Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1217results about "Circuit board tools positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

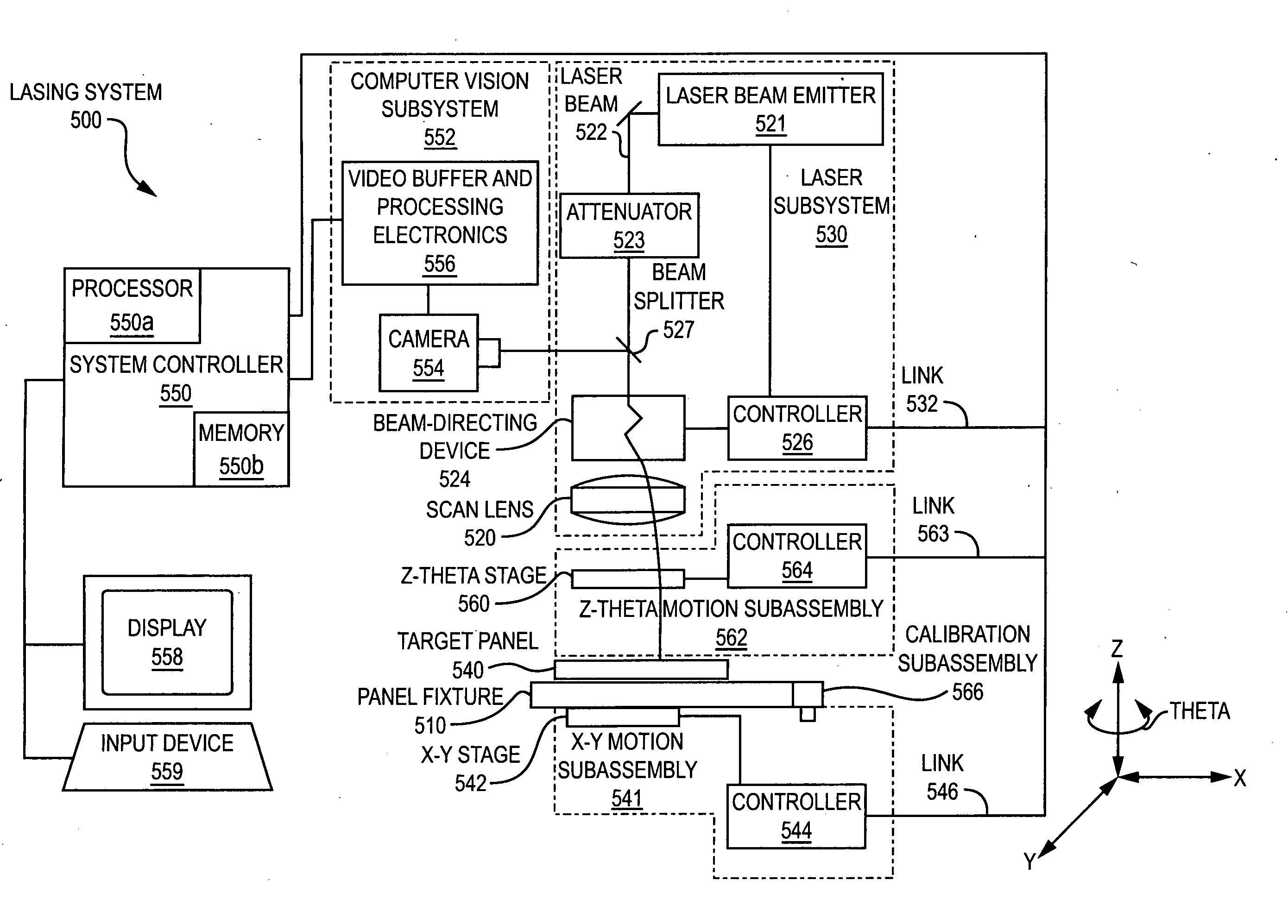

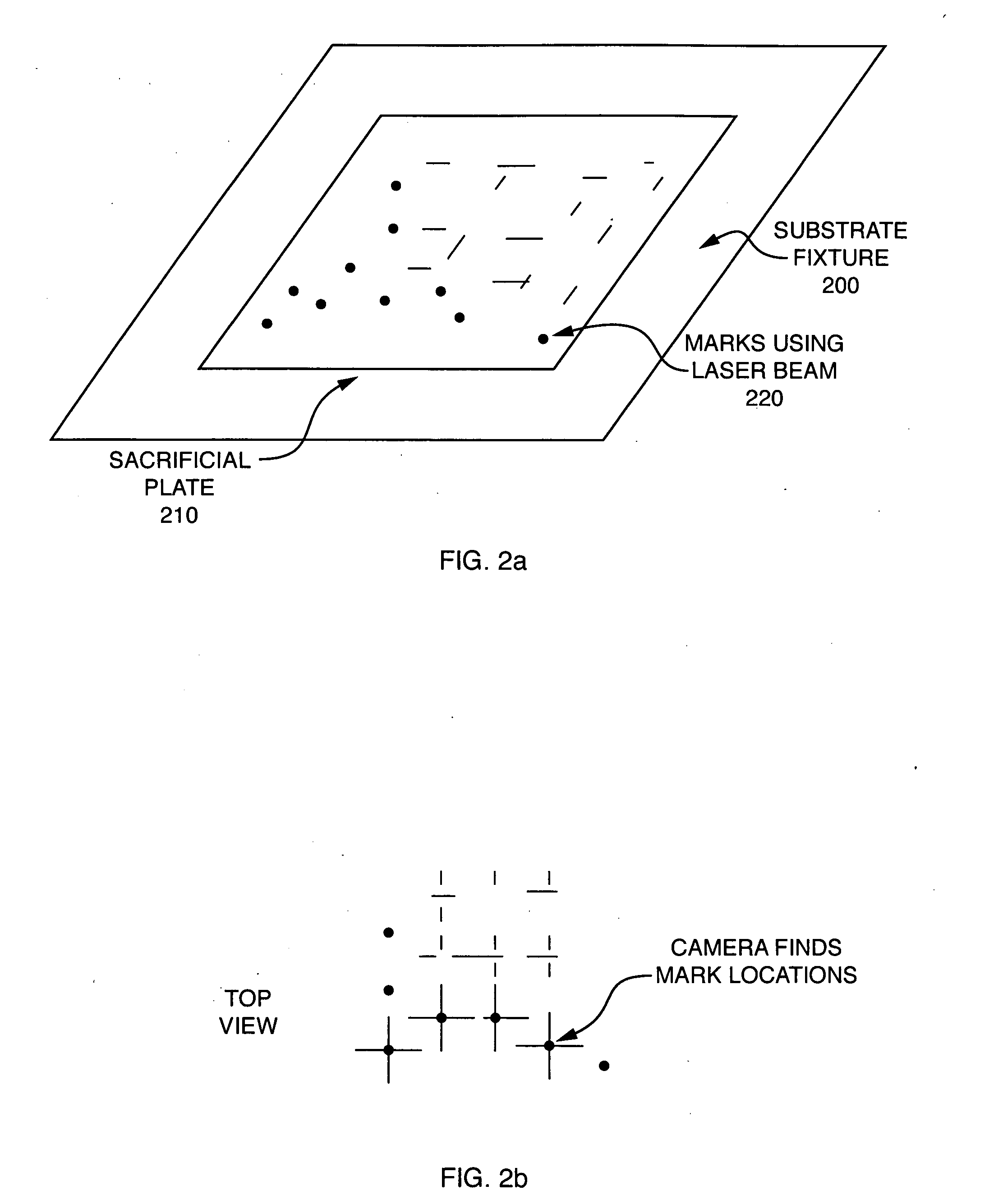

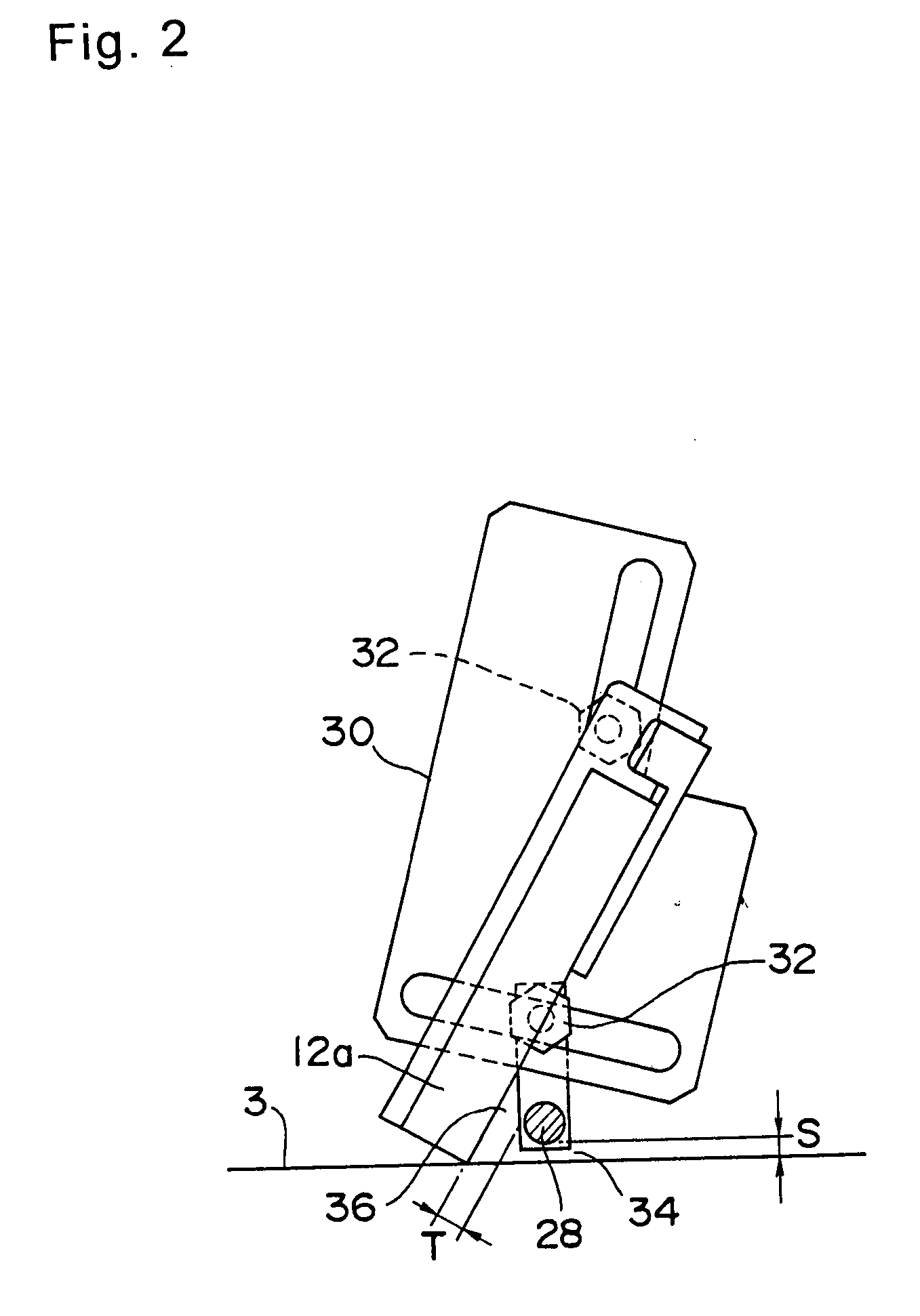

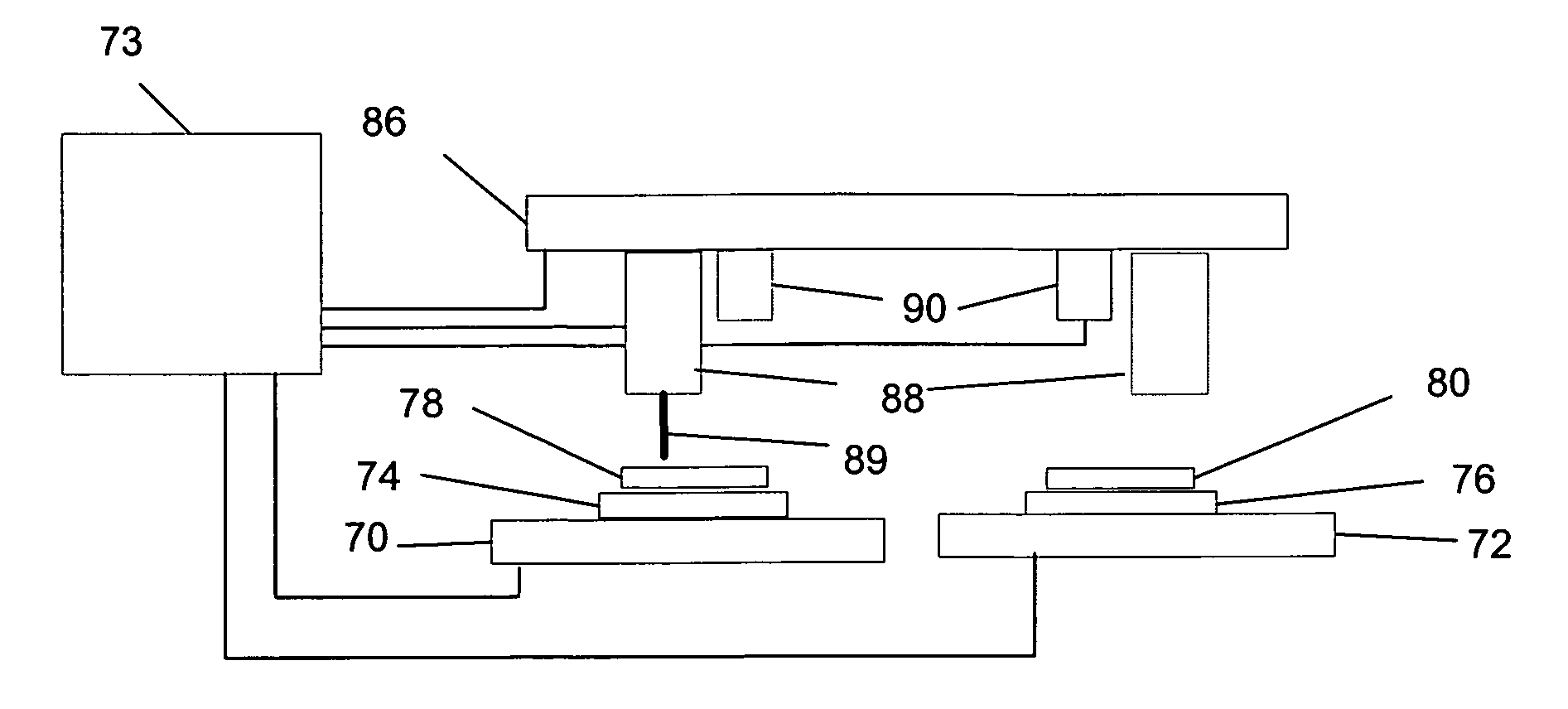

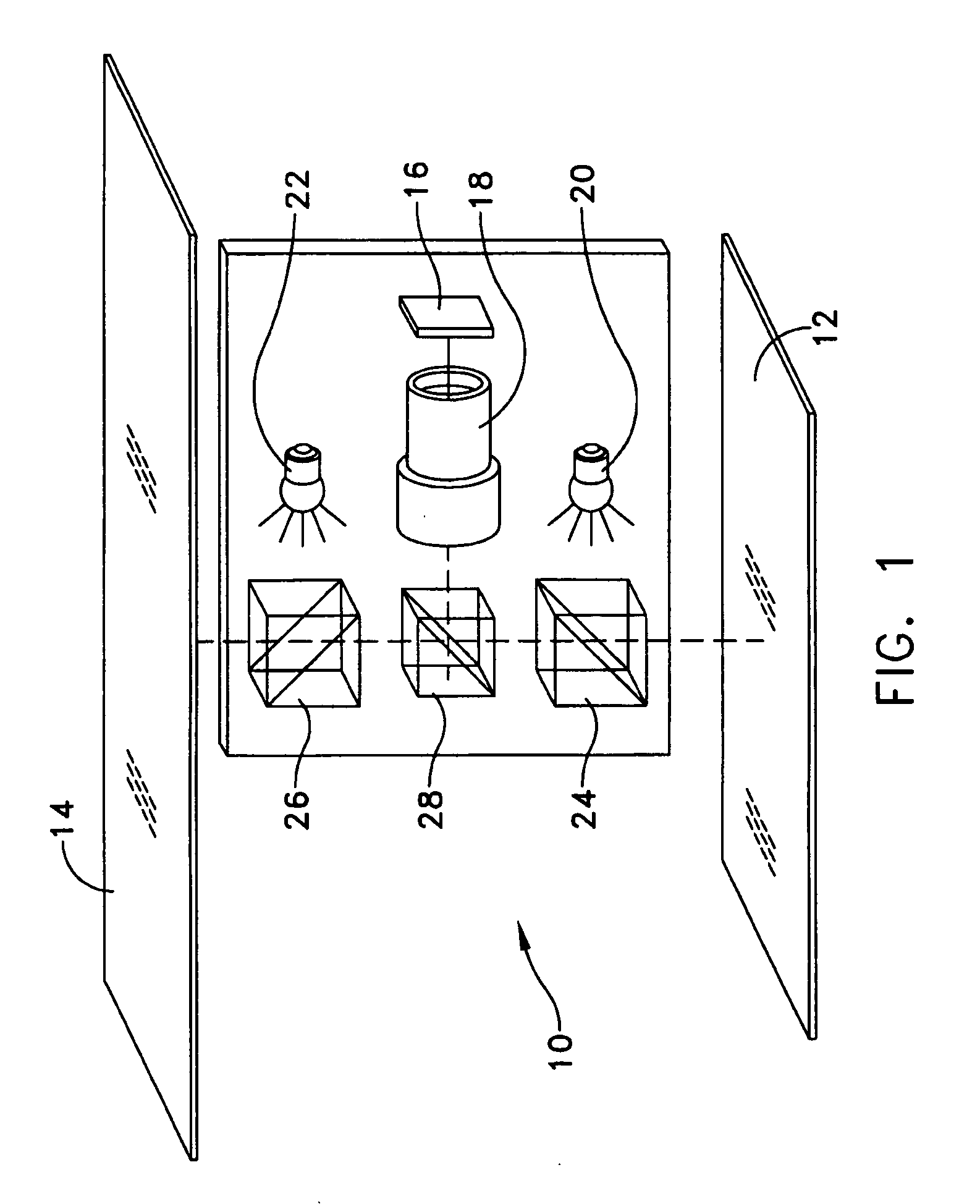

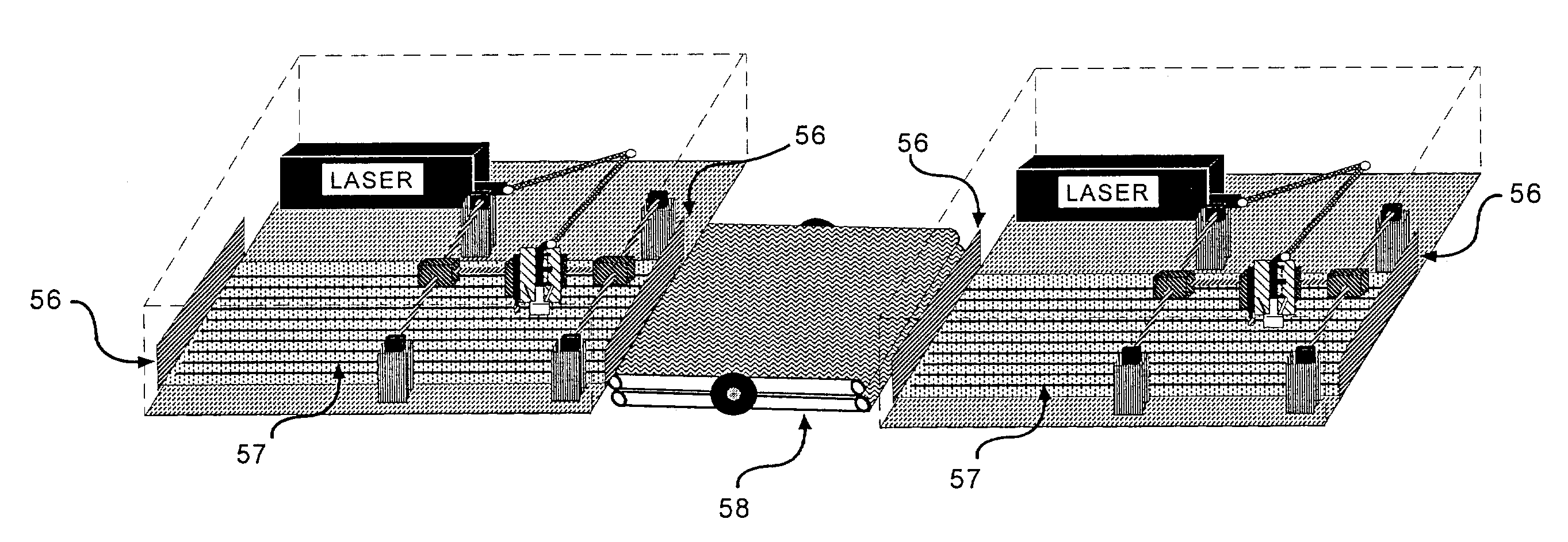

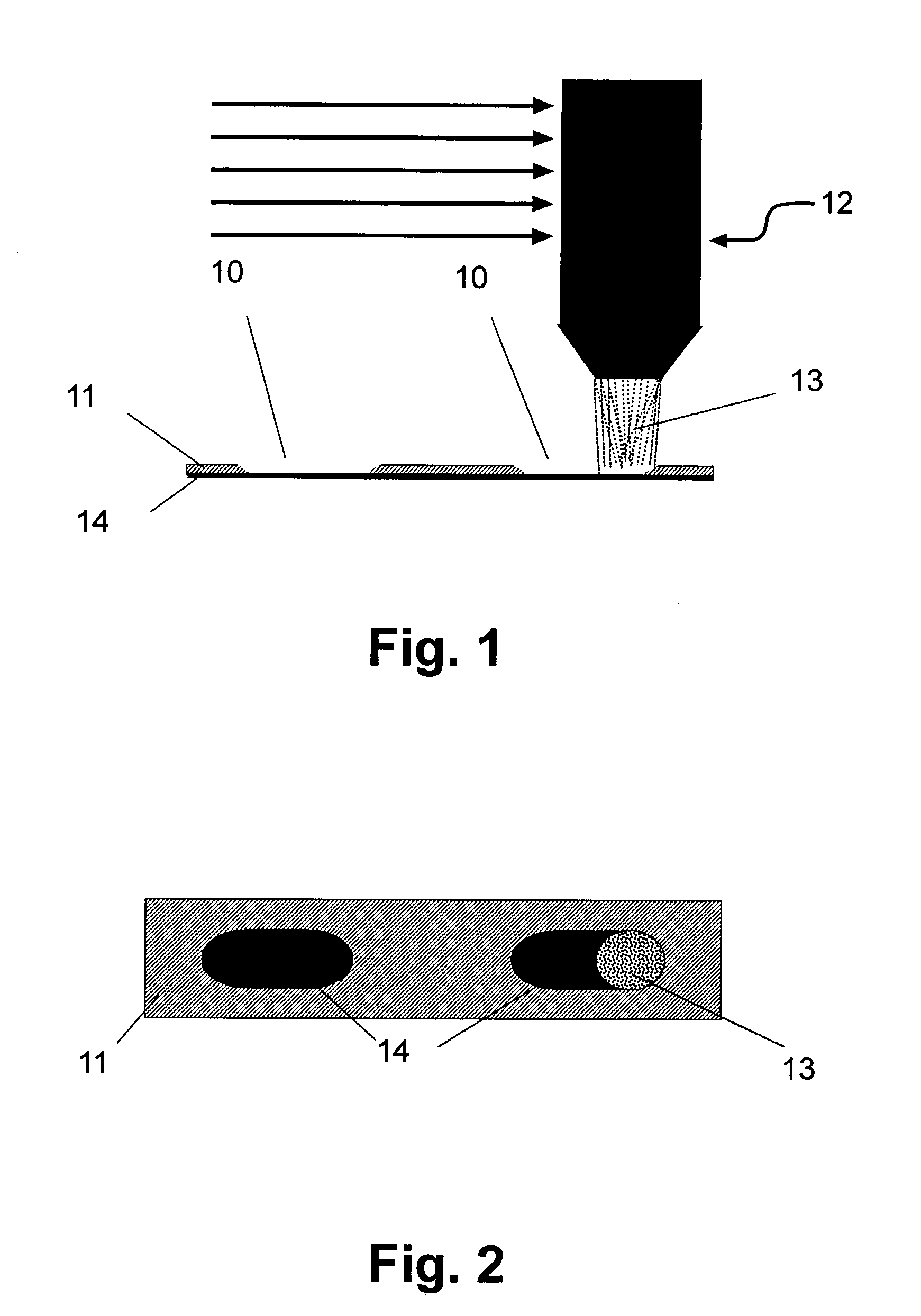

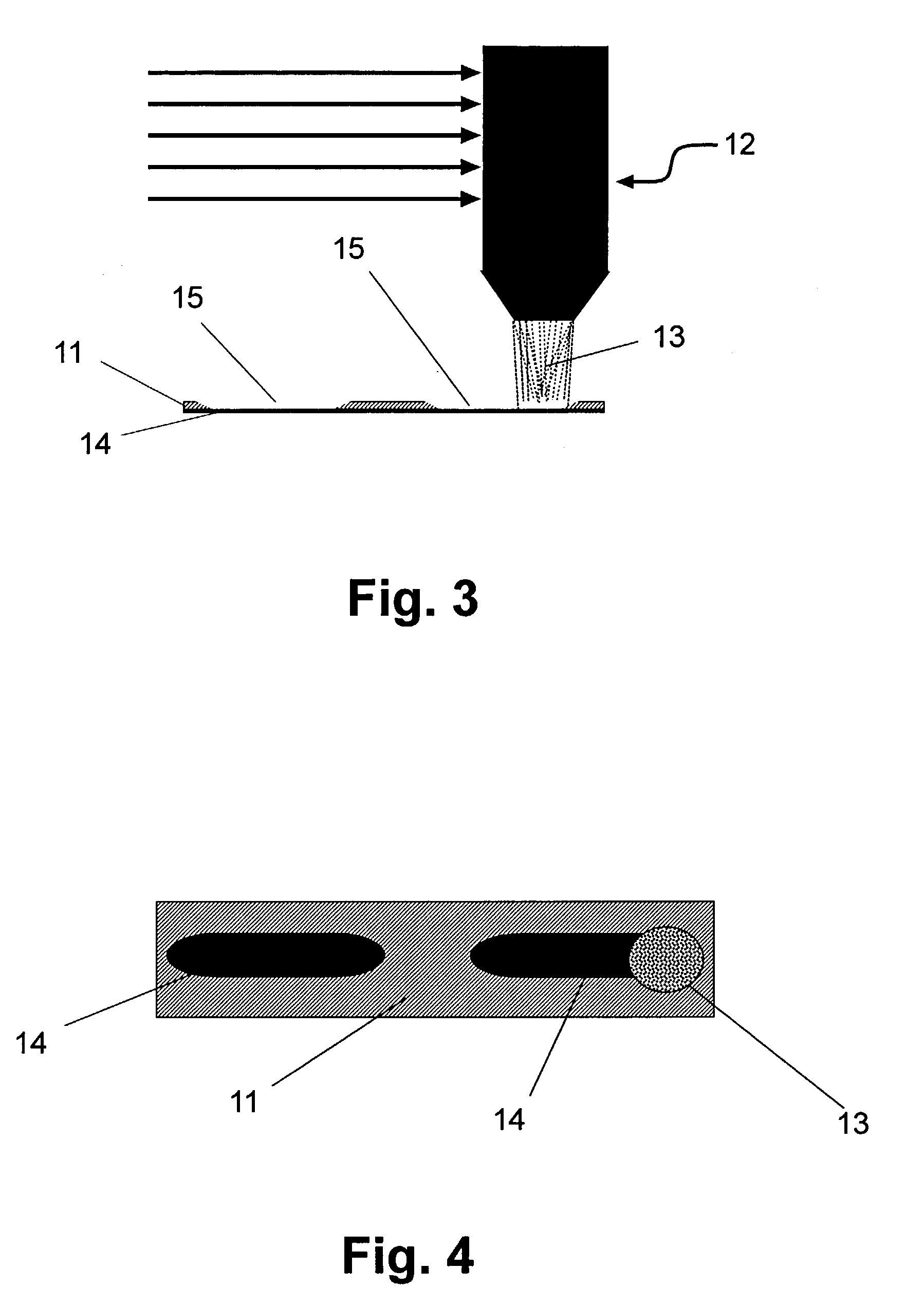

Laser trim motion, calibration, imaging, and fixturing techniques

InactiveUS20050205778A1Optimal lasing procedureOptimal procedureMaterial analysis using wave/particle radiationPrinted circuit aspectsBiomedical engineeringLaser trimming

