Corrosion inhibitor for gas field and preparation method thereof

A corrosion inhibitor, oil and gas field technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of poor film-forming performance, poor high temperature stability, and large temperature influence on corrosion inhibition performance, etc. Achieve the effect of changing solubility and distribution ratio, good anti-corrosion effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

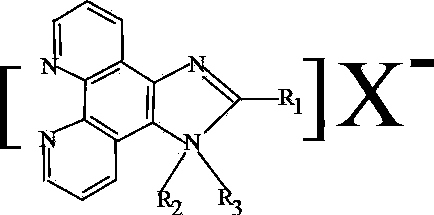

Method used

Image

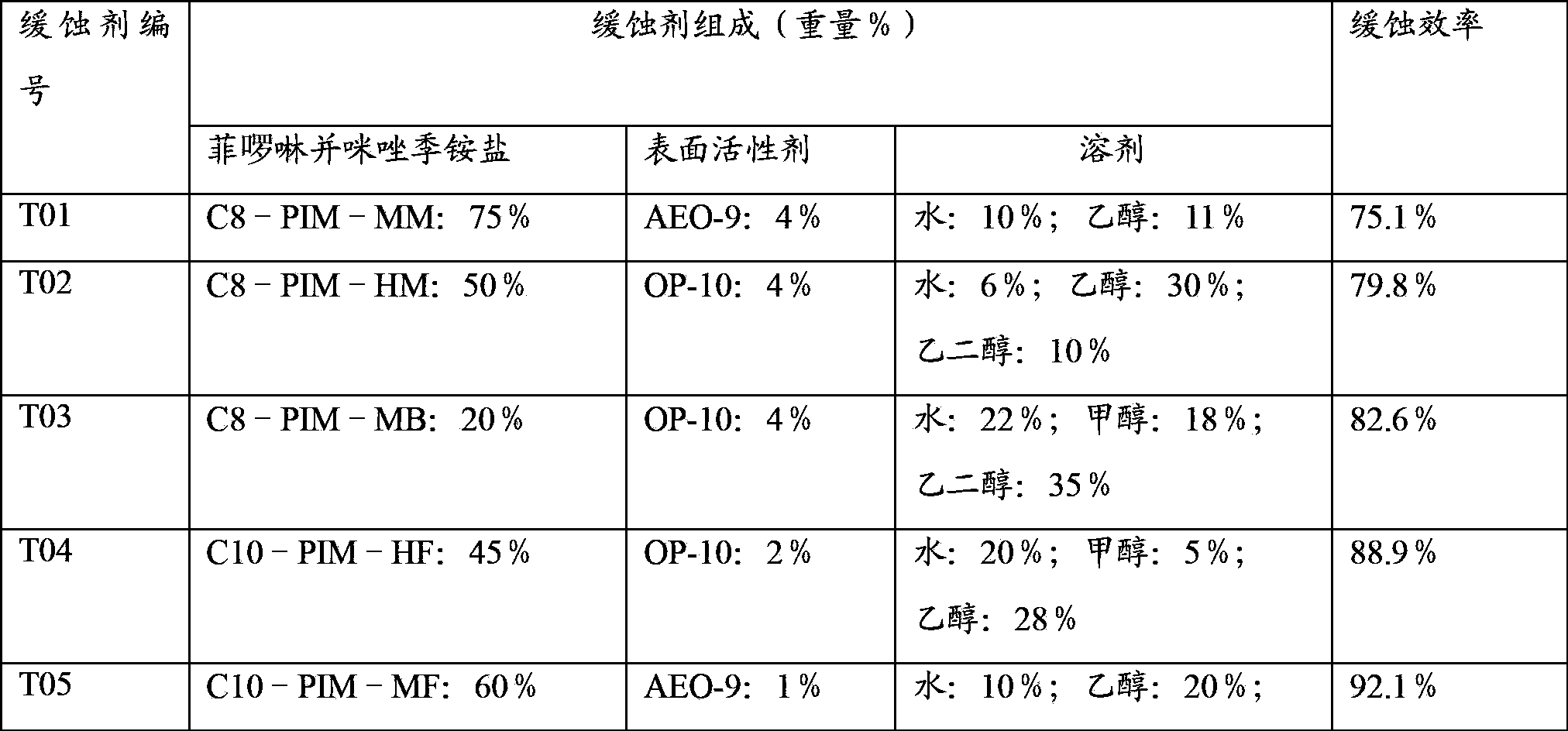

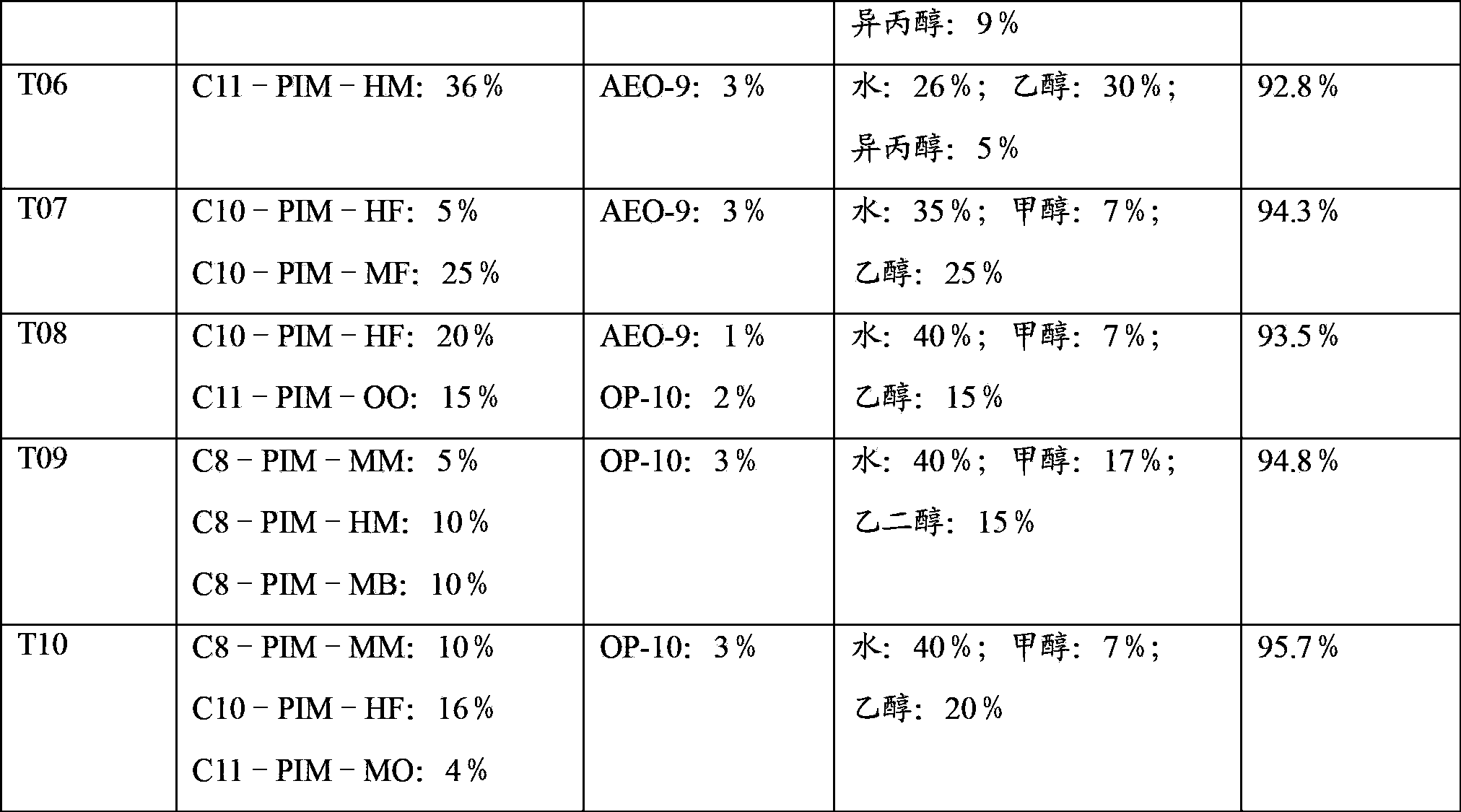

Examples

Embodiment 1

[0047] Preparation of 2-octyl-1,10-phenanthroline[5,6]-1-hydroimidazole:

[0048] In a reactor with a stirring and condensing device, 1,10-phenanthroline-5,6-dione, nonanal and ammonium acetate were dissolved in an appropriate amount of ethanol at a molar ratio of 1:1:5.5, and Under the protection of nitrogen, heat up to 80°C and reflux, react for 4 hours, cool to room temperature, add an appropriate amount of water to the system, filter the precipitated solid with suction, and dry to obtain the phenanthroline imidazole intermediate 2-octyl-1,10-phenanthrene Rolin[5,6]-1-hydroimidazole, represented by "C8-PIM".

Embodiment 2

