Magnesium alloy phosphorization solution and its phosphorized technology

A magnesium alloy and solution technology, applied in the direction of metal material coating process, etc., can solve the problems of substrate corrosion and coarse phosphating film crystals, and achieve the effects of strong adhesion, low cost and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Phosphating treatment of AZ91D magnesium alloy die casting samples.

[0021] Prepare the magnesium alloy phosphating solution according to the following formula:

[0022] Zinc oxide 1 g / liter aqueous solution

[0023] Phosphoric acid 10 grams per liter of aqueous solution

[0024] Accelerator Sodium Nitrate 6 grams per liter of aqueous solution

[0025] Corrosion inhibitor sodium fluoride 0.5 g / liter aqueous solution

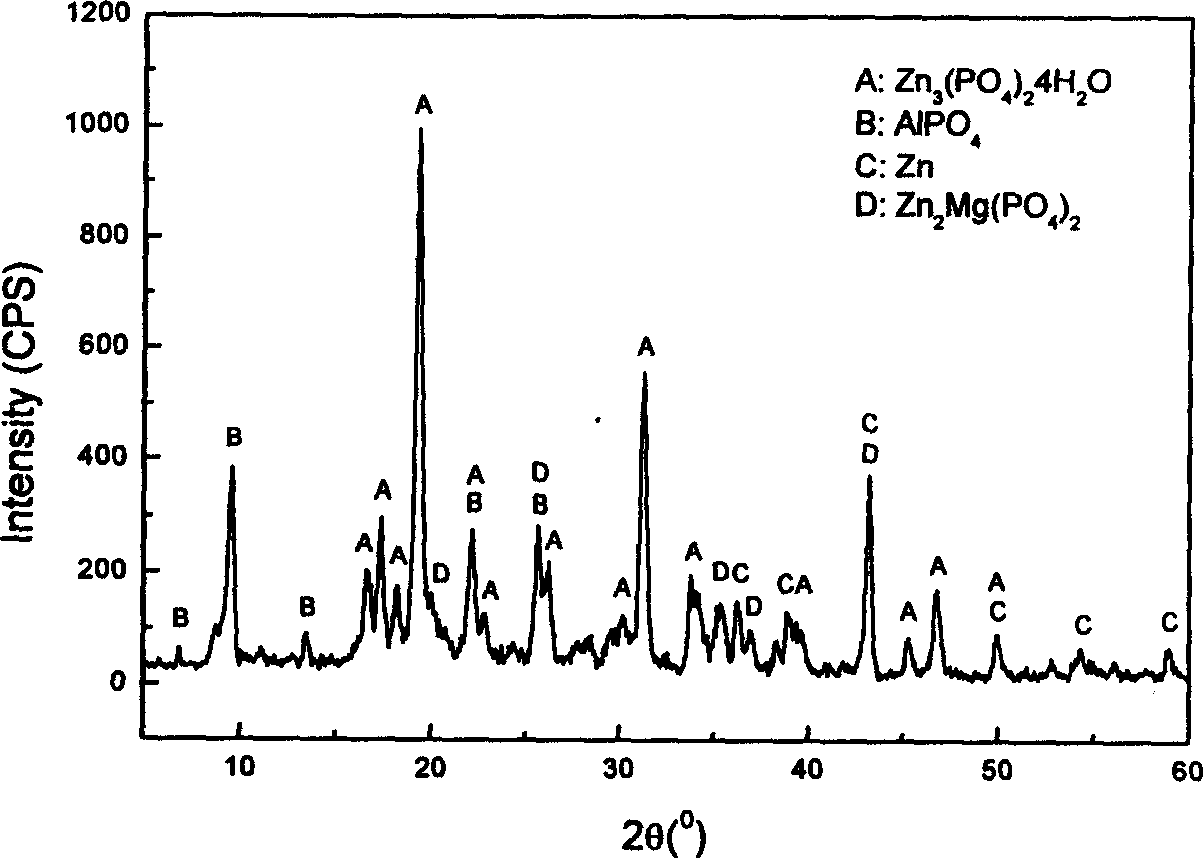

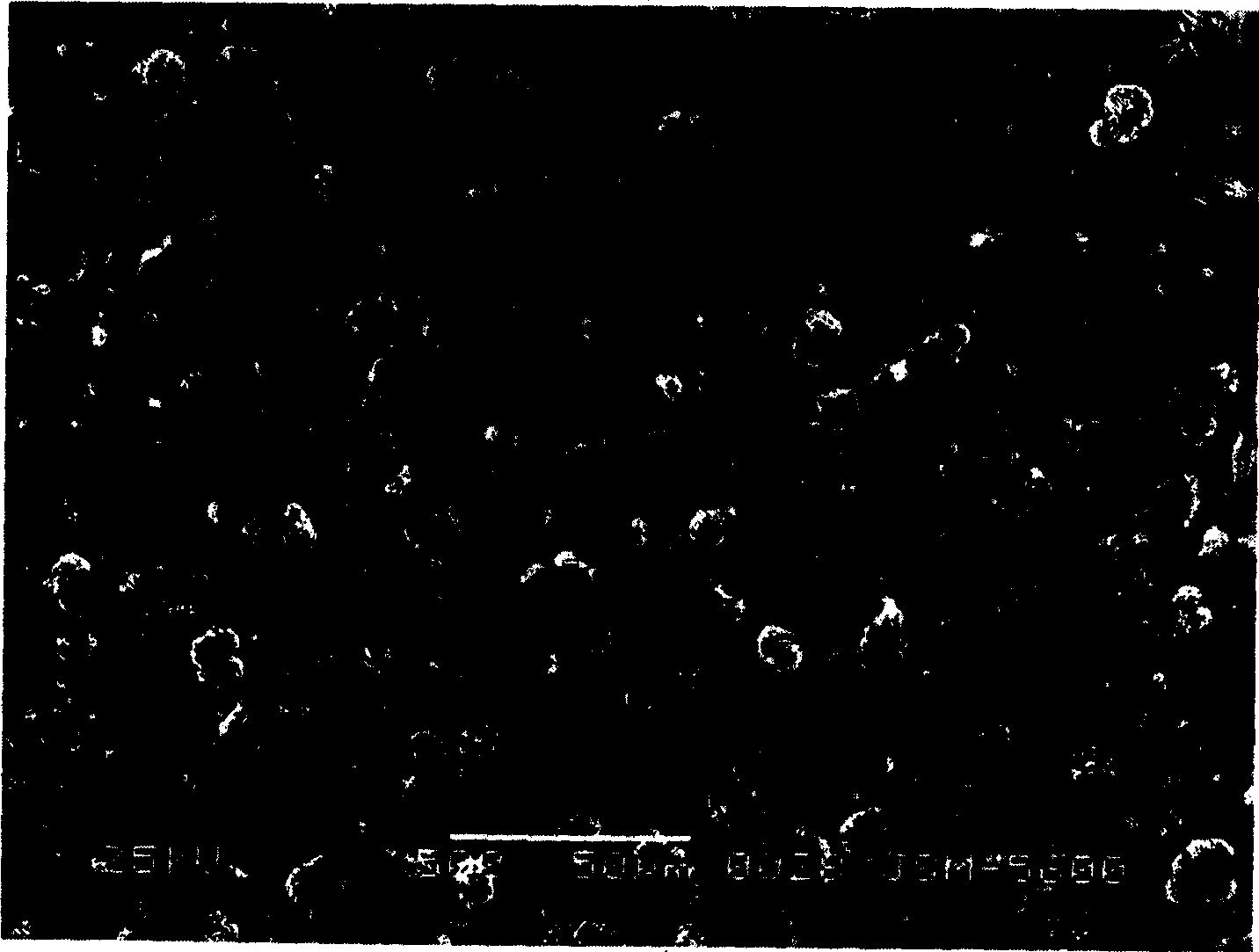

[0026] Degrease the surface of the AZ91D magnesium alloy sample and remove the oxide film, then wash it with water, then put it into and immerse in the phosphating solution prepared above to adjust the pH value to 2.6 with phosphoric acid or sodium hydrogen fluoride, statically at 25 °C Leave on for 3 minutes, then wash and dry. The SEM photo of the phosphating film obtained by technique of the present invention is shown in the attached figure 2 .

example 2

[0028] Phosphating treatment of AZ91D magnesium alloy die casting samples.

[0029] Prepare the magnesium alloy phosphating solution according to the following formula:

[0030] Zinc oxide 3 g / liter aqueous solution

