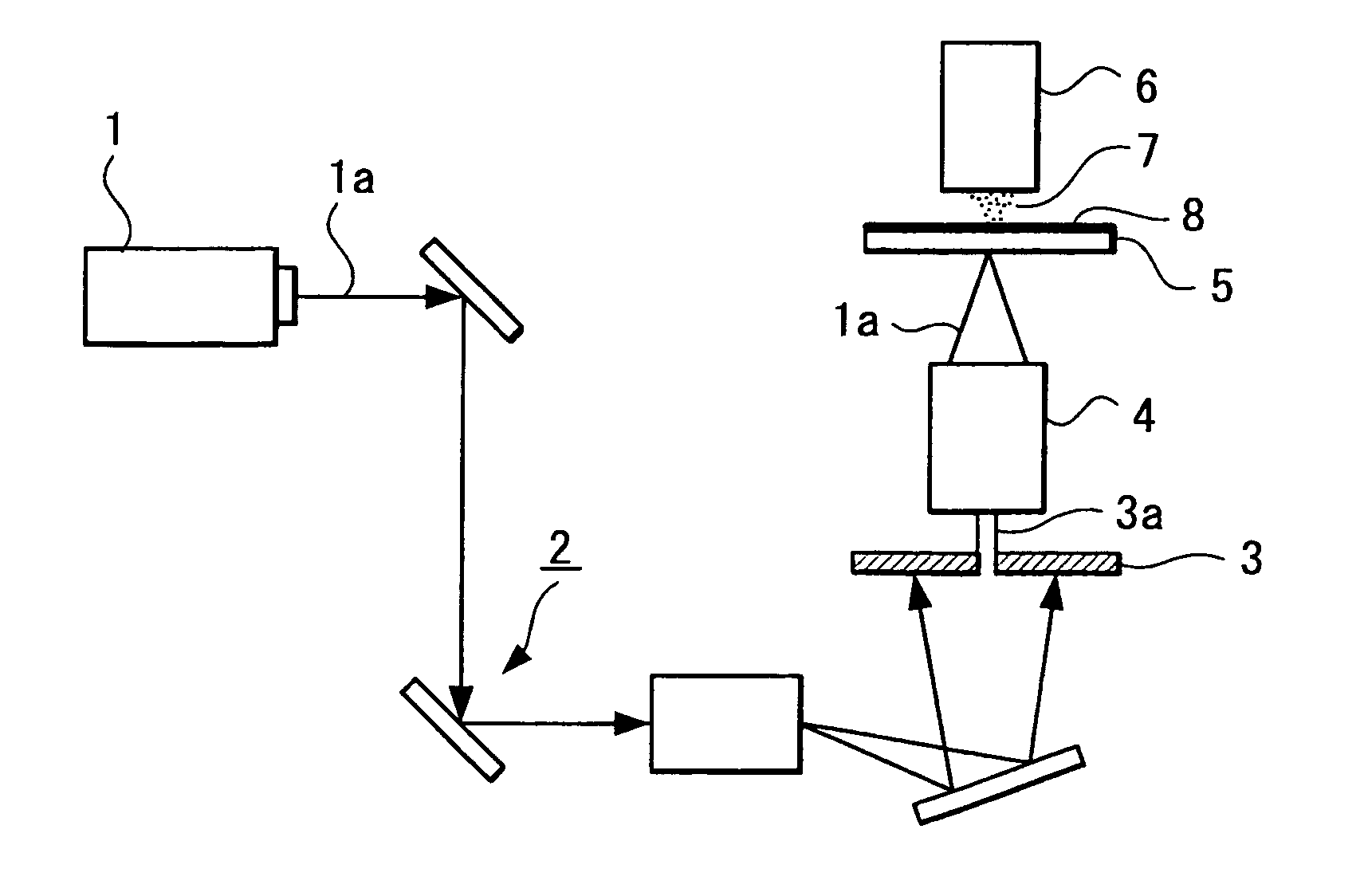

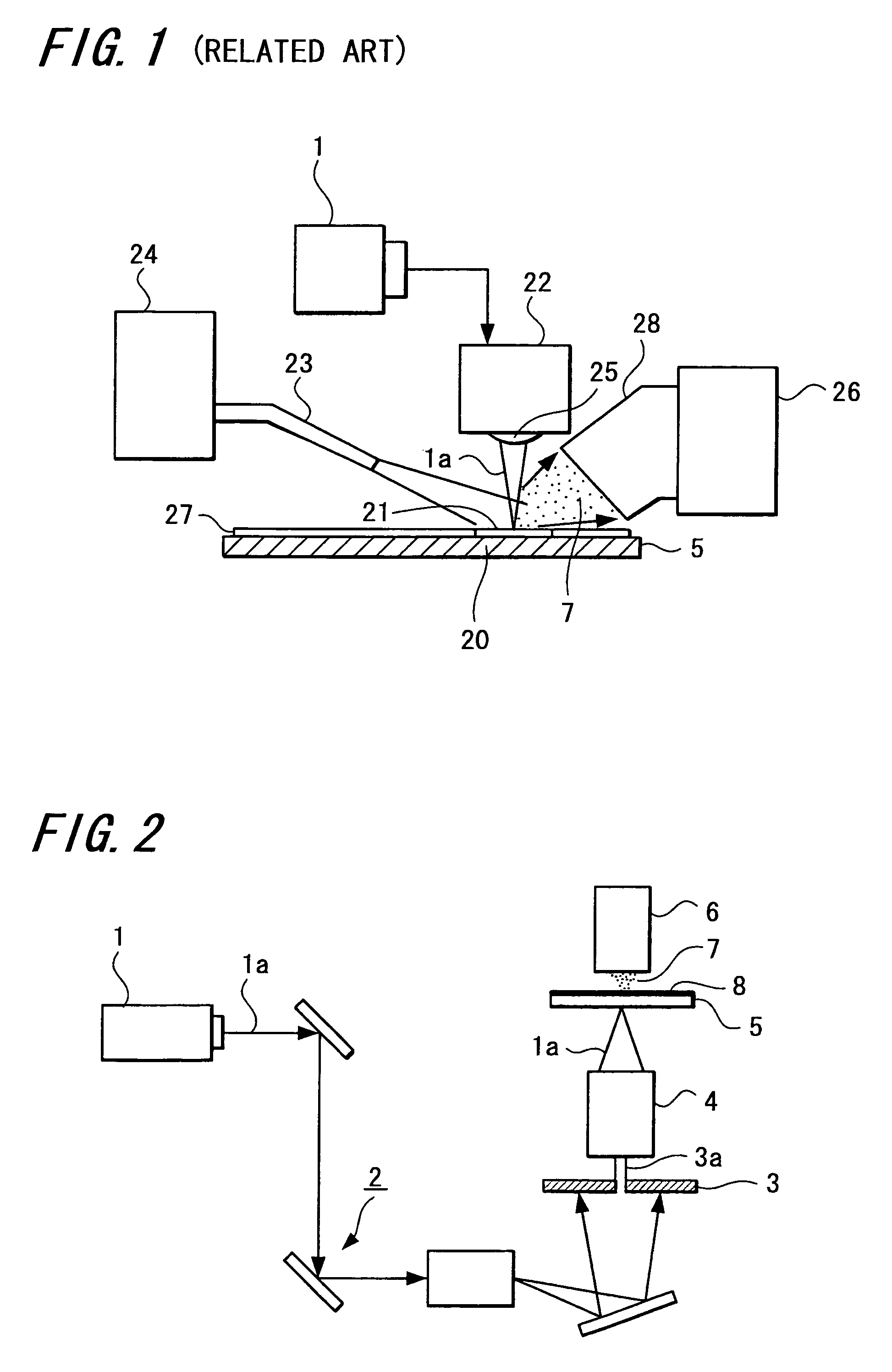

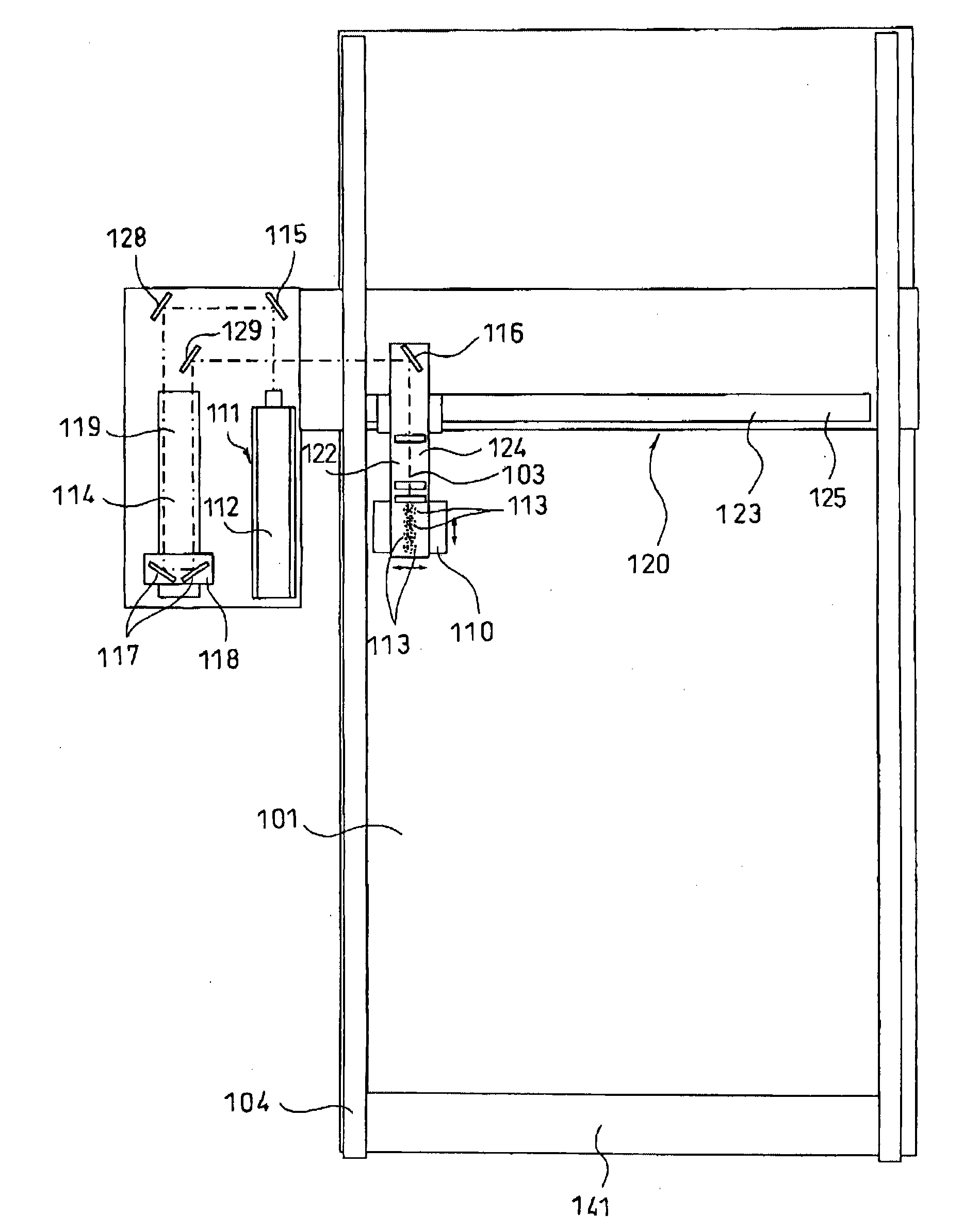

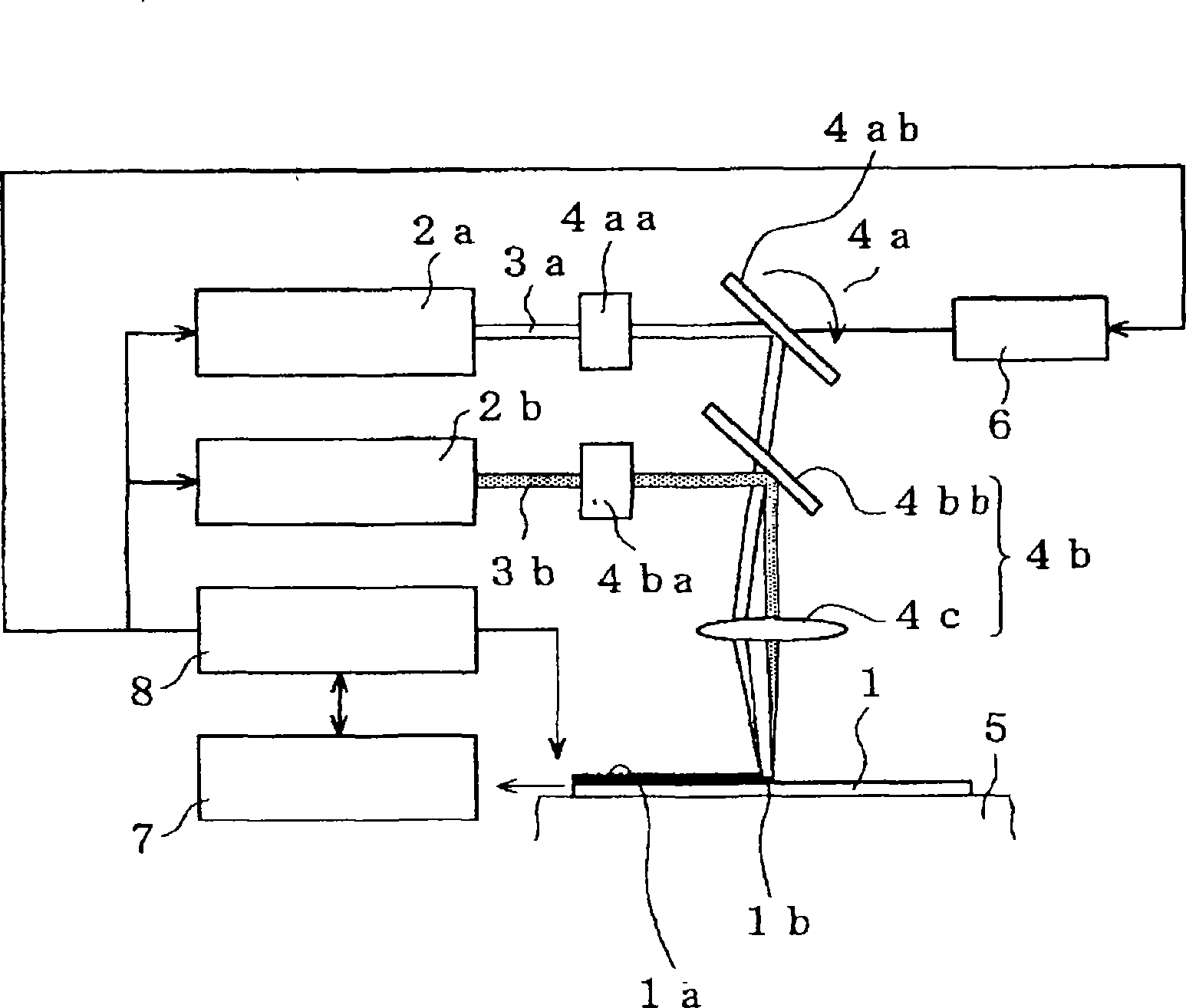

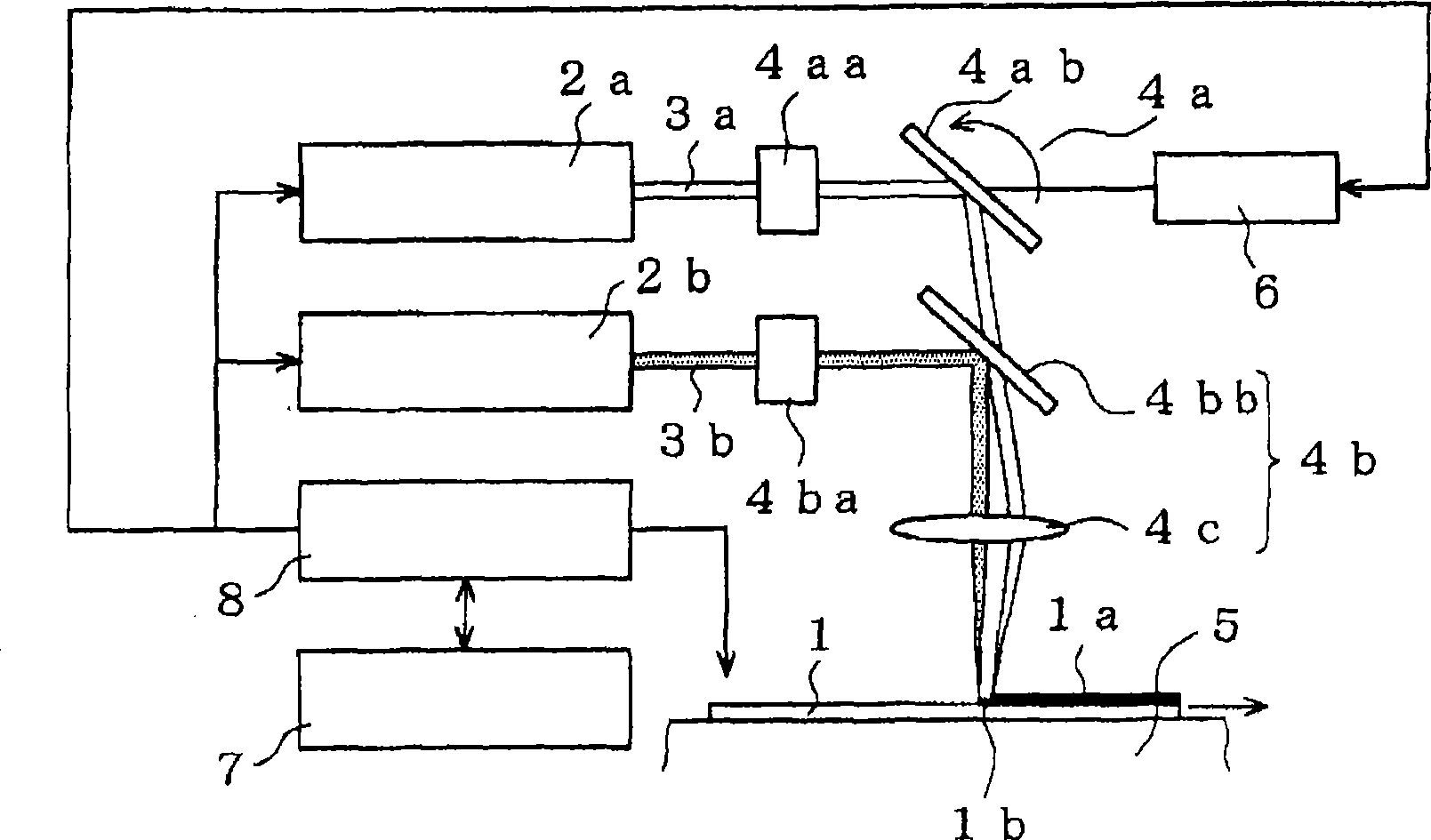

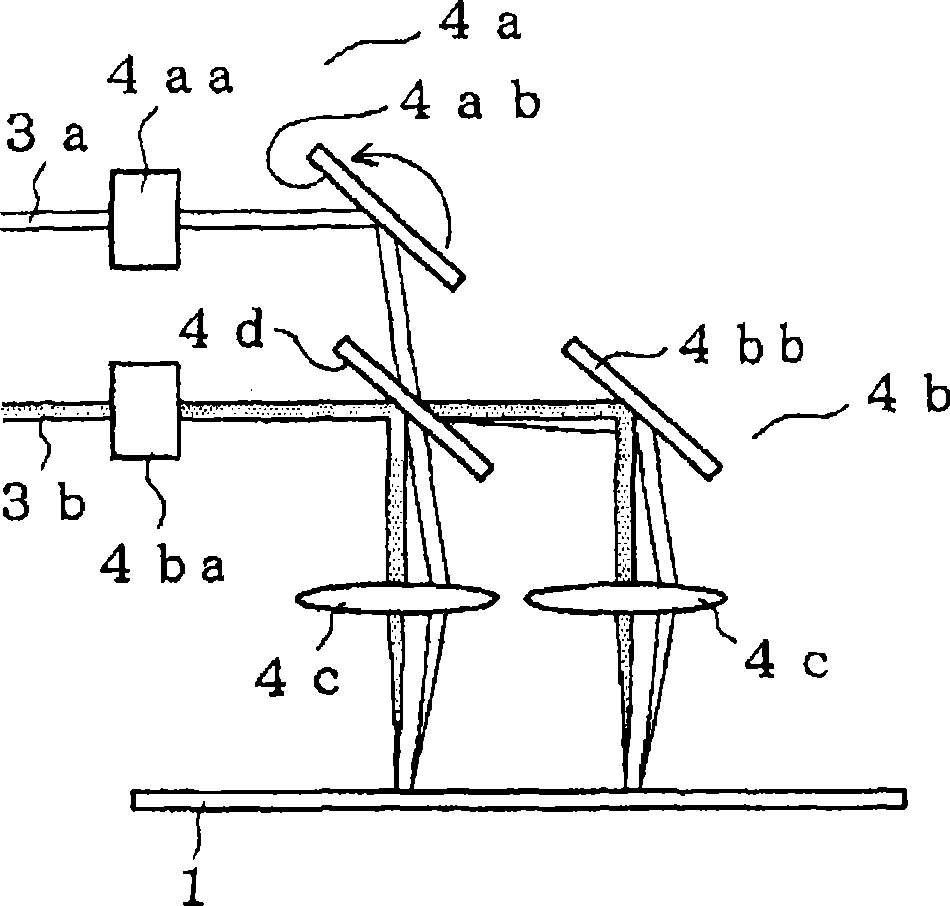

Laser processing method and laser processing apparatus

InactiveCN101432094AUnrestricted relative movement directionEfficient Laser ProcessingPrinted circuit aspectsConductive material electric discharge removalLaser processingLength wave

The present invention provides a method and an apparatus for efficiently processing in patterning of an electronic circuit board even when laser beams of differing intensities and wavelengths are irradiated in multiple stages. A laser processing apparatus is provided with first and second laser oscillators (2a, 2b) for emitting laser beams (3a, 3b) of which at least the wavelength or the intensities are different from each other; a stage apparatus (5) for moving a workpiece (1) to be processed; and optical systems (4a, 4b) for guiding the laser beams (3a, 3b) to prescribed positions of the workpiece (1). The optical systems (4a, 4b) can be moved by means of an adjusting device (6) according to the relative moving direction of the laser beams (3a, 3b) and the workpiece (1) to permit the prescribed position of the workpiece (1) to be irradiated with laser beams (3a, 3b) in that order so that the workpiece (1) can be processed by the laser beams (3a, 3b). Thus, efficient laser processing can be performed without limiting the relative moving direction of the laser beams and the workpiece and without unnecessary movement.

Owner:HITACHI ZOSEN CORP

Method for forming image on object surface including circuit substrate

By using a novel method, the exposure time of the photosensitive paste layer is reduced and the exposure fineness of the layer is improved, thereby developing a highly fine circuit substrate of high density having a thermal resistance at a reasonable cost. A circuit substrate is manufactured as follows. A photosensitive paste containing photoresist and a circuit