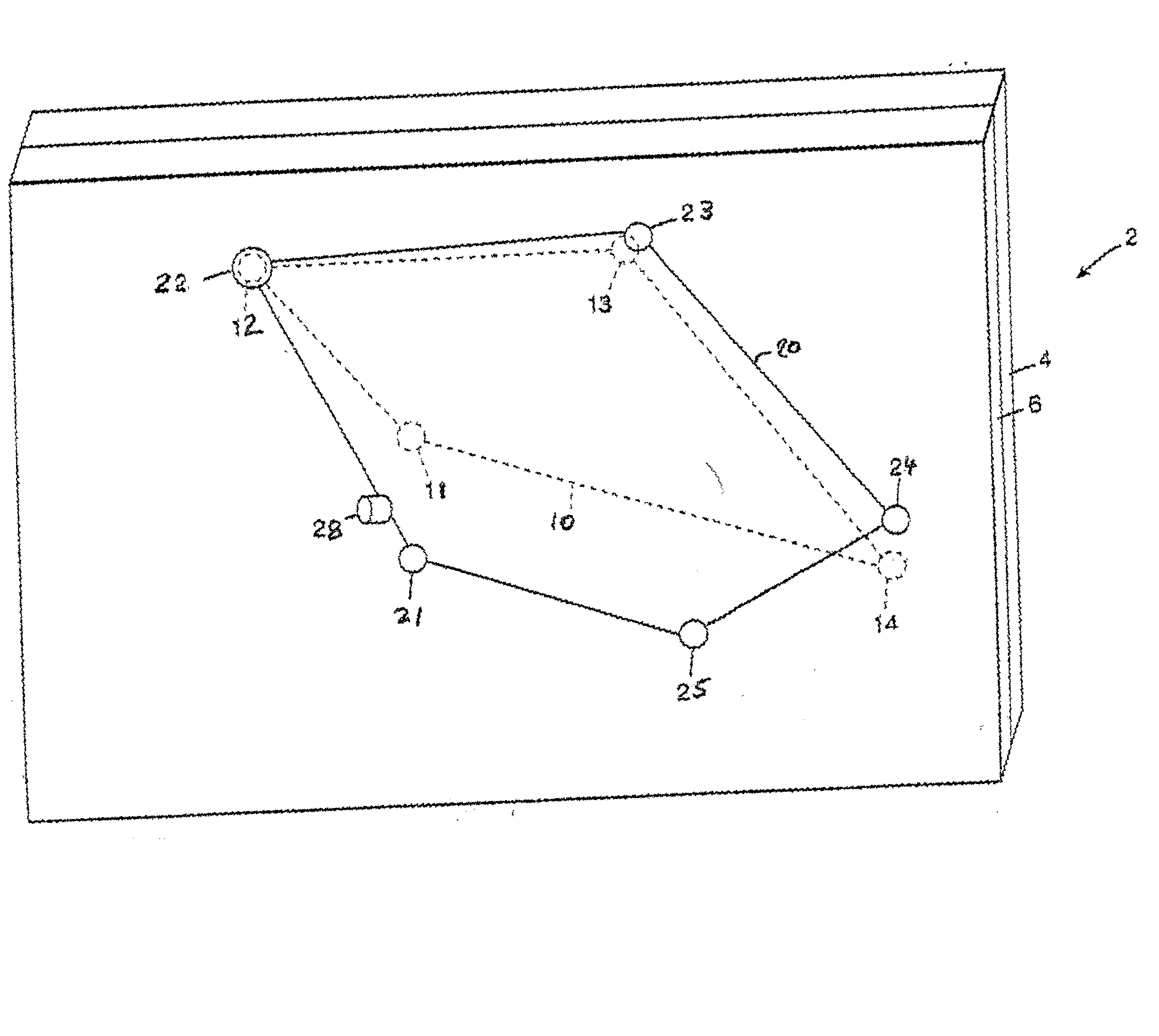

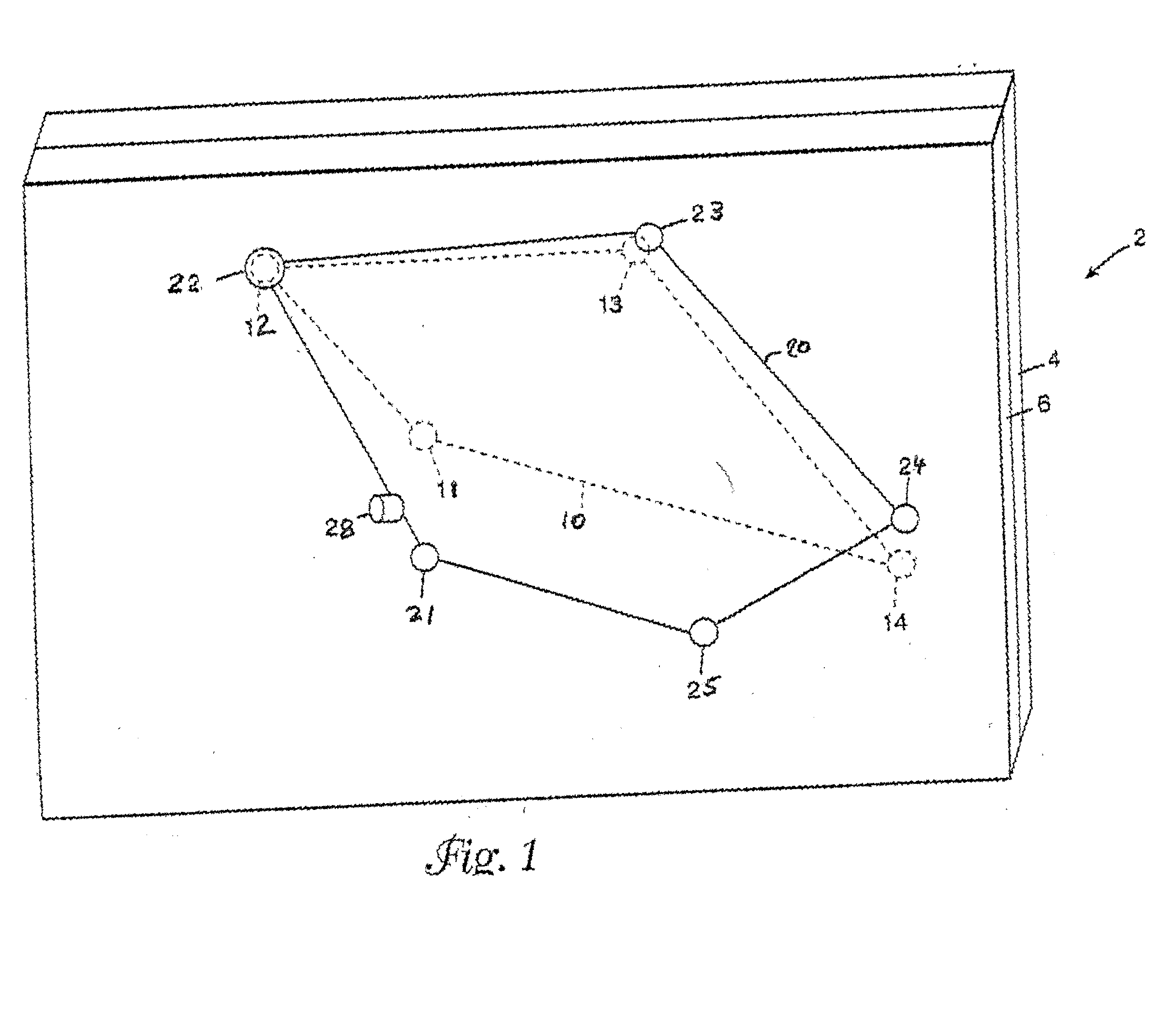

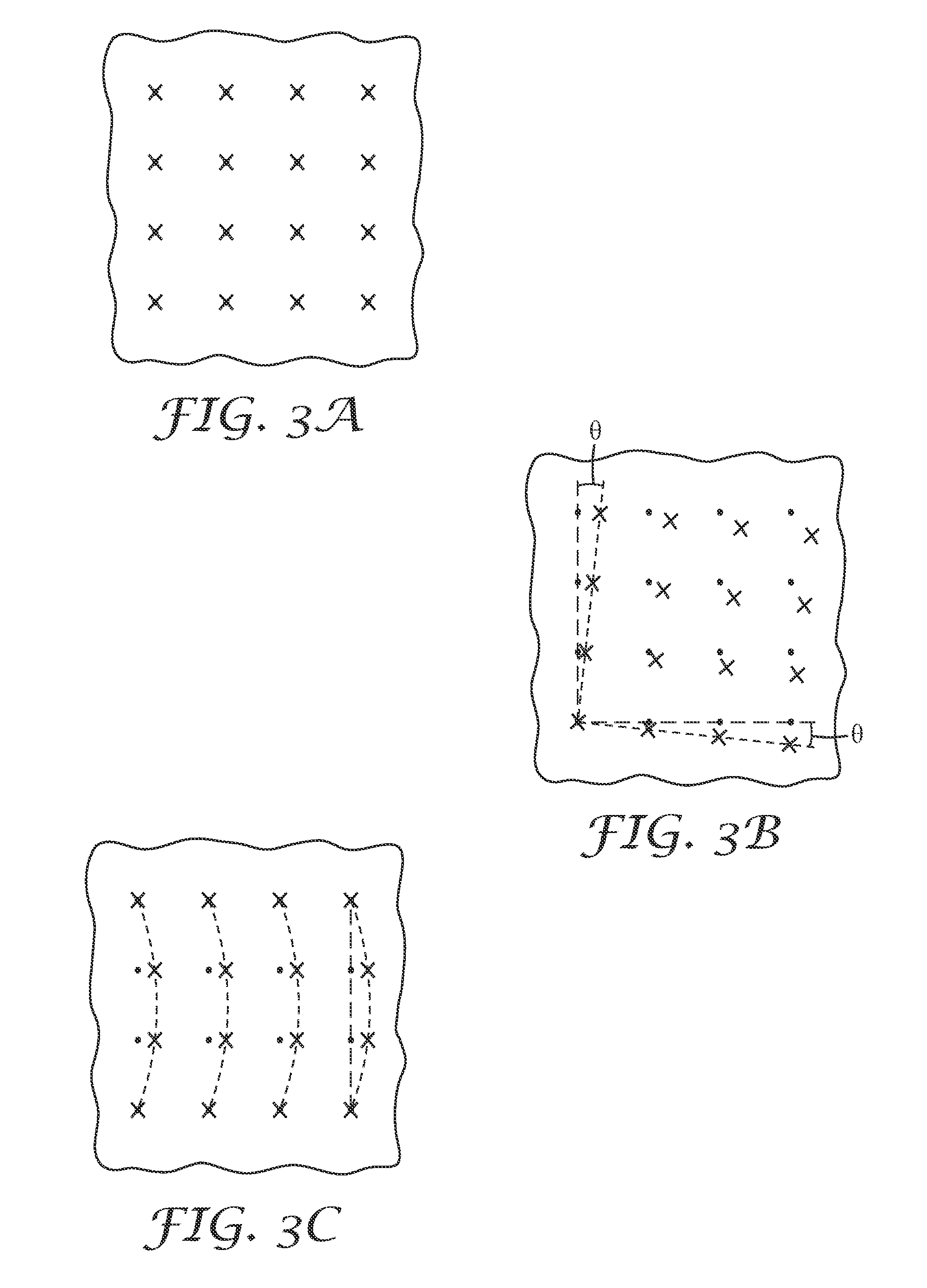

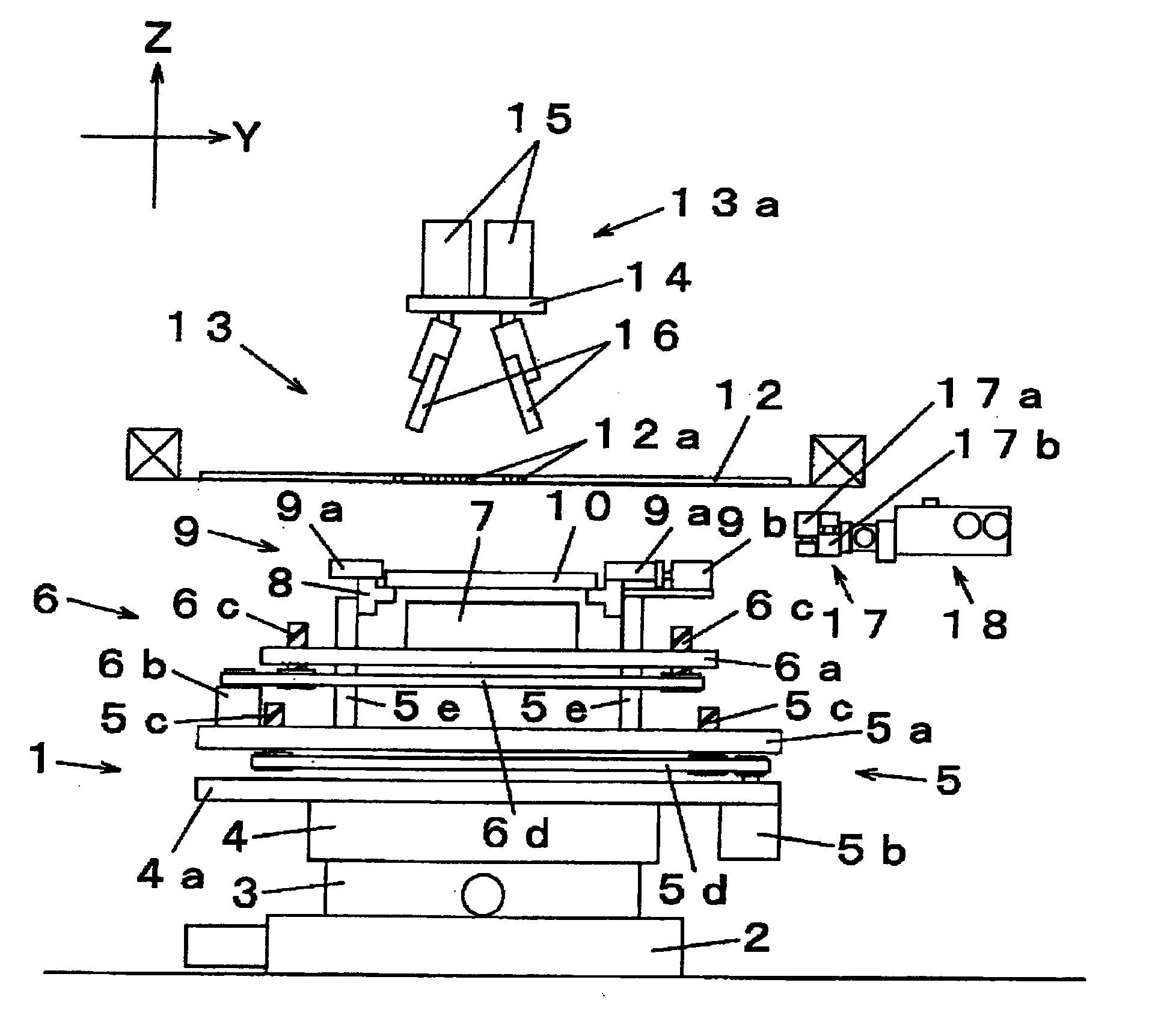

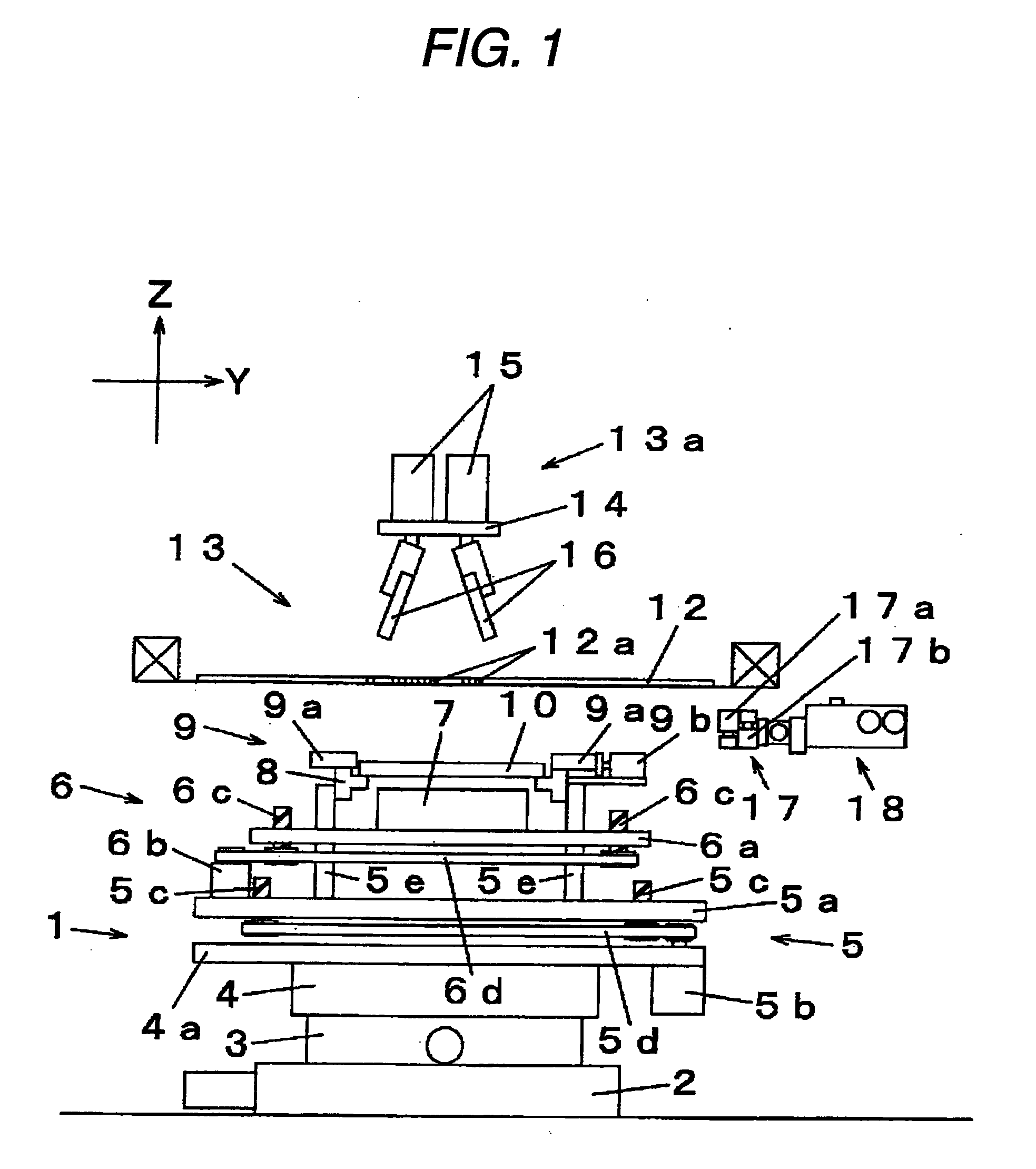

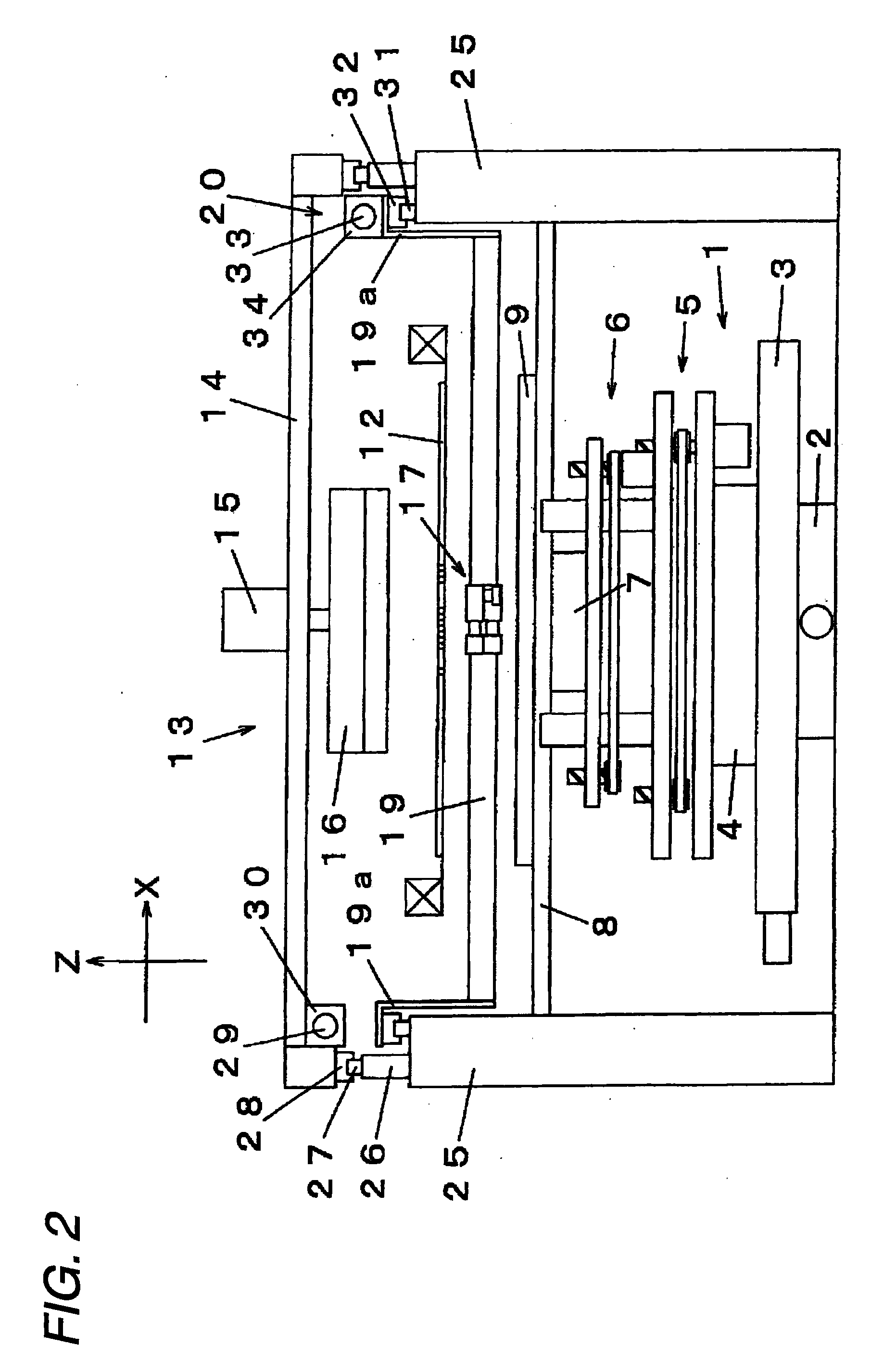

A system for probing circuit elements, includes a panel fixture, probe holder and stage. The fixture has a platen surface to support a work piece having work piece surface. The work piece surface is substantially parallel to the platen surface and has a target element thereon. The probe holder is configured to support a probe for detecting a characteristic of the target element. A stage rotates the probe holder about an axis substantially orthogonal to the platen surface, to align the probe with probe locations associated with the circuit element, so that the characteristic of the circuit element can detected by the probe. Fixturing motion can be optimized for efficient work piece manufacturing. Calibration and vision subassemblies are also provided.

Owner:THE GSI GRP LLC

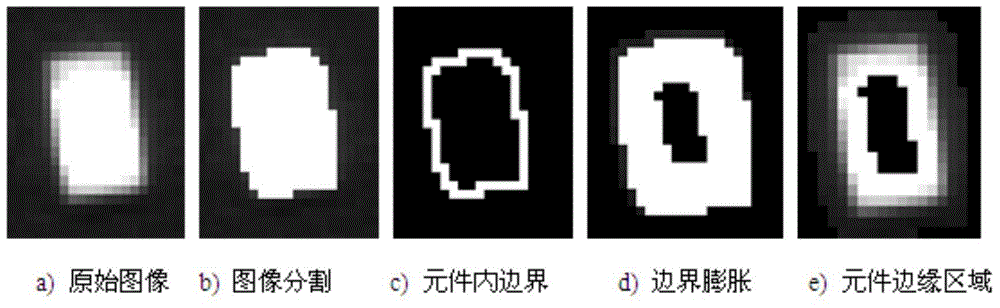

Detecting and error-correcting method capable of rapidly and accurately obtaining element center and deflection angle

ActiveCN104981105AFind out exactlyOvercoming complex shortcomingsPrinted circuit assemblingCircuit board tools positioningCurve fittingEdge extraction

A detecting and error-correcting method capable of rapidly and accurately obtaining an element center and a deflection angle is disclosed. Interested edge area can be rapidly and accurately found out through an automatic edge area extraction method based on combination of binary morphology and image reduction, and subsequent edge extraction image scope is minimized as possible. Pixel level edge is roughly positioned at first, and accordingly a sub-pixel edge is rapidly extracted by one-dimensional curve fitting method. The method overcomes the defect of complex algorithm of a conventional sub-pixel edge extraction algorithm based on two-dimensional images, and the time of extracting accurate sub-pixel edge can be shortened. Weighted least square rectangular edge fitting algorithm based on linear hazen paradigm can detect straight lines on any positions of an image, and effectively minimizes influence of outlier on fitting precision due to uneven edges. The central positions of a plurality of elements and deflect angles can be rapidly and accurately detected at once, and the efficiency of visual detection is improved.