[0031] Phosphoric acid 3 grams per liter of aqueous solution

[0032] Complexing agent sodium tartrate 4 grams per liter of aqueous solution

[0033] Accelerator sodium nitrate 0.1 g / liter aqueous solution

[0034] Corrosion inhibitor sodium fluoride 4.5 grams per liter of aqueous solution

[0035] Degrease the surface of the AZ91D magnesium alloy sample and remove the oxide film, wash it with water, then put it into and immerse it in the phosphating solution prepared above to adjust the pH value to 4.5 with phosphoric acid or sodium hydrofluoride, and statically at 15 °C. Leave on for 3 minutes, then wash and dry.

example 3

[0037] Phosphating treatment of AZ91D magnesium alloy die casting samples.

[0038] Prepare the magnesium alloy phosphating solution according to the following formula:

[0039] Zinc oxide 2 grams per liter of aqueous solution

[0040] Phosphoric acid 13 grams per liter of aqueous solution

[0041] Complexing agent sodium tartrate 5 grams per liter of aqueous solution

[0042] Accelerator Sodium Nitrate 2 grams per liter of aqueous solution

[0043] Corrosion inhibitor sodium fluoride 0.5 g / liter aqueous solution

[0044] Degrease the surface of the AZ91D magnesium alloy sample and remove the oxide film, wash it with water, then put it into and immerse it in the phosphating solution prepared above to adjust the pH value to 3.1 with phosphoric acid or sodium hydrofluoride, and statically at 49 °C. Leave it on for 50 minutes, then wash and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com