material is applied onto a substrate surface so as to form a photosensitive paste layer (4). This photosensitive paste layer (4) is plotted by a laser beam (8) so as to form a plotted area (7). The photosensitive paste layer (4) is developed and an exposed area (4a) or an unexposed area (4b) is removed so as to form a circuit pattern (17). This circuit pattern (17) is sintered to form a circuit pattern (20) composed of the circuit material. It is possible to form a highly fine circuit pattern of high density by laser beam plotting. Moreover, when a greensheet (2) is used as the substrate, it is possible to form a ceramic substrate (18) having a thermal resistance by sintering. Furthermore, by using this method, it is possible to form an arbitrary image on an arbitrary object.

Owner:DAIKEN CHEM

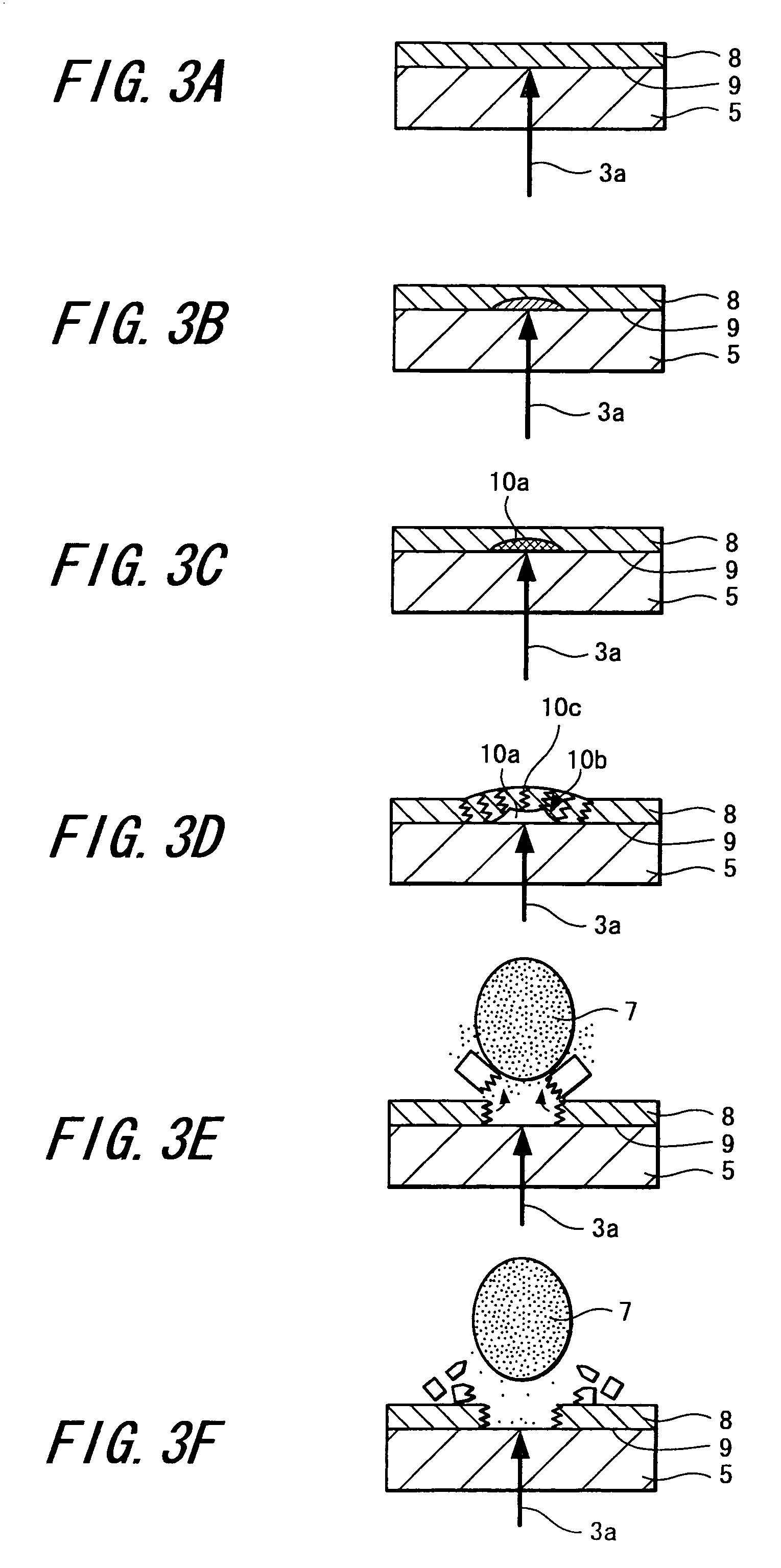

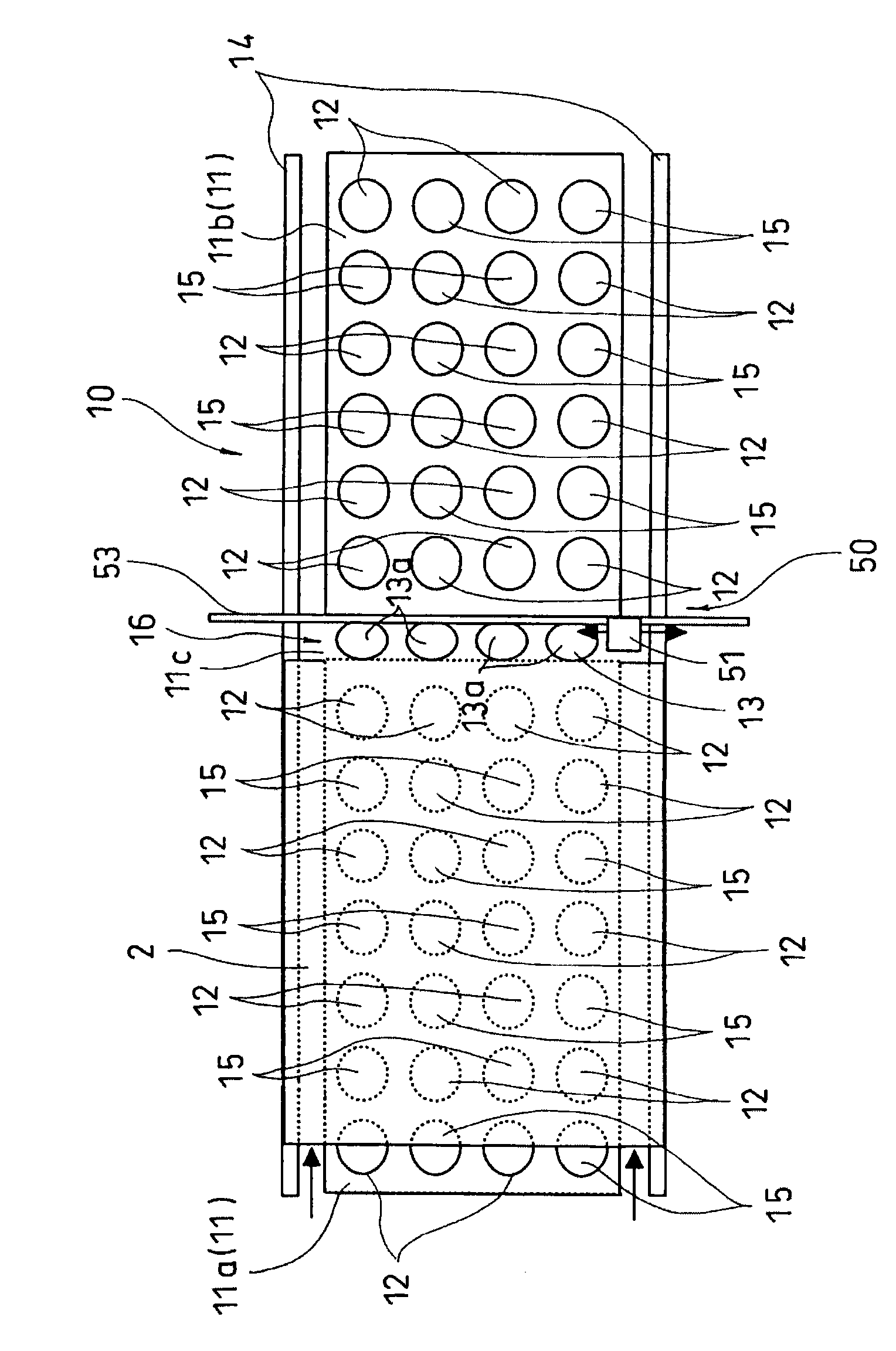

Laser processing apparatus and laser processing method, debris collection mechanism and debris collection method, and method for producing display panel

InactiveUS8283596B2Efficient removalReduce attachmentPhotomechanical apparatusSemiconductor/solid-state device manufacturingLaser processingOptoelectronics

A laser processing apparatus is provided for patterning with laser light a resin film or a metal film formed on a substrate. The apparatus includes a laser light source; and a debris collection device having a transmission window through which the laser light is transmitted, a vortex generation mechanism generating a vortex gas flow by allowing gas to flow into a region near a laser light-irradiated area of the resin film or the metal film, and a screening device having an opening through which the incident laser light passes and screening a flow of debris. The mechanism is placed close to the resin film or the metal film on the substrate. Debris generated by laser light irradiation and before and after being stacked on the object film is entrained in the vortex gas flow generated by the vortex generation mechanism and is exhausted to outside through the screening device.

