Method for performing induced synthesis on MOFs (metal-organic frameworks) membrane by implanting homologous metal oxide particles into surface of macroporous carrier by virtue of swabbing process

A macroporous carrier and oxide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of increasing the preparation of dense and defect-free membranes, and achieve scale-up, good stability, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

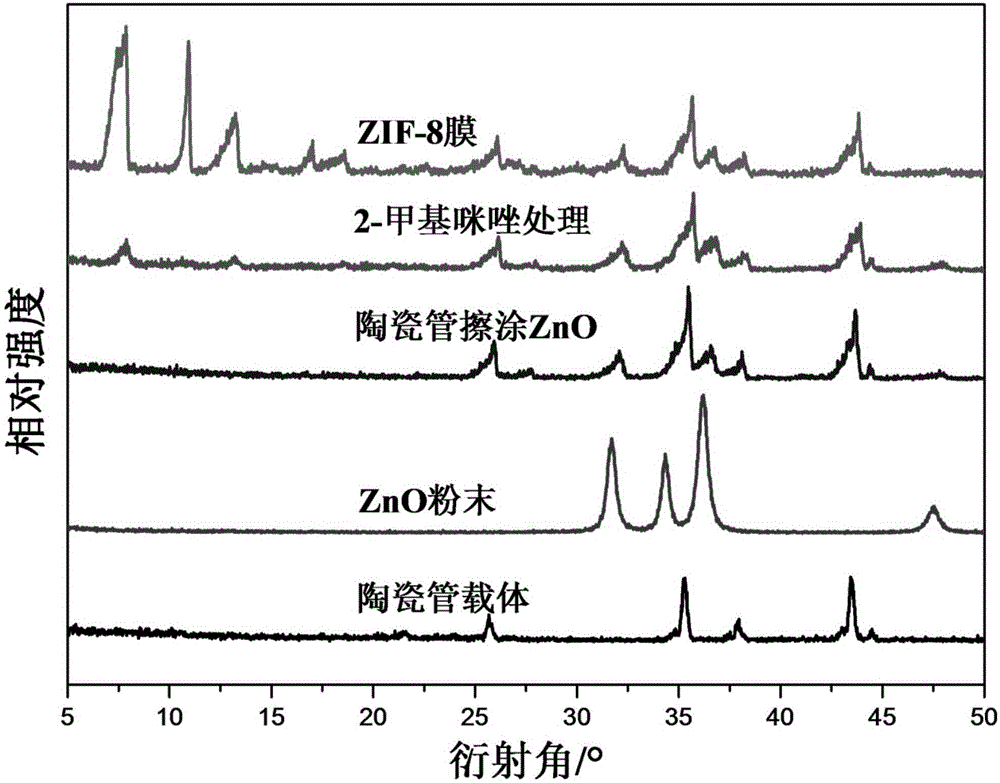

[0029] Example 1 Preparation of ZIF-8 film by wiping ZnO powder on macroporous alumina ceramic carrier

[0030] The macroporous alumina ceramic tube was sequentially treated with 1mol / L NaOH, 1mol / L HNO 3 And deionized water treatment, calcination at 500 ℃ for later use;

