Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

432results about "Conductive material removal by irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

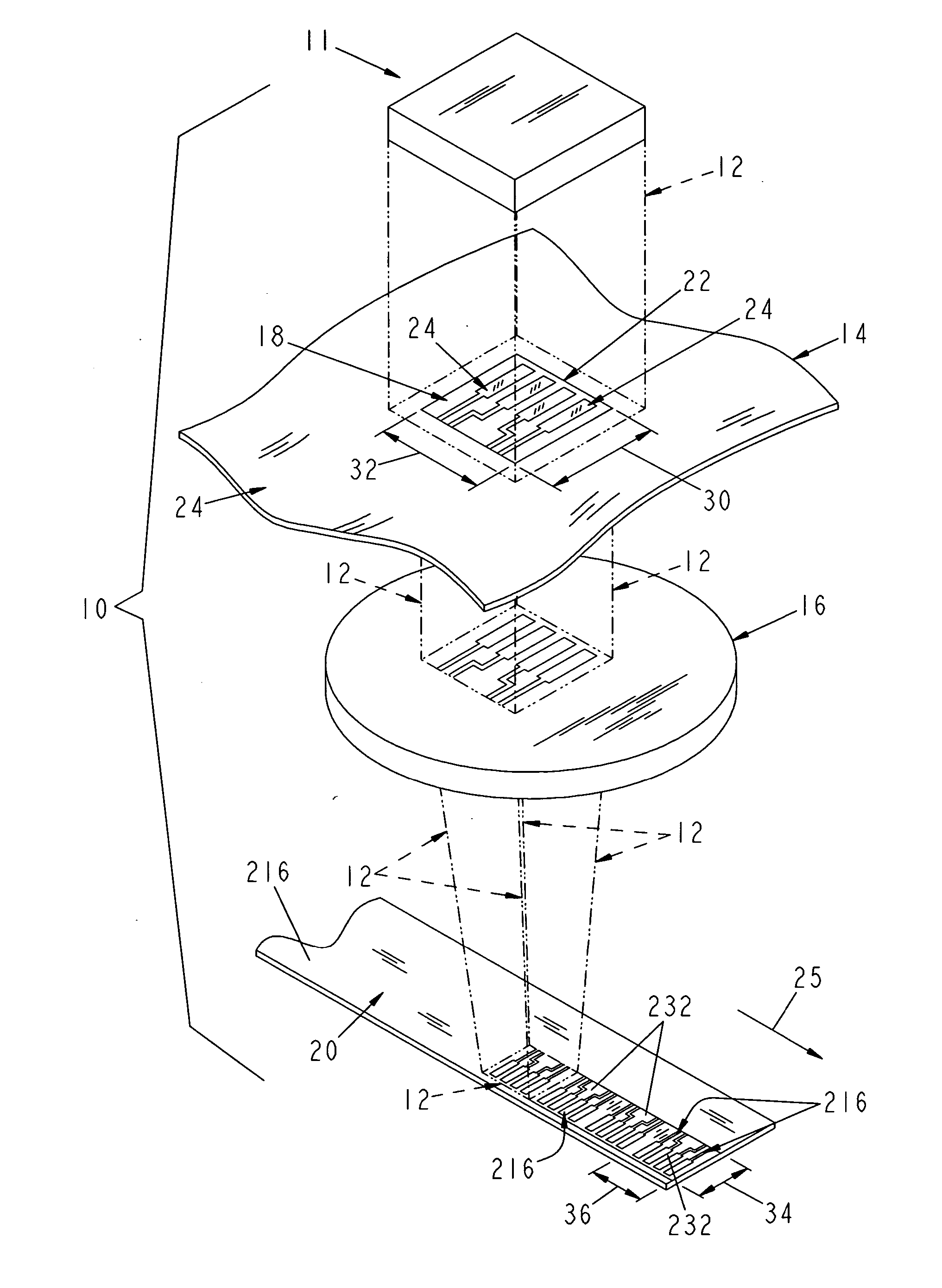

Method of making a biosensor

InactiveUS7073246B2Immobilised enzymesBioreactor/fermenter combinationsConductive materialsEngineering

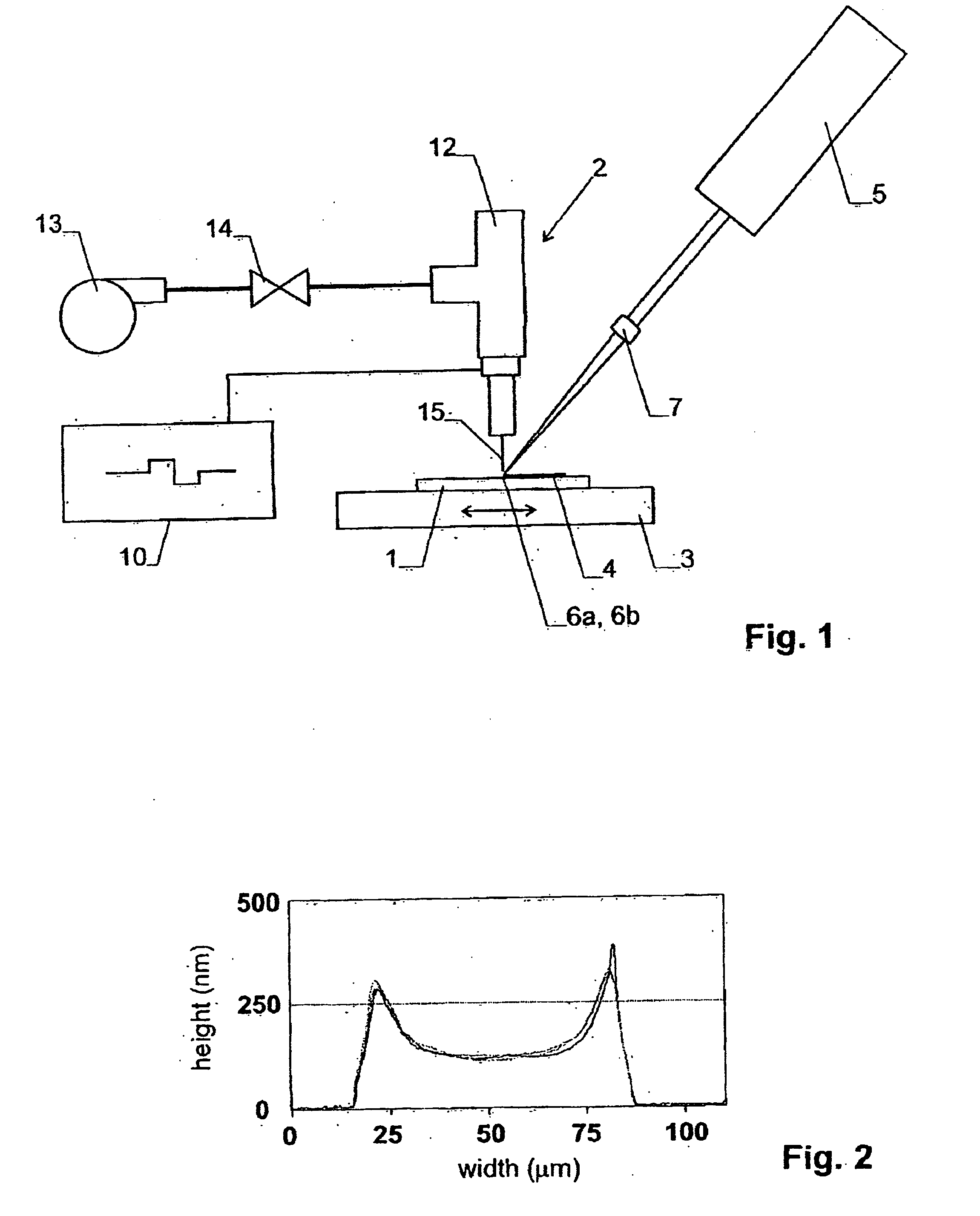

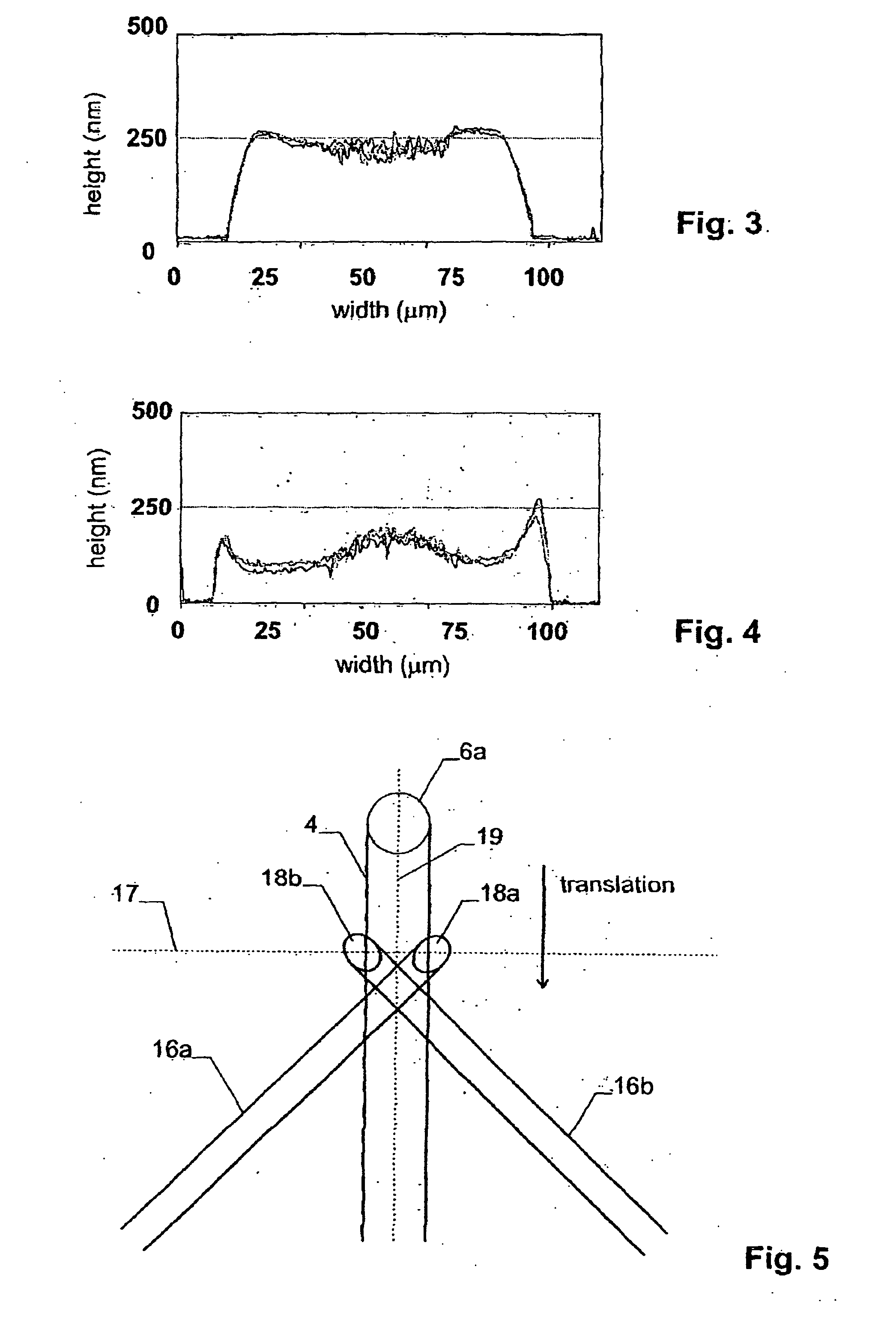

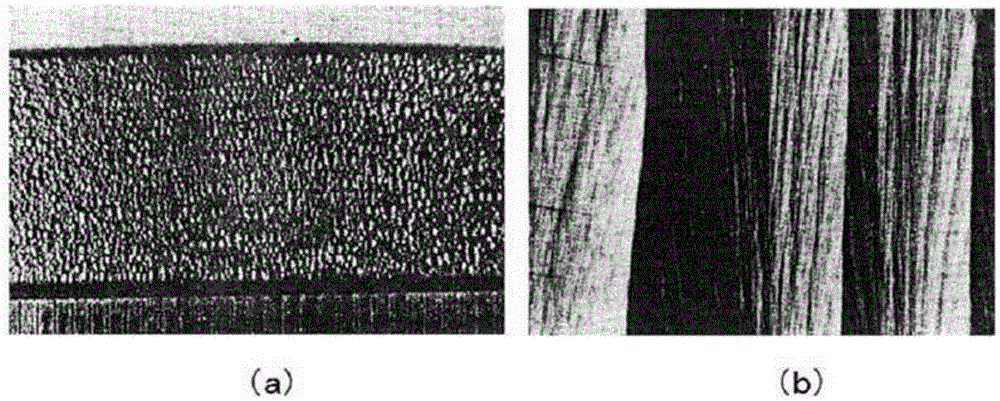

A method of making a biosensor is provided. The biosensor includes an electrically conductive material on a base and electrode patterns formed on the base, the patterns having different feature sizes. The conductive material is partially removed from the base using broad field laser ablation so that less than 90% of the conductive material remains on the base and that the electrode pattern has an edge extending between two points. A standard deviation of the edge from a line extending between two points is less than about 6 μm.

Owner:ROCHE DIABETES CARE INC +1

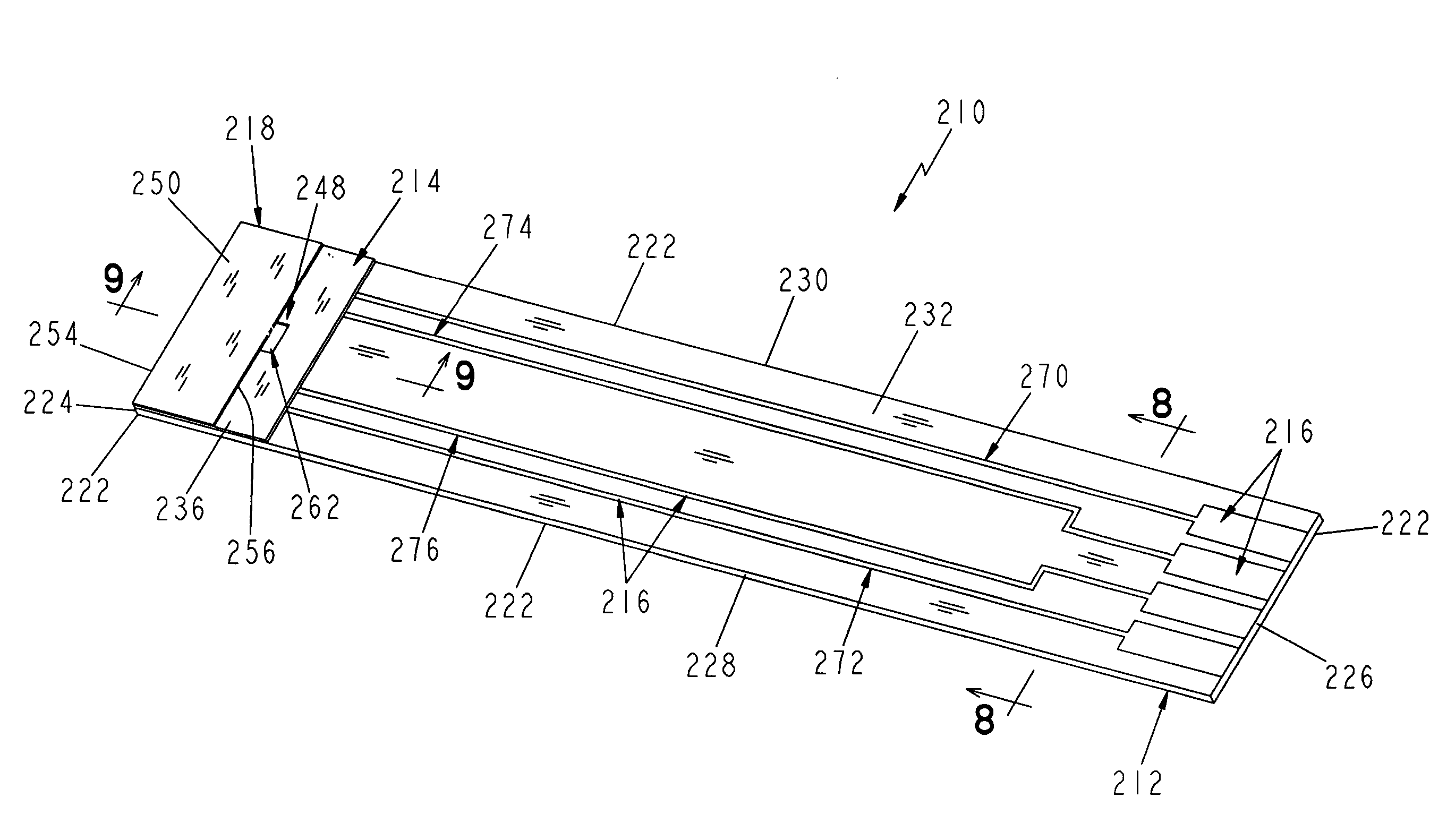

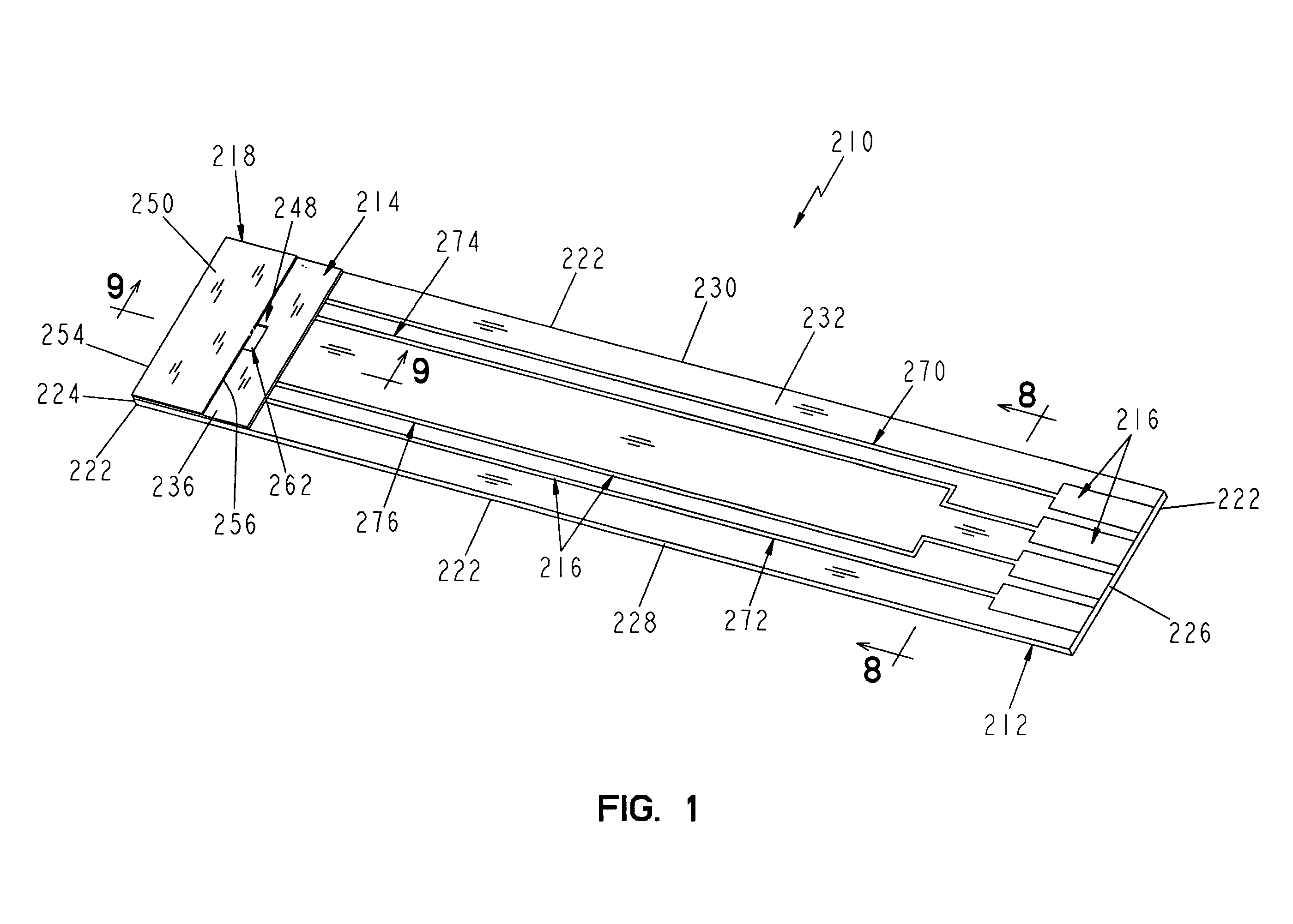

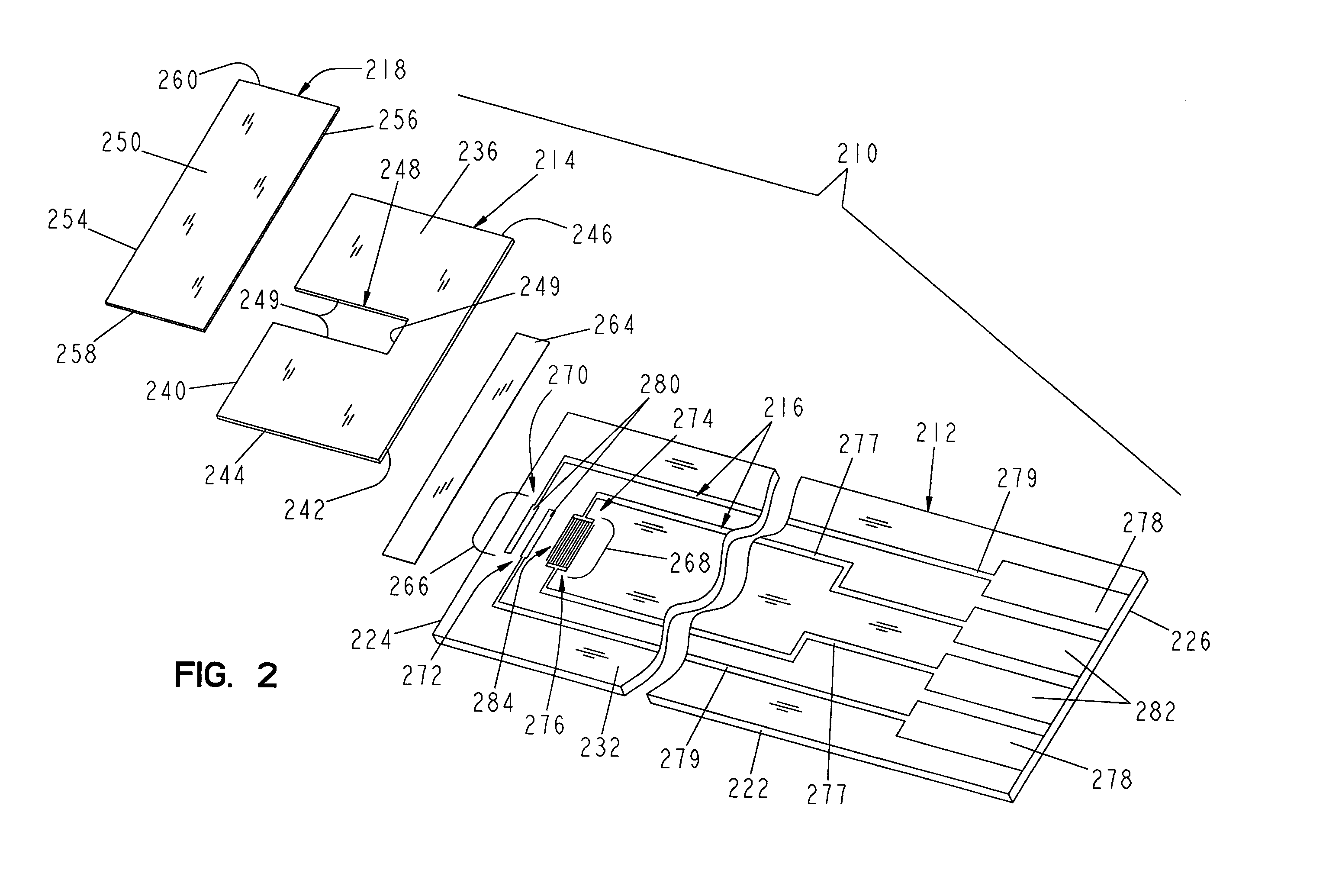

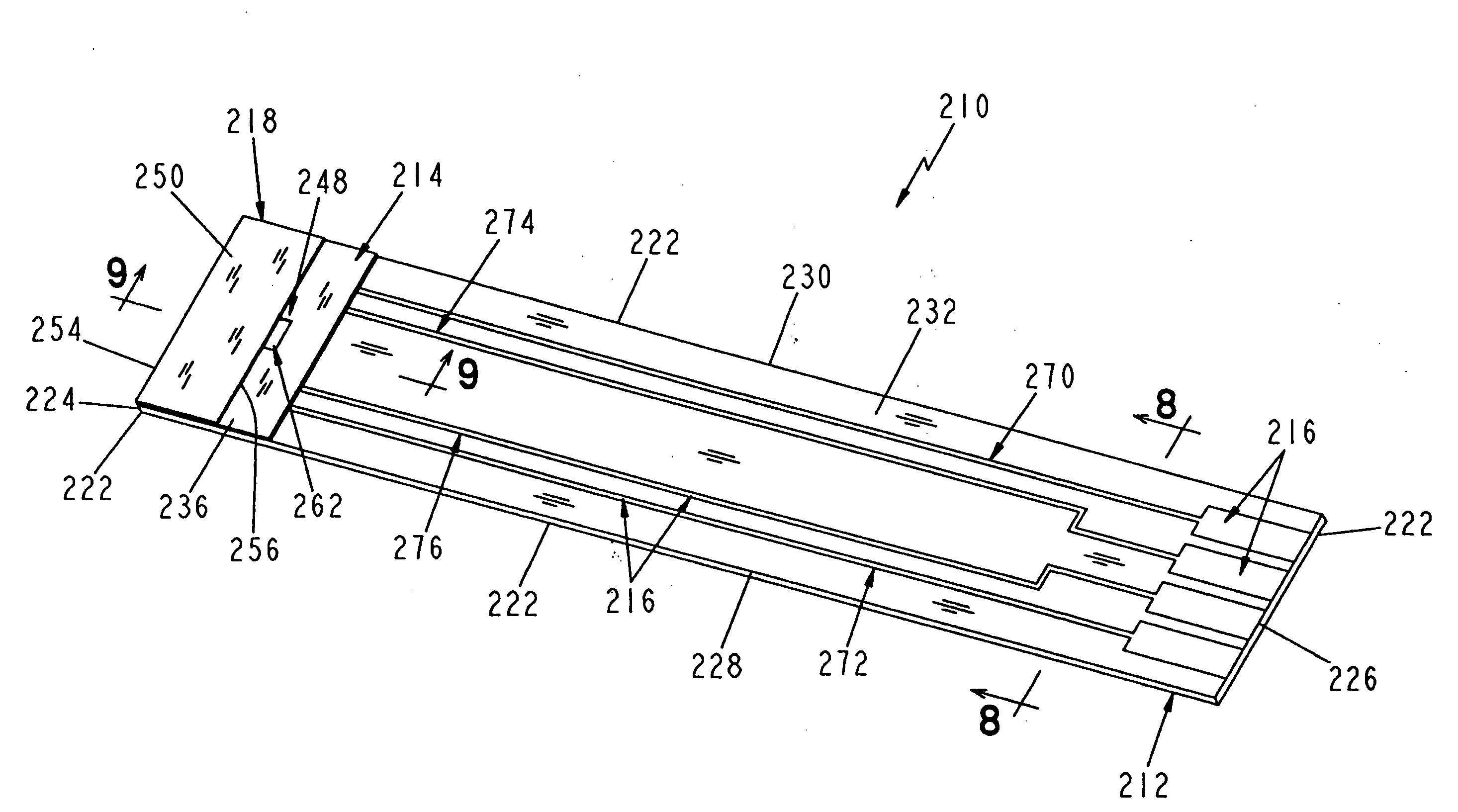

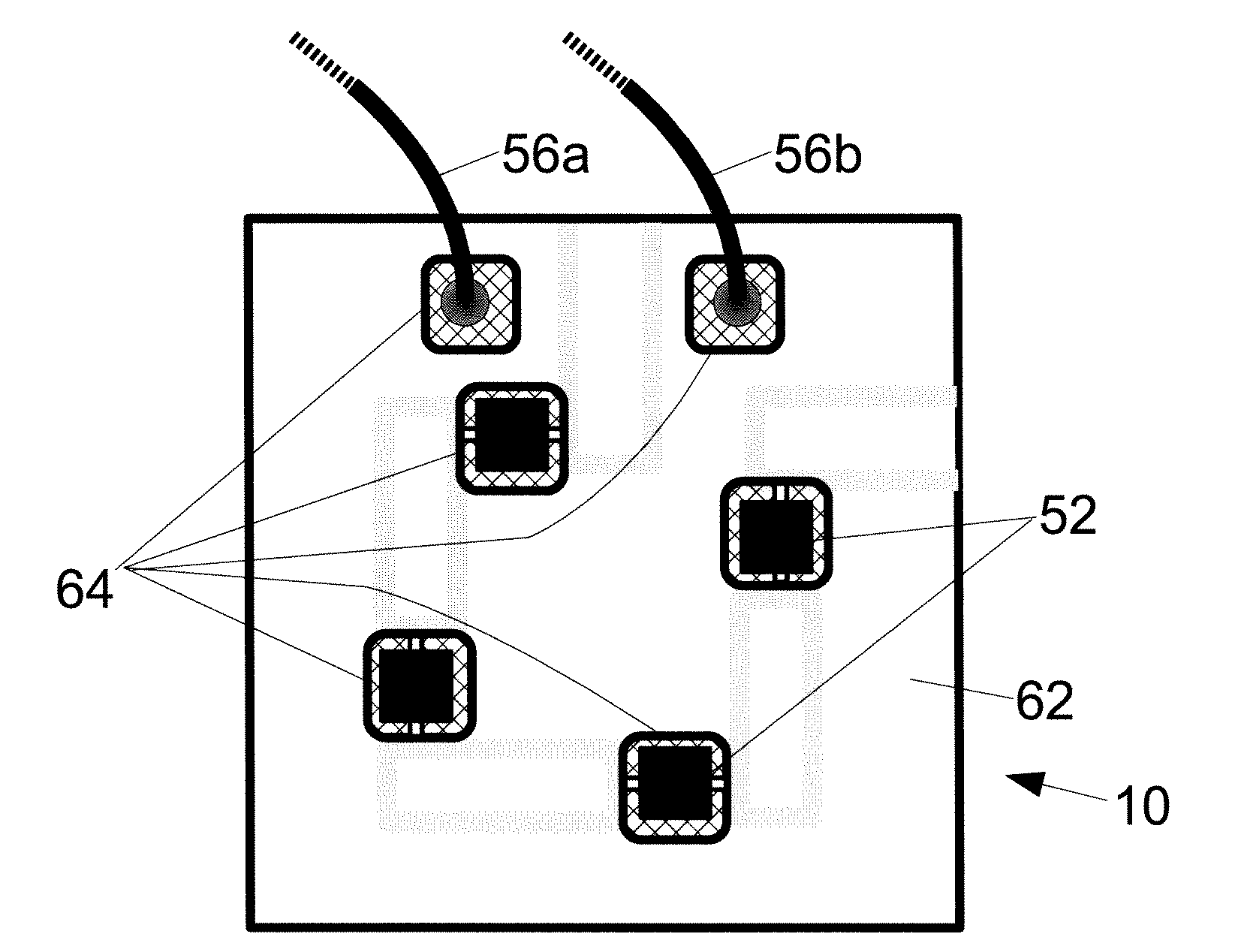

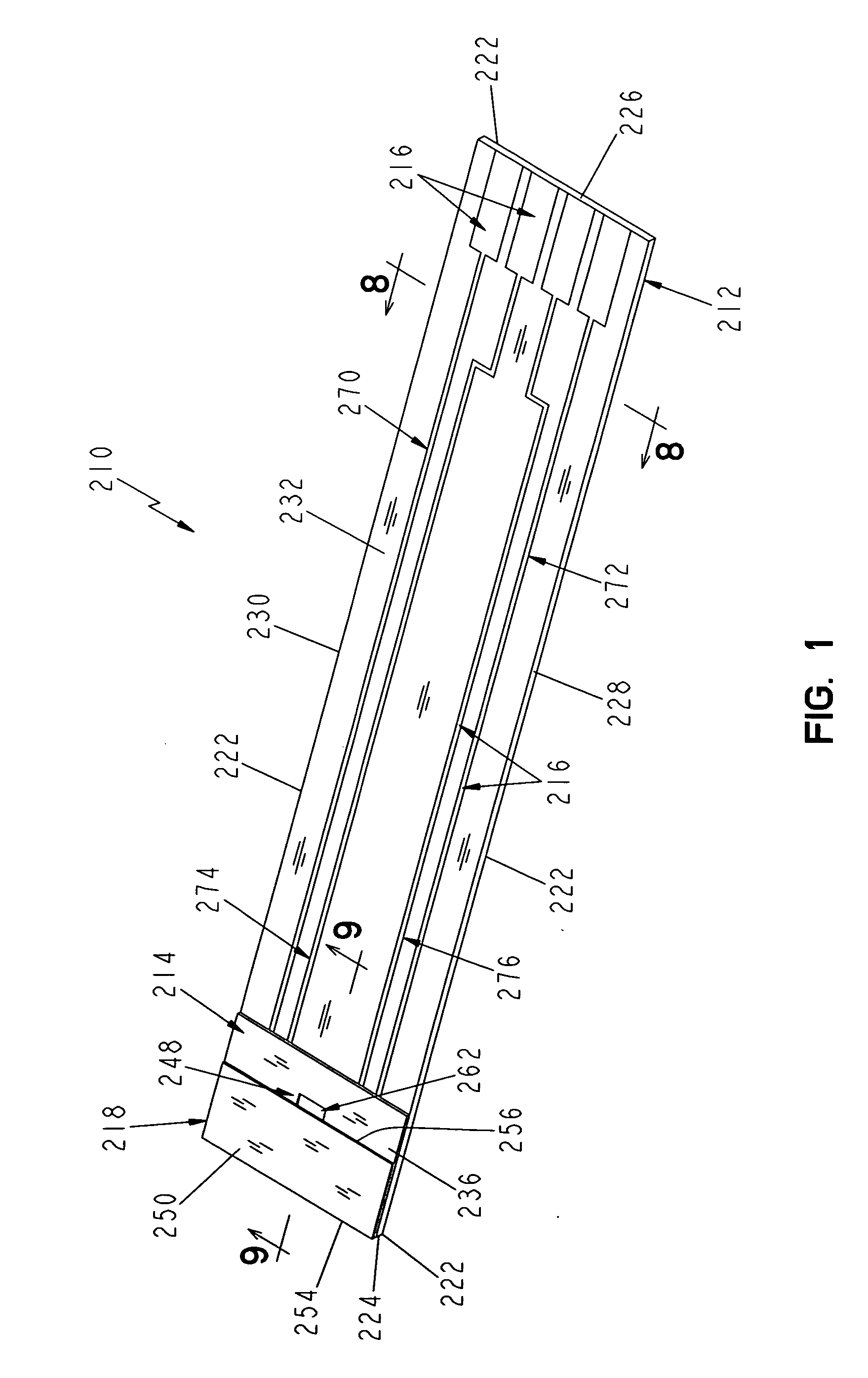

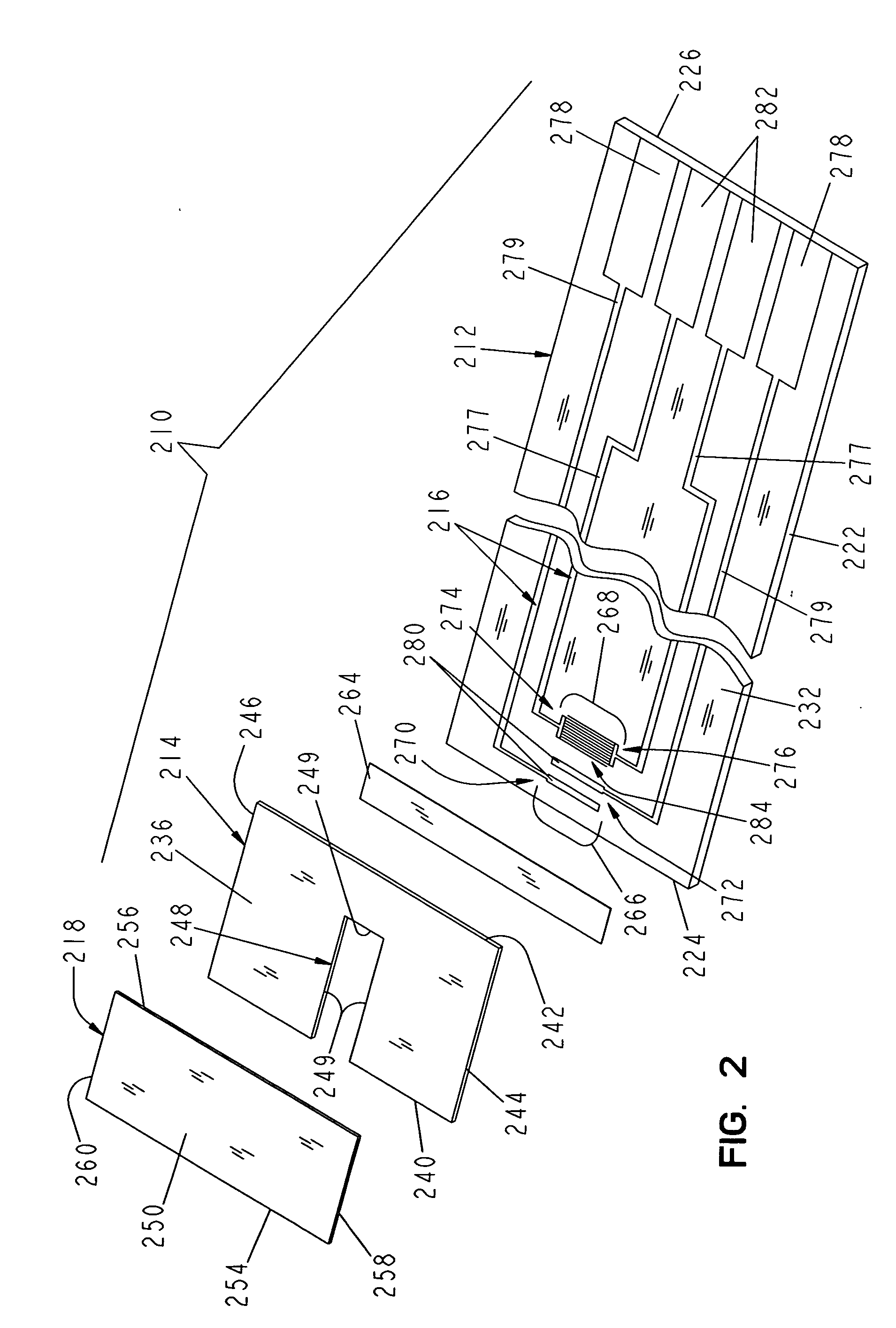

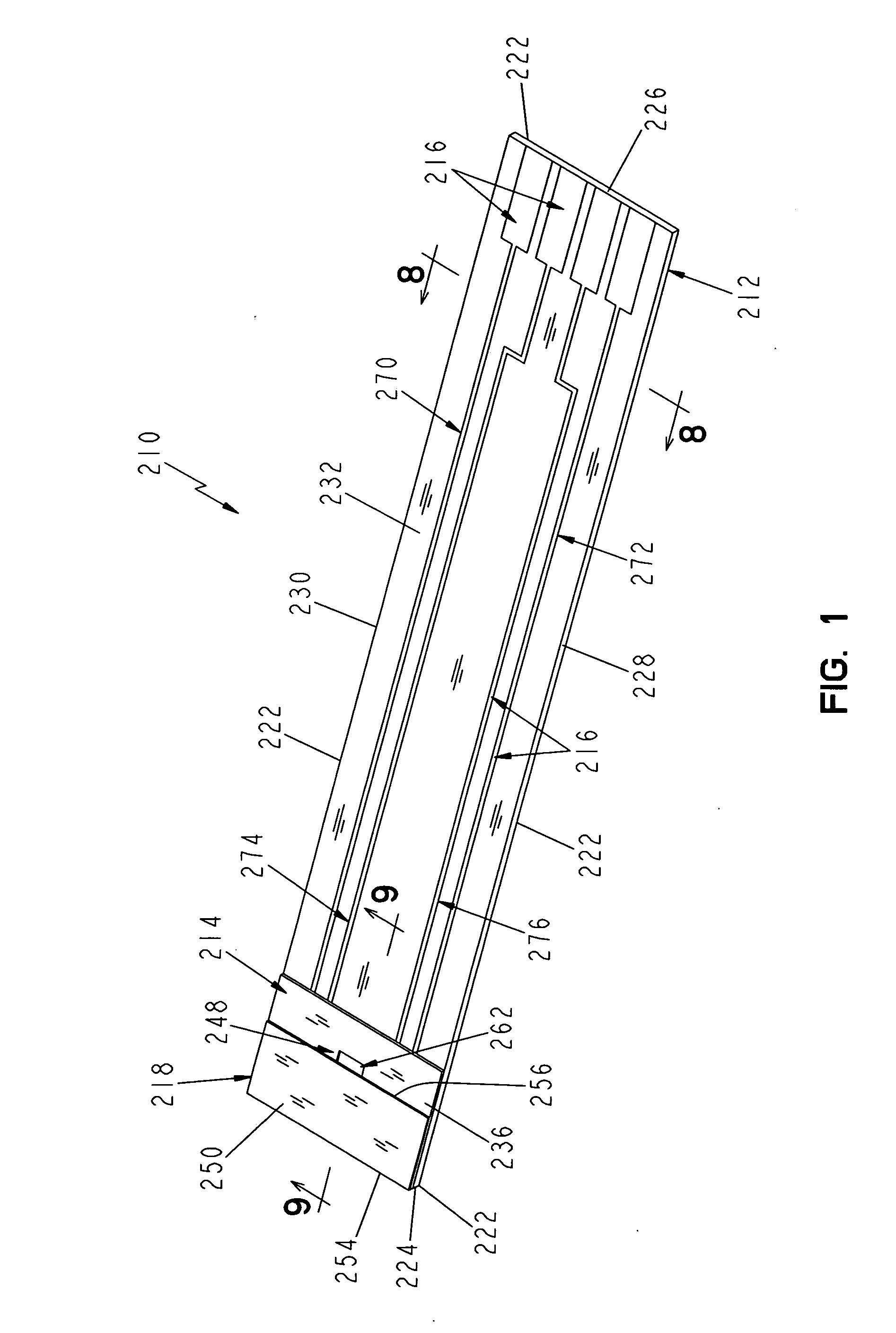

Biosensor and method of making

InactiveUS20050103624A1Immobilised enzymesBioreactor/fermenter combinationsElectrochemical biosensorNanosecond

