Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Ethylene glycol monophenyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

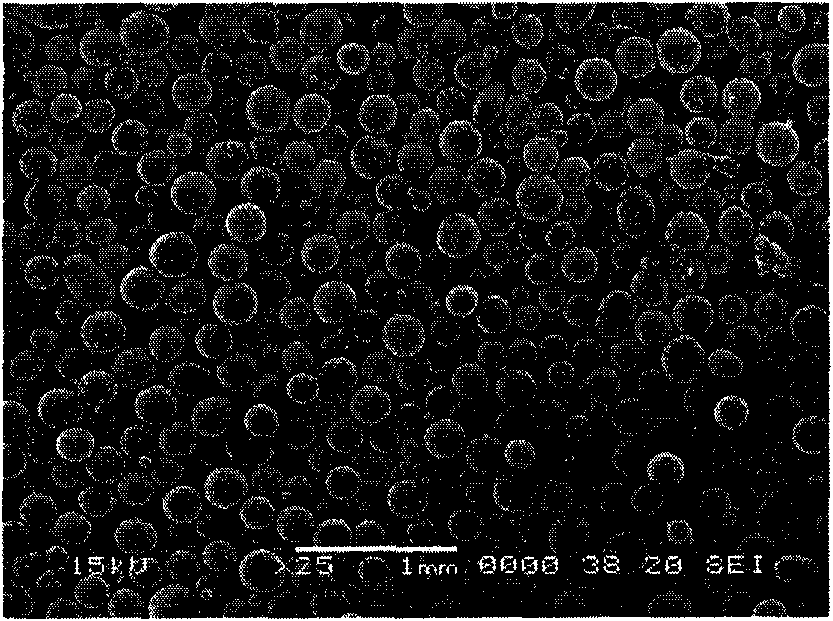

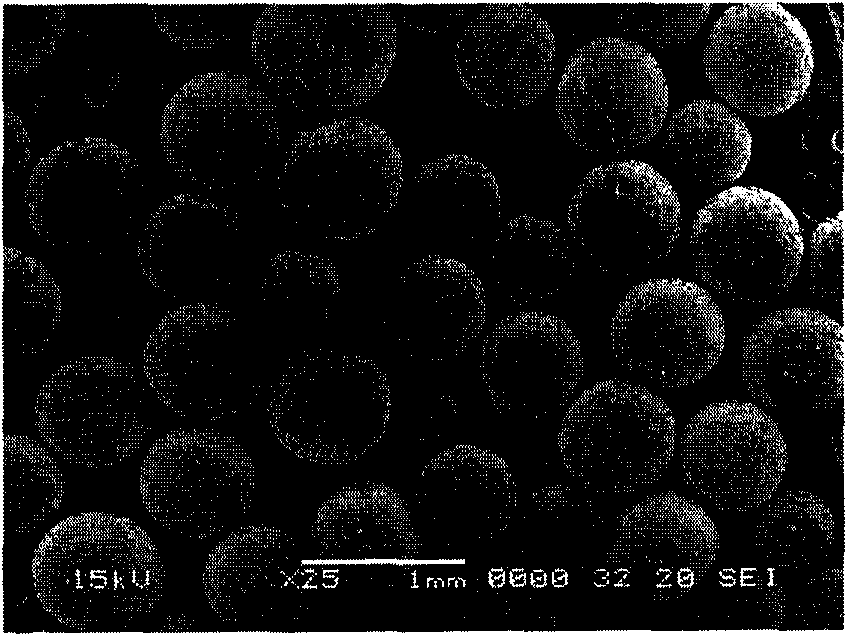

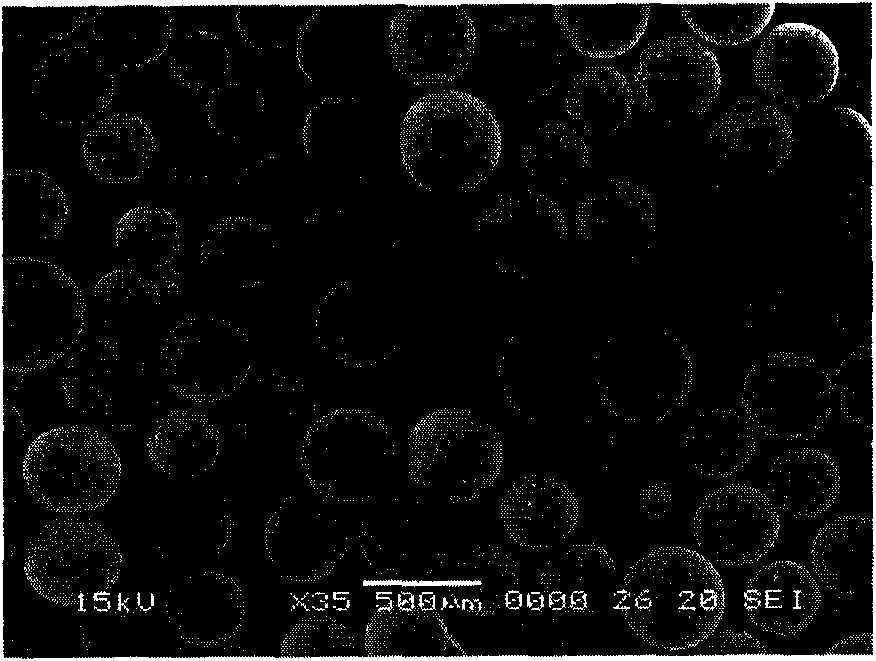

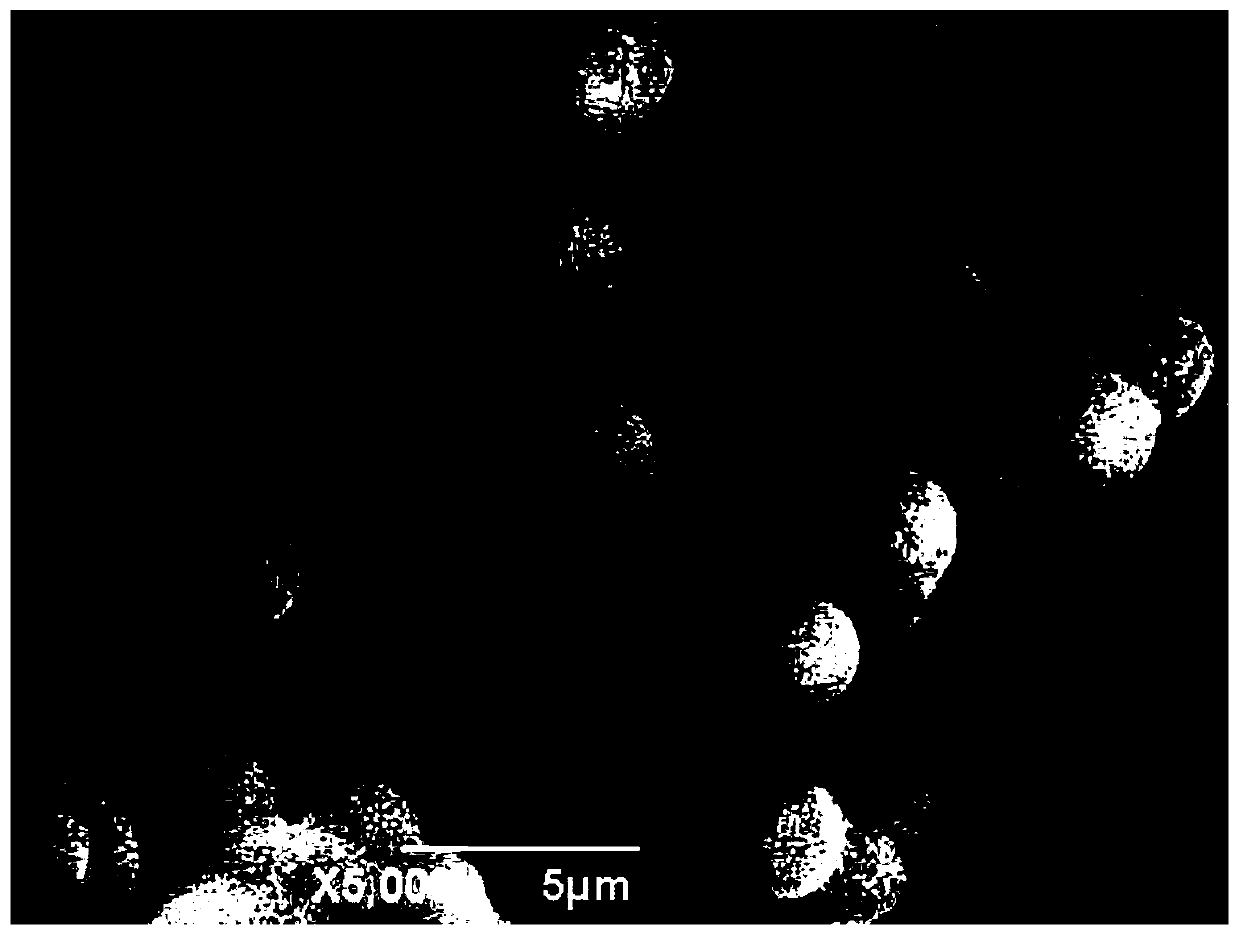

Preparation method of phenolic resin polymer microspheres

InactiveCN101624437AUniform particle size distributionFlat surfaceEthylene glycol monophenyl etherChromatographic separation

The invention discloses a preparation method of phenolic resin polymer microspheres. The method overcomes the defect that the former preparation method adopts a single stabilizer and can adopt different stabilizers as required to prepare phenolic microspheres of different grain diameter distributions to obtain a globular polymer with smooth surface and uniform grain fineness distribution. The method includes the steps of uniformly mixing stabilizer hydroxypropyl methyl cellulose (or carboxymethyl cellulose or arabicgum), ethylene glycol monophenyl ether, formic acid and formaldehyde, then slowly dipping concentrated sulfuric acid, after dipping, heating and stirring the reaction mixture under a certain temperature to react for a certain time and drying the product after separating, soaking in alkali solution and washing. The phenolic resin polymer microsphere prepared by the invention achieves high sphericity and the grain diameter ranging from 0.1-1.5mm by one step reaction, can be used as the base material of macromolecule absorbent and is used for the fields of biological medicines, chromatographic separation and environment treatment, etc.