Owner:GUANGDONG UNIV OF TECH

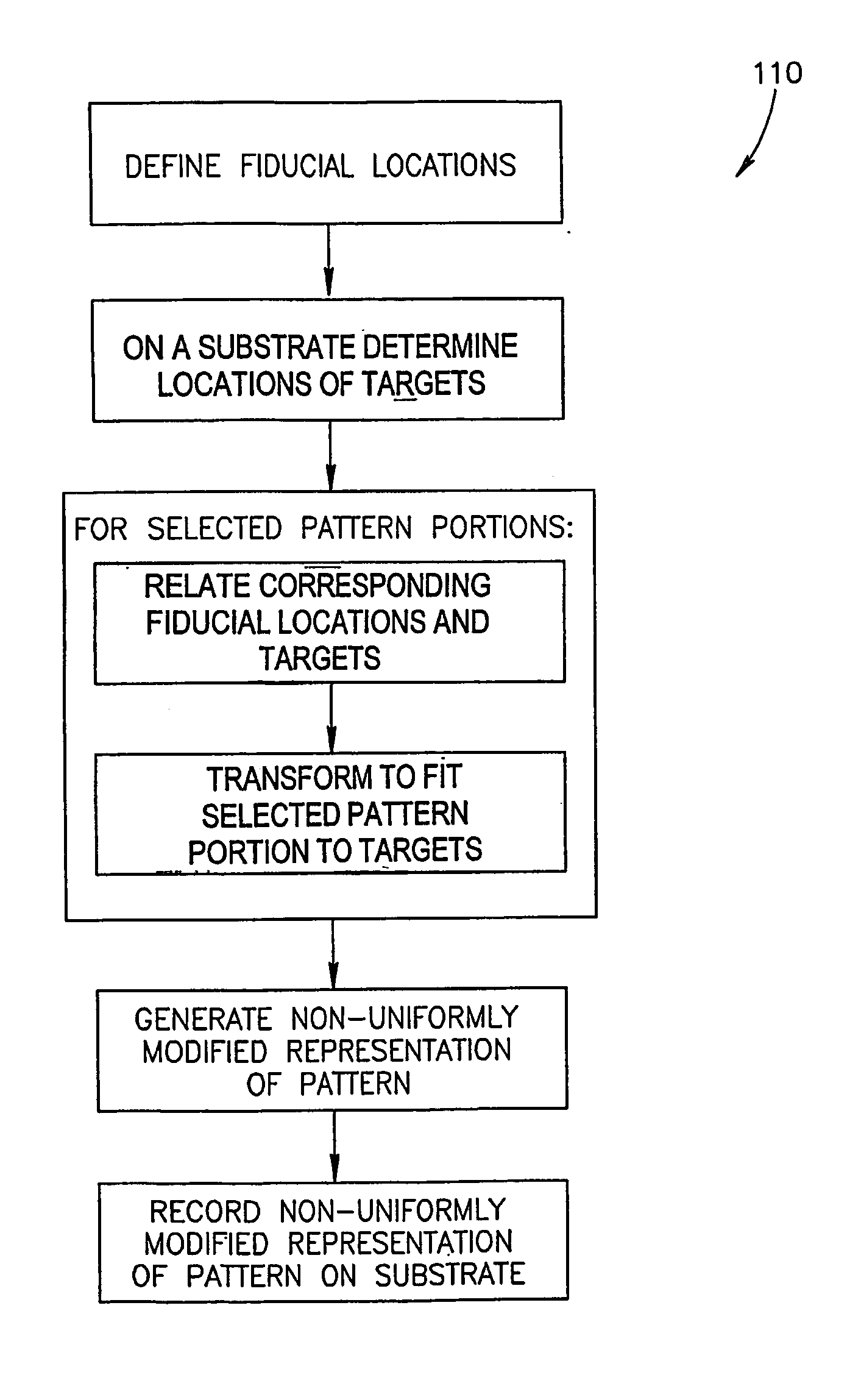

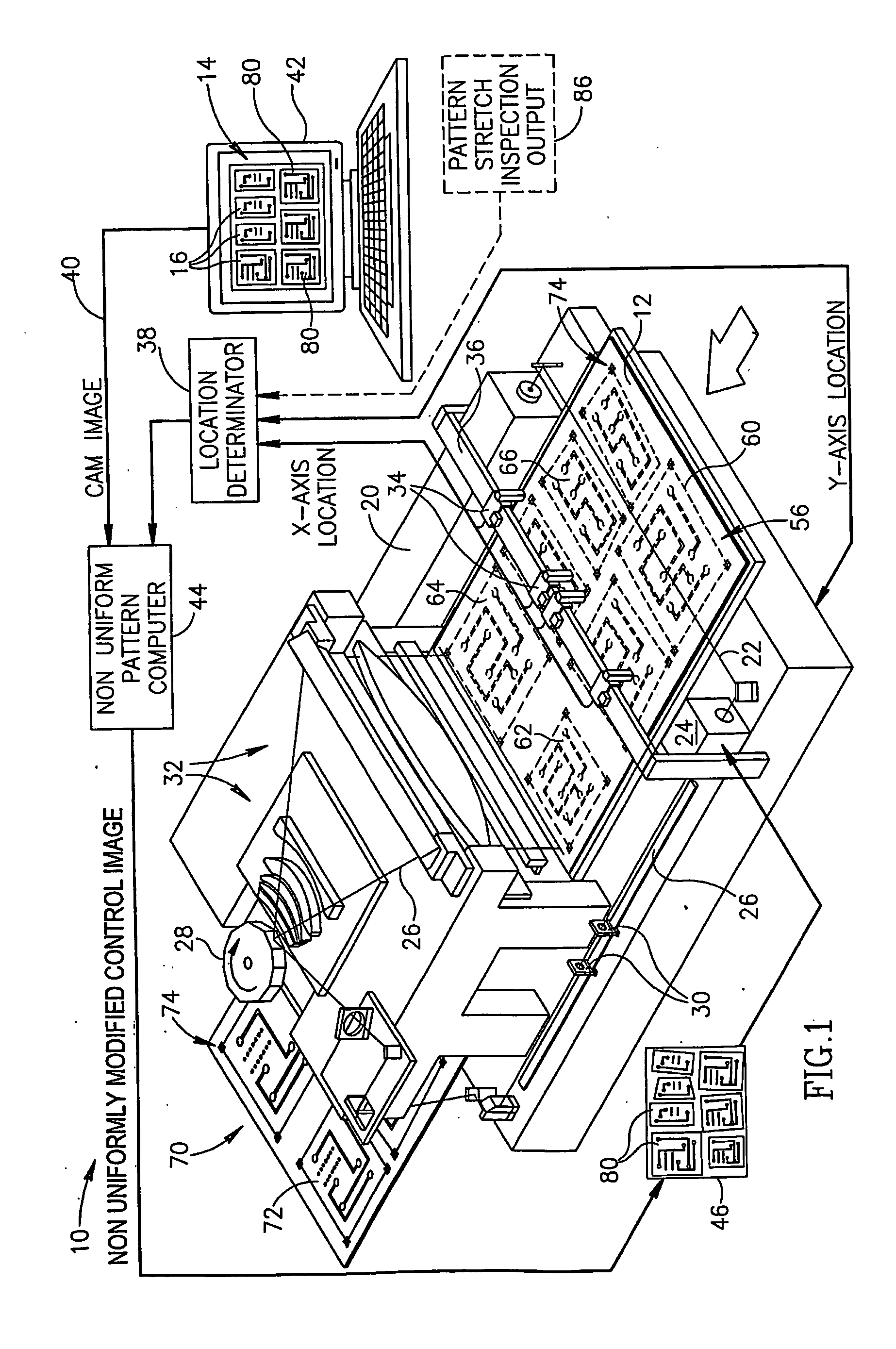

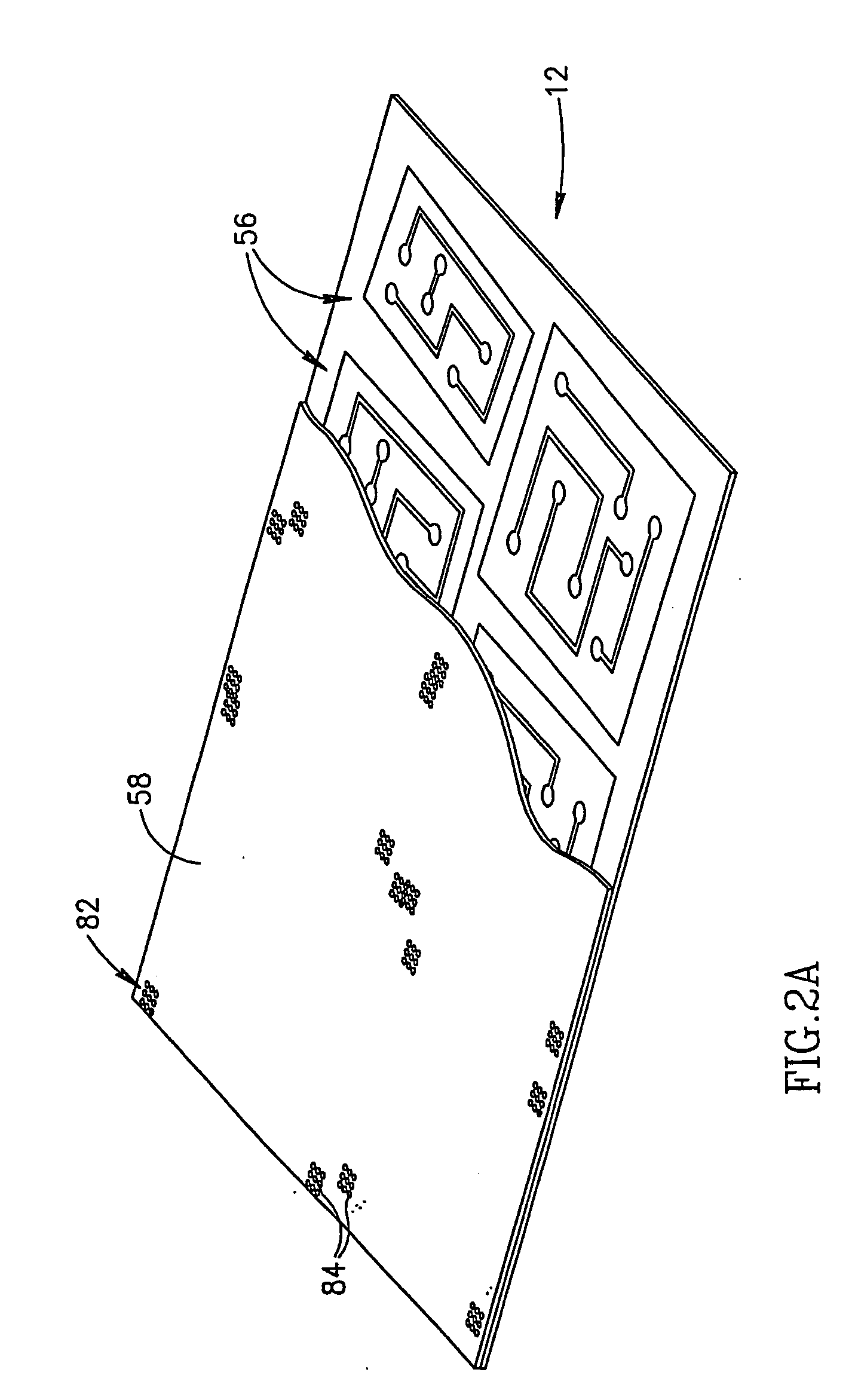

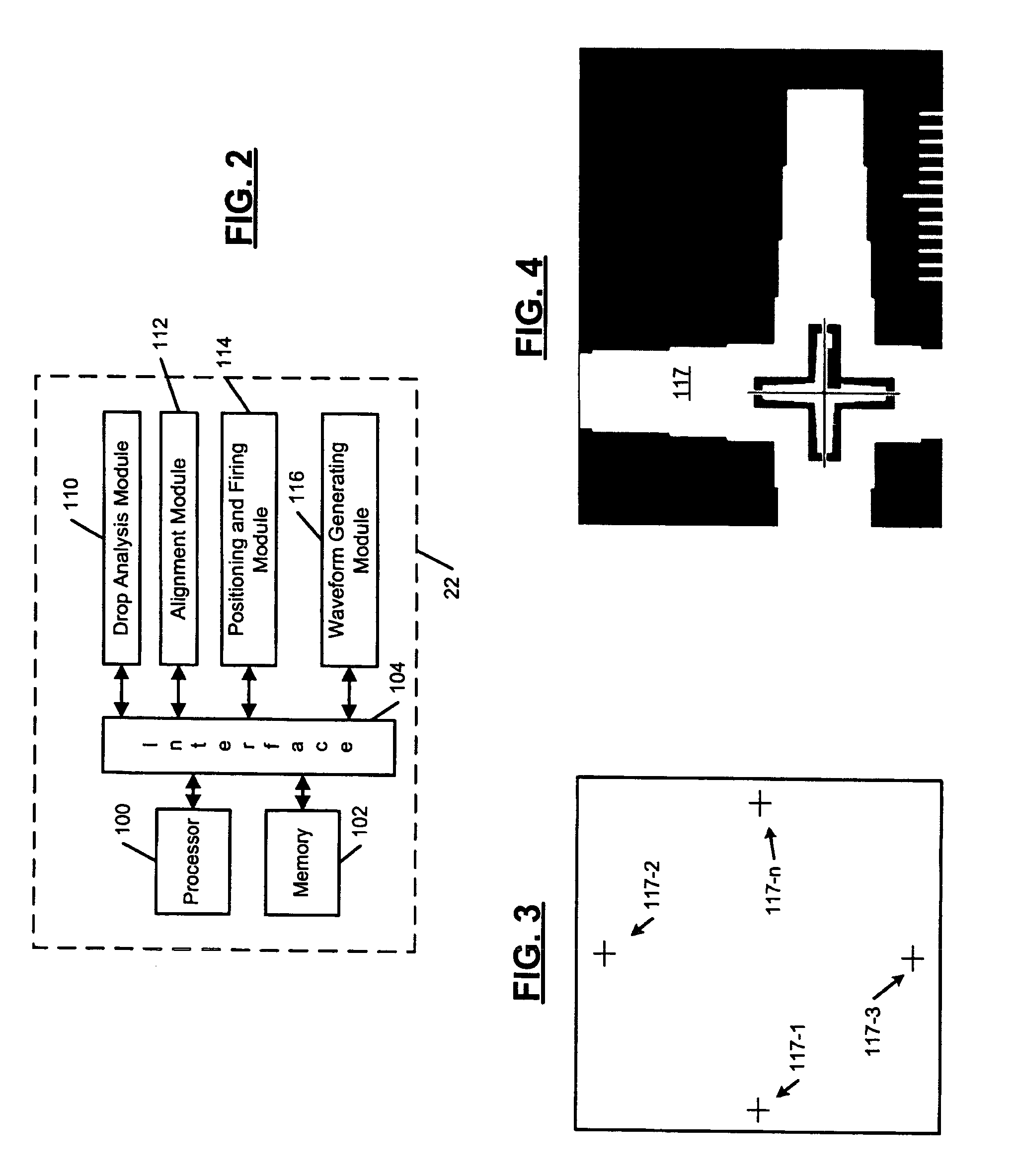

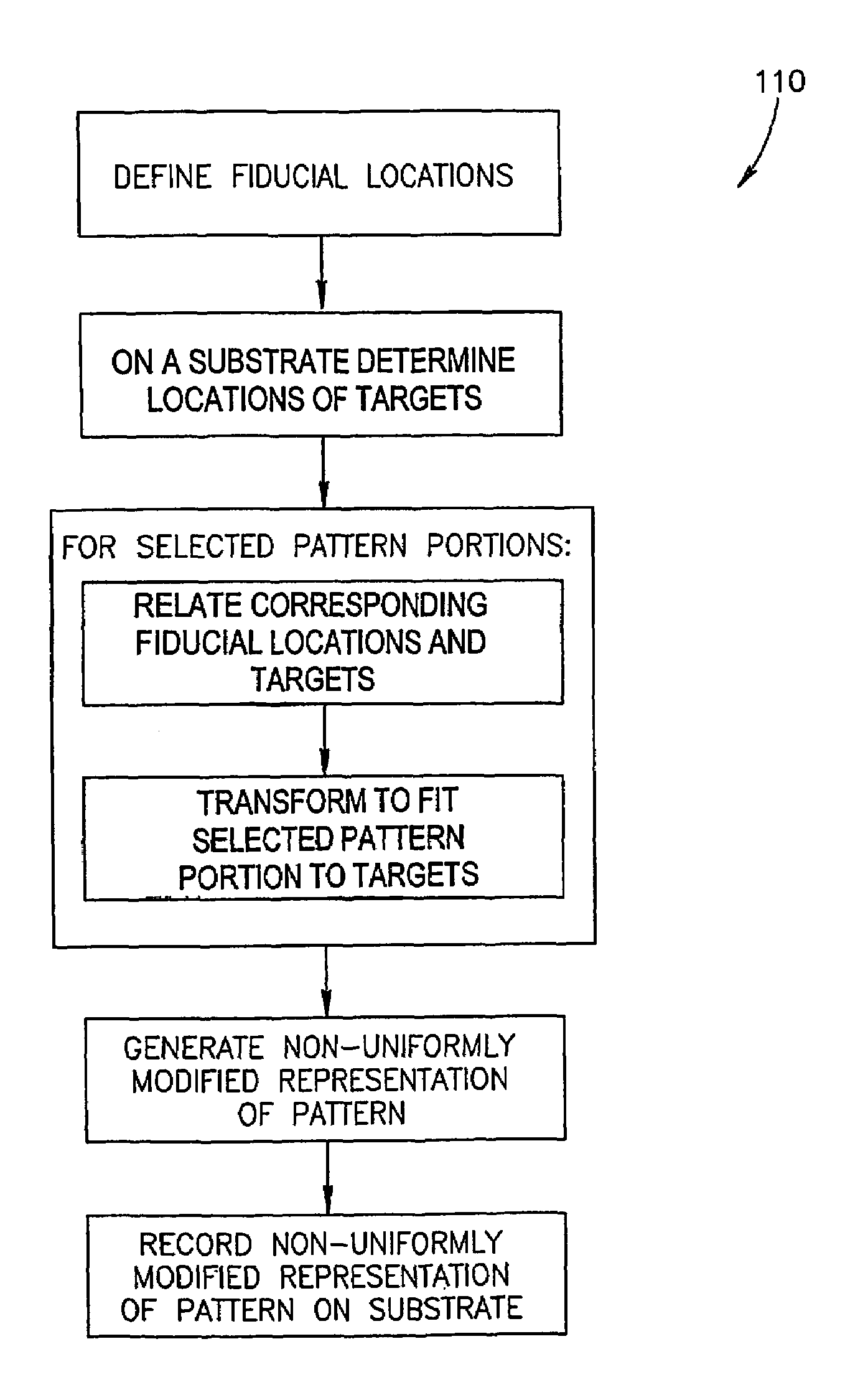

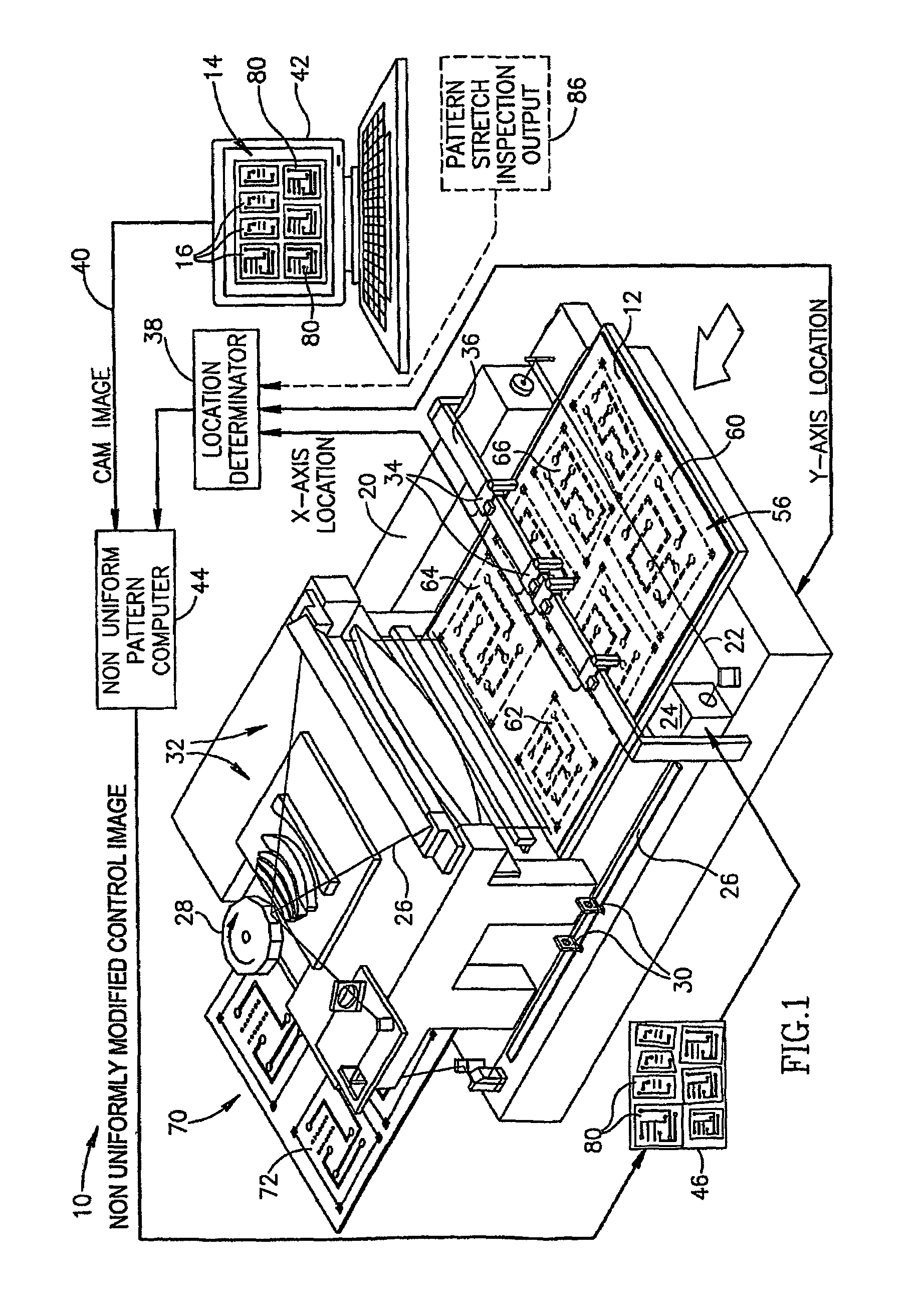

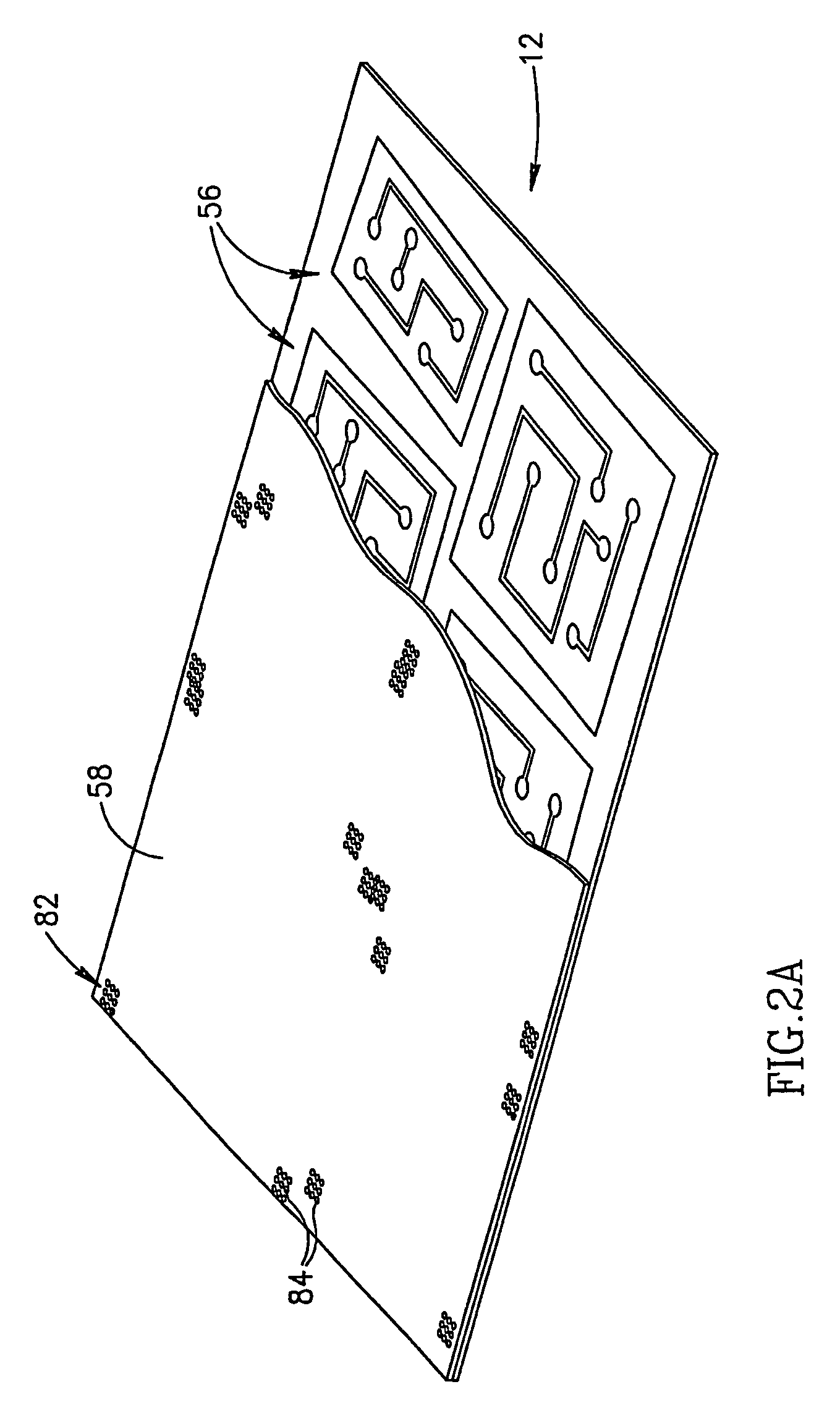

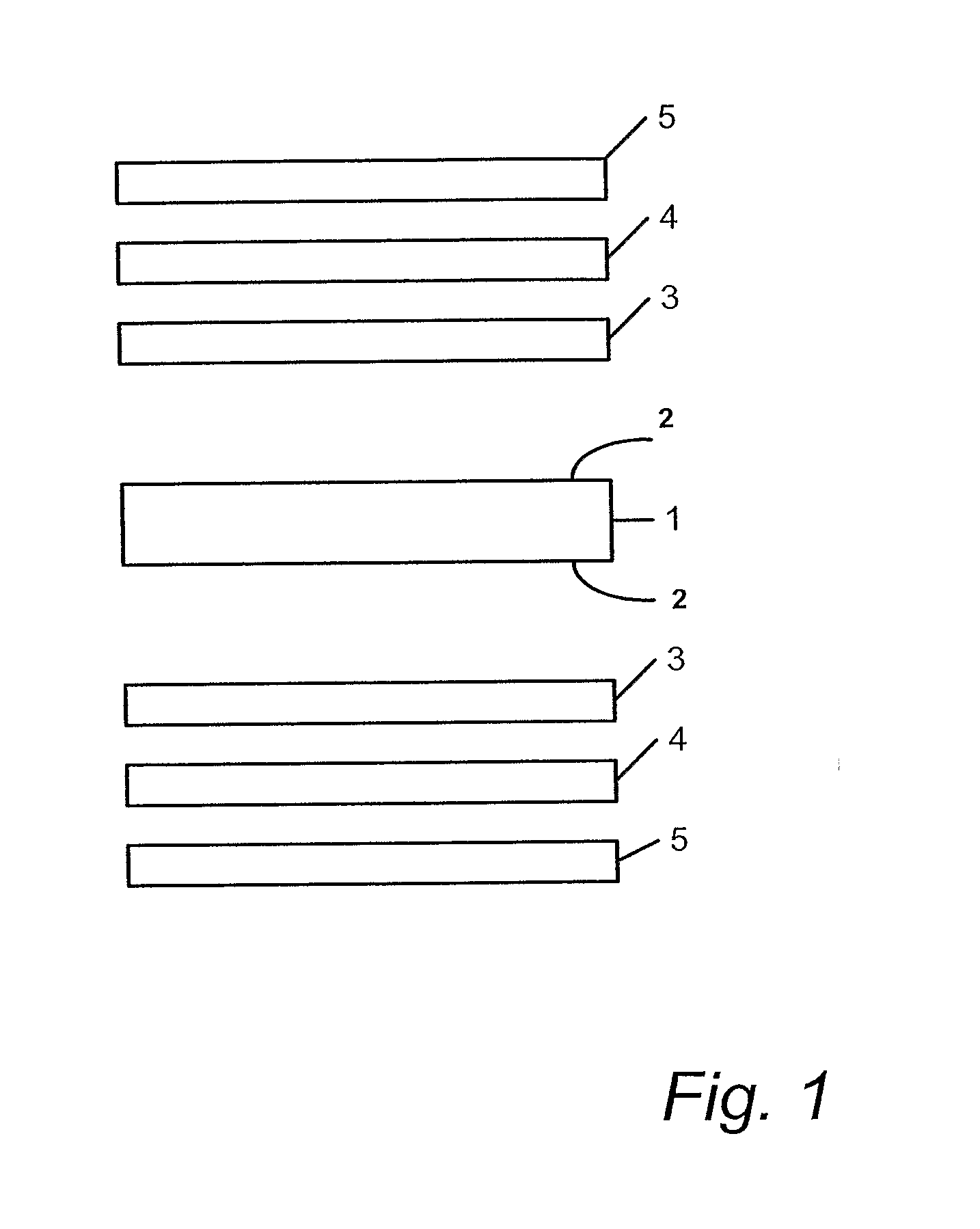

System and method for manufacturing printed circuit boards employing non-uniformly modified images

ActiveUS20050213806A1Non uniformCharacter and pattern recognitionCircuit board tools positioningEngineeringDigital control

A system and method for fabricating an electrical circuit in which a digital control image (46) is generated by non-uniformly modifying (44) a representation of an electrical circuit (40), such that an electrical circuit pattern (72) recorded on a substrate (12) using the digital control image (46) precisely fits an already formed electrical circuit portion (62).

Owner:ORBOTECH LTD

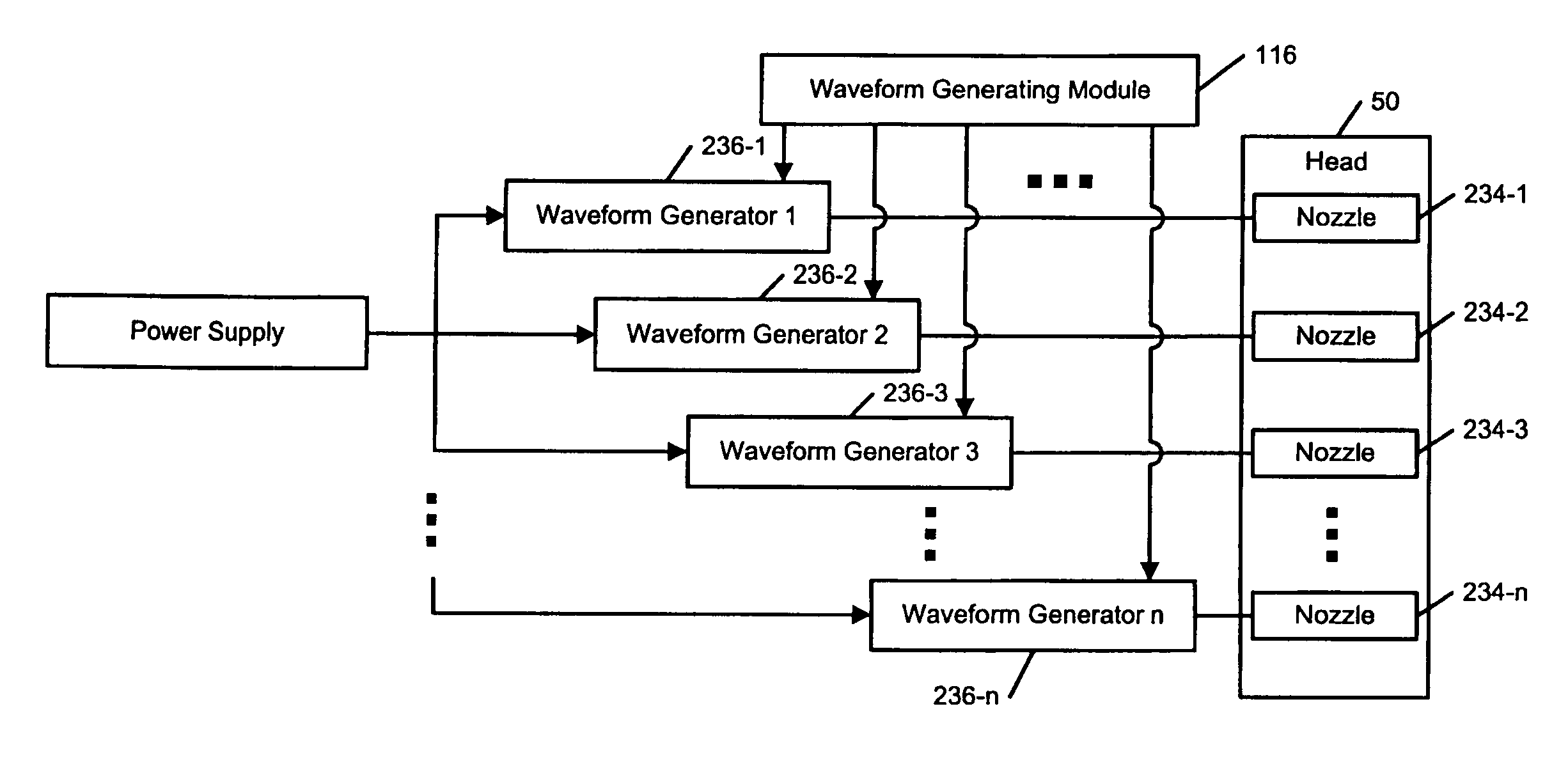

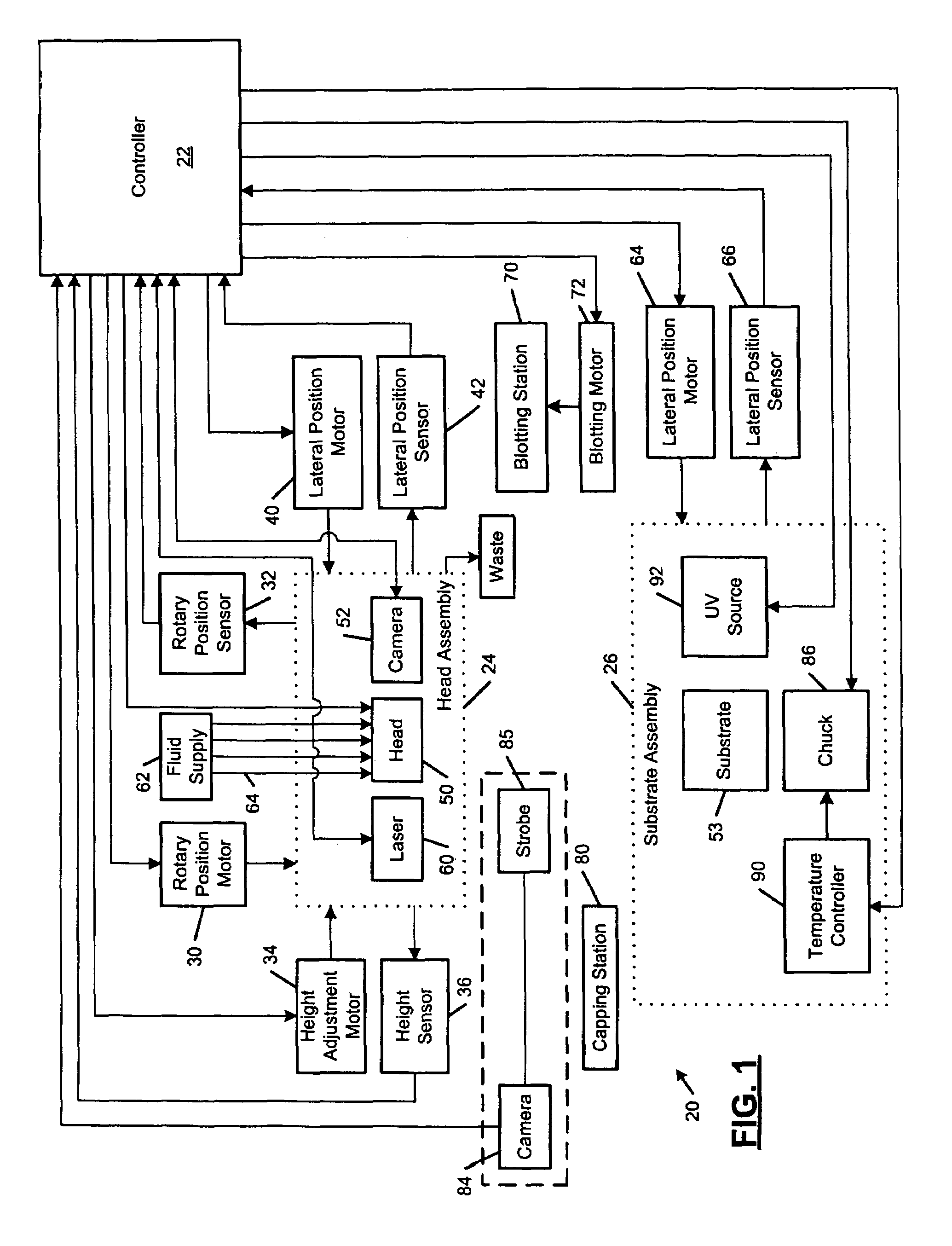

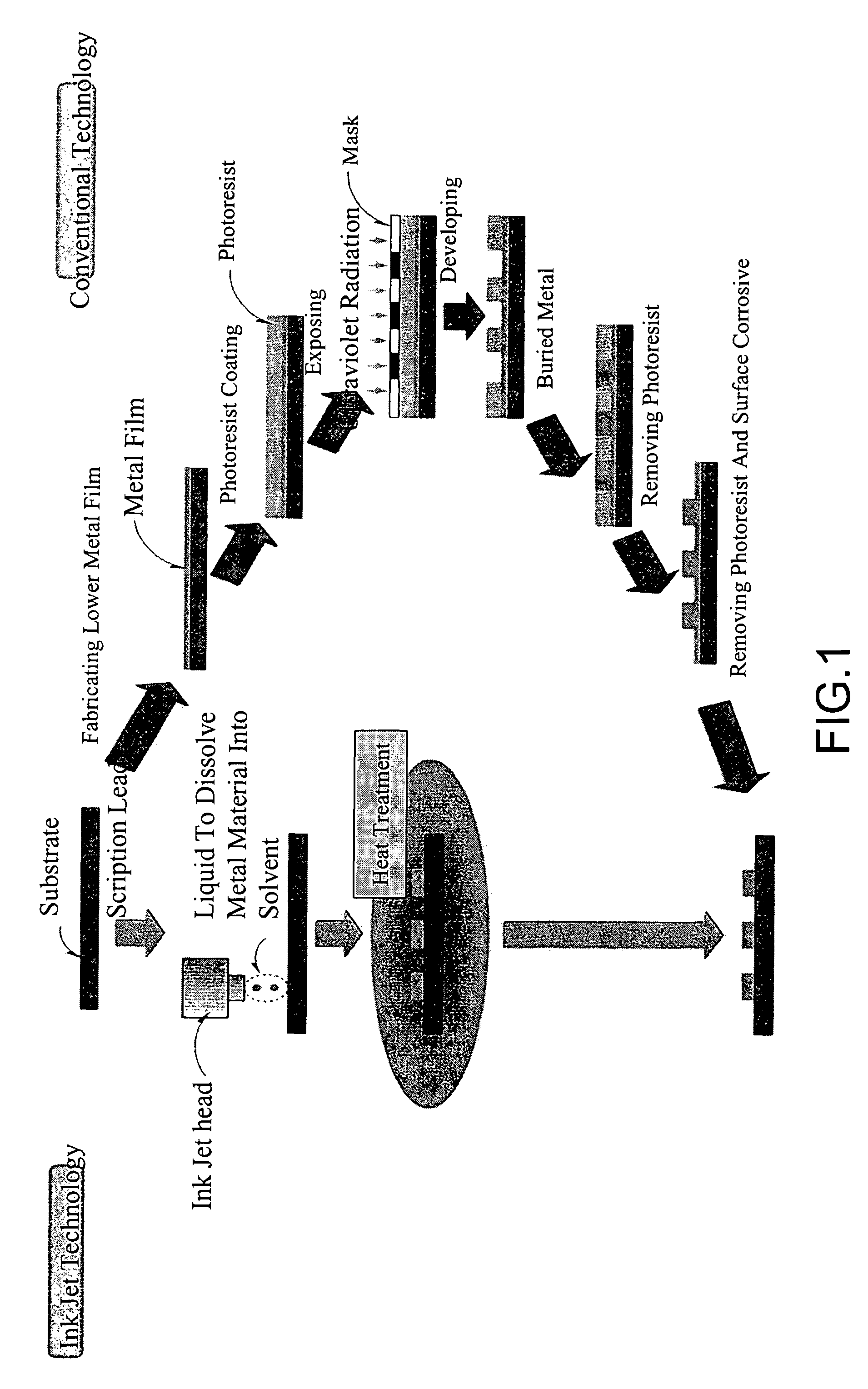

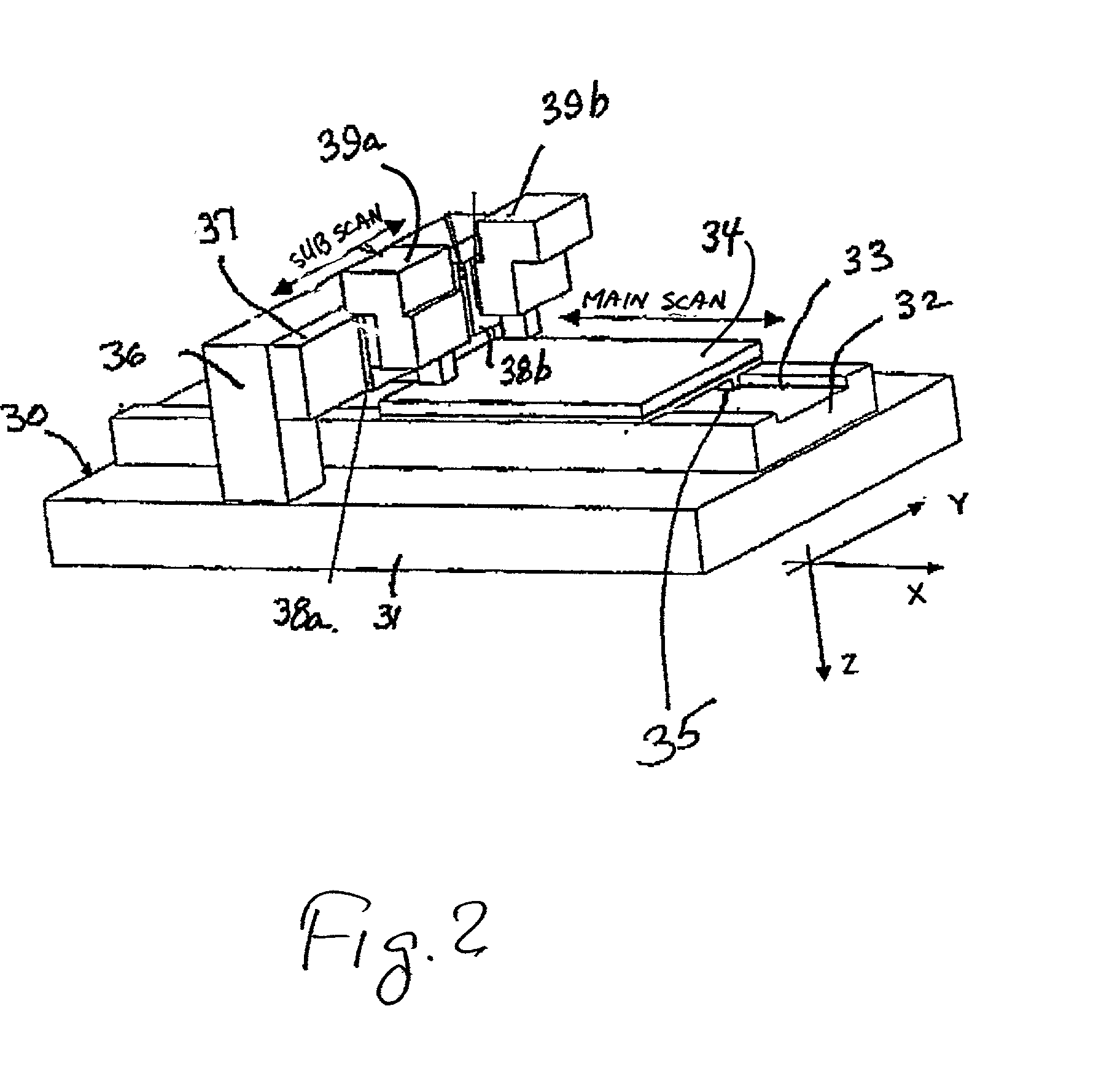

Industrial microdeposition system for polymer light emitting diode displays, printed circuit boards and the like

InactiveUS7270712B2Add featureCompensation changesInking apparatusSemiconductor/solid-state device detailsLED displayComputer module

A microdeposition system (20) and method deposits precise amounts of fluid material onto a substrate. A microdeposition head (50) includes a plurality of spaced nozzles. A positioning device controls a position of the microdeposition head relative to the substrate. A controller (22) includes a positioning module that communicates with the positioning device and that generates position control signals for the positioning device. A nozzle firing module communicates with the microdeposition head (50) and selectively generates nozzle firing commands to define features of at least one layer of an electrical device, such as resistors, traces and capacitors on a printed circuit board, polymer light emitting diodes, and light panels.

Owner:ULVAC INC

System and method for manufacturing printed circuit boards employing non-uniformly modified images

ActiveUS7508515B2Circuit board tools positioningCharacter and pattern recognitionEngineeringDigital control

A system and method for fabricating an electrical circuit in which a digital control image (46) is generated by non-uniformly modifying (44) a representation of an electrical circuit (40), such that an electrical circuit pattern (72) recorded on a substrate (12) using the digital control image (46) precisely fits an already formed electrical circuit portion (62).

