Position matching method and screen printer

A technology of screen printing and printing table, applied in the direction of screen printing, screen printing machine, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

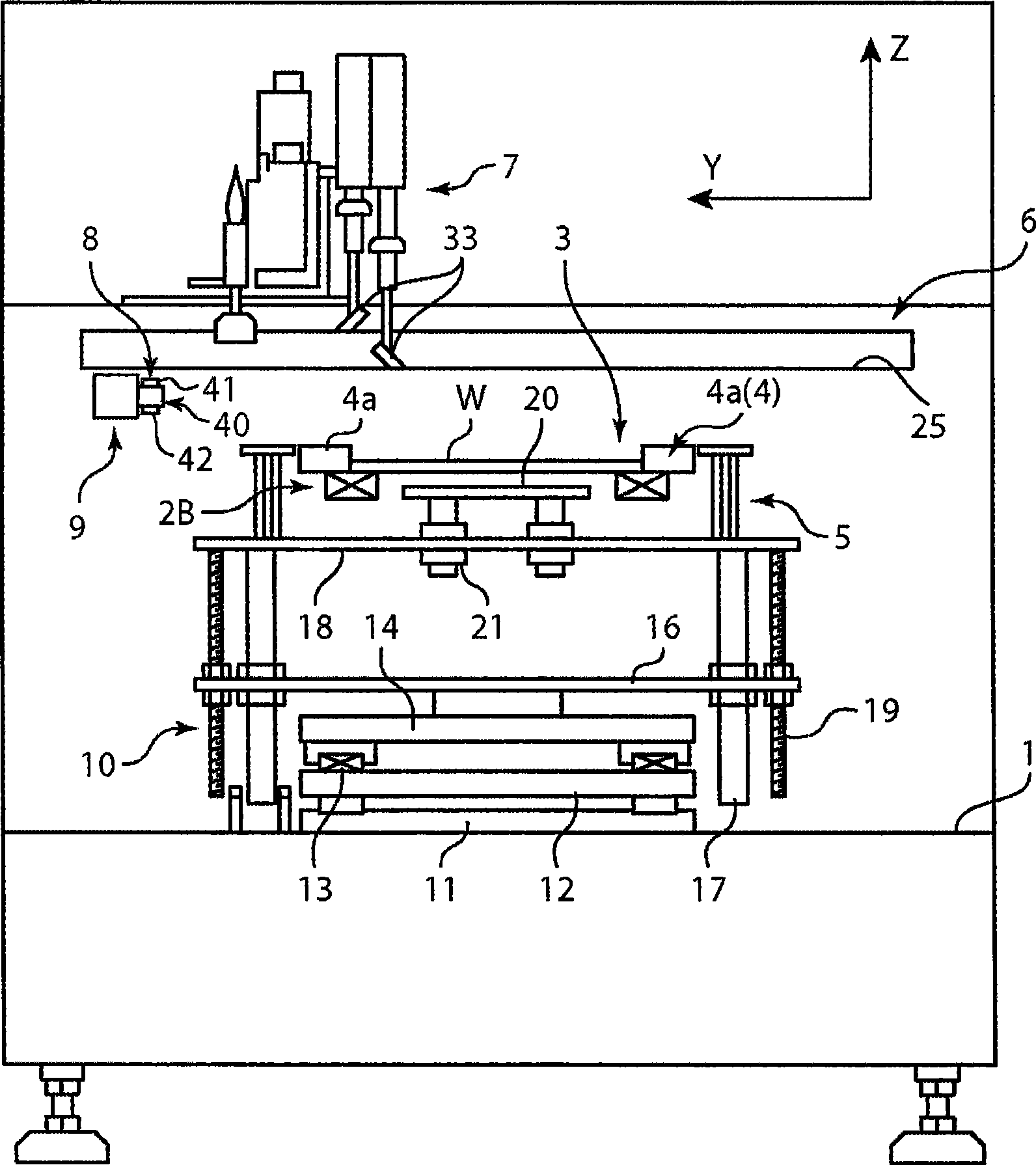

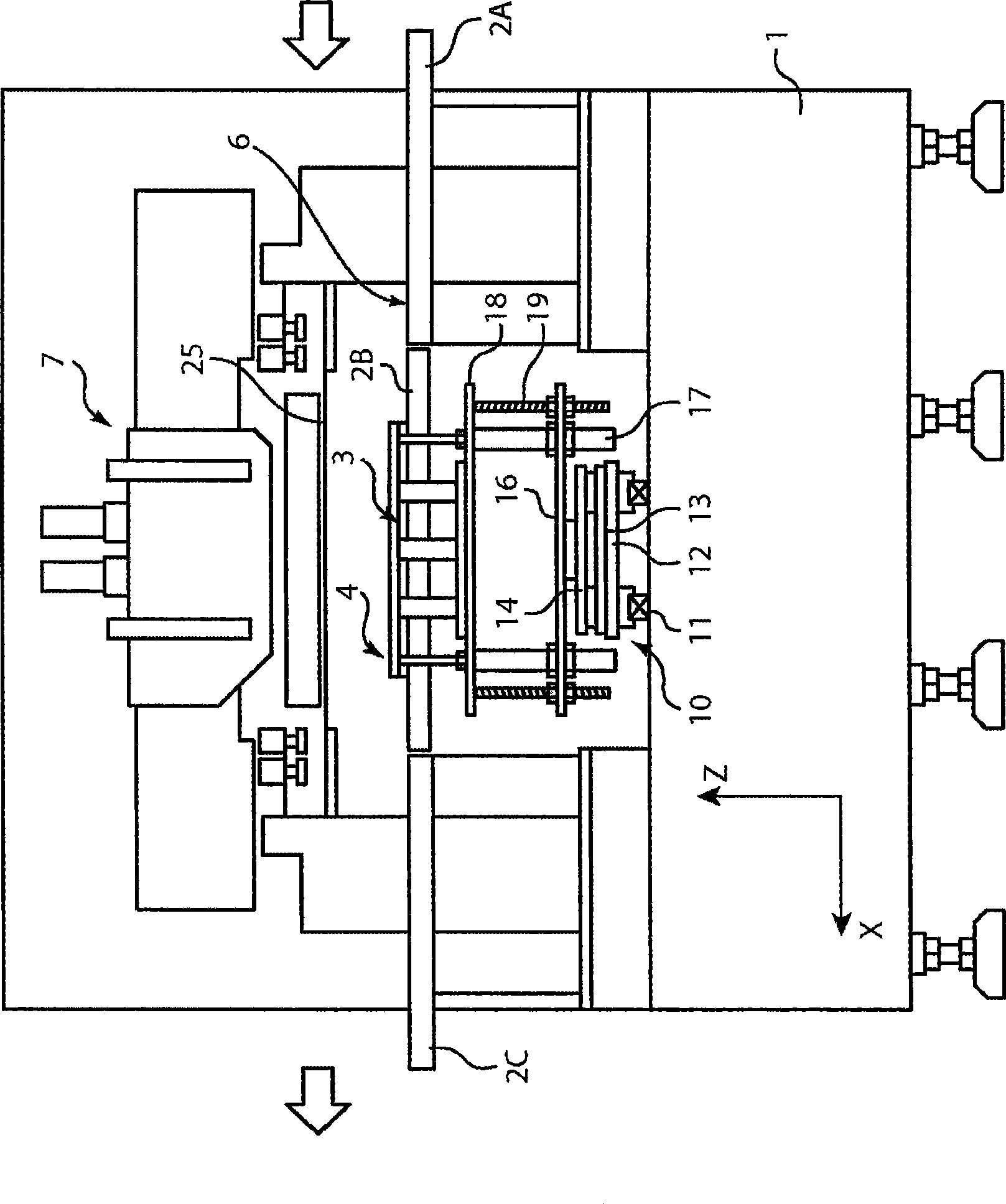

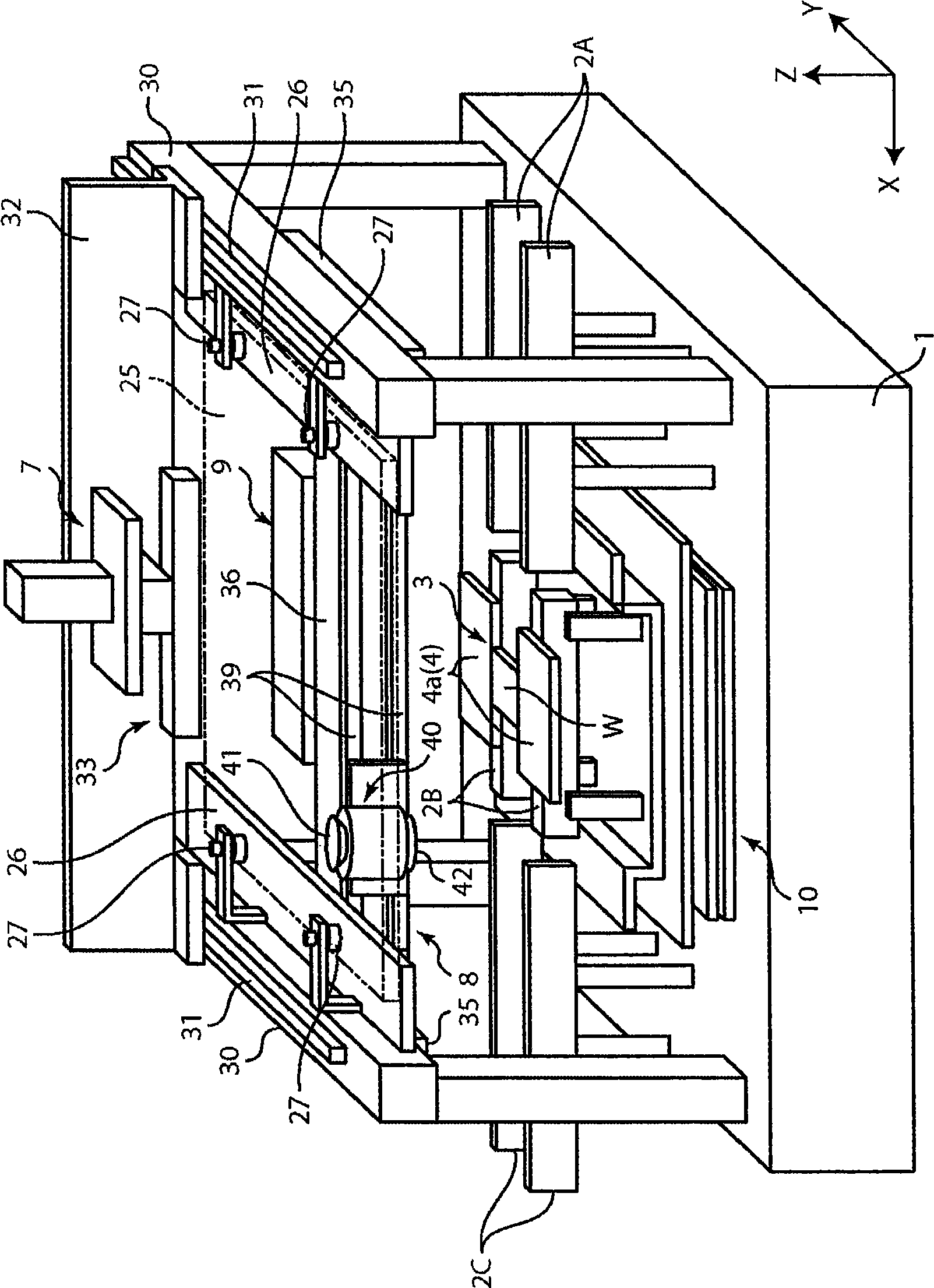

[0025] figure 1 , figure 2 A screen printing device according to the present invention (a screen printing device using the alignment method according to the present invention) is schematically shown, wherein, figure 1 It is a side view of the main part of the screen printing device with the case removed, figure 2 is the main view.

[0026] like figure 1 , figure 2 As shown, on the base 1 of the screen printing device (hereinafter referred to as the printing device), a printing table 3 is arranged, and on both sides of the printing table 3, a printed substrate W (hereinafter referred to as the substrate W) is arranged along the conveying line. ) the upstream conveyor belt 2A carrying it into the printing table 3 and the downstream conveyor belt 2C carrying it out of the printing table 3 .

[0027] In addition, in the following description, the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com