Owner:SONY CORP

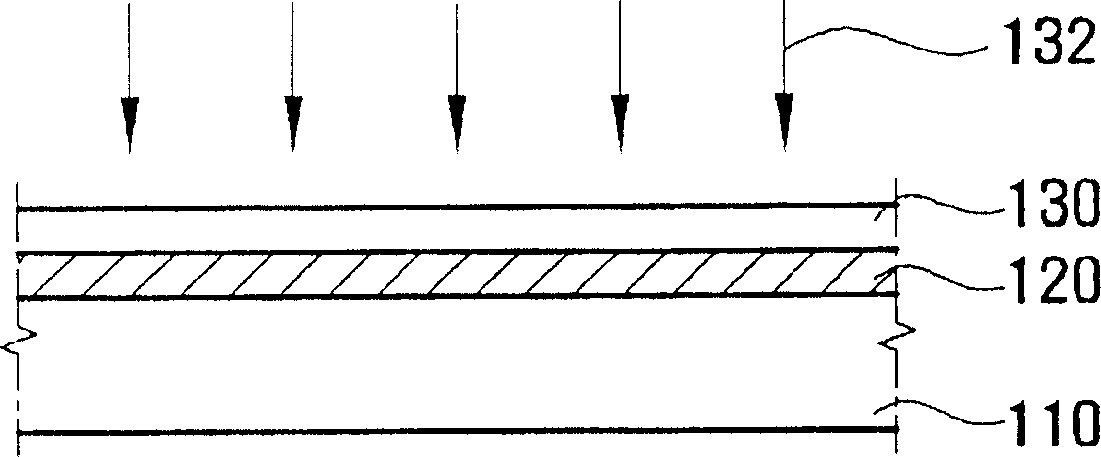

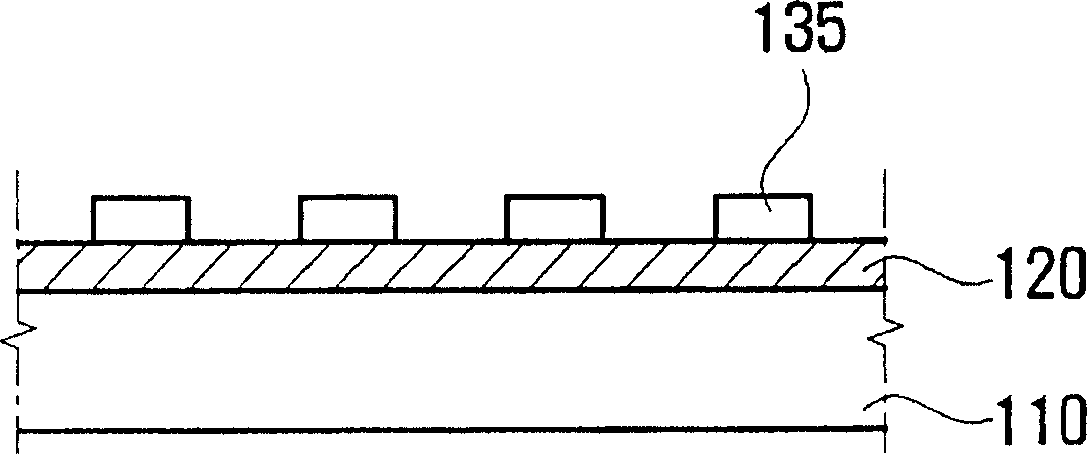

Method of manufacturing tape wiring substrate

InactiveUS20050205524A1Low production costSimple manufacturing processDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingManufacturing technology

A method of manufacturing a tape wiring substrate, by which the production cost can be reduced by a simplified manufacturing process. A fine wiring pattern having fine pitches can be formed. The method of manufacturing a tape wiring substrate includes preparing a base film, forming a metal layer on the base film, and processing the metal layer into a wiring pattern using a laser. In addition, the metal layer is partially removed using the laser, and a wiring pattern is formed by a subsequent wet etching.

Owner:SAMSUNG ELECTRONICS CO LTD

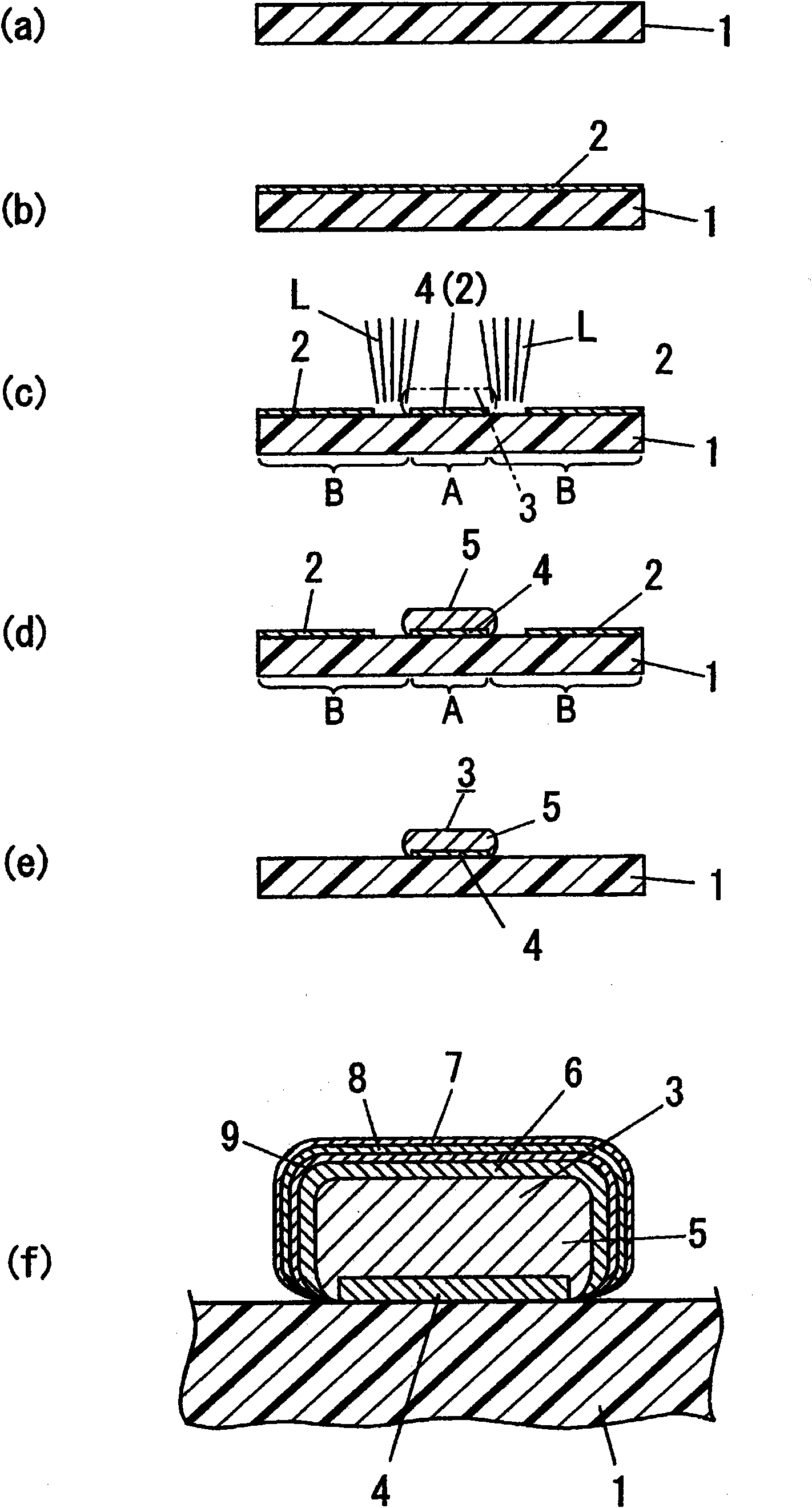

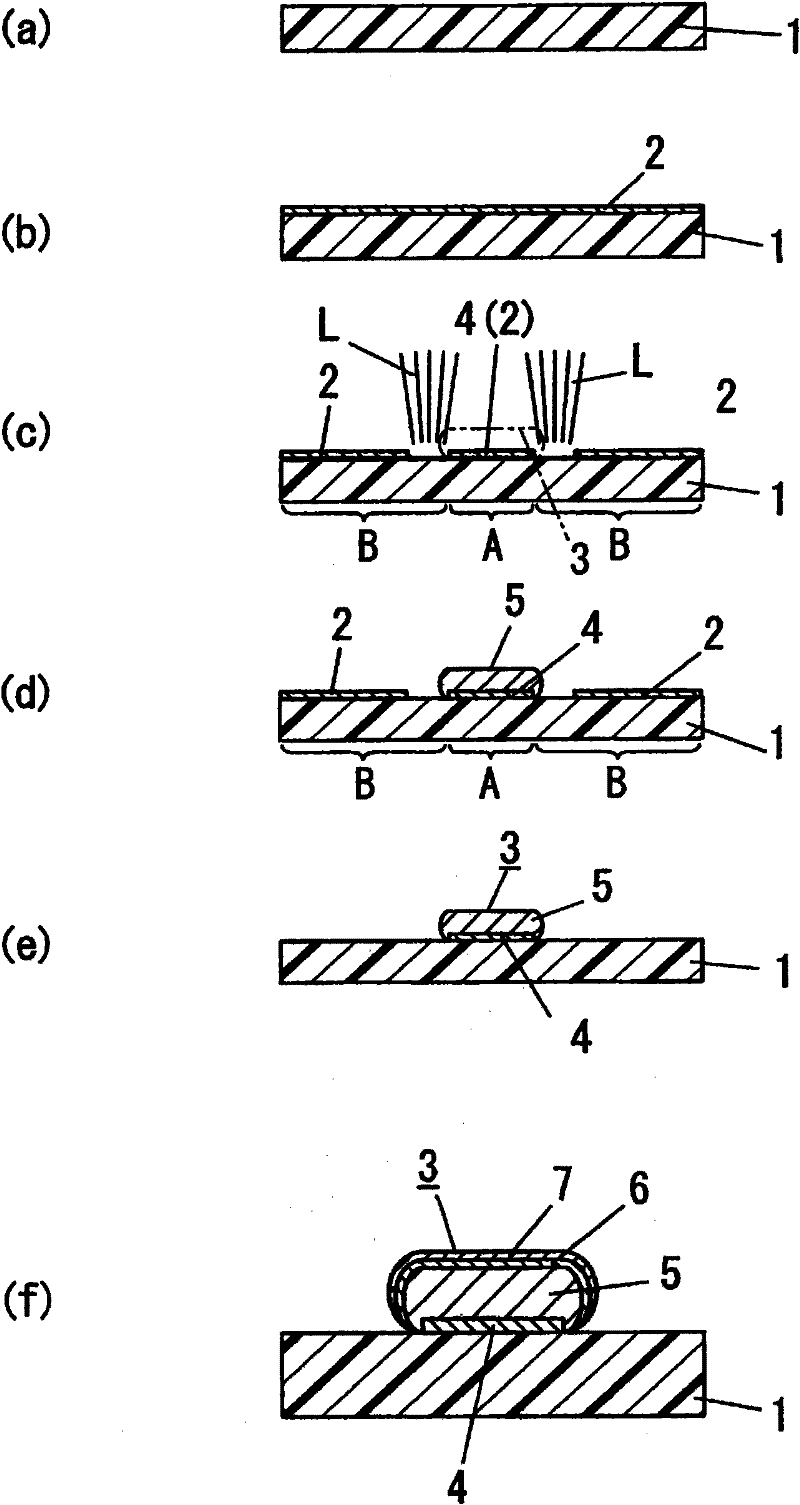

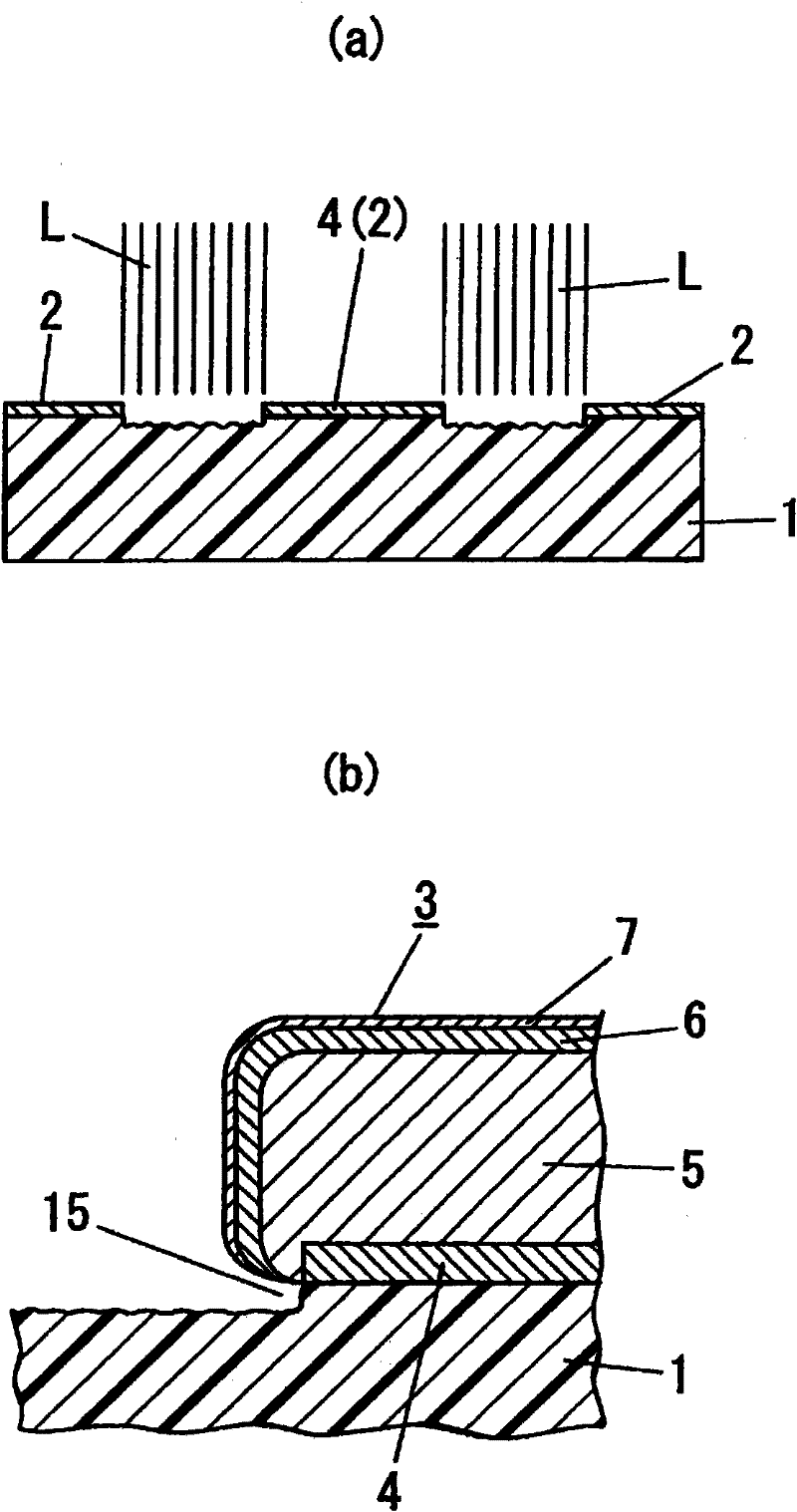

Method for embedding at least one component into a printed circuit board

ActiveCN104509222AImprove accuracyPrevent embeddingSolid-state devicesCircuit board tools positioningEngineeringPrinted circuit board

The invention relates to a method for embedding at least one component into a printed circuit board, comprising the steps of providing a lower metallic conductor foil (1) applied on a first metallic supporting layer (2), forming recessed alignment marks (3) in the conductor foil (1), applying an adhesive layer (4) in a registered manner in relation to the alignment marks (3), and placing a component (5) with the rear side thereof on the adhesive layer (4) with connection areas (6) facing upwards, curing the adhesive layer, embedding the component (5) into an insulating layer (11), applying a metallic upper conductor foil (9) and an upper metallic supporting layer (10), consolidating the construction, removing the supporting layers (2, 10), exposing the alignment marks (3) of the lower conductor foil (1) by removing the insulating layer (11), producing cutouts (12) ending at the lower conductor foil (1), producing holes (13) to the connection areas (6) of the component (5) in a registered manner in relation to the alignment marks, and applying a conductor layer to the top side of the construction, producing contact-connections (14) in the holes (13) to the connection areas (6) of the component (5), and structuring the conductor layer for producing conductor tracks (15).