Owner:ORBOTECH LTD

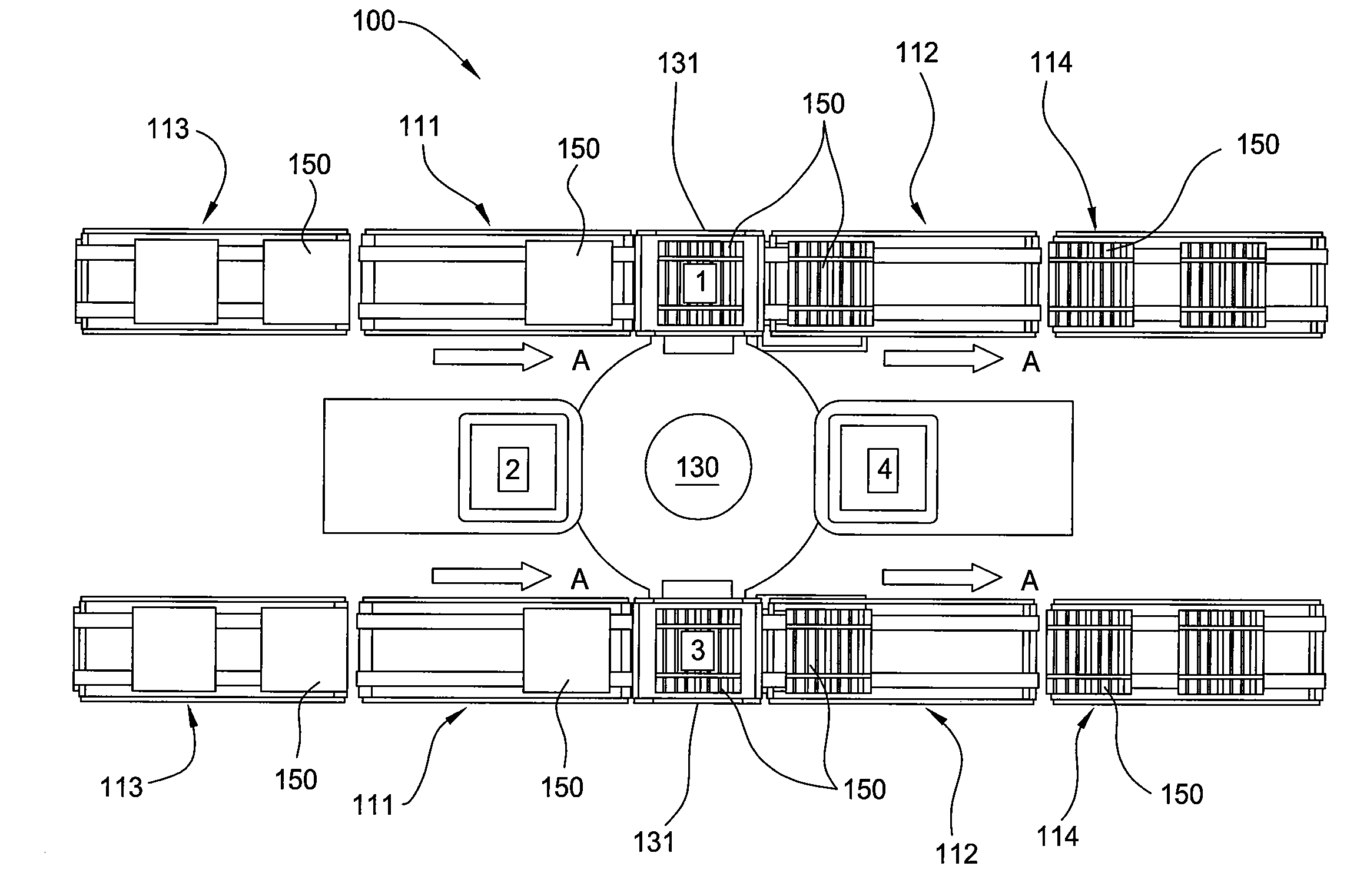

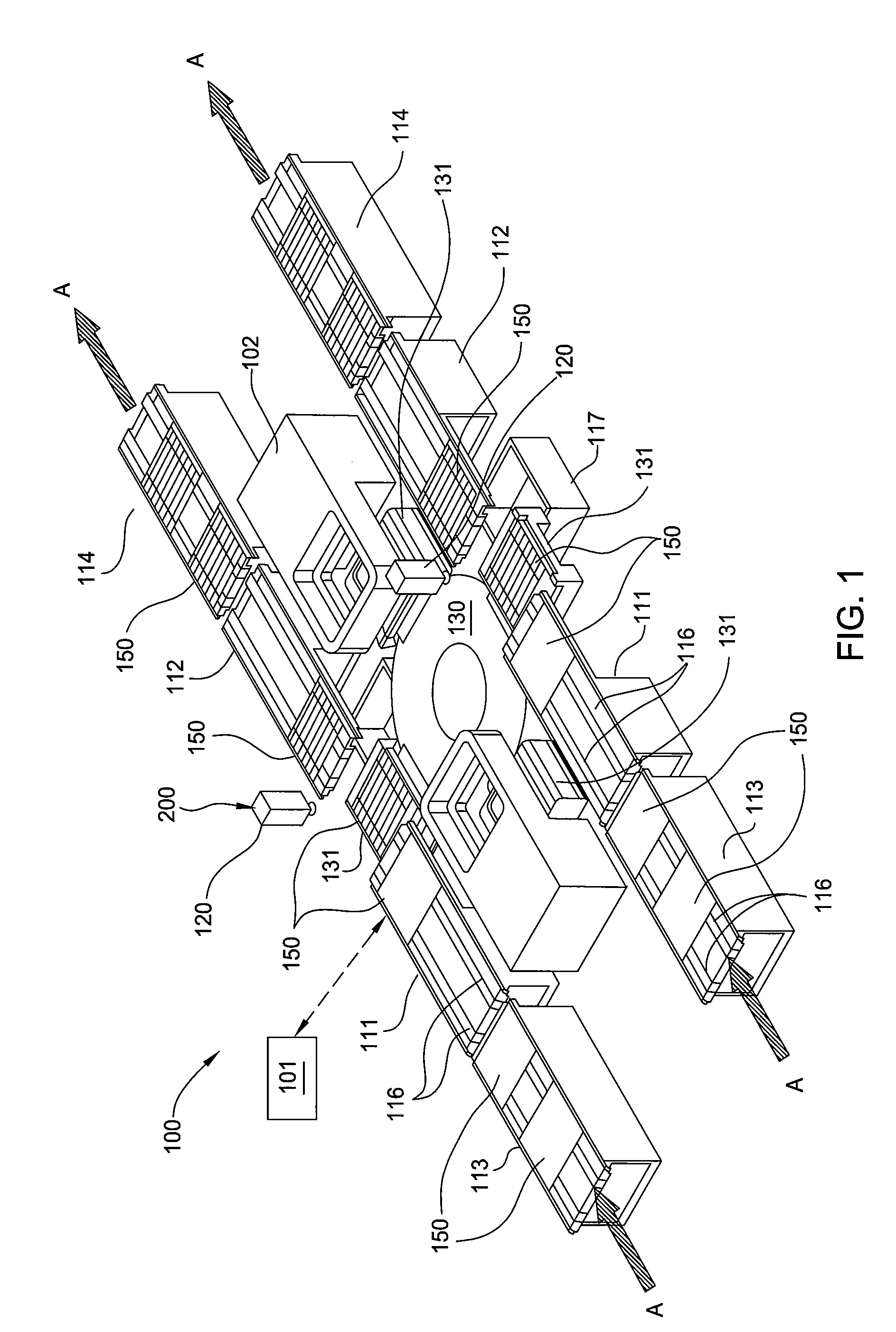

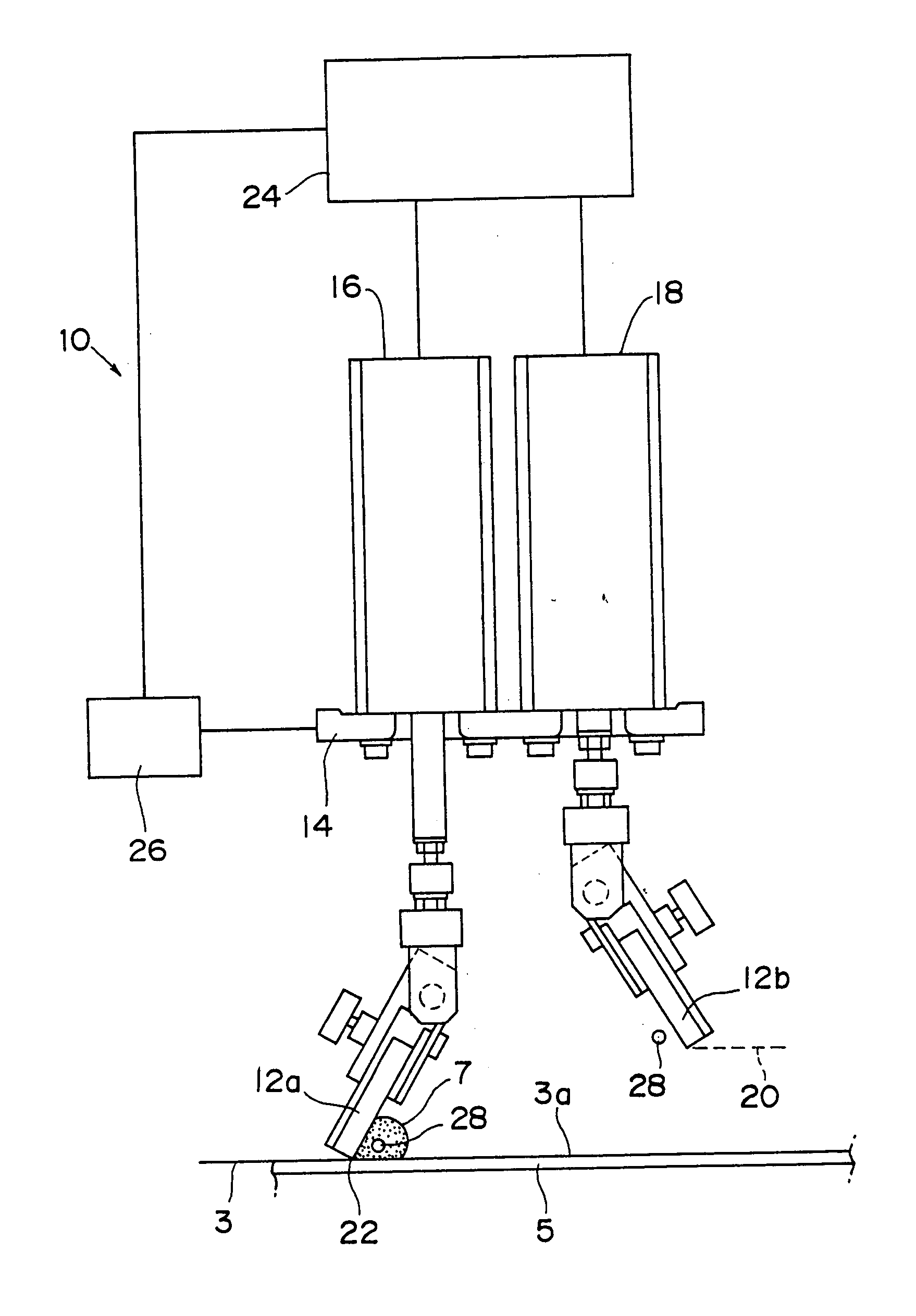

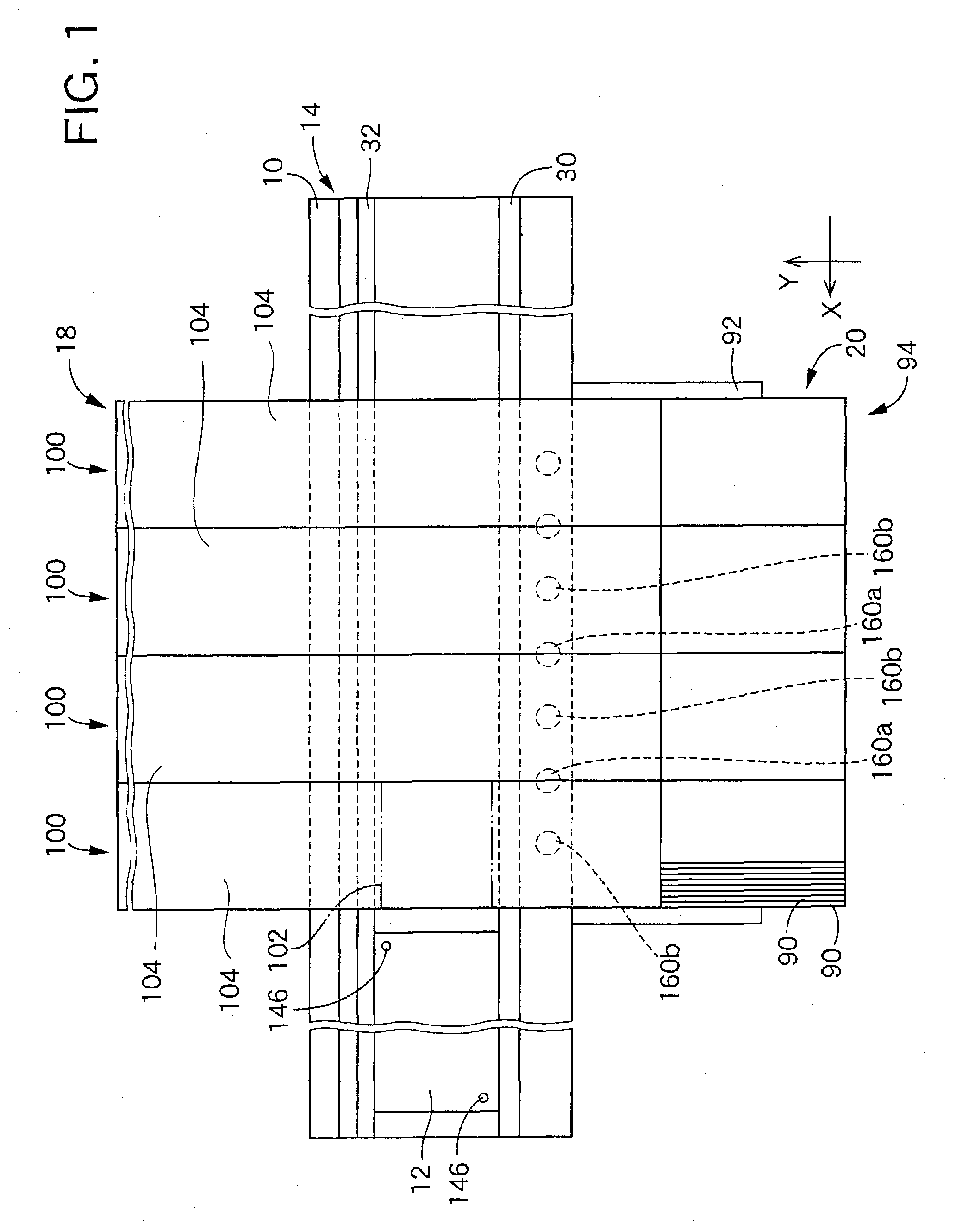

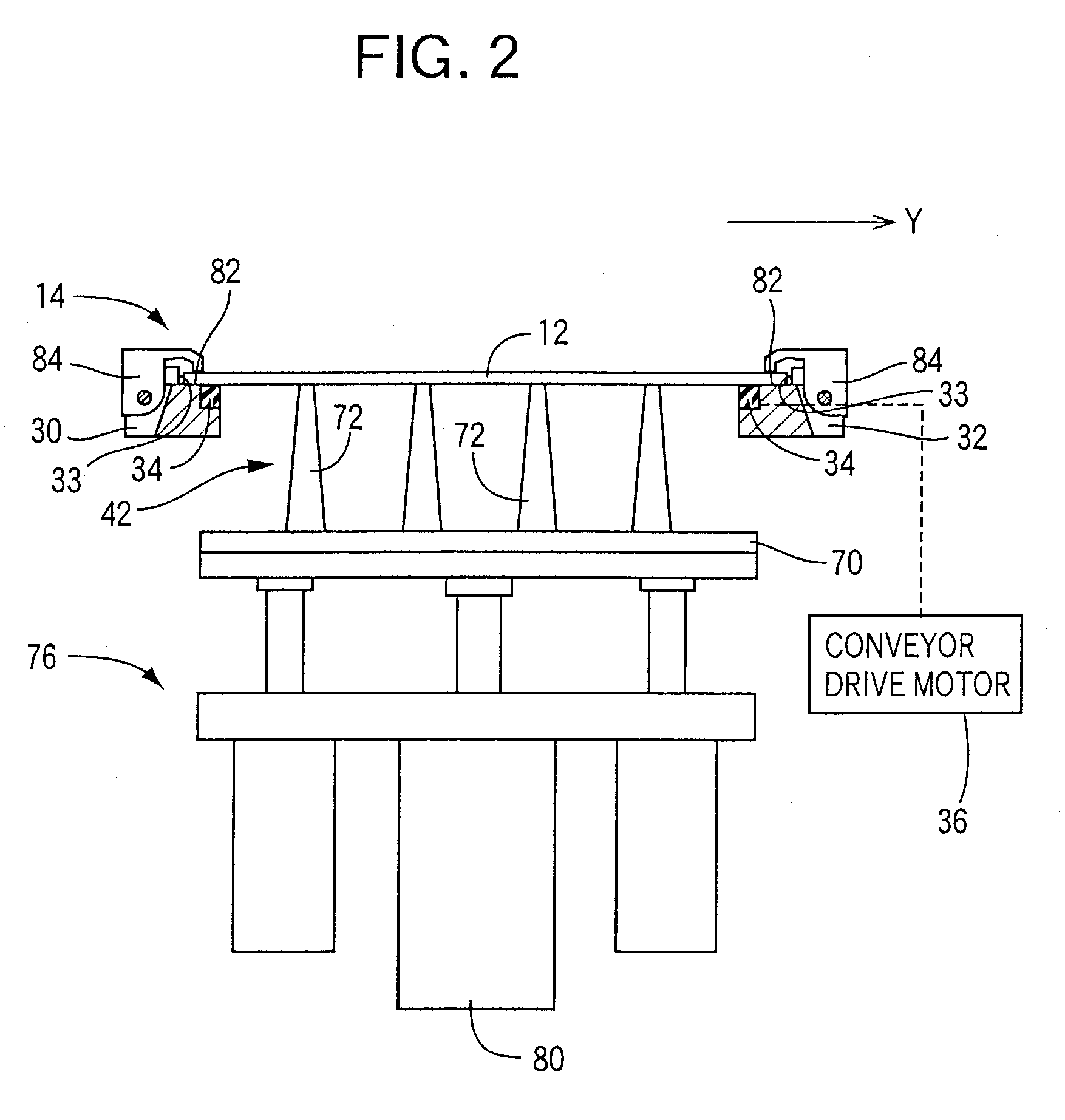

Accurate conveyance system useful for screen printing

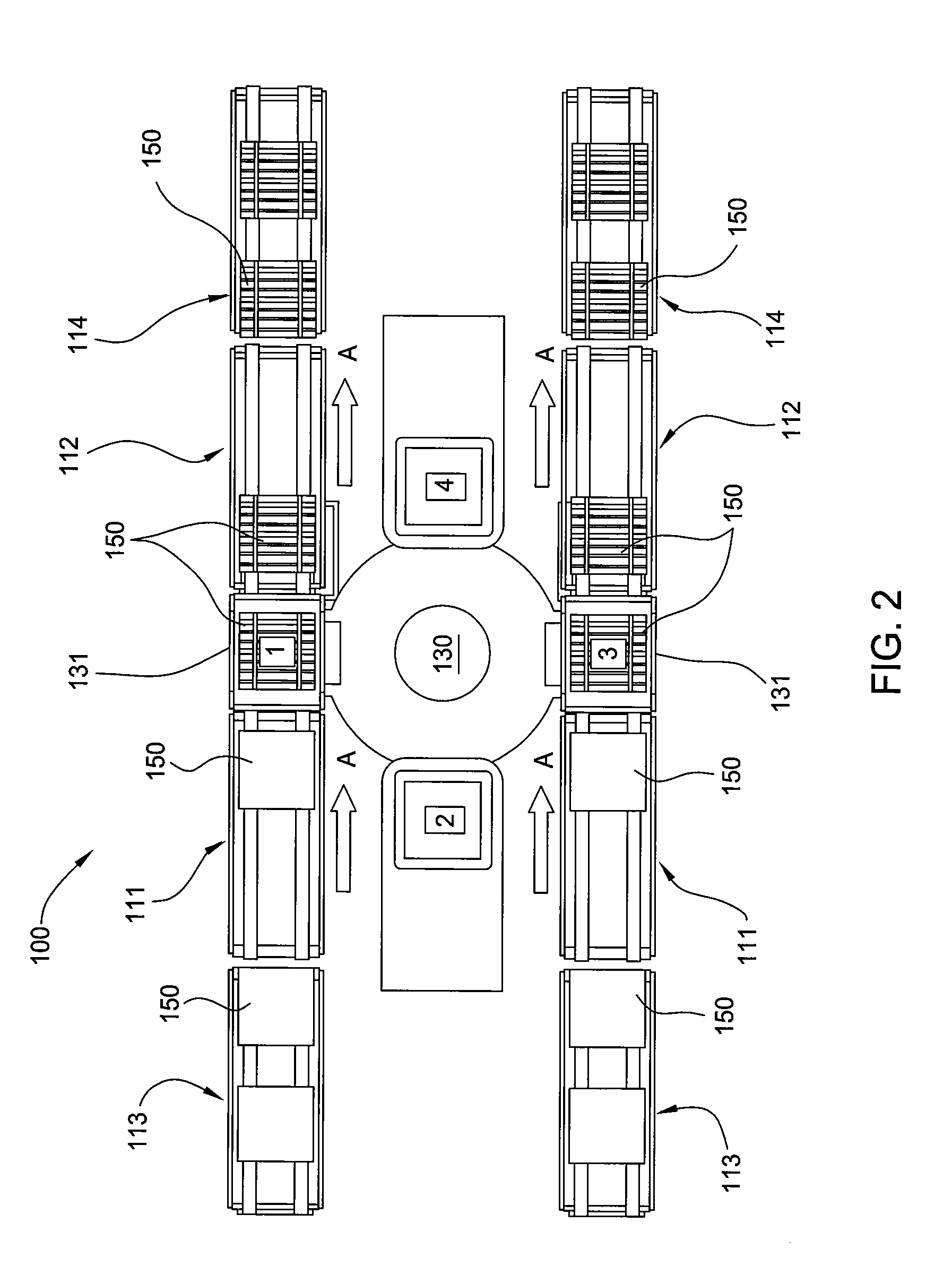

The present invention(s) provide an apparatus and method for processing substrates in a screen printing chamber that can deliver a repeatable and accurate screen printed pattern on one or more processed substrates. In one embodiment, the screen printing chamber is adapted to perform a screen printing process within a portion of a crystalline silicon solar cell production line in which a substrate is patterned with a desired material. In one embodiment, the screen printing chamber is a processing chamber positioned within the Rotary line tool or Softline™ tool available from Baccini S.p.A., which is owned by Applied Materials, Inc. of Santa Clara, Calif.

Owner:APPLIED MATERIALS INC

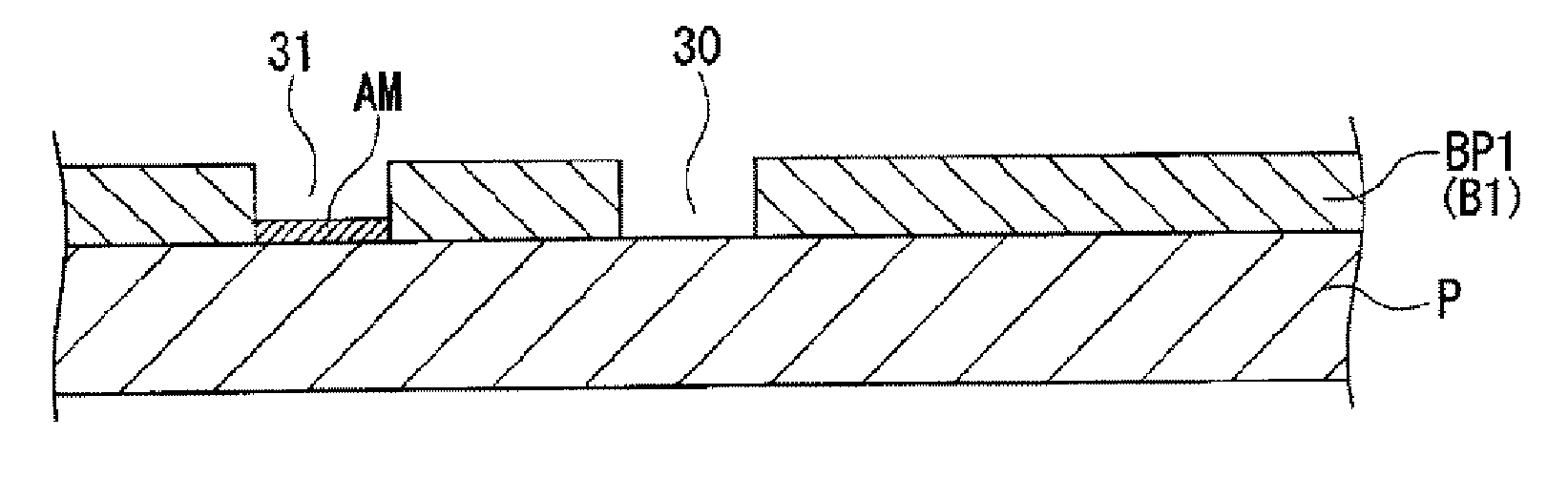

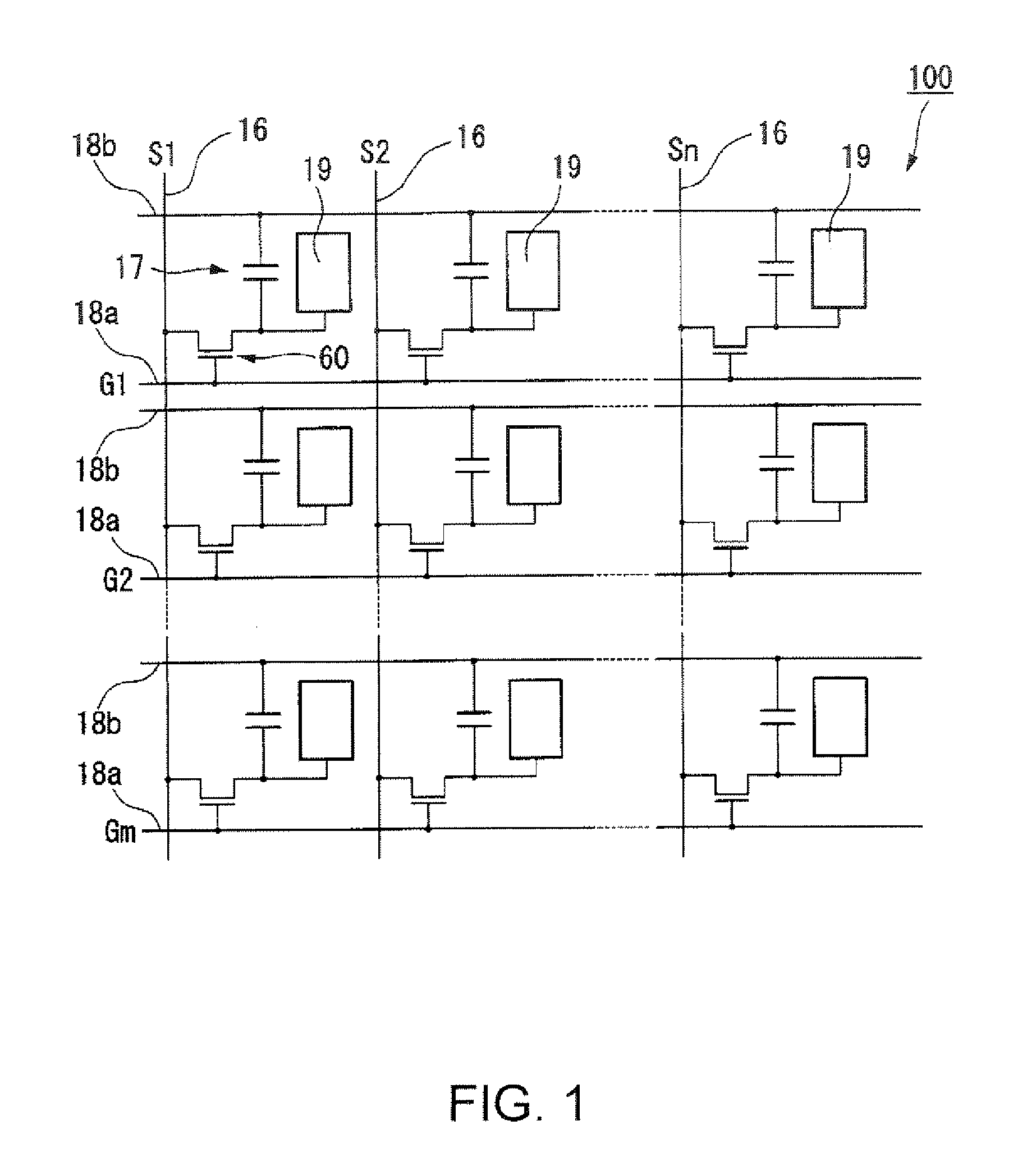

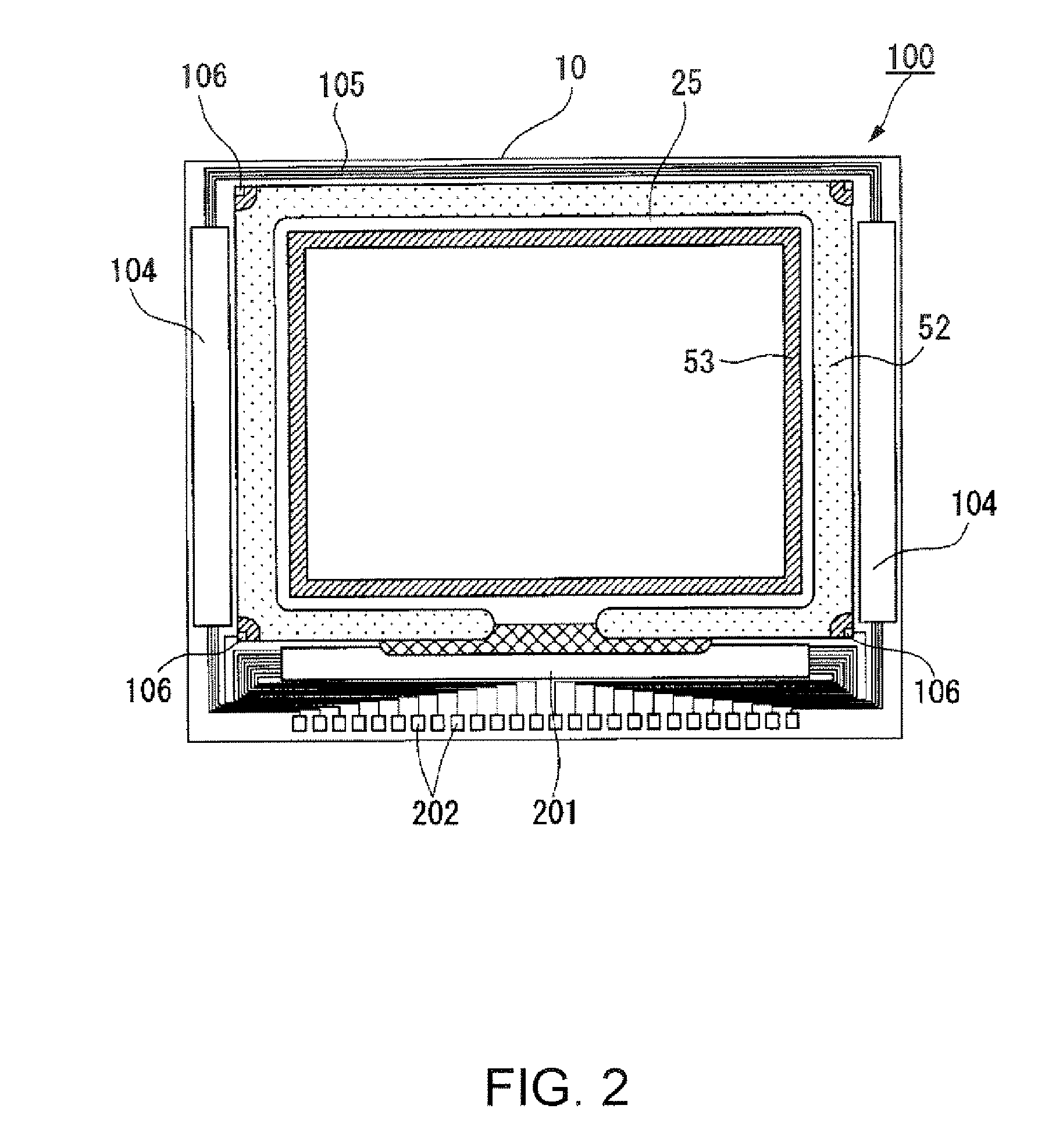

Method of forming pattern, film structure, electrooptical device and electronic equipment

InactiveUS20070099396A1Alignment precision is highLow transparencyPrinted circuit aspectsSolid-state devicesOptoelectronicsFilm structure

Owner:SEIKO EPSON CORP

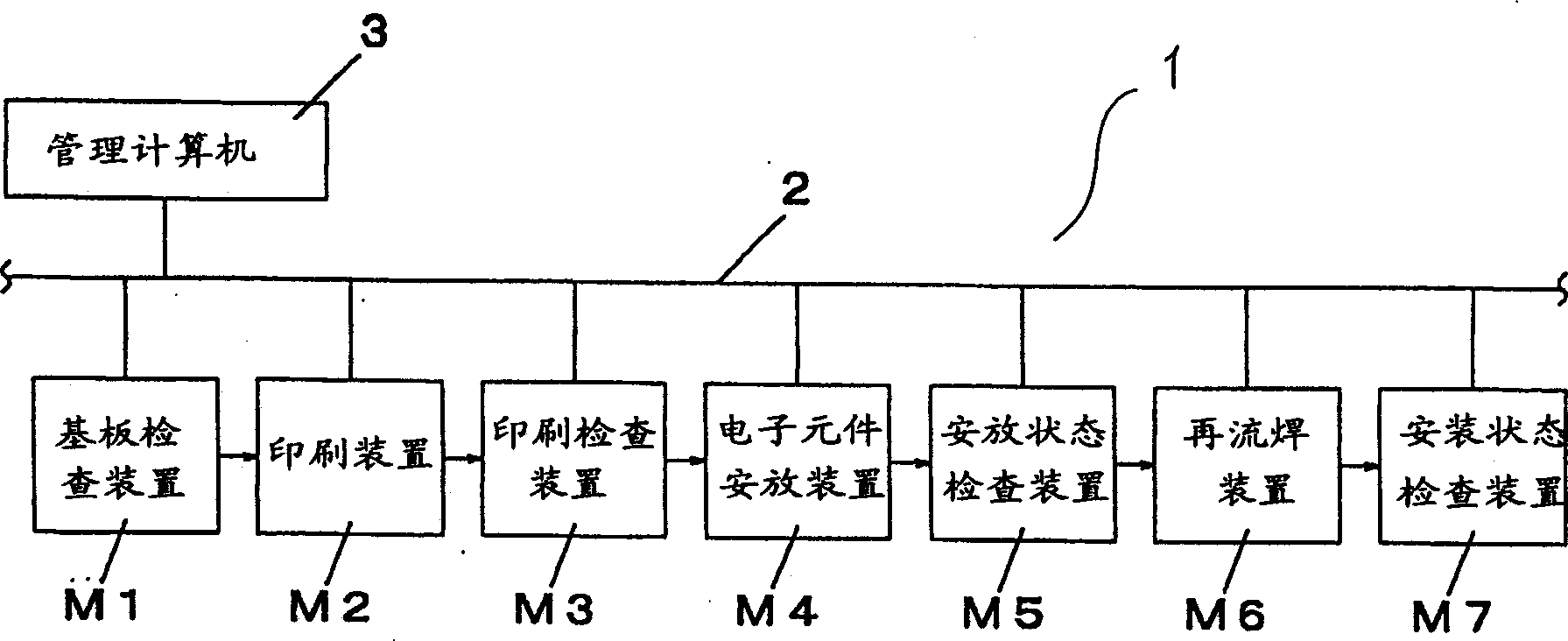

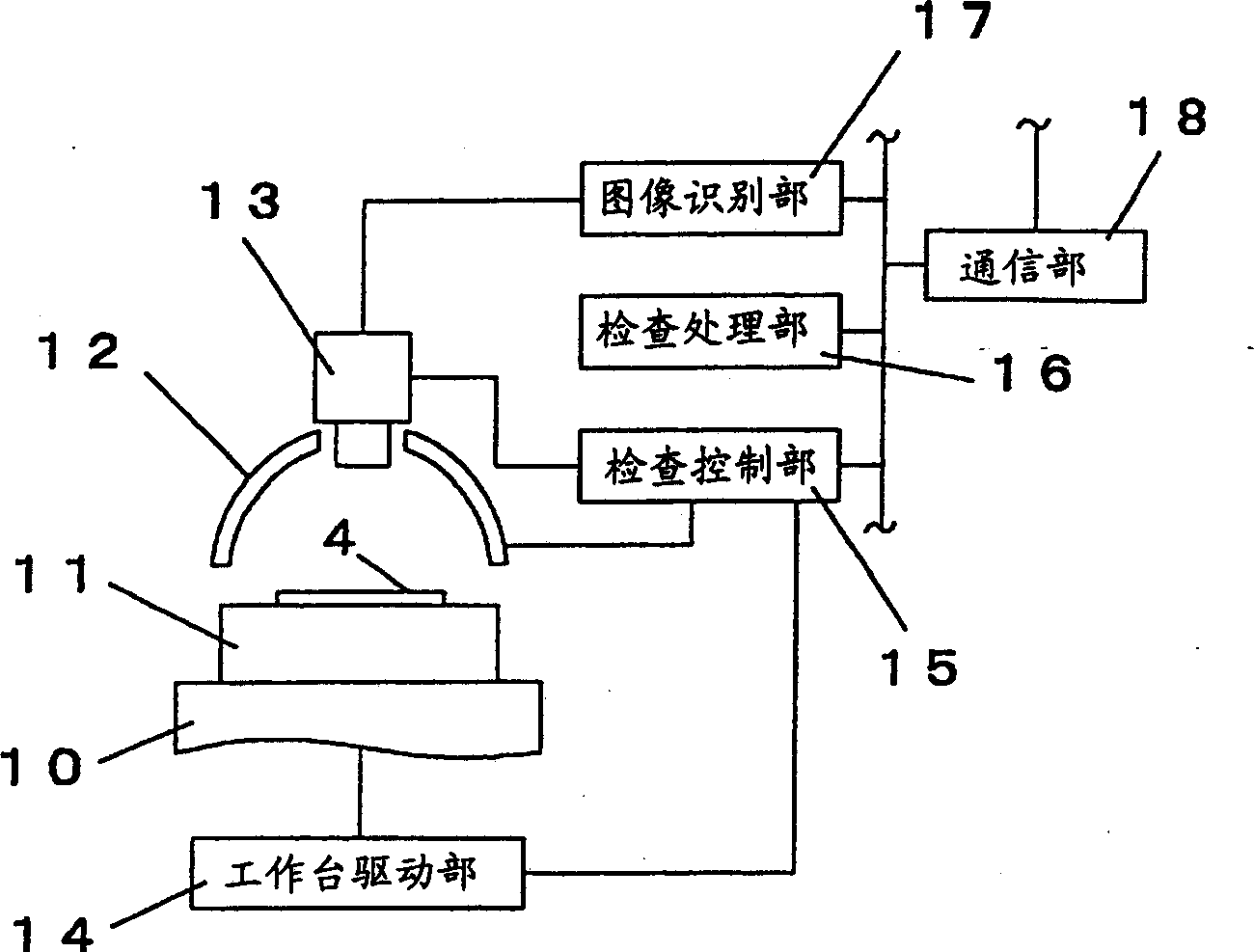

Element mounting system and mounting method

InactiveCN1350421AAccurate and effective quality managementAvoid wastingCircuit board tools positioningInspection/indentification of circuitsLocation detectionUnit operation

A component mounting system which includes a printer for printing solder on electrodes formed on a board; a first inspection unit for detecting positions of printed solder and outputting solder position detection results; a component mounting unit for picking up components from a component feeder carriage and placing the components on the board using mounting heads; a second inspection unit for inspecting positions of the components placed and outputting component position detection results; a soldering unit for soldering the components onto the board by heating and melting solder; and a main controller for updating at least a control parameter for controlling the printer operation or a control parameter for the component mounting unit operation based on at least the solder position detection results or component position detection results. The above configuration enables the accurate and efficient quality control throughout the mounting process.

Owner:PANASONIC CORP

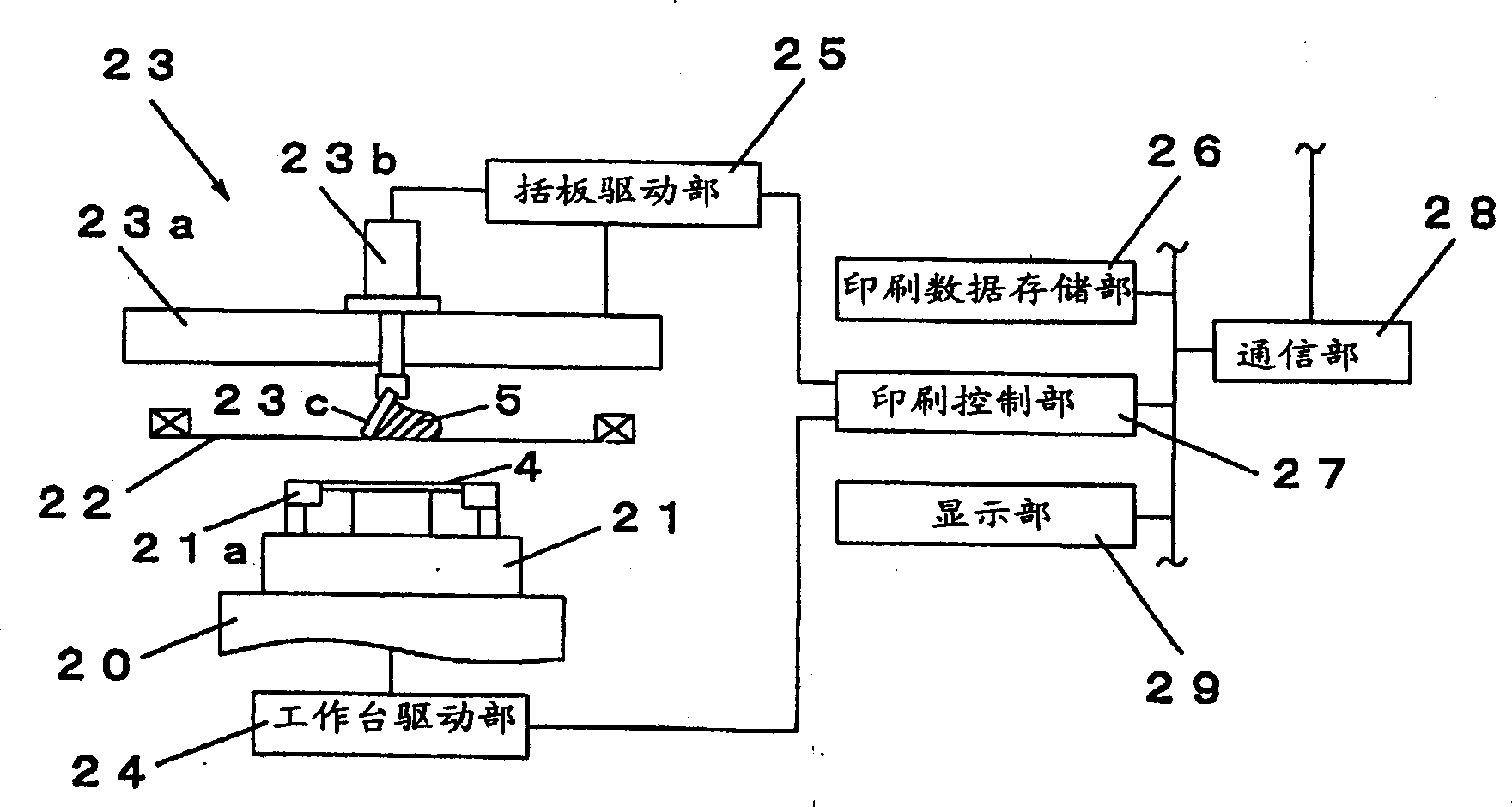

Solder past printing apparatus and printing method

InactiveUS20040108368A1Evenly filledTakingLiquid surface applicatorsScreen printersEngineeringSolder paste

When solder paste passes through a first gap (34) located between a pressurizing member (28) and a printing mask (3) during solder paste printing, a pressure directed toward the printing mask is applied from the pressurizing member to the solder paste.

Owner:PANASONIC CORP

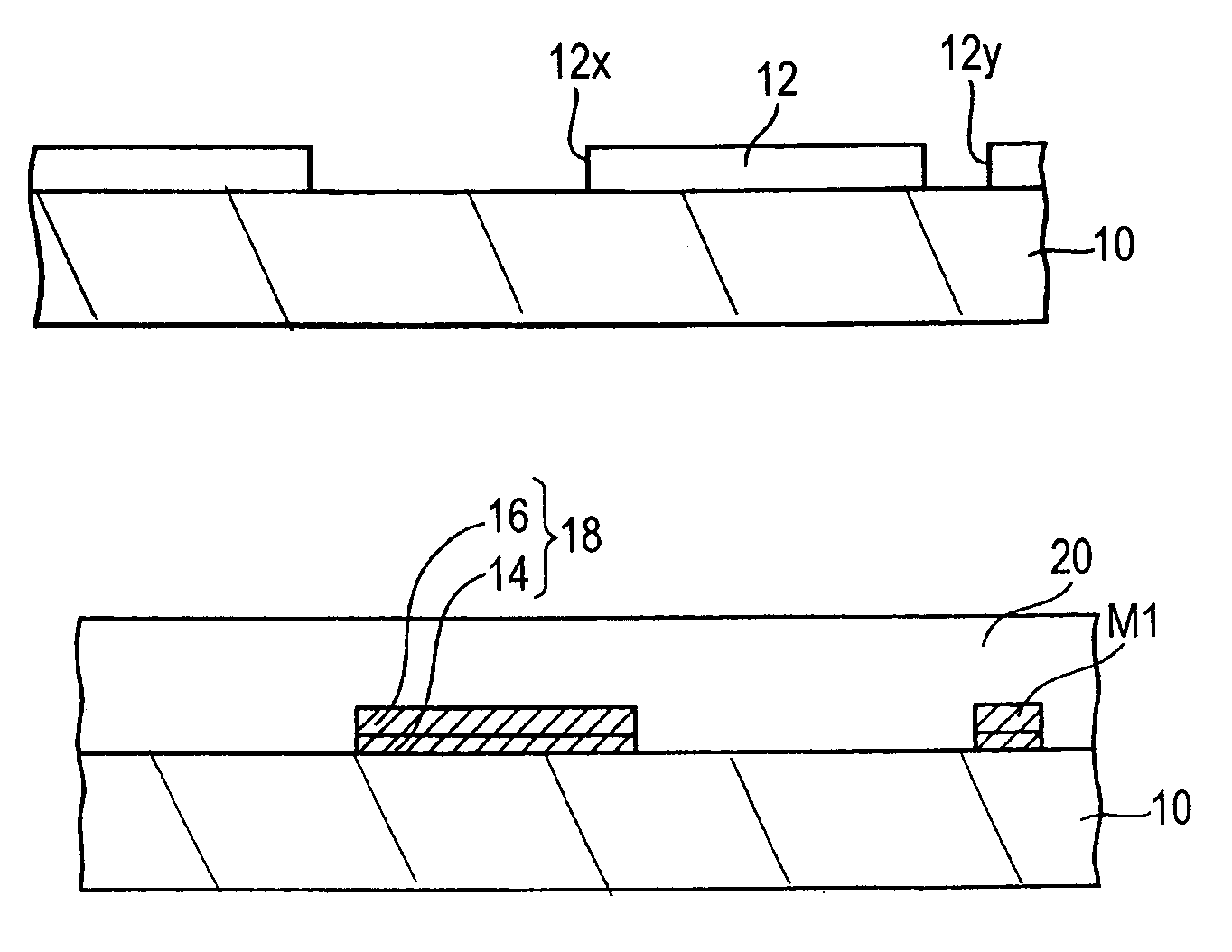

Method of manufacturing flexible circuit substrate

InactiveUS20060223236A1Improve responseIncrease the number ofPaper-money handling devicesSemiconductor/solid-state device detailsFlexible circuitsMetal sheet

Connection pads and alignment marks are formed on a long metal thin plate that is carried in a longitudinal direction, and then an insulating layer for covering the connection pads is formed. Then, via holes, which are aligned and arranged on the connection pads by utilizing the alignment marks, are formed in portions of the insulating layer. Then, n-layered (n is an integer of 1 or more) wiring layers connected to the connection pads via the via holes are formed, and the connection pads and the insulating layer are exposed by removing the metal thin plate.

Owner:SHINKO ELECTRIC IND CO LTD

Solder paste printing apparatus and printing method

InactiveUS20040035306A1TakingReduce printing timeMechanical cleaningInking apparatusEngineeringPrinting ink

When solder paste passes through a first gap (34) located between a pressurizing member (28) and a printing mask (3) during solder paste printing, a pressure directed toward the printing mask is applied from the pressurizing member to the solder paste.

Owner:PANASONIC CORP

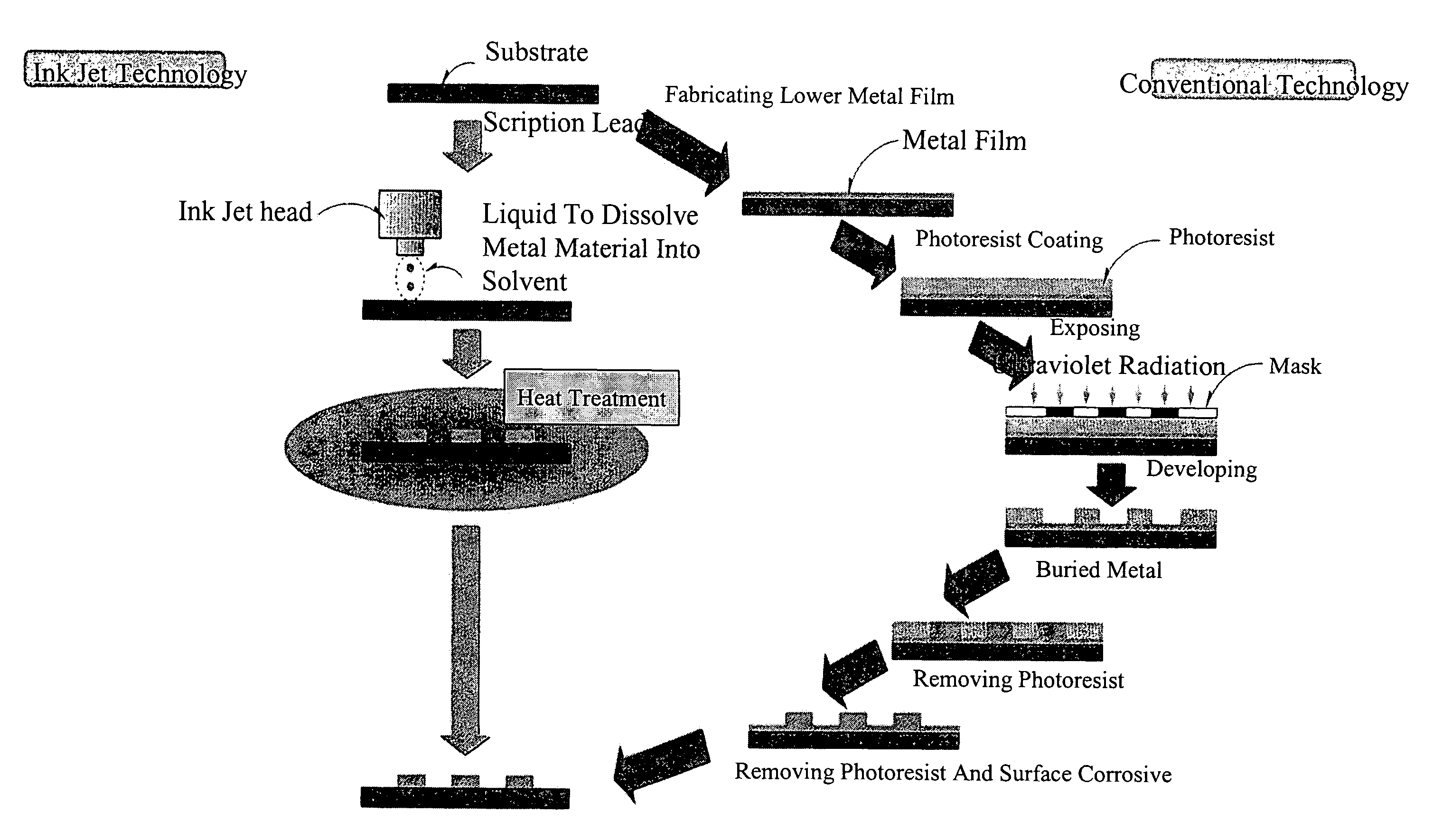

Pattern printing system and data processing method thereof

ActiveUS8248656B2Digitally marking record carriersSemiconductor/solid-state device manufacturingImage resolutionDisplay device

A pattern printing system and data processing method thereof are disclosed, which are suitable for printing patterns on printed circuit boards or data format rearrangement printing used in displays. The pattern printing method includes a process for interpreting scription data into matrix data, a procedure for modulating the print head resolution and the printing resolution, a procedure for interpreting and transmitting data commands, a procedure for rearranging memory data, and a procedure for firing data synchronously so as to achieve high-resolution printing and to continuously modulate any print data.