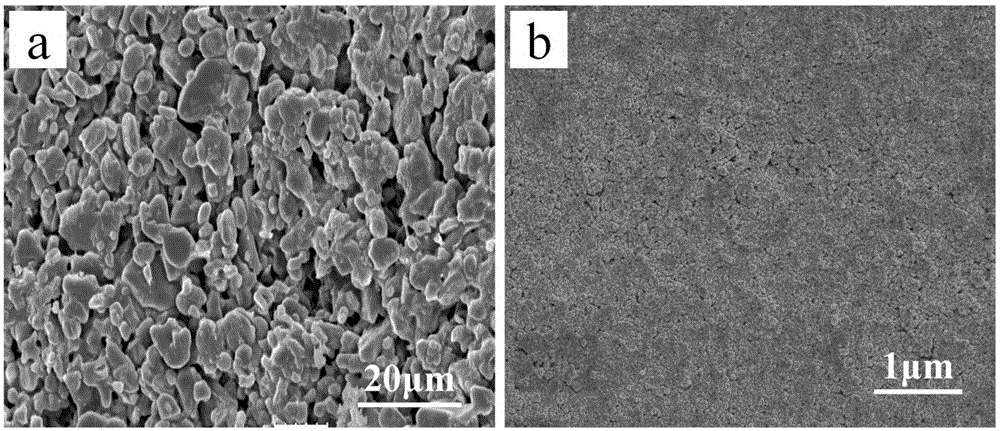

[0031] Load the commercially available 50nm ZnO powder on the surface of the ceramic carrier by wiping with bare hands;

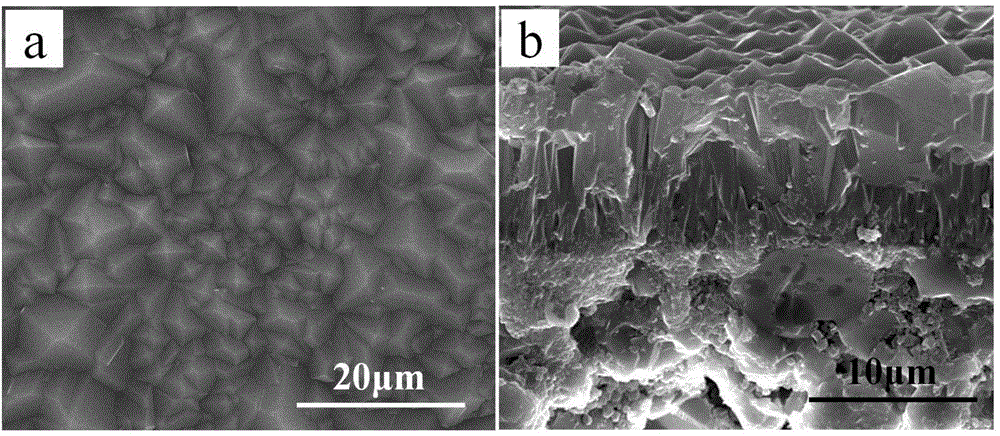

[0032] Place the ceramic tube coated with ZnO layer in 0.5mol / L methanol solution of 2-methylimidazole, and keep at 50°C for 2h to pretreat the ZnO layer;

[0033] Dissolve 0.47g of zinc chloride, 0.41g of 2-methylimidazole, and 0.25g of sodium formate into 70mL of anhydrous methanol, place the pretreated ceramic tube coated with ZnO powder vertically in a 100mL polytetrafluoroethylene kettle, and slowly Pour the film-forming liquid into the kettle. The polytetrafluoroethylene kettle was placed in an oven at 100°C for 5 hours. After natural cooling, the ceramic tube after the long fil...

Embodiment 2

[0035] Example 2 Preparation of ZIF-7 film by wiping ZnO powder on macroporous alumina ceramic carrier

[0036] The macroporous alumina ceramic tube was sequentially treated with 1mol / L NaOH, 1mol / L HNO 3 And deionized water treatment, calcination at 500 ℃ for later use;

[0037] Load the commercially available 50nm ZnO powder on the surface of the ceramic carrier by wiping with bare hands;

[0038] Place the ceramic tube coated with ZnO layer in 0.5mol / L benzimidazole N,N-dimethylformamide solution, and keep at 50°C for 20min to pretreat the ZnO layer;

[0039] Dissolve 1.34g of zinc nitrate and 0.68g of benzimidazole in 70mL of N,N-dimethylformamide, place the pretreated ceramic tube coated with ZnO powder vertically in a 100mL polytetrafluoroethylene kettle, and pour it slowly The film-forming liquid is in the kettle. The polytetrafluoroethylene kettle was placed in an oven at 100°C for 12 hours. After natural cooling, the ceramic tube after the long film was rinsed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com