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

Circuit board and its manufacturing method

InactiveCN1430463ACheap and easy to printPrinted circuit aspectsConductive material electric discharge removalElectrical conductorMetal powder

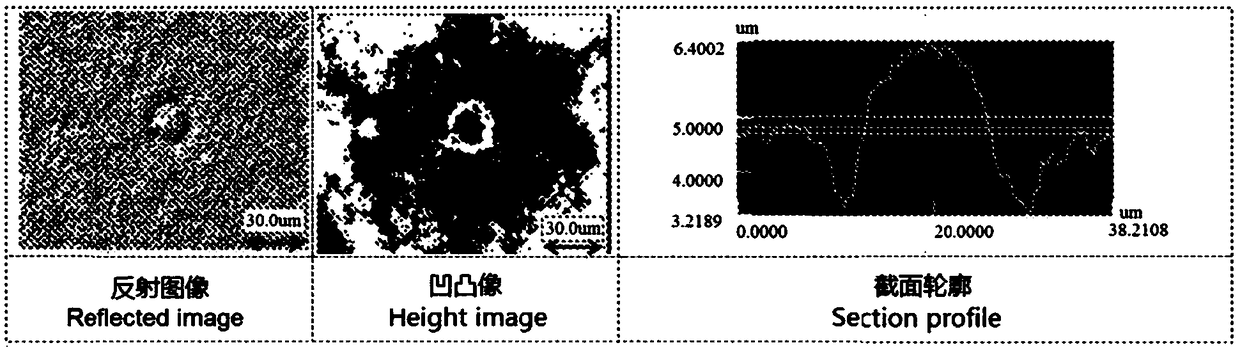

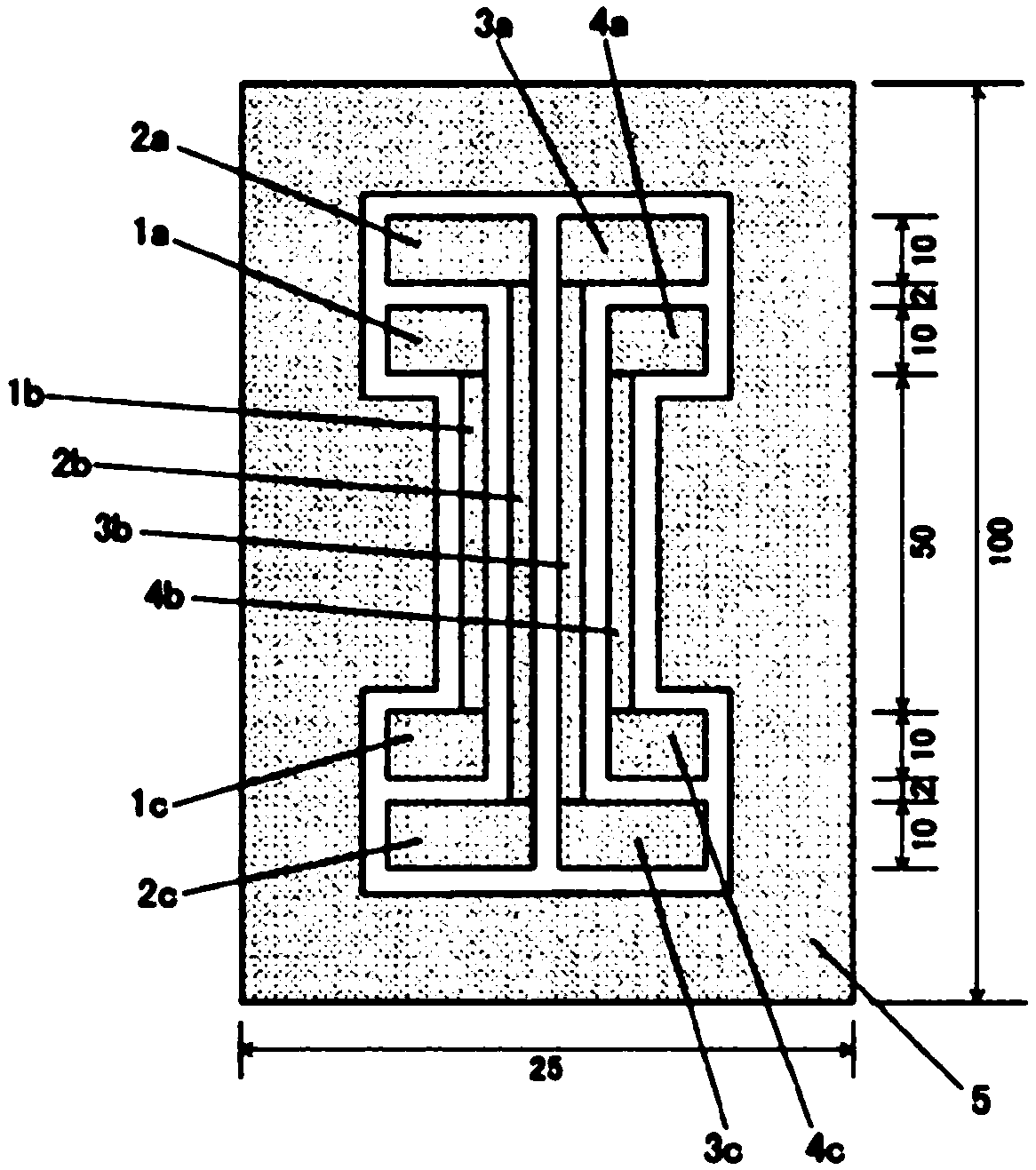

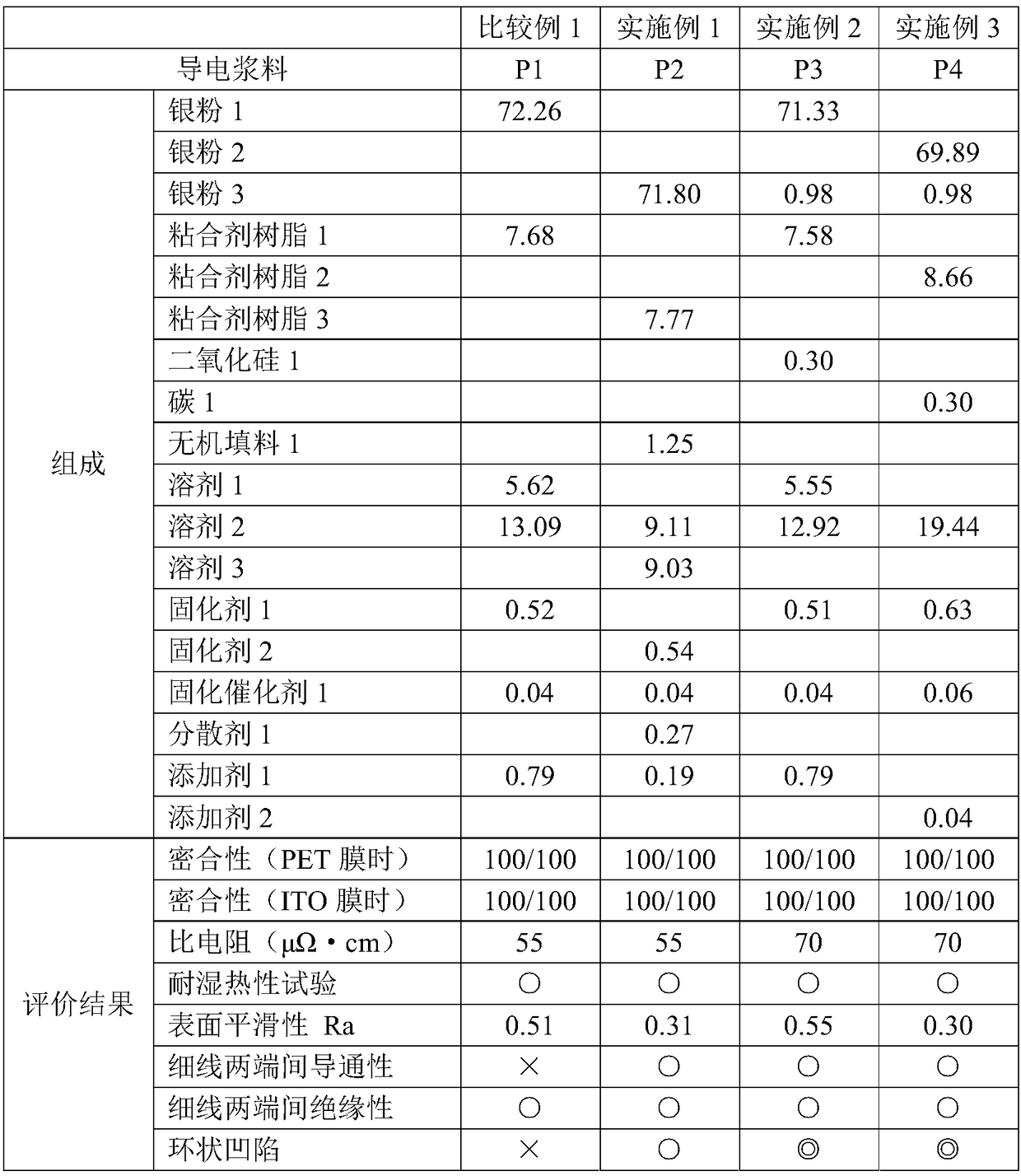

Conductive film and conductive paste for laser etching processing

ActiveCN108781505AAccelerate evaporationEasy to moveNon-conductive material with dispersed conductive materialConductive material electric discharge removalFine lineConductive paste

[Problem] To provide a conductive film which has excellent suitability for laser etching processing, capable of suppressing the occurrence of disconnect and short-circuits, even with difficult patterns such as narrow laser-etching width and long laser-etching distance. [Solution] Ring-shaped recess defects of the film surface are reduced using a conductive paste that contains at least: a polymer binder resin; a metal powder having an average particle diameter of 0.3 [mu]m to 6 [mu]m; and an organic solvent; and preferably silicon oxide or carbon particles having an average particle diameter of5 nm to 200 nm, and inorganic ion scavenger particles having a diameter of 50 nm to 3000 nm, whereby fine lines in which L / S = 50 / 50 [mu]m or less can be formed using laser etching.

Owner:TOYO TOYOBO CO LTD

Heat dissipating wiring board and method for manufacturing same

InactiveCN101467248AImprove reliabilityEasy to fillPrinted circuit detailsSemiconductor/solid-state device detailsMetalElectrical and Electronics engineering

A heat dissipating wiring board comprises: a metal wiring plate with a circuit pattern formed therein: a filler containing resin layer embedded with the metal wiring plate such that a top surface of the metal wiring plate is exposed; and a heat dissipating plate arranged on an under surface of the filler containing resin layer, wherein the circuit pattern is formed of a through groove provided in the metal wiring plate, and this through groove is made up of: a fine groove that opens at the top surface of the metal wiring plate; and an expanded groove that expands from a lower end of the fine groove toward the under surface of the metal wiring plate. The heat dissipating wiring board is capable of improving reliability against electric insulation due to a dust or the like in a space of the through groove.