Owner:LUDONG UNIVERSITY

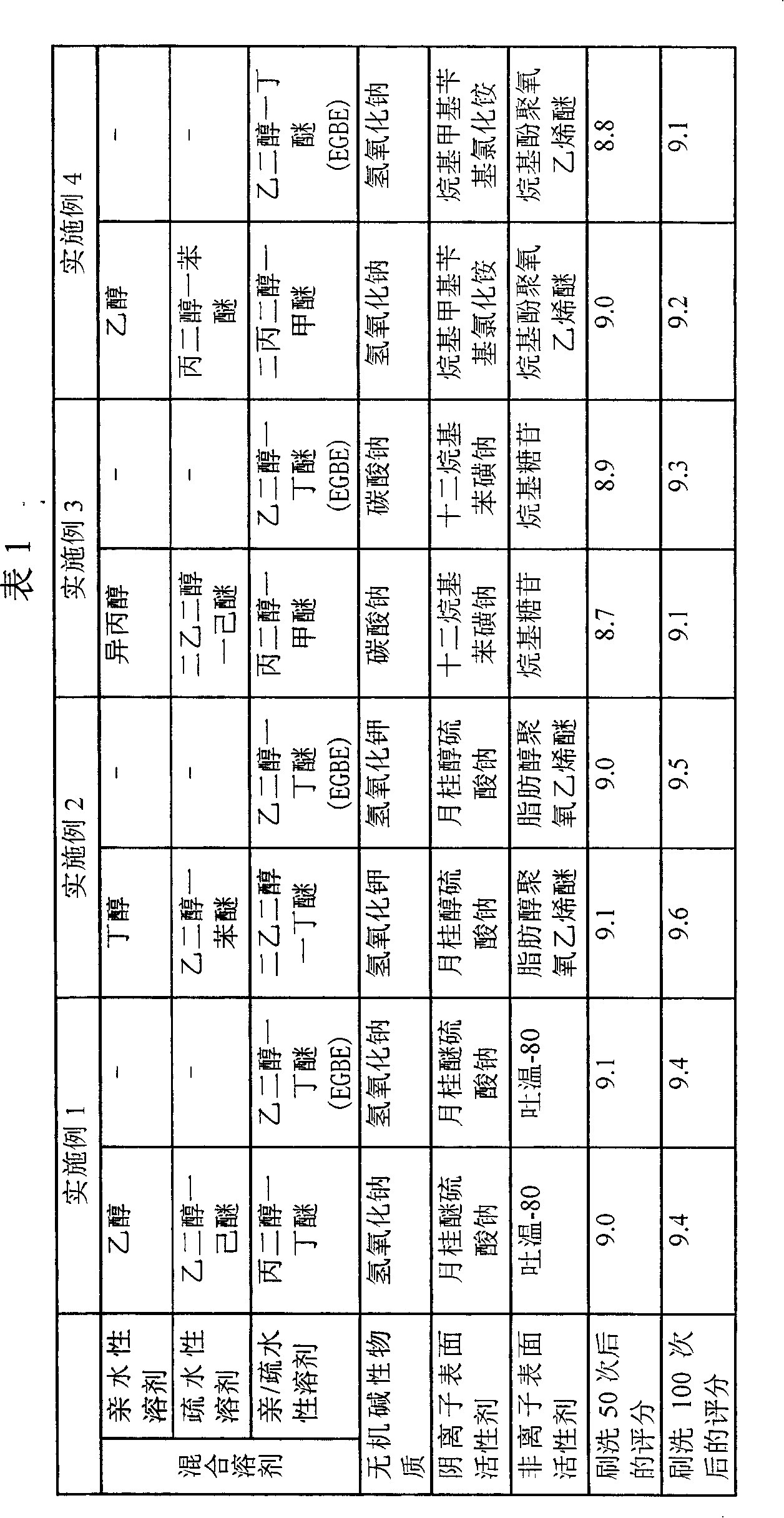

Kitchen detergent composition

InactiveCN101210213ANo toxicityEasy to cleanNon-ionic surface-active compoundsDetergent compounding agentsDiethylene glycol monobutyl etherEthylene glycol monophenyl ether

The invention relates to an alkaline kitchen cleanser composition with no ethylene glycol monobutyl ether (EGBE) for cleaning hard surface with heavy oil stains, and also relates to a mixture solvent capable of substituting for the EGBE solvent in the cleanser composition. The alkaline kitchen cleanser composition mainly comprises (a) a mixed solvent of a hydrophilic solvent and a hydrophobic solvent; (b) an inorganic alkaline substance; and (c) a surfactant. The mixed solvent includes the hydrophobic solvent selected from ethylene glycol monophenyl ether, ethylene glycol monohexyl ether and combination thereof, a hydrophilic diethylene glycol monobutyl ether solvent and a hydrophilic isopropyl alcohol solvent. The alkaline kitchen cleanser composition contains no EGBE, thus eliminating the latent toxicity. Meanwhile, the composition is at low cost and can be mixed to obtain better or more diversified smells.

Owner:SC JOHNSON & SON INC

Chinese herbal medicine antibacterial cotton fibers and production method thereof

InactiveCN104278356AHas antibacterial functionHigh strengthConjugated cellulose/protein artificial filamentsArtifical filament manufactureEthylene glycol monophenyl etherFiber

The invention discloses Chinese herbal medicine antibacterial cotton fibers. The Chinese herbal medicine antibacterial cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 20-23 parts of cotton fibers, 10-13 parts of modal fibers, 8-10 parts of bamboo pulp fibers, 7-9 parts of banana stem fibers, 5-8 parts of down feather fibers, 1-3 parts of sophora alopecuroide extract powder, 1-2 parts of attapulgite, 0.4-0.8 part of ammonium persulfate, 1.3-3.5 parts of glycine betaine, 18-22 parts of ethylene glycol monophenyl ether, 15-17 parts of benzyl benzoate, 4-5 parts of wild chrysanthemum, 3-4 parts of jasmine flowers, 1-2 parts of lonicera japonica, 100-110 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 106-110 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the Chinese herbal medicine antibacterial cotton fibers, the operation is simple, the cost is low and the operability is strong; the wild chrysanthemum, jasmine flowers and lonicera japonica are added so that the Chinese herbal medicine antibacterial cotton fibers have an antibacterial function and also have a flower flavor; and meanwhile, various animal and plant fibers are also added to the Chinese herbal medicine antibacterial cotton fibers so that the strength and the heat preservation performance of the cotton fibers are remarkably improved.