An electrochemical biosensor with electrode elements that possess smooth, high-quality edges. These smooth edges define gaps between electrodes, electrode traces and contact pads. Due to the remarkable edge smoothness achieved with the present invention, the gaps can be quite small, which provides marked advantages in terms of test accuracy, speed and the number of different functionalities that can be packed into a single biosensor. Further, the present invention provides a novel biosensor production method in which entire electrode patterns for the inventive biosensors can be formed all at one, in nanoseconds—without regard to the complexity of the electrode patterns or the amount of conductive material that must be ablated to form them.

Owner:ROCHE DIABETES CARE INC +1

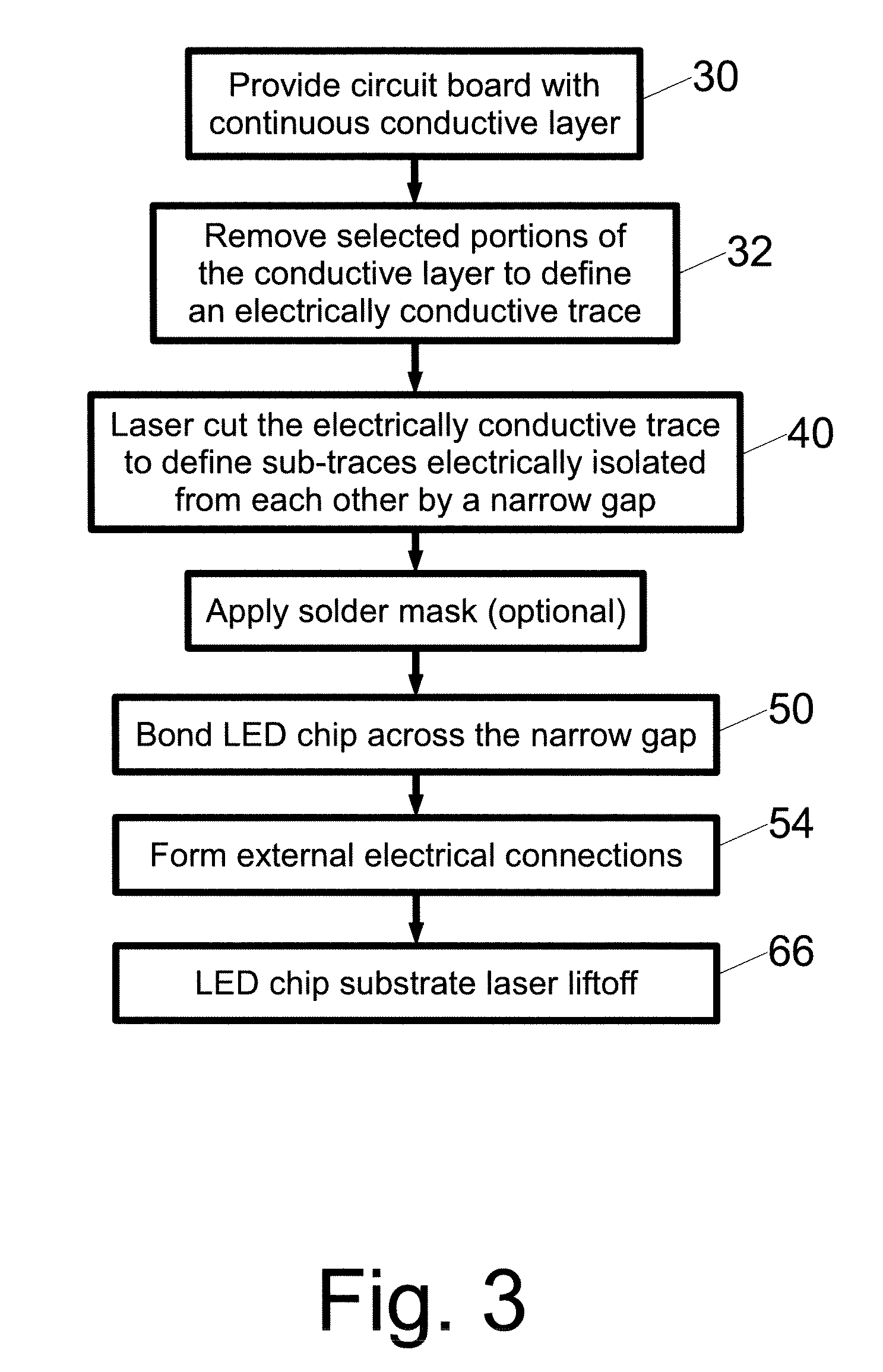

Circuit board for direct flip chip attachment

InactiveUS20090212317A1Semiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor packageLaser cutting

A packaging method comprises: forming a circuit board by forming a substantially continuous conductive layer on an insulating board and removing selected portions of the continuous conductive layer to define an electrically conductive trace; laser cutting the electrically conductive trace to define sub-traces electrically isolated from each other by a laser-cut gap formed by the laser cutting; and bonding a light emitting diode (LED) chip to the circuit board across or adjacent to the laser-cut gap, the bonding including operatively electrically connecting an electrode of the LED chip to one of the sub-traces without using an interposed submount. A semiconductor package comprises an LED chip flip-chip bonded to sub-traces of an electrically conductive trace of a circuit board, the sub-traces being electrically isolated from each other by a narrow gap of less than or about 100 microns.

Owner:LUMINATION

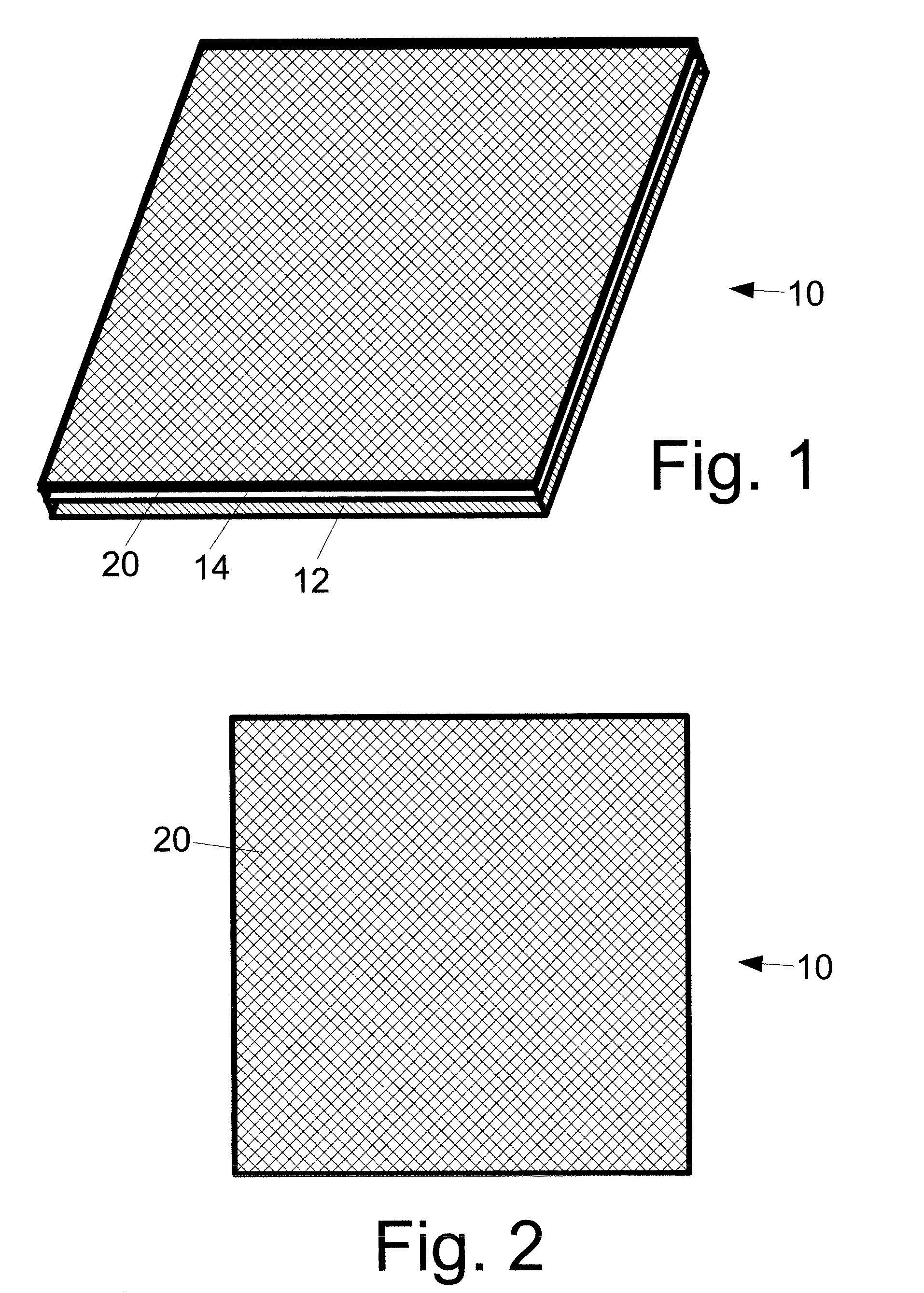

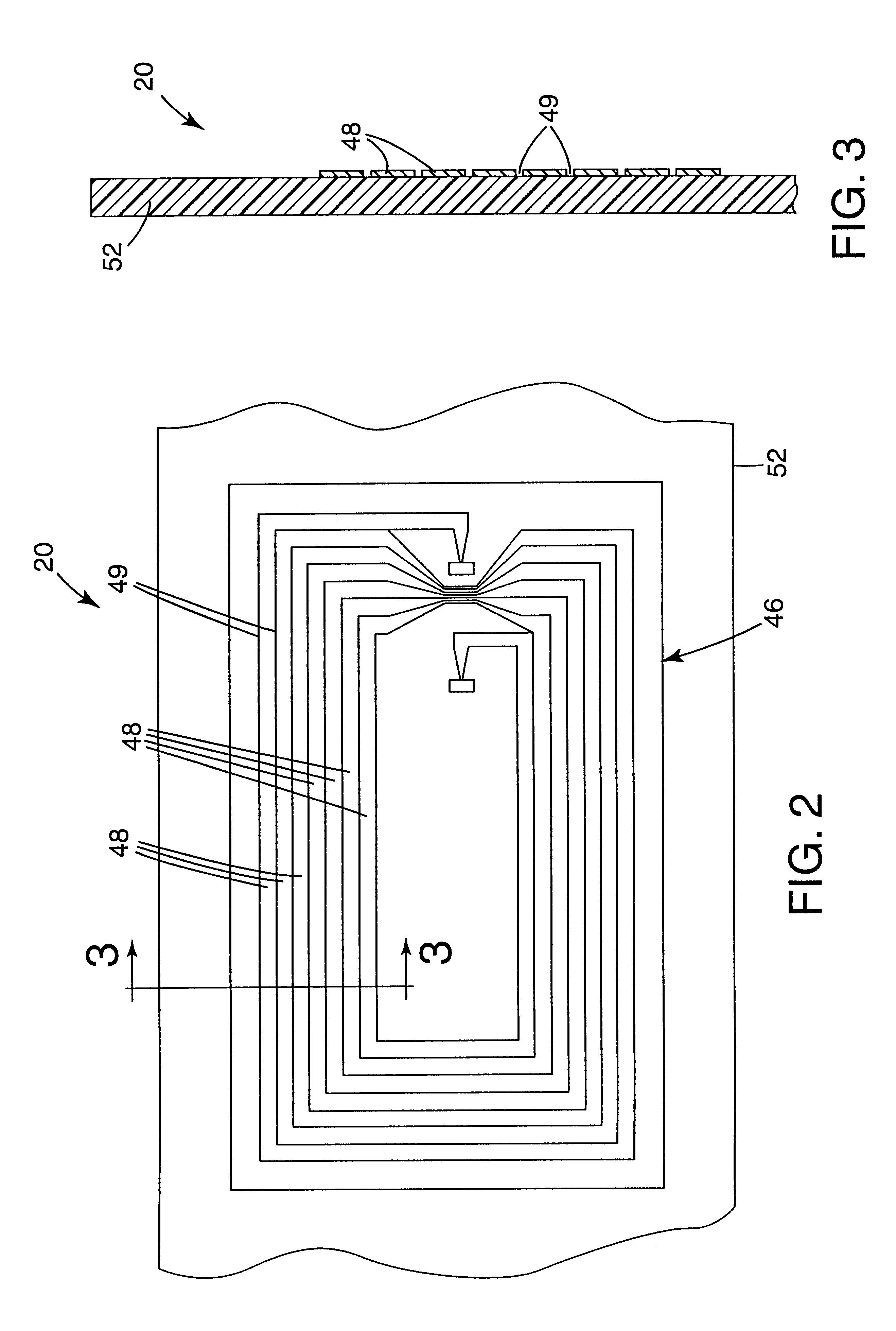

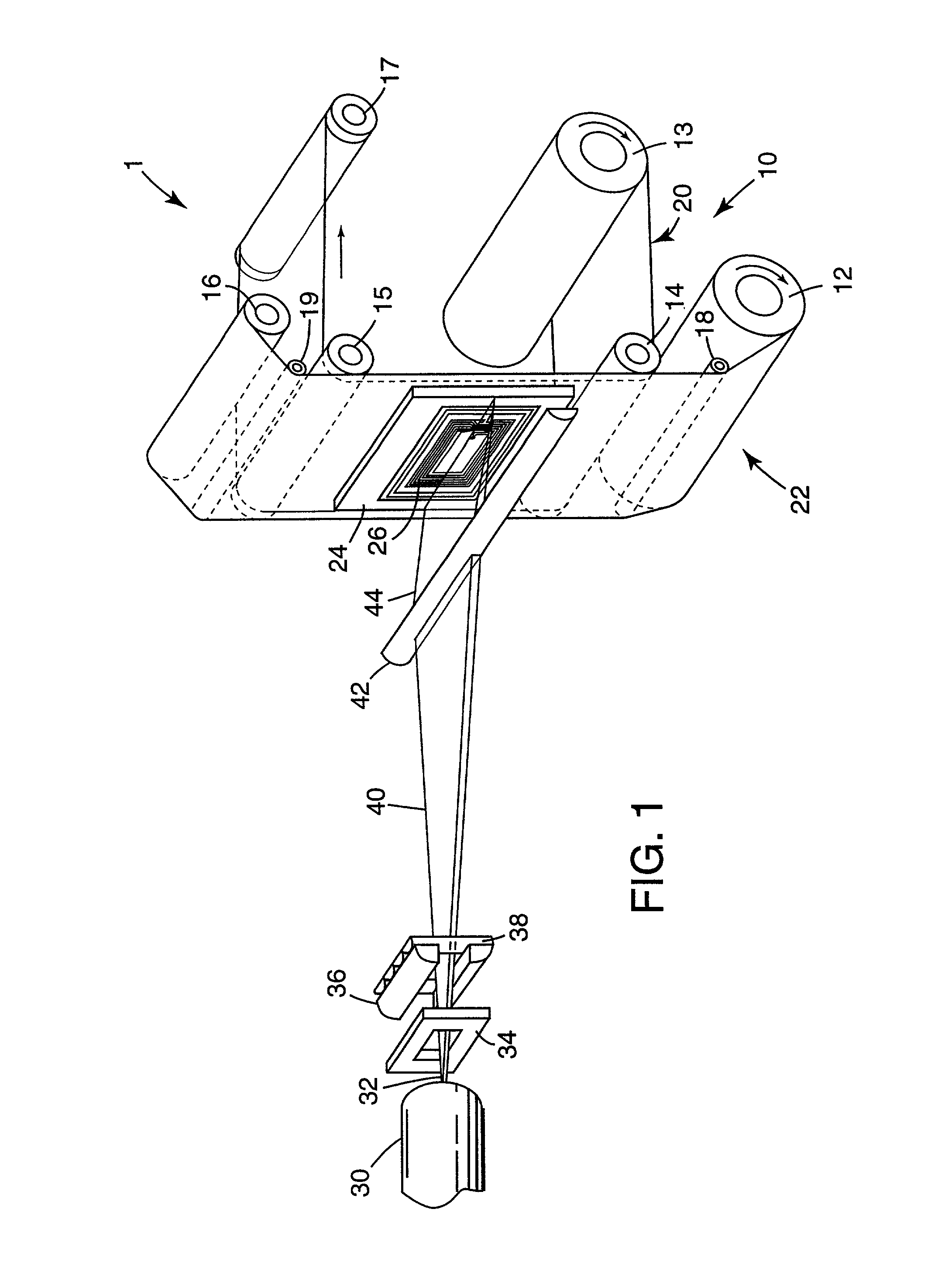

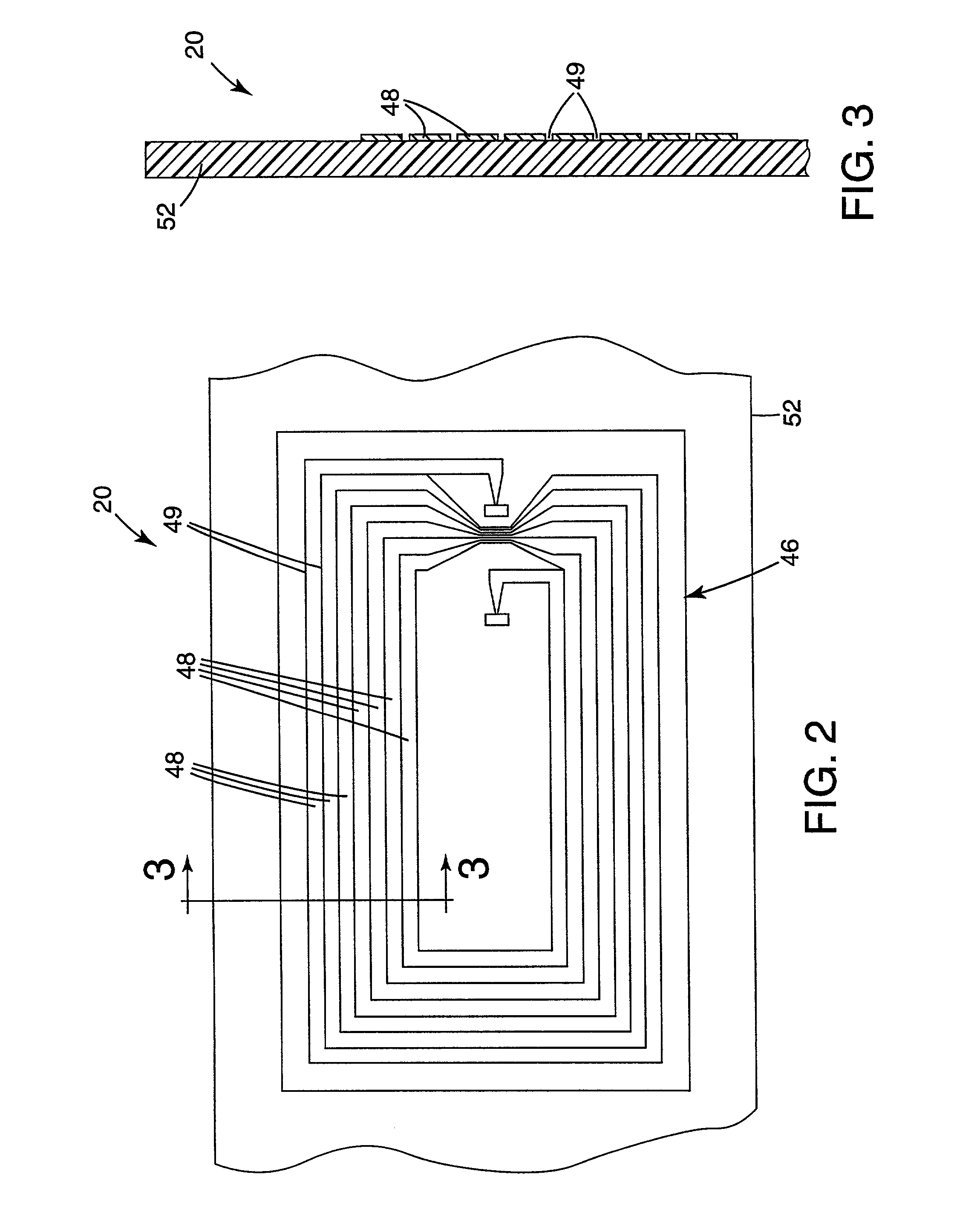

Imaged article on polymeric substrate

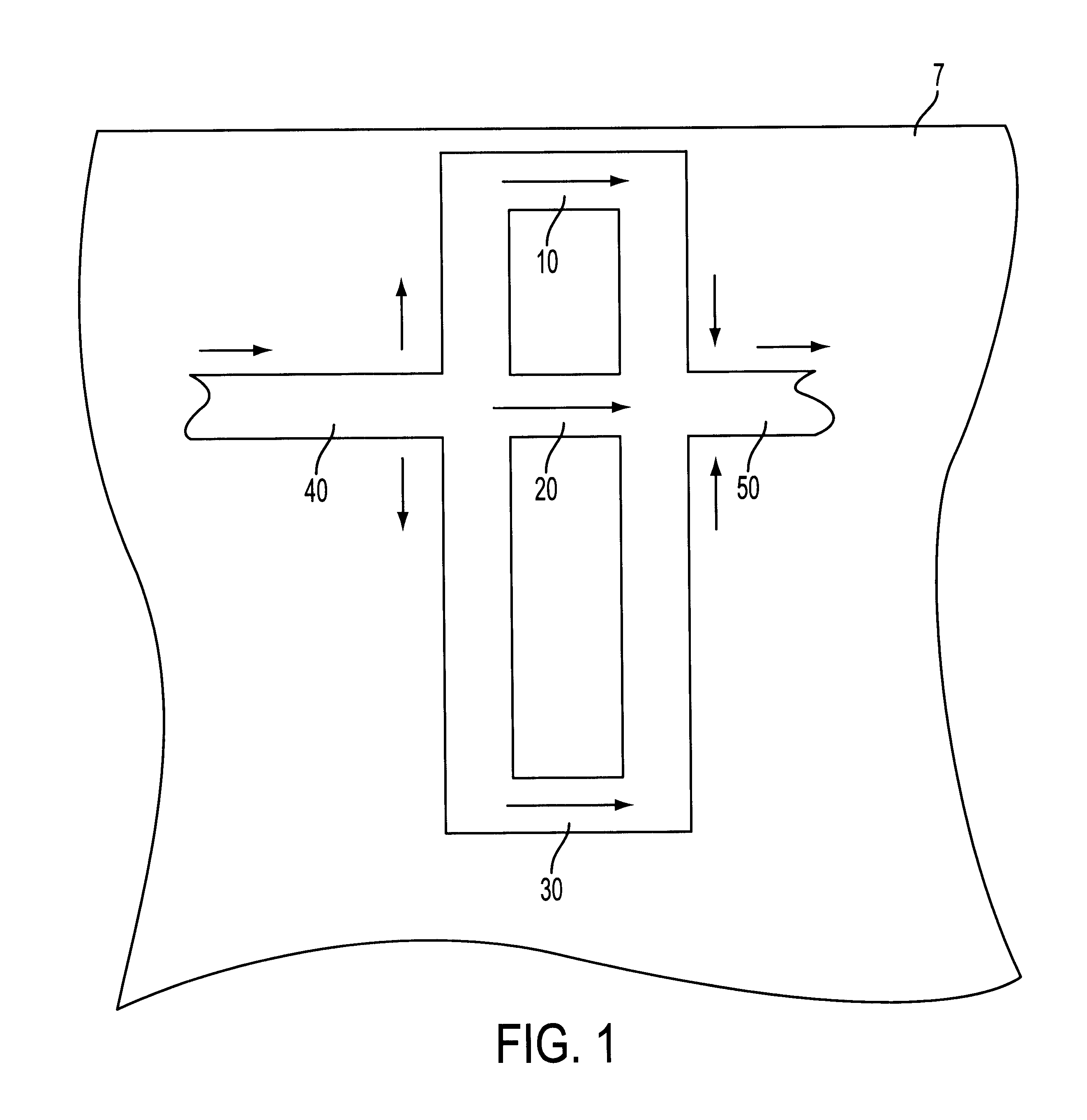

InactiveUS6203952B1Increasing the thicknessSmooth peelingAntenna supports/mountingsLoop antennasResistPolymer substrate

Patterned articles, such as RFID antenna, are made by subablation, a process comprising the steps of:A. providing a substrate having a coating, such as a metal or metal oxide, and an interface comprising the thin region where the coating and the substrate are closest to each other;B. exposing at least one part of the total area of the coating to a flux of electromagnetic energy, such as a focused excimer laser beam, sufficient to disrupt the interface but insufficient to ablate the coating; andC. removing the parts of the coating in registry with the portion of the interface area that was disrupted, by means such as ultrasonic agitation.The process has advantages over photo-resist processes in that there is no residual chemical resist left on the product and no undercutting of the pattern or image. It has advantages over laser ablation processes in that higher throughput is possible at the same energy level and there is no microscopic debris left on the product surface.

Owner:3M INNOVATIVE PROPERTIES CO

Method of making a biosensor

InactiveUS20060200981A1Microbiological testing/measurementBiological testingConductive materialsEngineering

A method of making a biosensor is provided. The biosensor includes an electrically conductive material on a base and electrode patterns formed on the base, the patterns having different feature sizes. The conductive material is partially removed from the base using broad field laser ablation so that less than 90% of the conductive material remains on the base and that the electrode pattern has an edge extending between two points. A standard deviation of the edge from a line extending between two points is less than about 6 μm

Owner:ROCHE OPERATIONS +1

Method of making a biosensor

InactiveUS20060200982A1Line/current collector detailsMicrobiological testing/measurementConductive materialsEngineering

A method of making a biosensor is provided. The method includes providing an electrically conductive material on a base and partially removing the conductive material using laser ablation from the base so that less than 90% of the conductive material remains on the base and at least one electrode pattern is formed from the conductive material. The at least one electrode pattern has an edge extending between two points. A standard deviation of the edge from a line extending between two points is less than about 6 μm along the length of the edge.

Owner:ROCHE DIABETES CARE INC +1

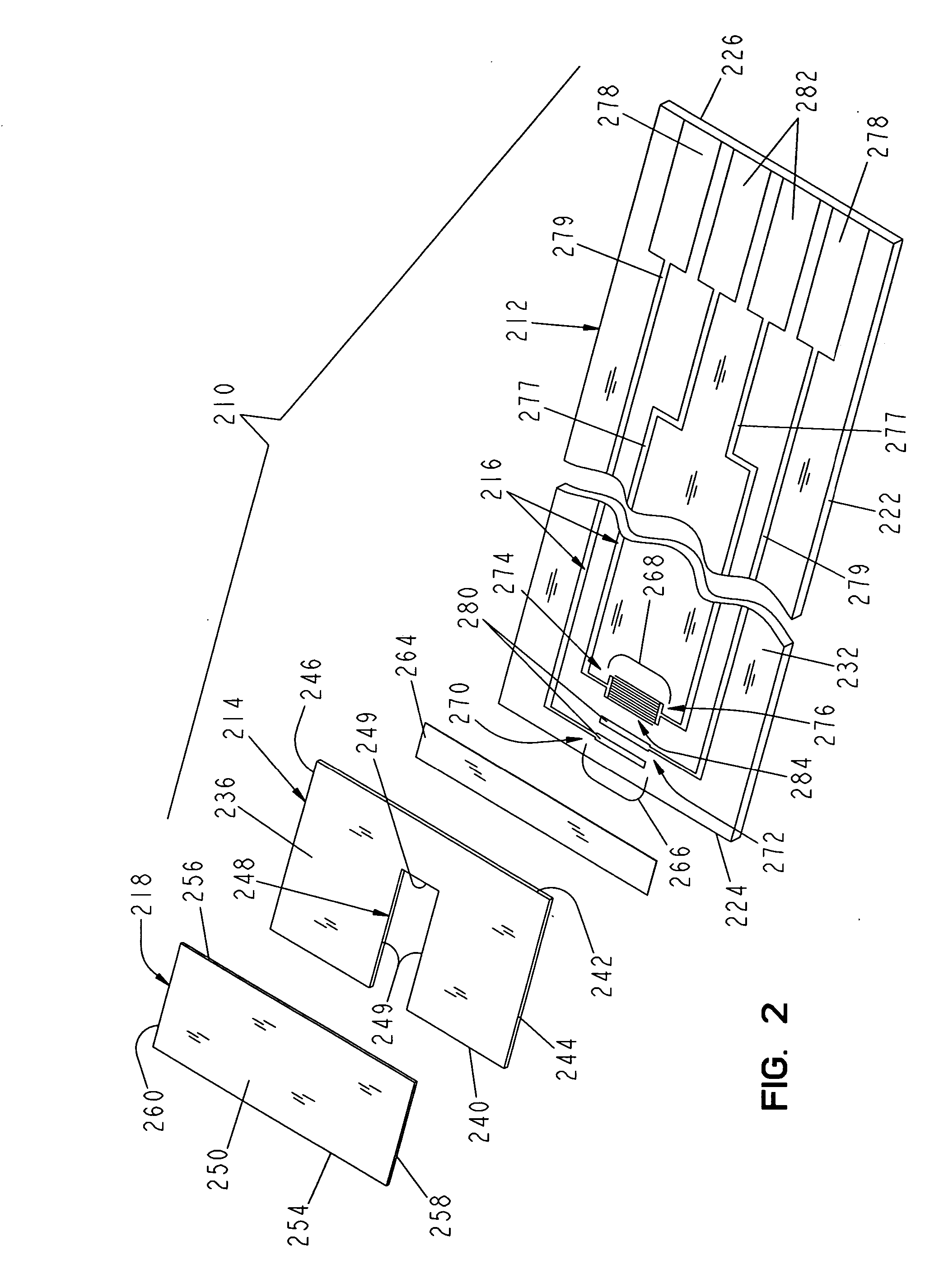

System and method for manufacturing embedded conformal electronics

ActiveUS20050029236A1Increase power generationMolten spray coatingThermoelectric device with peltier/seeback effectThermal sprayingEngineering

A method for fabricating an electronic device comprises providing a substrate (501), direct writing a functional material by a thermal spray on the substrate (502) and removing a portion of the function material to form the electronic or sensory device (503).

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Maskless nanofabrication of electronic components

InactiveUS20100035375A1Reduce the amount requiredEfficient methodRadiation applicationsSolid-state devicesElectronic structureNanoparticle

The present invention relates to systems, materials and methods for the formation of conducting, semiconducting, and dielectric layers, structures and devices from suspensions of nanoparticles. Drop-on-demand systems are used in some embodiments to fabricate various electronic structures including conductors, capacitors, FETs. Selective laser ablation is used in some embodiments to pattern more precisely the circuit elements and to form small channel devices.