Owner:PANASONIC CORP

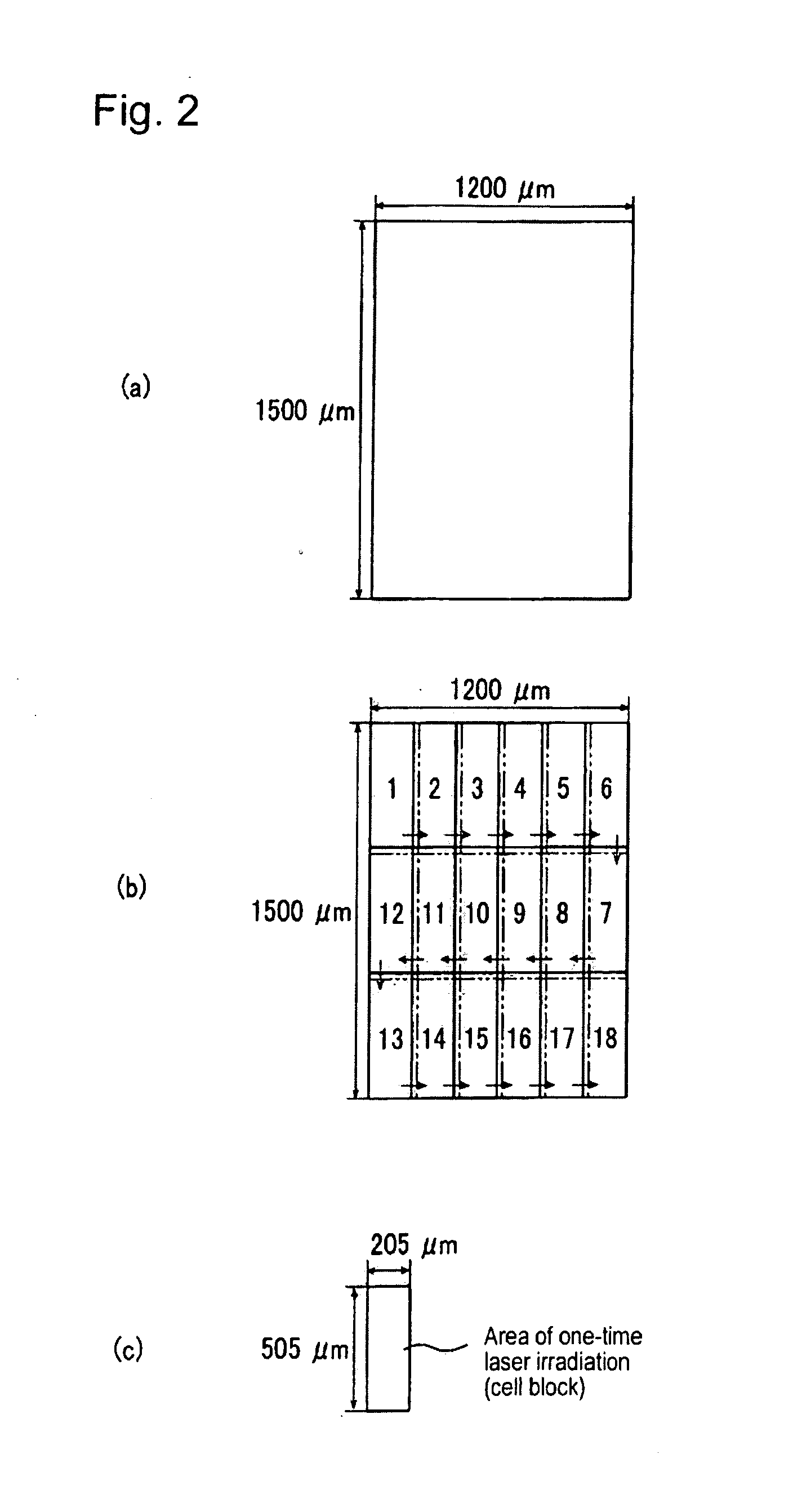

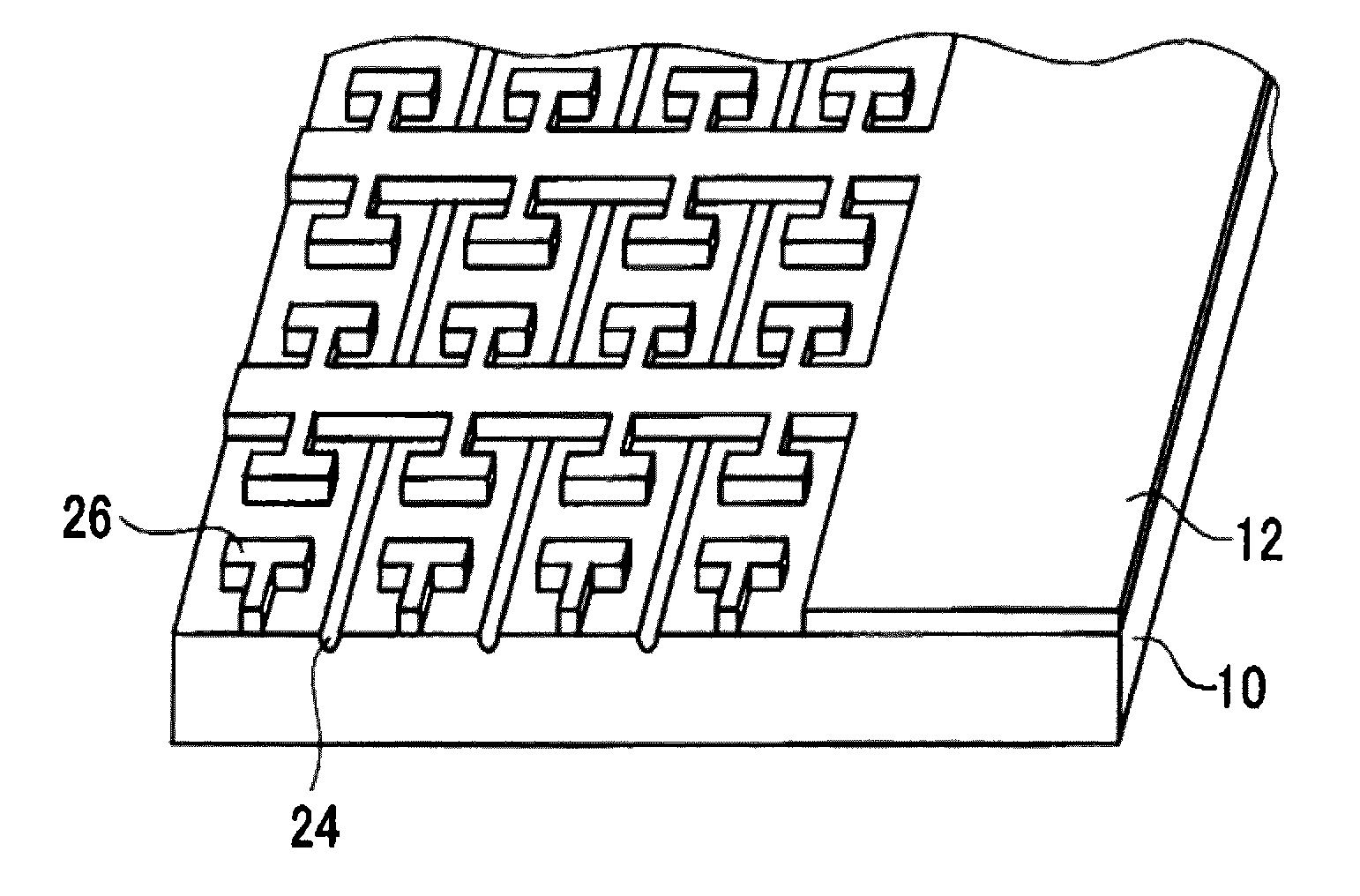

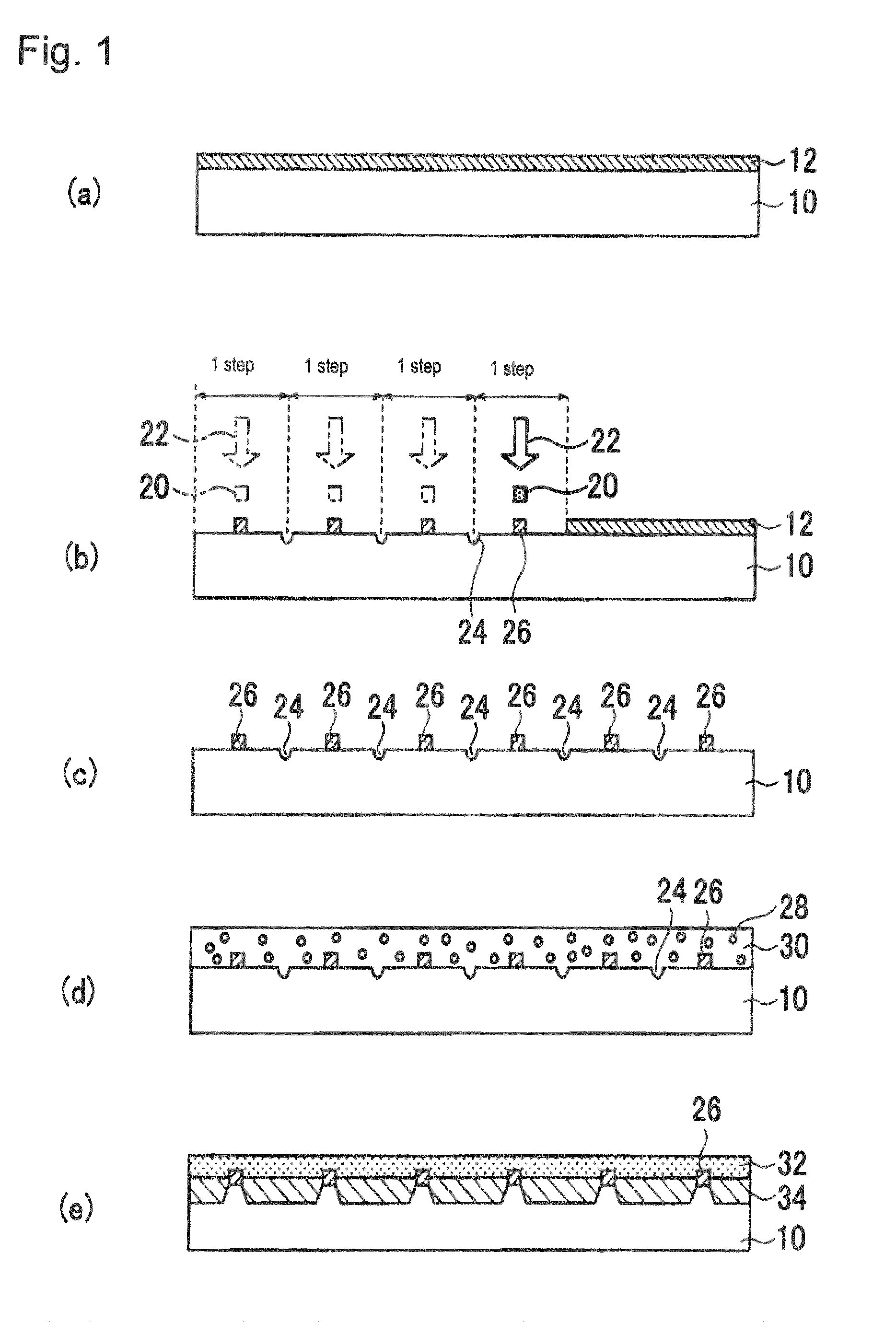

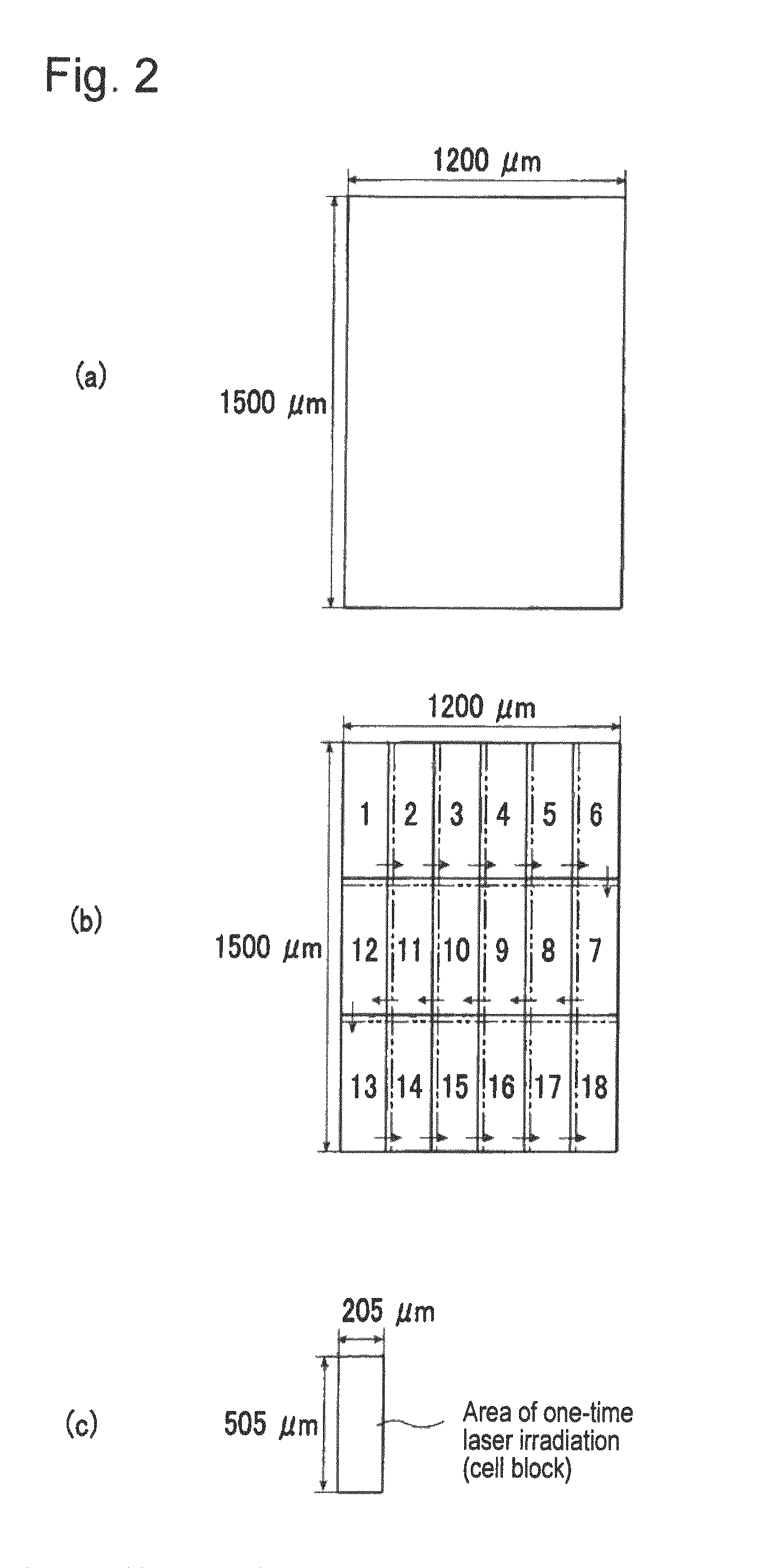

Glass substrate having circuit pattern and process for producing the same

InactiveUS20080311359A1Reduction and scattering of visible light transmittanceIncrease of strain stressSustain/scan electrodesStatic indicating devicesLaser lightOptoelectronics

The invention provides a process for producing a glass substrate (10) having a circuit pattern (26), which includes a circuit pattern formation step of forming a thin film layer (12) on a glass substrate and then irradiating the thin film layer with laser light (22) to form a circuit pattern on the glass substrate; a low-melting point glass deposition step of depositing a low-melting point glass (28) having a softening point of from 450 to 630° C. on the glass substrate having the circuit pattern formed thereon; and a sintering step of sintering the low-melting point glass to form a low-melting point glass layer (32) comprising the low-melting point glass sintered on the glass substrate having the circuit pattern formed thereon and to form a compatible layer (34) between the glass substrate and the low-melting point glass layer.

Owner:ASAHI GLASS CO LTD

Process for applying conductor tracks to the surface of plastics moldings

InactiveUS7171746B2Cost-effectivelyPorous dielectricsConductive material electric discharge removalElectrical conductorEngineering

A process is described in which surfaces of foamed plastics are provided with electrical conductor tracks, with the aid of selectively ablating processes.The process permits low-cost production of moldings from plastic with conductor tracks integrated on the surface.The products of the process may be used in the electrical and electronics industries, for example.

Owner:TICONA GMBH

Glass substrate having circuit pattern and process for producing the same

InactiveUS7846641B2Reduction and scattering of visible light transmittanceIncrease of strain stressSustain/scan electrodesStatic indicating devicesLaser lightOptoelectronics

A process for producing a glass substrate having a circuit pattern is disclosed. The process includes forming a thin film layer on a glass substrate and then irradiating the thin film layer with laser light to form a circuit pattern on the glass substrate; depositing a low-melting point glass having a softening point of from 450 to 630° C. on the glass substrate having the circuit pattern formed thereon; and sintering the low-melting point glass to form a low-melting point glass layer which includes the low-melting point glass sintered on the glass substrate having the circuit pattern formed thereon and which forms a compatible layer between the glass substrate and the low-melting point glass layer.

Owner:ASAHI GLASS CO LTD

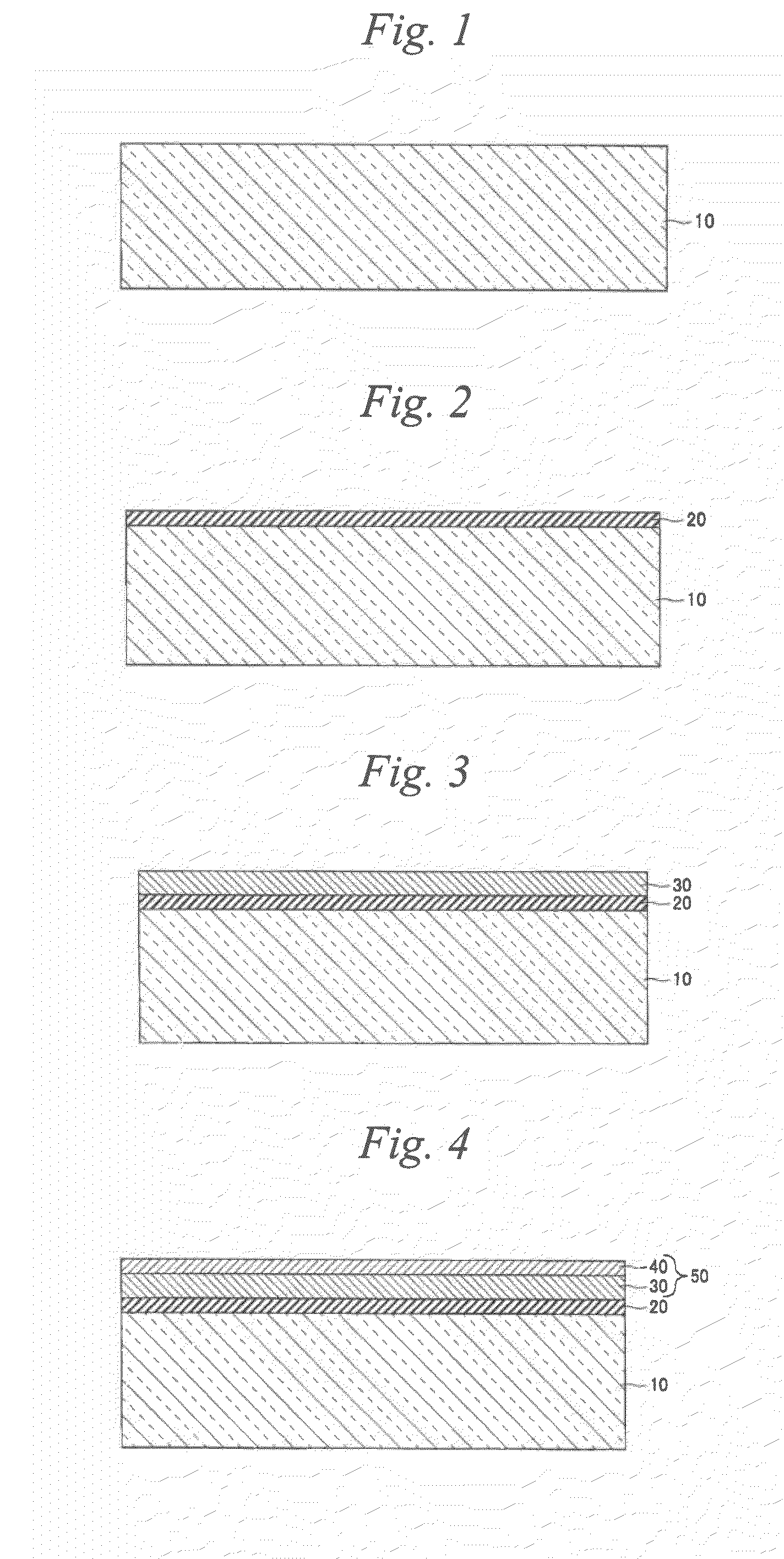

Process for producing substrate provided with metal pattern and substrate provided with metal laminate

InactiveUS8648278B2Easy to processPromote absorptionGas discharge electrodesGas discharge vessels/containersMetallic materialsOptoelectronics

Owner:AGC INC

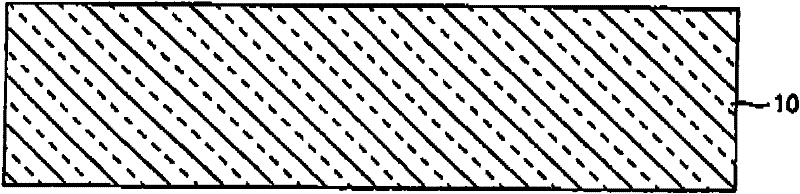

Process for producing substrate provided with metal pattern and substrate provided with metal laminate