[0050] Preparation of 2-decyl-1,10-phenanthroline[5,6]o-1-hydroimidazole:

[0051] In a reactor with a stirring and condensing device, undecanal, 1,10-phenanthroline-5,6-dione, and ammonium acetate were dissolved in an appropriate amount of ethanol at a molar ratio of 1:1:7, under nitrogen Under protection, heat up to 78°C and reflux for 6 hours, cool to room temperature, add an appropriate amount of water to the system, filter the precipitated solid with suction, and dry to obtain the phenanthroline imidazole intermediate 2-decyl-1,10-phenanthroline [5,6]-1-hydroimidazole, represented by "C10-PIM".

Embodiment 3

[0053] Preparation of 2-undecyl-1,10-phenanthroline[5,6]-1-hydroimidazole:

[0054] In a reactor with a stirring and condensing device, lauric aldehyde, 1,10-phenanthroline-5,6-dione and ammonium acetate were dissolved in an appropriate amount of ethanol at a molar ratio of 1:1:9, under nitrogen protection Lower the temperature to 82°C and reflux for 2 hours, cool to room temperature, add an appropriate amount of water to the system, filter the precipitated solid with suction, and dry to obtain the phenanthroline imidazole intermediate 2-undecyl-1,10-phenanthro Phylo[5,6]-1-hydroimidazole, represented by "C11-PIM".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com