Owner:RGT UNIV OF CALIFORNIA +1

Biosensor and method of making

Owner:ROCHE DIABETES CARE INC +1

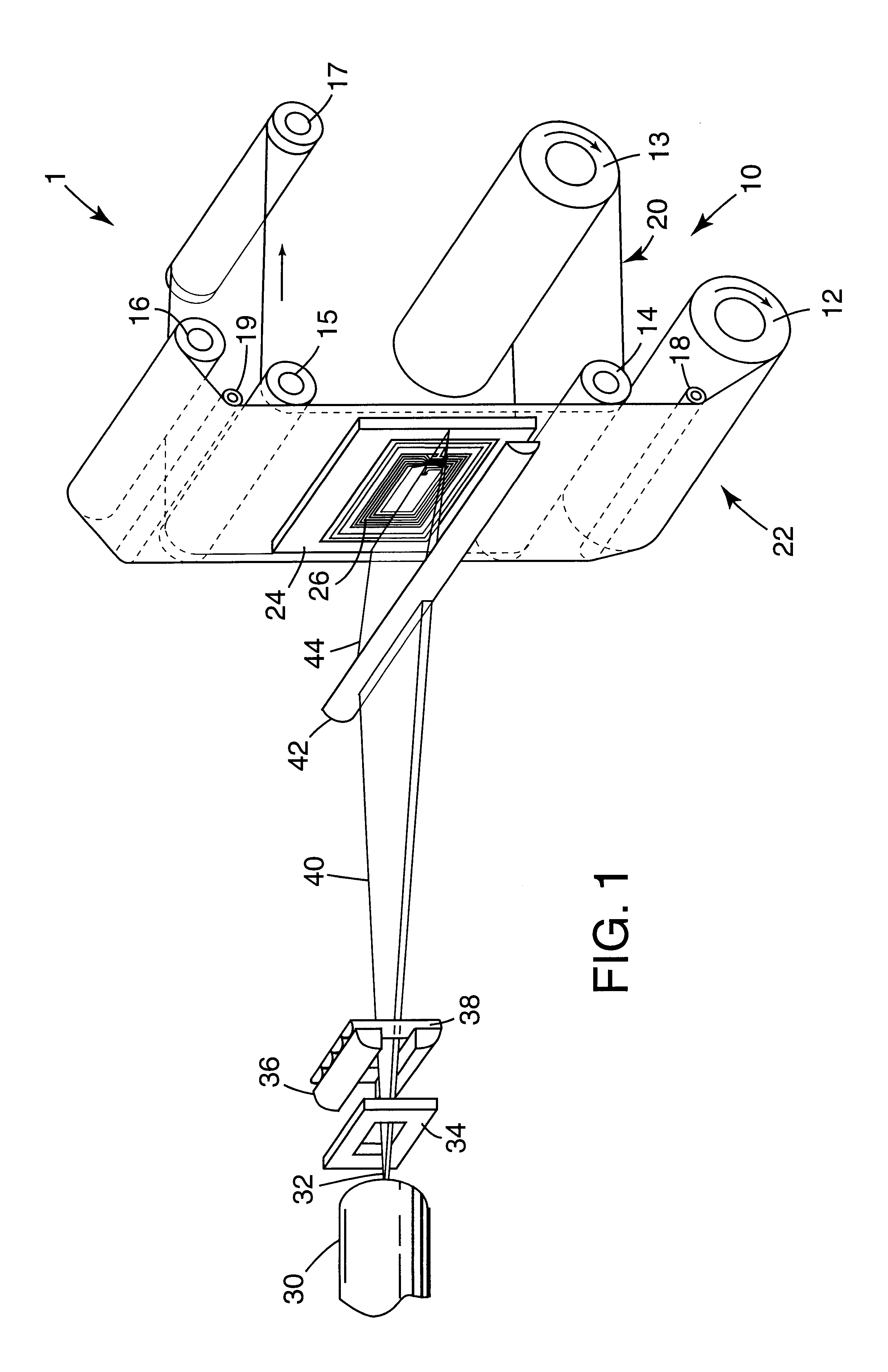

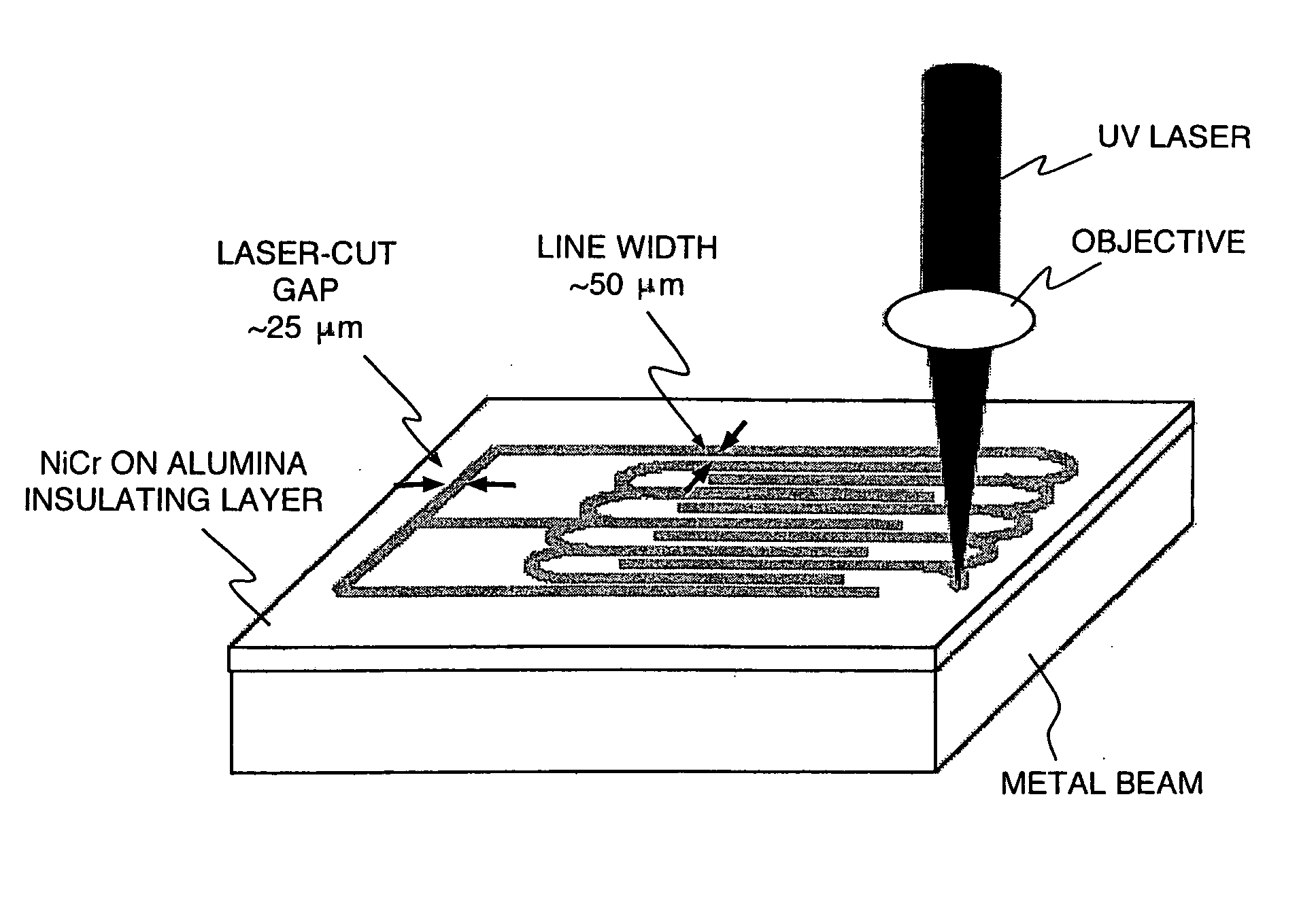

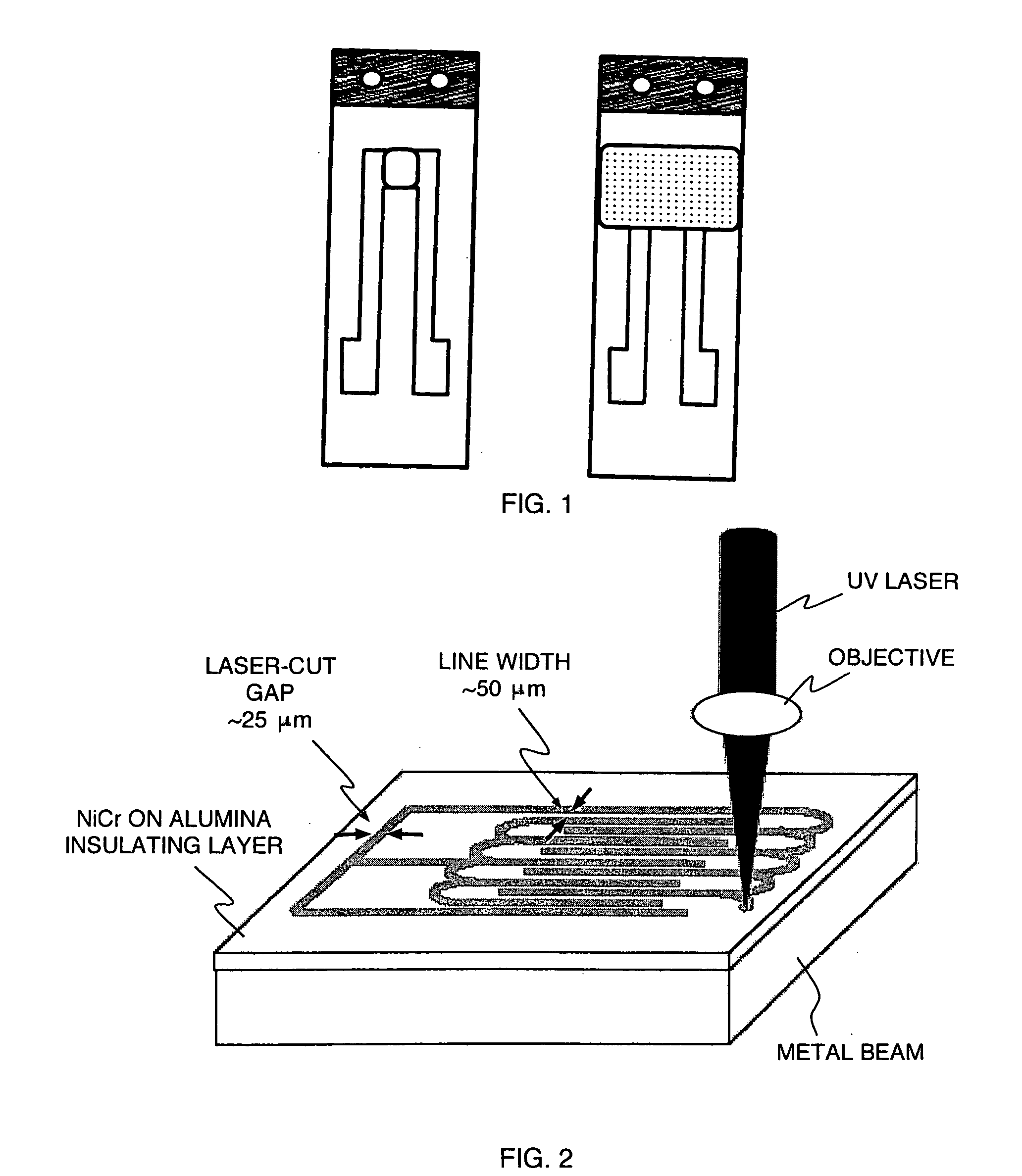

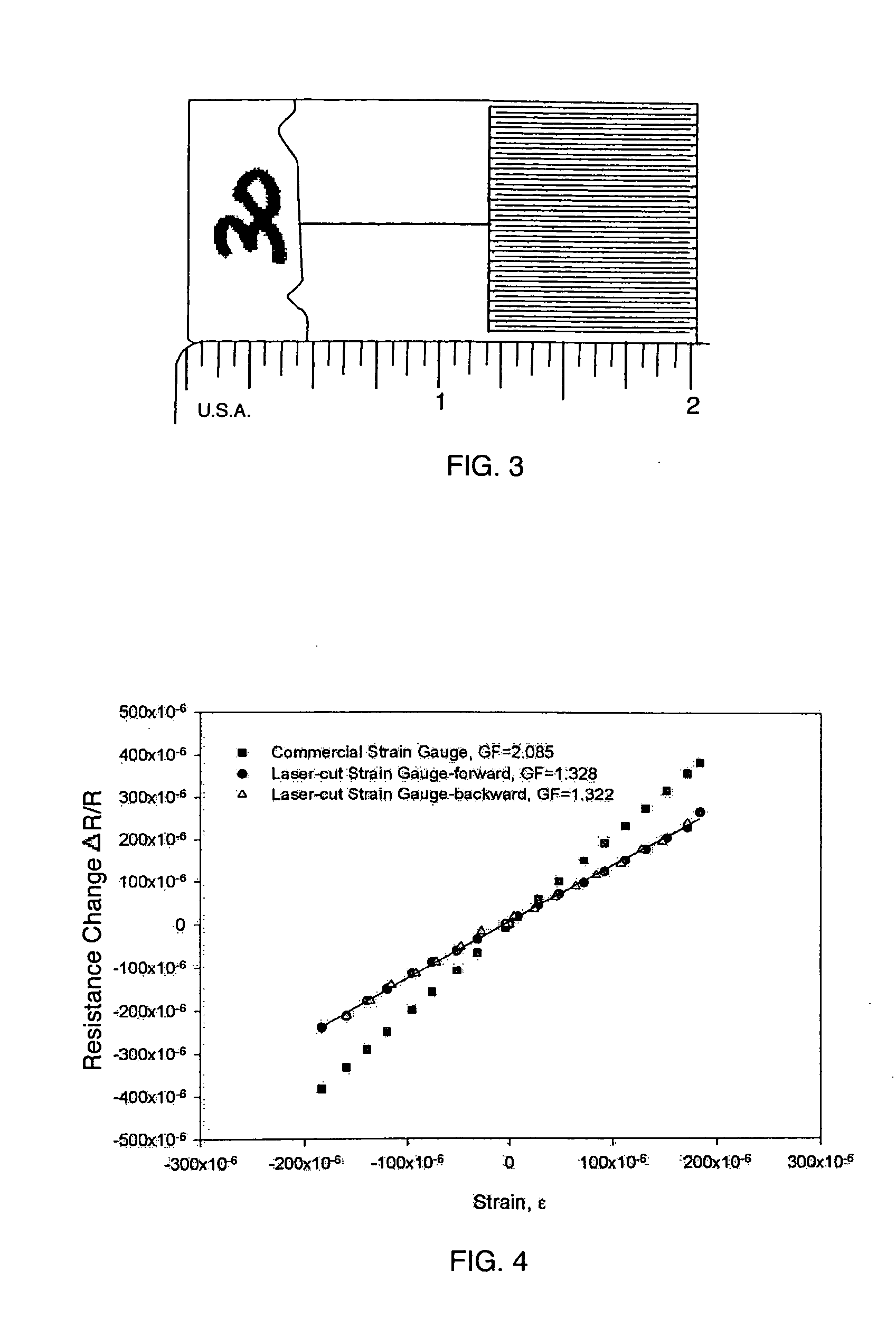

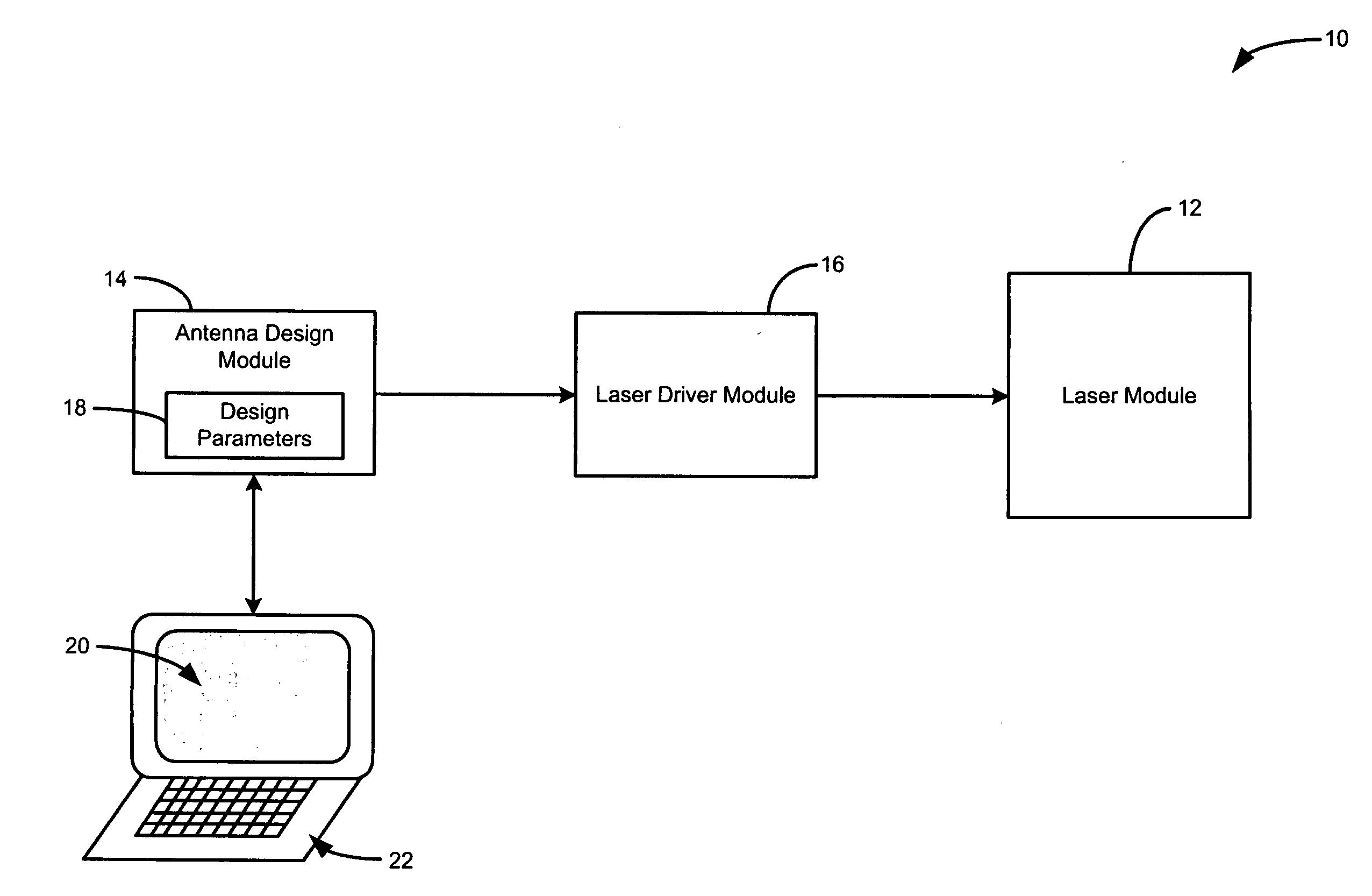

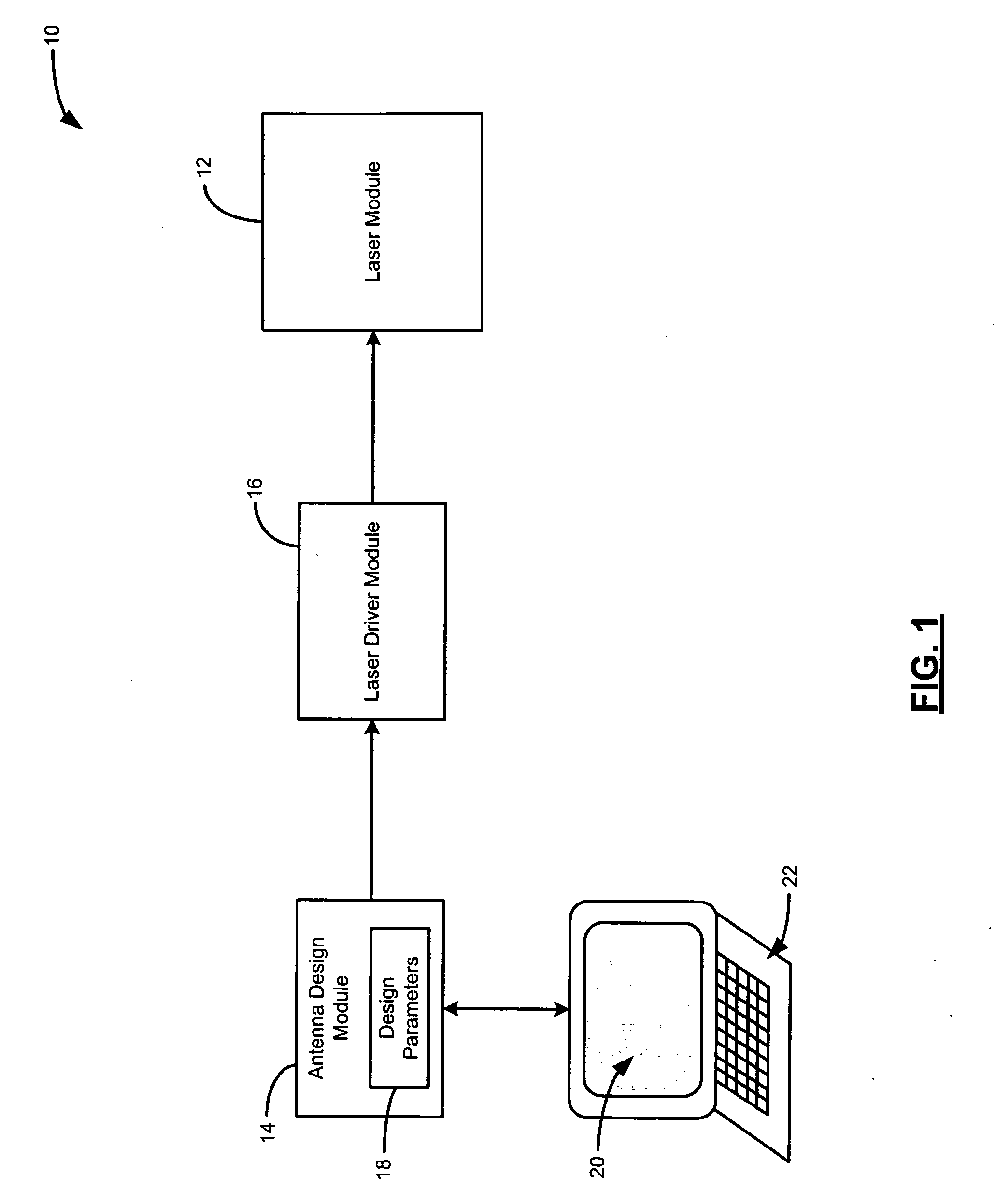

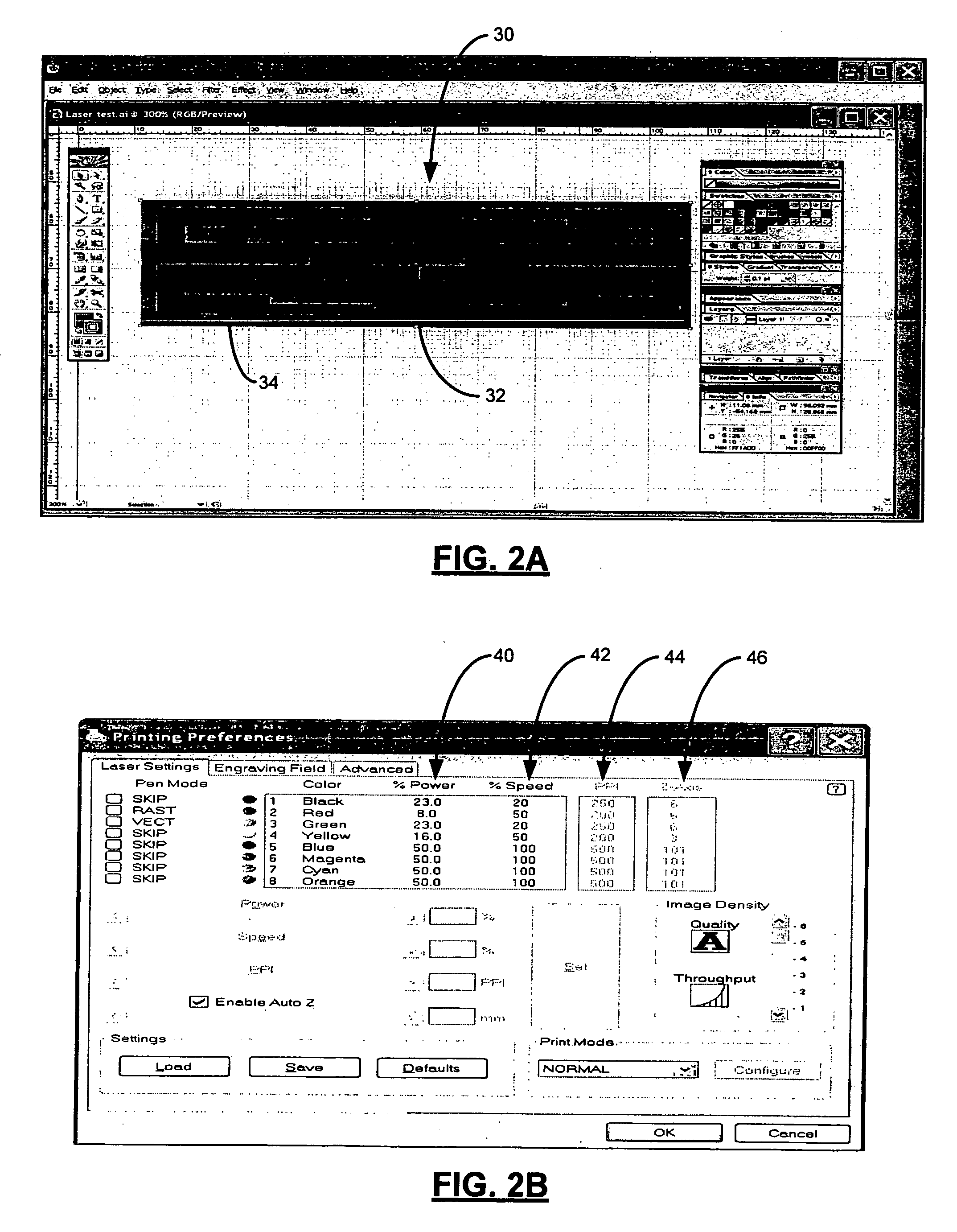

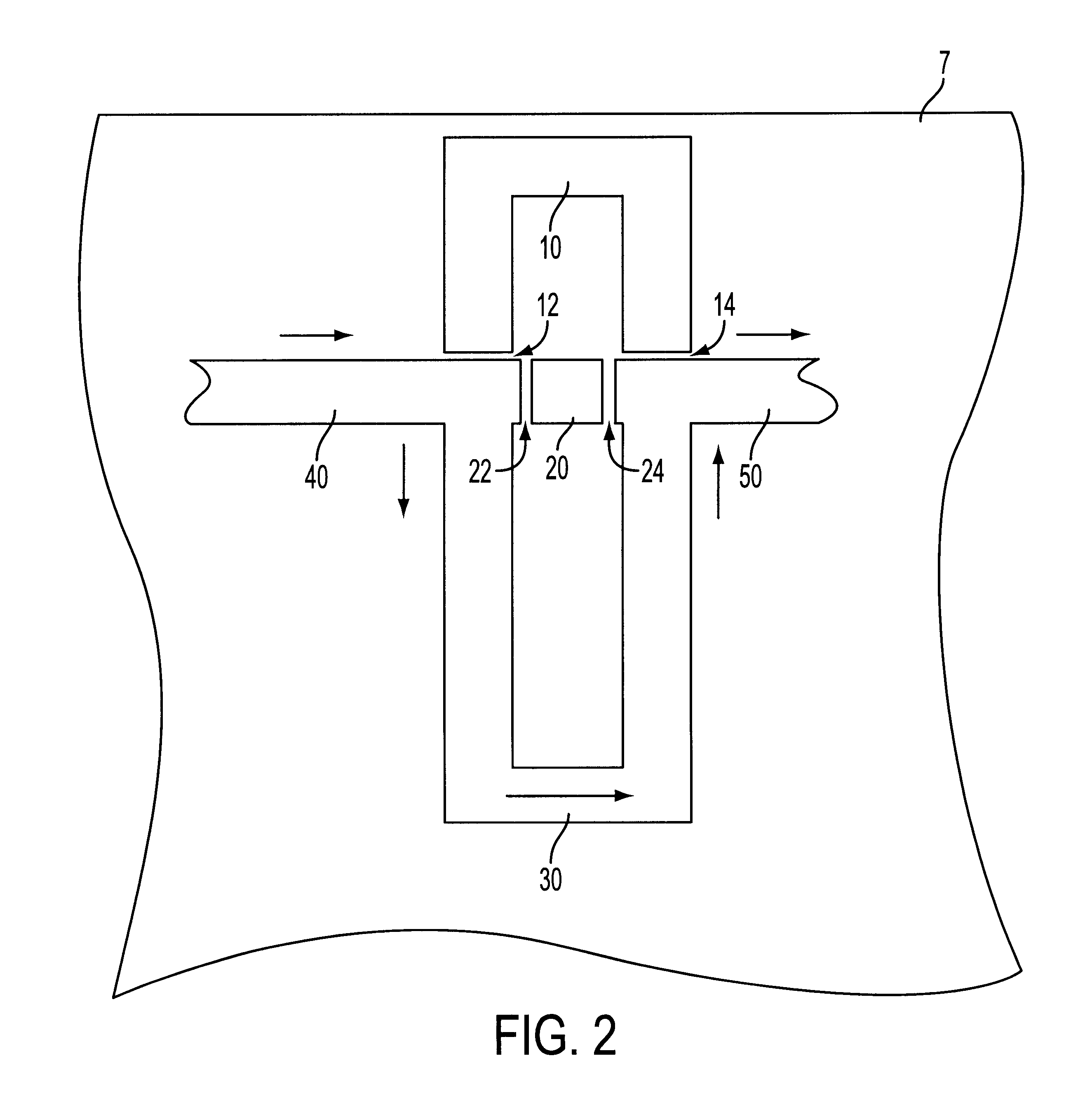

Laser ablation prototyping of RFID antennas

InactiveUS20070130754A1Less powerRecord carriers used with machinesBurglar alarm by hand-portable articles removalAntenna designEngineering

A laser ablation radio frequency identification (RFID) antenna prototyping system includes an antenna design module, an ablation laser, and a laser driver. The antenna design module includes design parameters for an RFID antenna prototype. The laser driver communicates with the antenna design module and the ablation laser. The laser driver uses the design parameters to direct the ablation laser to heat a portion of a conductive ink layer that is formed on a substrate.

Owner:ZIH CORP

Method and apparatus for reducing signal timing skew on a printed circuit board

An apparatus and method are described for reducing the timing skew on a printed circuit board including a plurality of conductive traces interconnecting a first node and a second node. At least one section is removed from at least one printed circuit board trace to thereby sever a trace and prevent signals passing from the first node to the second node from following the severed trace. In this manner, signal path length can be adjusted to reduce timing skews in the circuit. Sections are removed from the traces by using a laser, CVD, a router, a plasma or by passing sufficient current through weakened areas of the traces.

Owner:MICRON TECH INC

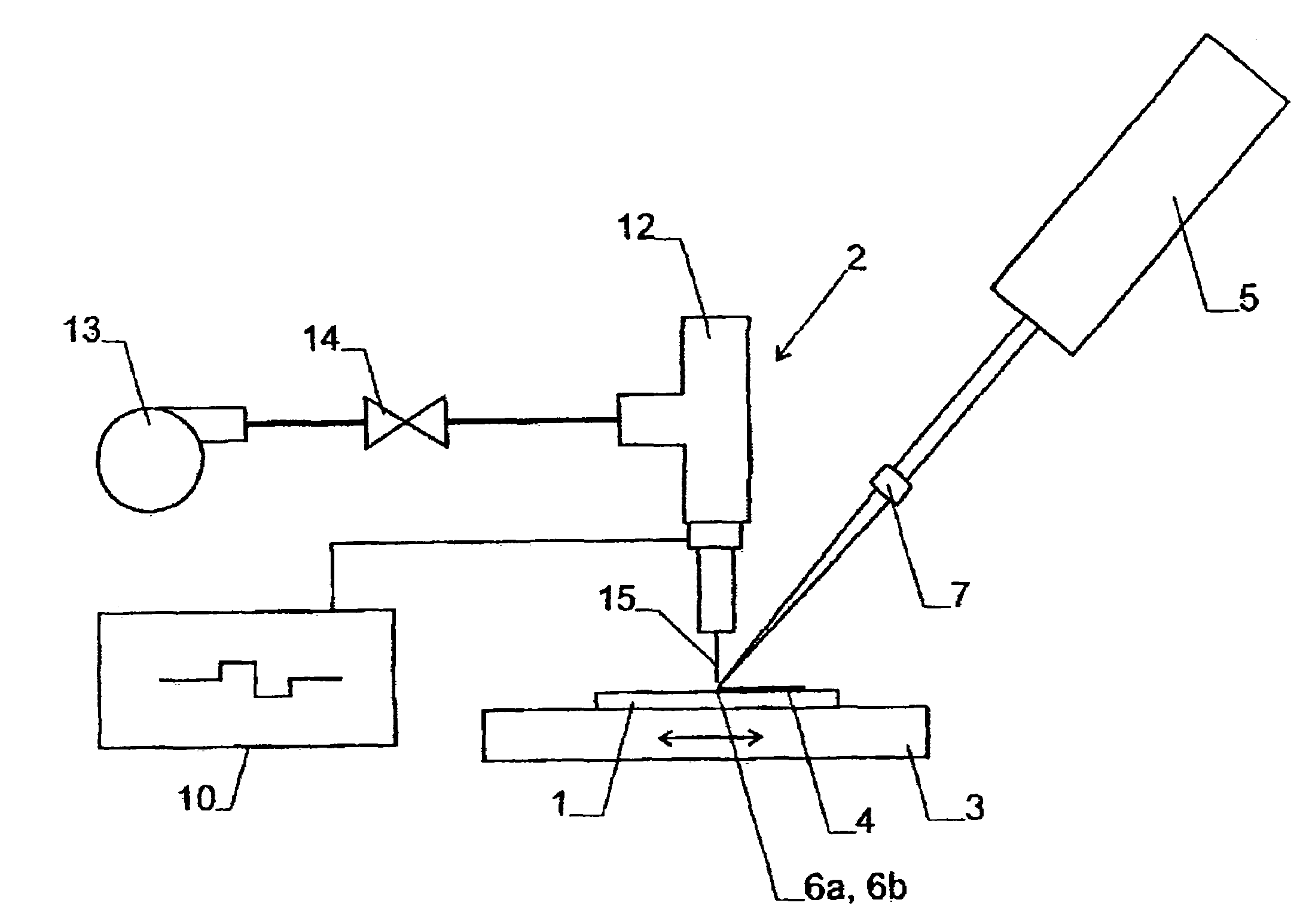

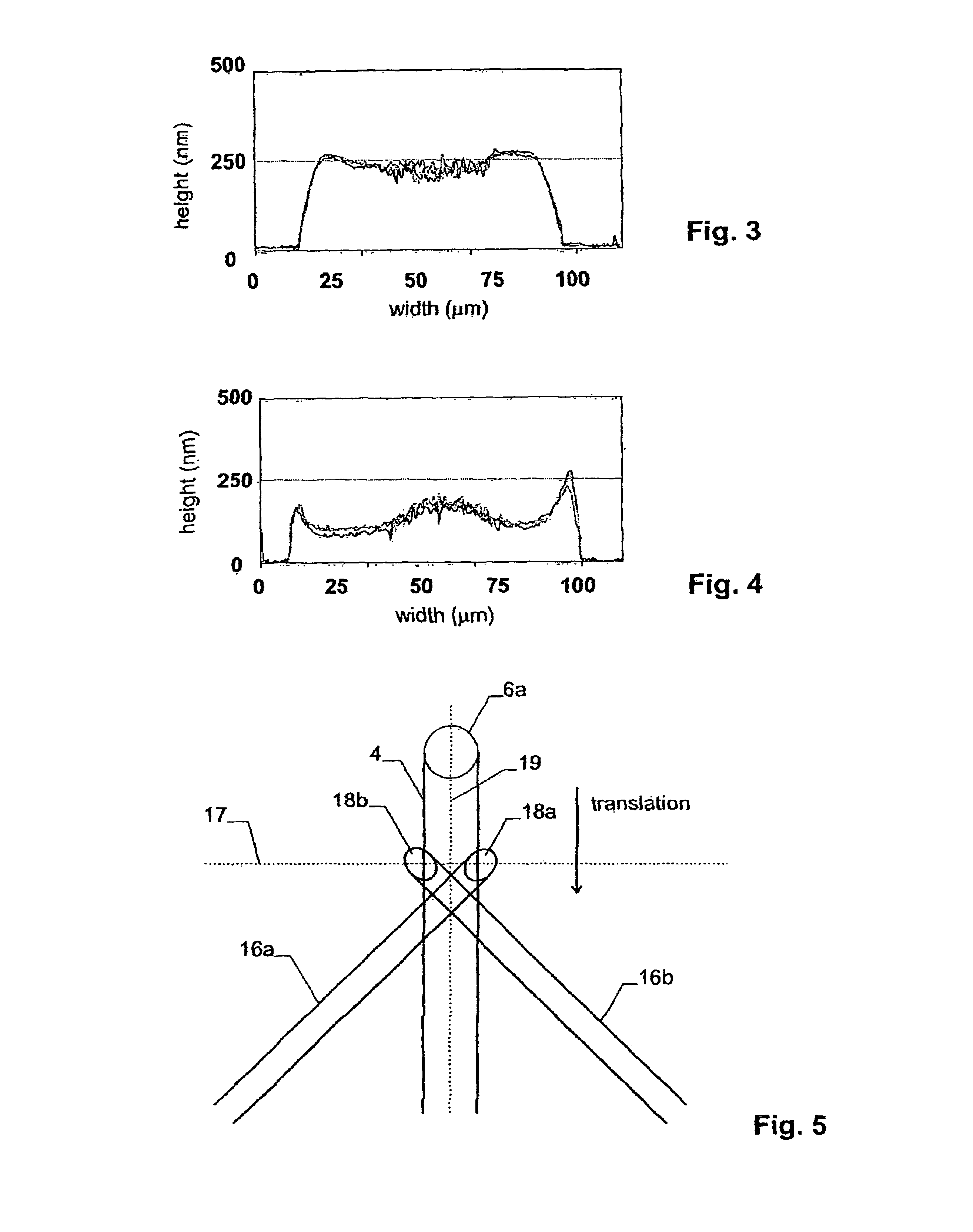

Method for patterning thin films

InactiveUS20010006766A1Great throughput and outputReduce impactPhotography auxillary processesAntenna supports/mountingsResistMicroscopic scale

Patterned articles, such as RFID antenna, are made by subablation, a process comprising the steps of: A. providing a substrate having a coating, such as a metal or metal oxide, and an interface comprising the thin region where the coating and the substrate are closest to each other; B. exposing at least one part of the total area of the coating to a flux of electromagnetic energy, Such as a focused excimer laser beam, sufficient to disrupt the interface but insufficient to ablate the coating, and C. removing the parts of the coating in registry with the portion of the interface area that was disrupted, by means such as ultrasonic agitation. The process has advantages over photo-resist processes in that there is no residual chemical resist left on the product and no undercutting of the pattern or image. It has advantages over laser ablation processes in that higher throughput is possible at the same energy level and there is no microscopic debris left on the product surface.