Owner:IND TECH RES INST

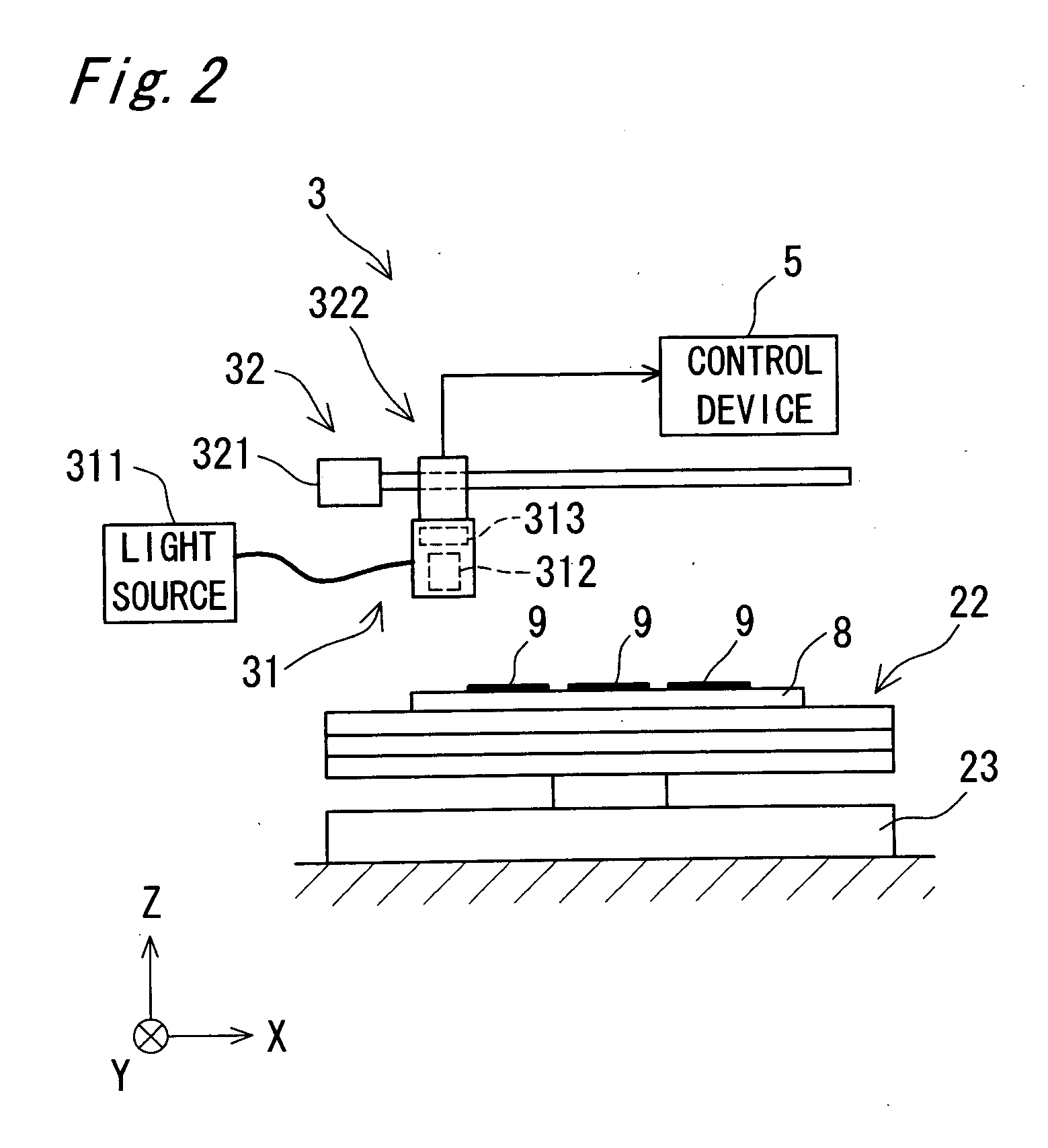

Method and apparatus for laser processing

InactiveUS7834293B2Reduce eliminateShorten the timeSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLight beam

Owner:ELECTRO SCI IND INC

Method and program for obtaining positioning errors of printed-wiring board, and electronic-circuit-component mounting system

InactiveUS7036215B2High positioning accuracyEasy to understandPrinted circuit assemblingLine/current collector detailsComputer hardwareComputer science

Owner:FUJI CORP

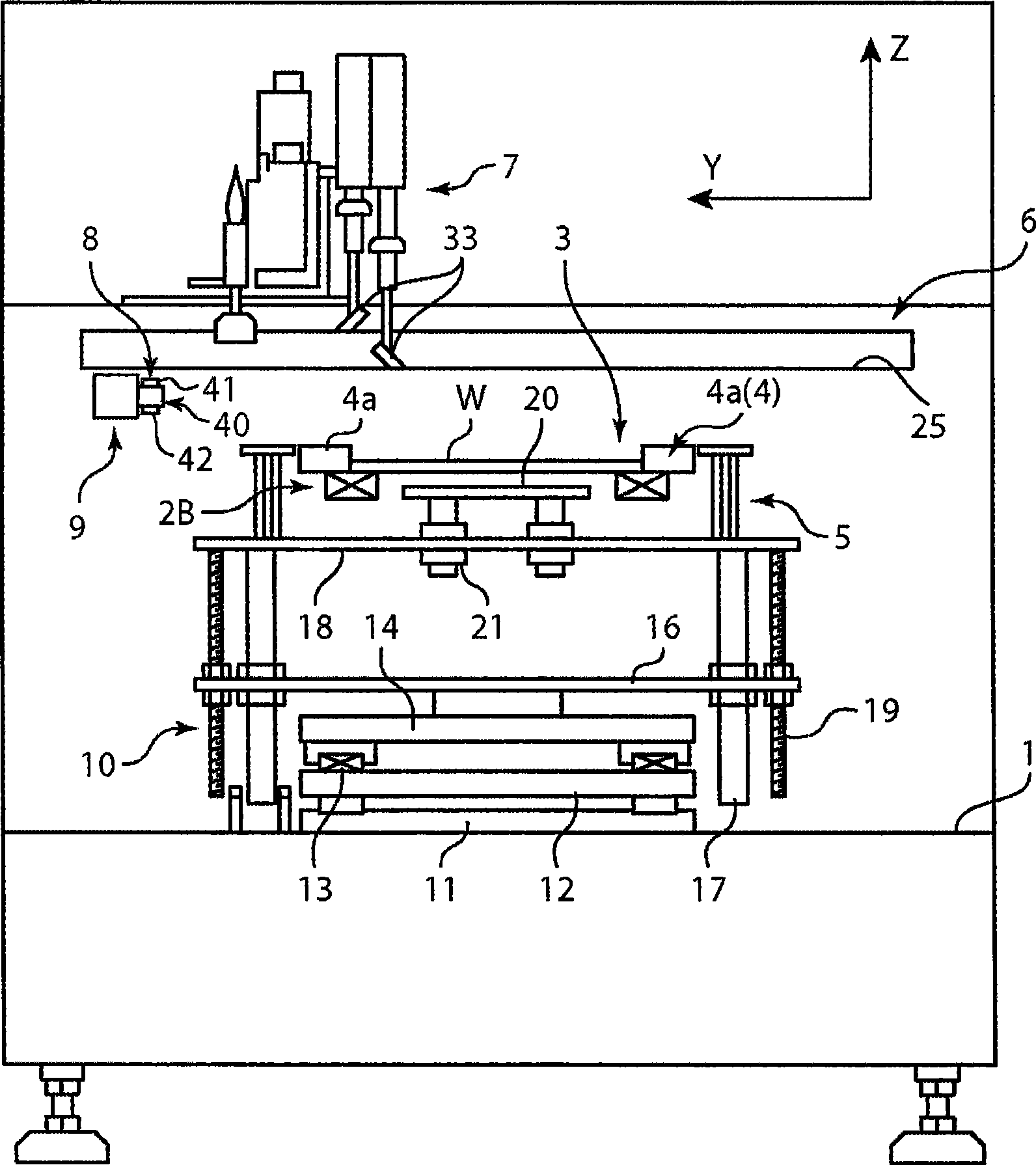

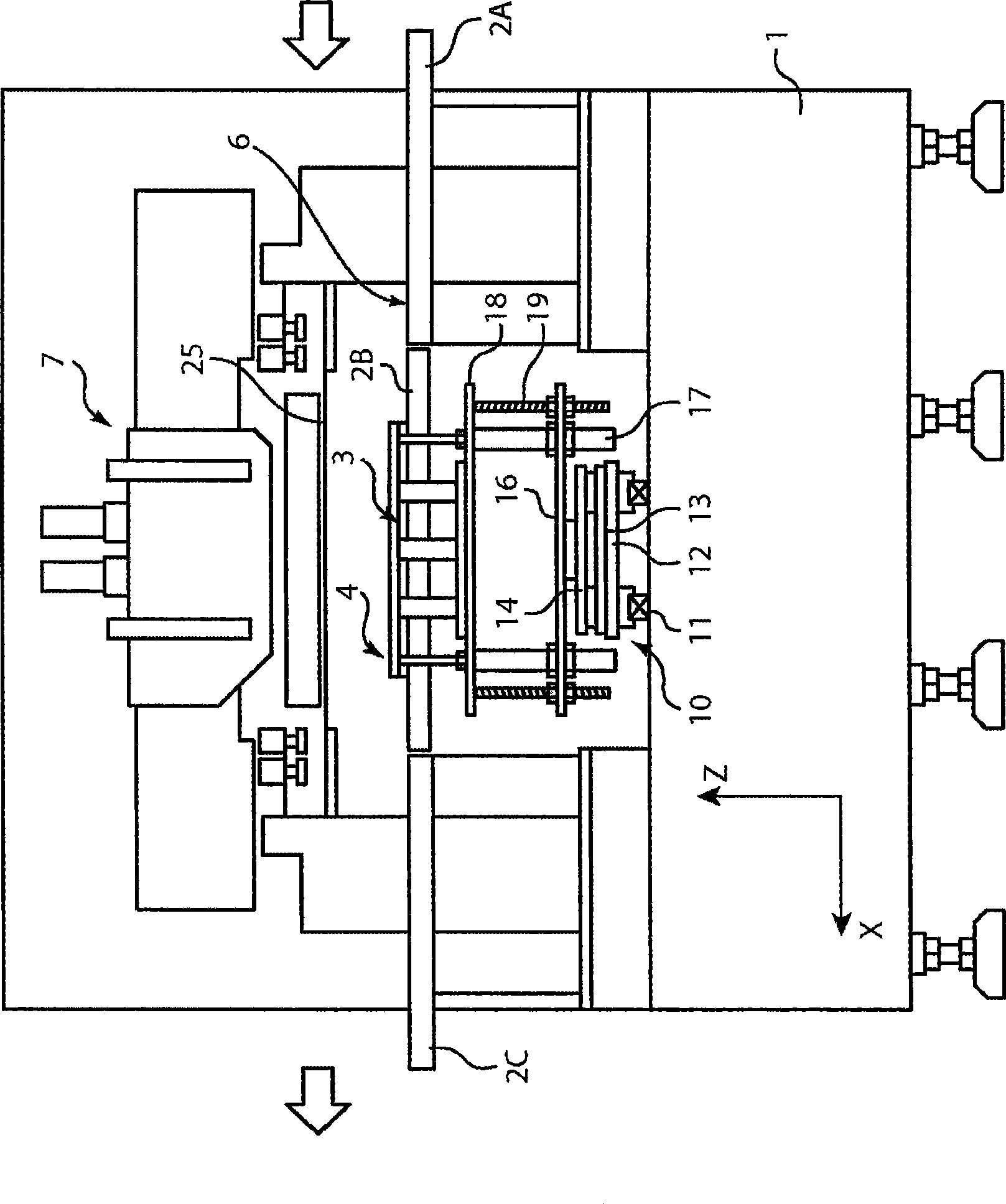

Position matching method and screen printer

The invention relates to a position matching method for a screen printing device and a screen printing device. The screen pringting device includes a mask sheet (25), a movable printing stage (3), a camera head (40) having a mask recognition camera (41) and a substrate recognition camera (42), and a controller for controlling them. The controller executes mark recognition of the substrate (W) by using the substrate recognition camera (42). The camera head (40) is driven / controlled so as to execute mask recognition of the mask sheet (25) periodically by using the recognition camera (41) while the same mask sheet is used. Moreover, according to the latest mask position information acquired by the mark recognition of the mask sheet (25) and the substrate position information, the controller obtains a correction amount based on the position shift between the mask sheet (25) and the substrate (W) and drives / controls the printing state (3) according to the correction amount so as to mount the substrate (W) on the mask sheet (25).

Owner:YAMAHA MOTOR CO LTD

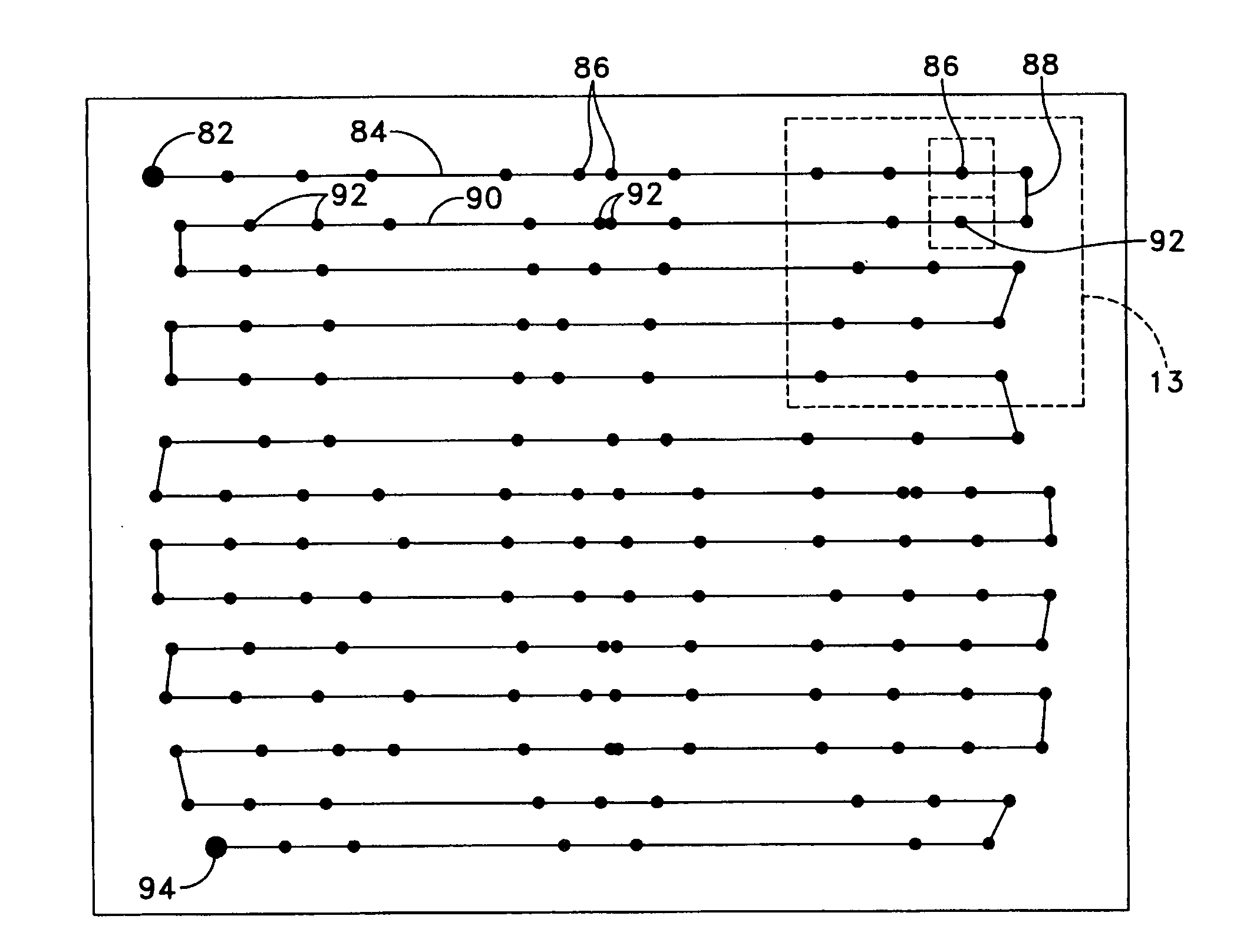

Optimal imaging system and method for a stencil printer

A stencil printer for depositing solder paste onto an electronic substrate includes a frame and a stencil coupled to the frame. A dispenser is coupled to the frame, with the dispenser and the stencil being configured to deposit solder paste onto the plurality of pads of the electronic substrate. An imaging system is configured to capture images of regions of interest of at least one of the electronic substrate and the stencil. The stencil printer further includes a controller coupled to the imaging system, with the controller being configured to control movement of the imaging system to capture images of regions of interest of at least one of the electronic substrate and the stencil extending generally along a first axis before moving the imaging system in another direction. A method for dispensing material on a substrate is further disclosed.

Owner:SPEEDLINE TECH

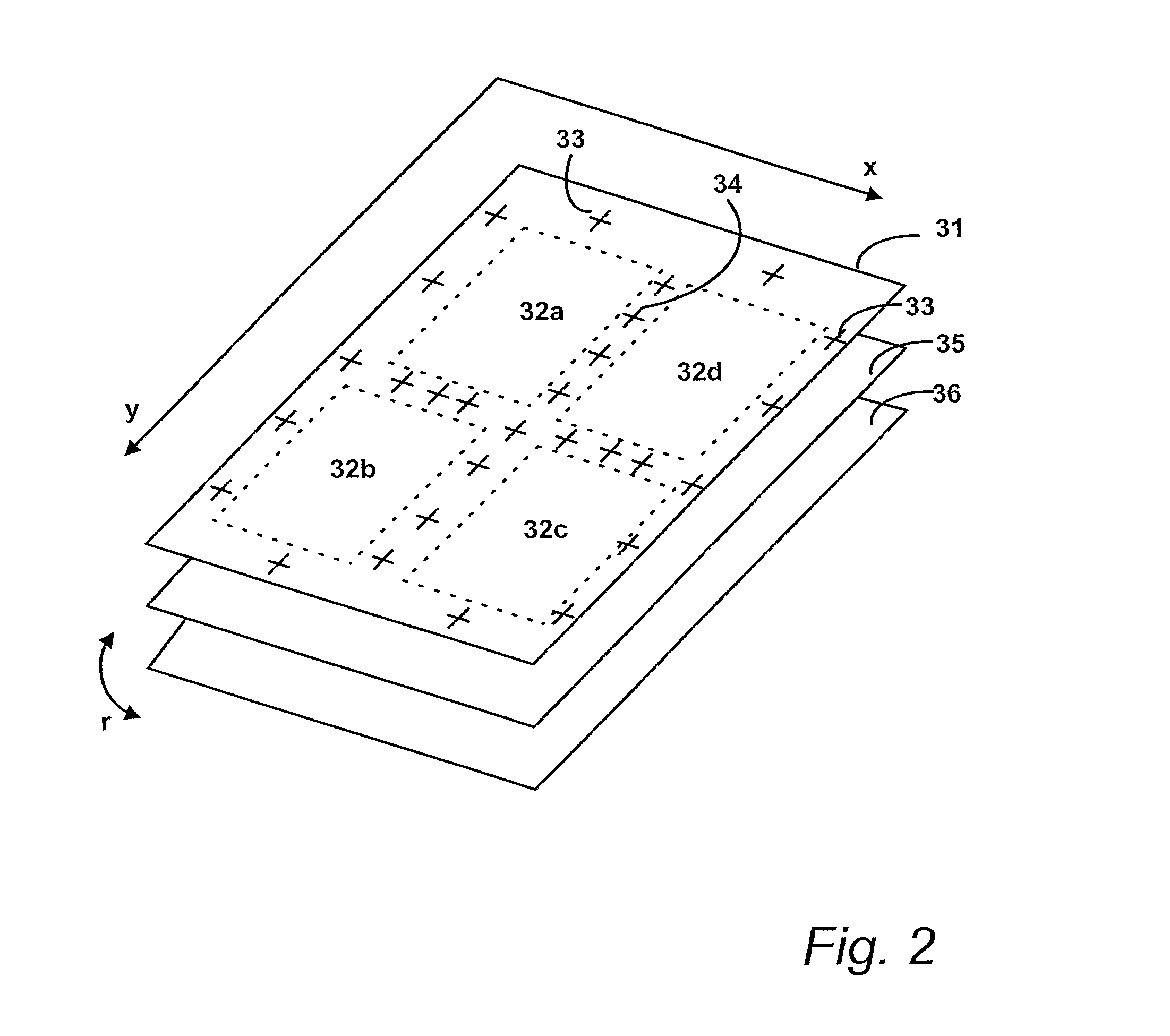

Method and apparatus for registration control in production by imaging

InactiveUS20020118350A1Reduce misregistrationSemiconductor/solid-state device manufacturingCircuit board tools positioningControl dataEngineering

A method and apparatus for imaging an overlying conductive pattern over an underlying conductive pattern on a substrate, by determining deviations between the actual locations and the nominal locations of predetermined reference targets in the underlying conductive pattern on the substrate; and utilizing the determined deviations for modifying the scanning control data used for imaging the image data of the overlying conductive pattern in order to reduce misregistration thereof with respect to the underlying conductive pattern. Preferably, the reference targets are predetermined connection sites in the underlying conductive pattern to be precisely located with respect to connection sites in the overlying conductive pattern. The reference features may be assigned different weights according to their registration importance, and the deviations may be determined according to a threshold which varies with the weight assigned to the respective reference feature.

Owner:KODAK IL

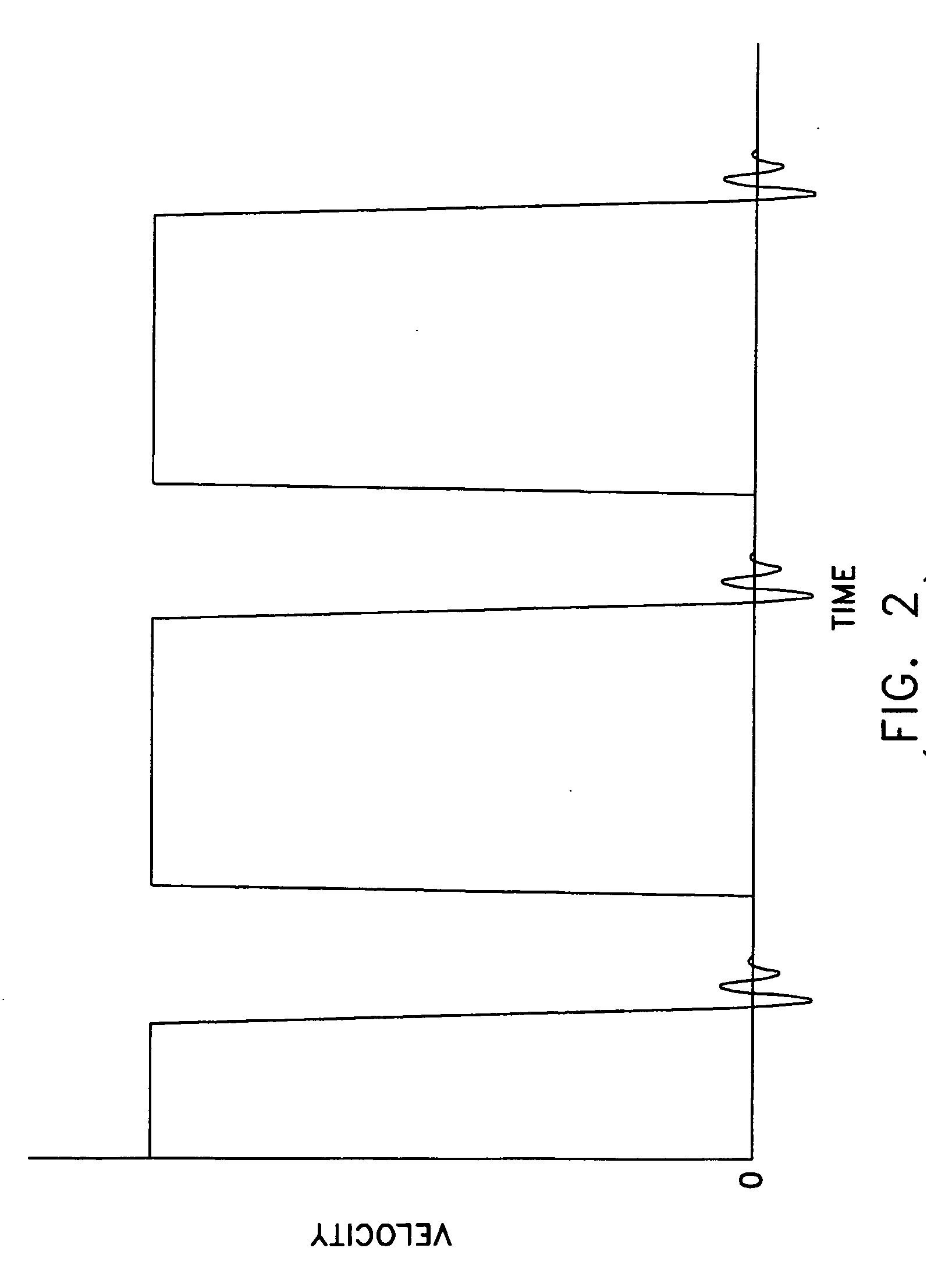

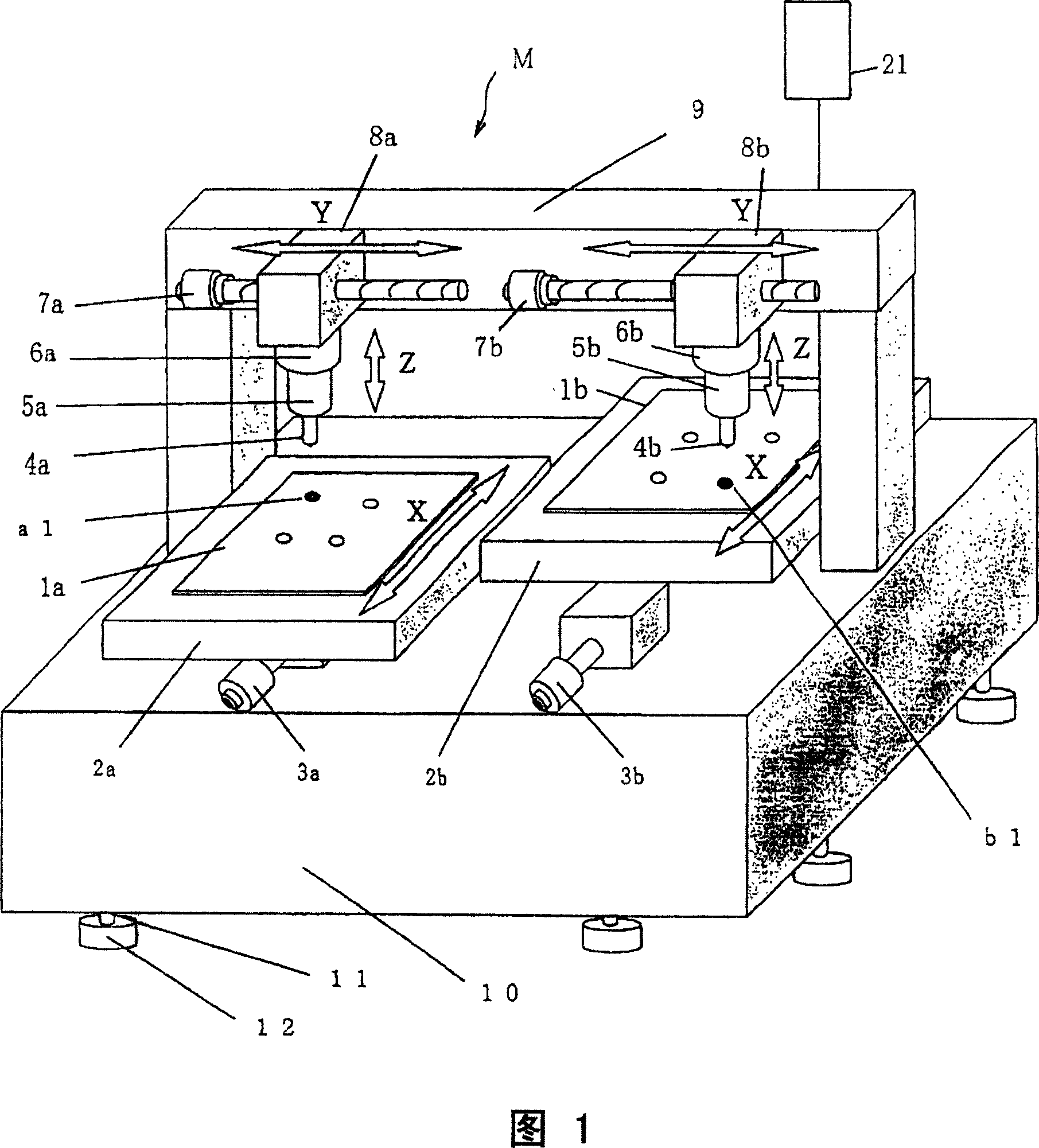

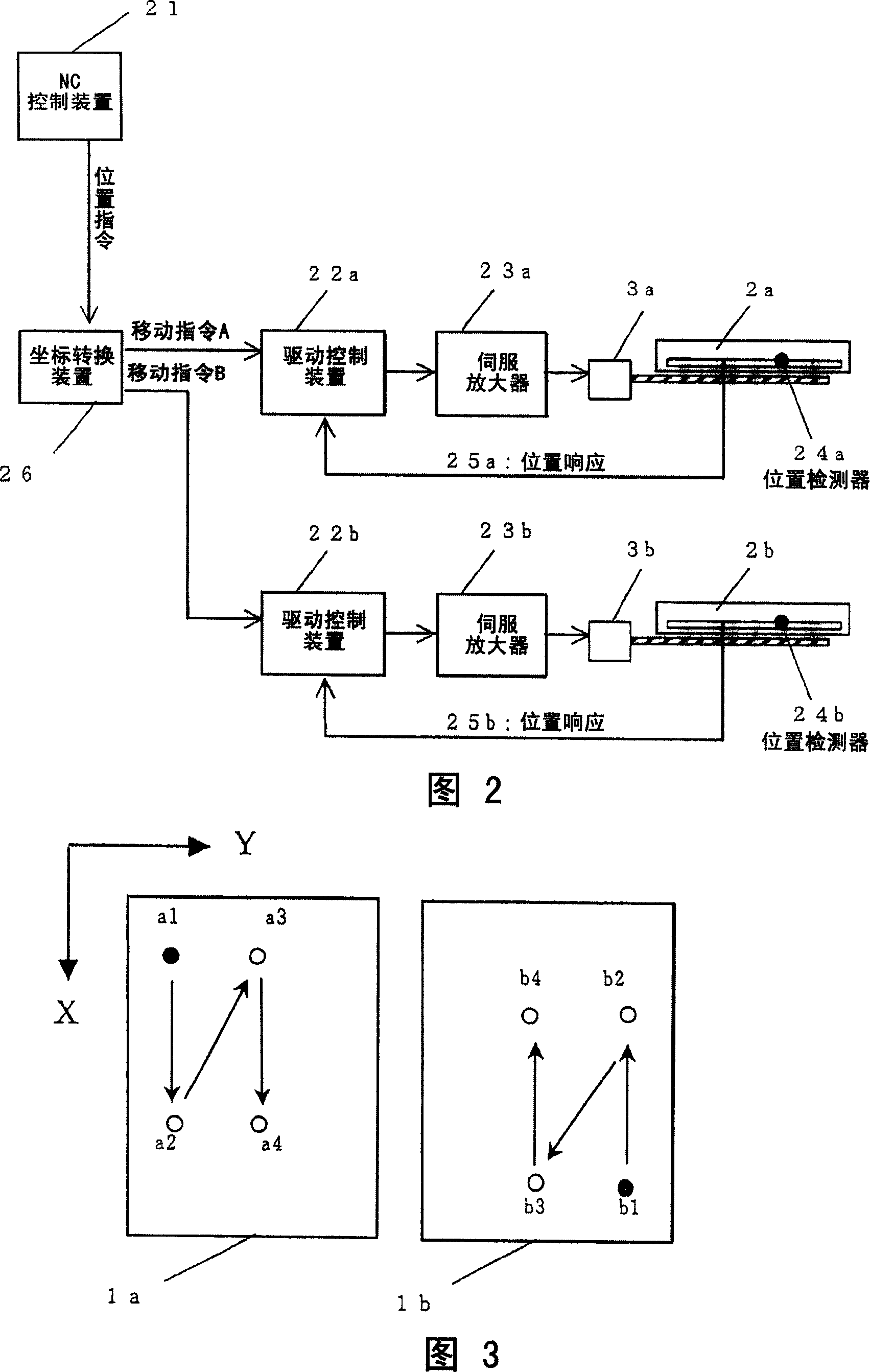

Printed circuit board processing device and drilling processing method therefor

InactiveCN101022701AReduce rocking vibrationAvoid vibrationCircuit board tools positioningFeeding apparatusProcessing accuracyDrill hole

The device has printed circuit boards mounted on respective tables, and a control unit controlling an X-axis drive section and a Y-axis drive section to move an X-direction axle and Y-direction axle in a direction. The axles are positioned in processing positions by the X-axis drive section and a Y-axis drive section. The axes are determined such that drills are put into a printed circuit board by a Z-axis drive section to drill holes. The z-axis drive section moves a spindle into corresponding z-direction. An independent claim is also included for a method for drilling a printed circuit board processing device.