Owner:ANHUI SWAN TECH IND GRP

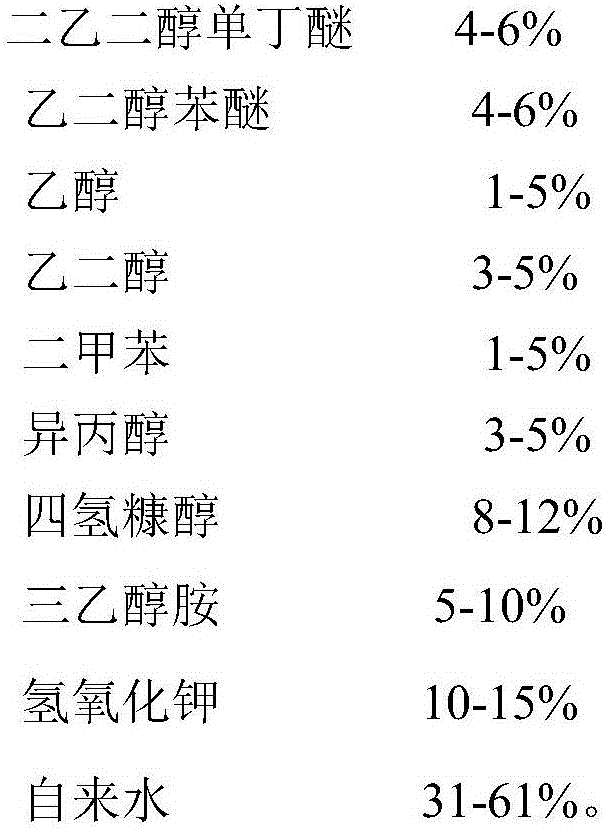

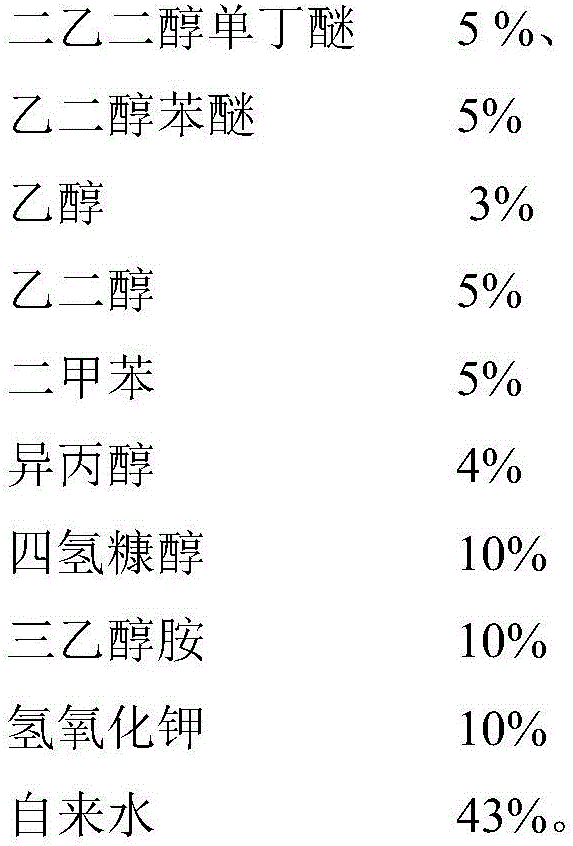

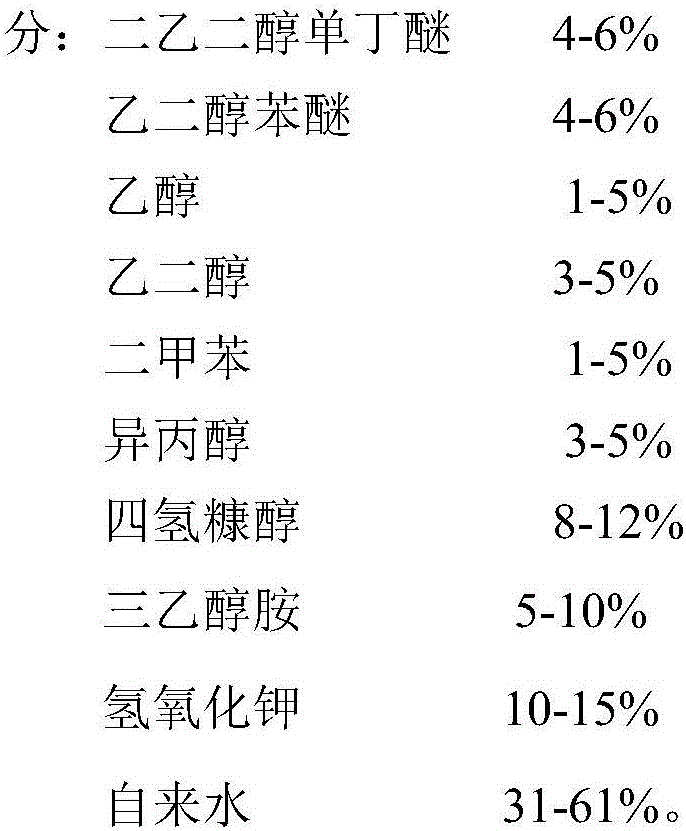

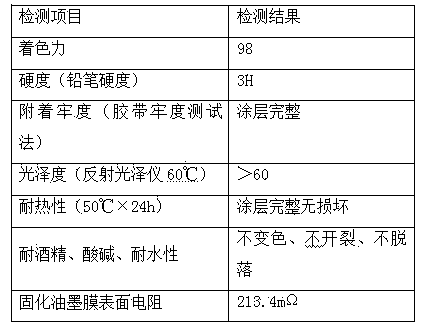

Mobile phone touch screen polarizer cleaning agent and preparation method and application thereof

InactiveCN106833958AImprove securityEasy to cleanDetergent mixture composition preparationOrganic non-surface-active detergent compositionsDiethylene glycol monobutyl etherEthylene glycol monophenyl ether

The invention discloses a mobile phone touch screen polarizer cleaning agent and a preparation method and application thereof. The mobile phone touch screen polarizer cleaning agent is prepared by, by mass percentage, 4-6% of diethylene glycol monobutyl ether, 4-6% of ethylene glycol monophenyl ether, 1-5% of ethanol, 3-5% of ethylene glycol, 1-5% of dimethyl benzene, 3-5% of isopropanol, 8-12% of tetrahydrofurfuryl alcohol, 5-10% of triethanolamine, 10-15% of potassium hydroxide and 31-61% of tap water. During use, the mobile phone touch screen polarizer cleaning agent is boiled and used for cleaning a polarizer. The mobile phone touch screen polarizer cleaning agent has the advantages that the prepared cleaning agent is a water-soluble cleaning agent and is high in safety performance, good in cleaning ability, good in dissolving performance on colloid and resin residues, capable of increase cleaning efficiency, capable of satisfying cleanliness requirements, low in use amount, long in service life, less prone to volatilization, capable of effectively lowering cleaning cost and evident in practical value.

