Ultra-high strengthen, high-conductivity CuNiSi series elastic copper alloy and method for preparing same

An elastic copper alloy, high electrical conductivity technology, applied in the field of CuNiSi elastic copper alloy and its preparation, can solve the problems of unspecified alloy composition and preparation process, achieve excellent stress relaxation resistance and comprehensive performance, simple production process, Effect of improving stress relaxation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

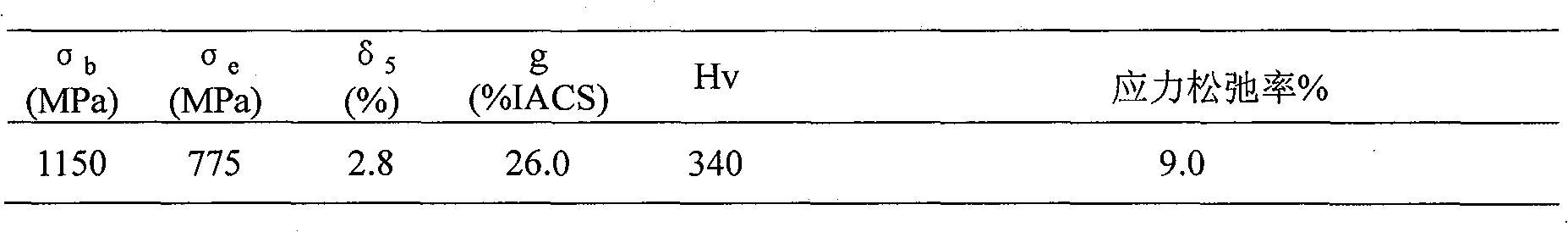

Embodiment 1

[0071] Embodiment 1: Alloy composition: Ni: 8.2wt%; Si: 1.8wt%; Sn: 0.5wt%; Mg: 0.2wt%; Zr: 0.2wt%;

[0072] Firstly, dry the electrolytic copper, nickel, silicon, and tin and put them into a heating furnace to melt them, protect them with nitrogen and calcined charcoal, and melt them at a melting temperature of 1300-1450°C, cast them into ingots, and mill the impurities on the surface of the ingots; Carry out secondary remelting at 1300°C-1450°C, protect with nitrogen and calcined charcoal, after the ingot is completely melted, lower the furnace temperature to 1200°C-1250°C, then use copper-zirconium master alloy, magnesium and Add in the form of copper-magnesium alloy, form a CuNiSiSnMgZr alloy melt after melting, and cast the CuNiSiSnMgZr alloy melt into an ingot;

[0073] (2) Homogenization treatment and hot rolling

[0074] The ingots obtained by CuNiSiSnMgZr alloy melt casting are milled to remove surface defects, homogenized in a hydrogen protection furnace at 920 ° C ...

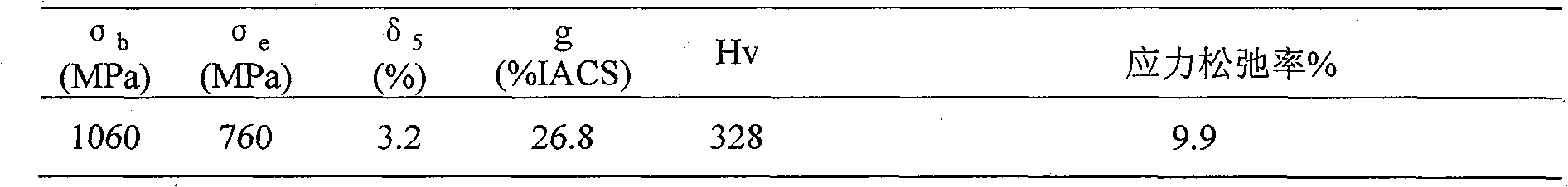

Embodiment 2

[0083] Embodiment 2: Alloy composition: Ni: 6.4wt%; Si: 1.2wt%; Sn: 0.3wt%; Mg: 0.1wt%; Zr: 0.1wt%;

[0084] Firstly, dry the electrolytic copper, nickel, silicon, and tin and put them into a heating furnace to melt them, protect them with nitrogen and calcined charcoal, and melt them at a melting temperature of 1300-1450°C, cast them into ingots, and mill the impurities on the surface of the ingots; Carry out secondary remelting at 1300-1450°C, protect with nitrogen and calcined charcoal, after the ingot is completely melted, lower the furnace temperature to 1200°C-1250°C, and then use copper-zirconium master alloy for zirconium, copper for magnesium - adding in the form of a magnesium alloy, forming a CuNiSiSnMgZr alloy melt after melting, and casting the CuNiSiSnMgZr alloy melt into an ingot;

[0085] (2) Homogenization treatment and hot rolling

[0086] The ingots obtained by CuNiSiSnMgZr alloy melt casting are milled to remove surface defects, homogenized in a hydrogen p...

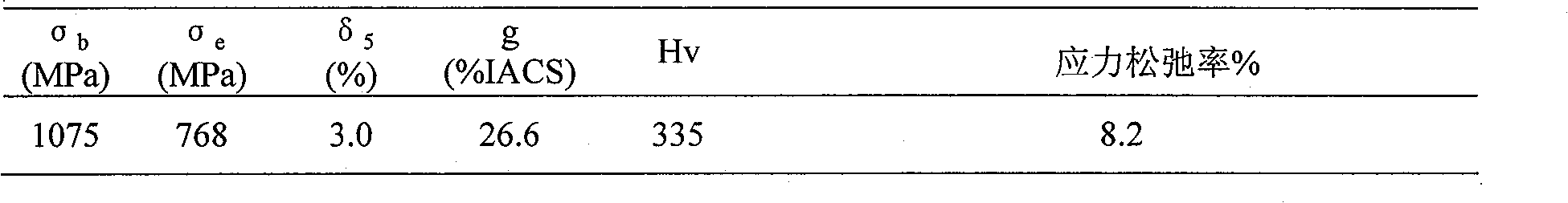

Embodiment 3

[0095] Embodiment 3: Alloy composition: Ni: 7.3wt%; Si: 1.5wt%; Sn: 0.4wt%; Mg: 0.15wt%; Zr: 0.15wt%;

[0096] Firstly, dry the electrolytic copper, nickel, silicon, and tin and put them into a heating furnace to melt them, protect them with nitrogen and calcined charcoal, and melt them at a melting temperature of 1300-1450°C, cast them into ingots, and mill the impurities on the surface of the ingots; Carry out secondary remelting at 1300-1450°C, protect with nitrogen and calcined charcoal, after the ingot is completely melted, lower the furnace temperature to 1200°C-1250°C, and then use copper-zirconium master alloy for zirconium, copper for magnesium - adding in the form of a magnesium alloy, forming a CuNiSiSnMgZr alloy melt after melting, and casting the CuNiSiSnMgZr alloy melt into an ingot;

[0097] (2) Homogenization treatment and hot rolling

[0098] The ingots obtained by CuNiSiSnMgZr alloy melt casting are milled to remove surface defects, homogenized in a hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com