Owner:HITACHI SEIKO LTD

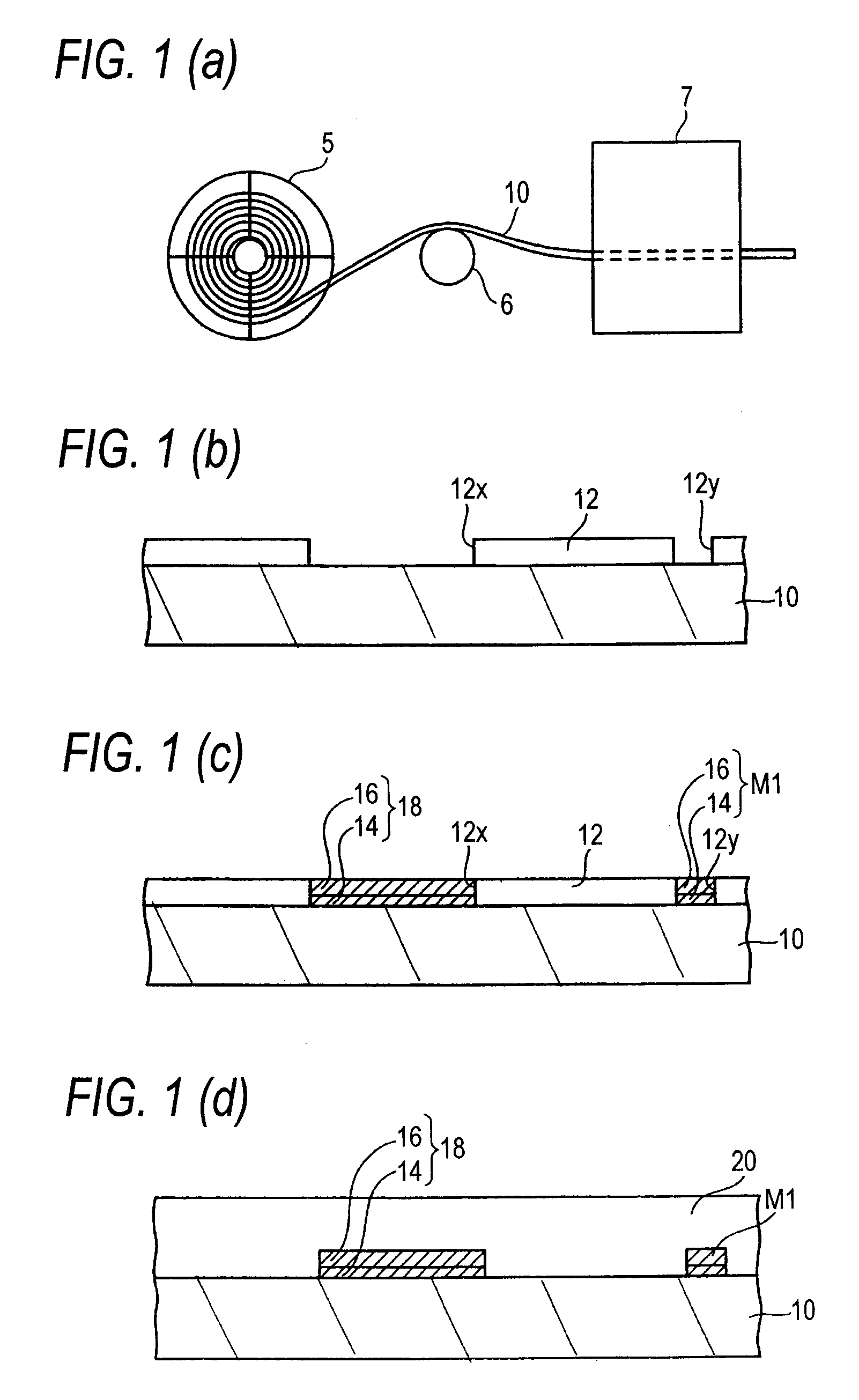

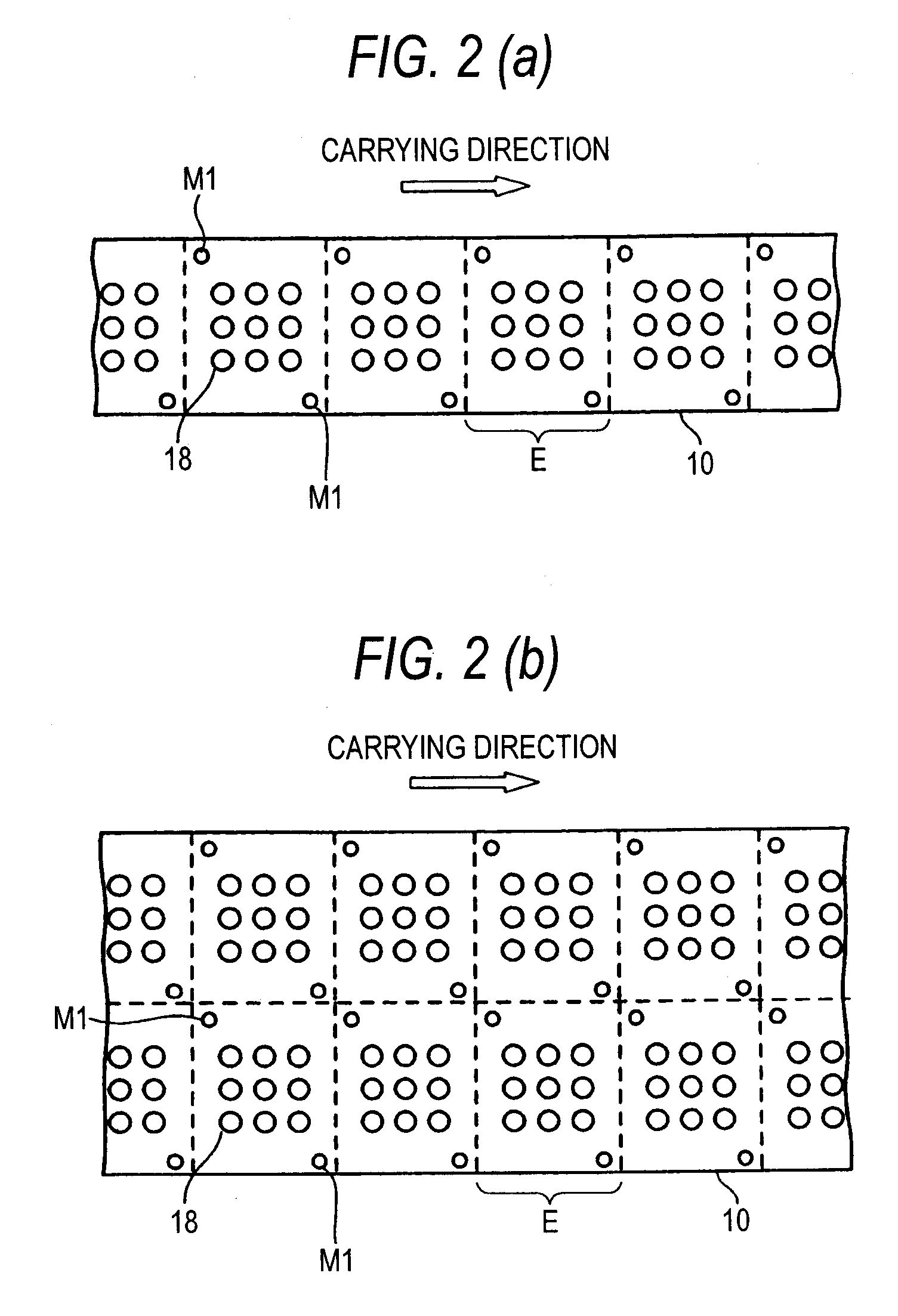

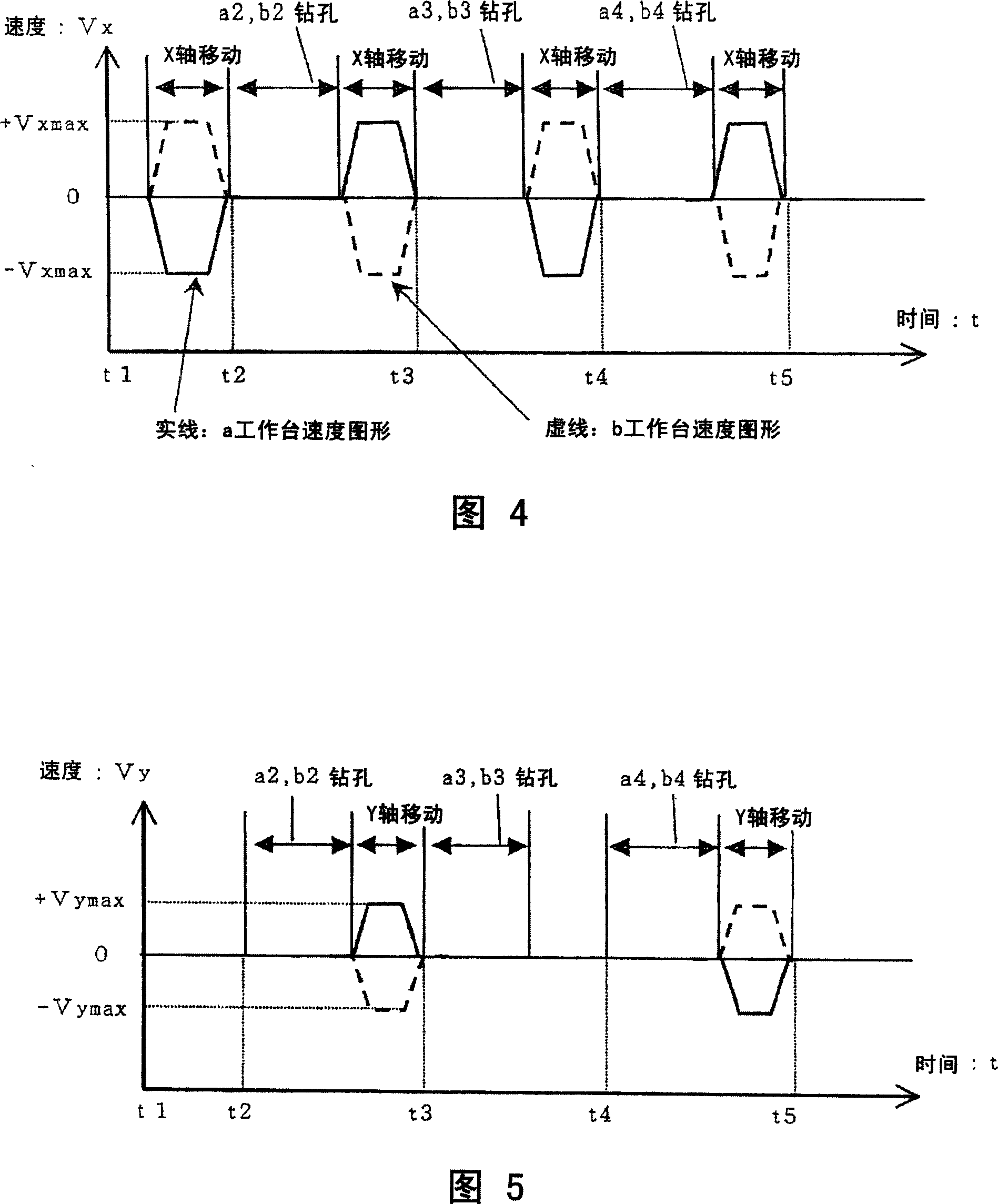

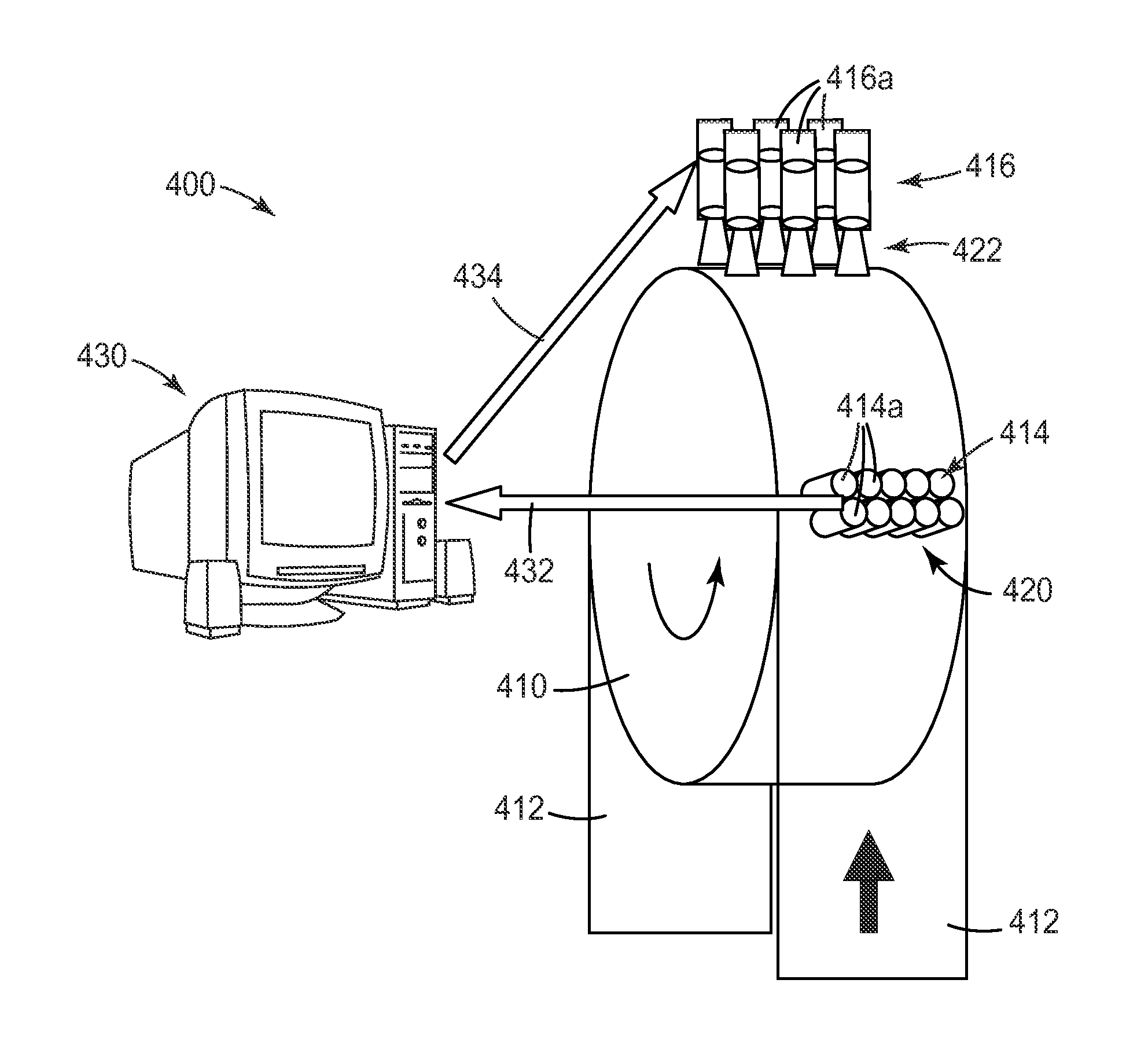

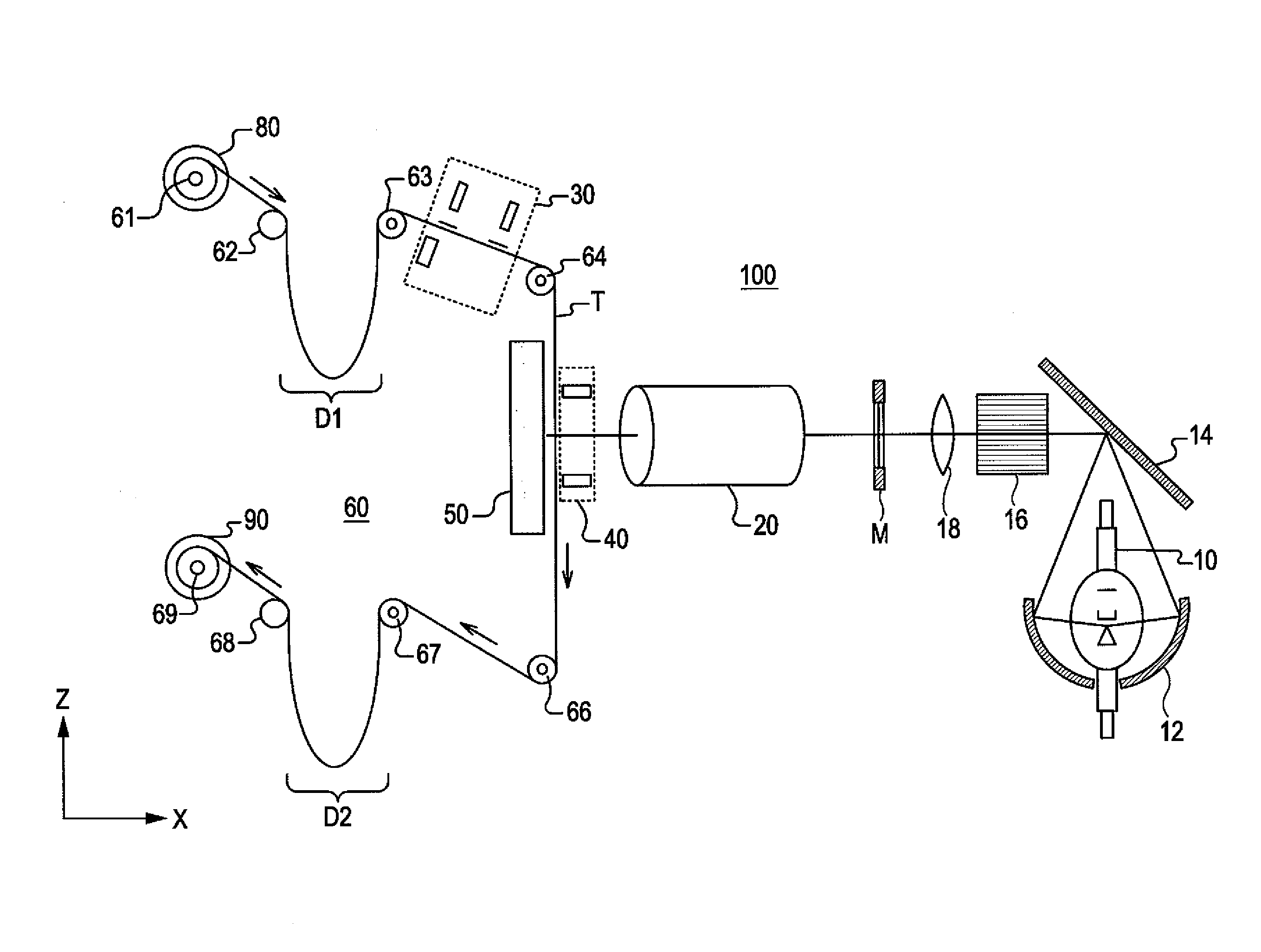

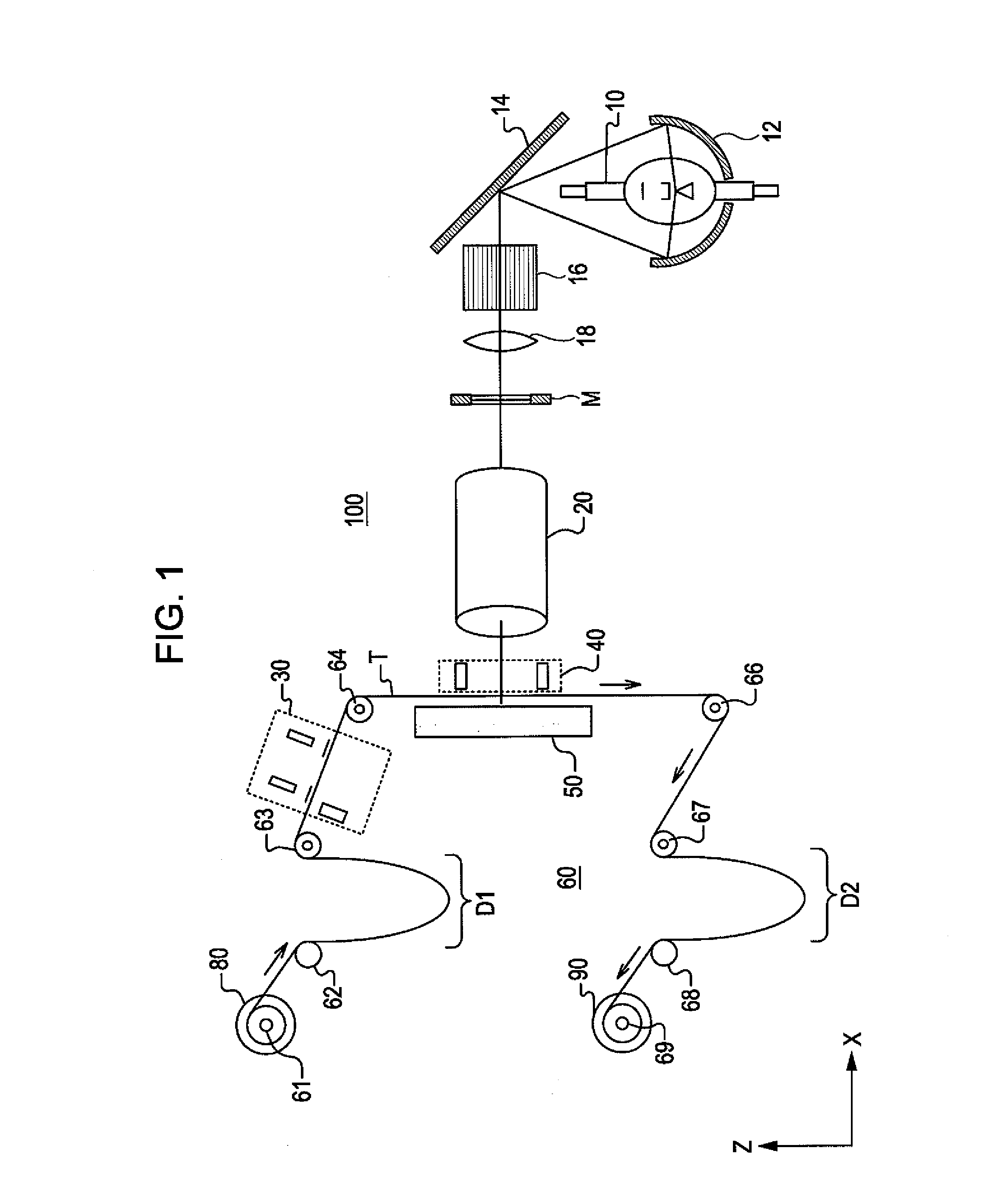

Roll-to-roll digital photolithography

InactiveUS20110253425A1Alignment error is smallFunctionality and performance improvementsPrinted circuit aspectsSemiconductor/solid-state device manufacturingFlexible circuitsEngineering

Methods of making flexible circuit films include providing a polymer film or other flexible substrate having a plurality of alignment marks and a photosensitive material thereon. The substrate passes around a suitable roller, belt, or other inelastic conveyor such that the substrate and the conveyor move together at least from a first location to a second location. Positions of a first set of the alignment marks on a first portion of the substrate are measured when such portion is at the first location, and the measured positions can be used to calculate a distortion of the substrate. The photosensitive material is then patternwise exposed when the first portion of the substrate has moved to the second location. The patternwise exposing is based on the measured positions of the first set of alignment marks, and may include exposing the web with a distortion-adjusted pattern. Related systems and articles are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

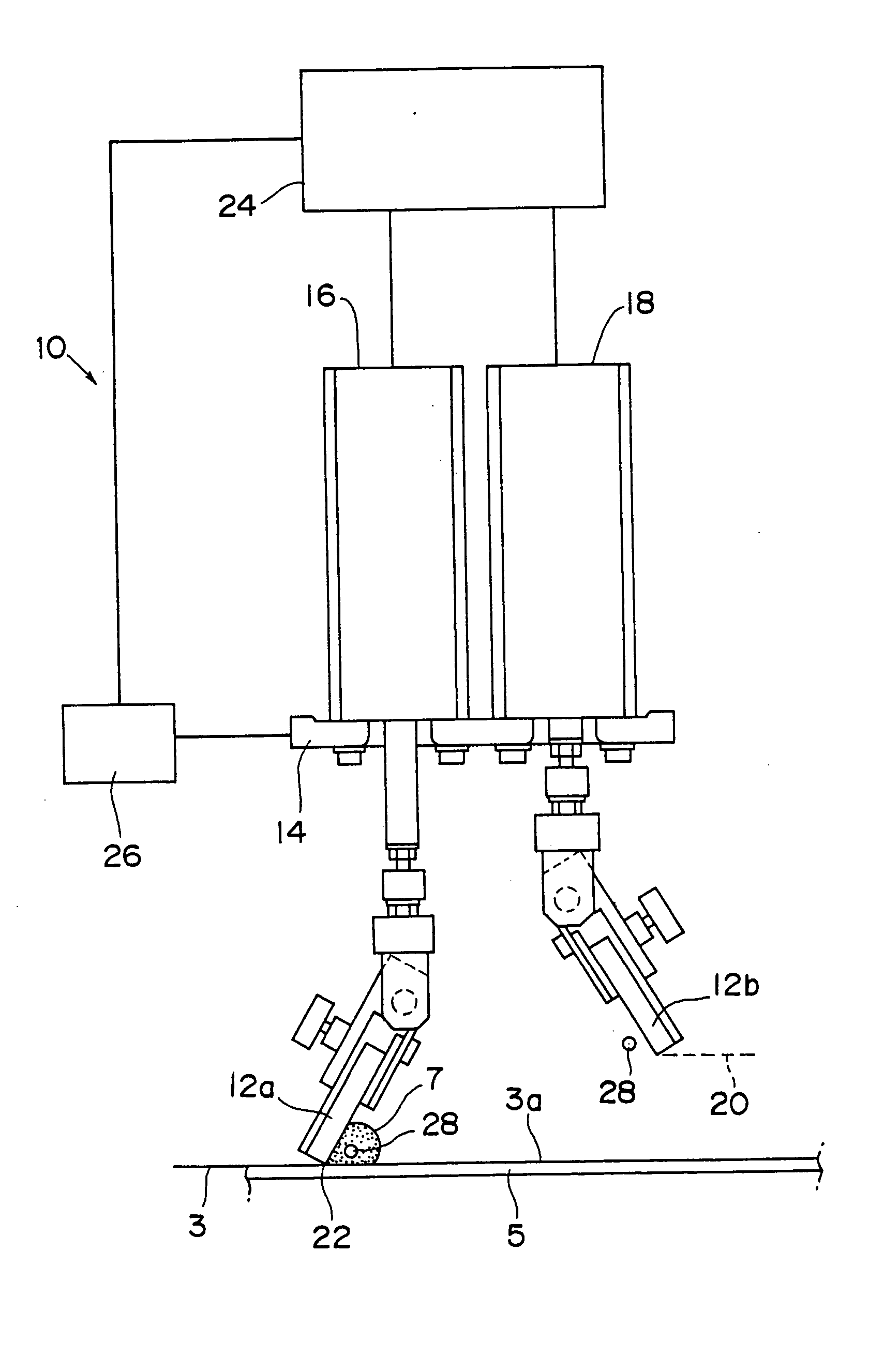

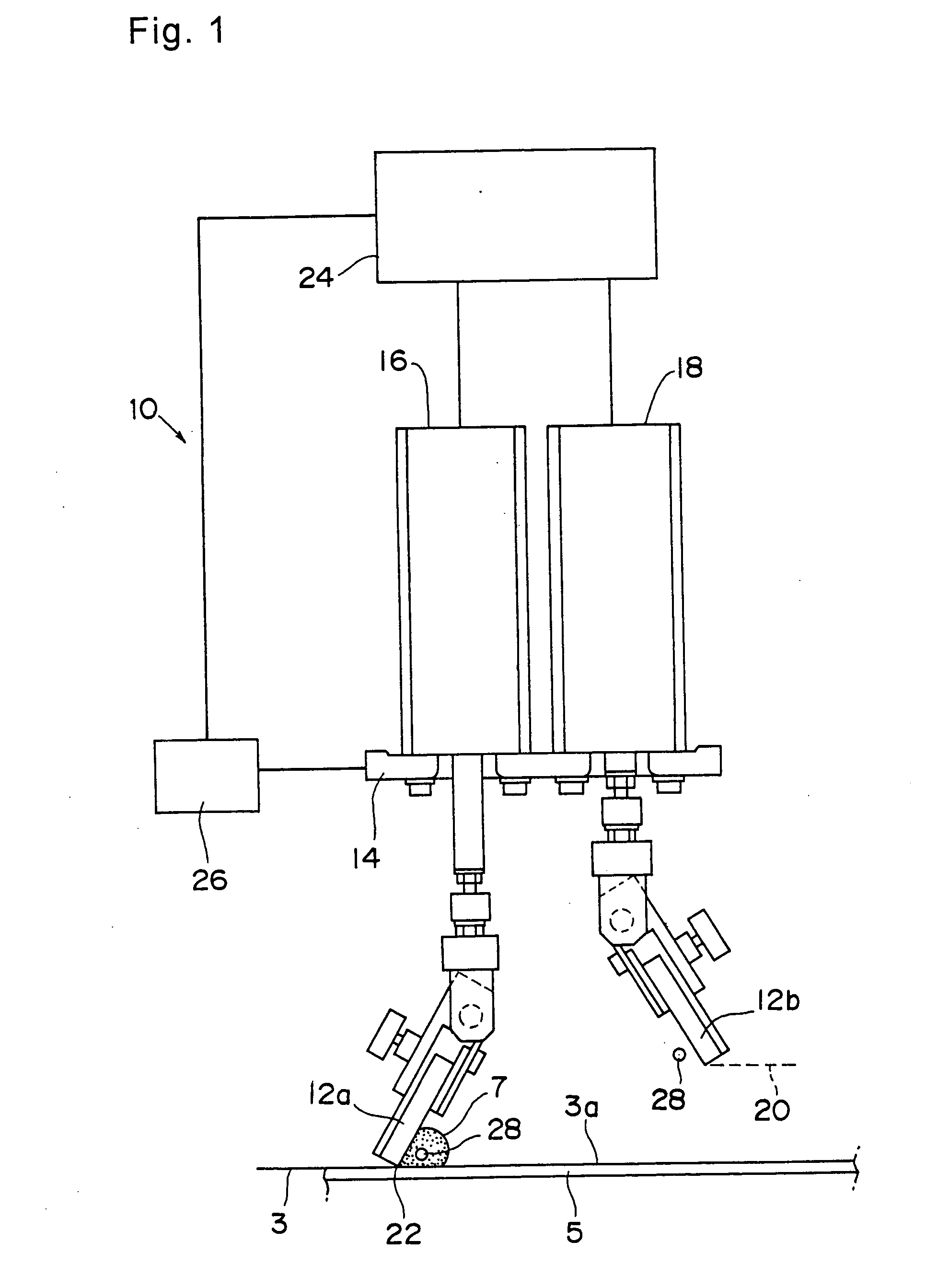

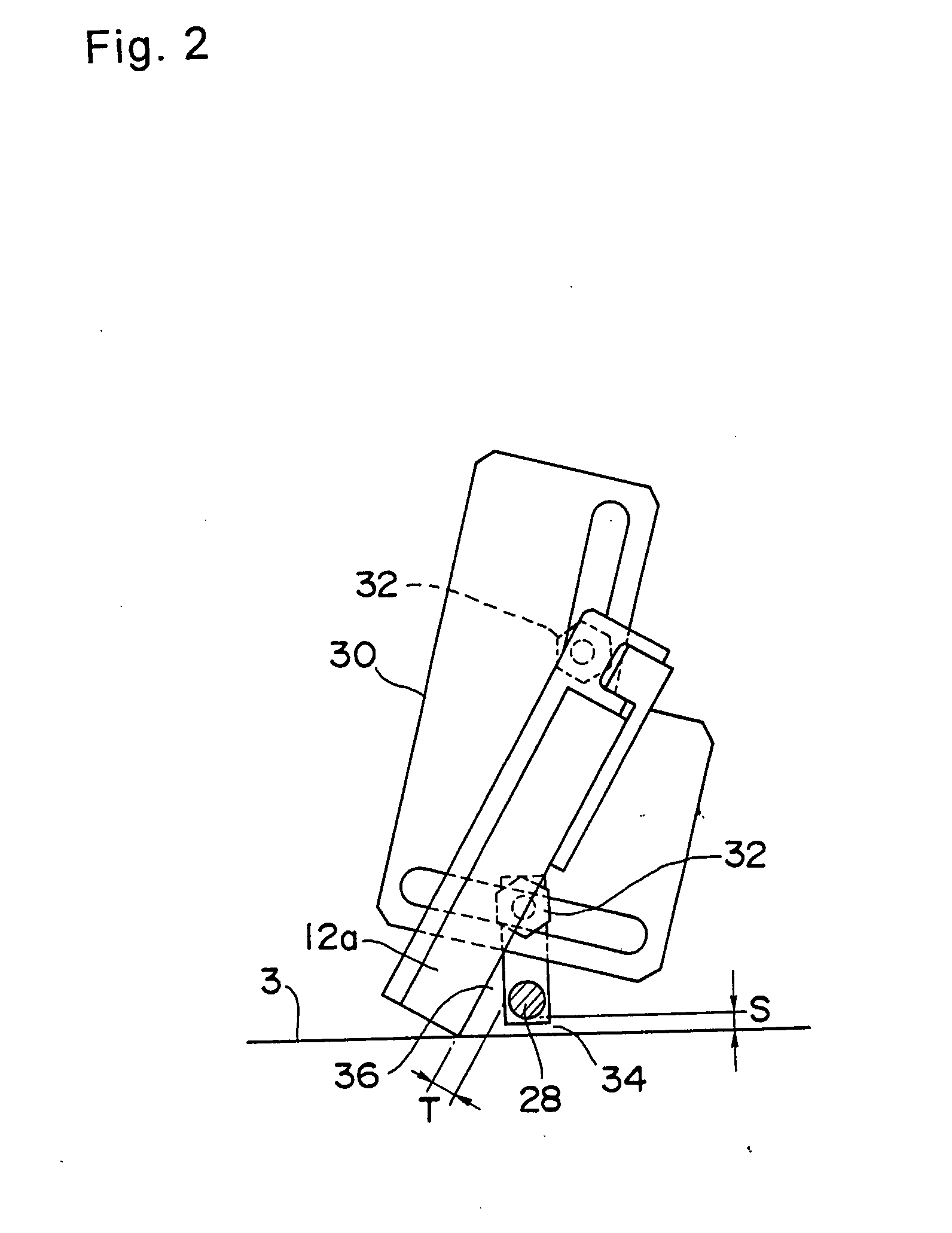

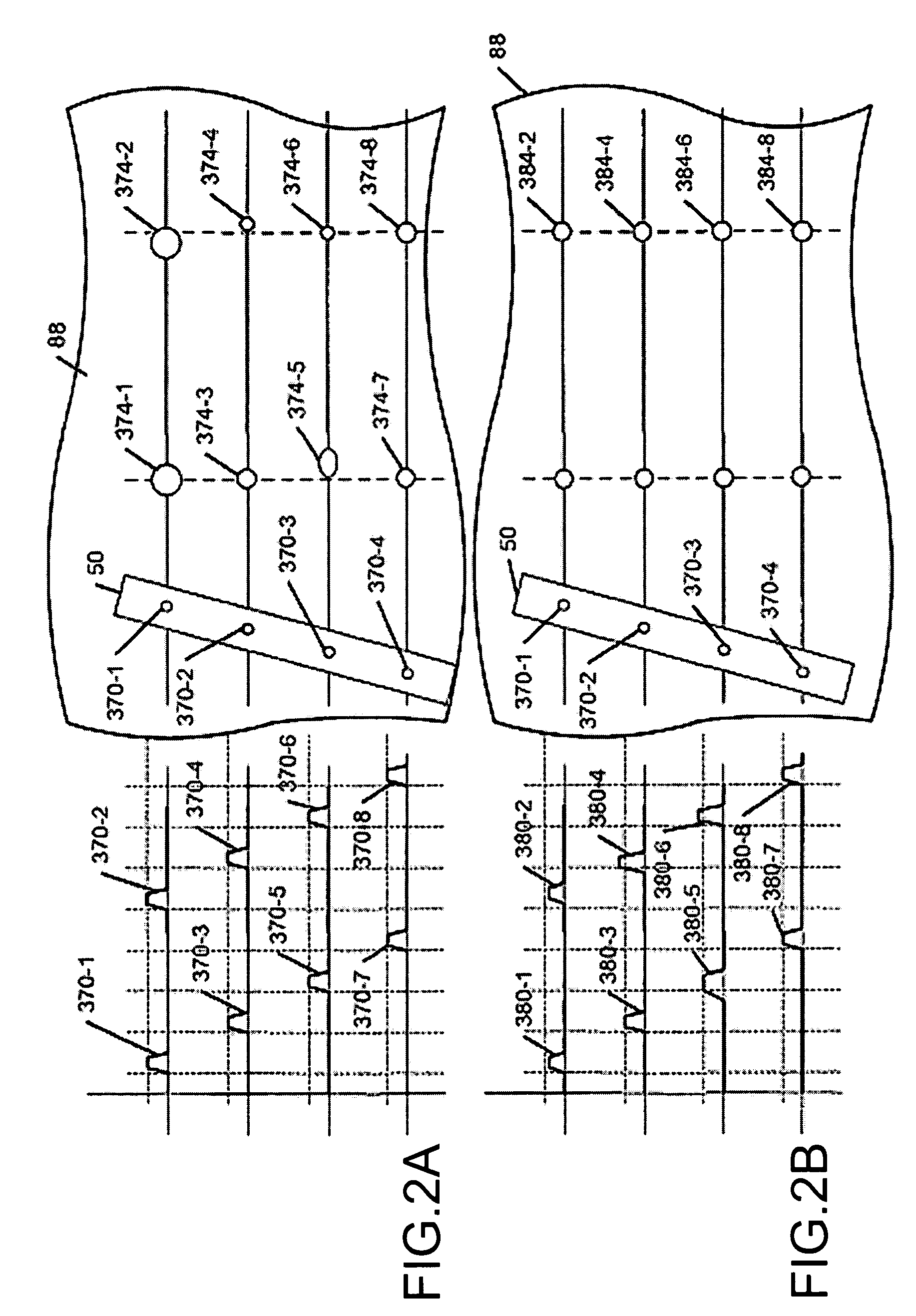

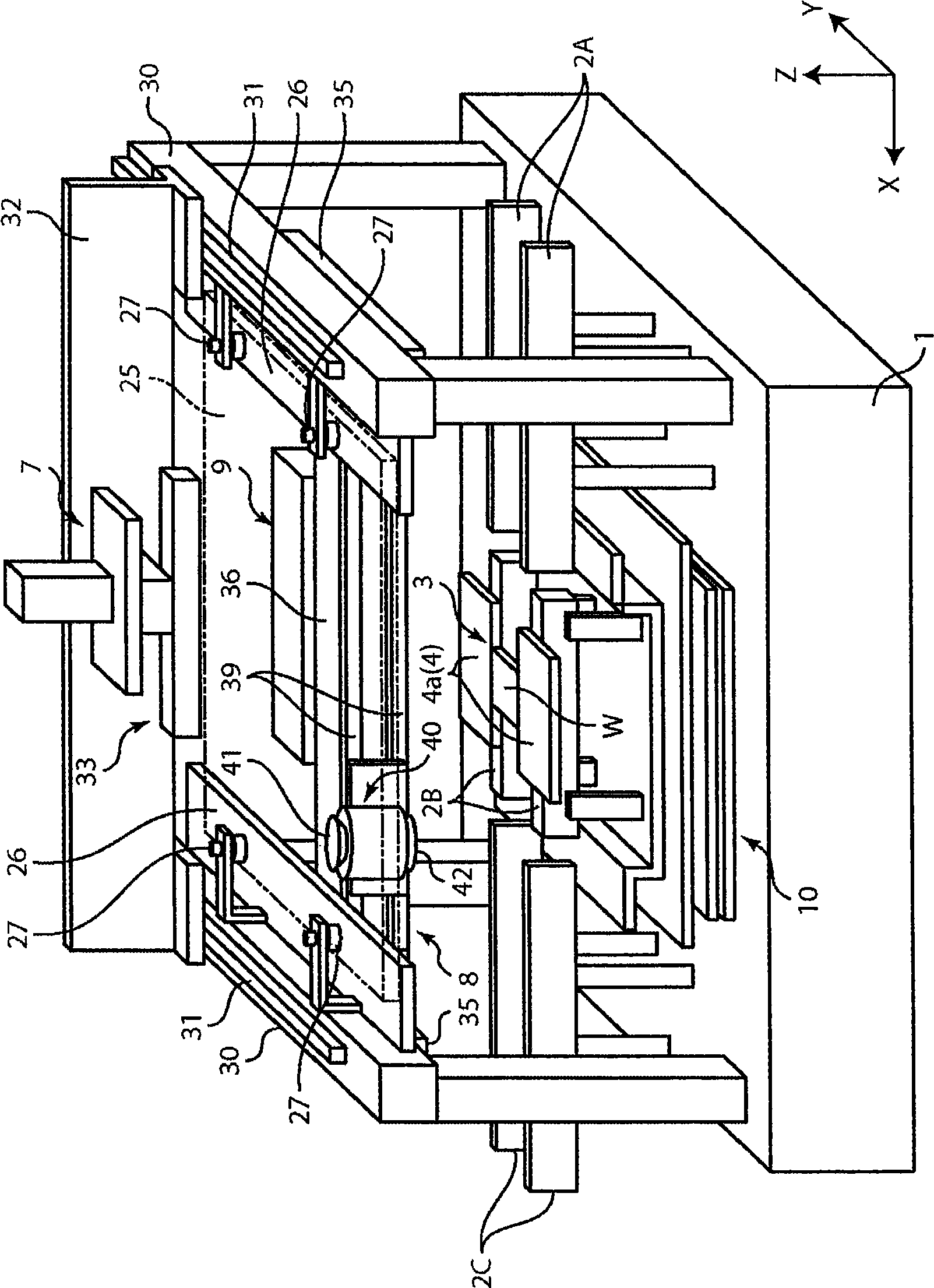

Conveyorized blind microvia laser drilling system

InactiveUS7062845B2High peak powerMaterial removalCircuit board tools positioningPrinted resistor incorporationComputer moduleEngineering

A laser drilling system for drilling blind vias in printed circuit board panels, multichip modules and chipscale packages with top and bottom surfaces and which include multiple dielectric polymer and metal layers. The system includes a first laser module comprising a laser able to form at least one via per pulse through one or more polymer layers. The vias are circular or non-circular in shape. An articulated arm is adapted to move at a speed of about 200 inches per second and at an acceleration of about 5 g's or more. A beam delivery unit is attached to the articulated arm and a conveyor adapted to move panels at a constant speed. The first laser module positioned on a separate track from the conveyor moves at a faster rate than the conveyor to drill the top surface. A second laser module is positioned to move on another separate track from the conveyor movable at a faster rate so as to drill the bottom surface.

Owner:MARGER JOHNSON & MCCOLLOM P C

Screen printing apparatus and screen printing method

ActiveUS20080289518A1Improve positional deviation stateLiquid surface applicatorsInking apparatusScreen printingEngineering

In supply of feedback data to improve a positional deviation quantity and a deviation state of a soldering paste printed on individual substrates held on the carrier, a plurality of average values of individual positional deviation for each of the individual substrates are obtained, and then, if the deviation value ΔM indicating a difference between the maximum value Mmax and the minimum value Mmin of the plurality of average values M of individual positional deviation is less than or equal to the tolerance value Δ(t), an intermediate value of the maximum value Mmax and the minimum value Mmin is obtained, and the positioning parameters of the mask plate and the carrier are corrected based on the intermediate value (Mmax+Mmin) / 2.

