Preparation method of lubricating rust-preventive oil

A technique for lubricating and anti-rusting, preparation steps, applied in the field of preparation of lubricating and anti-rust oil, which can solve the problems of general effect of lubricating and anti-rust oil, failure to meet production requirements, short anti-rust cycle, etc., shorten the esterification reaction time, save Catalyst cost, effect of improving antirust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

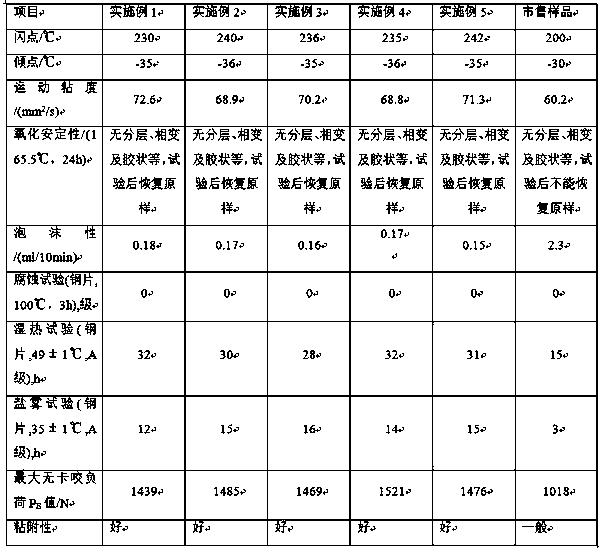

Examples

preparation example Construction

[0029] Preparation of immobilized ionic liquid liquid: take SiO 2 Add 20 parts of mesoporous molecular sieves and 15 parts of absolute ethanol into a round-bottomed flask equipped with a magnetic stirrer, stir and heat to 56°C and keep the temperature constant; take 15 parts of phosphotungstic acid-benzothiazole ionic liquid graft copolymer and dissolve in Add 10 parts of absolute ethanol to a round bottom flask, slowly add 6.5 parts of concentrated hydrochloric acid and 7 parts of distilled water dropwise, stir evenly while adding, let it stand for a long time to form a gel after the dropwise addition, and then put it at 55°C Aging for 12 hours; the obtained colloid was vacuum-dried at 110°C for 6 hours to obtain an immobilized ionic liquid catalyst;

[0030] Preparation of rosin borate: Take 58 parts of rosin and add it to a reaction kettle equipped with a magnetic stirrer, heat it to 108°C to melt it, take 65 parts of diethanolamine and slowly add it dropwise to the reactio...

Embodiment 2

[0034] Preparation of phosphotungstic acid-benzothiazole ionic liquid graft copolymer: Take 30 parts of phosphotungstic acid and double-distilled water into a round bottom flask and stir it magnetically, while heating to 88°C to completely dissolve it, and then lower the temperature to 36°C ℃, add 16 parts of 1mol / L nitric acid solution, then 12 parts of initiator cerium ammonium nitrate and 30 parts of benzothiazole, and react in nitrogen atmosphere for 4 hours; wash the obtained product repeatedly with methanol, and then mix the product with an appropriate amount of twice distilled water Add it into a flask and stir it magnetically, then heat it to 88°C to dissolve it completely, then add 30 parts of sulfuric acid solution with a mass fraction of 98% to react at a constant temperature for 20 hours, then wash the residue with ethyl acetate, and dry it in vacuum at 40°C for 12 hours to obtain Phosphotungstic acid-benzothiazole ionic liquid graft copolymer;

[0035] Preparation...

Embodiment 3

[0040] Preparation of phosphotungstic acid-benzothiazole ionic liquid graft copolymer: Take 40 parts of phosphotungstic acid and double-distilled water into a round-bottomed flask and stir it magnetically, while heating to 85°C to dissolve it completely, and then lower the temperature to 35°C ℃, add 19 parts of 1mol / L nitric acid solution, then 14 parts of initiator cerium ammonium nitrate and 40 parts of benzothiazole, and react in a nitrogen atmosphere for 4 hours; wash the obtained product repeatedly with methanol, and then mix the product with an appropriate amount of twice distilled water Add it into a flask and stir it magnetically, then heat it to 85°C to dissolve it completely, then add 45 parts of a sulfuric acid solution with a mass fraction of 98% to react at a constant temperature for 24 hours, then wash the residue with ethyl acetate and dry it in vacuum at 40°C for 12 hours to obtain Phosphotungstic acid-benzothiazole ionic liquid graft copolymer;

[0041] Prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com