Owner:3M INNOVATIVE PROPERTIES CO

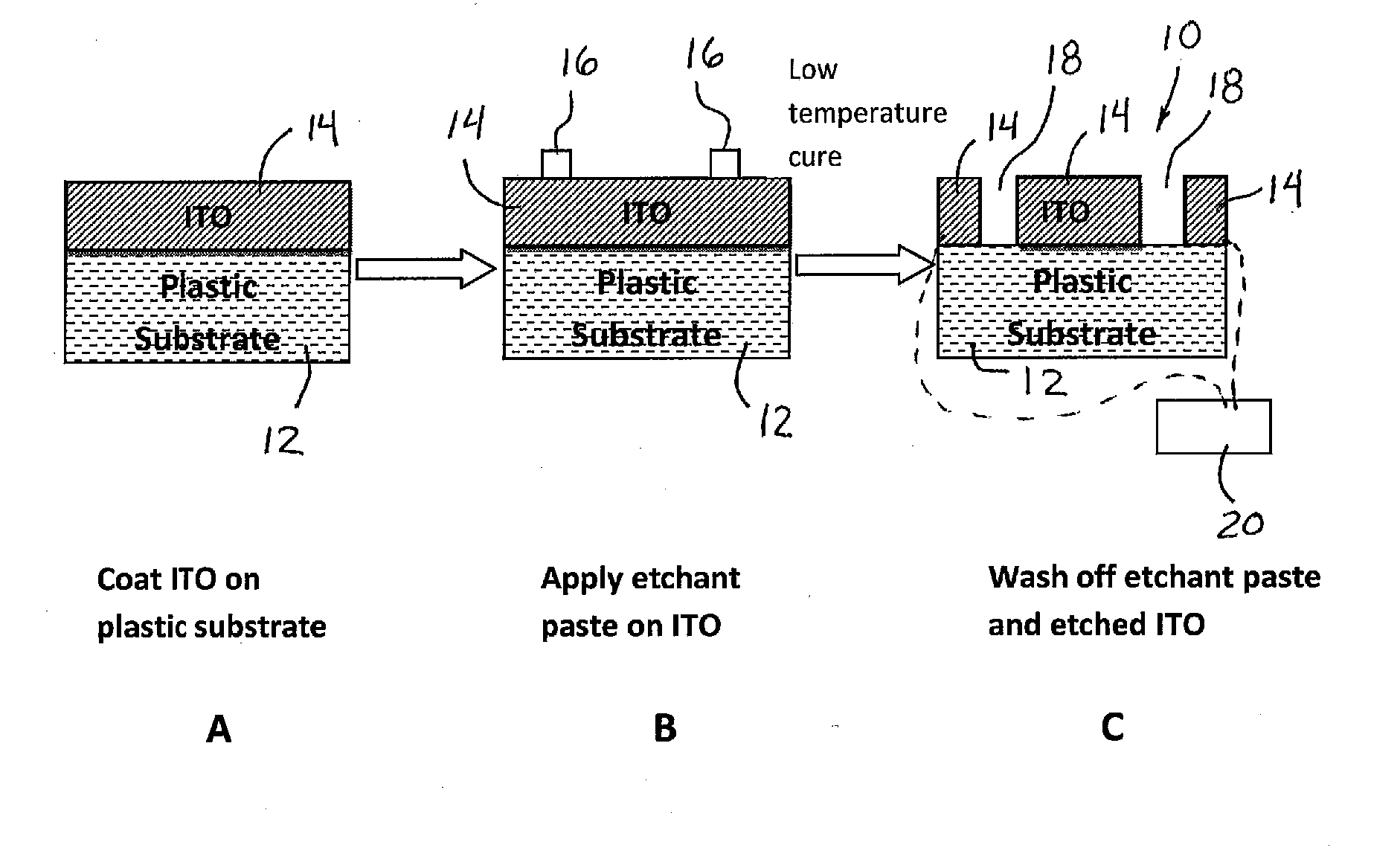

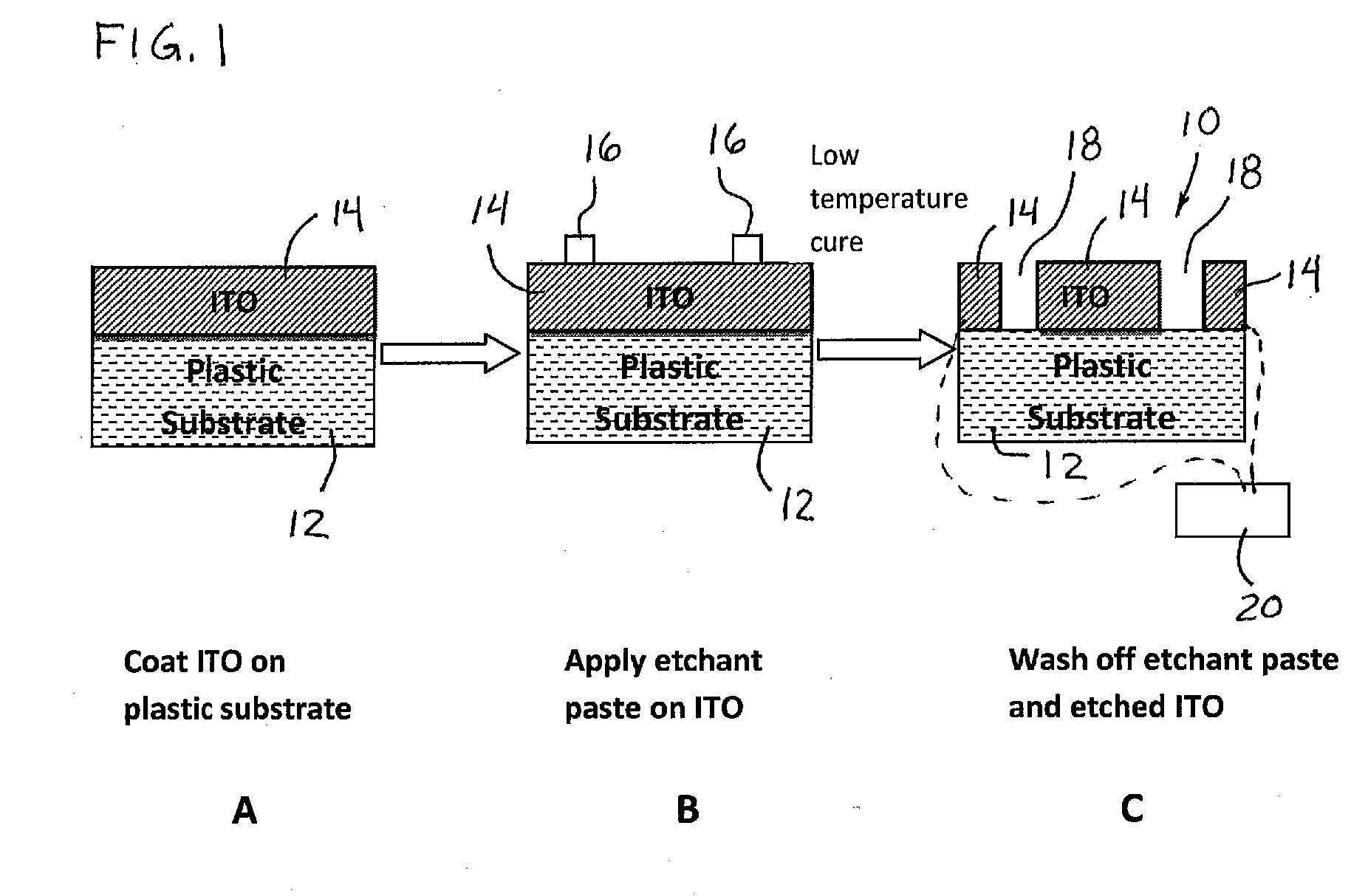

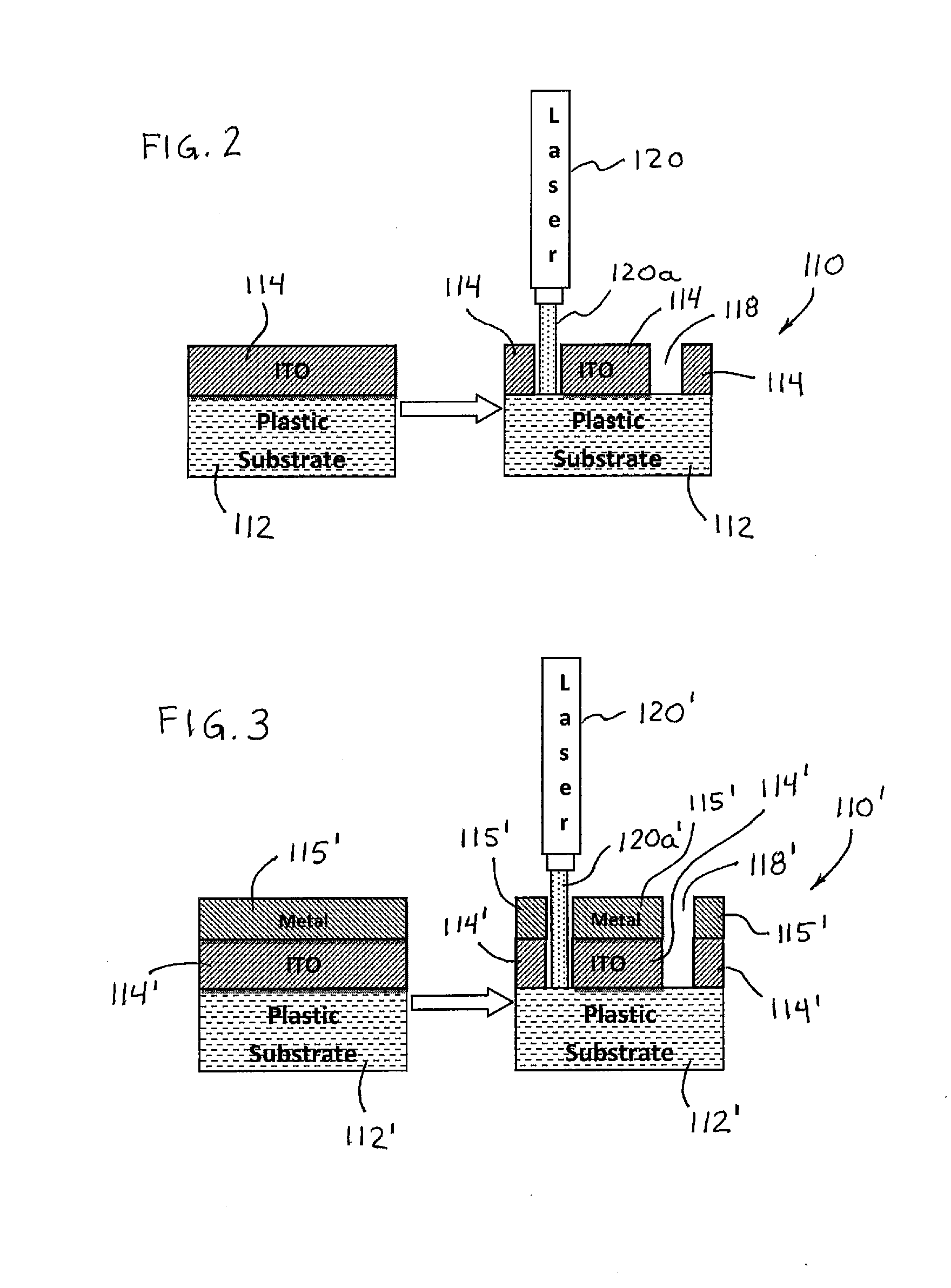

Plastic capacitive touch screen and method of manufacturing same

ActiveUS20100200539A1Produced cost-effectivelySimplify manufacturing stepsPrinted circuit aspectsWelding/soldering/cutting articlesCapacitanceEtching

A method of removing portions of a conductive layer comprising a transparent conductive material and / or a metallic material disposed on a plastic substrate used for capacitive touchscreen devices includes providing a plastic substrate having a conductive layer disposed on a surface thereof and removing portions of the conductive layer at the surface of the plastic substrate to establish a pattern of electrically isolated conductive portions on the surface of the plastic substrate. The conductive portions or traces are electrically connected to a touchscreen controller, which is operable to determine a location of a touch or proximity of an object at or near the surface of the plastic substrate responsive to a detected change in capacitance. The removal process may comprise etching or laser ablating portions of the conductive layer at the surface of the plastic substrate.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

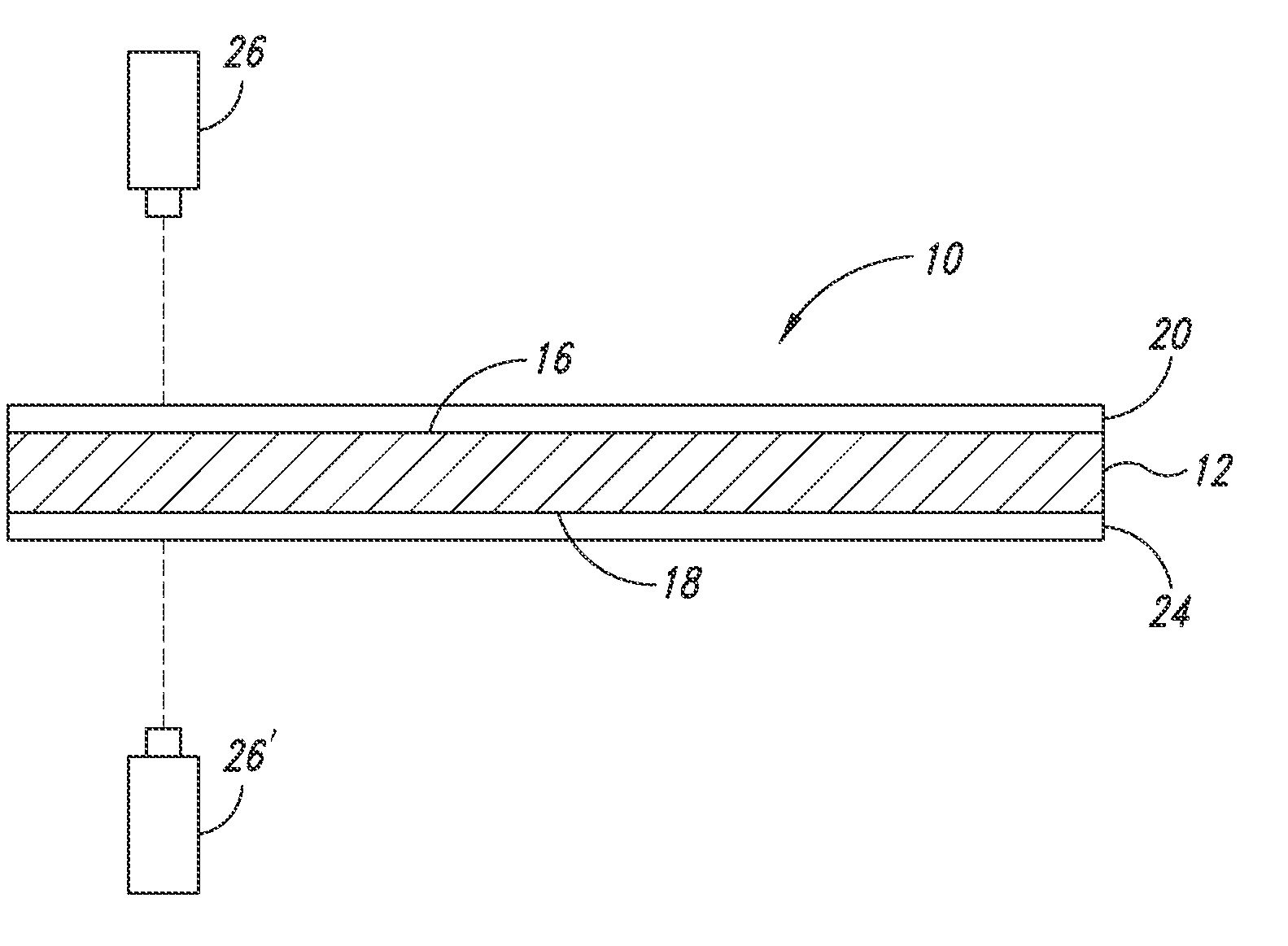

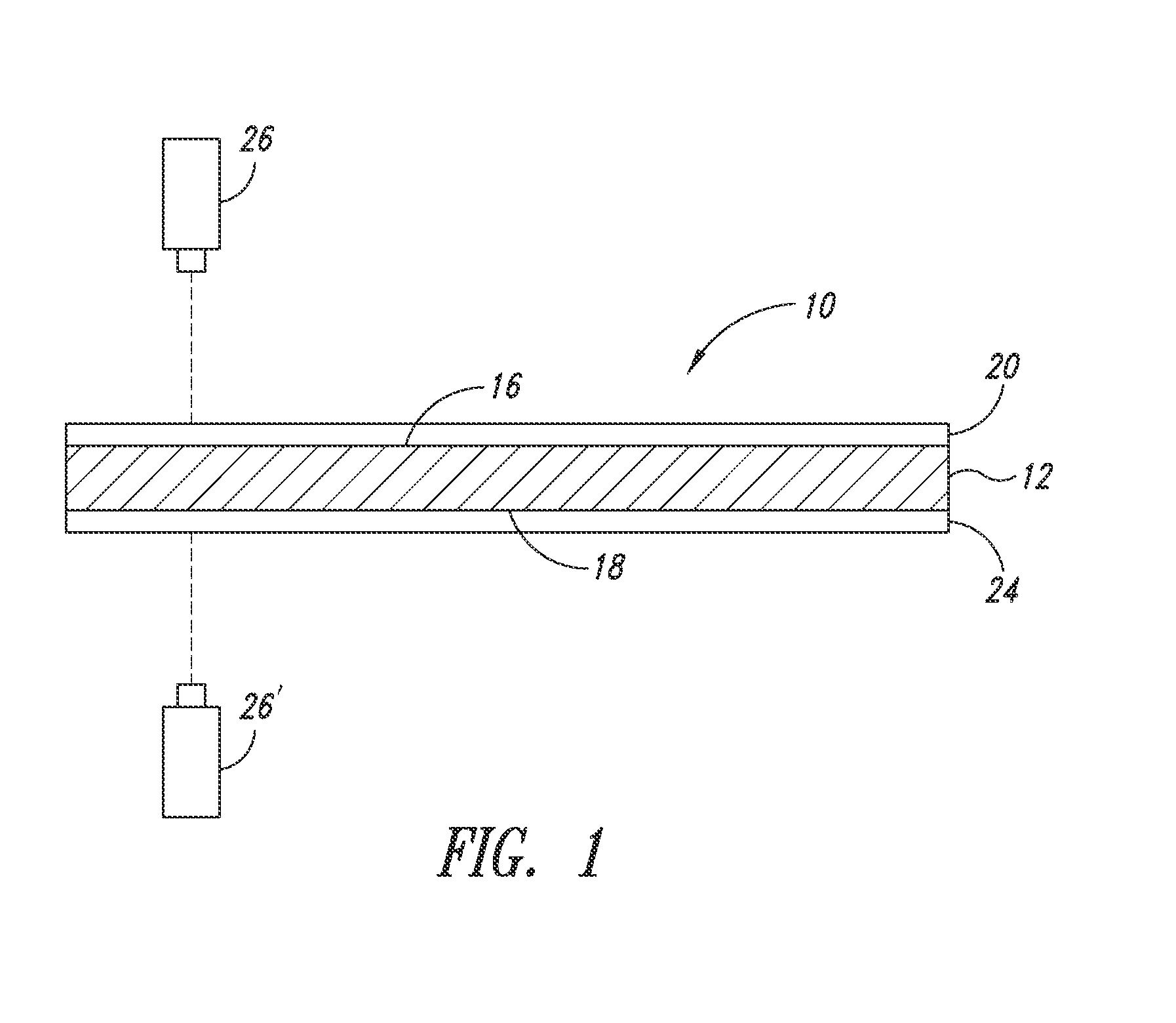

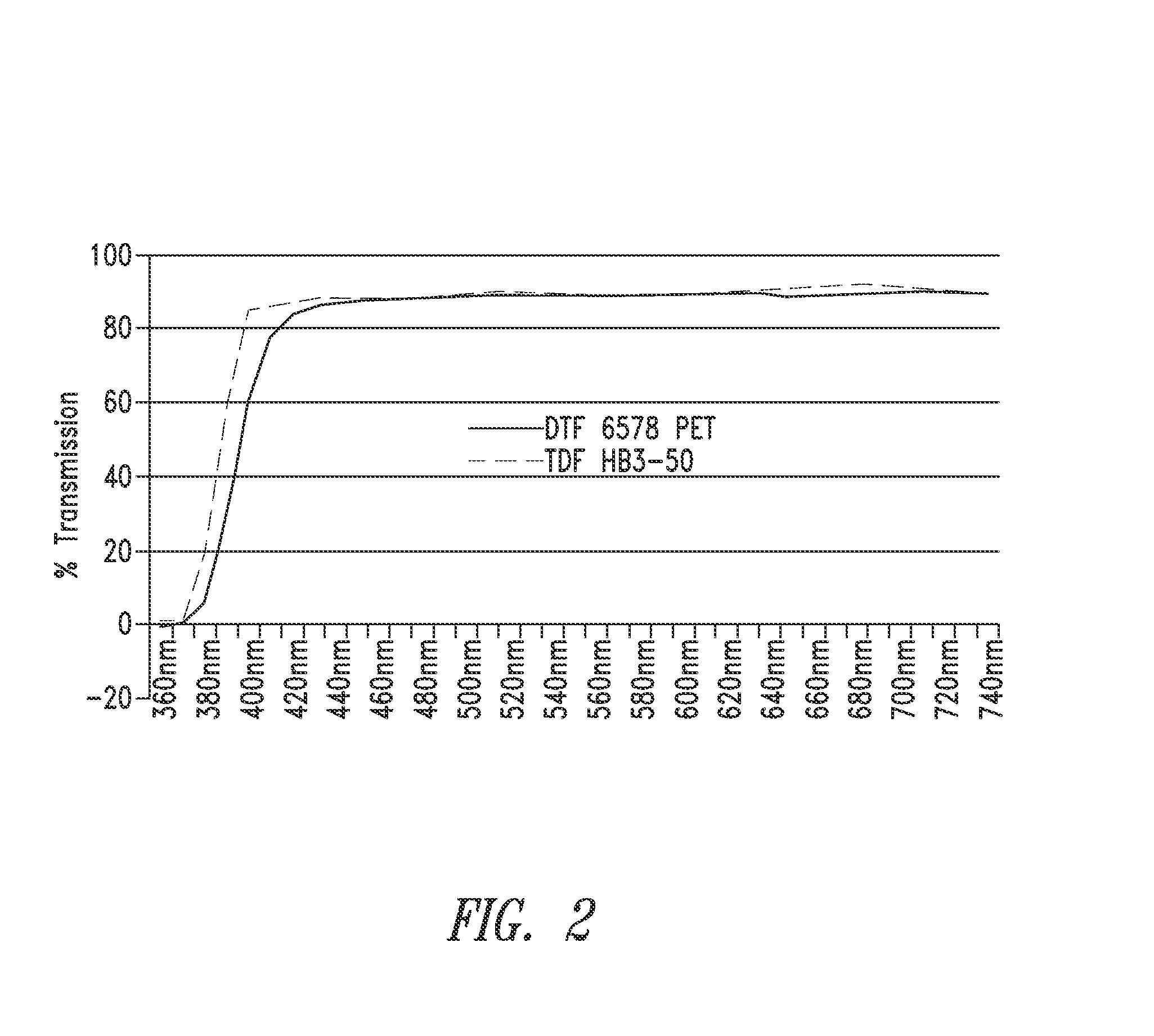

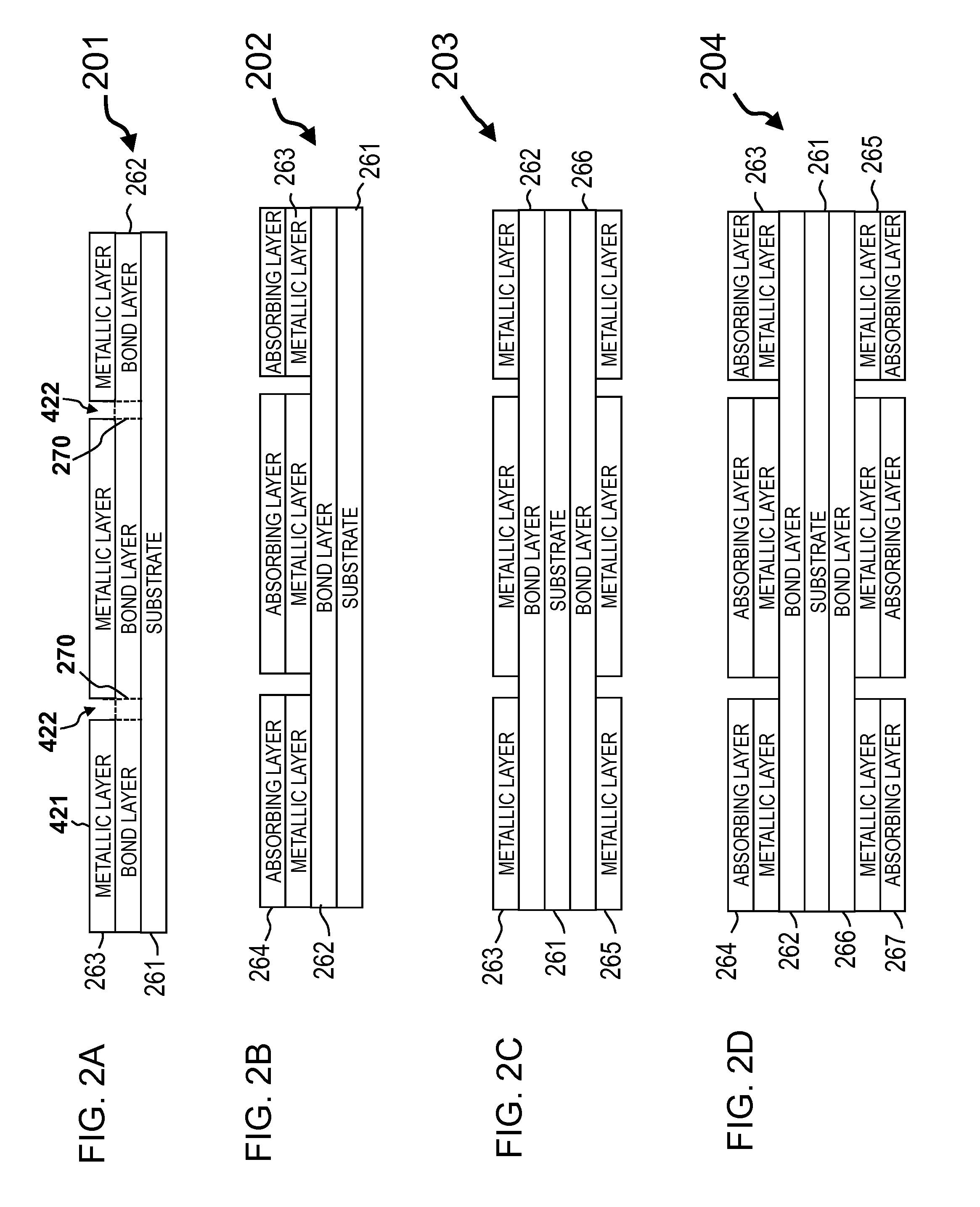

Two-sided laser patterning on thin film substrates

InactiveUS20140202742A1Improve throughputLight absorption dielectricsCircuit optical detailsLaser patterningTransparent conducting film

Owner:CHAMP GREAT INTL

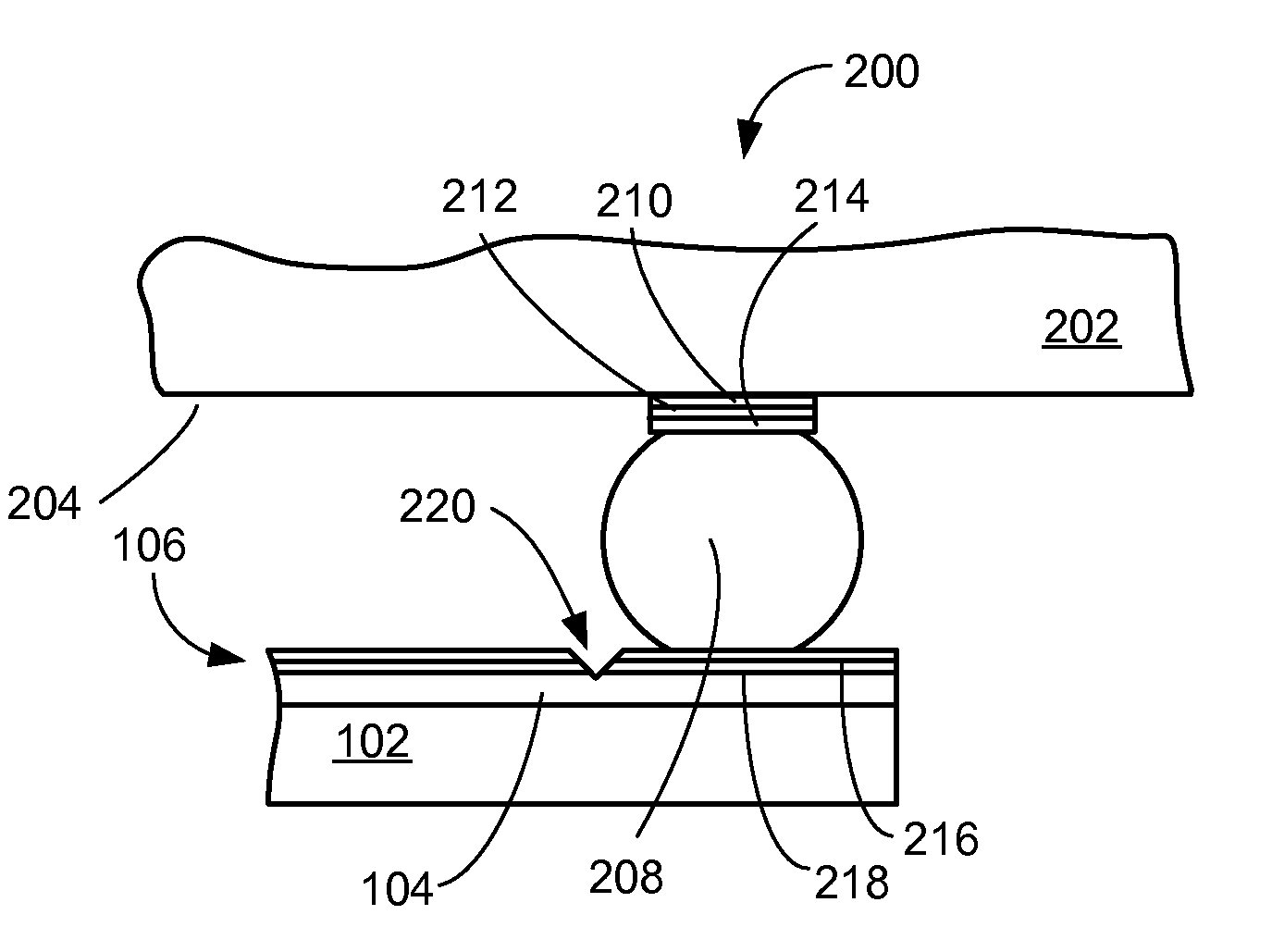

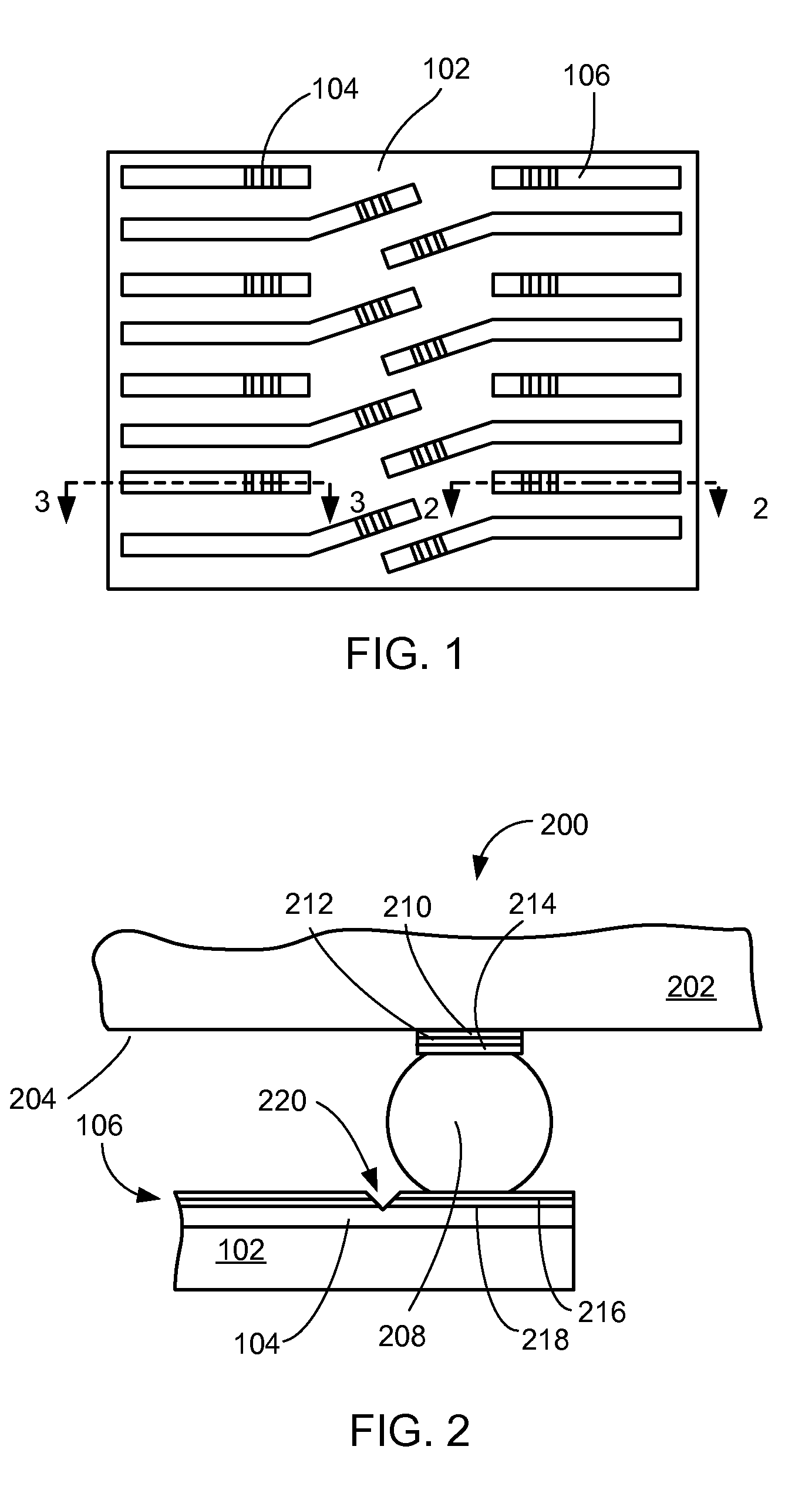

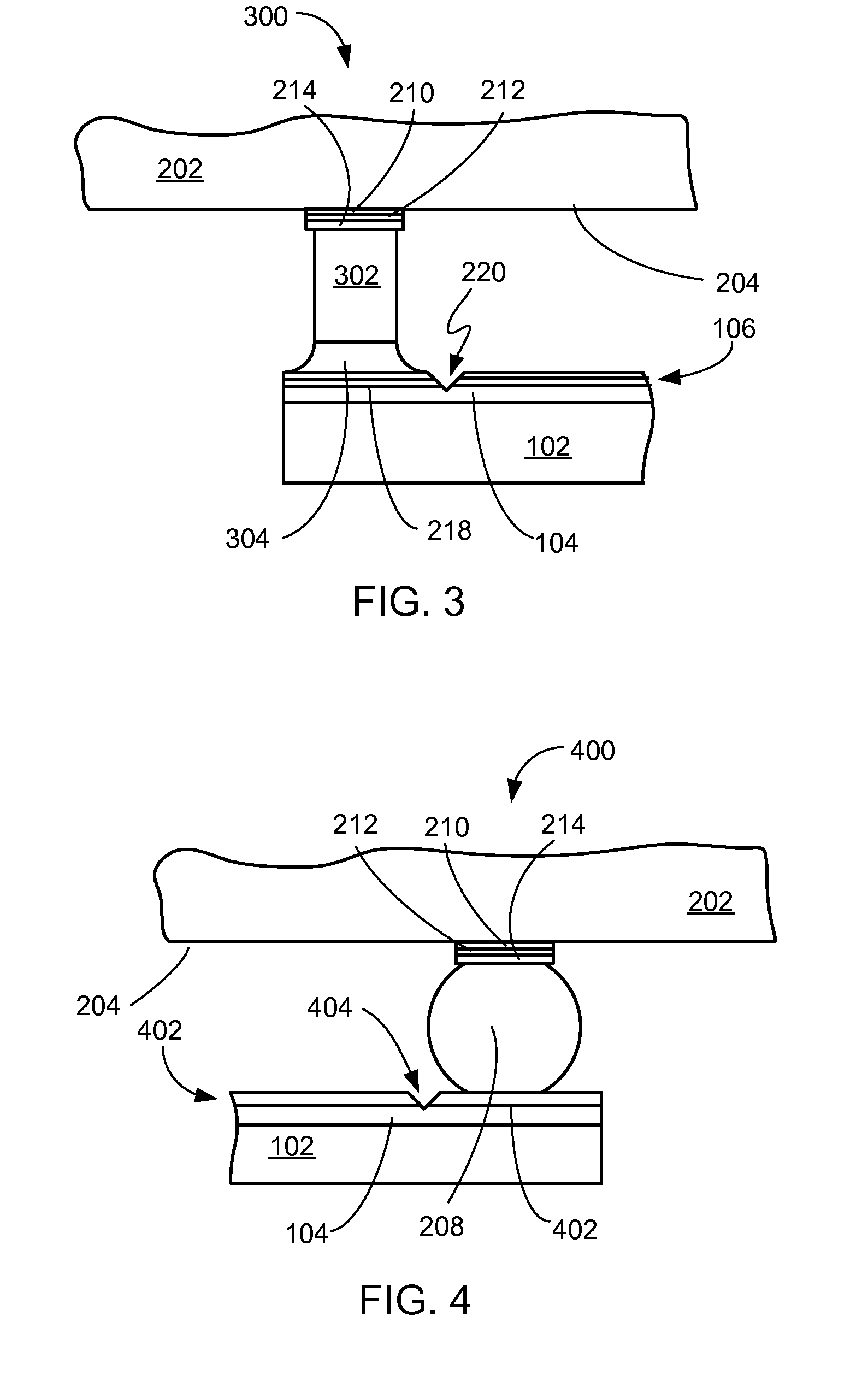

Flip chip interconnection system

ActiveUS20090236756A1Semiconductor/solid-state device detailsPrinted circuit aspectsFlip chip interconnectInterconnection

A flip chip interconnection system includes: providing a conductive lead coated with a protective coating; forming a groove through the protective coating to the conductive lead for controlling solder position on a portion of the conductive lead; and attaching a flip chip having a solderable conductive interconnect to the portion of the conductive lead.