Owner:PANASONIC CORP

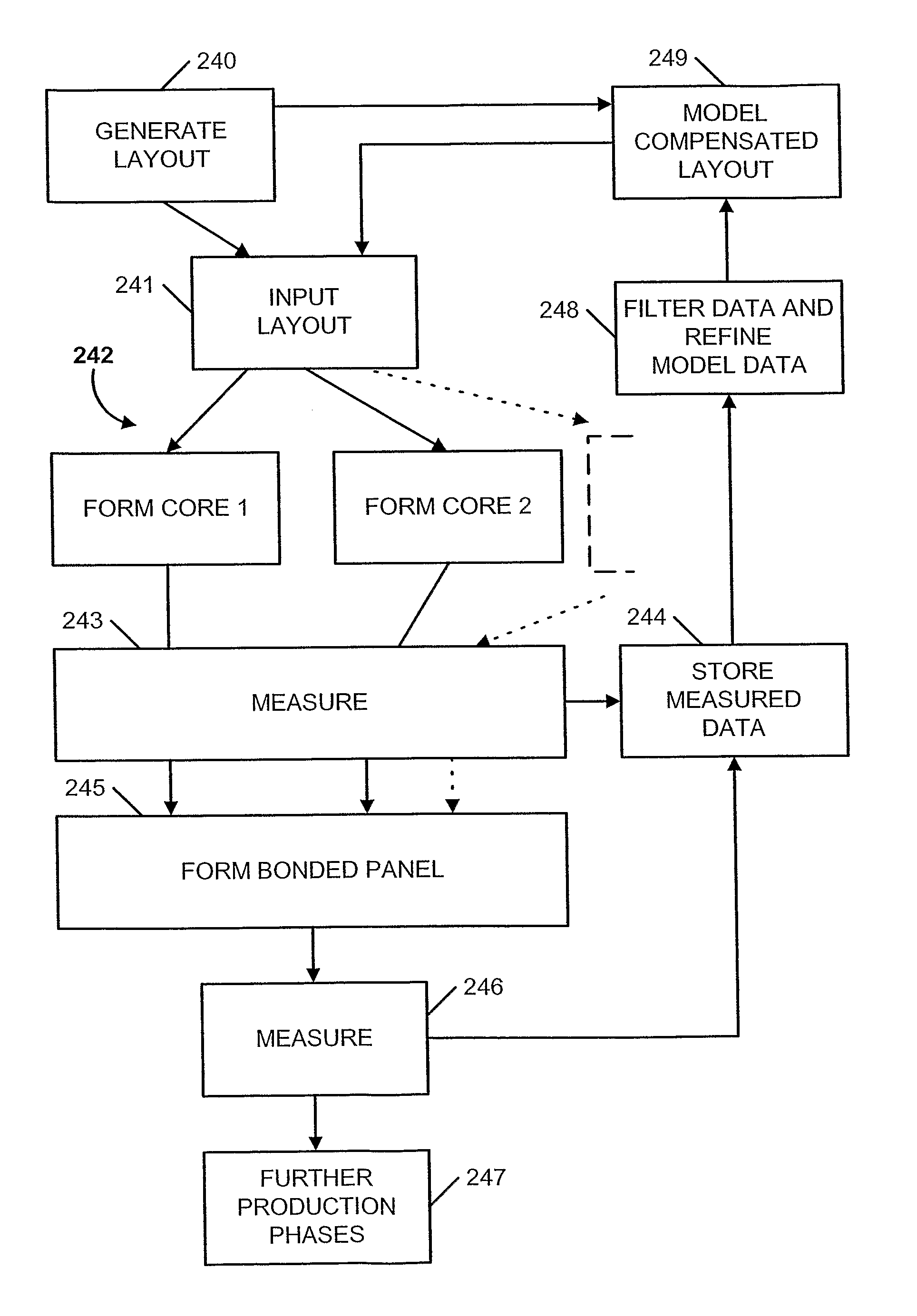

Registration System and Method

ActiveUS20110130860A1Precise positioningPrinted circuit aspectsSemiconductor/solid-state device manufacturingNonlinear distortionElement model

Printed circuit boards are manufactured by forming a composite layer using a control system which models a production process to generate data using non-linear compensation techniques to compensate for non-linear distortion occurring in a circuit layout applied to a constituent layer. Measurement data of actual circuit layouts is used to update stored values of parameters used in the modelling process. In one form of the model, the desired layout in the composite layer is represented by an array of cells and cell sizes corresponding to an initial stage of the production process are calculated, the model working backwards from the final state of the production process to the initial state, and a finite element model used to determine corresponding positions of cells, taking account of interaction between cells, from which the compensation data is calculated.

Owner:XACTPCB LTD

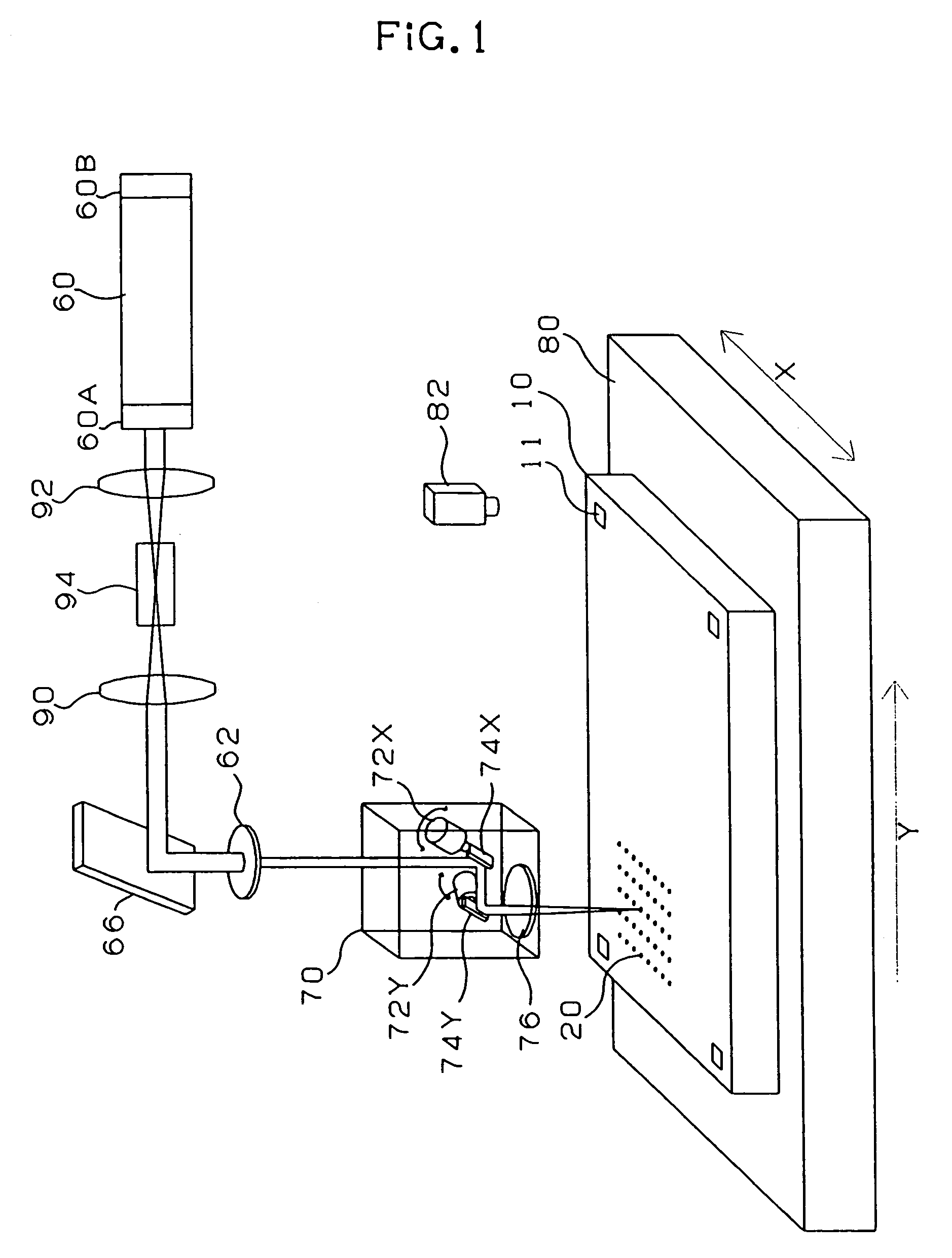

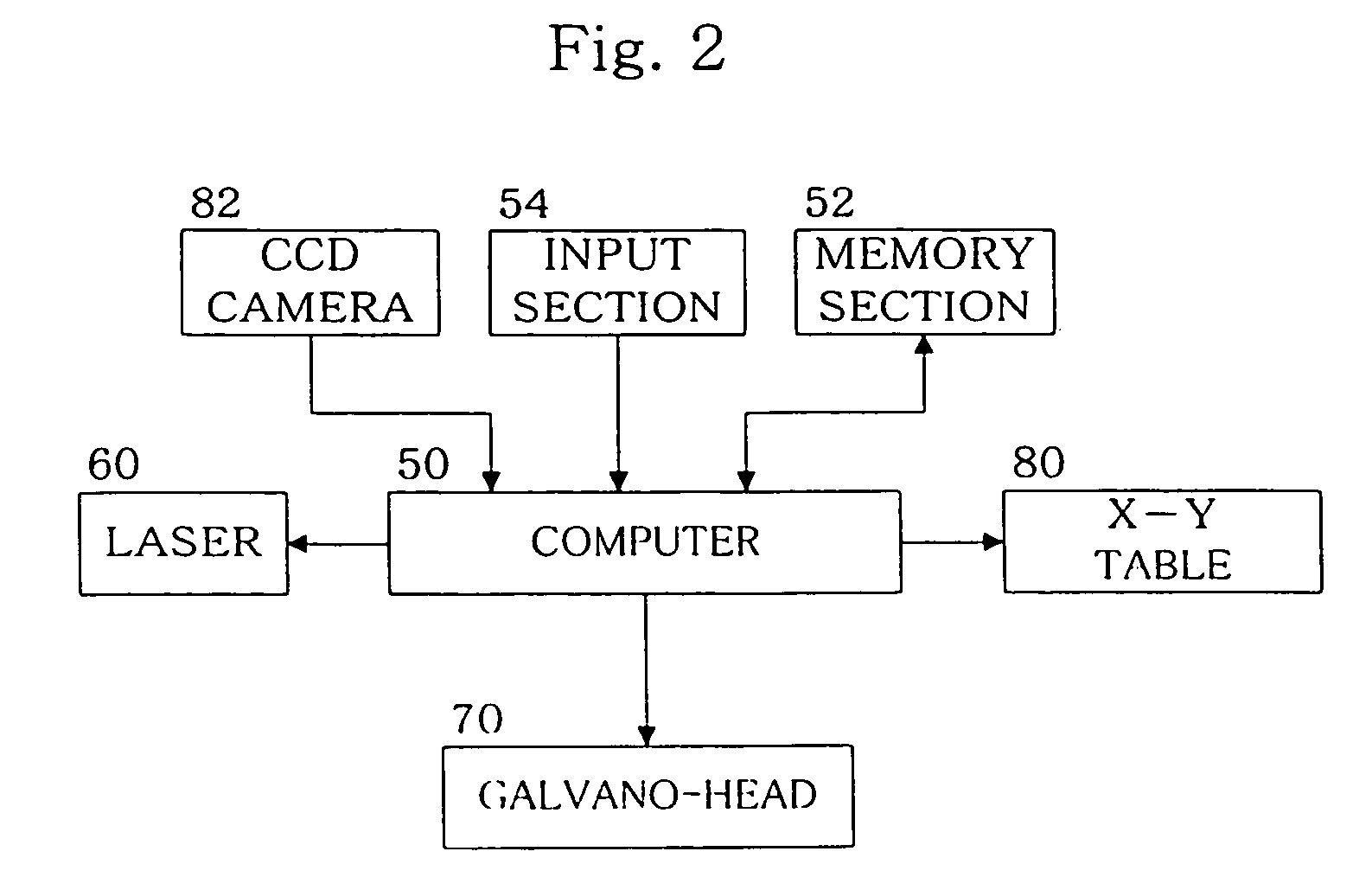

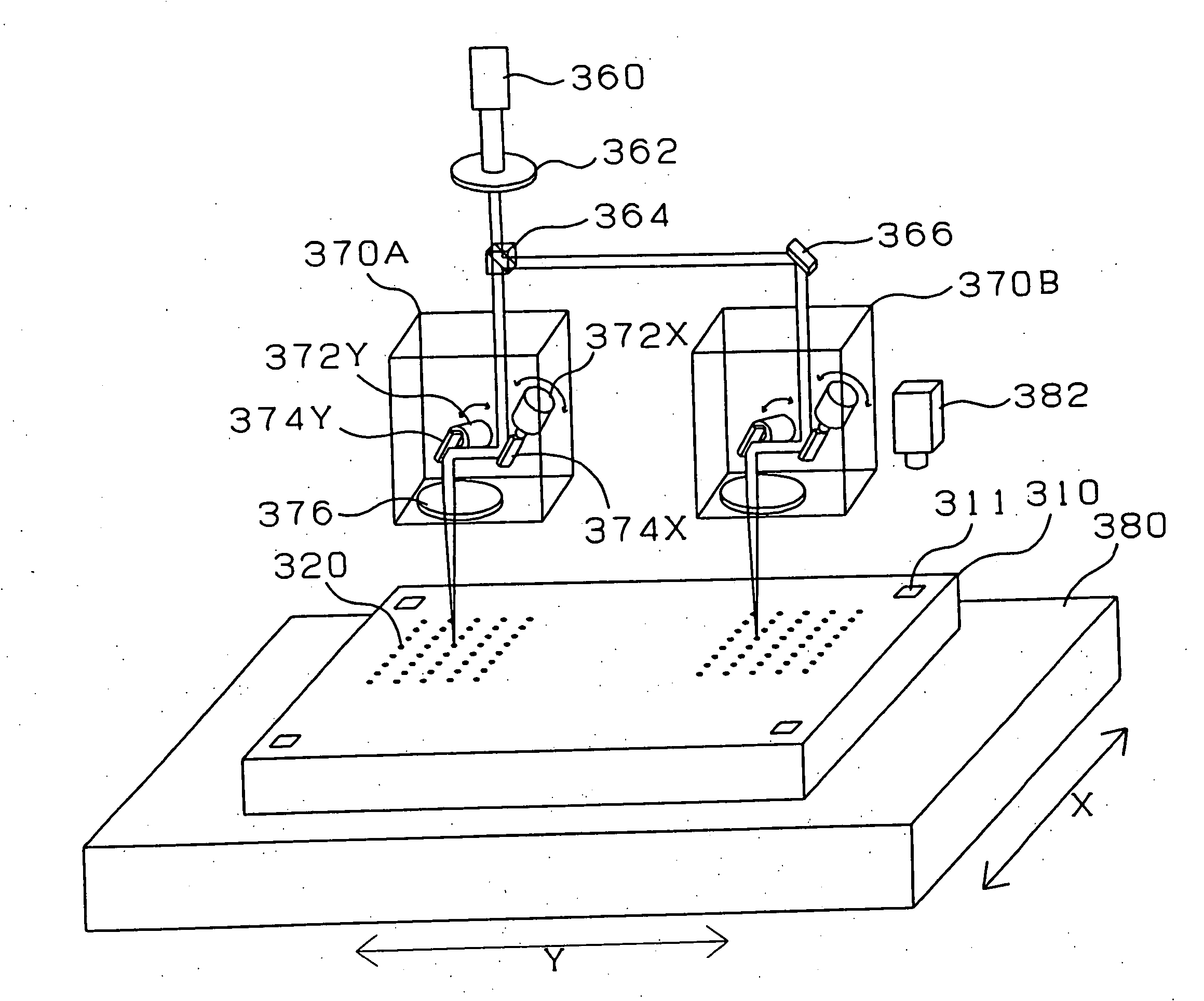

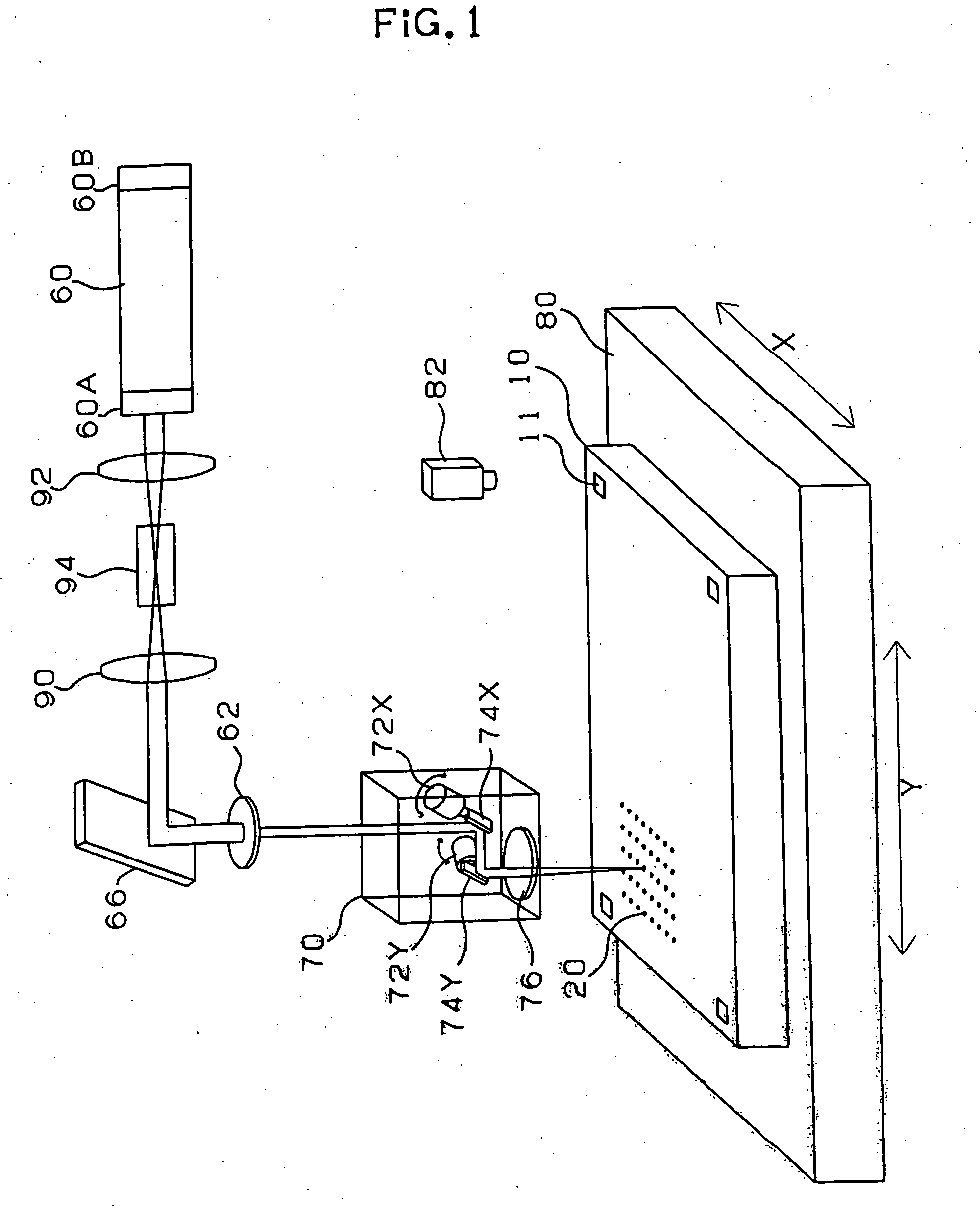

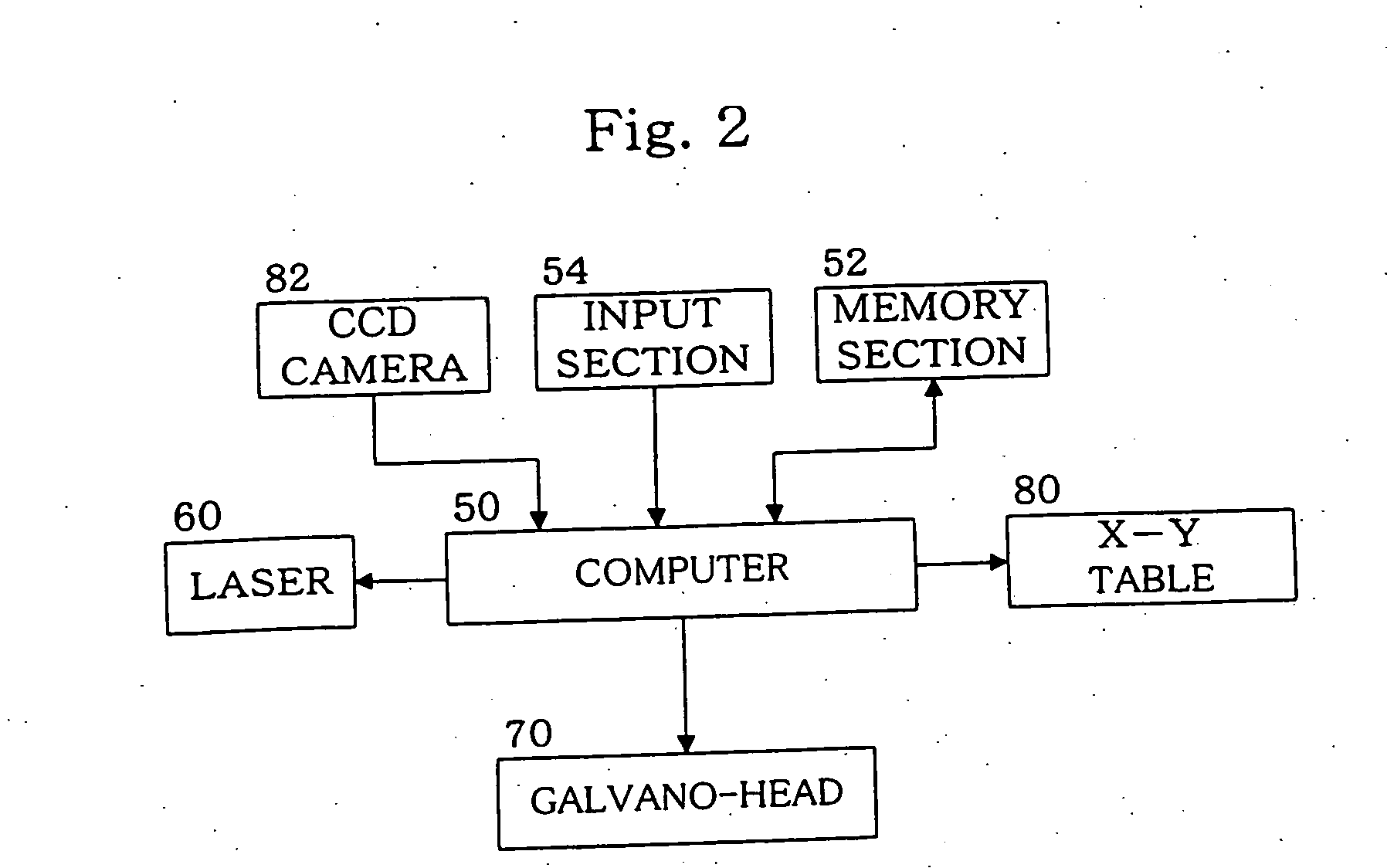

Laser machining apparatus, and apparatus and method for manufacturing a multilayered printed wiring board

InactiveUS7456372B2Low costSimple structurePrinted circuit aspectsCircuit board tools positioningLaser processingManufactured apparatus

There is provided a laser processing apparatus, a multilayer printed wiring board manufacturing apparatus, and a manufacturing method to form via holes of ultra-fine diameter. The laser beam from the CO2 laser oscillator (60) is converted to the shortened wavelength beam by a tellurium crystal (94) to control diffraction of the laser beam. Simultaneously, when the laser beam is condensed, a limit value of the condensation limit is reduced. Thereby, the spot diameter of laser beam is reduced and a hole for via hole is bored on the interlayer insulation resin on a substrate (10). Therefore, even when the laser beam output is raised to form a deeper hole, the hole diameter is not widened and thereby a hole for a small diameter via hole can be formed.

Owner:IBIDEN CO LTD

Laser machining apparatus, and apparatus and method for manufacturing a multilayered printed wiring board

InactiveUS20060138097A1Simple structurePrinted circuit aspectsCircuit board tools positioningManufactured apparatusOptoelectronics

There is provided a laser processing apparatus, a multilayer printed wiring board manufacturing apparatus, and a manufacturing method to form via holes of ultra-fine diameter. The laser beam from the CO2 laser oscillator (60) is converted to the shortened wavelength beam by a tellurium crystal (94) to control diffraction of the laser beam. Simultaneously, when the laser beam is condensed, a limit value of the condensation limit is reduced. Thereby, the spot diameter of laser beam is reduced and a hole for via hole is bored on the interlayer insulation resin on a substrate (10). Therefore, even when the laser beam output is raised to form a deeper hole, the hole diameter is not widened and thereby a hole for a small diameter via hole can be formed.

Owner:IBIDEN CO LTD

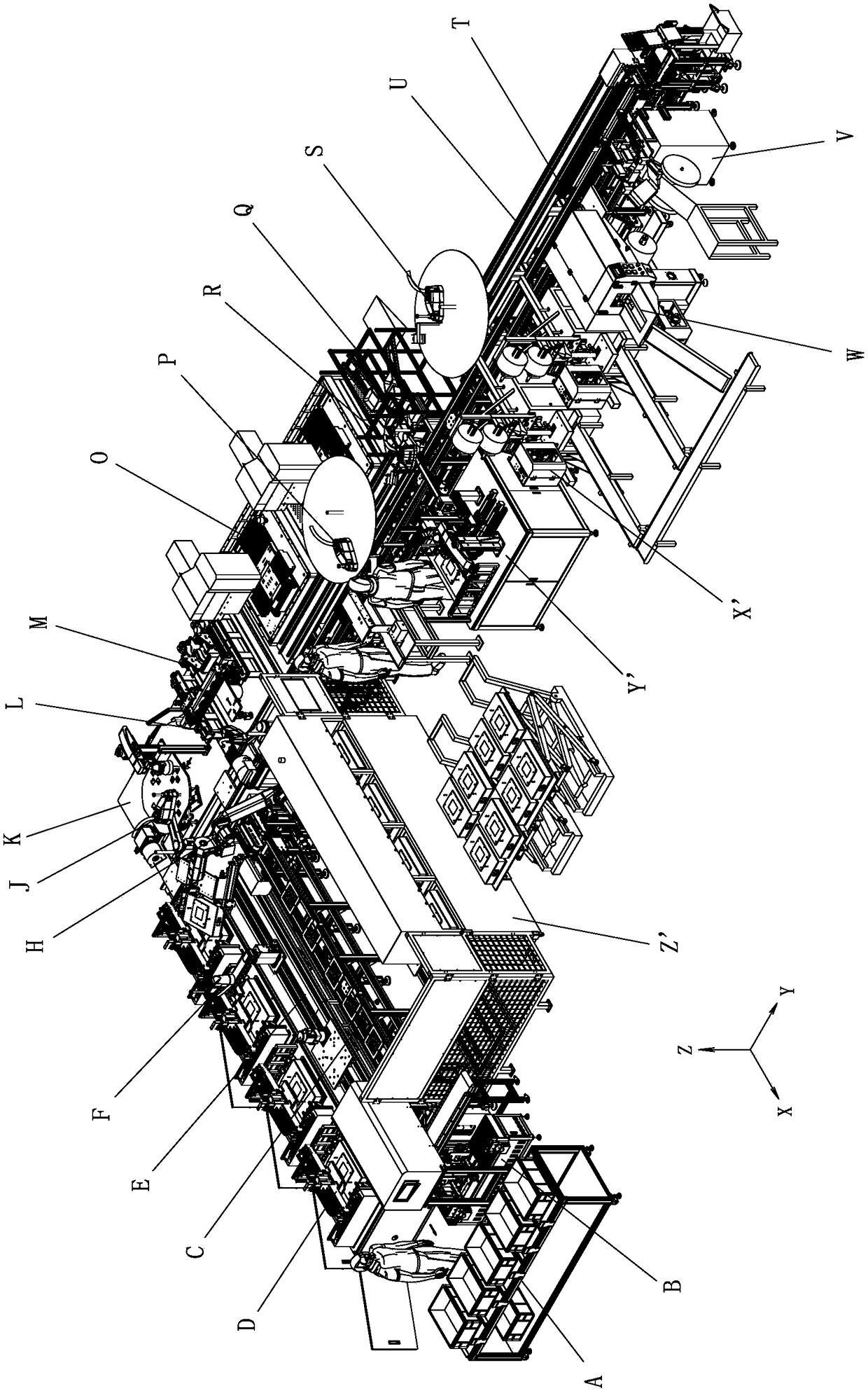

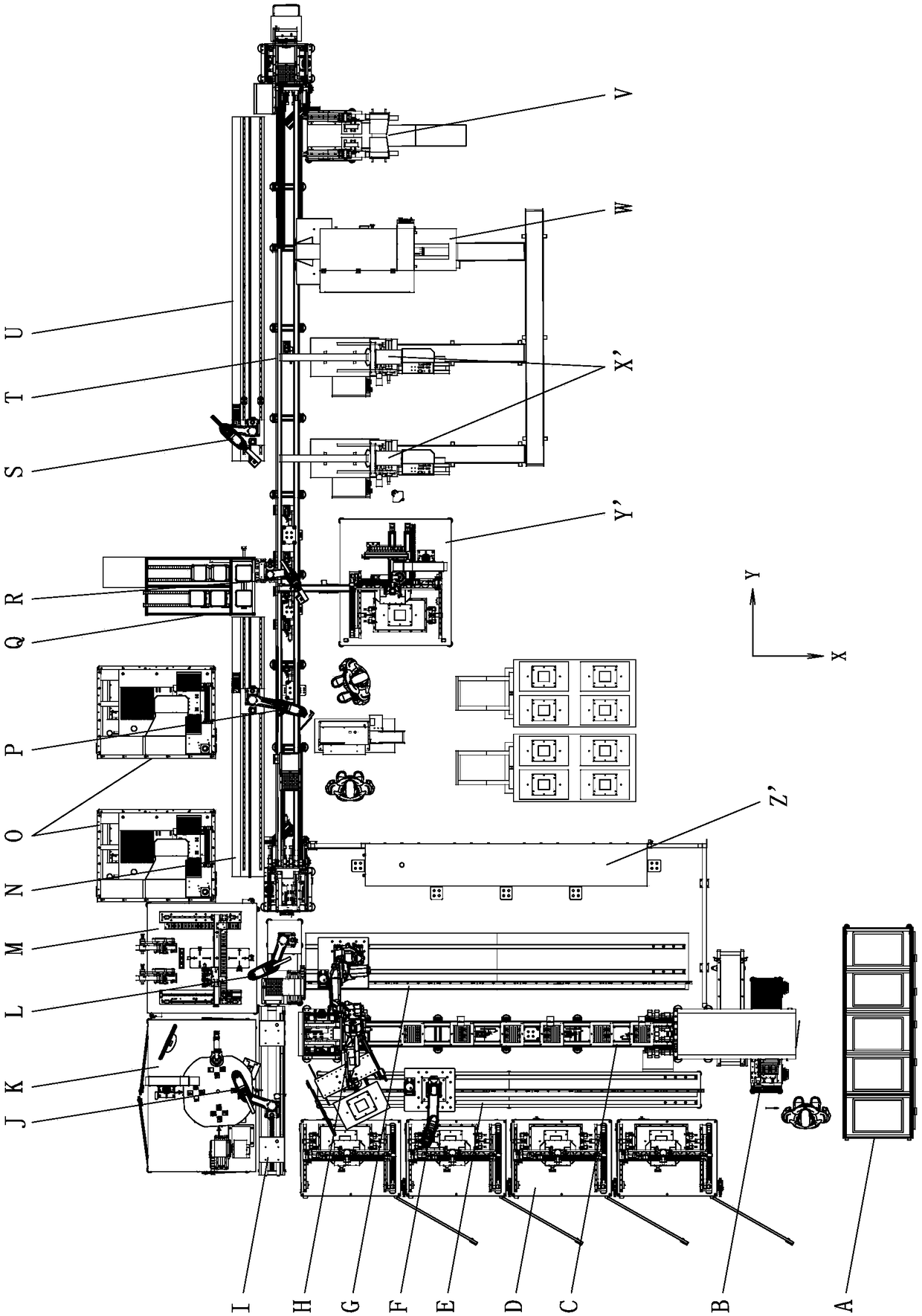

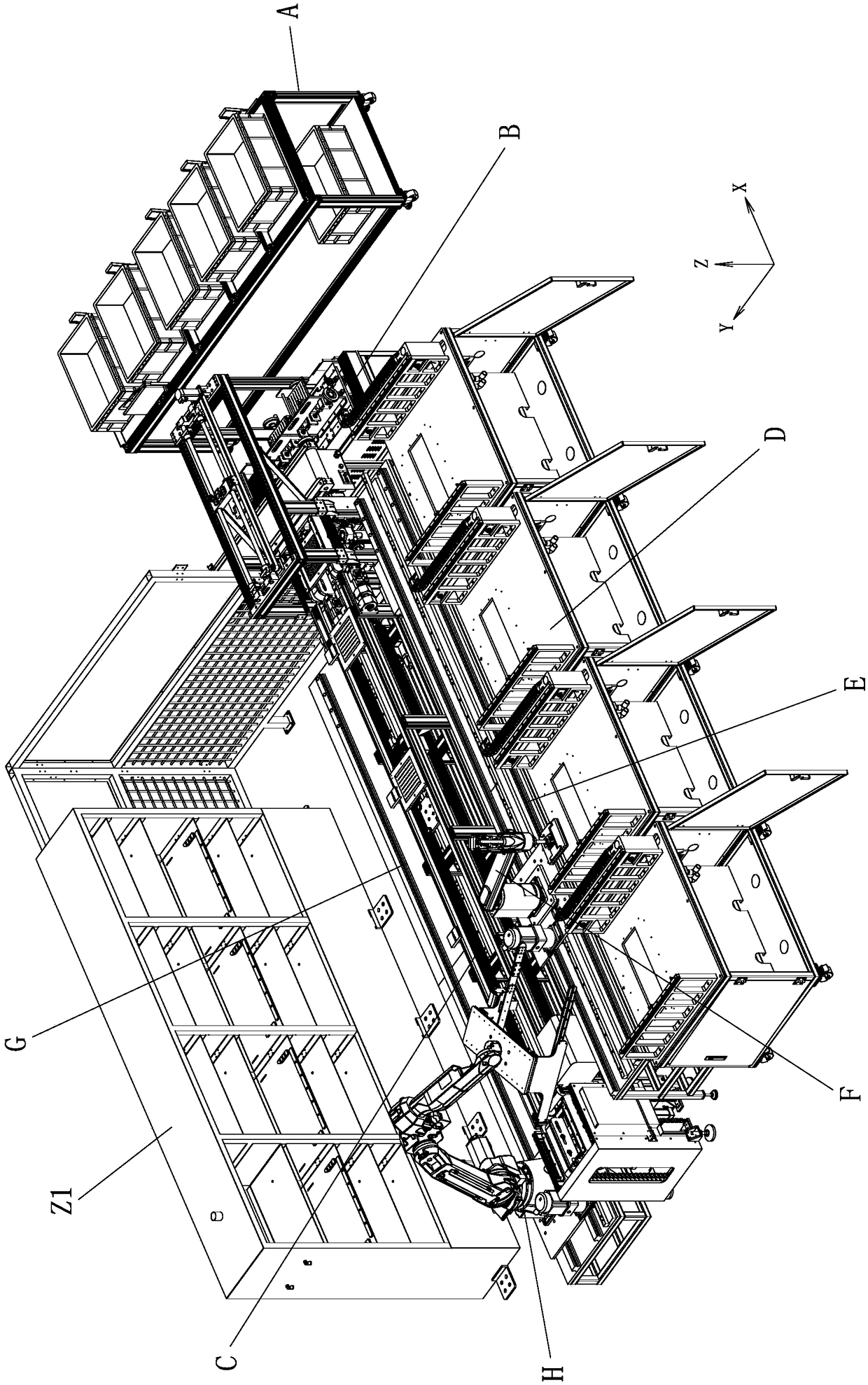

Automatic PCB production line

PendingCN108282991AReduce in quantityReduce labor intensityCircuit board tools positioningElectrical componentsProduction lineLoading unloading

The invention relates to an automatic PCB production line. The automatic PCB production line comprises a production transmission line, multi-station loading equipment, PCB burning equipment, PCB coding equipment, PCB labeling equipment, PCB separation equipment and a PCB package system, wherein the production transmission line is used for driving a PCB to move along the production line, the multi-station loading equipment is used for loading the PCB onto a loading transmission line, the PCB burning equipment is used for burning the PCB, the PCB coding equipment is used for coding the PCB, thePCB labeling equipment is used for labeling the PCB, the PCB separation equipment is used for separating the PCB, and the PCB package system is used for packaging the PCB. The processes of automatic burning, coding, labeling, separation and package are achieved by matching of an industrial robot, automatic induction position and automatic loading unloading operation are achieved, and the purpose of high-efficiency and safe production is achieved; and moreover, different PCBs can be produced and worked, the automatic PCB production line is wide in application range and high in universality andpracticability, the arrangement number of the equipment can be greatly reduced, and the manual cost and the investment cost are reduced.