Owner:希玛石油制品(镇江)有限公司

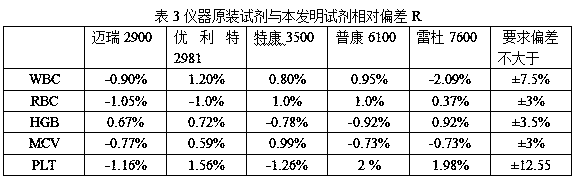

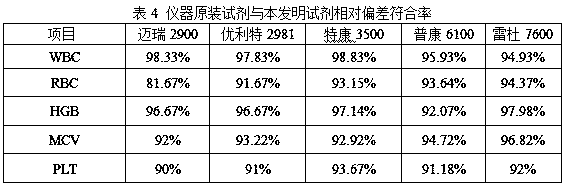

Method for preparing 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene

ActiveCN104030899AEasy to recycleRaw materials are cheap and easy to getOrganic chemistryOrganic compound preparationEthylene glycol monophenyl etherChemical synthesis

The invention discloses a method for preparing 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene and belongs to the technical field of chemical synthesis. The method is characterized by comprising the following steps: reacting 9-fluorenone and ethylene glycol monophenyl ether in hydrogen fluoride in the presence of a promoter to obtain 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene; at the end of the reaction, evaporating to reclaim hydrogen fluoride from the reaction system, diluting residues with alkaline liquid; extracting, washing and re-crystallizing to obtain 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene. The method has the advantages of use of low-price and easily available raw materials, high reaction yield, convenience in acid catalyst reclamation, generation of less 'three waste', environmental friendliness and the like, and has a high industrial application value.

Owner:ZHEJIANG ZHONGXIN FLUORIDE MATERIALS CO LTD

Rustproof type special conductive printing ink and preparation method thereof

InactiveCN104312272APromote environmental protectionAnti-rustInksEthylene glycol monophenyl etherAcrylic resin

The invention relates to a special printing ink and particularly relates to a rustproof type special conductive printing ink and a preparation method thereof. The printing ink comprises the following raw materials in parts by weight: 2 to 3 parts of inositol hexaphosphate, 3 to 4 parts of azone, 20 to 30 parts of a 400-mesh stannic oxide powder, 3 to 5 parts of ferrocene, 50 to 60 parts of epoxy acrylic resin, 12 to 18 parts of a DBE solvent, 10 to 12 parts of ethyl alcohol, 1 to 2 parts of ethylene glycol monophenyl ether, 16 to 20 parts of vinegar naphtha, 1 to 2 parts of 2,5-ditert-butylhydroquinone and 2 to 4 parts of an additive. The printing ink provided by the invention takes the epoxy acrylic resin as a connecting material, and adopts the environment-friendly and low-toxicity solvent, the ferrocene and the tin oxide in the raw materials are excellent in electric conductivity and have high thermal stability, the prepared printing ink is stable and uniform in electric conductivity and also has a certain rustproof property, and has a good adhesive power to a metal base material, the material surface seepage force is strong, the curing speed is fast, and the special printing ink is particularly suitable for being used for materials such as printed circuits, electric plates, electroplated bottom layers and the like.

Owner:合肥宏图彩印有限公司

Stripping liquid composition for photoresist

InactiveCN1402089AAggressiveInvasiveness does not produceSemiconductor/solid-state device manufacturingPhotosensitive material processingSolubilityEthylene glycol monophenyl ether

Provided is an exfoliating solution composition for photoresist, which is excellent in solubility and exfoliating property and has the low corrosiveness against metal wires and minimizes the impregnation into O-rings and pipe lines and has low volatility and low toxicity which minimizes the environmental pollution and the toxicity problems for the operators. The exfoliating solution composition comprises 10-40wt% of an organic amine compound and 10-80wt% of at least one protogenic polar solvent selected from the group consisting of ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, ethylene glycol monobutyl ether, ethylene glycol monophenyl ether, butyl carbitol, diethylene glycol monoethyl ether, and etc., wherein the composition always contains at least 5-30wt% of dipropylene glycol monomethyl ether and / or dipropylene glycol monomethyl ether acetate as a low toxic / hydrophilic polar solvent in the polar solvent.

Owner:DUKSUNG

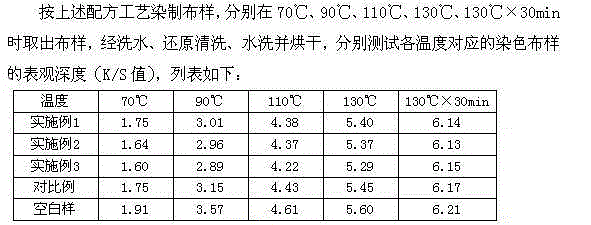

A kind of environment-friendly high-temperature leveling agent and preparation method thereof

ActiveCN103790043BMeet the needs of environmentally friendly and efficient high temperature leveling agentThe group ratio is reasonableDyeing processEthylene glycol monophenyl etherDiphenyl ether

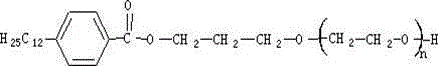

The invention discloses an environment-friendly high-temperature leveling agent, which solves the problems of poor environmental protection, poor leveling property and dyeing penetration, and unsatisfactory leveling effect existing in the leveling agent of the prior art. It is mixed with different components: dodecyl propylene glycol benzoate polyoxyethylene ether 45~50%, sodium dodecyl diphenyl ether disulfonate 35~45%, ethylene glycol monophenyl ether 10~ 15%, the sum of the above components is 100%. The environment-friendly high-temperature leveling agent of the invention has the advantages of simple components, low cost, environmental protection, good leveling property and penetrating property. The invention also discloses a preparation method of an environment-friendly high-temperature leveling agent, first preparing polyoxyethylene dodecyl benzoate polyoxyethylene ether, and then combining Sodium diphenyl ether disulfonate and ethylene glycol monophenyl ether can be mixed according to the proportion. The preparation method of the invention has simple process steps and high process controllability.

