Low-cost high-performance vegetarized single-crystal high-temperature alloy and preparation method thereof

A superalloy, high-performance technology, applied in the field of superalloys, can solve problems such as limiting the promotion and application of single crystal superalloys, reducing cost performance, and being unable to further develop environmental resistance design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

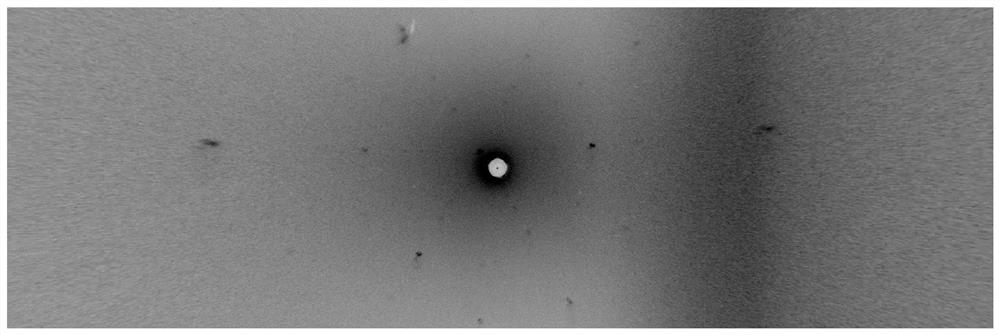

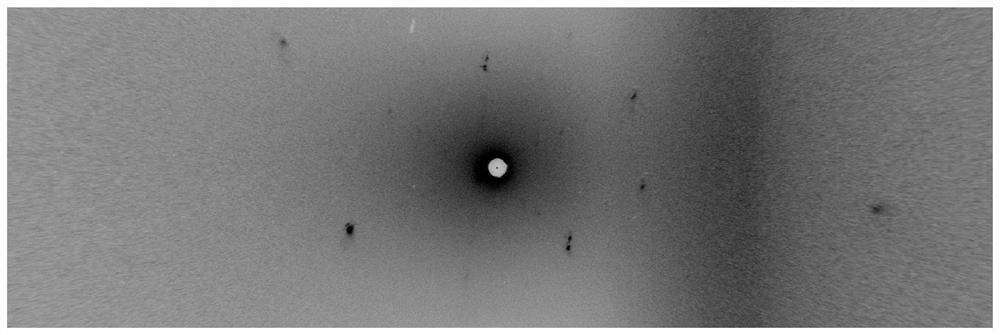

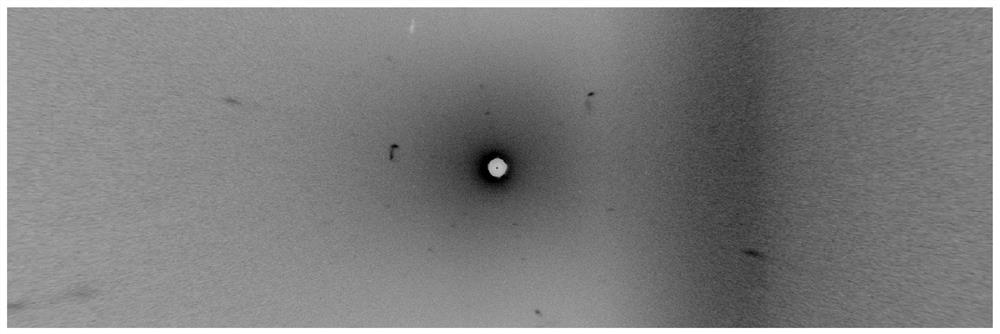

Image

Examples

preparation example Construction

[0036]The present invention provides a method for preparing a plain single crystal superalloy according to the above technical solution, comprising the following steps:

[0037] (1) smelting alloy raw material to obtain master alloy ingot;

[0038] (2) directional solidification is performed after the mother alloy ingot obtained in the step (1) is melted to obtain an alloy ingot;

[0039] (3) The alloy ingot obtained in the step (2) is sequentially subjected to solution treatment and isothermal transformation heat treatment to obtain a plain single crystal superalloy.

[0040] In the present invention, the alloy raw material is smelted to obtain a master alloy ingot.

[0041] The present invention does not have a special limitation on the specific types and proportions of the alloy raw materials, and the metal element or the intermediate alloy can be selected according to the proportion of each element in the alloy product. The source of the alloy raw material is not particu...

Embodiment 1

[0056] A low-cost and high-performance plain single-crystal superalloy, which is composed of the following components in terms of mass percentage: 9% of Al, 9% of Cr, 6% of Co, 12% of W and the balance of Ni;

[0057] The preparation method of the plain single crystal superalloy is composed of the following steps:

[0058] (1) Smelting the alloy raw material, and cooling to obtain a master alloy ingot; the smelting temperature is 1600°C, and the smelting holding time is 1.5h;

[0059] (2) The master alloy ingot obtained in the step (1) is melted at 1500° C. and then cast into a wax mold for 0.5 h, followed by directional solidification to obtain an alloy ingot with [111] crystal orientation; The pulling rate is 3mm / min;

[0060] (3) The alloy ingot obtained in the step (2) is successively subjected to solution treatment and isothermal transformation heat treatment, and after cooling, a plain single crystal superalloy is obtained; , and then kept at 1250° C. for 12 hours; the...

Embodiment 2

[0063] A low-cost and high-performance plain single-crystal superalloy, which is composed of the following components in terms of mass percentage: 9% of Al, 9% of Cr, 6% of Co, 12% of Mo and the balance of Ni;

[0064] The preparation method of the plain single crystal superalloy is composed of the following steps:

[0065] (1) Smelting the alloy raw material, and cooling to obtain a master alloy ingot; the smelting temperature is 1600°C, and the smelting holding time is 1.5h;

[0066] (2) The master alloy ingot obtained in the step (1) is melted at 1500° C. and then cast into a wax mold for 0.5 h, followed by directional solidification to obtain an alloy ingot with [111] crystal orientation; The pulling rate is 3mm / min;

[0067] (3) The alloy ingot obtained in the step (2) is successively subjected to solution treatment and isothermal transformation heat treatment, and after cooling, a plain single crystal superalloy is obtained; , and then kept at 1250° C. for 12 hours; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com