Impact-smashing-resistant wear-resistant steel and preparation method thereof

A wear-resistant steel and impact-resistant technology, which is applied in the field of impact-resistant and wear-resistant steel and its preparation, can solve the problems of poor toughness, low impact toughness, and no obvious improvement in wear resistance, and achieve superior wear resistance and impact Toughness, excellent friction and wear properties, and good prospects for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0055] A preparation method of impact-resistant and wear-resistant steel, the steps are as follows:

[0056] (1) Smelting: Put the ingredients into the electric arc furnace according to the ratio and melt them. After the metallurgical composition meets the requirements, control the temperature to about 1520-1540°C and cast it into a φ450mm×2050mm round ingot. After the round ingot is demoulded, remove the scale and pits, etc. defect;

[0057] (2) High-temperature homogenization: heat the φ450mm×2050mm steel ingot to 1265±10°C, keep it warm for 11 hours, and then cool it to 1180±10°C with the furnace to prepare for forging;

[0058] (3) Upsetting: Upsetting the 1180°C steel ingot along the height direction of the steel ingot to a height of 45%, then finishing (that is, using a press to flatten the irregular edges), returning to the furnace and heating at 1180±10°C for 3 hours, and then The second upsetting, finishing, return to the furnace at 1180±10°C for 3 hours, and then ca...

Embodiment 1

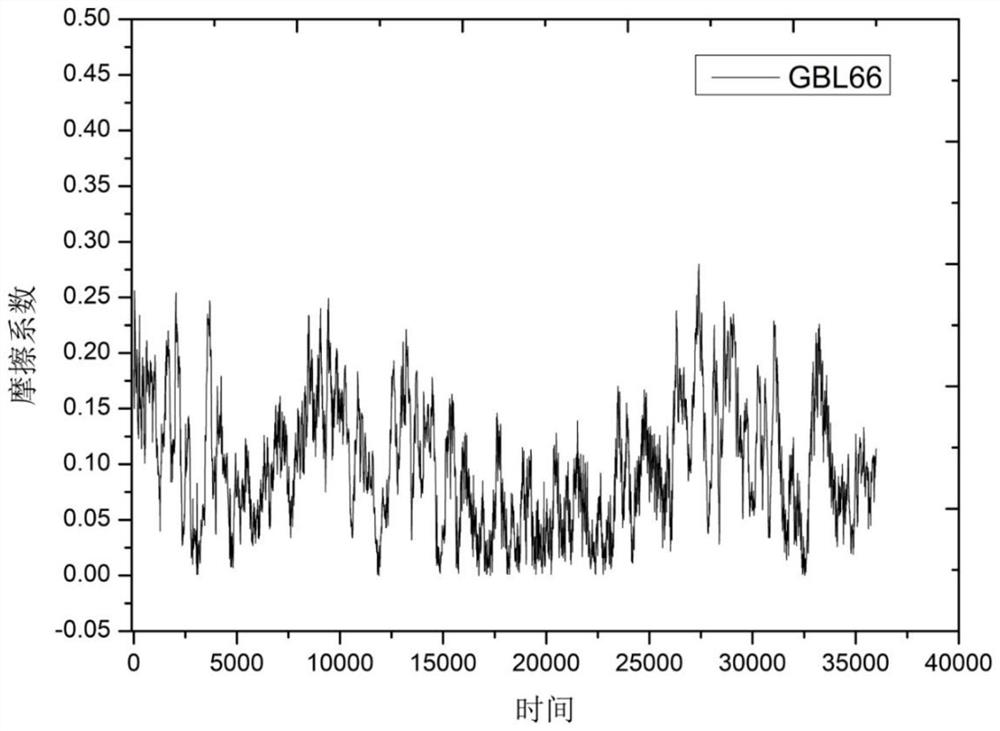

[0069] The friction and wear coefficient test result figure of the anti-smashing and wear-resistant steel obtained in embodiment 1 is as follows figure 2 As shown, traditional die steels, such as H13 and 8418 steels, have a friction and wear coefficient of 0.4 to 0.6. Compared with H13 steel and 8418 steel, the friction and wear coefficient of the test steel of the present invention is significantly reduced, which means that the wear resistance is obviously improved.

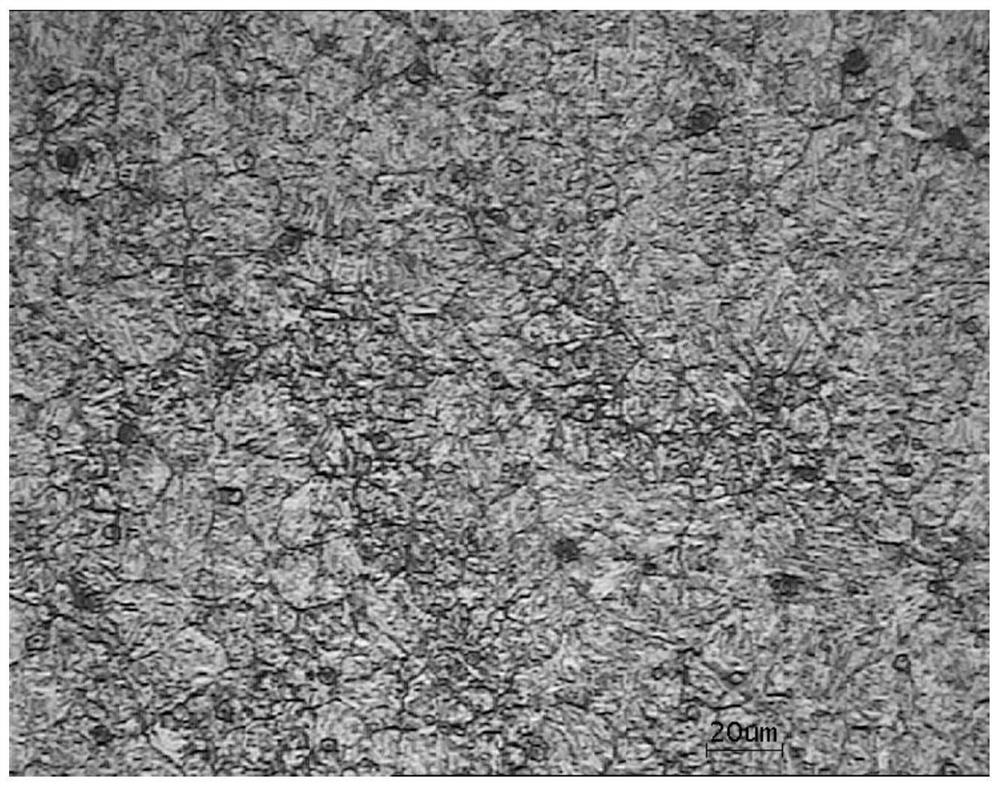

[0070] The metallographic structure diagram (400 times) of the anti-smashing wear-resistant steel that embodiment 1 makes is as follows figure 1 shown by figure 1 It can be seen that densely dispersed precipitates are distributed in the matrix and grain boundaries. This type of precipitates is mainly metastable and stable carbides. This type of carbides not only has high hardness, but is also not easy to coarsen, which can improve wear resistance during use. Sexuality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com