Owner:HANGZHOU MEIGAO HUAYI CHEM

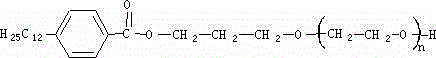

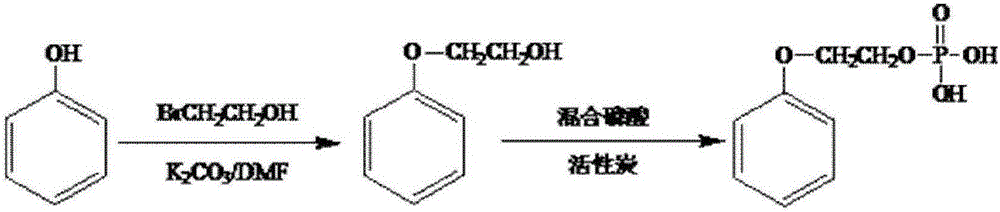

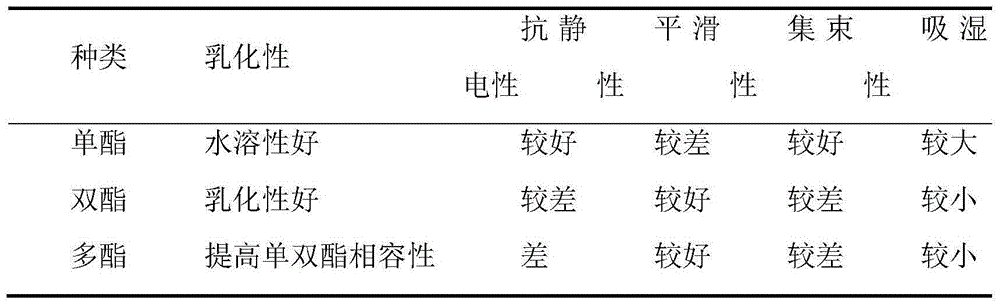

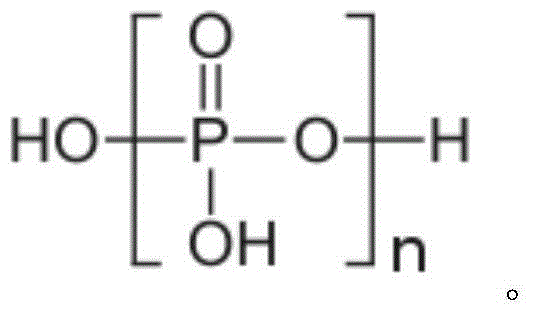

Preparation method of ethylene glycol monophenyl ether phosphomonoester surfactant

ActiveCN105080421AGood alkali resistanceImprove permeabilityTransportation and packagingMixingEthylene glycol monophenyl etherPolymer science

The invention discloses a preparation method of ethylene glycol monophenyl ether phosphomonoester surfactant and belongs to the technical field of surfactant. The preparation method disclosed by the invention comprises the steps of mixing phenol with 2-bromoethanol, dissolving the mixture in dimethylformamide, then adding and uniformly agitating potassium carbonate for reaction, adding distilled water to separate liquid, and increasing the temperature of solution at a lower layer to 160 to 180 DEG C to remove residual dimethylformamide in the solution; then adding polyphosphoric acid into the solution, agitating the solution and increasing the temperature to 60 to 80 DEG C, then adding 1.65 to 5g of catalyst for reaction, adding and uniformly agitating P2O5 for reaction, and adding distilled water with volume of 3 to 5 percent of total volume of the solution to perform hydrolysis for 1 to 3h at 60 to 80 DEG C to obtain the ethylene glycol monophenyl ether phosphomonoester surfactant. The preparation method of ethylene glycol monophenyl ether phosphomonoester surfactant has the advantages that the conversion rate of the prepared ethylene glycol monophenyl ether phosphomonoester is high, the monoester content highly reaches 86 to 86 percent, the alkali resistance of the surfactant is extremely high and the permeability is excellent.

