Preparation of polyurethane curing agent with low free toluene diisocyanate

A technology of toluene diisocyanate and polyurethane curing agent, which is applied in the field of preparation of polyurethane curing agent, can solve the problems of unstable adducts and impracticality, and achieve the effects of good stability, unchanged paint film performance and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

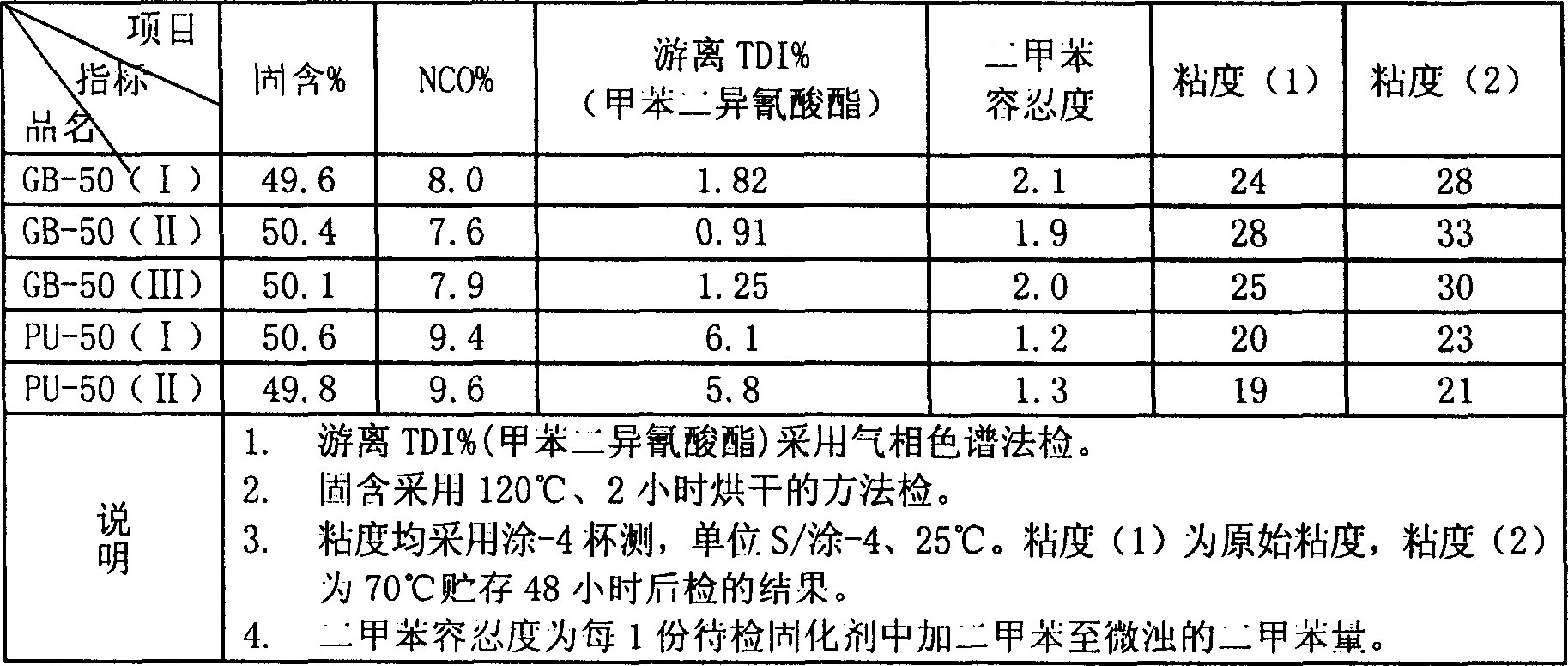

Examples

Embodiment 1

[0026] In a tank equipped with a stirrer, thermometer and 2 In a protected 1000ml four-neck flask, add 325 grams of TDI and 295 grams of butyl acetate, heat up, and put 71 grams of trimethylolpropane and 43 grams of 2-octanol into the reaction at 65 ° C in five batches, and then at 70 ° C Keep warm for 4 hours, and check the weight percentage of NCO. When it is 11.1%, the solid content is 60%. Cool down to 55°C, add 0.48g of AC960-1, and keep warm at 50°C-60°C. 1 hour, detect the weight percentage of free NCO group and free toluene diisocyanate once, when the weight percentage of NCO is 9.3% and the weight percentage of free toluene diisocyanate is 0.89%, add 0.92 gram chlorine immediately Benzoyl, cooled to 25 ° C, can be discharged.

Embodiment 2

[0028] In a tank equipped with a stirrer, thermometer and 2 In a protected 1000ml four-neck flask, add 318 grams of TBI and 420 grams of butyl acetate, heat up to 60°C, put 72 grams of trimethylolpropane and 31 grams of n-octanol into the reaction in five batches, and keep warm at 70°C for 3 hours , when the weight percentage of NCO is 9.5%, the solid content is 50%, cool down to 60°C, add 0.3g of AC960-1, keep warm at 60°C, and detect NCO and free toluene diisocyanate every 1 hour When the weight percentage of NCO is 8.0% and the weight percentage of free toluene diisocyanate is 1.68%, add 0.57 gram of benzoyl chloride immediately, cool to 25 ℃, get final product material. Embodiment three:

Embodiment 3

[0029] In a tank equipped with a stirrer, thermometer and 2In a protected 1000ml four-neck flask, add 478 grams of TDI and 210 grams of ethyl acetate, raise the temperature to 55°C, put 110 grams of trimethylolpropane and 27 grams of 1-butanol into the reaction in six batches, and keep the reaction at 65°C After 4 hours, when the weight percentage of NCO is 13.65%, the solid content is 75%, cool down to 55°C, add 0.25g of AC960-1, react at 50-60°C, and detect NCO every 1 hour And the weight percentage of free toluene diisocyanate, when the weight percentage of detection NCO is 11.6% and the weight percentage of free toluene diisocyanate is 0.95%, add 0.53 gram benzoyl chloride immediately, be cooled to 25 ℃, the material can be discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com