Method for prolonging playing time of snow melting function of environmental protection snow-melting agent

A technology of action time and snow melting agent, applied in the field of traffic environment safety, can solve the problems of short snow melting time, high corrosion of metal and concrete, etc., and achieve the effect of prolonging action time, good light transmittance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

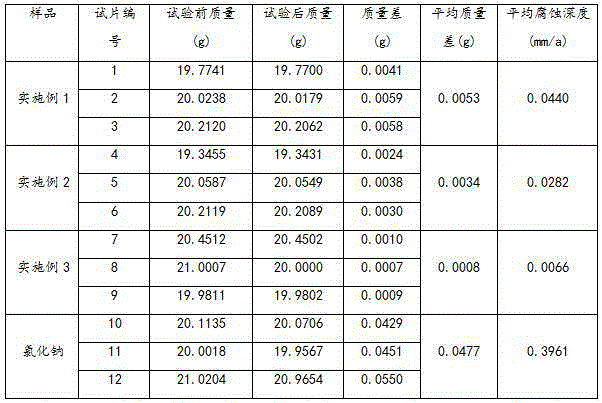

Embodiment 1

[0027] (1) Stir and mix 70 parts of sodium chloride and 20 parts of calcium chloride to obtain a chloride salt mixture; mix 35 parts of sodium silicate, 30 parts of sodium dihydrogen phosphate, 10 parts of sodium tartrate and 25 parts of thiourea to obtain Corrosion inhibitor; 60 parts of urea and 40 parts of sodium bicarbonate are mixed according to the proportion to obtain a pH regulator;

[0028] (2) Stir and mix 90 parts of chlorine salt mixture, 5 parts of corrosion inhibitor and 5 parts of pH regulator prepared in step (1) to obtain the crude deicing agent;

[0029] (3) Stir, pulverize and granulate the homogeneously mixed crude deicing agent, and pass through a standard sieve with an aperture of 6 mm to obtain granular environmental deicing deicing agent;

[0030] (4) Put the solid PDMS in the lower layer of the closed heating furnace, and put the granular environmentally friendly snow-melting agent prepared in step (3) on the upper layer of the heating furnace. The two...

Embodiment 2

[0033] (1) Stir and mix 70 parts of sodium chloride and 20 parts of calcium chloride to obtain a chloride salt mixture; mix 35 parts of sodium silicate, 30 parts of sodium dihydrogen phosphate, 10 parts of sodium tartrate and 25 parts of thiourea to obtain Corrosion inhibitor; 60 parts of urea and 40 parts of sodium bicarbonate are mixed according to the proportion to obtain a pH regulator;

[0034] (2) Stir and mix 90 parts of chlorine salt mixture, 5 parts of corrosion inhibitor and 5 parts of pH regulator prepared in step (1) to obtain the crude deicing agent;

[0035] (3) Stir, pulverize and granulate the homogeneously mixed crude deicing agent, and pass through a standard sieve with an aperture of 6mm to obtain granular environmentally friendly deicing deicing agent;

[0036] (4) Put the solid PDMS in the lower layer of the closed heating furnace, and place the granular environmentally friendly snow-melting agent prepared in step (3) on the upper layer of the heating furn...

Embodiment 3

[0039] (1) Stir and mix 70 parts of sodium chloride and 20 parts of calcium chloride to obtain a chloride salt mixture; mix 35 parts of sodium silicate, 30 parts of sodium dihydrogen phosphate, 10 parts of sodium tartrate and 25 parts of thiourea to obtain Corrosion inhibitor; 60 parts of urea and 40 parts of sodium bicarbonate are mixed according to the proportion to obtain a pH regulator;

[0040] (2) Stir and mix 90 parts of chlorine salt mixture, 5 parts of corrosion inhibitor and 5 parts of pH regulator prepared in step (1) to obtain the crude deicing agent;

[0041] (3) Stir, pulverize and granulate the homogeneously mixed crude deicing agent, and pass through a standard sieve with an aperture of 6 mm to obtain granular environmental deicing deicing agent;

[0042] (4) Put the solid PDMS in the lower layer of the closed heating furnace, and put the granular environmentally friendly snow-melting agent prepared in step (3) on the upper layer of the heating furnace. The two c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com