Owner:STATS CHIPPAC LTD

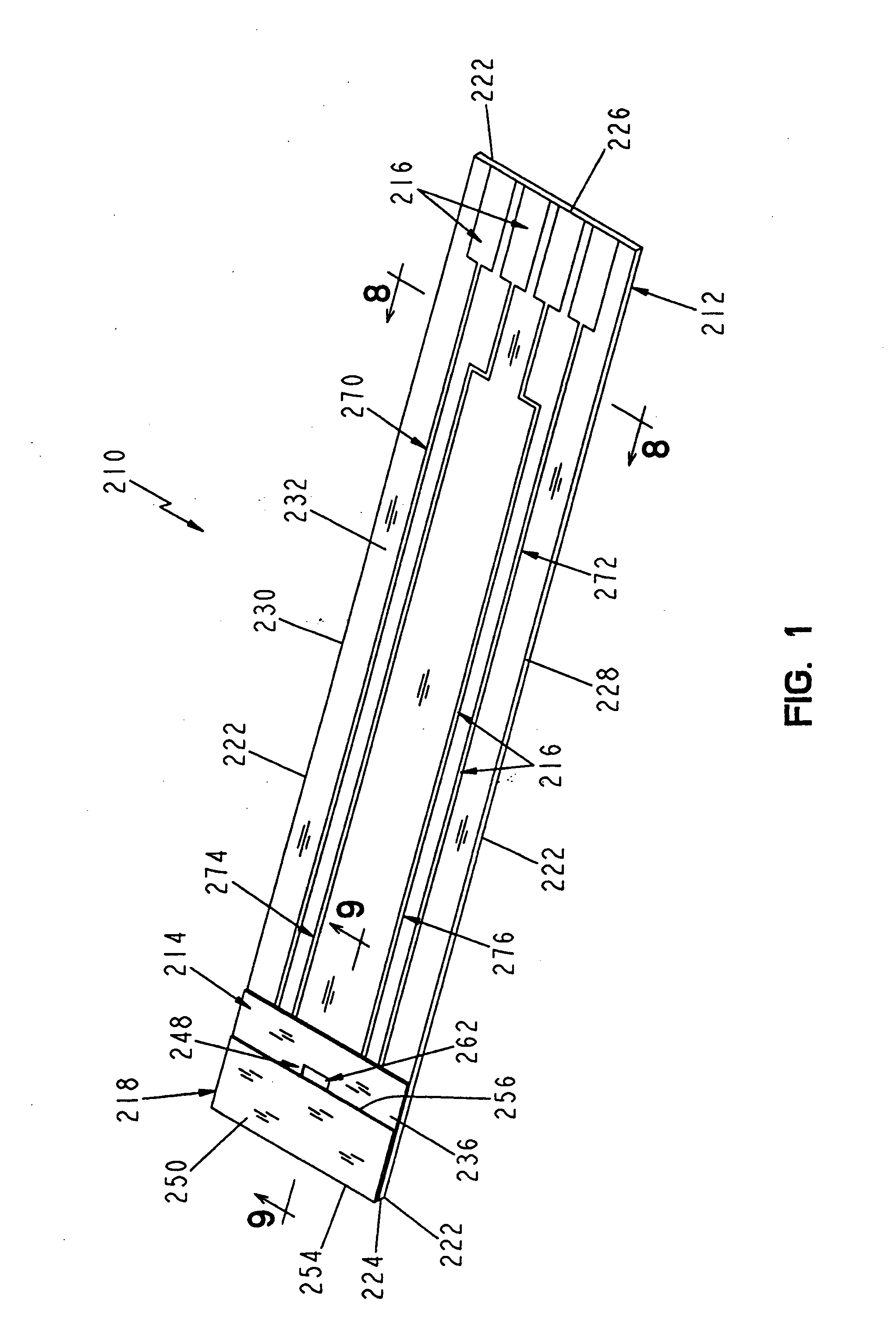

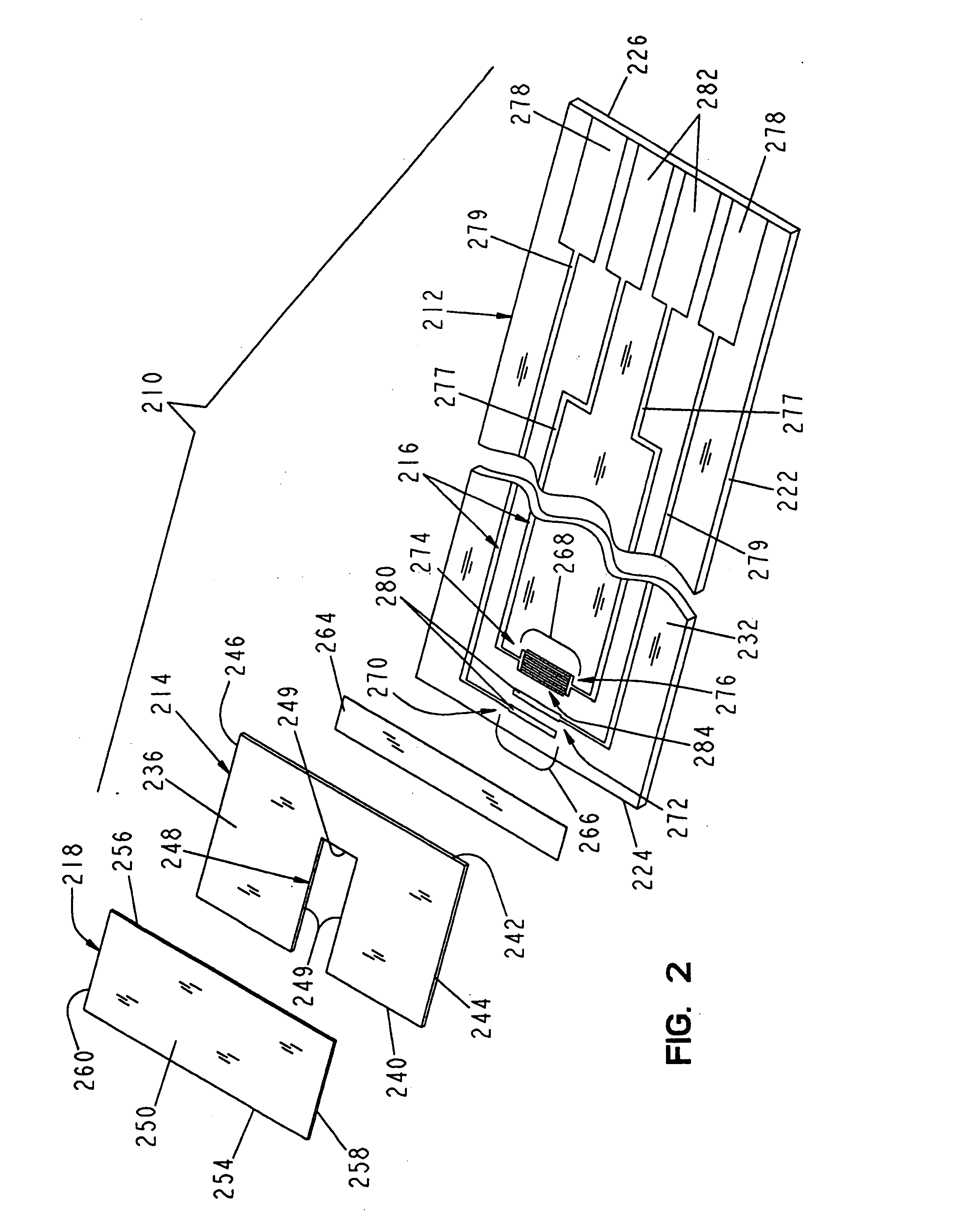

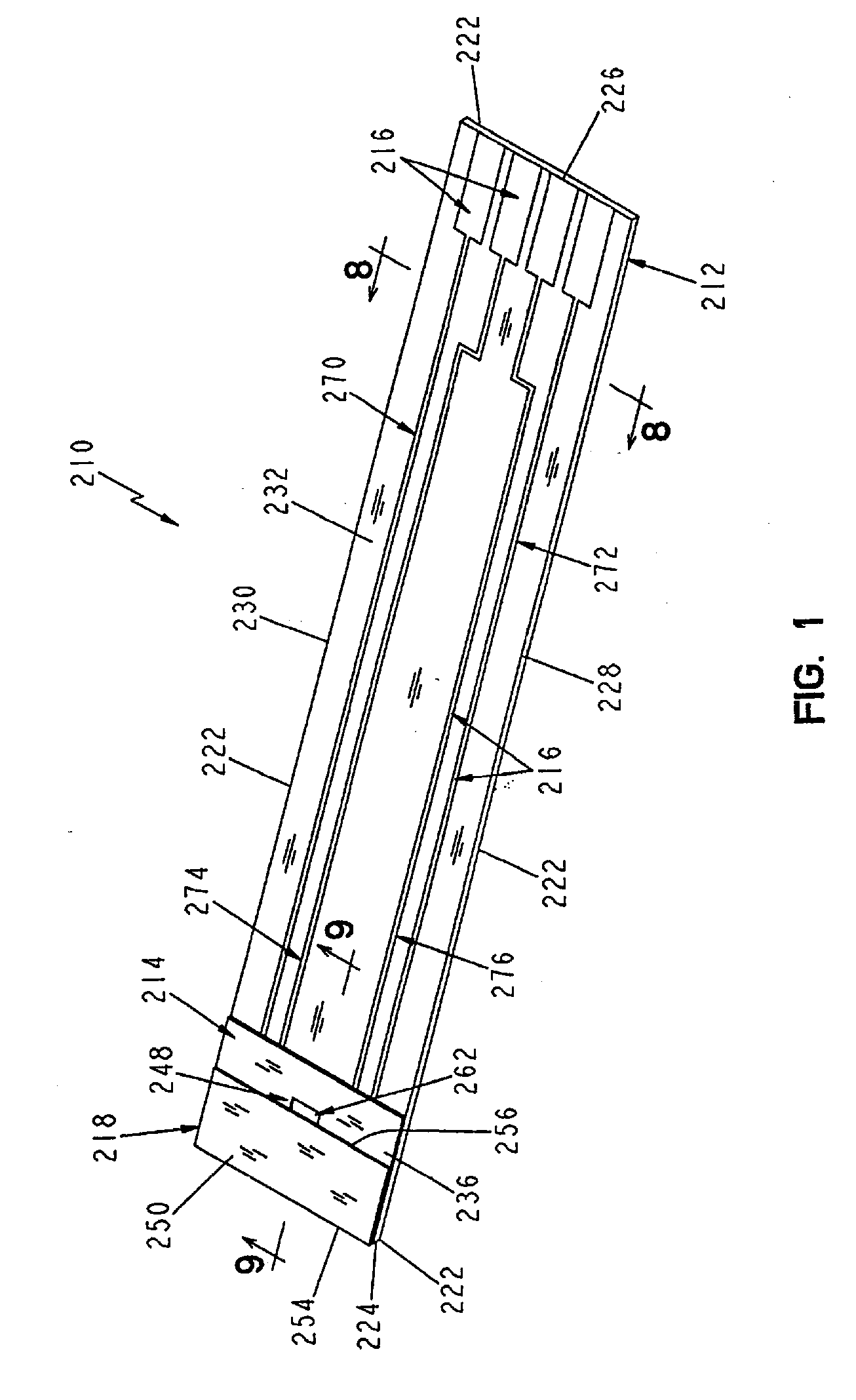

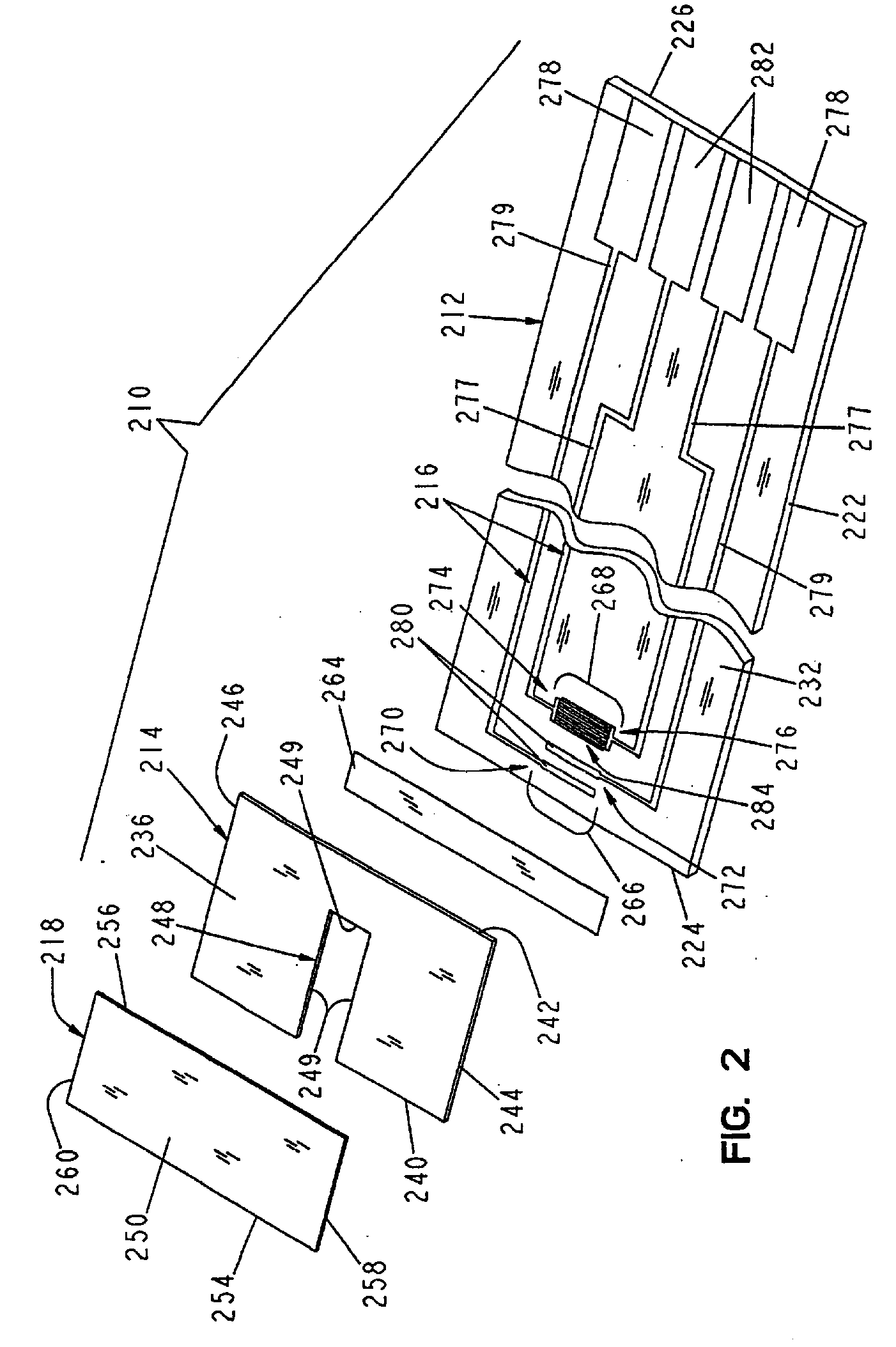

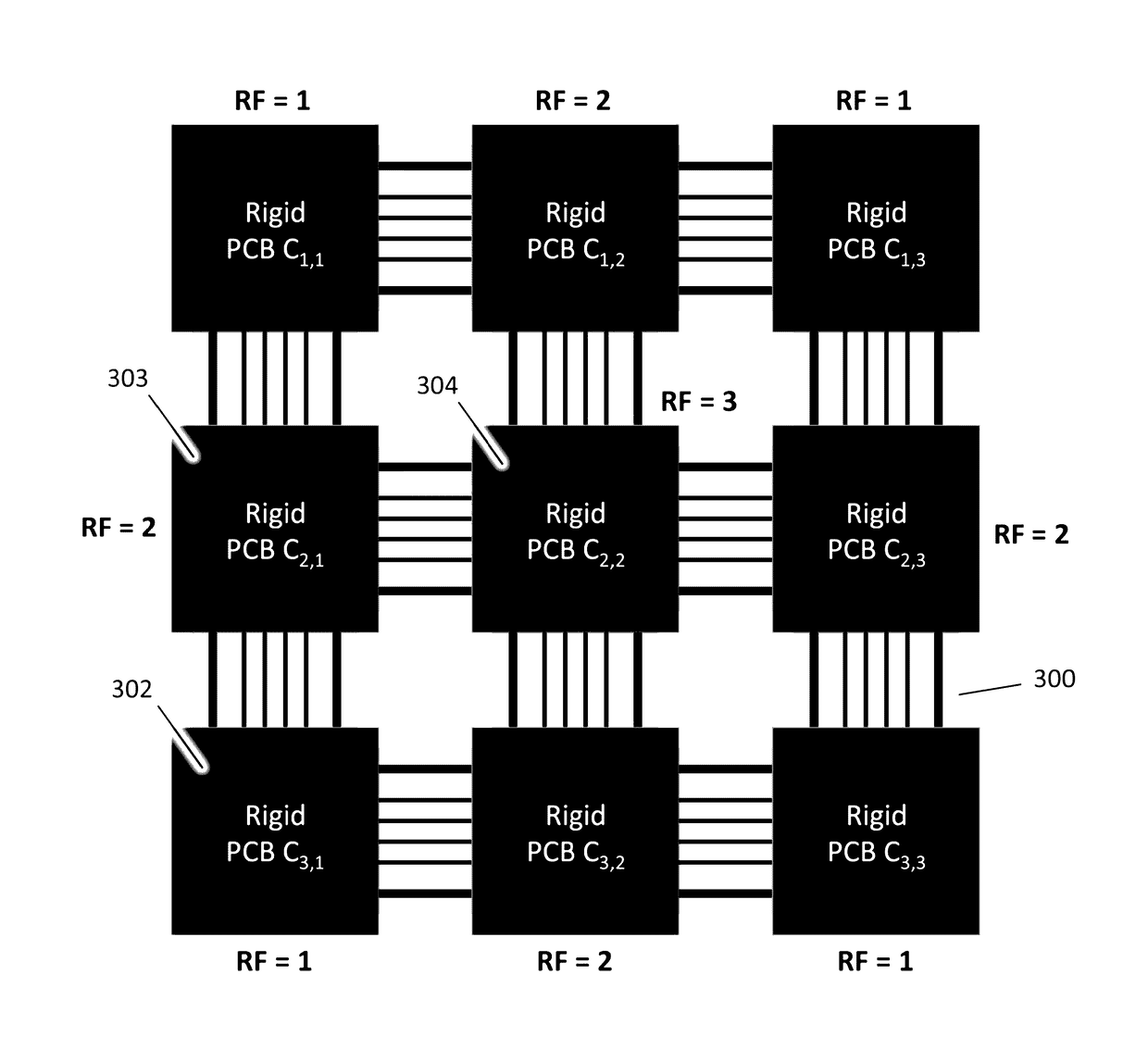

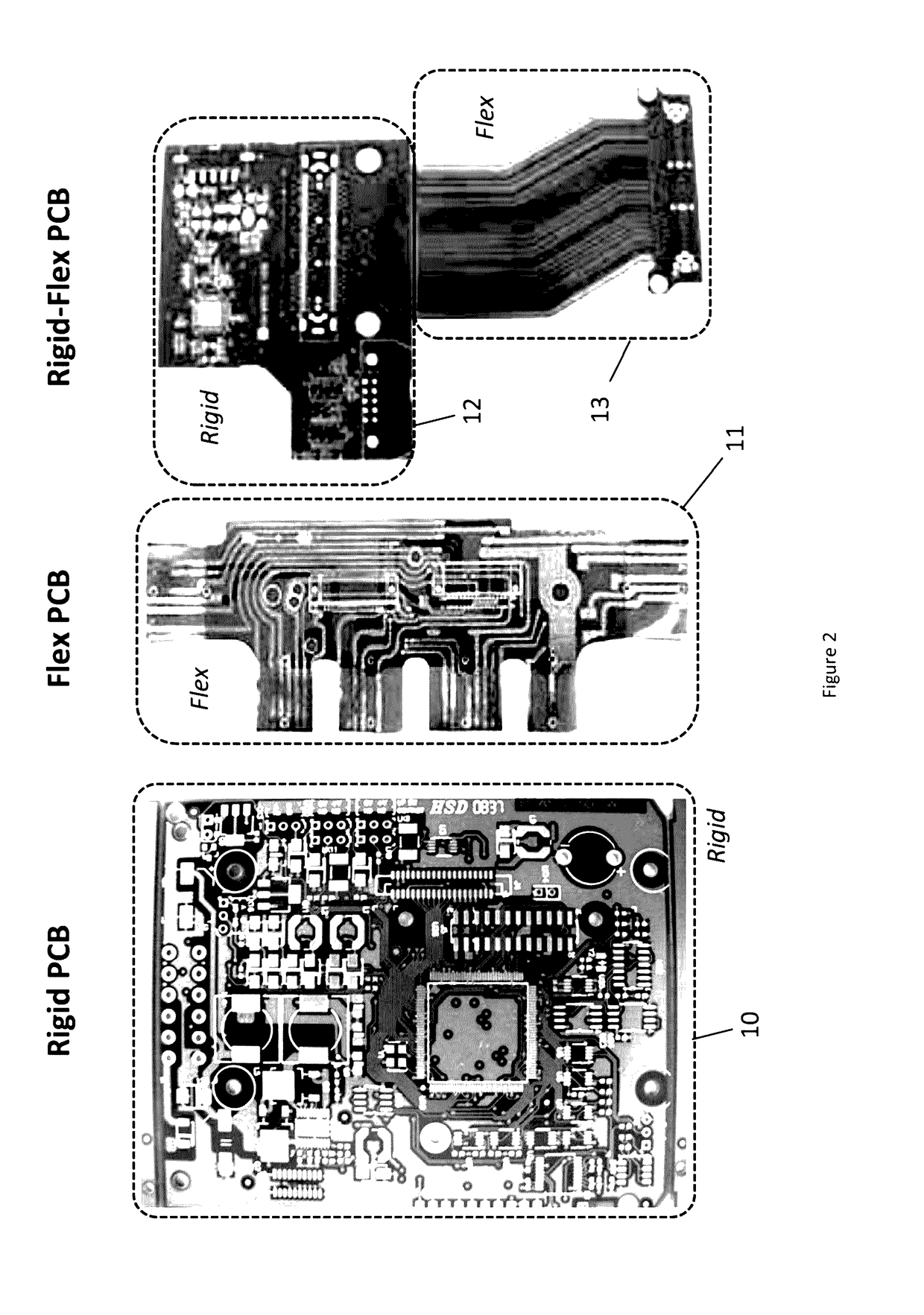

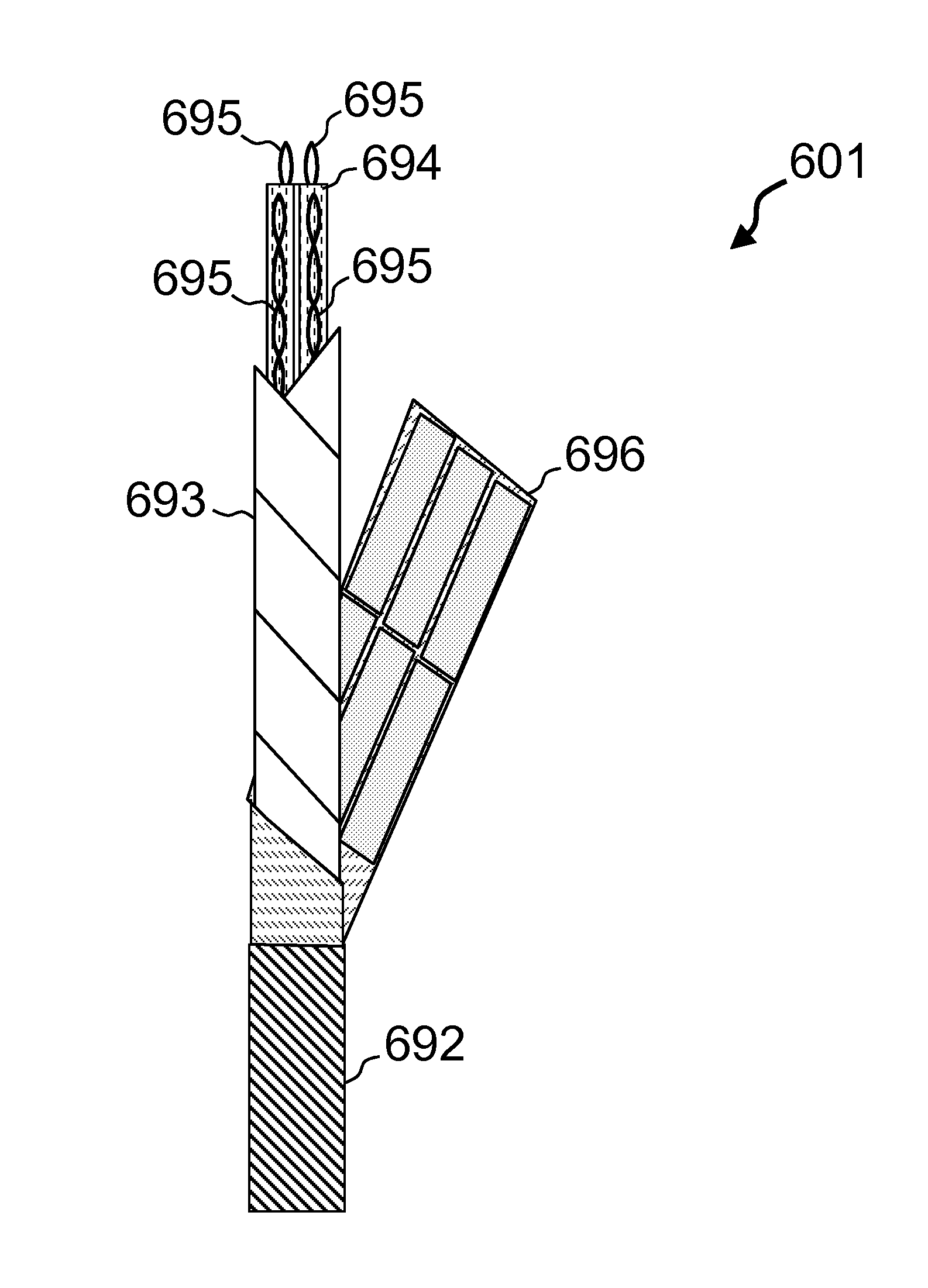

3D Bendable Printed Circuit Board With Redundant Interconnections

ActiveUS20170118838A1Eliminate needDurability and ease of usePrinted circuit assemblingPrinted circuit aspectsElectrical connectionInterconnection

A rigid-flex PCB includes an array of rigid PCB “islands” interconnected by a flexible PCB formed into flexible connectors. The conductive and insulating layers of the flexible PCB extend into the rigid PCBs, giving the electrical connections to the rigid PCBs added resistance to breakage as the rigid-flex PCB is repeatedly stressed by bending and twisting forces. In addition, the durability of the rigid-flex PCB is enhanced by making the power and signal lines driving the rigid PCBs redundant so that a breakage of a line will not necessarily affect the operation of the rigid PCB to which it is attached. The rigid-flex PCB is particularly applicable to light pads used in phototherapy, wherein LEDs mounted on the rigid-PCBs are powered and controlled through the redundant lines in the flexible PCB.

Owner:ADVENTIVE INT LTD

Maskless nanofabrication of electronic components

InactiveUS7682970B2Reduce the amount requiredEfficient methodRadiation applicationsSolid-state devicesElectronic structureNanoparticle

Owner:RGT UNIV OF CALIFORNIA +1

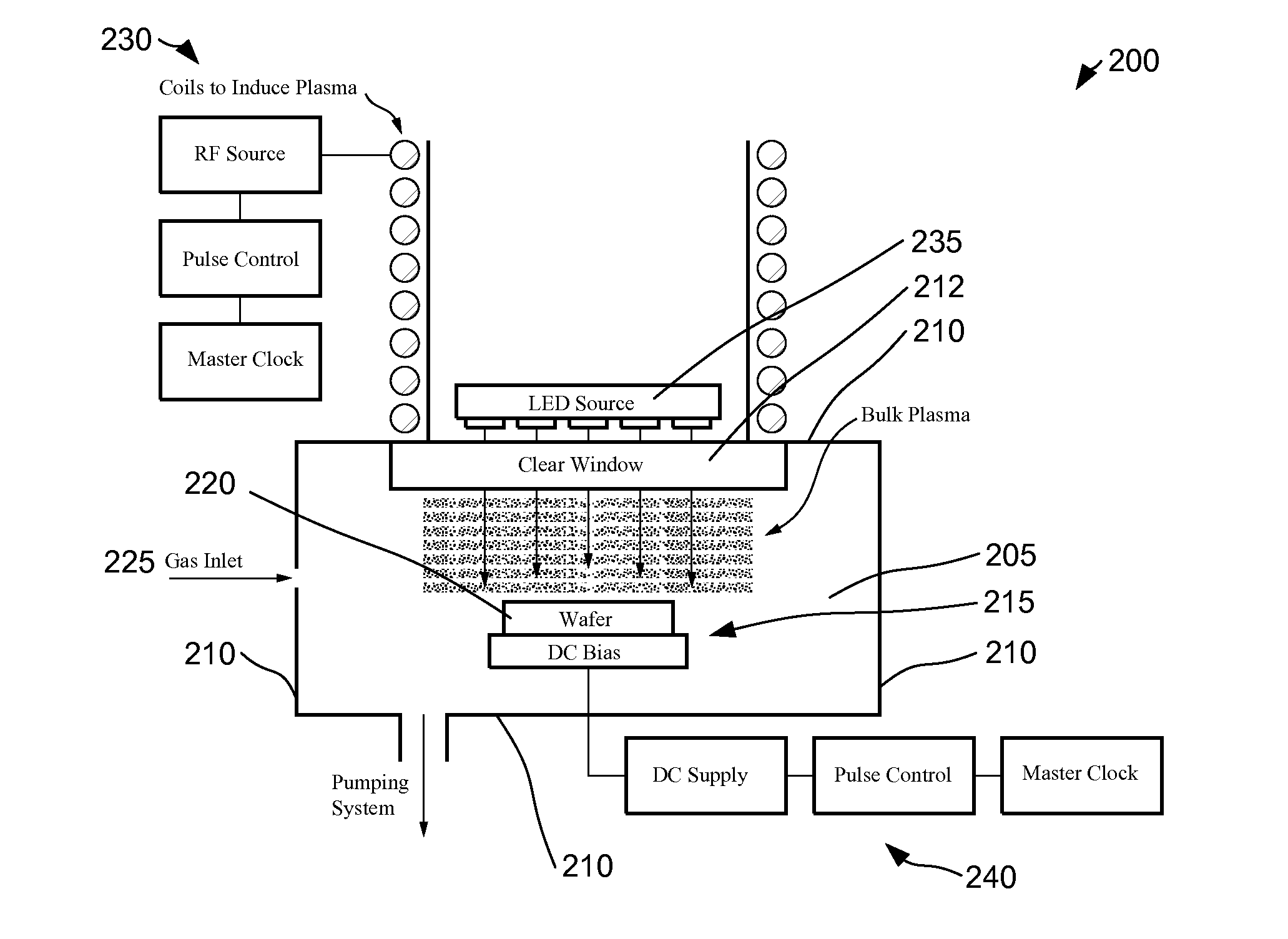

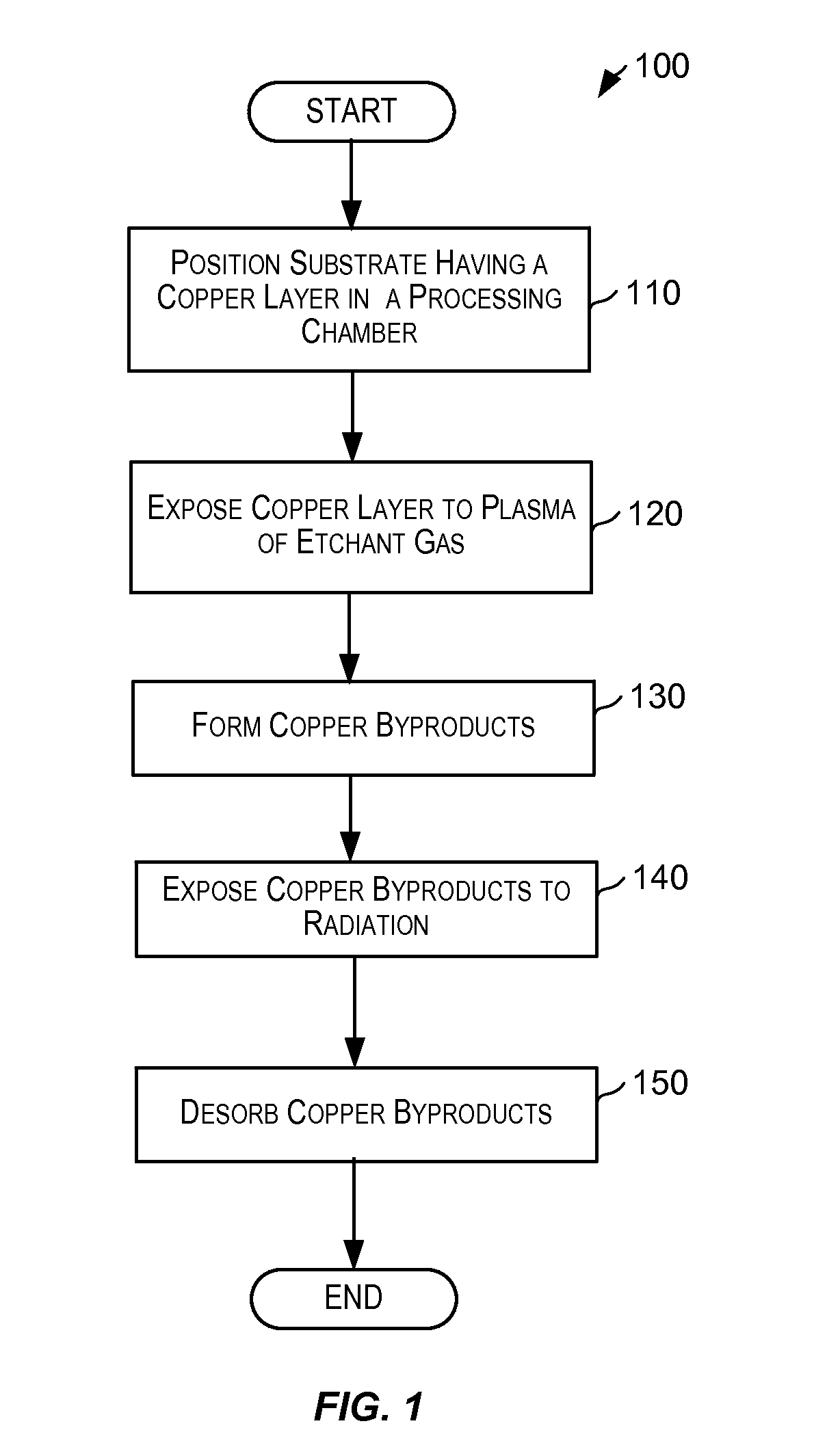

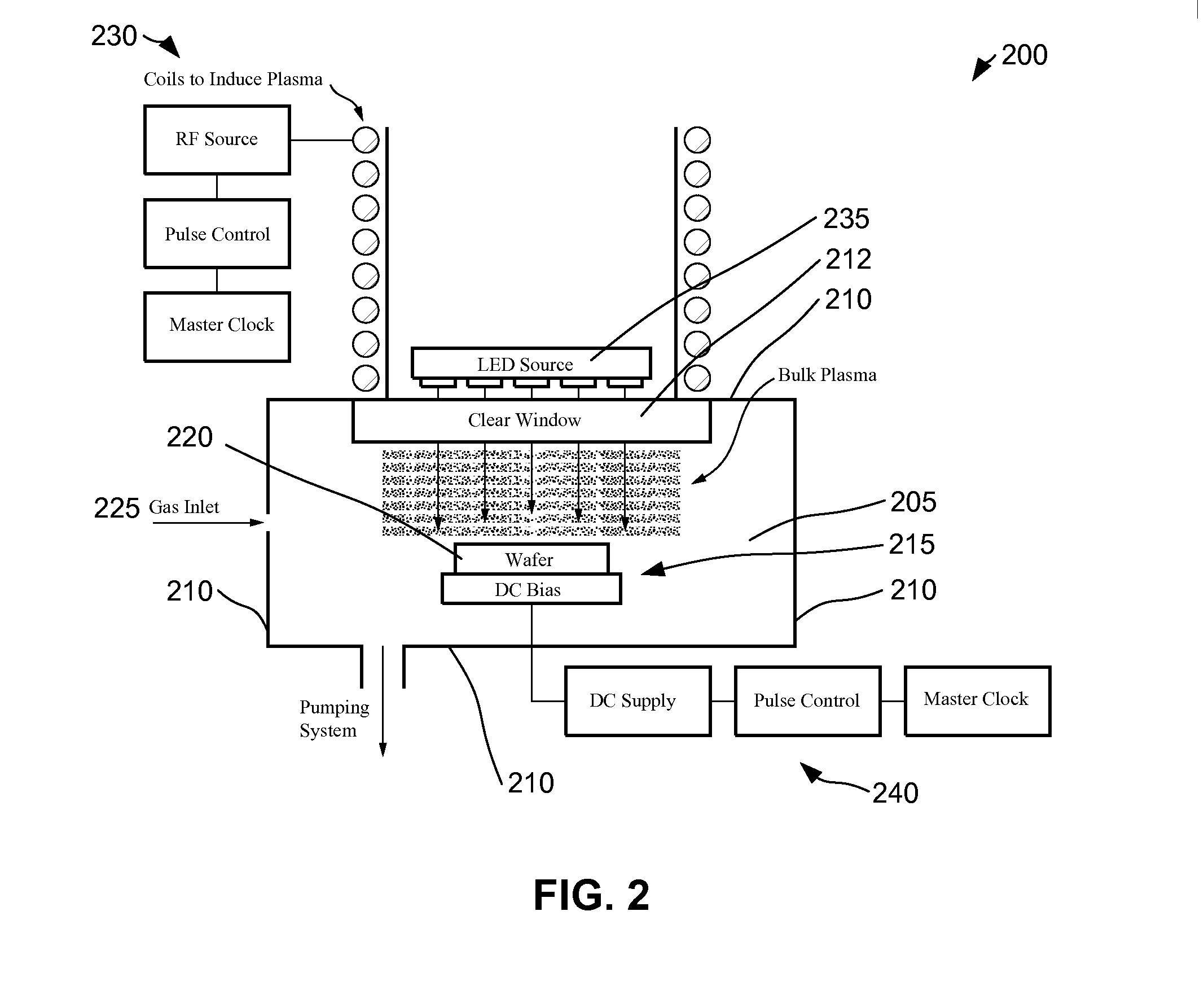

Process for etching metal using a combination of plasma and solid state sources

InactiveUS20150099369A1Reduce the temperatureElectric discharge tubesSemiconductor/solid-state device manufacturingPhysical chemistryAnalytical chemistry

An apparatus configured to remove metal etch byproducts from the surface of substrates and from the interior of a substrate processing chamber. A plasma is used in combination with a solid state light source, such as an LED, to desorb metal etch byproducts. The desorbed byproducts may then be removed from the chamber.