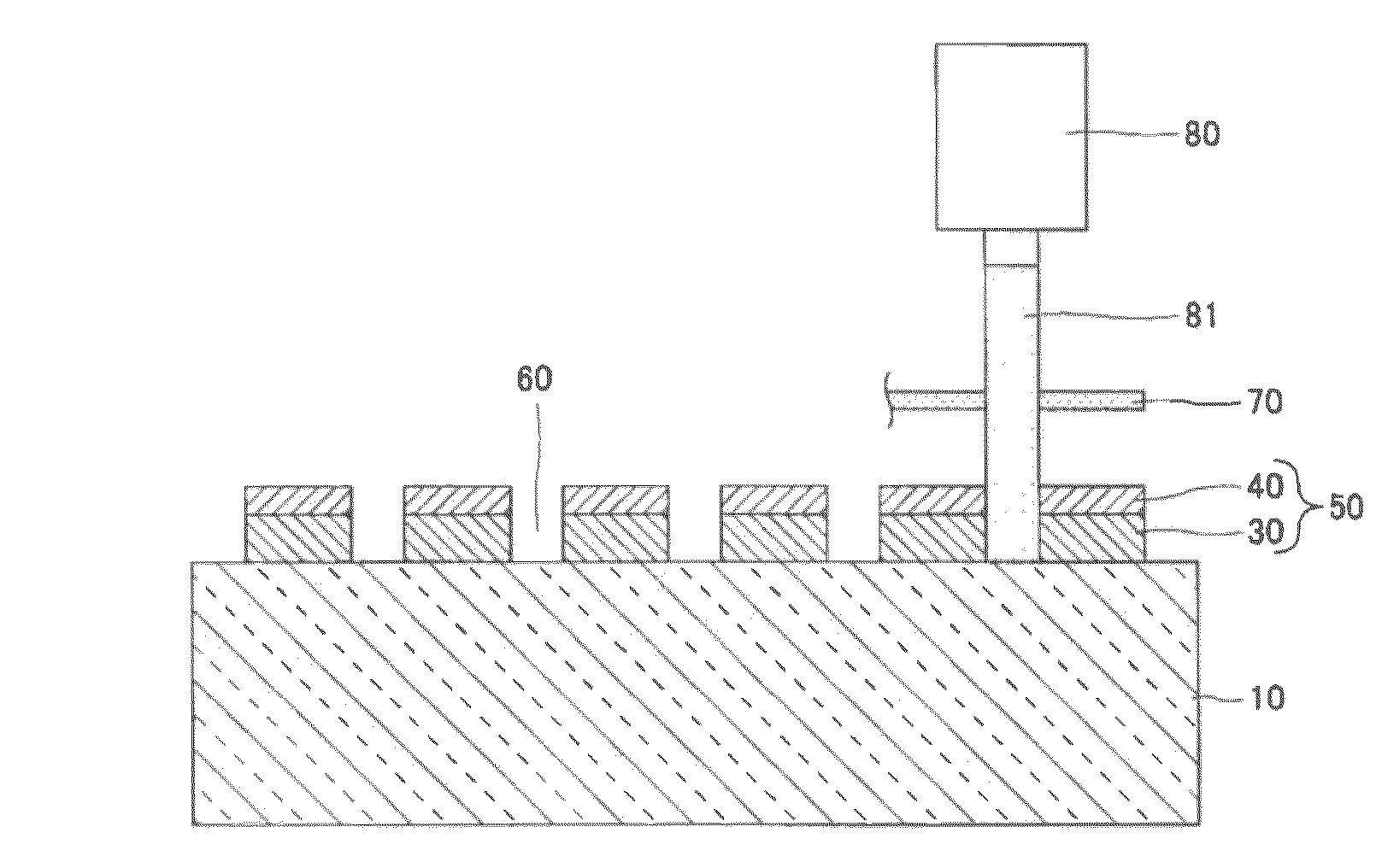

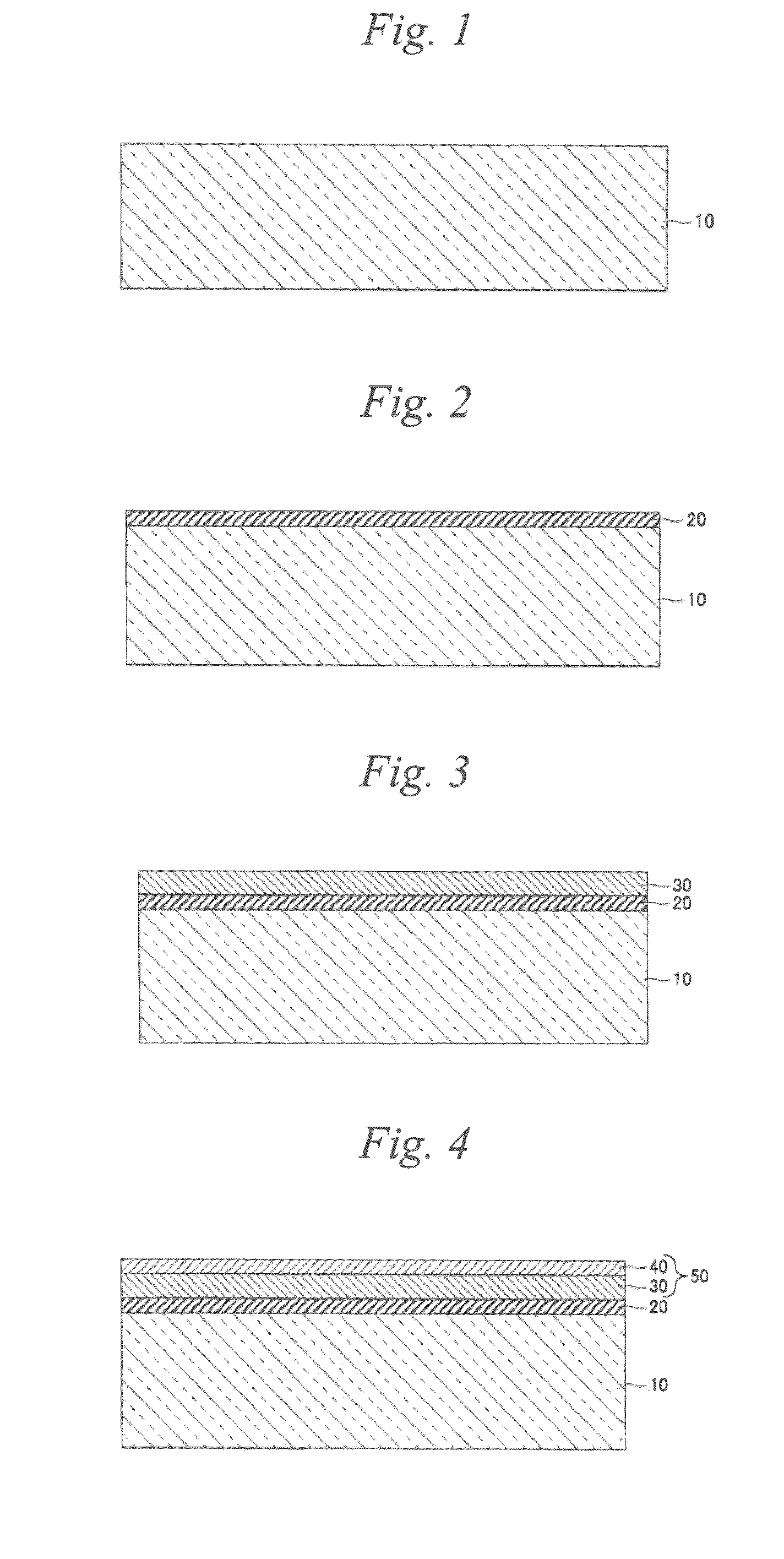

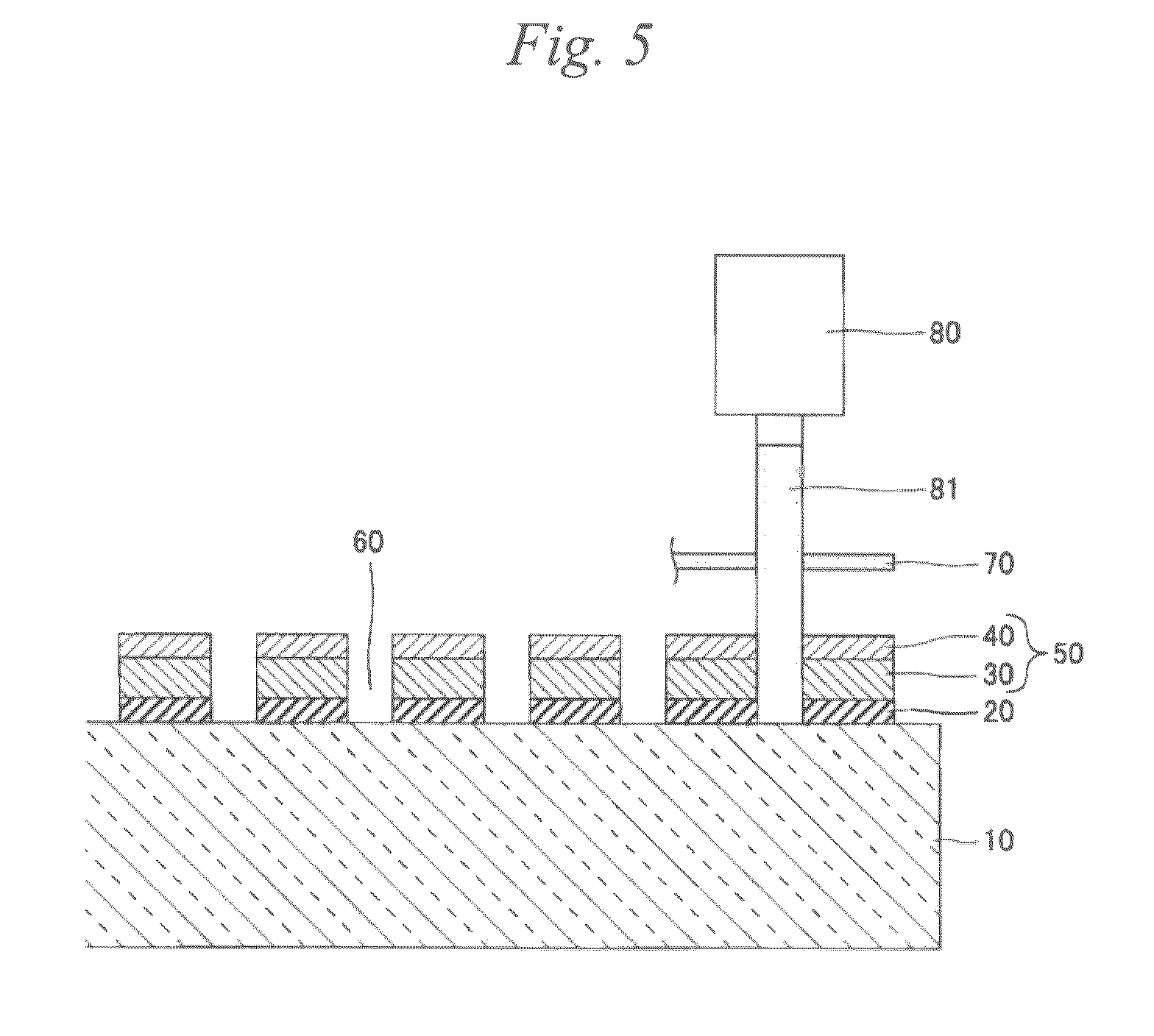

InactiveUS20110249340A1Easy to processFormed with easeGas discharge electrodesGas discharge vessels/containersMetallic materialsOptoelectronics

The present invention relates to a process for producing a substrate provided with a metal pattern by forming a pattern of a metal layer on a substrate using a laser light, the process including: a step of preparing a substrate in which the metal layer is formed on a surface thereof; a step of forming on the metal layer an assist layer which comprises a metal material different from that of the metal layer and which has a light absorptivity for the laser light different from that of the metal layer, thereby forming a metal laminate on the substrate; and a step of patterning the metal layer by irradiating the metal laminate with the laser light to remove a laser light-irradiated portion of the metal laminate, thereby forming a metal pattern on the substrate.

Owner:ASAHI GLASS CO LTD

Circuit board and method for manufacturing the same

InactiveCN101849447BInhibit corrosion reactionAvoid corrosionPrinted circuit aspectsConductive material electric discharge removalEngineeringLaser beams

A circuit board is provided with an insulating substrate (1) and a circuit (3) formed on the insulating substrate (1). The circuit is provided with a plated base layer (4) whereupon a pattern is formed by irradiating a metal thin film (2) applied on a surface of the insulating substrate (1) with a laser beam (L) along the profile of the circuit (3) and partially removing the metal thin film (2) from the profile of the circuit (3). The circuit is also provided with a Cu-plated layer (5), an Ni-plated layer (6) and an Au-plated layer (7), which are formed by metal plating, on a surface of the plated base layer (4) in this order from the side of the plated base layer. Between the Ni-plated layer (6) and the Au-plated layer (7), a first intermediate plated layer (8) having a less noble metal than Au with respect to reference electrode potential is formed in contact with the Au-plated layer, and a second intermediate plated layer (9) having a more noble metal than the metal in the first intermediate plated layer with respect to the reference electrode potential is formed in contact with the first intermediate plated layer (8).

