Method for preparing anticorrosive paint for surface of ocean oil well pipe and coating treatment method of anticorrosive paint on pipe surface

A technology for anti-corrosion coatings and oil well pipes, used in anti-corrosion coatings, devices for coating liquids on surfaces, special surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

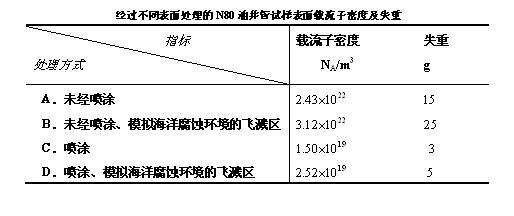

Image

Examples

Embodiment

[0042] In this embodiment, the preparation process and coating process are as follows:

[0043] A. Coating preparation process

[0044] (one). Raw material formulations for design coatings

[0045] (1) The dosage of the main raw material coating matrix:

[0046] Epoxy resin 100 grams;

[0047] Take epoxy resin as 100% as the measurement basis, and add other raw materials:

[0048] Plasticizer triphenyl phosphate 20 grams,

[0049] Curing agent ethylenediamine or / and polyamide 12 grams,

[0050] Solvent dibutyl phthalate 20 grams;

[0051] (2) Addition amount of auxiliary raw material additives:

[0052] Take the above epoxy resin as 100% as the benchmark, and add other raw material additives:

[0053] Methyl isobutyl ketone 10 grams,

[0054] Xylene 5 grams,

[0055] Butyl synthetic rubber 4 grams,

[0056] Silicone resin 7 grams,

[0057]Ketimine 20 grams,

[0059] Glass powder (120 mesh) 10 grams,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com