Owner:APPLIED MATERIALS INC

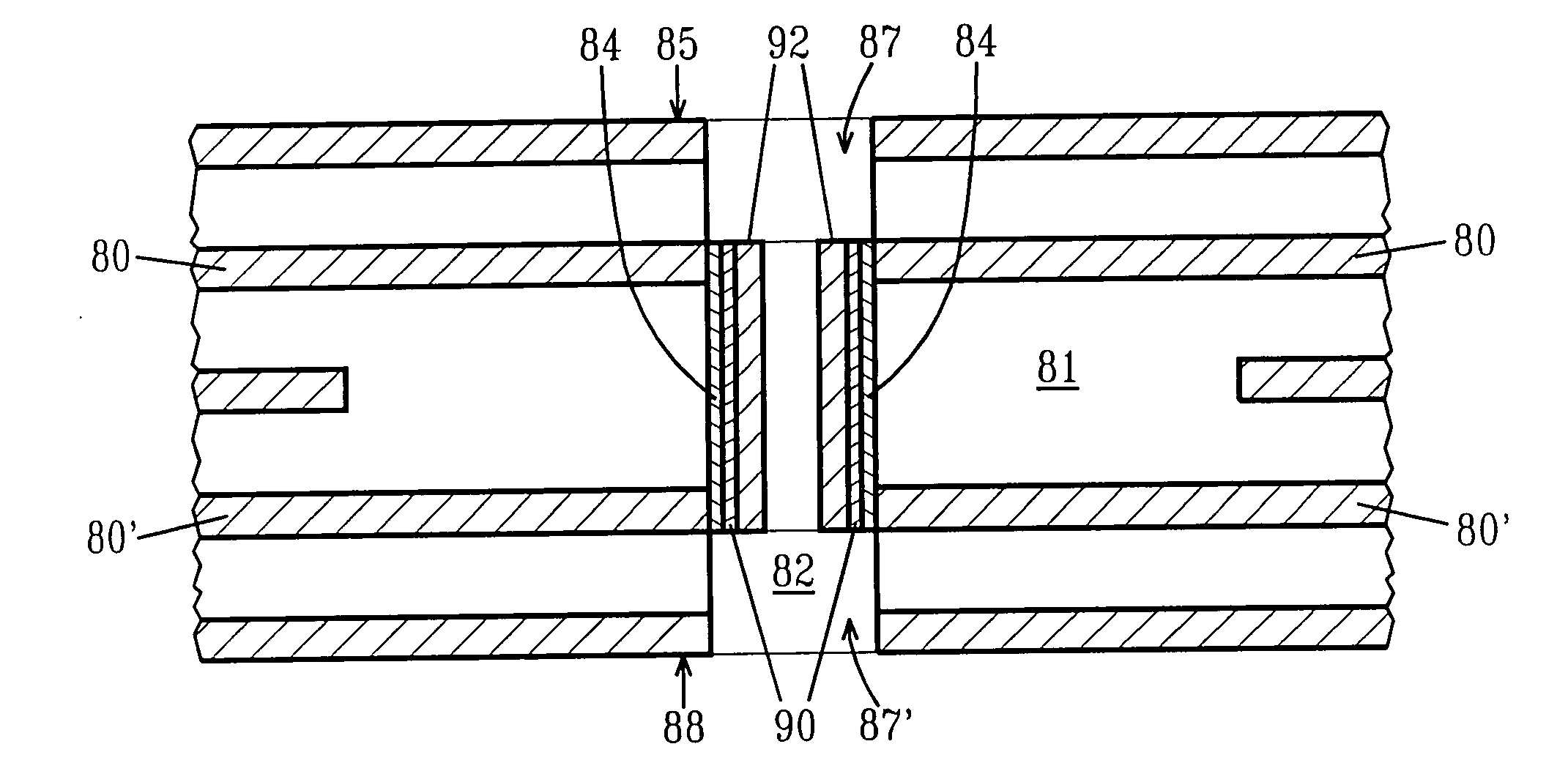

Manufacture of printed circuit boards with stubless plated through-holes

ActiveUS20070246252A1Electrical connection printed elementsSurface layering apparatusCopper platingCopper interconnect

A process of copper plating a through-hole in a printed circuit board, and the printed circuit board made from such process. The process comprises: providing a printed circuit board with at least two copper interconnect lines separated by an insulator in the vertical direction; providing a through-hole in the printed circuit board in the vertical direction such that the interconnect lines provide a copper land in the through-hole; applying a seed layer to an interior surface of the through-hole; removing an outermost portion of the seed layer from the interior surface of the through-hole with a laser; applying copper on the seed layer.

Owner:IBM CORP

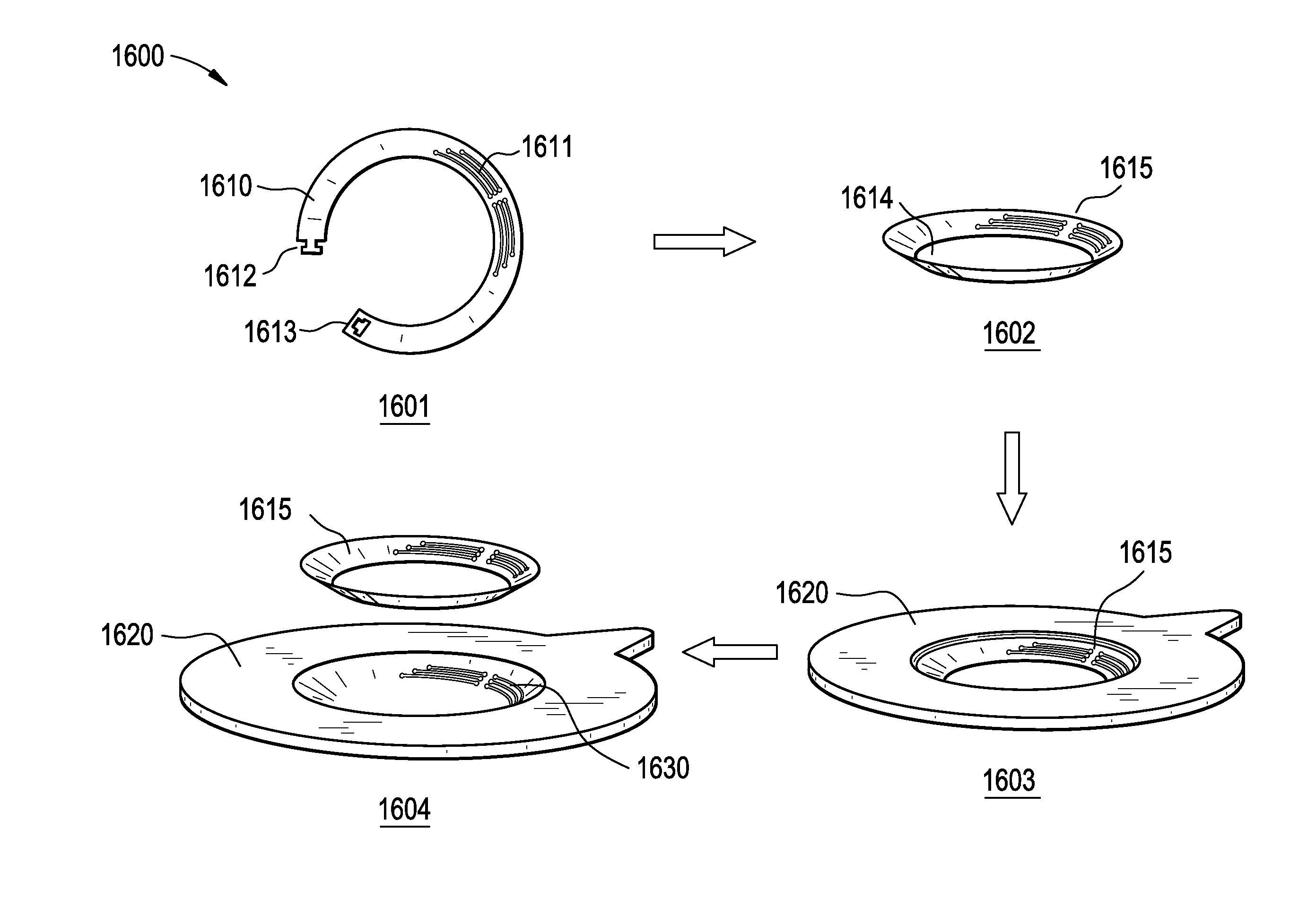

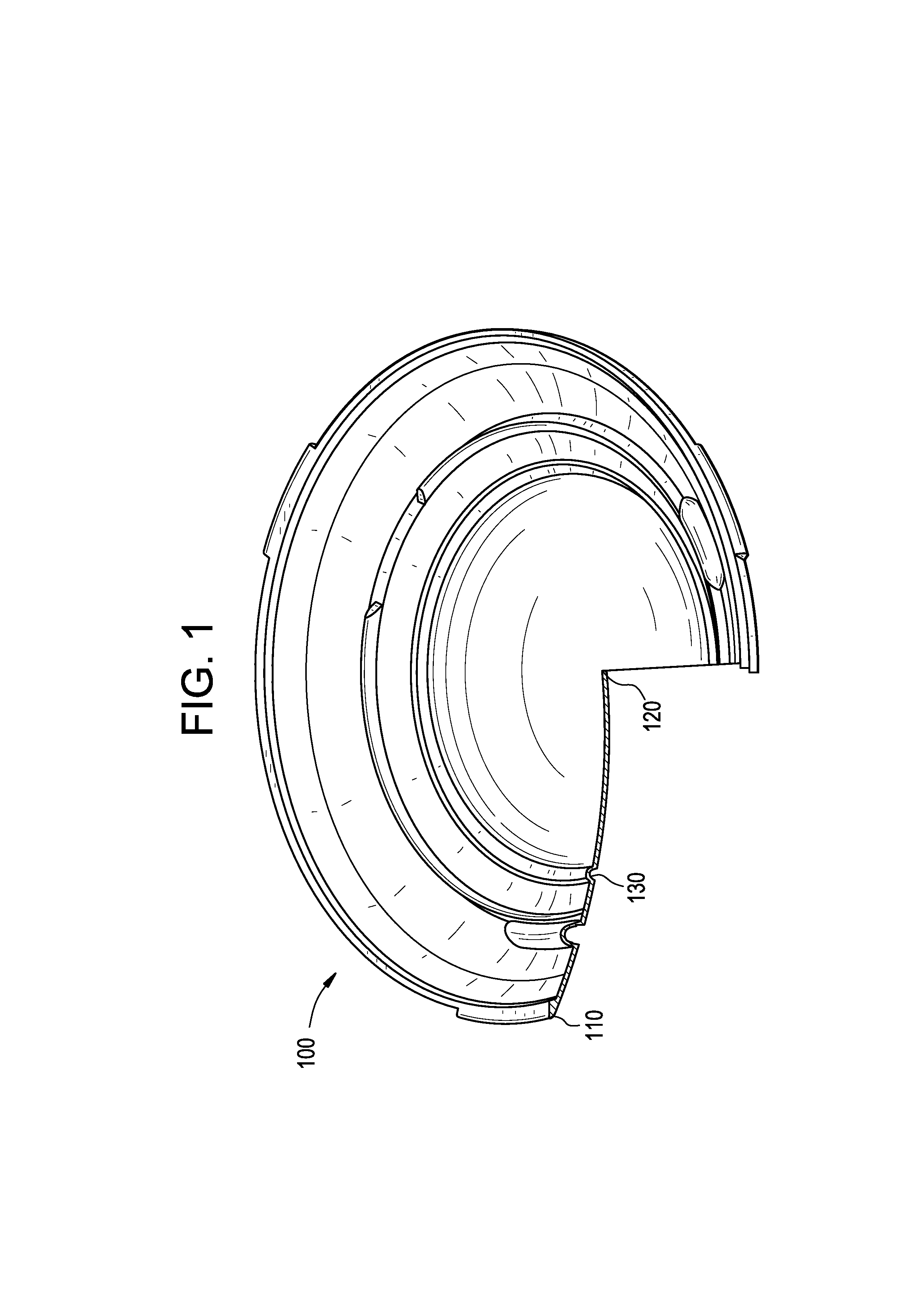

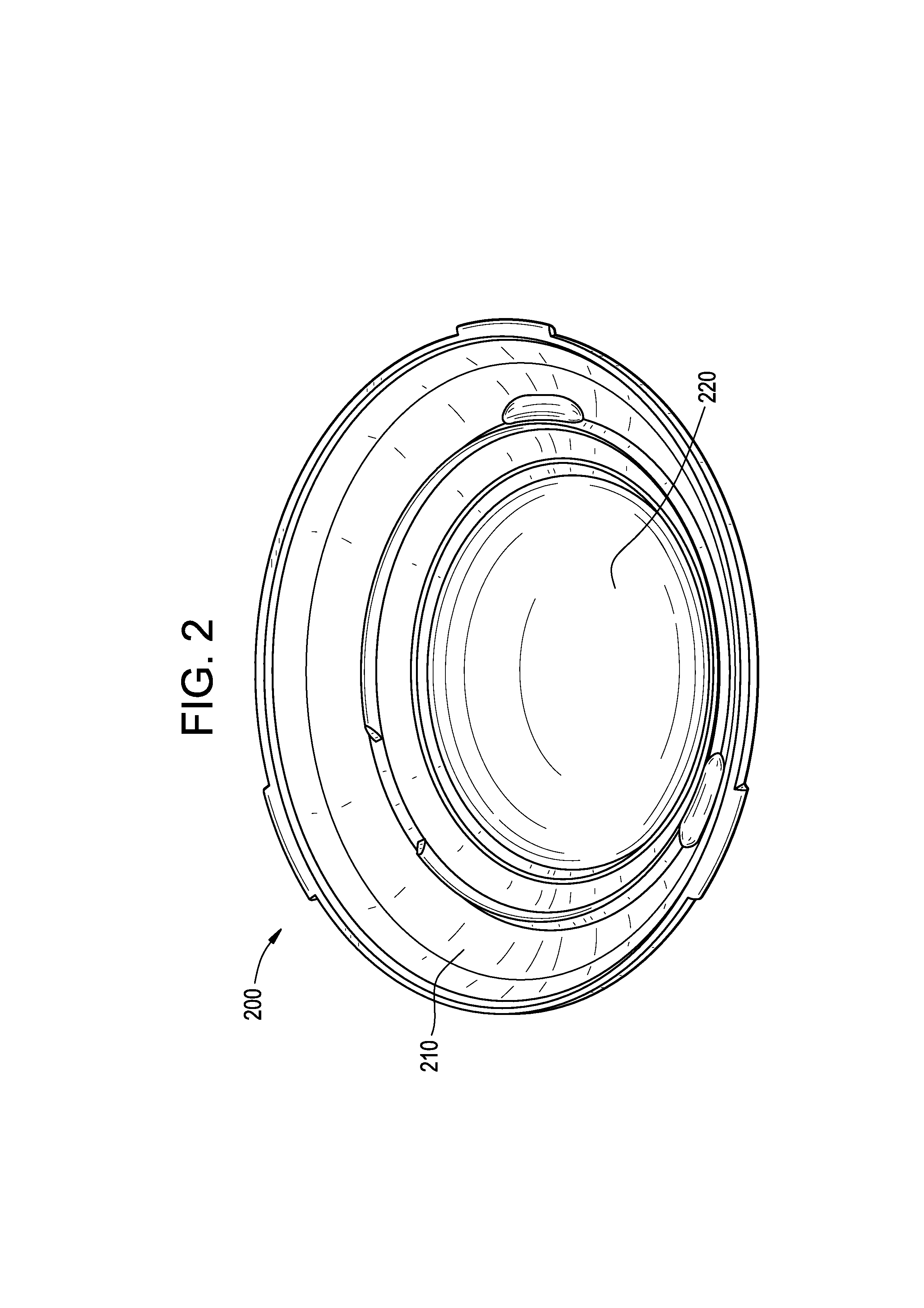

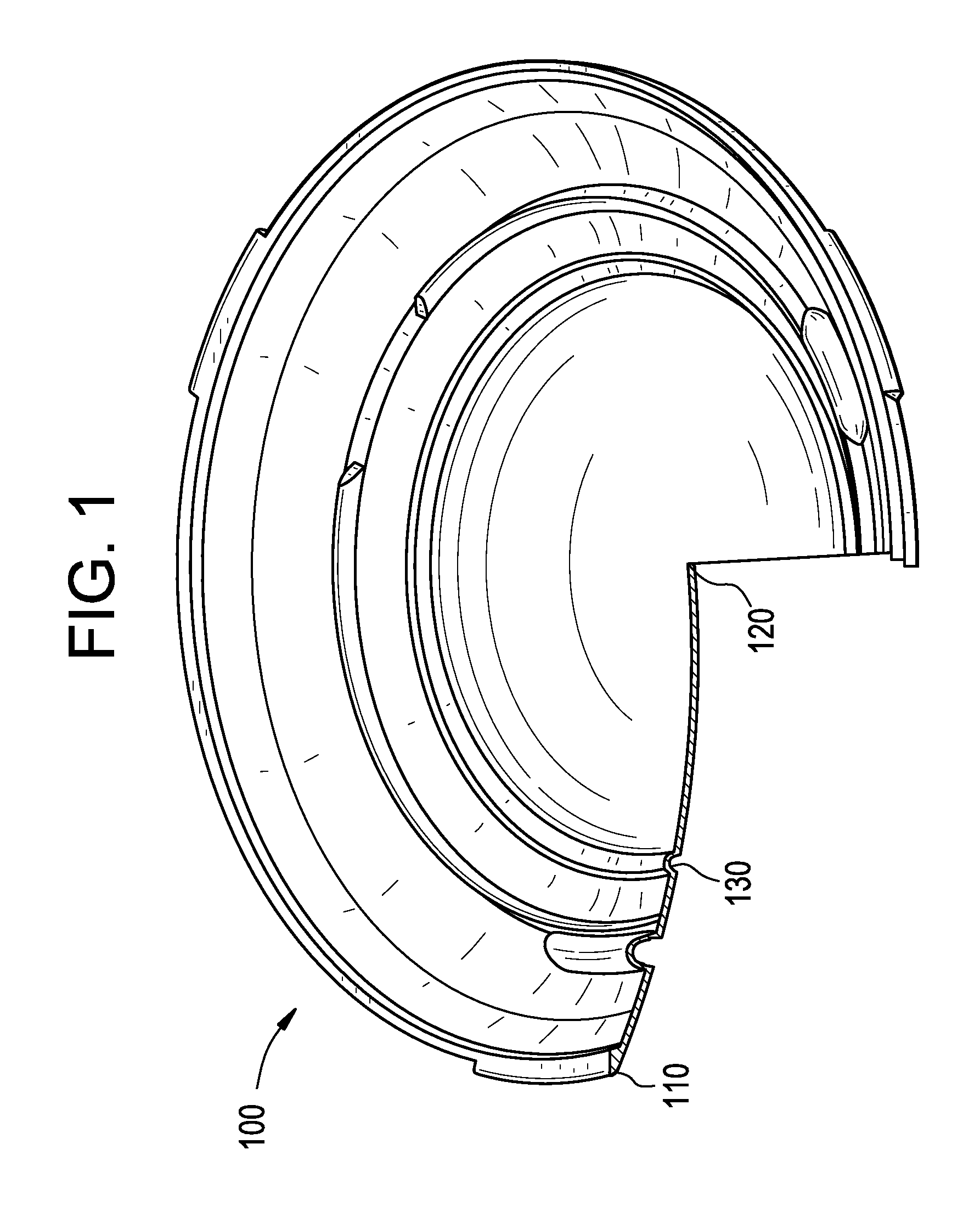

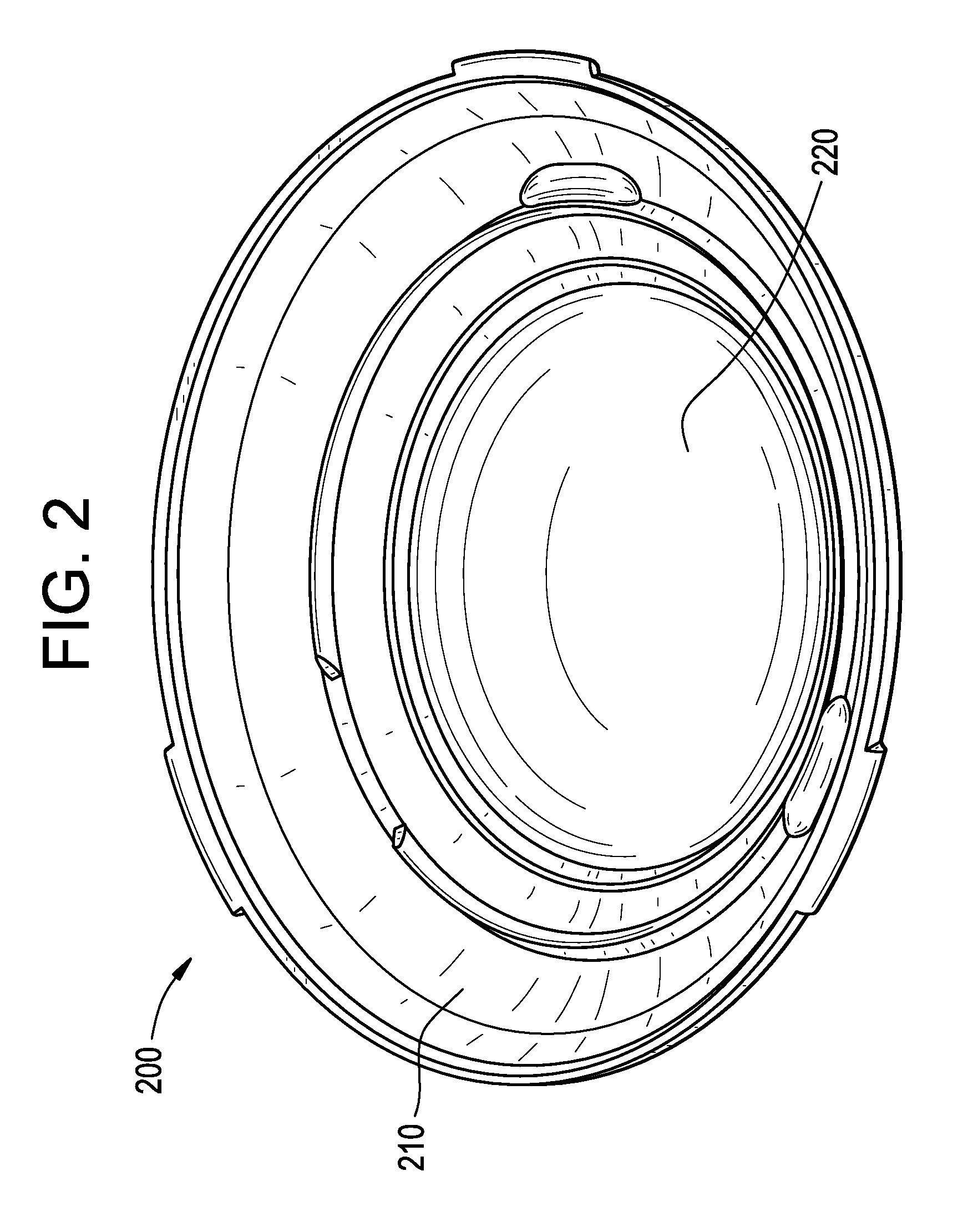

Methods and apparatus to form electrical interconnects on ophthalmic devices

ActiveUS20130174978A1Overcome disadvantagesOptical articlesPretreated surfacesOphthalmological deviceElectricity