Owner:PANASONIC CORP

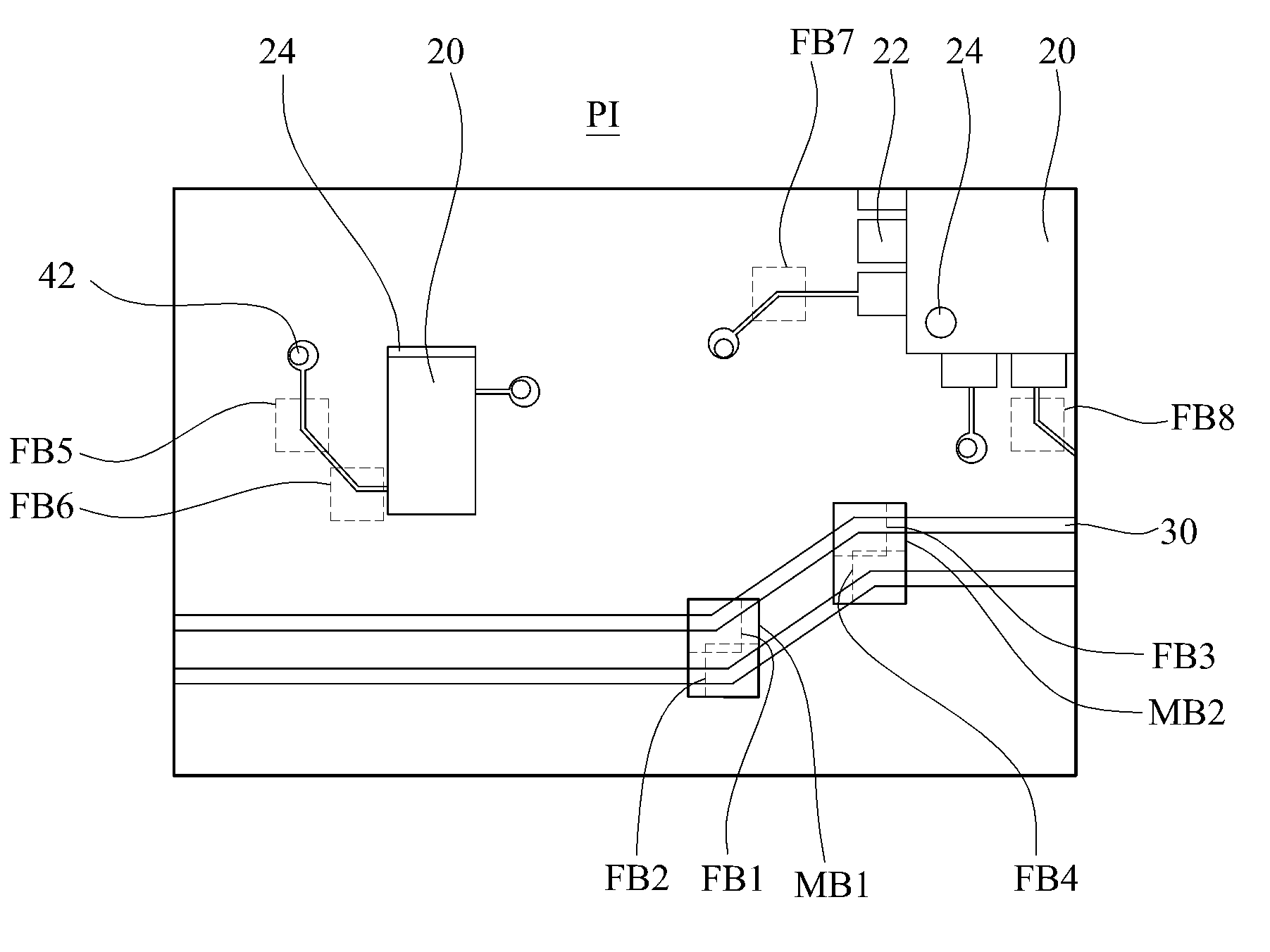

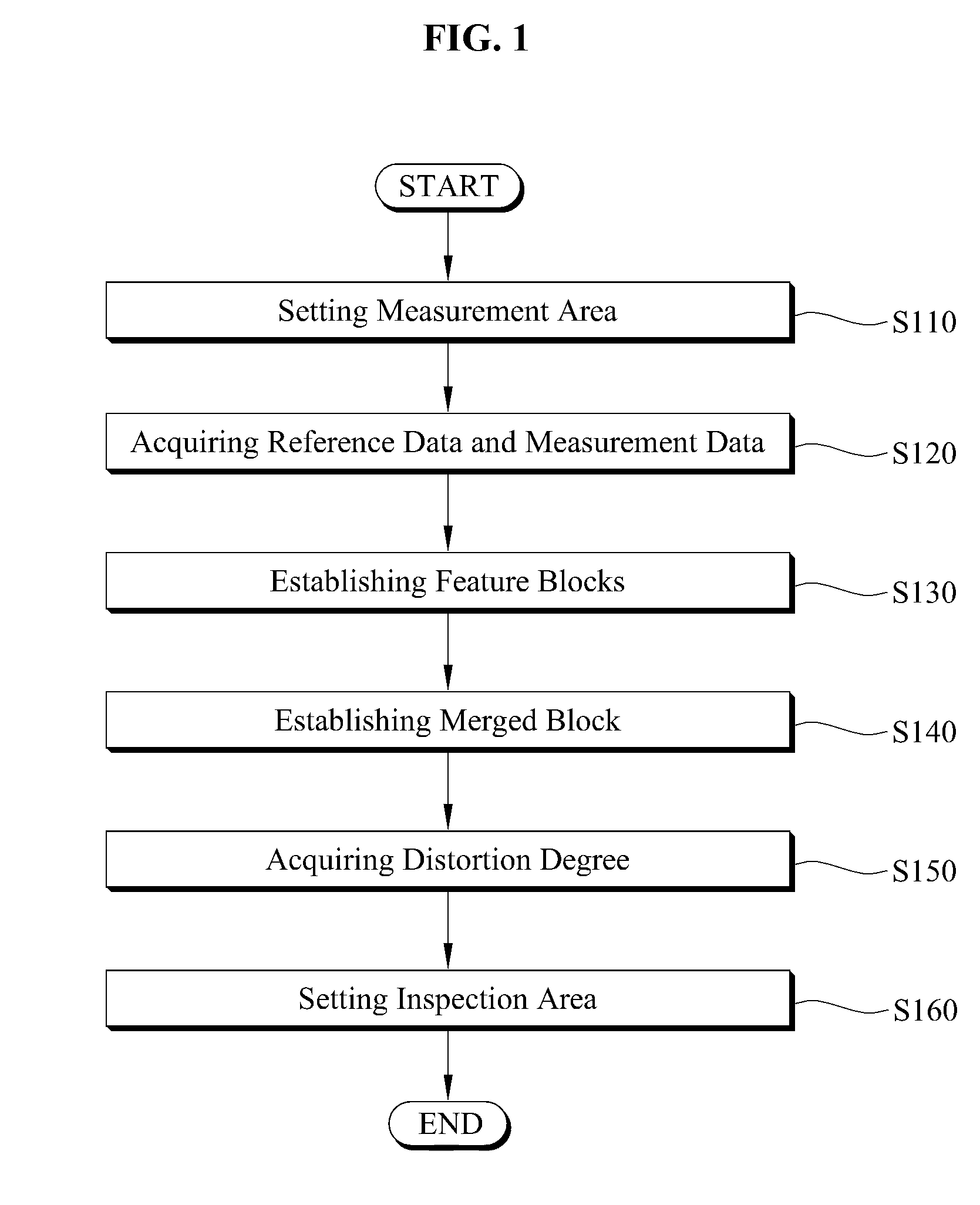

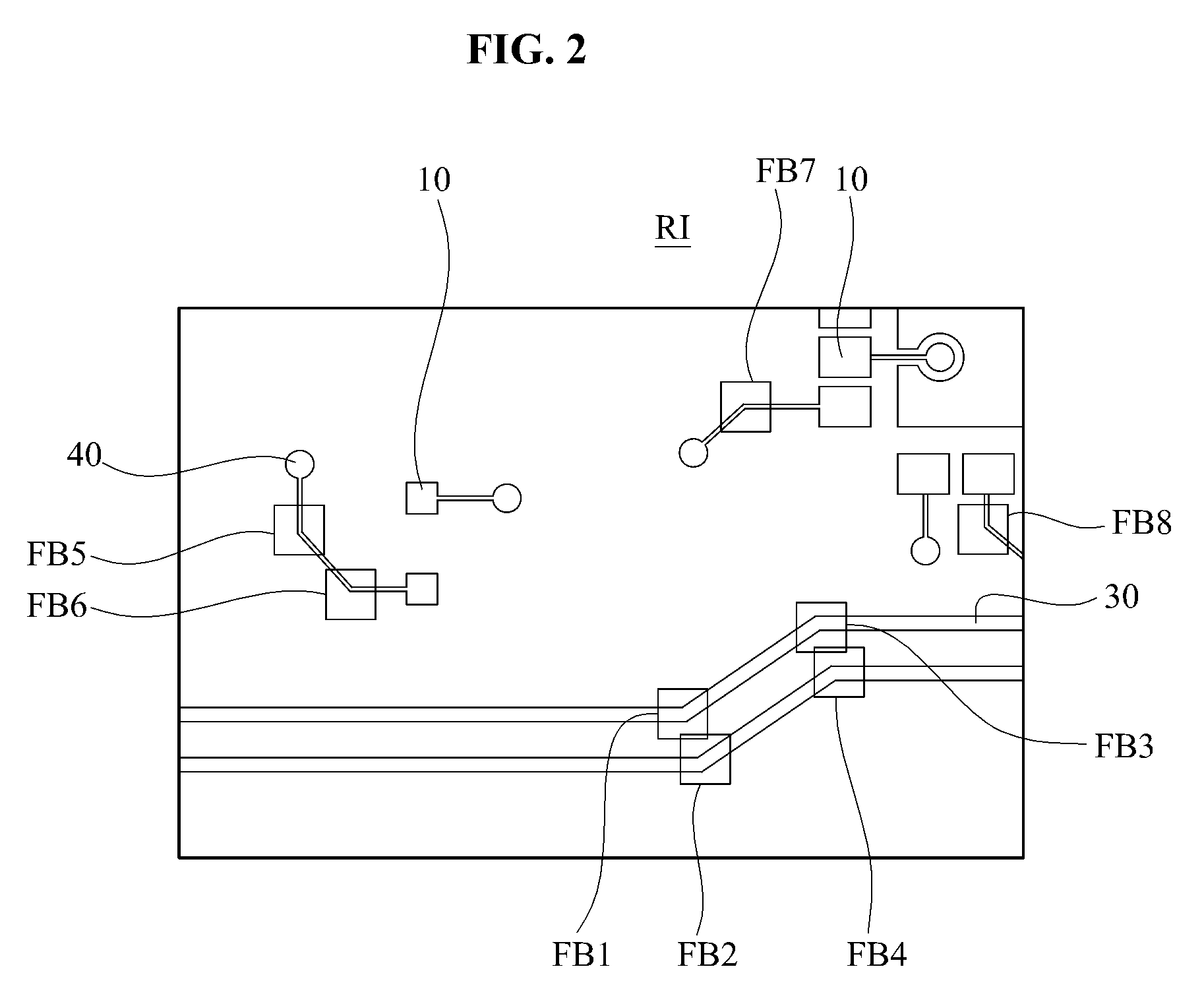

Inspection method

ActiveUS9092843B2Compensation DistortionChoose accuratelyImage enhancementImage analysisPattern recognitionComputer vision

In order to inspect a board, firstly, a measurement area is set on a board, and reference data and measurement data of the measurement area are acquired. Then, a plurality of feature blocks is established by a block unit so as to include a predetermined shape in the measurement area, and a merged block is established by merging feature blocks overlapped in the feature blocks. Thereafter, a distortion degree is acquired by comparing reference data and measurement data corresponding to a feature block except for the merged block and / or the merged block, and the distortion degree is compensated for, to set an inspection area in the target measurement area. Thus, an inspection area, in which distortion is compensated for, may be correctly set.

Owner:KOHYOUNG TECH

Circuit board and method of producing the same

InactiveUS6764747B2Improve accuracyAvoid it happening againDecorative surface effectsGlass/slag layered productsElectrical conductorMetal powder

A circuit board comprising a resin molded article which includes a metal powder coated by an insulation film and a metal conductor which is formed by metal deposition over a circuit pattern drawn by laser beam irradiation on the surface of the resin molded article through electroless plating, and the method of producing the same.