Owner:广东埃华路机器人工程有限公司

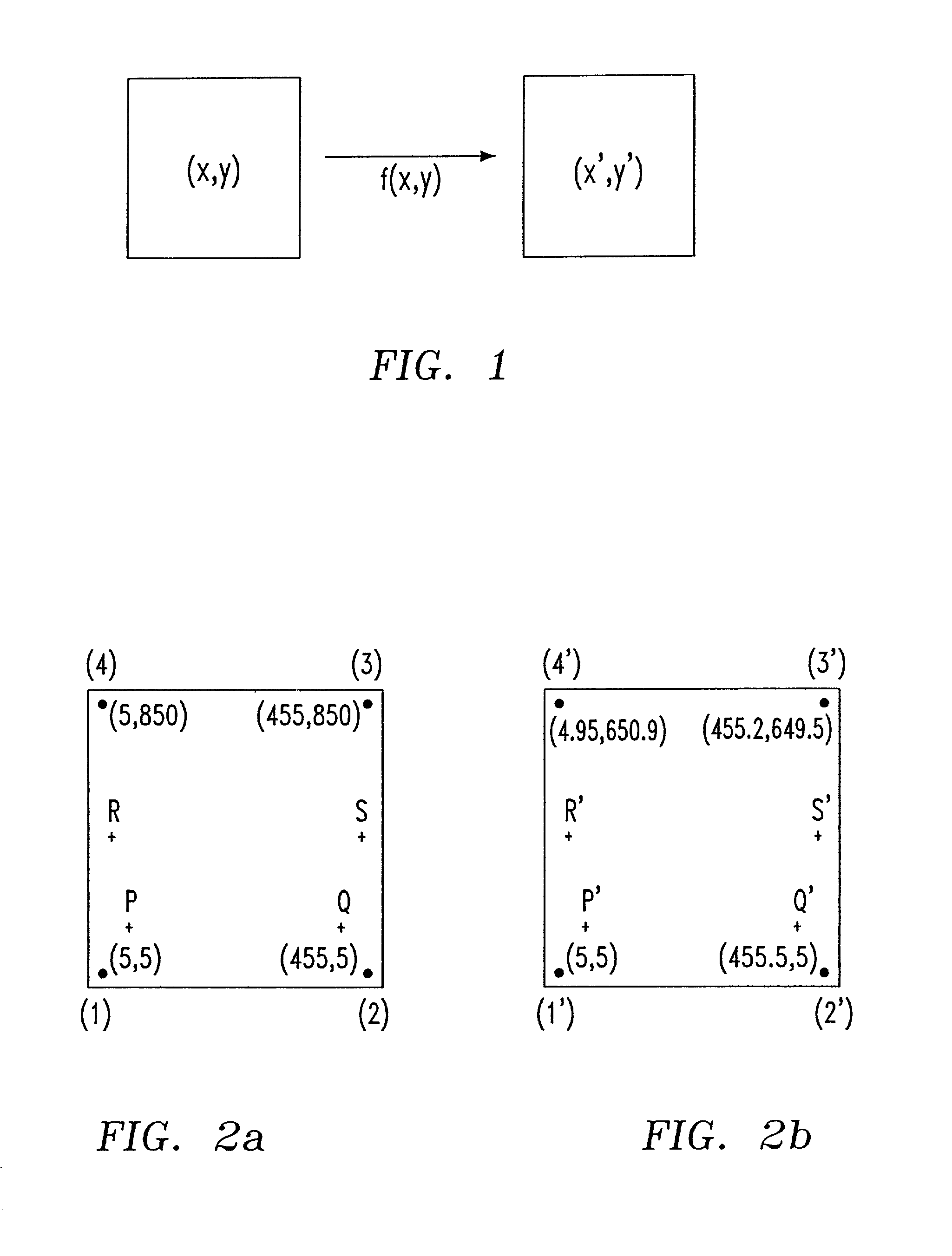

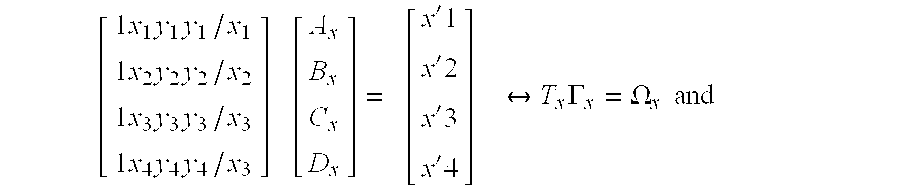

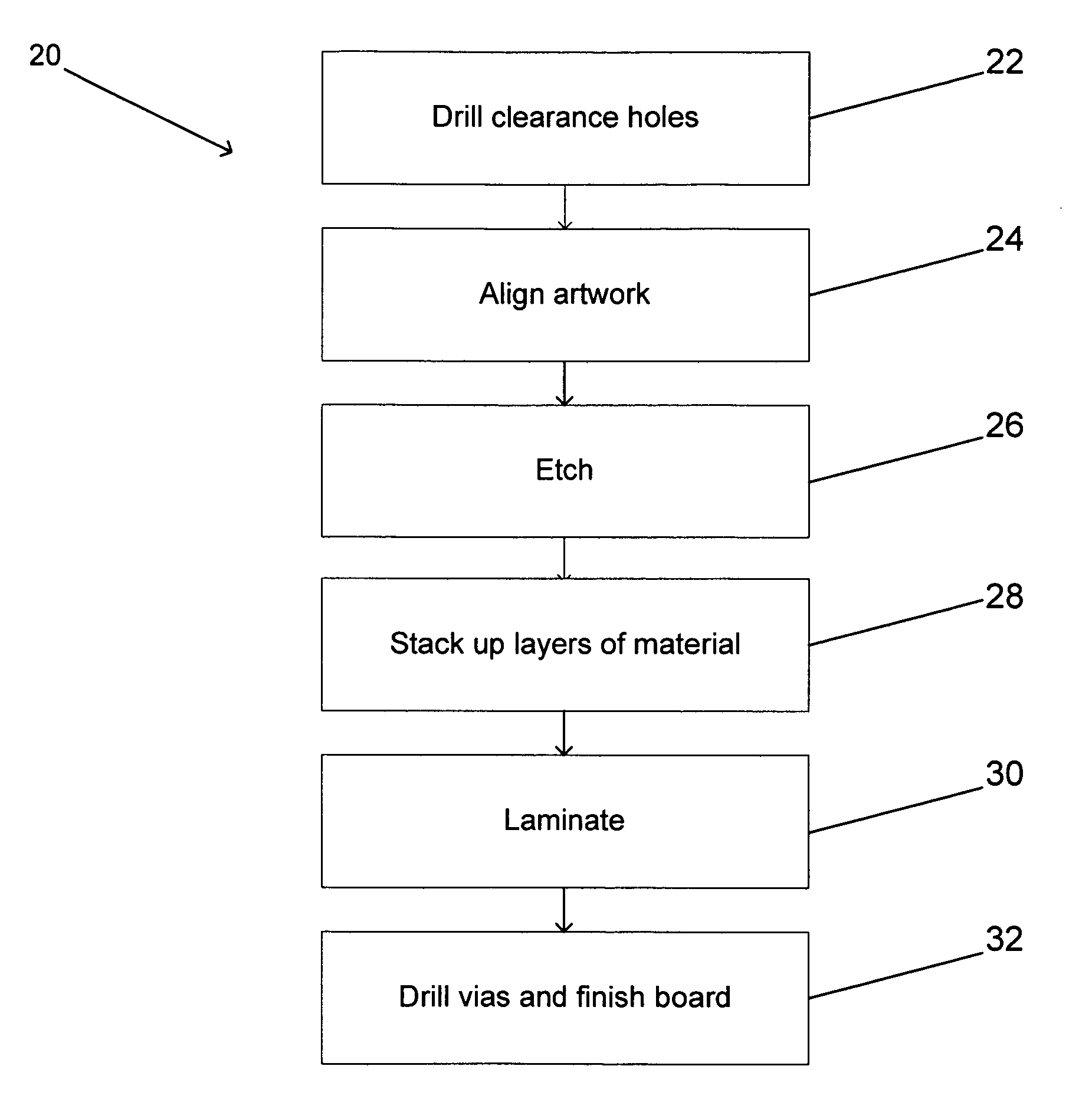

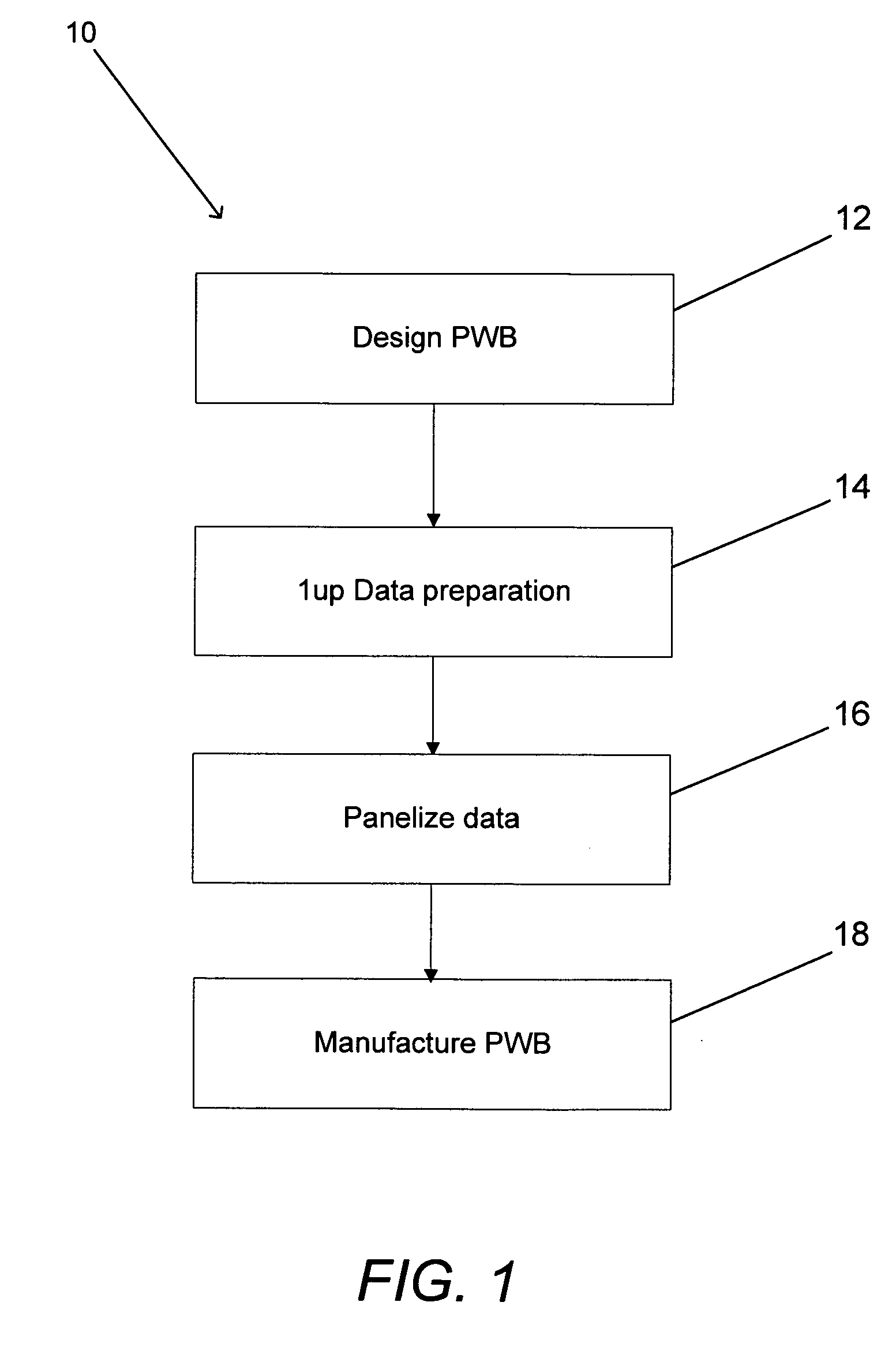

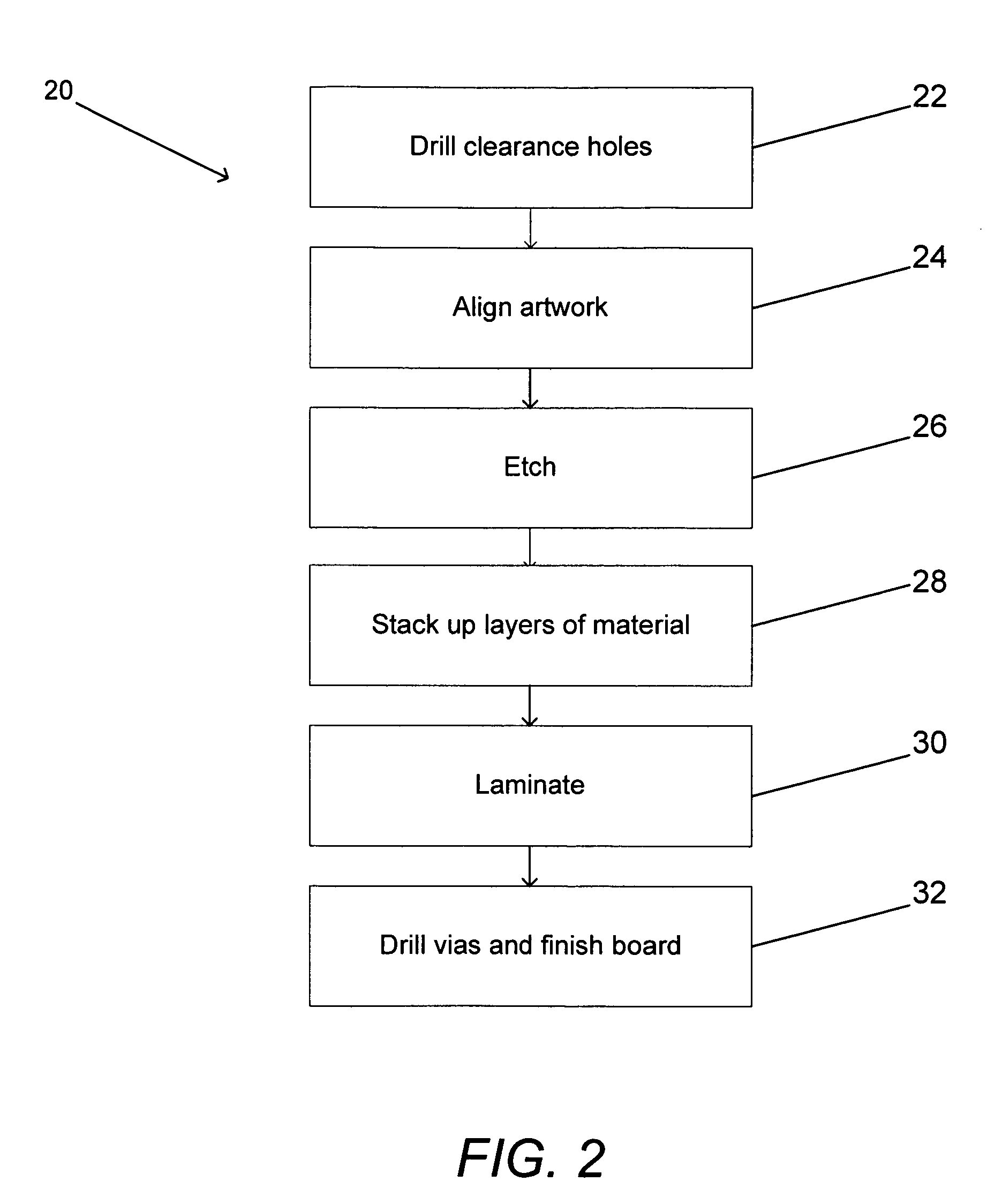

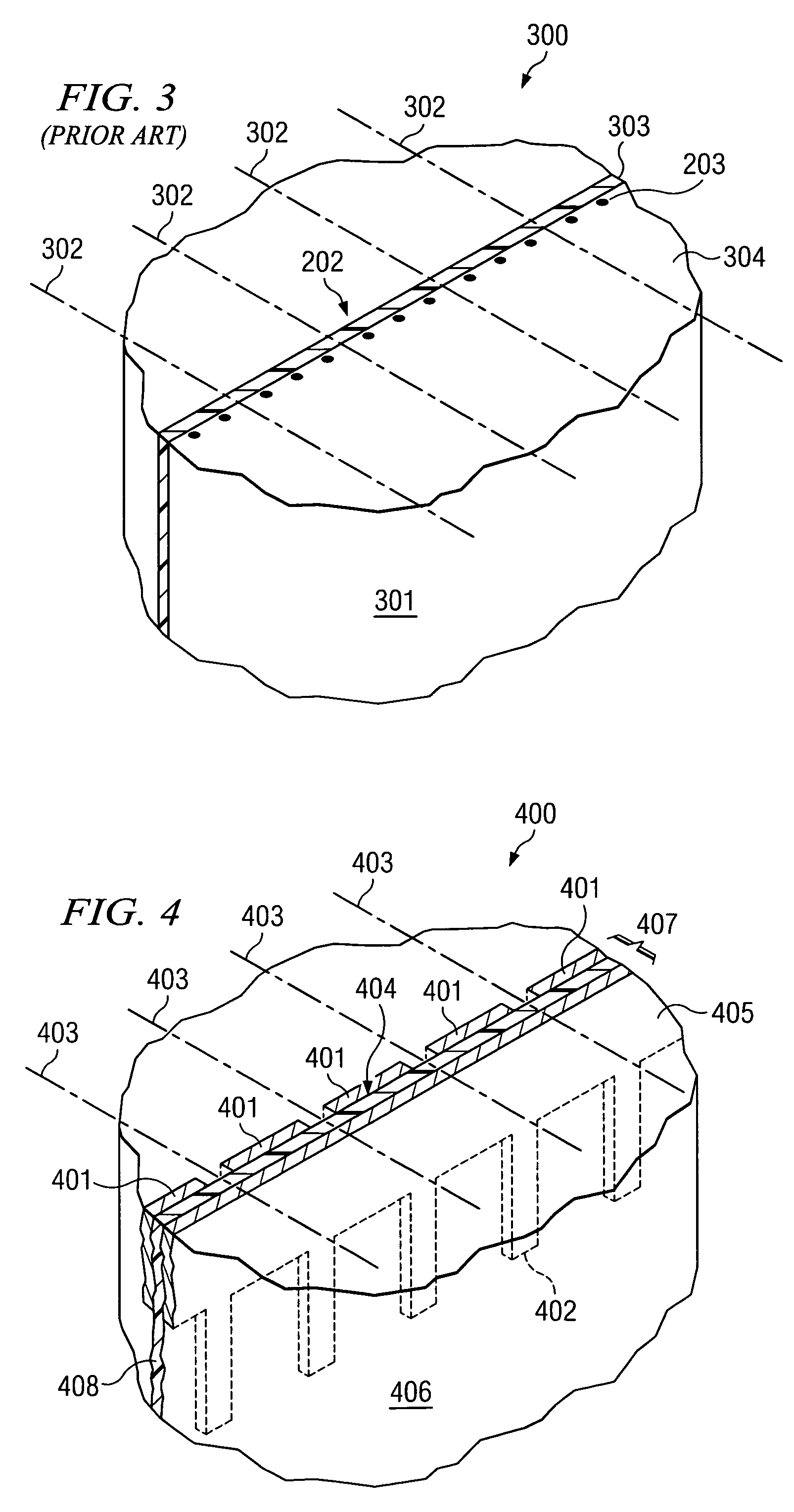

Model for modifying drill data to predict hole locations in a panel structure

InactiveUS20030130826A1Printed circuit aspectsCircuit board tools positioningMathematical modelEngineering

A method of creating a mathematical model which is employed in the determination of at least one work location in a multi-layered laminated circuit panel. The mathematical model for modifying drill data takes into consideration translational and rotational compensations caused by the encountered stretching or shrinking of the multi-layered panel subsequent to pressing or due to thermally processing, whereby the mathematical model may be utilized to modify drill data in order to accurately predict hole or via locations.

Owner:IBM CORP

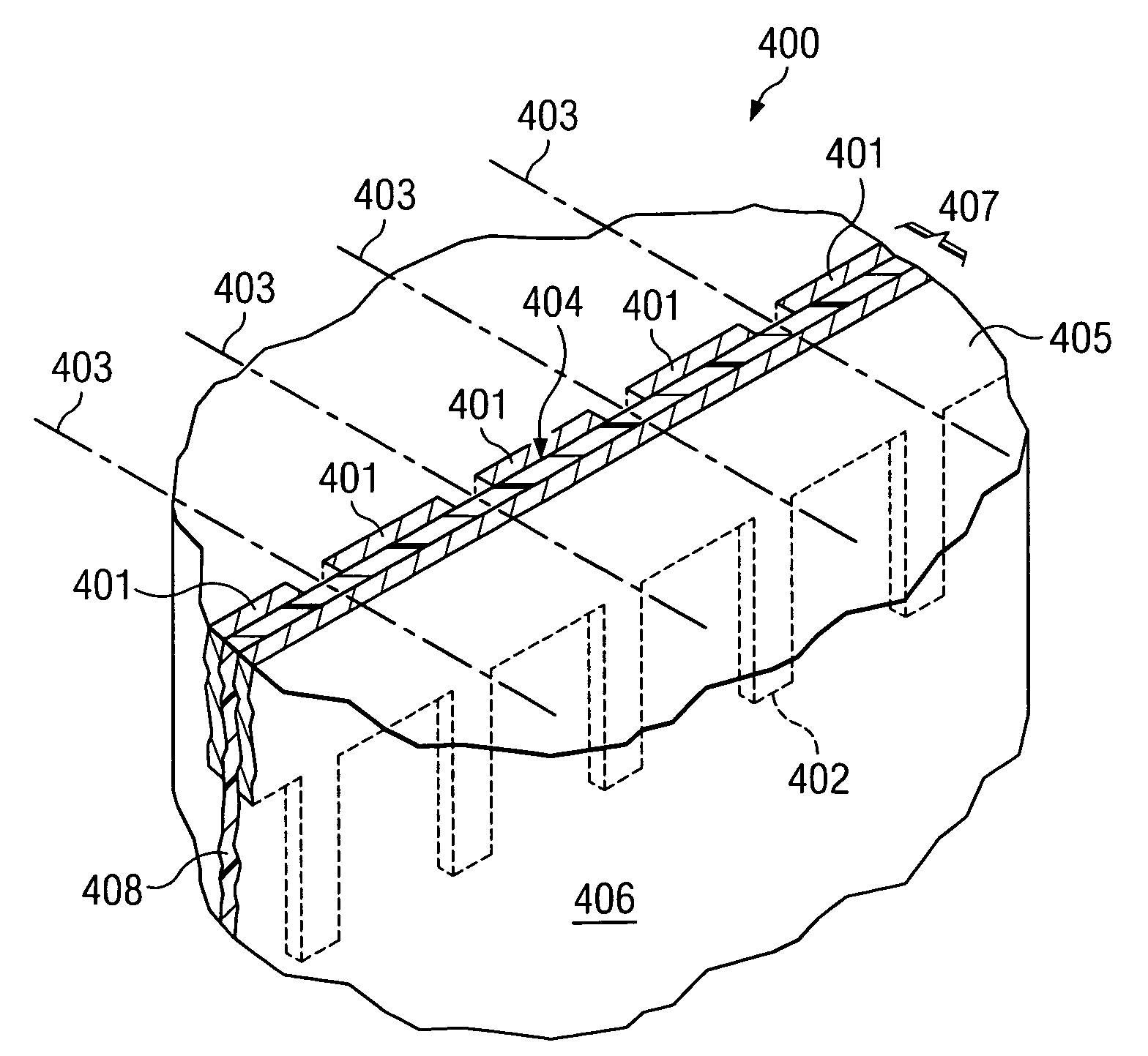

Manufacturing process: how to construct constraining core material into printed wiring board

InactiveUS20060231198A1Precise alignmentImprove manufacturing yieldLamination ancillary operationsPrinted circuit aspectsManufacturing technologyEngineering

Processes for manufacturing printed wiring boards including electrically conductive constraining cores are disclosed. Several of the processes enable precise alignment of tooling holes used by tools to perform processes with respect to various panels and subassemblies used to form finished printed wiring boards. Modifications to Gerber files that can increase manufacturing yield and provide the ability to detect faulty printed wiring boards in a panelized array of printed wiring boards are also discussed. One embodiment of the invention includes aligning the weave of a woven panel of electrically conductive material relative to a tool surface using at least a pair of references and forming tooling holes in the panel of electrically conductive material.

Owner:STABLCOR TECH

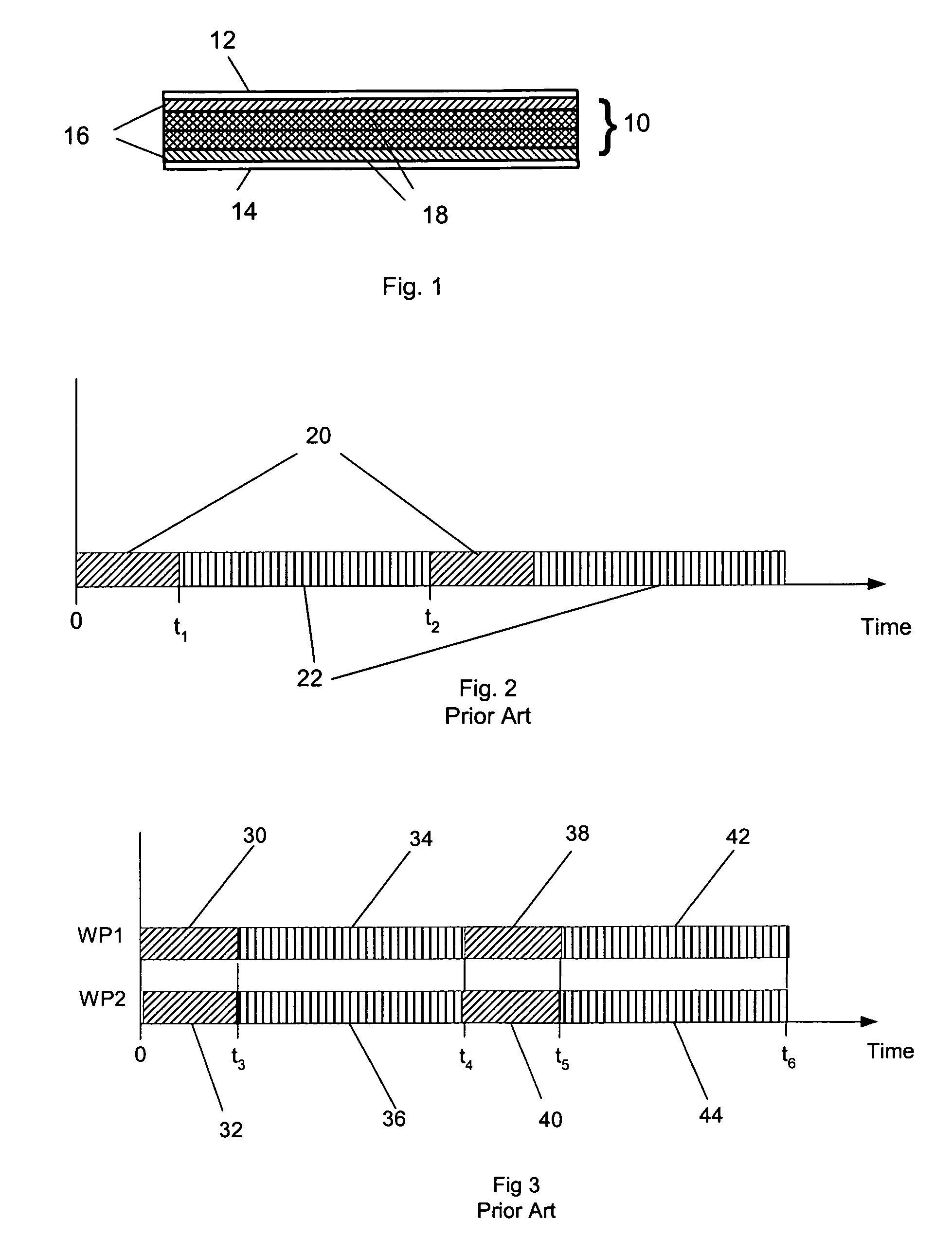

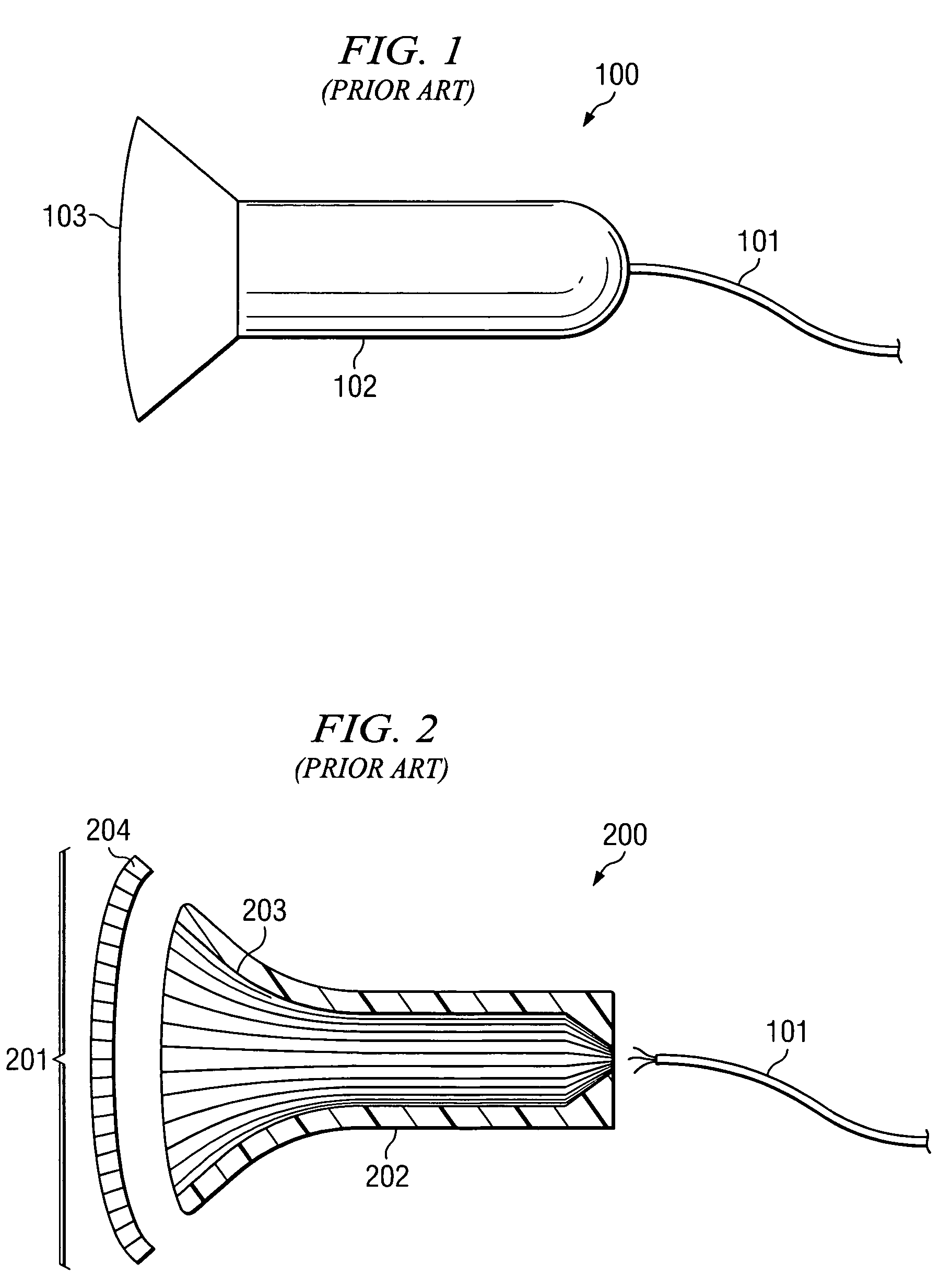

Alignment features for dicing multi element acoustic arrays

ActiveUS7449640B2Increase profitPiezoelectric/electrostriction/magnetostriction machinesPrinted circuit aspectsLeading edgeAcoustic array

A method and system include a cable including a plurality of conductors terminating at a leading edge of the cable, and markers disposed at the leading edge providing visual reference points at one or more predetermined positions, the markers being separate from the plurality of conductors.

Owner:FUJIFILM SONOSITE

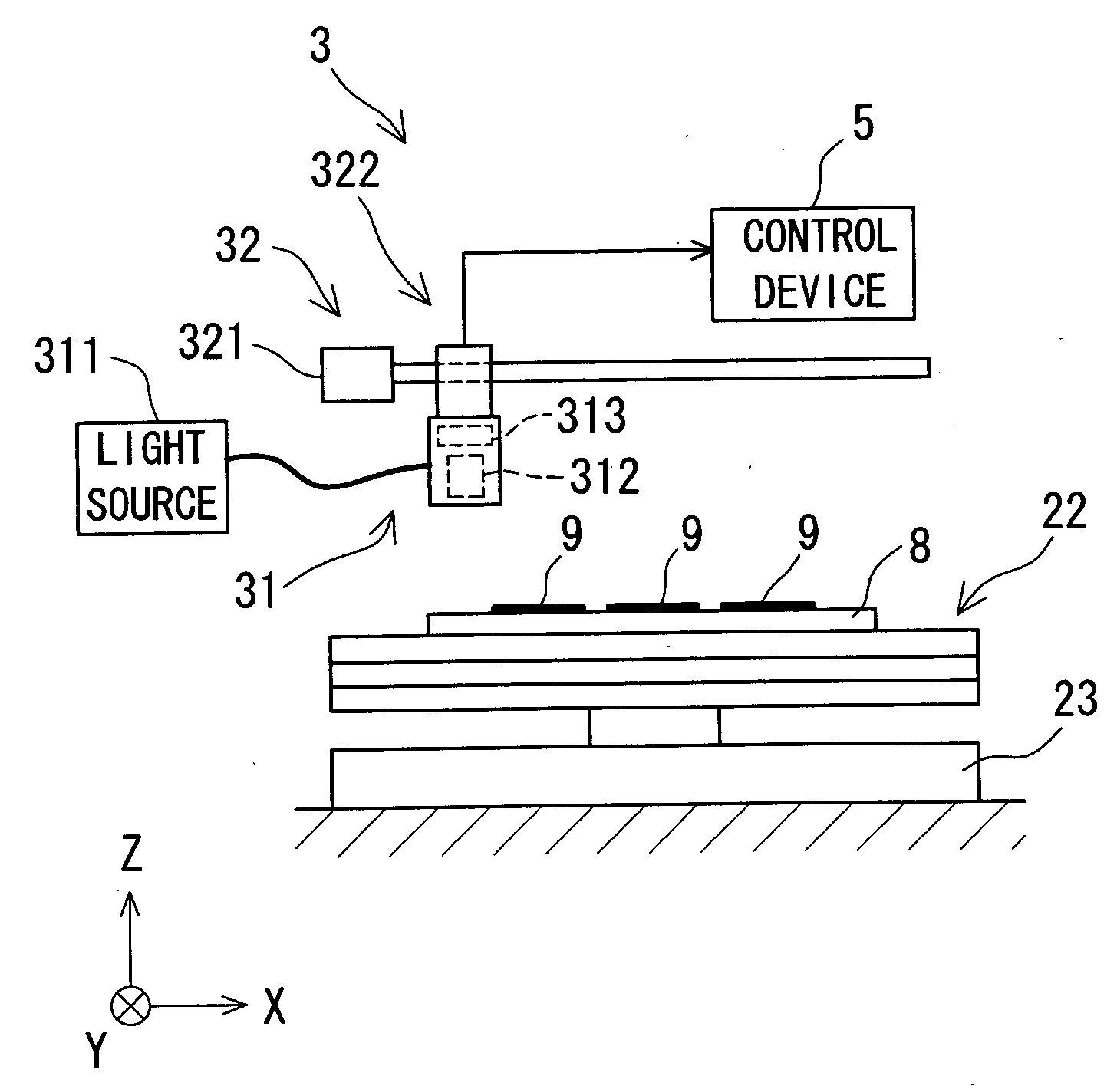

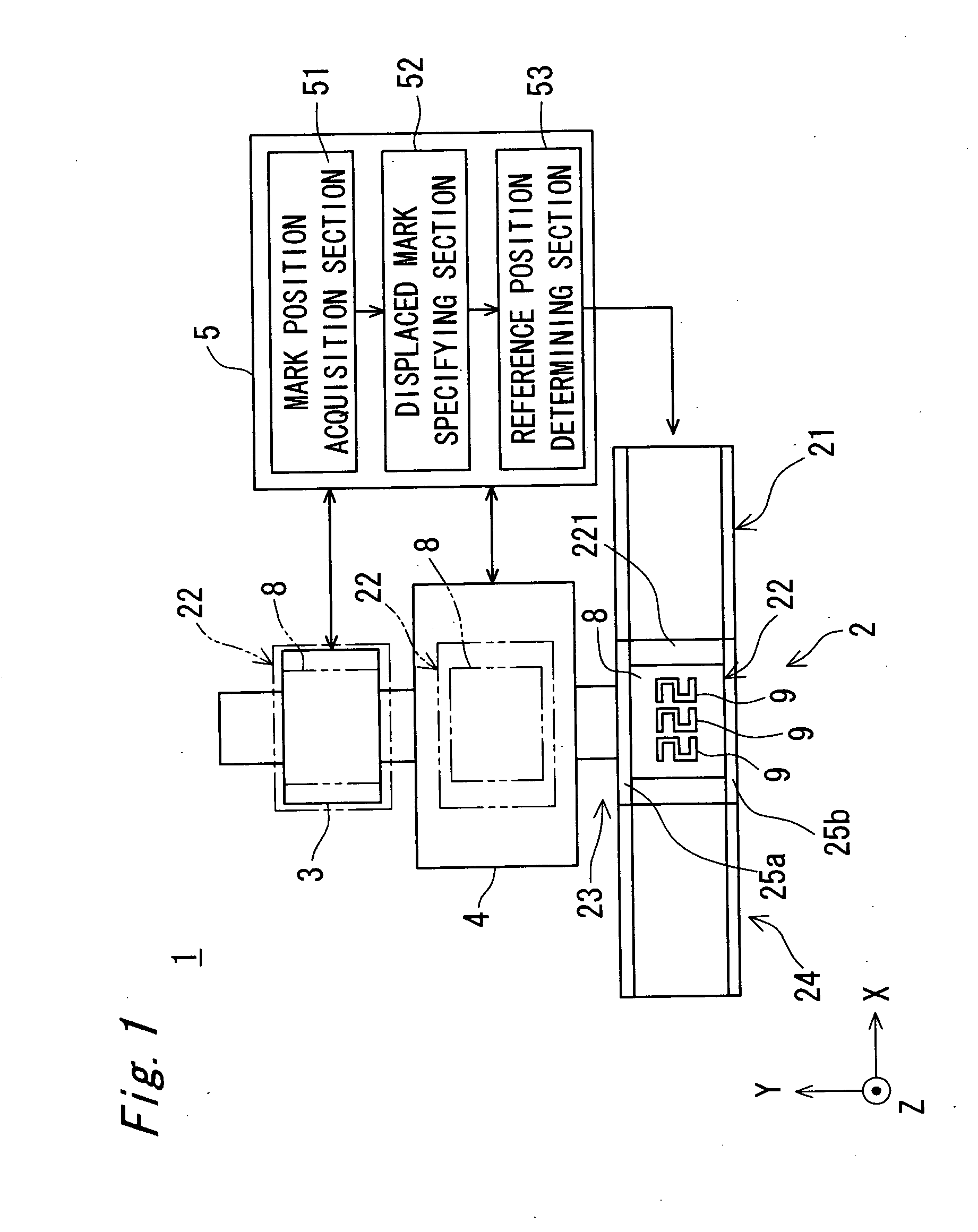

Reference position determining method and apparatus for electronic component mounting

InactiveUS20060048383A1Improve accuracyImprove efficiencyAssembly machinesCircuit board tools positioningMarking outElectronic component

In a printing apparatus, individual positional data for positions of four object marks provided on a plurality of FPCs held on a conveyance tray are acquired by a mark position acquisition section based on an image acquired by an image acquisition unit. In a displaced mark specifying section, relative positional relations of four object marks are determined, and compared with a reference positional relation, by which a displaced object mark is specified. Then, in a reference position determining section, a reference position for a plurality of FPCs on a conveyance tray is determined based on a plurality of object marks resulting from excluding the displaced object mark out of the four object marks. Thus, a reference position in execution of printing in a printing unit can be determined with high precision.

Owner:PANASONIC CORP

Exposure device with mechanism for forming alignment marks and exposure process conducted by the same

ActiveUS20090059195A1Accurate transferReduce riskPrinted circuit aspectsSolid-state devicesEngineeringRoll film

The present invention relates to an exposure device for transferring circuit patterns of a mask to a roll-film-shaped object. The exposure device includes a supply reel rotation section that is constituted by a supply reel around which the object is wound and that feeds the object by rotating the supply reel, at least one guide roller for guiding the object fed from the supply reel rotation section, an exposure stage on which the circuit patterns are transferred to the object guided by the guide roller, and an alignment mark forming section which forms, on the object, alignment marks that are used to align the mask with the object and which is positioned between the guide roller and the exposure stage.

Owner:ORC MFG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com