Owner:JOHNSON & JOHNSON VISION CARE INC

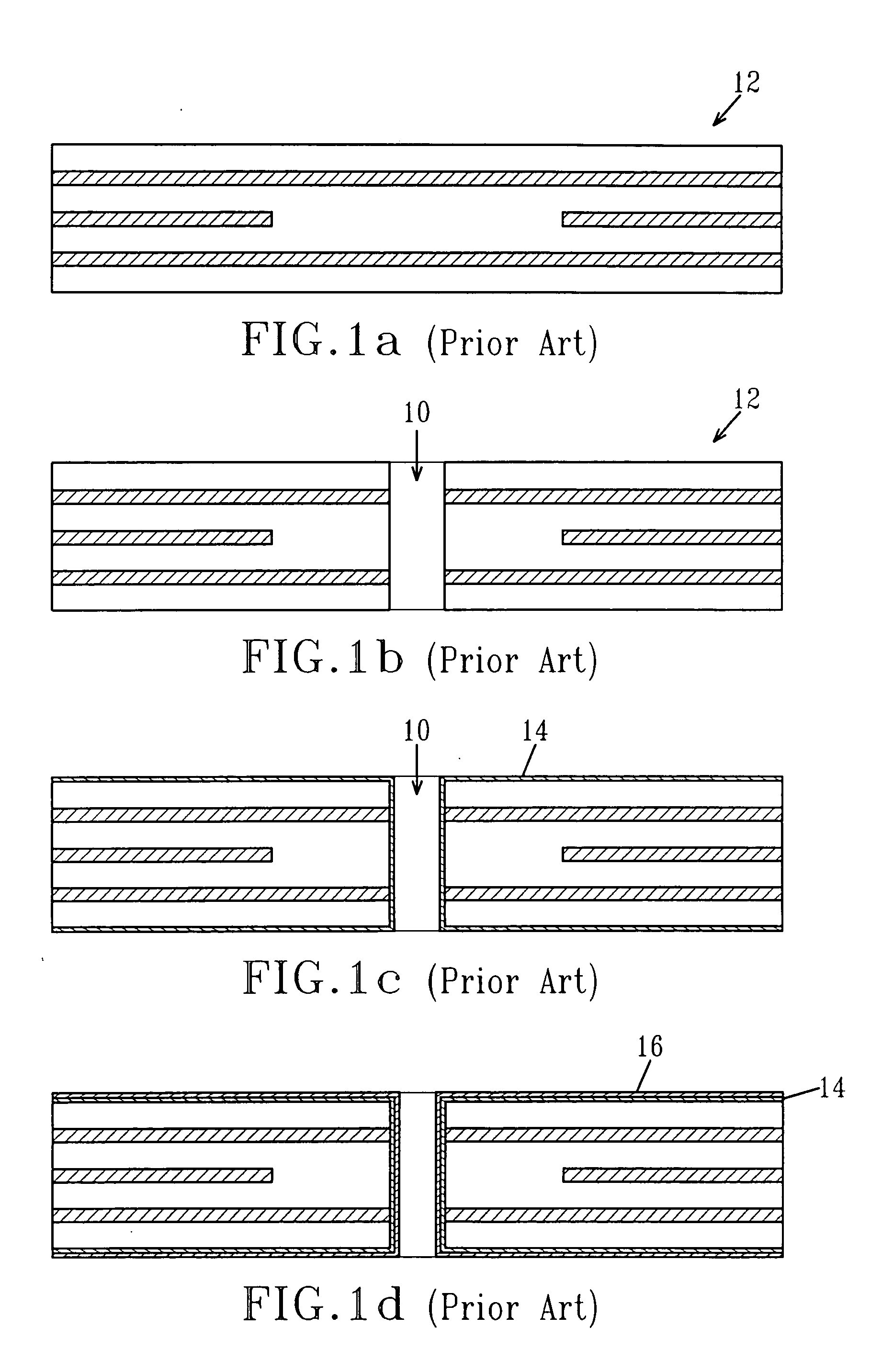

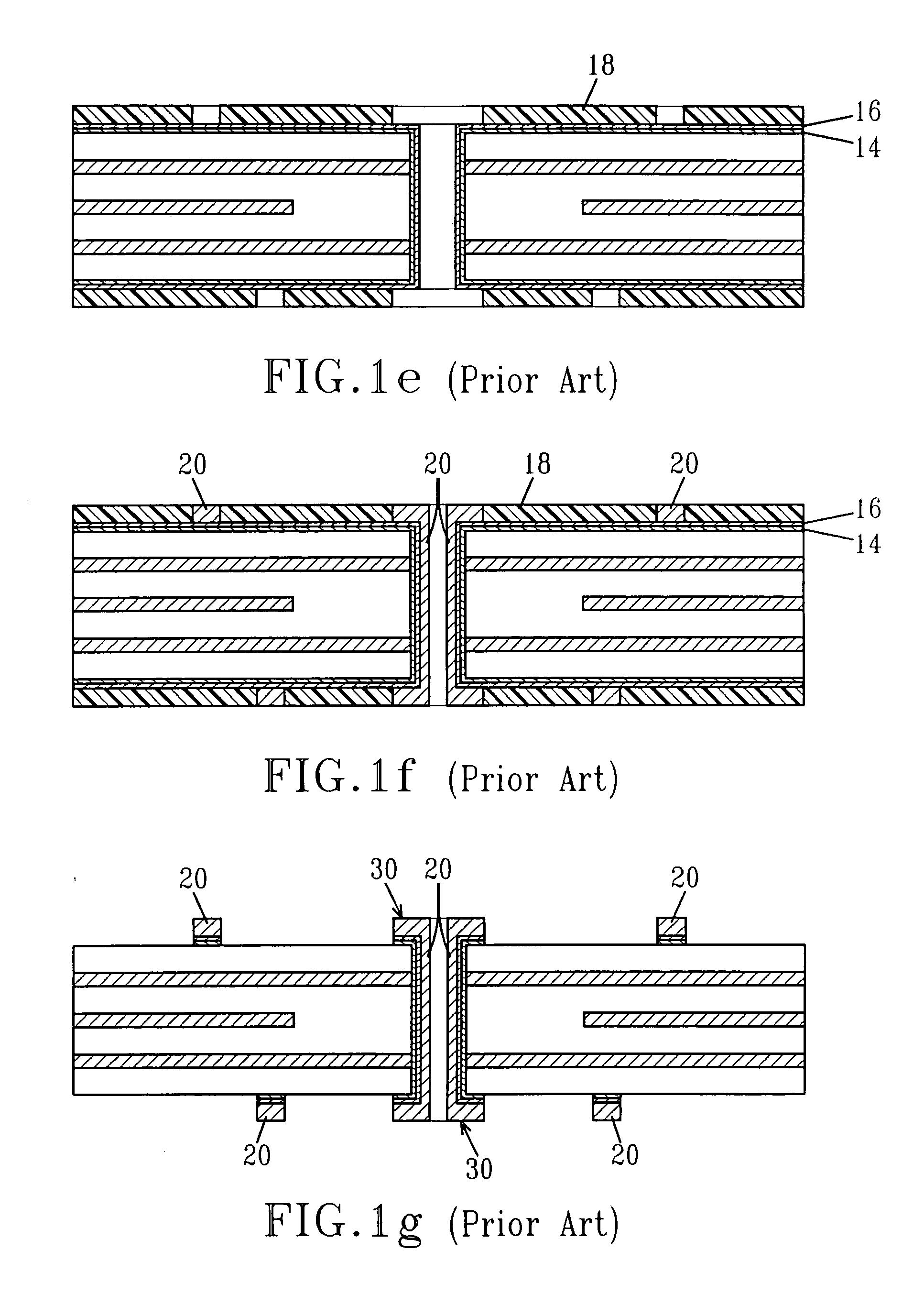

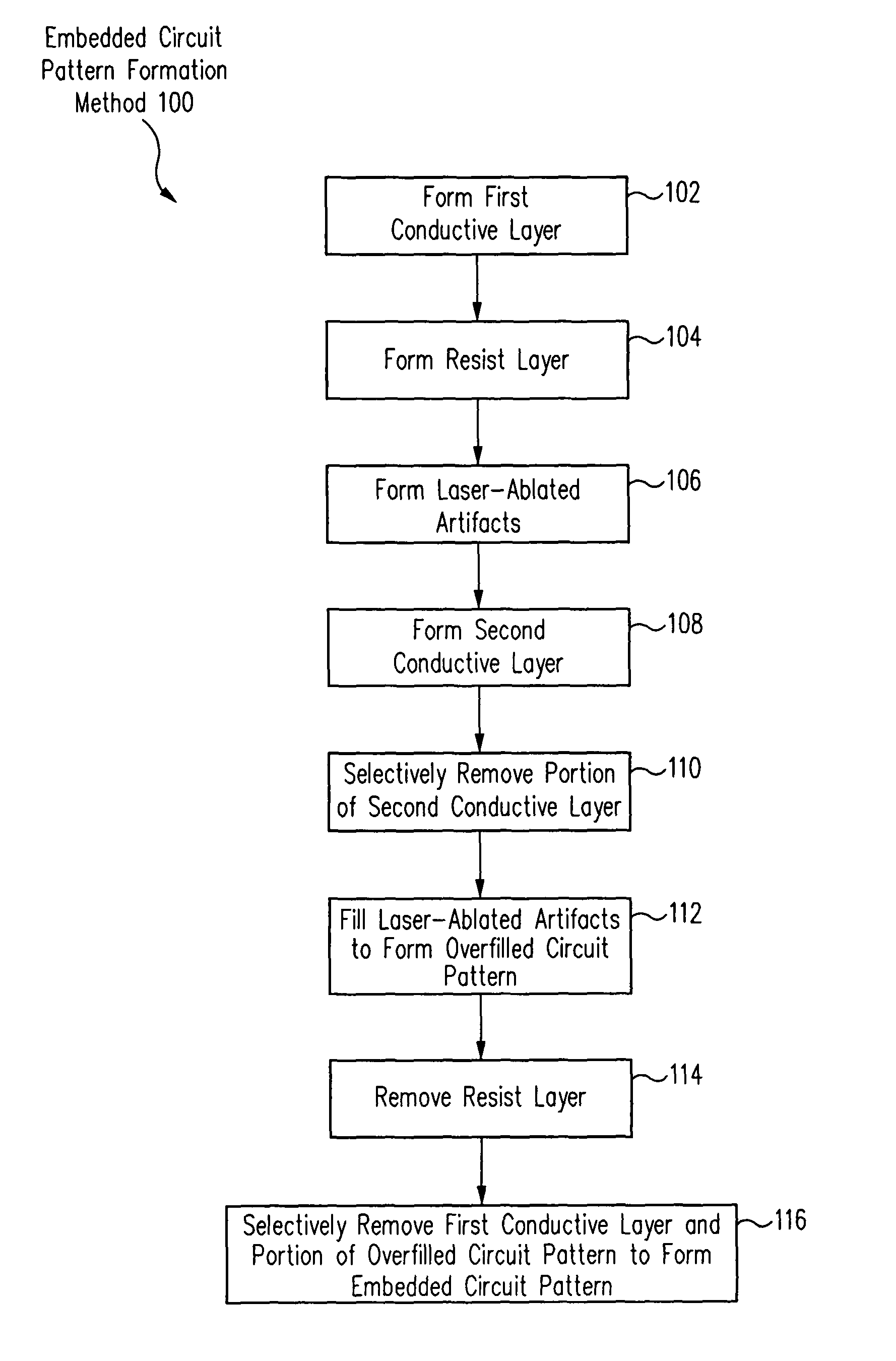

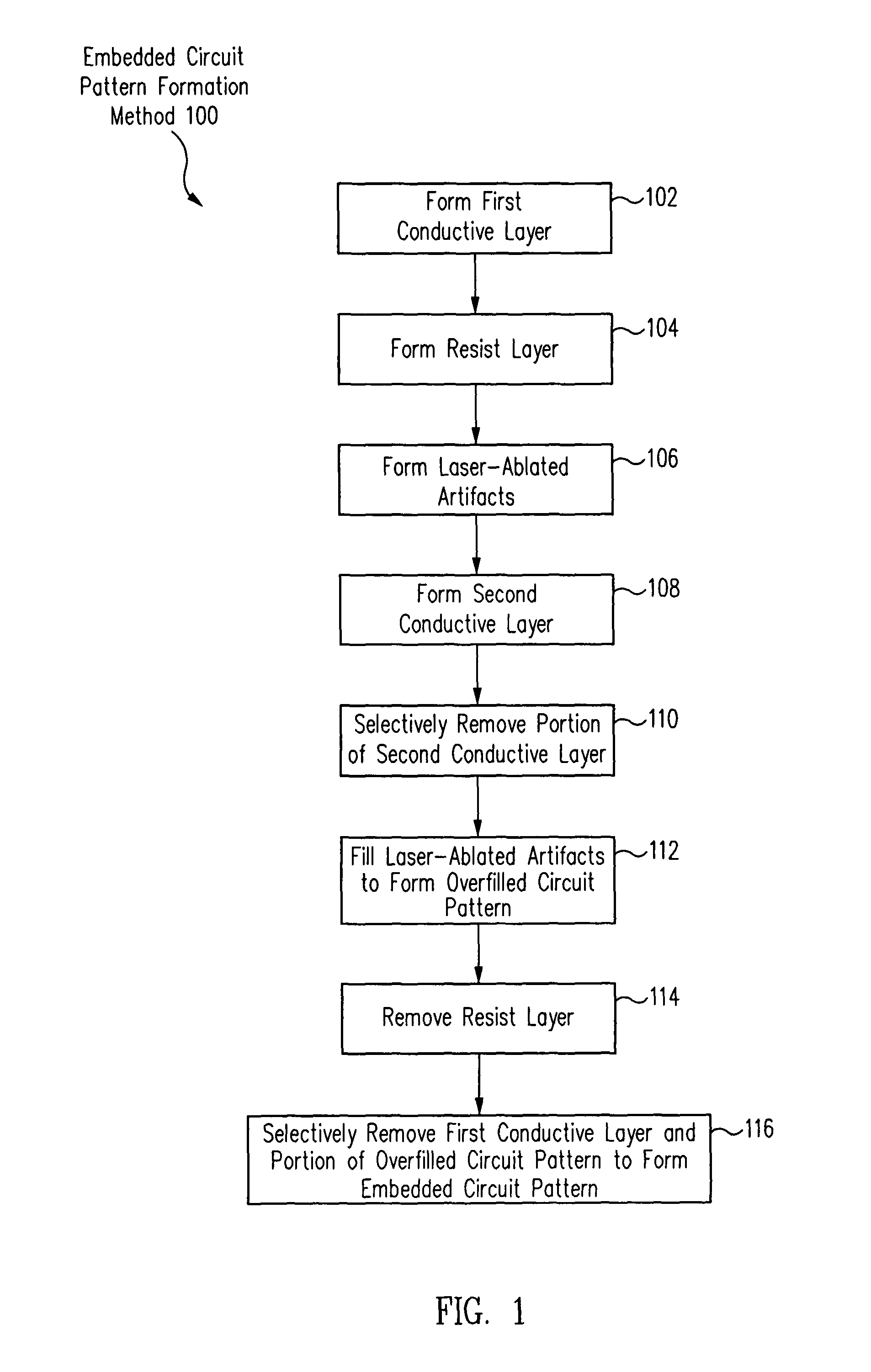

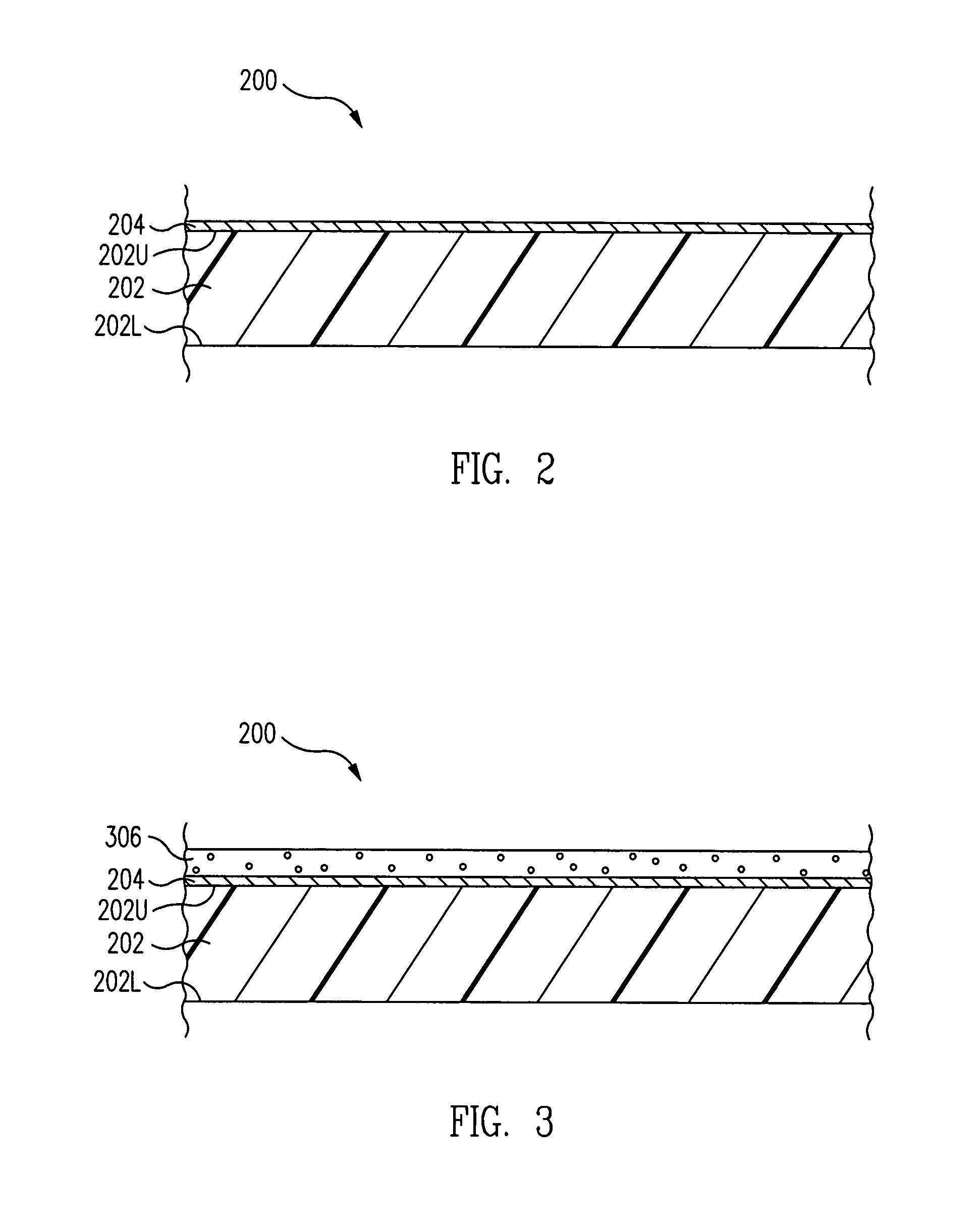

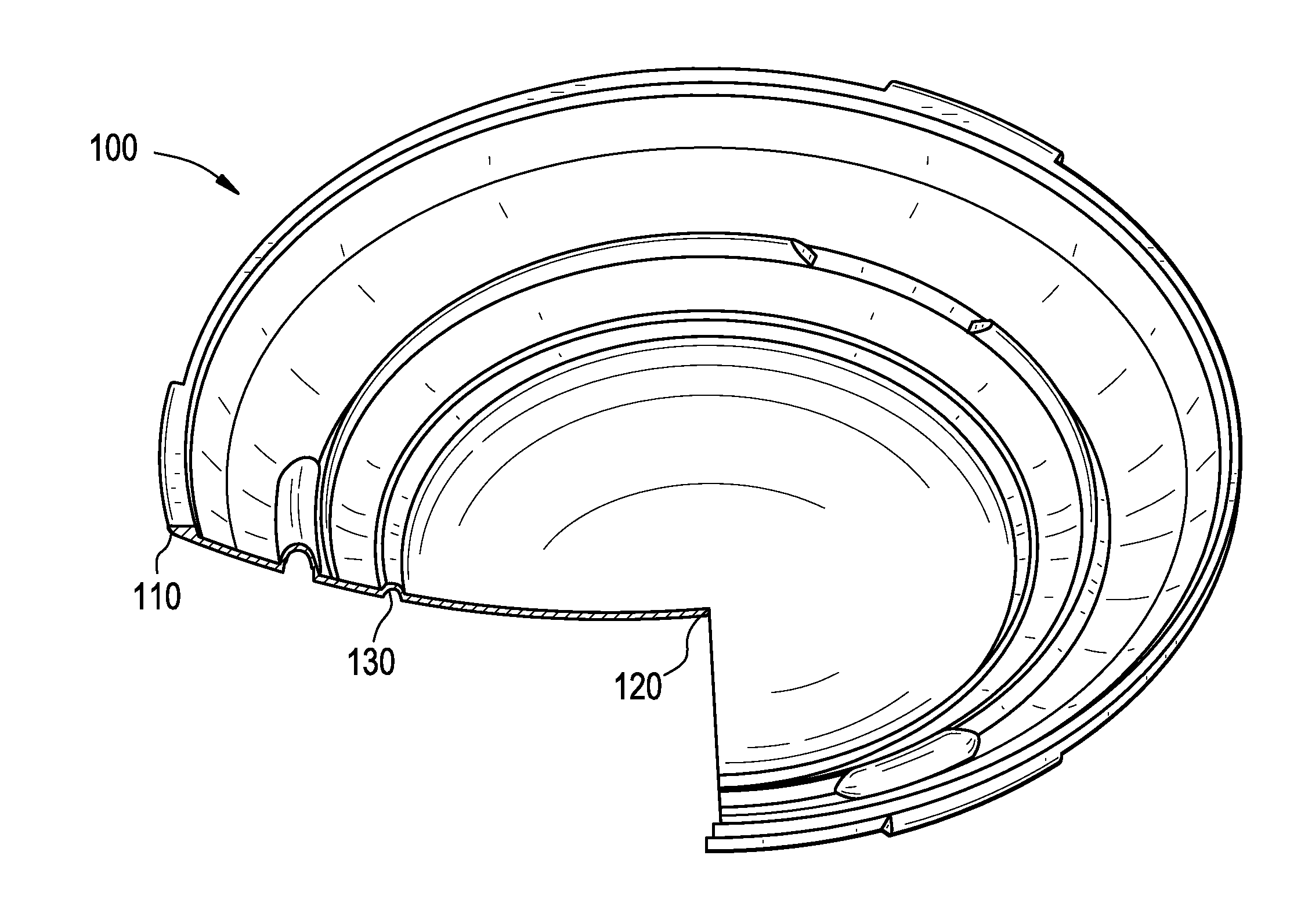

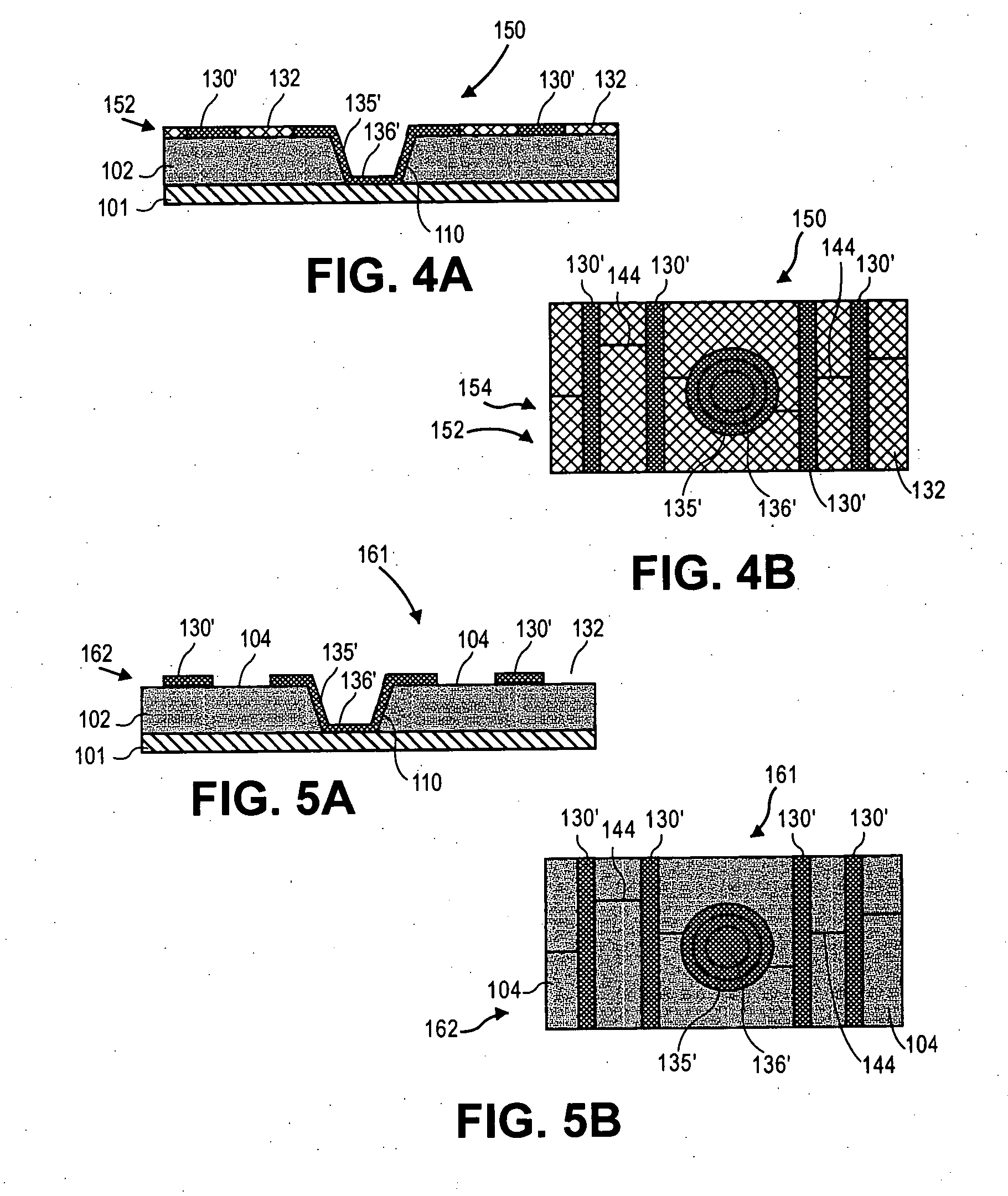

Method of fabricating an embedded circuit pattern

ActiveUS7752752B1Method is fastLow costElectrical connection printed elementsConductive material removal by irradiationResistDielectric layer

A method of fabricating a substrate includes forming a first conductive layer on a dielectric layer, forming a resist layer on the first conductive layer, and forming laser-ablated artifacts through the first resist layer, through the first conductive layer, and at least partially into the dielectric layer. A second conductive layer is formed within the laser-ablated artifacts. The laser-ablated artifacts are filled to form an overfilled circuit pattern. The resist layer and the first conductive layer are removed. Further, a portion of the overfilled circuit pattern is removed to form an embedded circuit pattern embedded within the dielectric layer.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Methods and apparatus to form electrical interconnects on ophthalmic devices

InactiveUS20130152386A1Printed circuit assemblingElectrically conductive connectionsOphthalmological deviceElectrical interconnect

Owner:JOHNSON & JOHNSON VISION CARE INC

Method and apparatus for a printed circuit board using laser assisted metallization and patterning of a substrate

InactiveUS20070144769A1Printed electric component incorporationSemiconductor/solid-state device detailsOptoelectronicsLaser assisted

A printed circuit is made by laser projection patterning a metal panel of a substrate, laminating a dielectric layer on the metal panel, laser irradiating the substrate to form vias in the substrate, laser activating a seed coat on the substrate, washing the seed coat from an unpatterned portion of the substrate, forming a patterned build-up layer on the substrate, and etching away a metal plating forming metal protrusions.

Owner:INTEL CORP

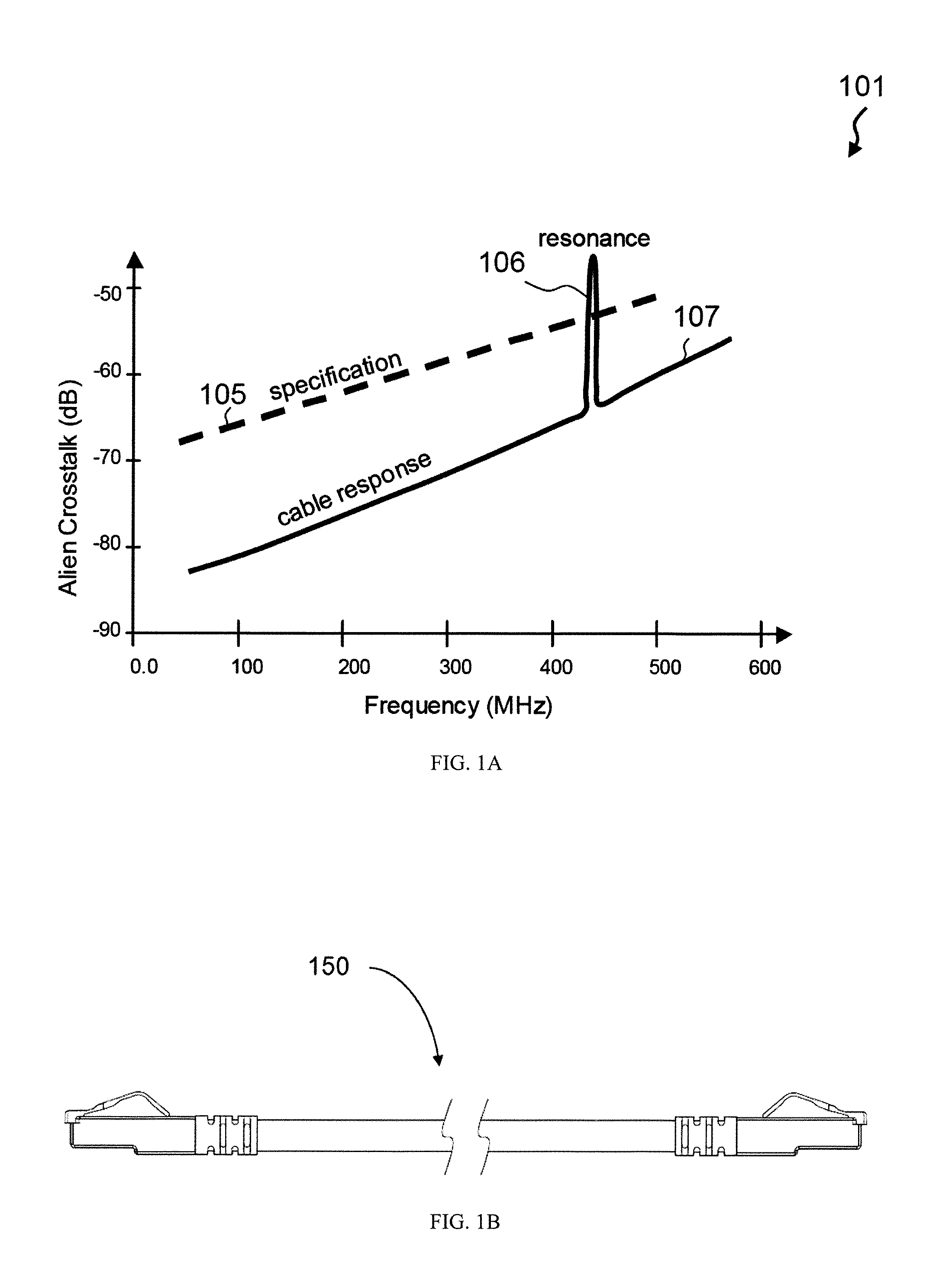

Communication cable including a mosaic tape

ActiveUS8558115B2Improved reduction of alien crosstalkLimit their tolerancePower cables with screens/conductive layersInsulated cablesEngineeringLaser ablation

Owner:PANDUIT

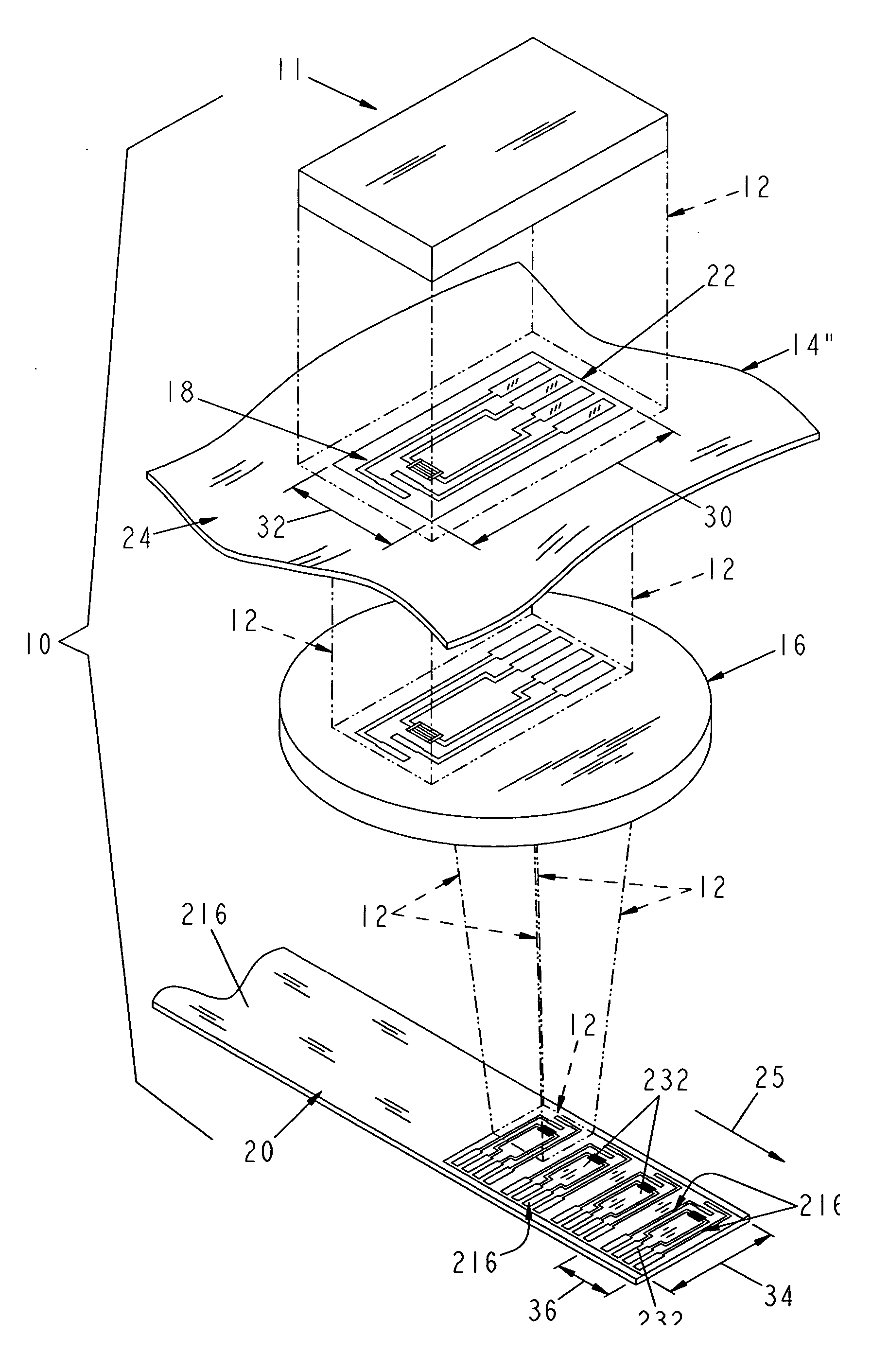

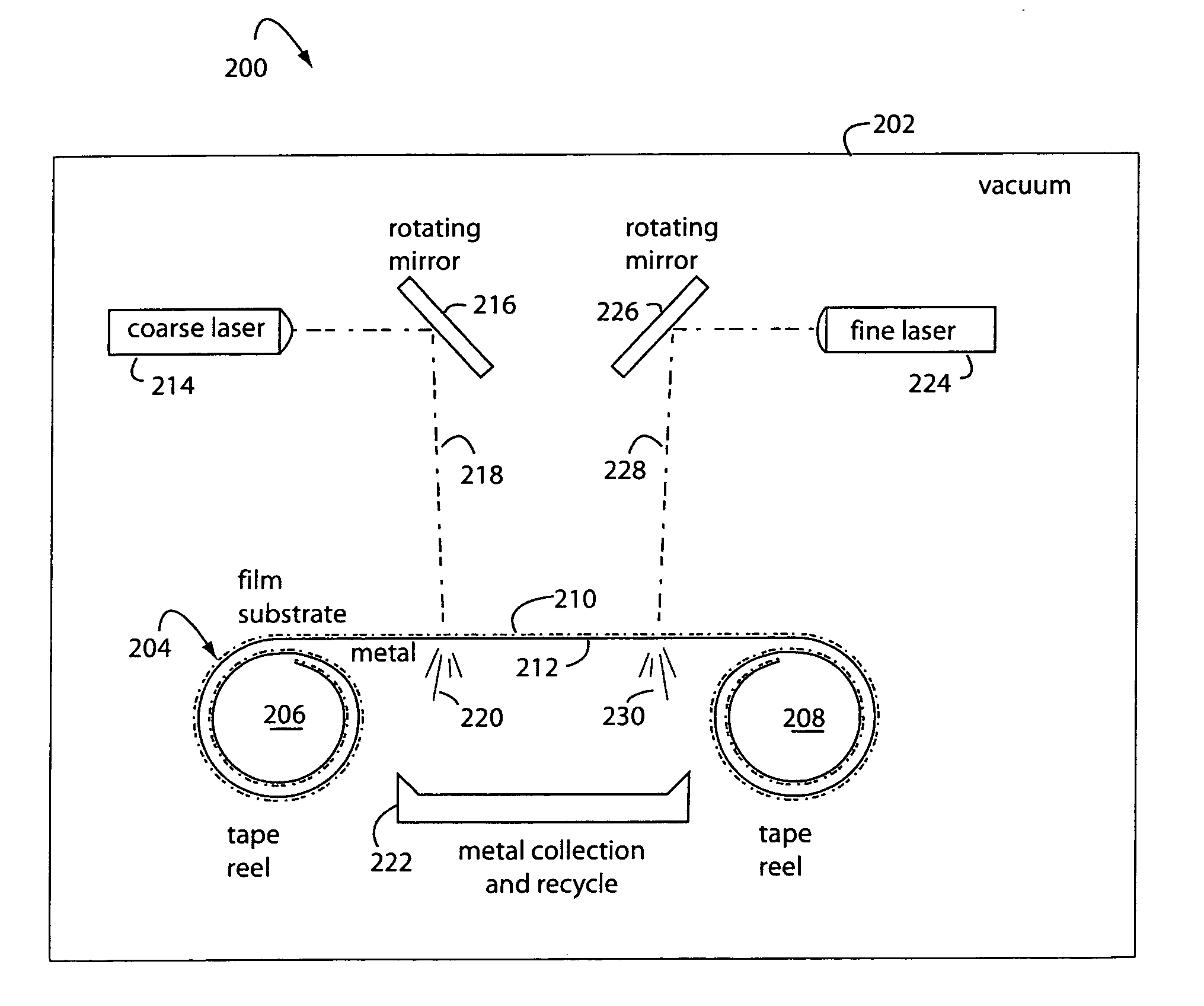

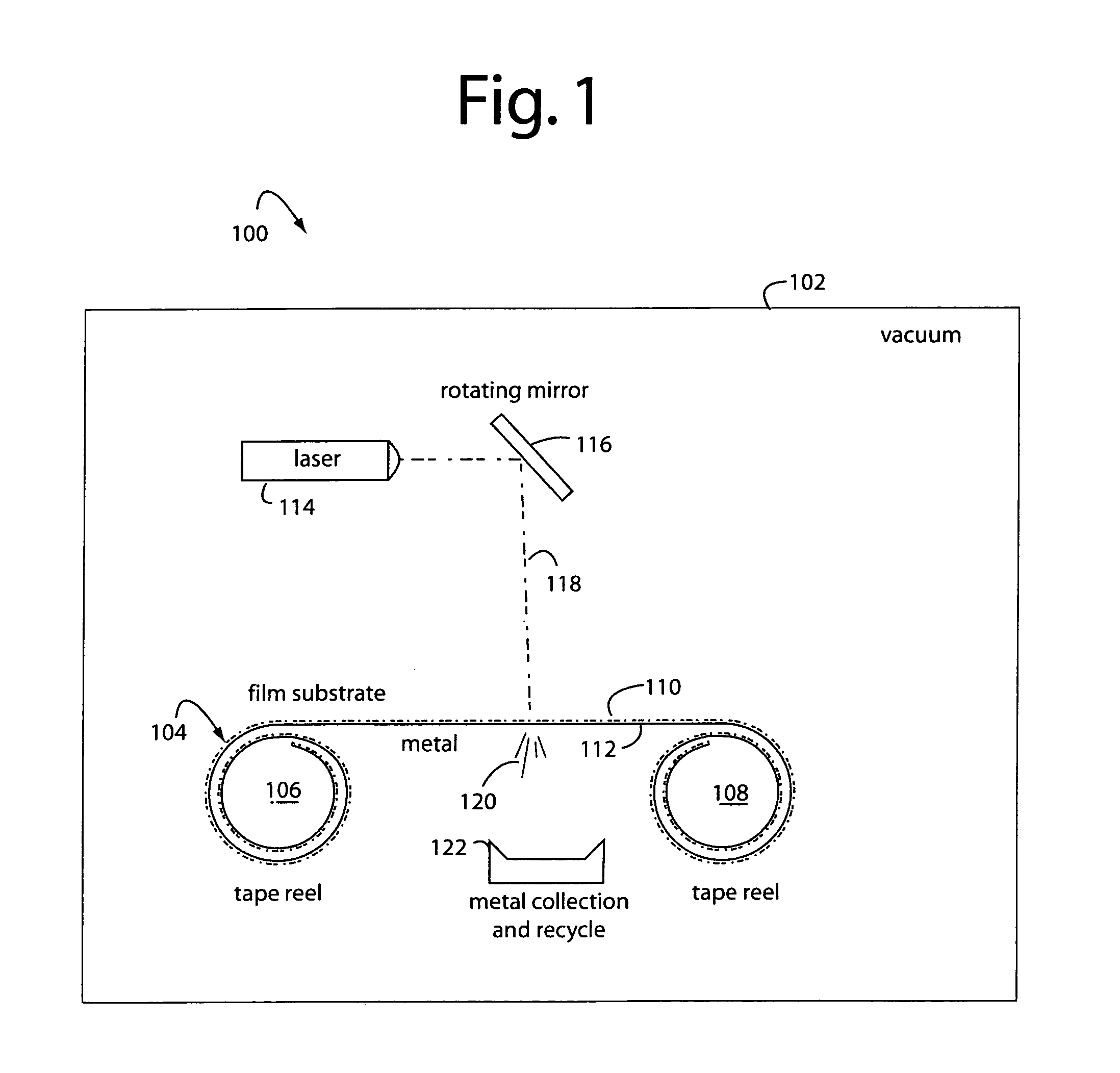

Reverse side film laser circuit etching

InactiveUS7633035B2Low cost-per-unitEasy to recycleTransparent dielectricsWelding/soldering/cutting articlesLithographic artistEtching

A direct-write laser lithography system comprises a reel-to-reel feed system in a vacuum chamber that presents the clear film-side of a single-sided metal-clad tape to a laser for direct patterning of the metal. The laser beam is swept laterally across the tape by rotating mirrors, and is intense enough to ablate the metal but not so strong as to destroy the tape substrate. In one instance, two specialized lasers are used, one set to ablate large field areas, and the other tuned to scribe fine features and lines. The ablated metal blows off in a downward direction and is collected for recycling.