Owner:马鞍山市恺鸾鑫实业有限责任公司

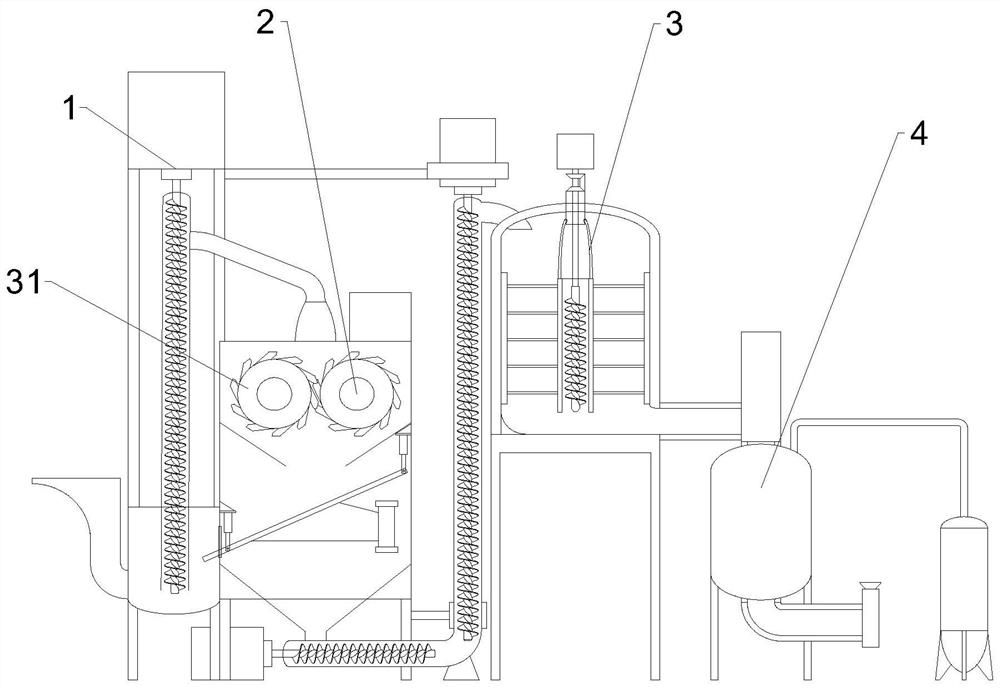

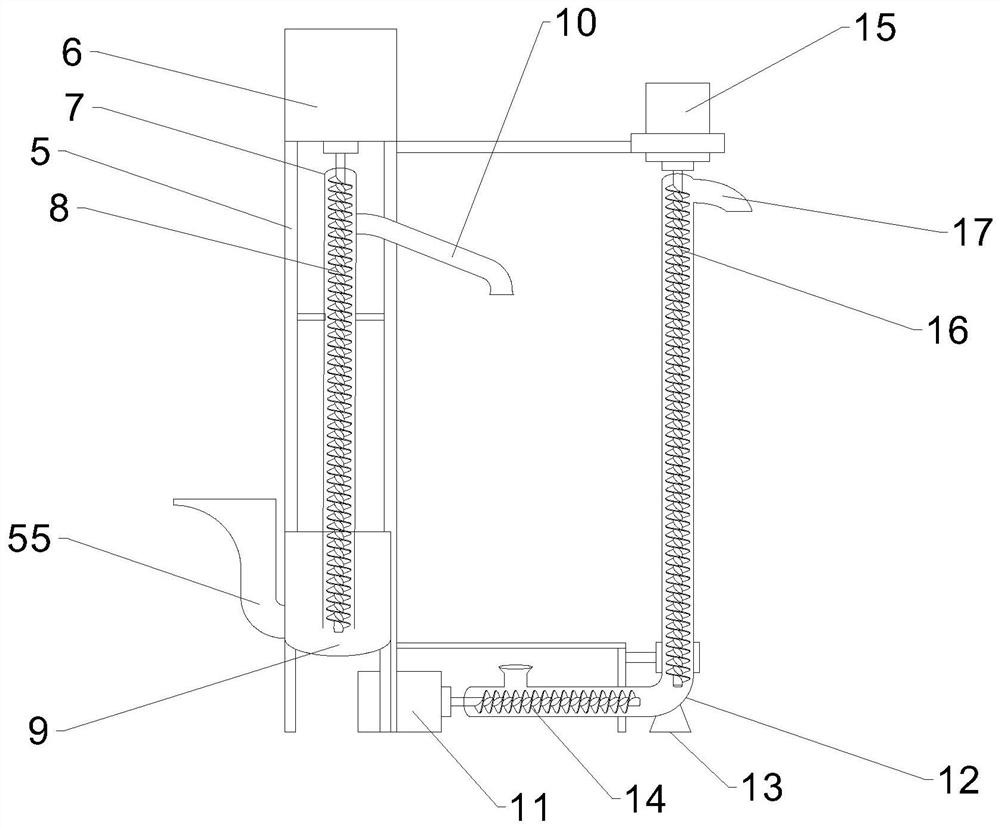

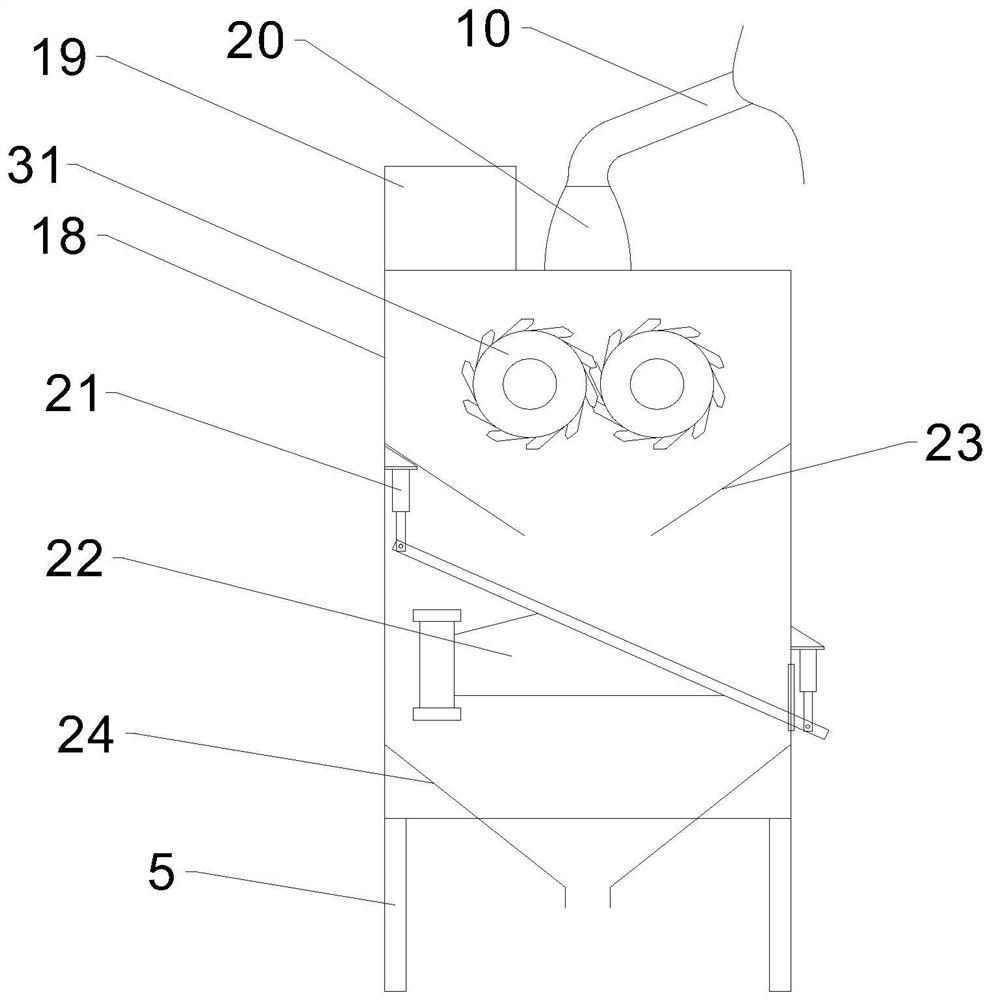

High-toughness halogen-free low-smoke flame-retardant power tube and preparation method thereof

