Functional fertilizer and repair agents for repairing soil heavy metal

A technology for heavy metals and remediation agents, applied in soil conditioning materials, organic fertilizers, fertilizer mixtures, etc., can solve problems such as high cost and secondary pollution, and achieve the effects of low cost, environmental friendliness, and control of heavy metal migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

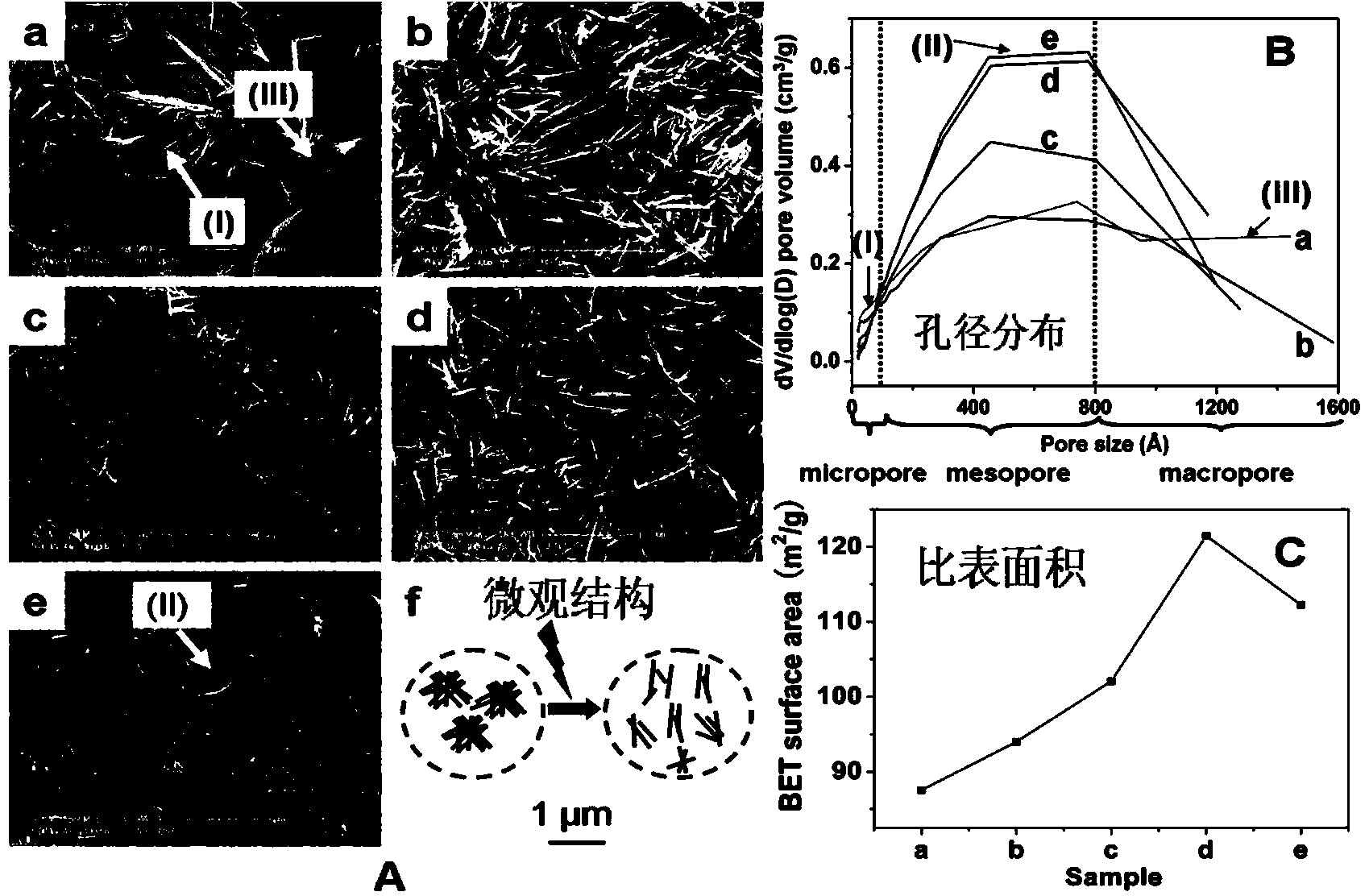

Image

Examples

Embodiment 1

[0020] (1) By weight, mix 7 parts of attapulgite (colloidal grade) and 1 part of chitosan evenly, and add water to prepare a suspension with a concentration of 50g / L. Stir at 30°C for 20 minutes. Then use high-energy electron beam (5MeV, 10kGy) to irradiate for 10 minutes, so that chitosan is grafted on the surface of attapulgite rod crystals to form attapulgite-chitosan composites, and then dried at 30 degrees Celsius and crushed into 200 meshes;

[0021] (2) By weight, 1 part of the substance obtained in (1), 2 parts of biochar (rice husk ash, 200 mesh, 40% carbon content, 200 mesh) and 2 parts of sodium thiosulfate (200 mesh) Mix evenly to get the soil heavy metal remediation agent;

[0022] (3) Spread the restorative agent obtained in (2) evenly on the soil surface at an amount of 20kg per mu, and then plow the land.

Embodiment 2

[0024] (1) By weight, mix 11 parts of attapulgite (colloidal grade) and 3 parts of chitosan evenly, add water to form a suspension with a concentration of 100g / L, and stir for 40 minutes at 50°C. Then use high-energy electron beam (10MeV, 50kGy) to irradiate for 20 minutes to graft chitosan on the surface of attapulgite rod crystals to form attapulgite-chitosan composites, then dry at 60 degrees Celsius and pulverize into 400 meshes;

[0025] (2) By weight, 3 parts of the substance obtained in (1), 5 parts of biochar (rice husk ash, 400 mesh, 65% carbon content, 400 mesh) and 4 parts of sodium thiosulfate (400 mesh) Mix evenly to get the soil heavy metal remediation agent;

[0026] (3) Spread the restorative agent obtained in (2) evenly on the soil surface at an amount of 10kg per mu, and then plow the land.

Embodiment 3

[0028] (1) By weight, mix 7 parts of attapulgite (colloidal grade) and 1 part of chitosan evenly, and add water to prepare a suspension with a concentration of 50g / L. Stir at 30°C for 20 minutes. Then use high-energy electron beam (5MeV, 10kGy) to irradiate for 10 minutes, so that chitosan is grafted on the surface of attapulgite rod crystals to form attapulgite-chitosan composites, and then dried at 30 degrees Celsius and crushed into 200 meshes;

[0029] (2) By weight, 1 part of the substance obtained in (1), 2 parts of biochar (rice husk ash, 200 mesh, 40% carbon content, 200 mesh) and 2 parts of sodium thiosulfate (200 mesh) Mix evenly to get the soil heavy metal remediation agent;

[0030] (3) Add the restorative agent obtained in (2) to the organic fertilizer at a ratio of 5% by weight, and granulate to obtain the heavy metal repair organic fertilizer.

[0031] (4) Spread the restoration fertilizer obtained in (3) evenly on the soil surface at an amount of 60kg per mu, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com