Owner:MU GAHAT HLDG

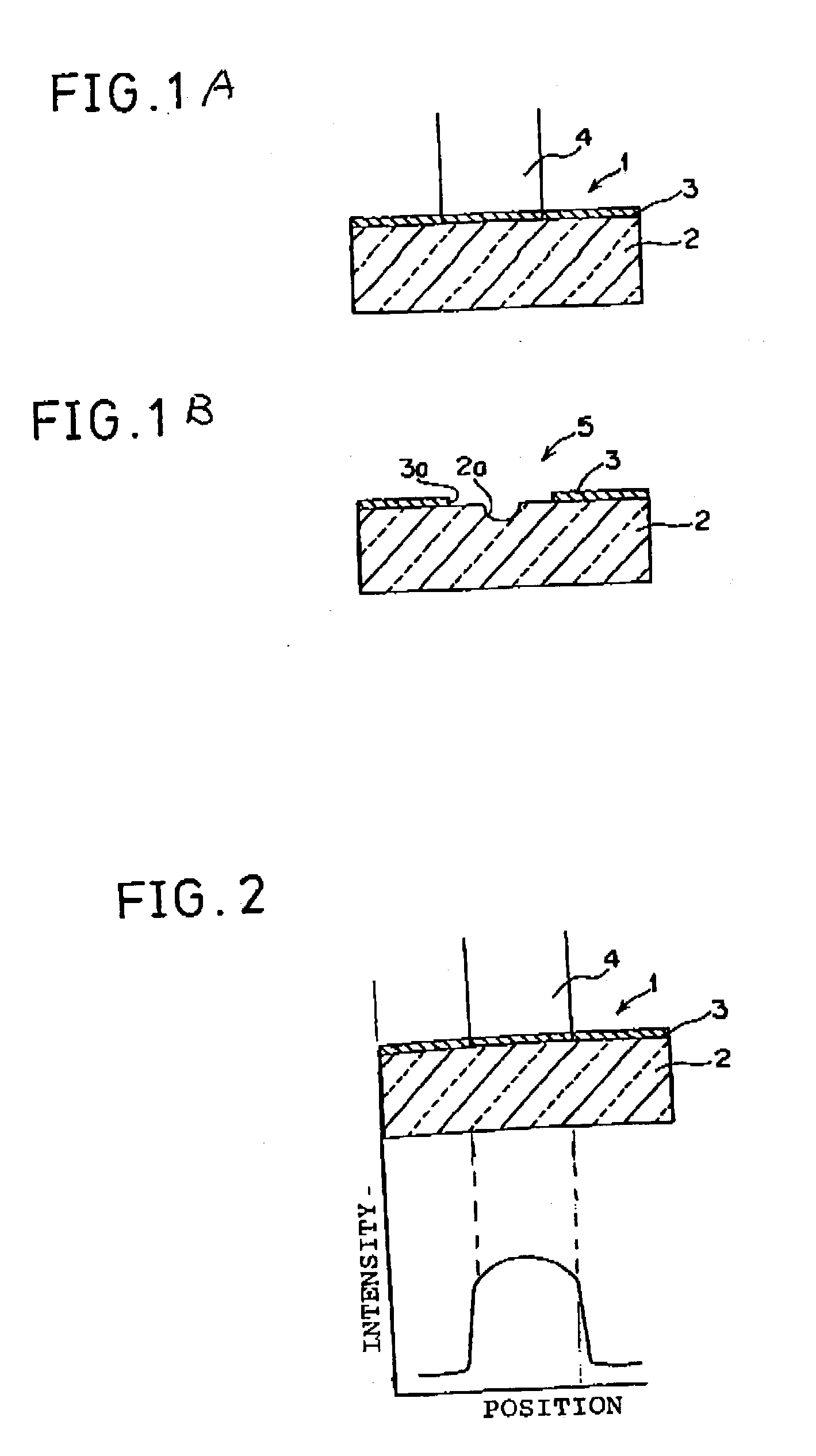

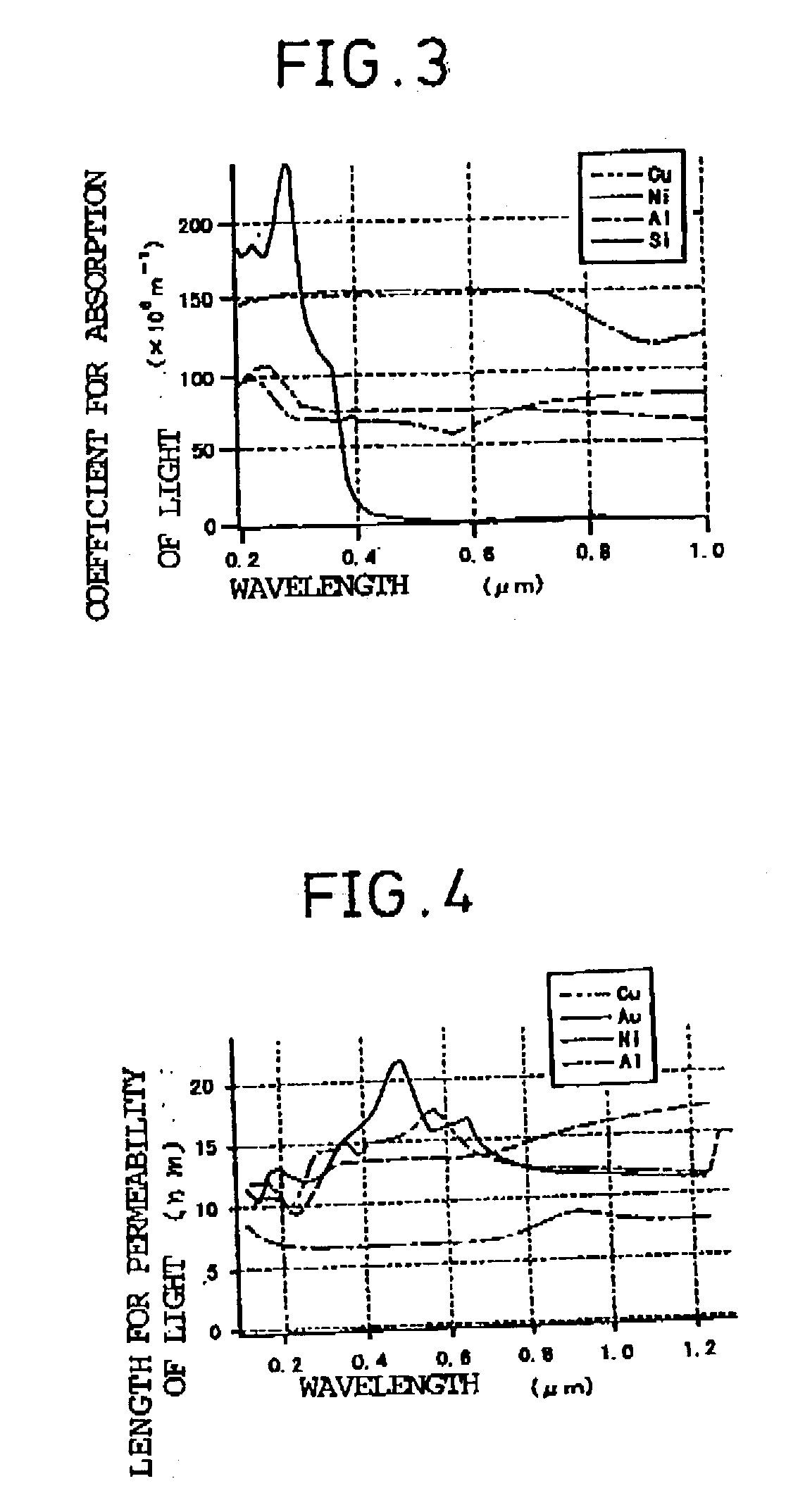

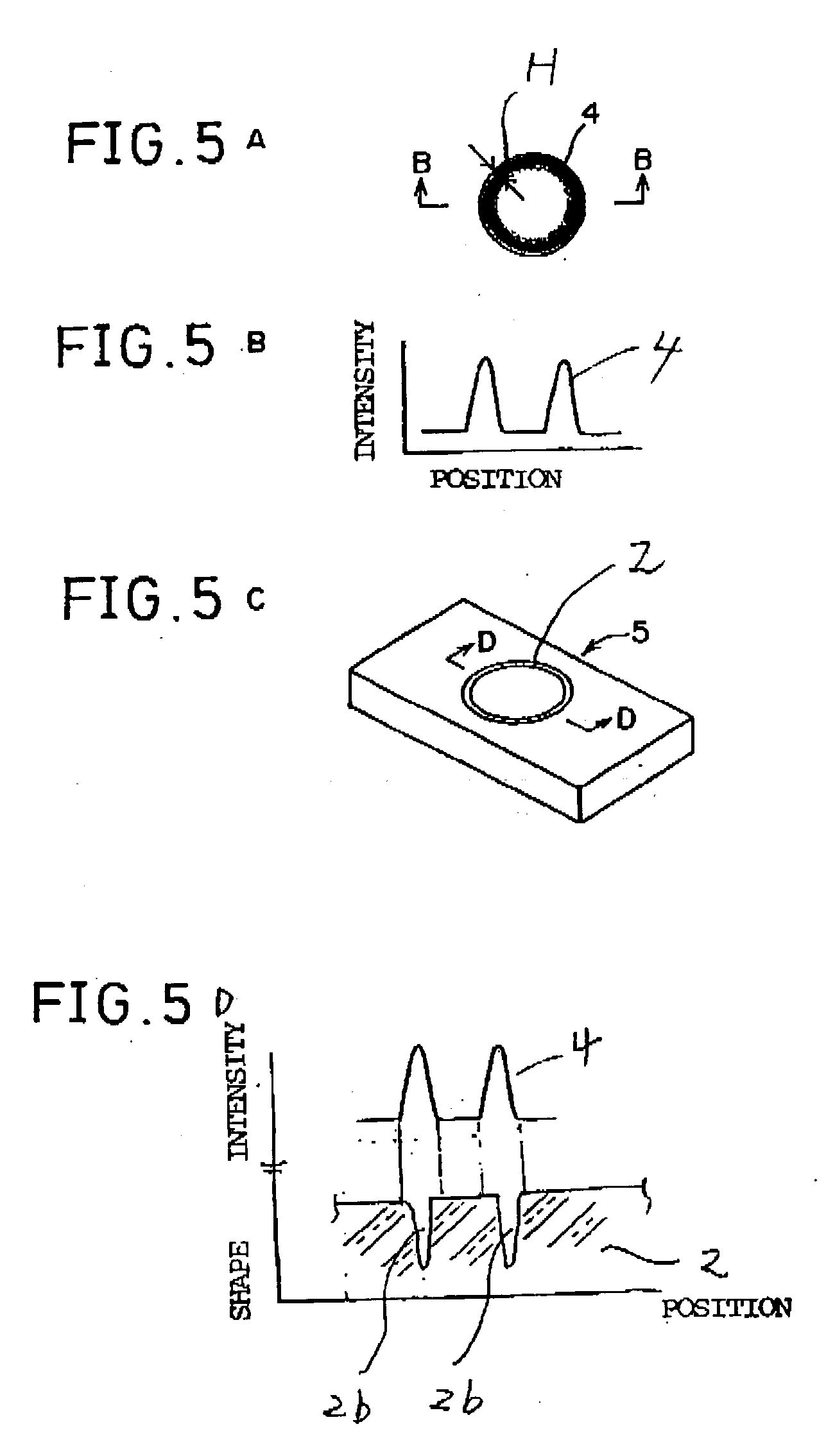

Method for processing by laser, apparatus for processing by laser, and three-dimensional structure

InactiveUS20030213770A1Solve the real problemWeaken energyDecorative surface effectsLaminationLaser processingHigh absorption

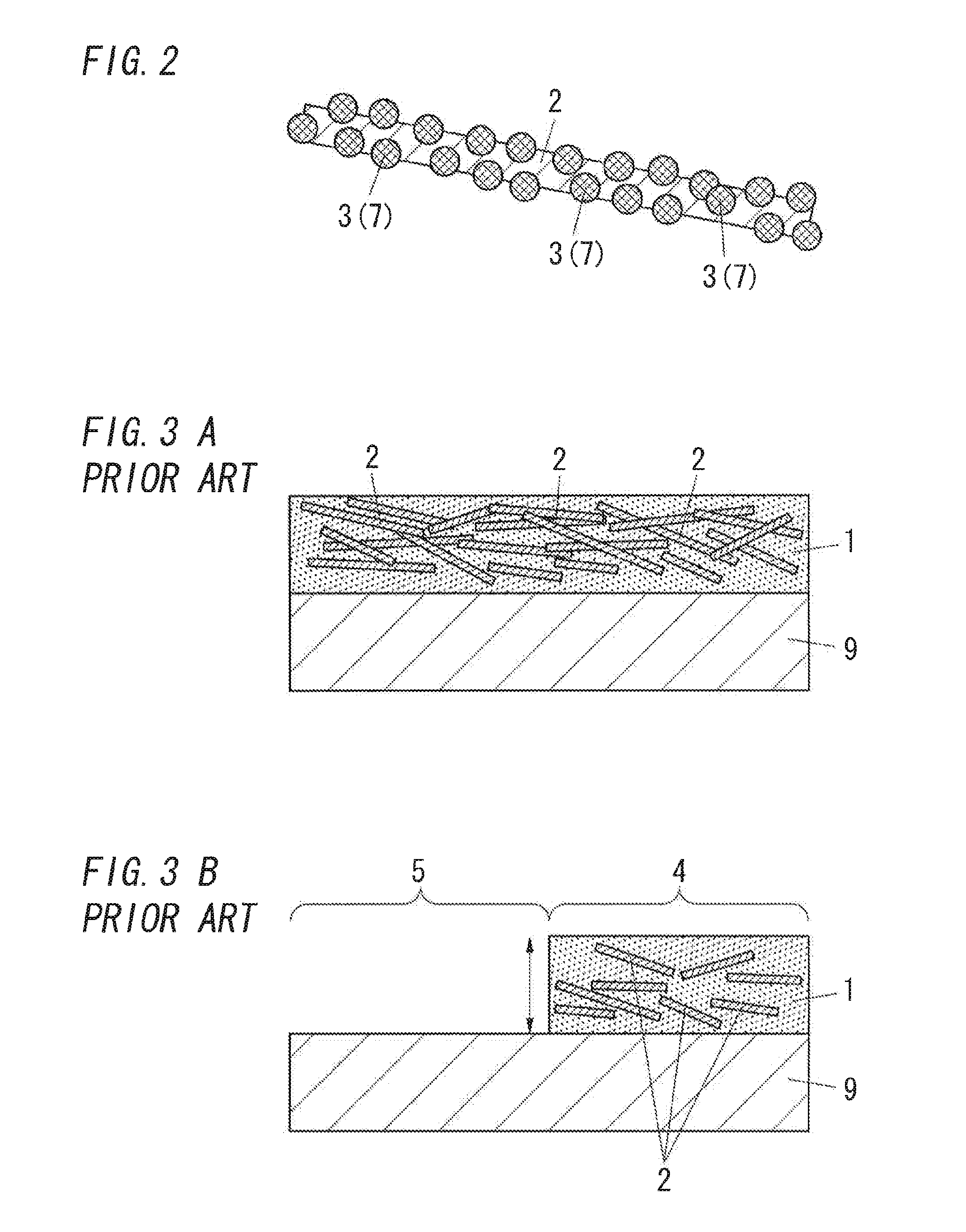

A laser processing method capable of performing fine and highly accurate processing by low energy is obtained. The invention relates to the laser processing method where laser beam for processing (4) is irradiated on a processing object (2) and the laser beam for processing (4) directly removes a part of the processing object (2). The processing object (2) is made of a glass substrate, metal thin film (3) having high absorption to laser beam for processing (4) is formed on a surface of glass substrate, into which laser beam for processing (4) is made incident, the laser beam for processing (4) is irradiated from a surface of metal thin film (3), and matter is directly removed by irradiation of laser beam onto the processing object (2) in order to form a region finer than an irradiation region of laser beam for processing (4) on the processing object (2).

Owner:RICOH KK

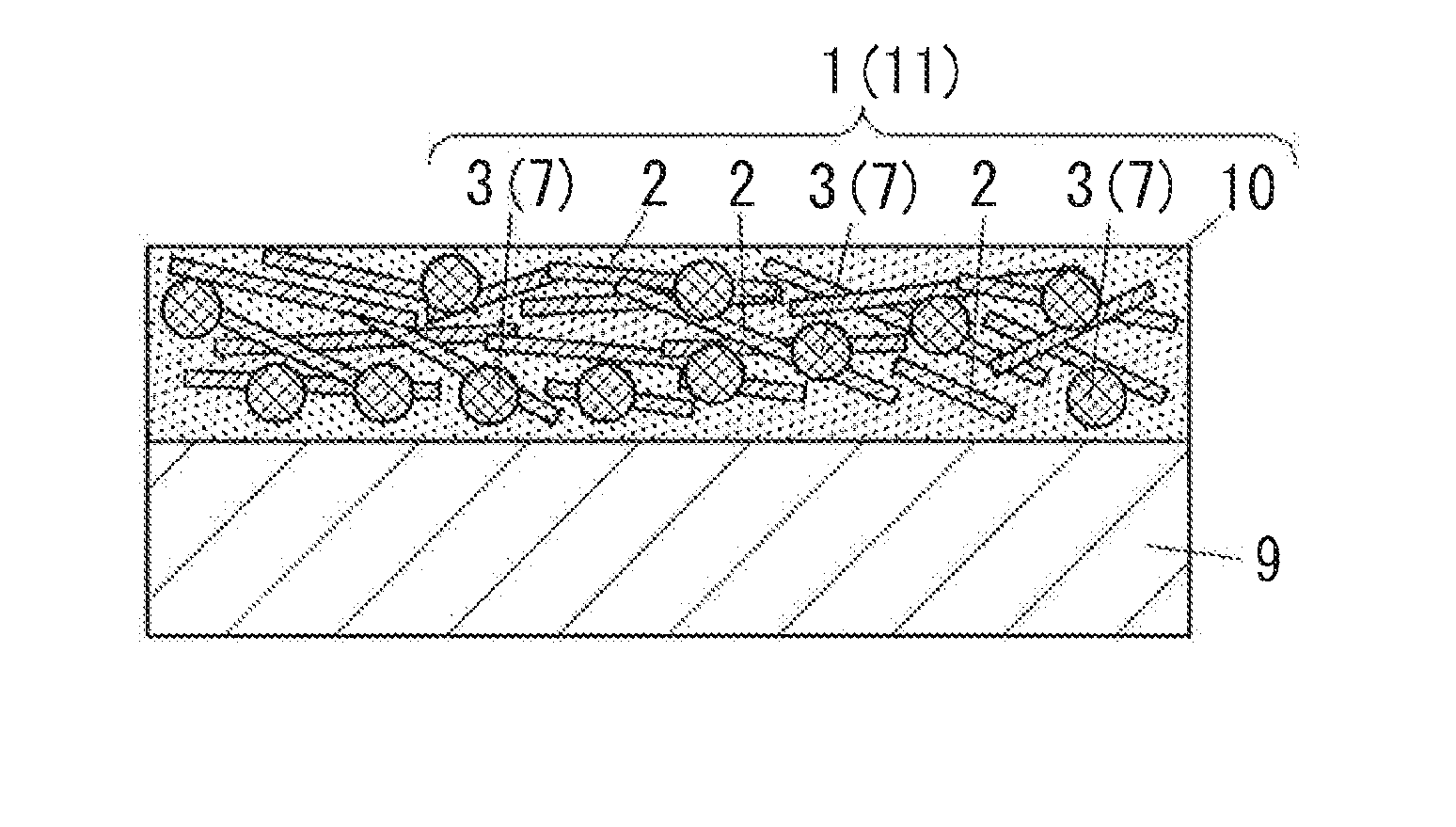

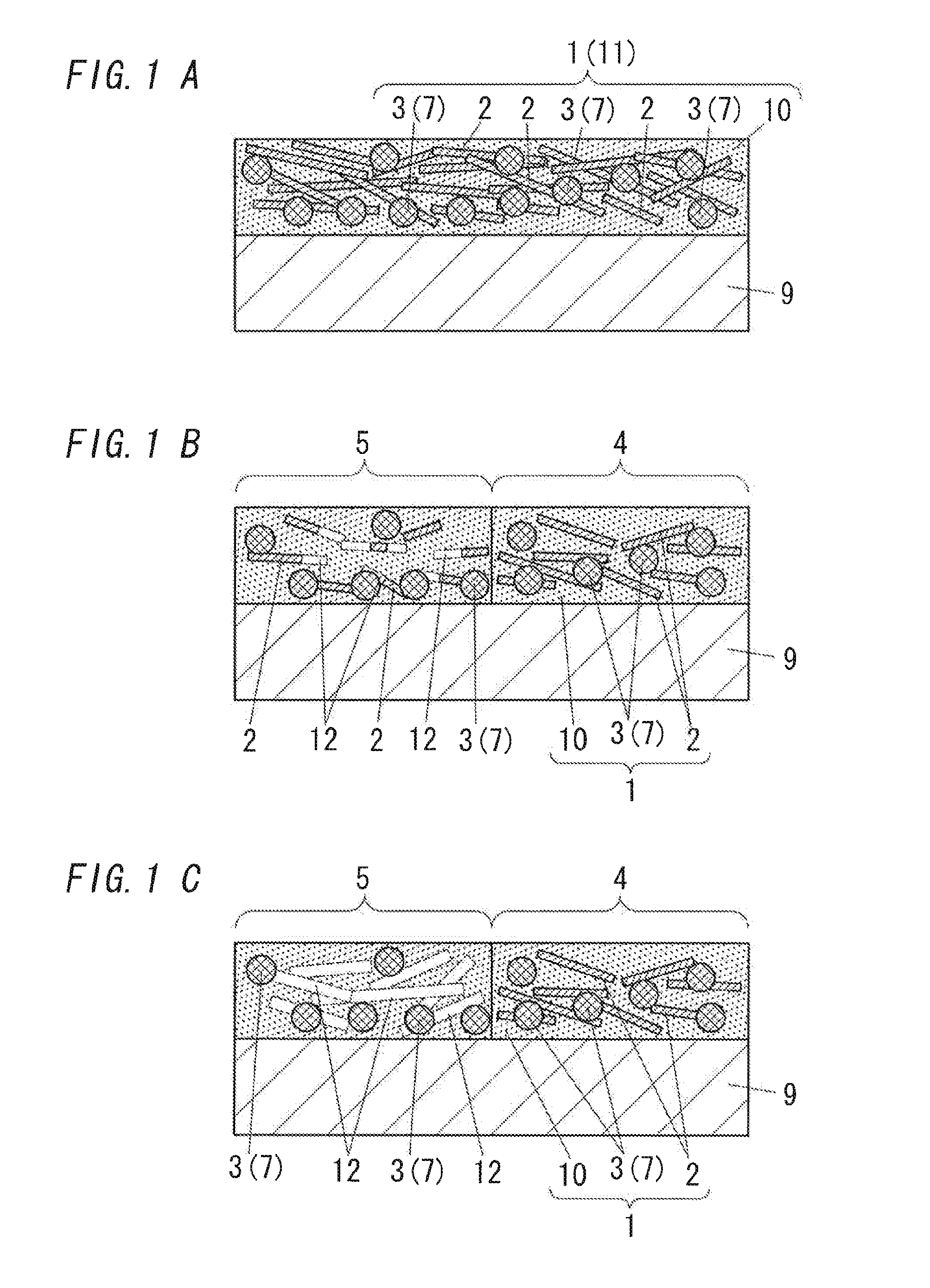

Transparent conductive film, substrate carrying transparent conductive film, and production method thereof

InactiveUS20150027755A1Reduce in quantityReduce level differenceMaterial nanotechnologyRadiation applicationsTransparent conducting filmMaterials science

Provided is a transparent conductive film wherein an electrically conductive region is converted to an electrically insulating region more readily and rapidly than traditional conductive films and the level difference between the electrically conductive region and the electrically insulating region is smaller. The transparent conductive film has an electrically conductive region 4 and an electrically insulating region 5. The electrically conductive region 4 contains a resin component 10, a metal nanowire 2 and an insulation-promoting component 3. The insulation-promoting component 3 has a light absorption higher than that of the metal nanowire 2. The electrically insulating region 5 is defined by a region which contains a resin component 10 but not the metal nanowire 2 or a region which contains a resin component 10 and additionally a metal nanowire 2 having an aspect ratio of smaller than that of the metal nanowire 2.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

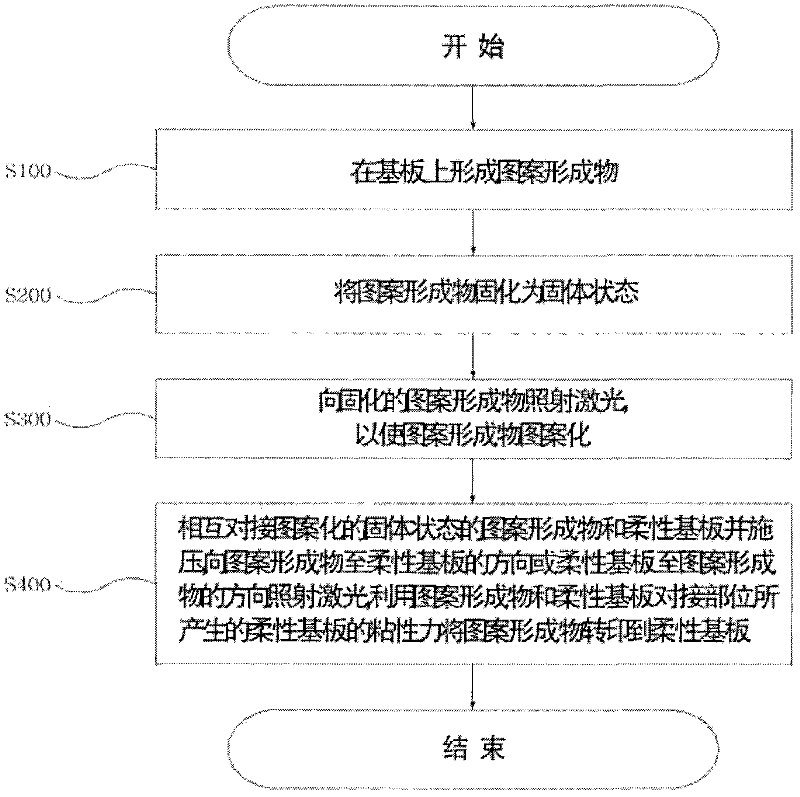

Pattern transfer method and apparatus therefor

InactiveCN102452239AForm evenlyUniform transferTransfer printingDuplicating/marking methodsElectromagnetic shieldingElectronic book

The present invention relates to methods and apparatuses for transferring pattern, a flexible display panel, a flexible solar cell, an electronic book, a thin film transistor, an electromagnetic-shielding sheet, and a flexible printed circuit board applying thereof. A pattern transfer method related to the present invention comprises: a first step of forming a pattern material on a substrate; a second step of hardening the pattern material in the solid state; a third step of patterning the pattern material by irradiating a laser beam to the hardened pattern material in the solid state; and a fourth step of pressing the patterned pattern material in the solid state and a flexible substrate facing each other and transferring the pattern material to the flexible substrate by a viscous force of the flexible substrate occurring in a facing part between the pattern material and the flexible substrate by irradiating the laser beam from the pattern material to the flexible substrate or from the flexible substrate to the pattern material.

Owner:KOREA ADVANCED INST OF SCI & TECH

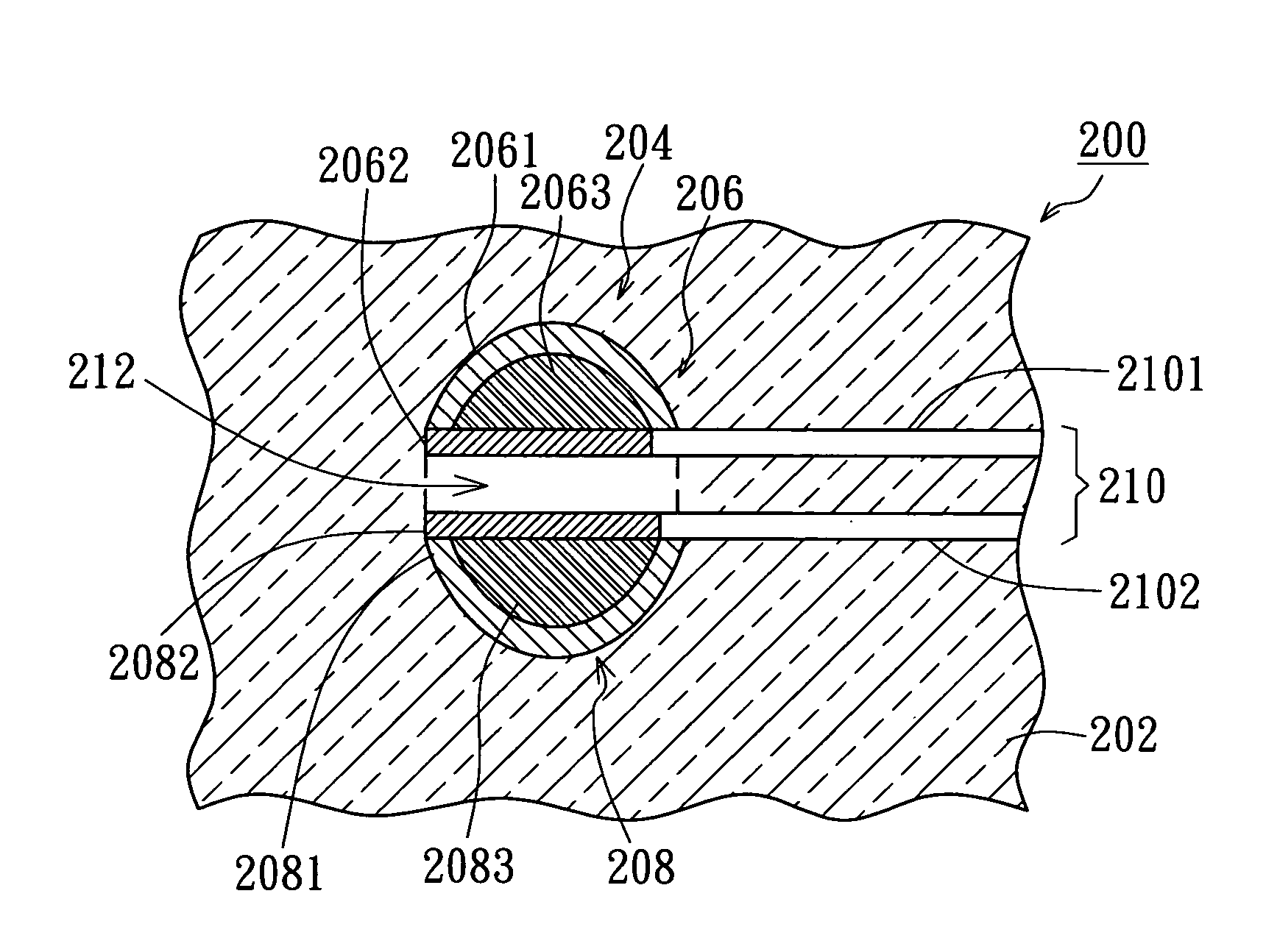

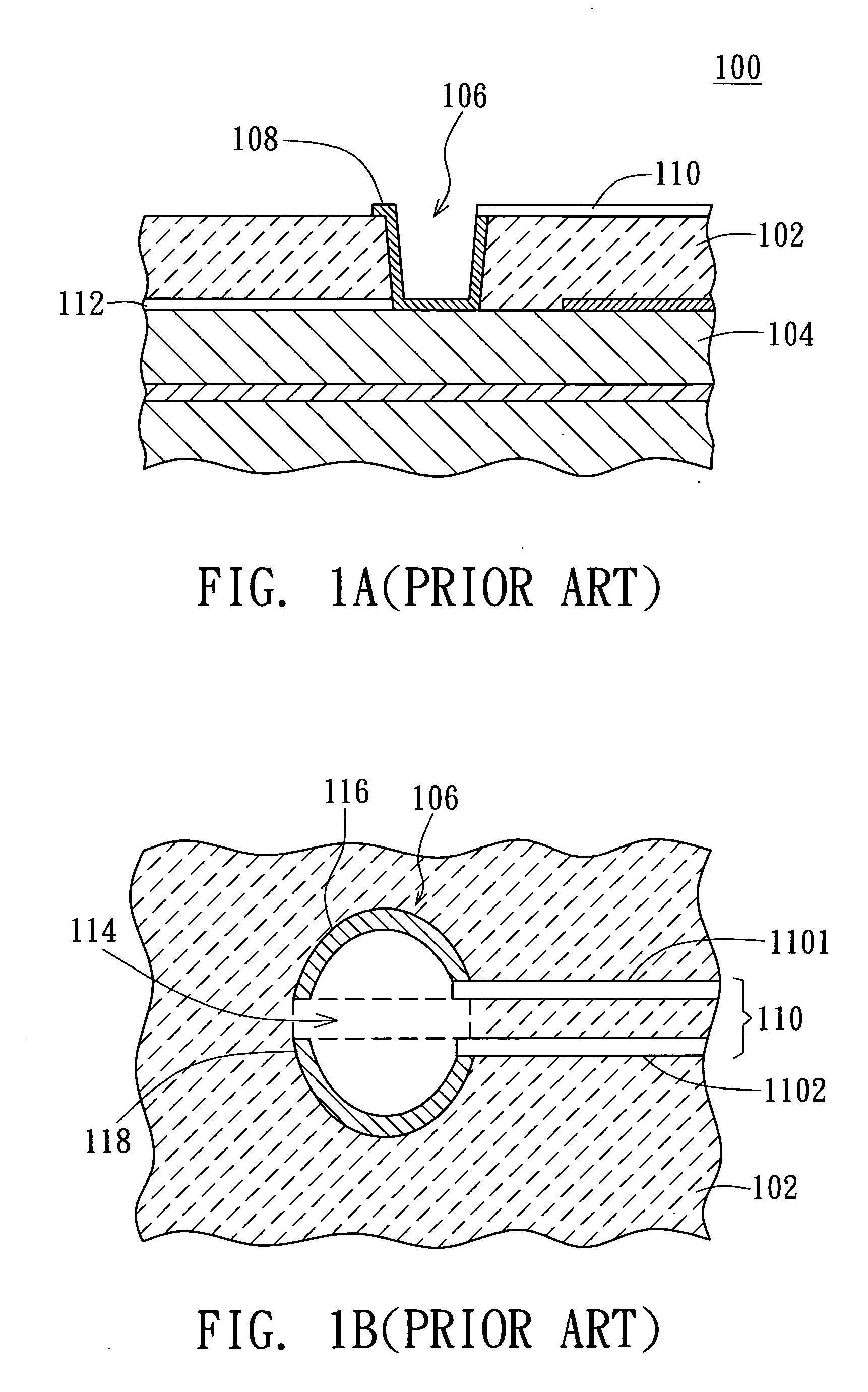

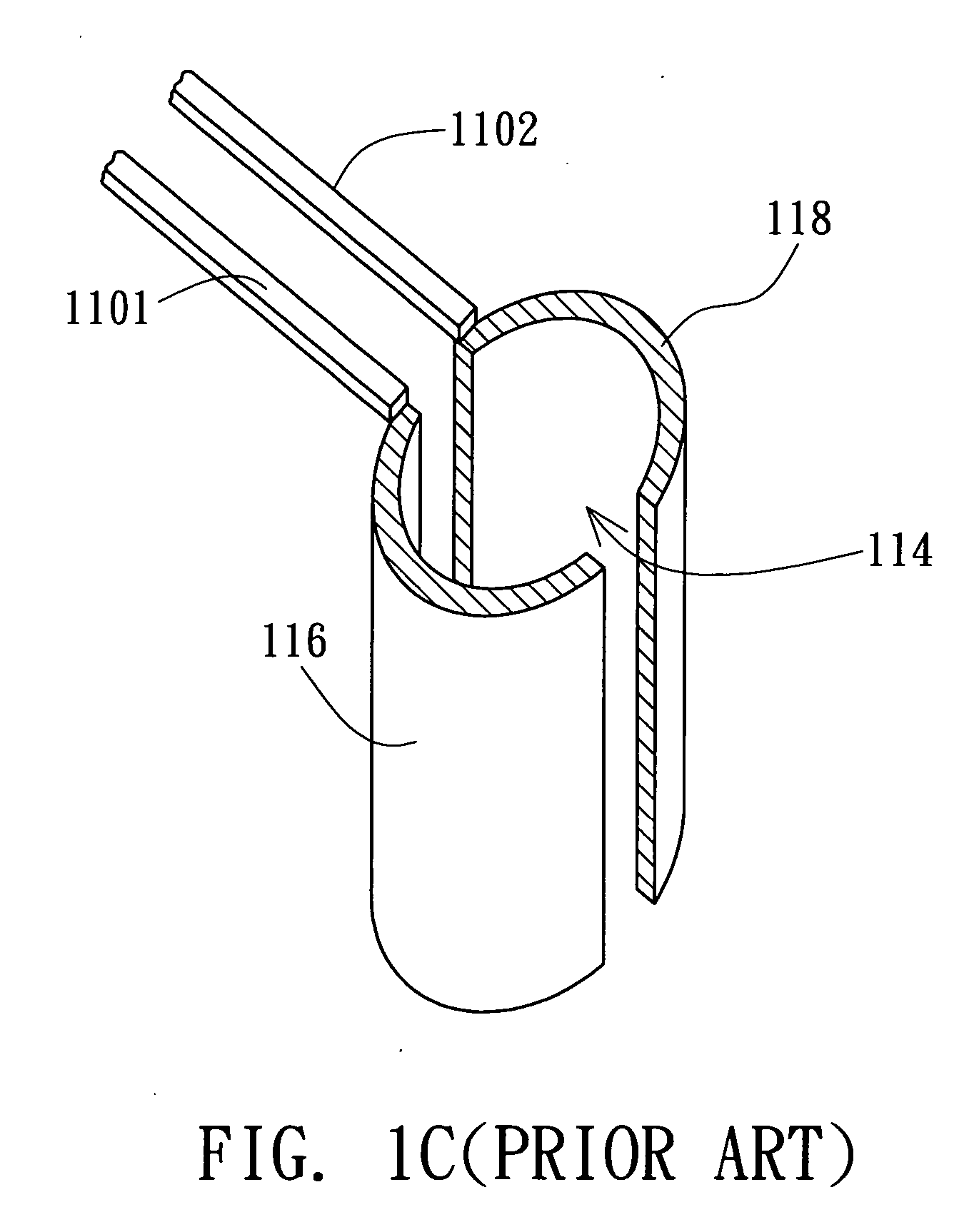

Substrate with micro-via structures by laser technique

ActiveUS20050133251A1Reduce noise disturbanceReduce reflectionPrinted circuit aspectsHigh frequency circuit adaptationsLaser technologyLaser cutting

A substrate to which a laser technique is applied includes a signal layer, a micro via structure, and a differential signal pair. The micro via structure is divided into a first conductive column and a second conductive column after a laser-cutting step. The first conductive column includes a first flat conductive layer, and the second conductive column includes a second flat conductive layer. A first trace of the differential signal pair is parallel to and electrically connected to the first flat conductive layer. A second trace of the differential signal pair is parallel to and electrically connected to the second flat conductive layer. The distance between the first trace and the second trace is the same as the distance between the first flat conductive layer and the second flat conductive layer. The reflection of high-speed signals and the noise interferences can be reduced.

Owner:ADVANCED SEMICON ENG INC

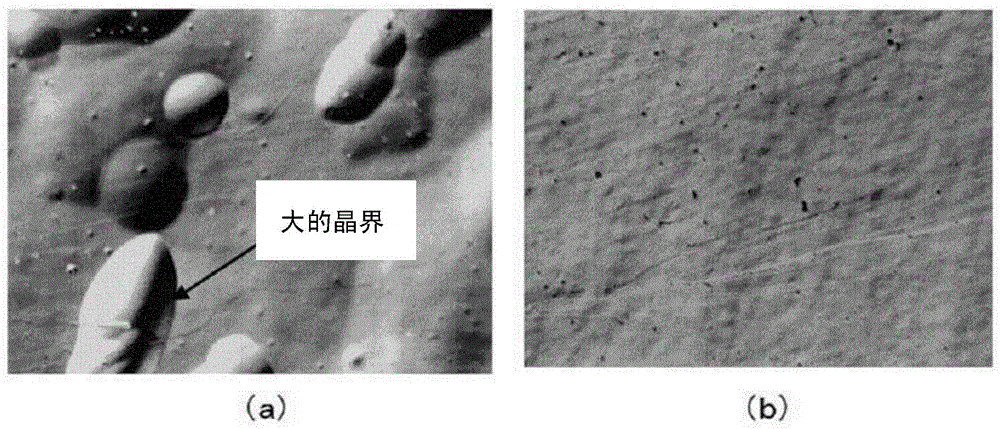

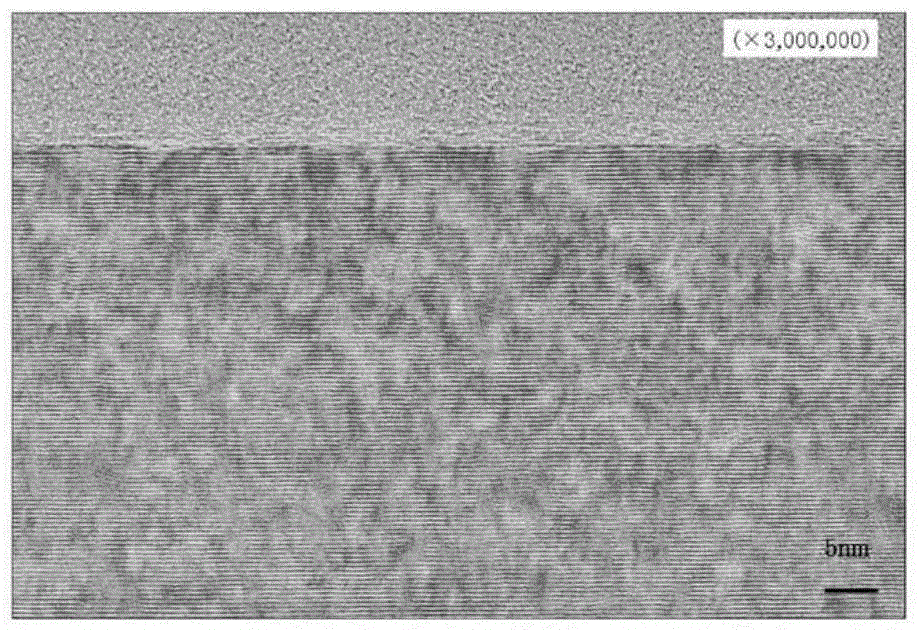

Graphite sheet, method for producing same, laminated board for wiring, graphite wiring material, and method for producing wiring board

The present invention is firstly a graphite sheet having a thickness of 9.6 [mu]m or less and more than 50 nm and a thermal conductivity along the a-b plane direction at 25 DEG C of 1950 W / mK or more. The present invention is secondly a graphite sheet having a thickness in a range of less than 9.6 [mu]m and 20 nm or more, an area of 9 mm2 or more, and a carrier mobility along the a-b plane direction at 25 DEG C of 8000 cm2 / V.sec or more.

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com