Owner:MTEX MATSUMURA CORP

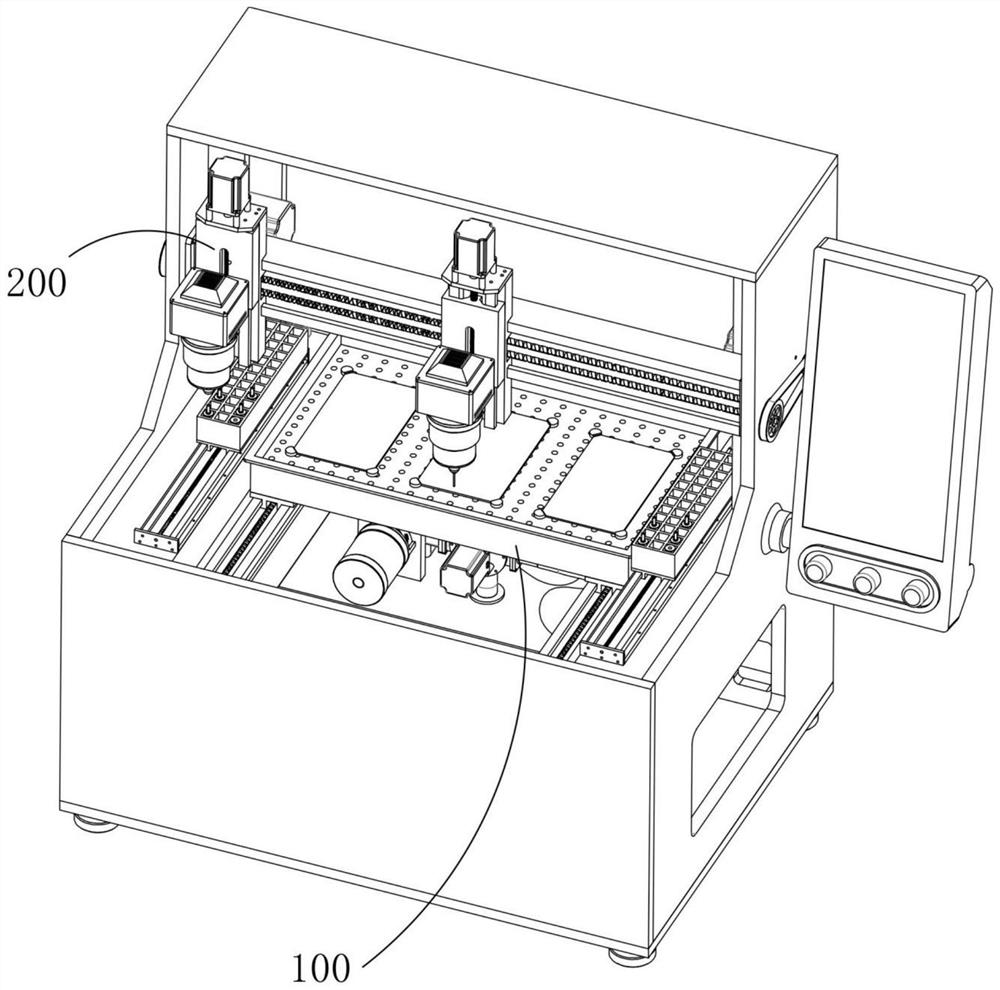

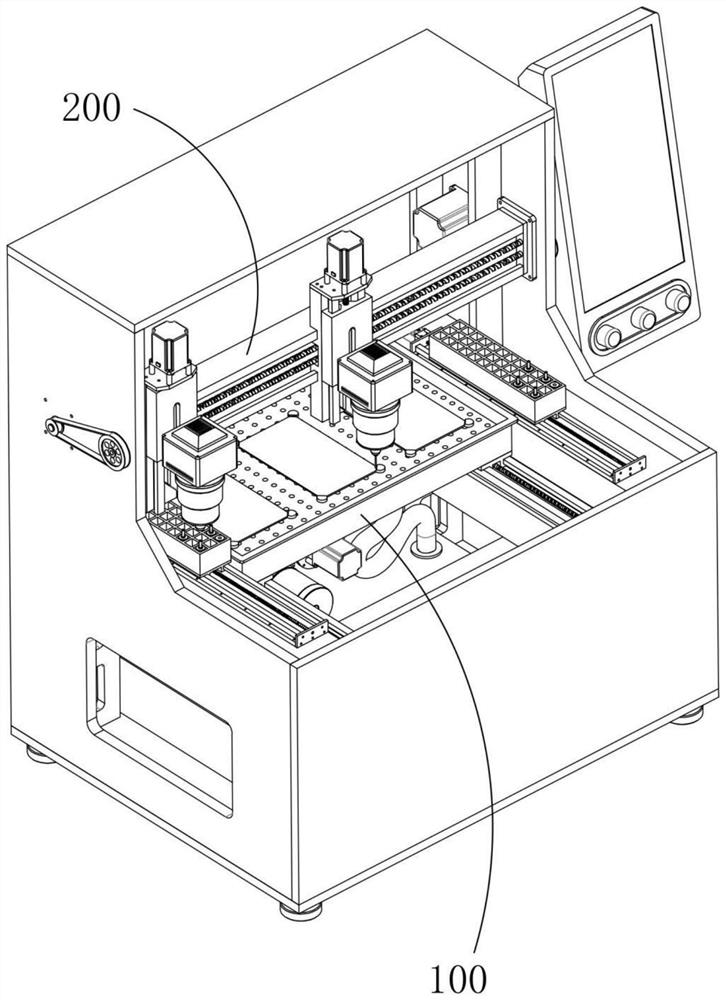

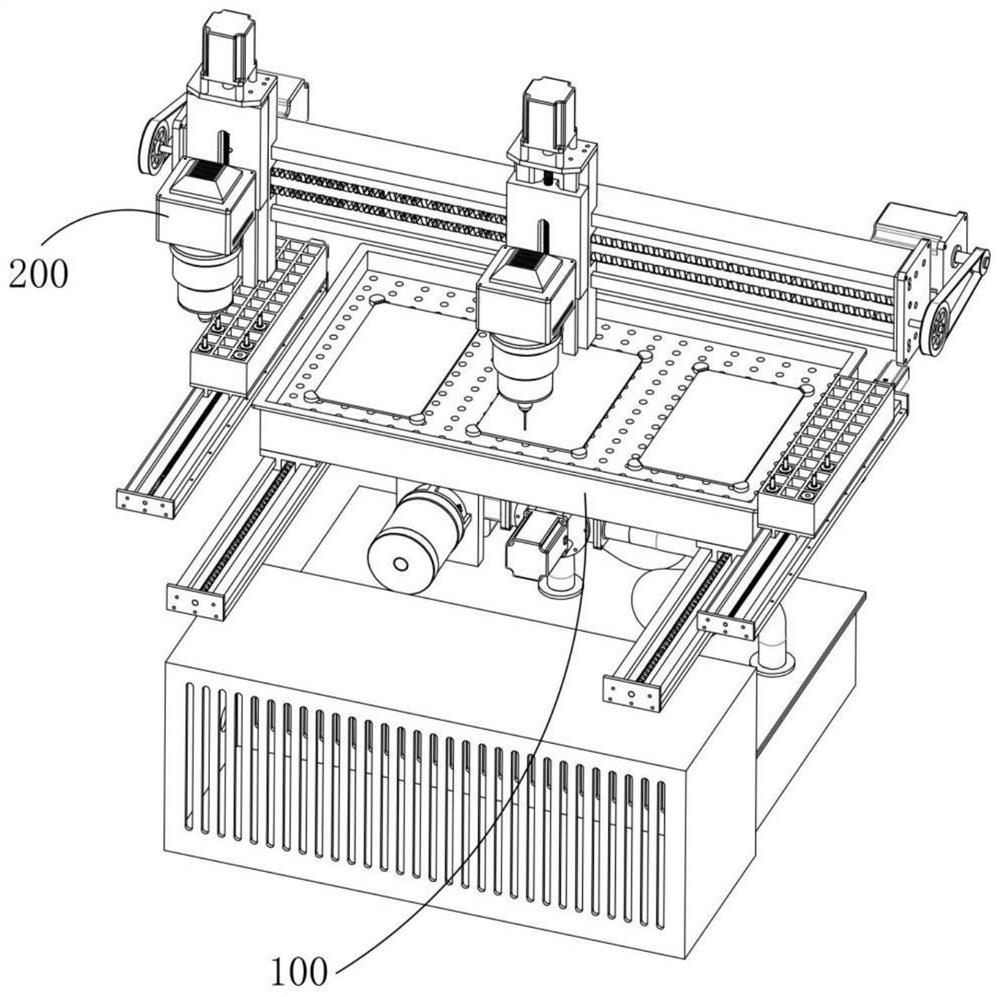

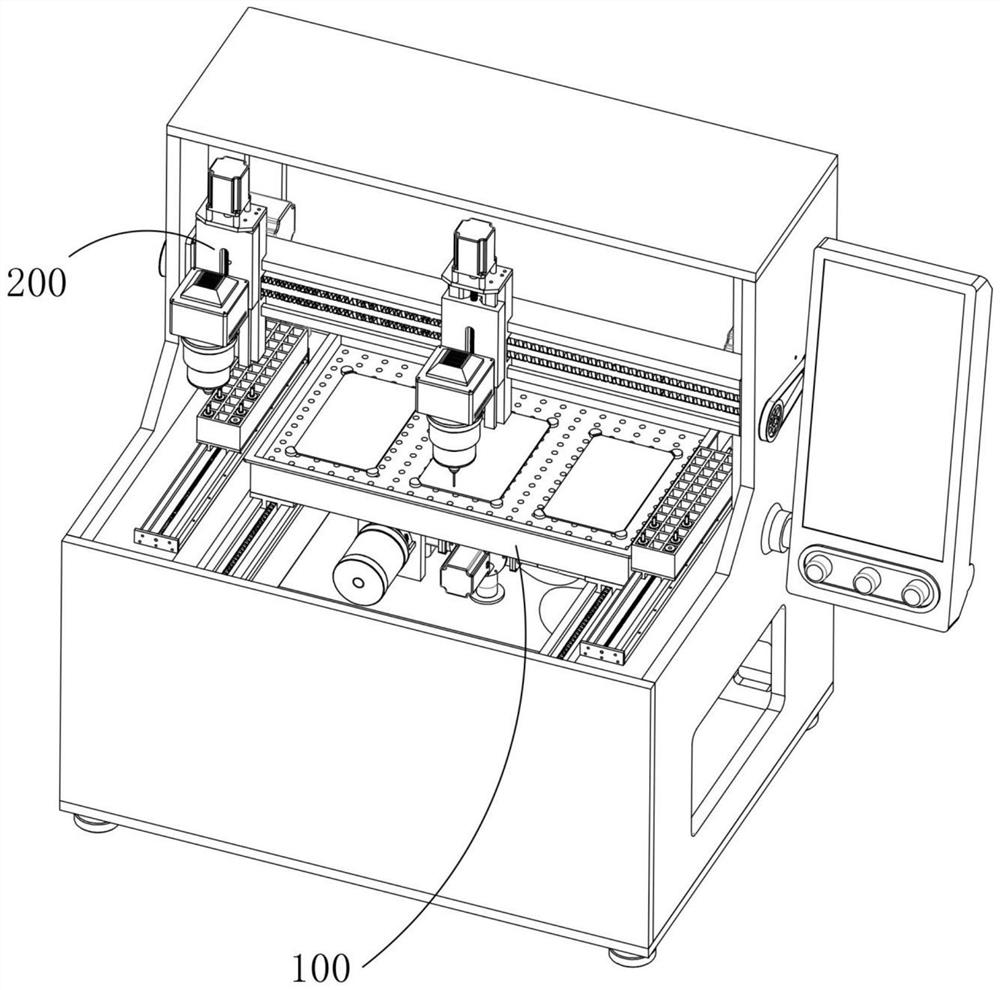

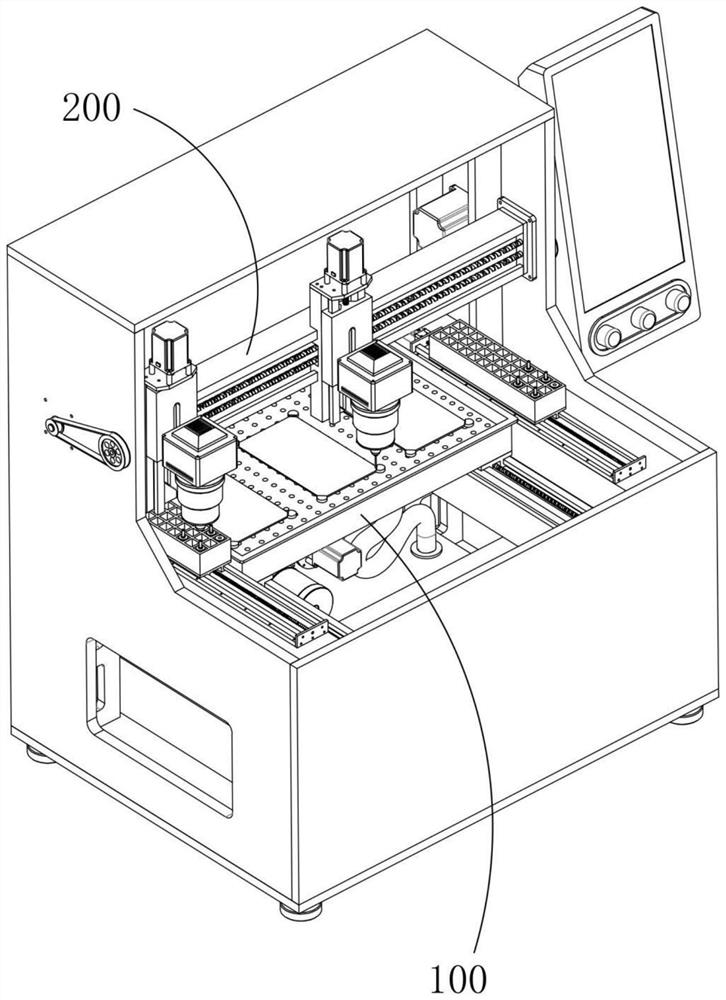

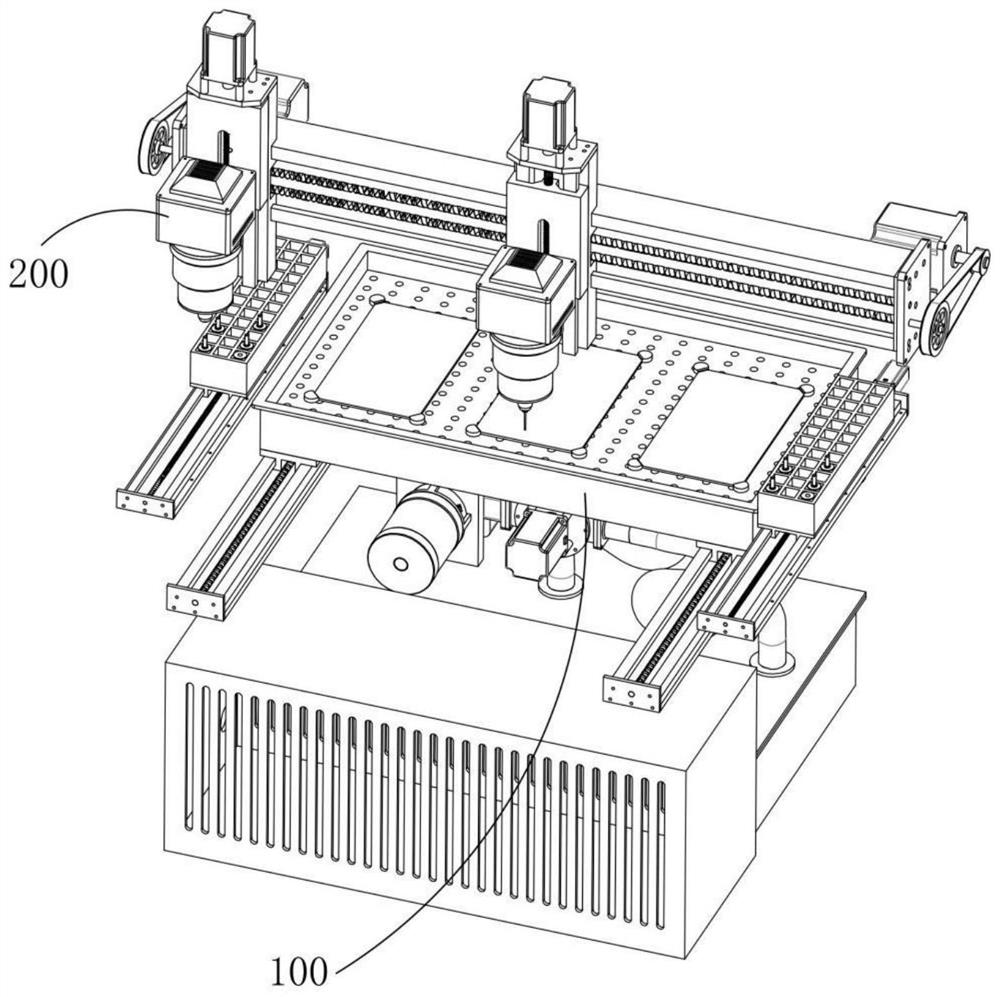

Double-position alternating type numerical control high-speed printed circuit board electric spark etching equipment

ActiveCN113873773AAchieve uninterrupted etchingEffect of etching processConductive material electric discharge removalConductive pattern polishing/cleaningNumerical controlLiquid medium

The invention discloses double-position alternating type numerical control high-speed printed circuit board electric spark etching equipment, belongs to the field of circuit boards, and solves the problems that in the prior art, when conductive materials of a printed circuit board are etched in an electric spark mode, generated impurities are partially mixed in a liquid medium and partially attached to the surface of the circuit board, impurities need to be removed after the circuit board is taken out, and etching is interrupted when an electrode tip needs to be replaced in the assembling process in the etching process. When the liquid medium is discharged, the liquid medium is dragged to perform one-way surging, on one hand, impurities mixed with the liquid medium are dragged to surge away from the circuit board and be discharged along with the liquid medium, and on the other hand, the impurities attached to the surface of the printed circuit board are slightly brushed to be separated from the surface of the circuit board and discharged along with the liquid medium. Through cooperation of the two etching mechanisms, electrode tip replacement is achieved, and the etching process is uninterrupted.

Owner:深圳市格安电子有限公司

A double-position alternating numerical control high-speed printed circuit board electric spark etching equipment

ActiveCN113873773BAchieve uninterrupted etchingEffect of etching processConductive material electric discharge removalConductive pattern polishing/cleaningNumerical controlEtching

The invention discloses a double-position alternating numerical control high-speed printed circuit board electric spark etching equipment, which belongs to the field of circuit boards, and solves the problem of impurities generated when the printed circuit board is etched with conductive materials by means of electric sparks in the prior art Mixed in the liquid medium, partly attached to the surface of the circuit board, the problem of impurity removal after the circuit board is taken out, and the problem of intermittent etching when the electrode tip needs to be replaced due to the assembly process during the etching process; while the liquid medium is discharged, it is pulled The liquid medium surges in one direction. On the one hand, the traction itself surges away from the circuit board with the impurities mixed with the liquid medium and is discharged with the liquid medium. On the other hand, the impurities attached to the surface of the printed circuit board are gently flicked to remove them The surface of the circuit board is discharged along with the liquid medium. Through the cooperation of two sets of etching mechanisms, the replacement of the electrode head is realized but the etching process is uninterrupted.

Owner:深圳市格安电子有限公司

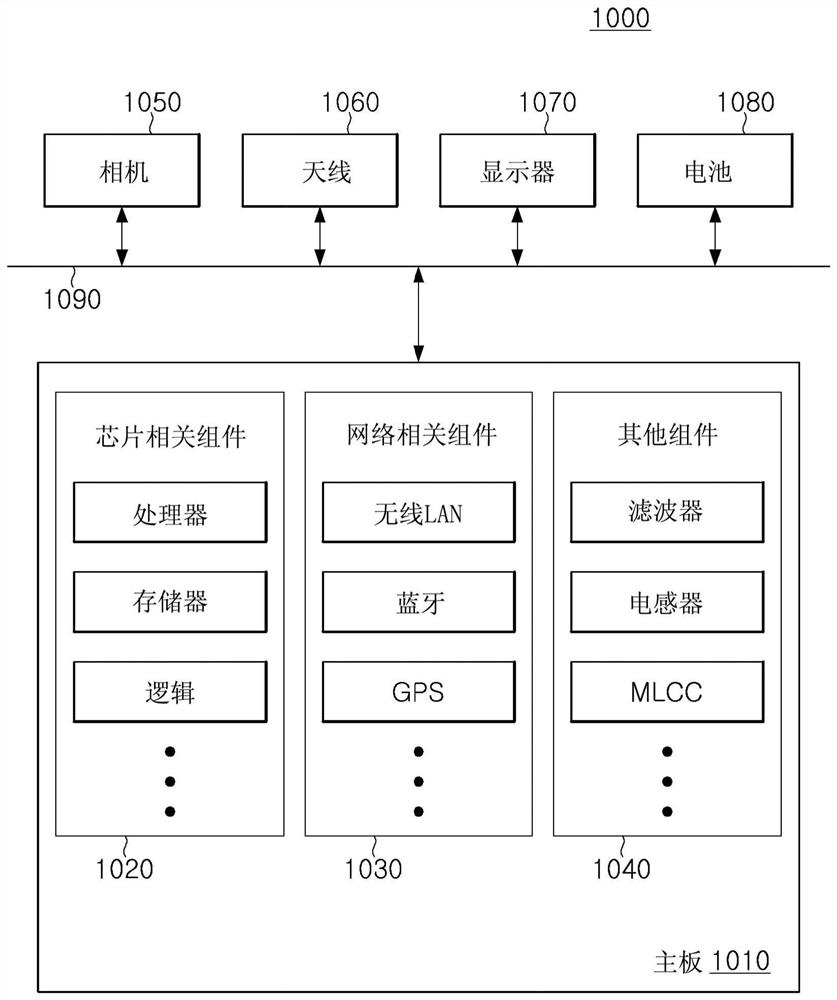

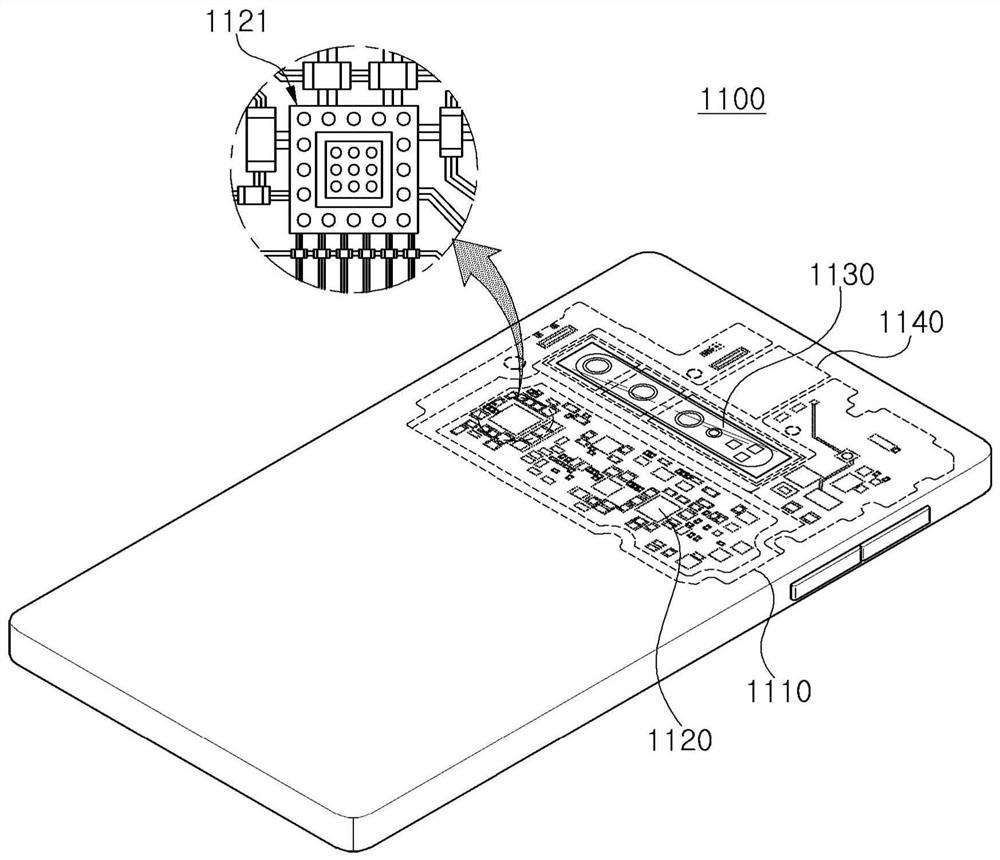

Printed circuit board and method of manufacturing the same

PendingCN114375090ASemiconductor/solid-state device detailsPrinted circuit aspectsHemt circuitsMechanical engineering

The invention provides a printed circuit board and a method of manufacturing the same. The printed circuit board includes an insulating layer and a circuit layer disposed on the insulating layer. The circuit layer includes a first circuit pattern and a second circuit pattern. Each of the first circuit pattern and the second circuit pattern has a first side surface, a second side surface opposite to the first side surface, and a top surface connected to an end of the first side surface and an end of the second side surface when viewed from a cross section. The first side surface of the first circuit pattern and the first side surface of the second circuit pattern face each other. A height of the first side surface of the first circuit pattern is greater than a height of the second side surface of the first circuit pattern, and a height of the first side surface of the second circuit pattern is greater than a height of the second side surface of the second circuit pattern.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Popular searches

Input/output processes for data processing Conductive material chemical/electrolytical removal Multilayer circuit manufacture Conductive material removal by irradiation Laser beam welding apparatus Layered product treatment Lamination Lamination apparatus Electrical equipment Electrical connection printed elements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com