PendingCN113087995ACrushed fullyStir wellGrain treatmentsTubular articlesEthylene glycol monophenyl etherMelting tank

The invention discloses a high-toughness halogen-free low-smoke flame-retardant power tube and a preparation method thereof. Modified resin is prepared from the following raw materials in parts by weight: 75-90 parts of isotactic polyethylene resin, 8-11 parts of ethylene glycol monophenyl ether superfine powder, 4-6 parts of nitrile rubber, 4-6 parts of halogen-free flame retardant powder, 1-4 parts of a synergistic flame retardant and 6-18 parts of ultrahigh molecular weight polyethylene resin. Raw material particles with overlarge particle sizes are conveyed into a material storage box to be crushed again, the screened raw materials are conveyed into a mixing mechanism, the raw materials entering a material mixing tank are mixed uniformly through circular stirring, the raw material particles entering a melting tank are subjected to circular stirring from inside to outside, the melting tank is kept vacuum through a vacuum pump, the melting speed of the raw material particles is increased, and the high-toughness halogen-free low-smoke flame-retardant electric power tube is obtained through extrusion, so that the situation that the performance of the electric power tube is uneven due to uneven raw materials is avoided, and the yield of the electric power tube is greatly increased.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Preparation method of dihydroxy oxethyl fluorene

InactiveCN103058833AIncrease production capacityEasy to useEther separation/purificationOrganic compound preparationEthylene glycol monophenyl etherChemical synthesis

The invention belongs to the field of chemical synthesis, and relates to a preparation method of dihydroxy oxethyl fluorine. The method comprises the following steps of: executing condensation reaction of ethylene glycol monophenyl ether and 9-fluorenone in the presence of catalyst mercaptoethanol, extracting and purifying the reaction liquid by water-organic solvent, and then, obtaining the target product after recrystallization. With the preparation method provided by the invention, the reaction time is reduced, the yield is improved, the crystal form and the liquidity of products are improved, the solvent of a single type is more beneficial for recycling, and the technical operation is simplified, so that the preparation method is suitable for industrial production.

Owner:常州市正锋光电新材料有限公司

Water-based flame-retardant damping paint

InactiveCN107383977APlay a damping effectGood compatibilityFireproof paintsEthylene glycol monophenyl etherWater based

The invention discloses water-based flame-retardant damping paint, and belongs to the technical field of paint. A preparation method of the water-based flame-retardant damping paint comprises the steps of preparing mixed powder by taking mica, bentonite and the like as raw materials, performing mixed dispersion with water and cetyl trimethyl ammonium bromide to obtain a suspension, performing centrifugal separation with castor oil and dimethyl carbinol, collecting a precipitate, performing drying to obtain a damping filler, adding the damping filler to epoxy resin, grafting an acrylic acid monomer, performing rotary evaporation to obtain a damping filler modified resin emulsion, preparing modified guar gum by taking guar gum as a raw material, mixing the water, ethylene glycol monophenyl ether, a defoaming agent and the like, adding ground calcium carbonate, expanded graphite and the like, performing grinding to obtain slurry, mixing the slurry with the damping filler modified resin emulsion, the modified guar gum and the like, and performing discharge to obtain the water-based flame-retardant damping paint. The prepared damping paint has the advantages of good low-temperature damping performance, wide damping temperature range and good flame retardance, is moderate in drying time and better in workability, and has a wide application prospect.

Owner:常州三伊化工有限公司

Aerosol type wax-free paint remover

InactiveCN107641369AReduce dosageInhibit swellingChemical paints/ink removersEthylene glycol monophenyl etherMethanol

The invention discloses an aerosol type wax-free paint remover. A formula of the aerosol type wax-free paint remover comprises the following components in parts by weight: 16.0 to 24.0 parts of an environment-friendly high-boiling-point solvent AGSE, 2.0 to 6.5 parts of solvent oil, 0.8 to 3.6 parts of ethylene glycol monophenyl ether, 2.0 to 4.0 parts of propylene glycol monomethyl ether, 26.0 to40.0 parts of dichloromethane, 5.0 to 12.0 parts of methanol, 2.0 to 9.0 parts of formic acid microcapsules, 1.5 to 3.5 parts of a thickening agent and 12.0 to 26 parts of a propellents. With adoption of the technical scheme, the paint remover has the following advantages: 1, a low-boiling-point solvent and a high / medium-boiling-point solvent are compounded to cooperatively reduce the volatilization speed rate and achieve extremely high dissolving power and penetrability; 2, by dual formic acid microcapsulation, a tank body is prevented from being corroded by formic acid, a paint removing effect is enhanced; and the stability of the product is improved; 3, the thickening agent is added to retard product loss and increase the utilization rate of the product, and no wax is contained, so that influence on recoating after complete flushing is eliminated; 4, by vaporization heat absorption of the propellents, the surface temperature of a workpiece is reduced, the volatilization speed of the product is low, and the characteristics of flexibility and convenience for construction and good atomization are achieved.

Owner:GUANGDONG SANVO CHEM IND TECH

Carbon deposit cleansing agent of engine and preparation method of carbon deposit cleansing agent

The invention belongs to the field of cleansing agents of an engine, and particularly relates to a carbon deposit cleansing agent of an engine and a preparation method of the carbon deposit cleansingagent. The carbon deposit cleansing agent comprises the following raw materials in parts by mass of 28-64 parts of diethylene glycol ether acetate, 28-65 parts of diethylene glycol monophenyl ether, 28-65 parts of N-methyl pyrrolidone, 2-8 parts of a lactic acid solution, 1-5 parts of Long-chain carboxylate polyoxyethylene-18, 1-6 parts of isothiazolinone, and 1-9 parts of an alkaline solution. The carbon deposit cleansing agent disclosed by the invention adopts a manner that a positive ion surface active agent is collocated with the diethylene glycol ether acetate, the diethylene glycol monophenyl ether and the N-methyl pyrrolidone, so that the problems that in the prior art, when carbon deposit is washed with a solvent, an anionic surface active agent and a plasticizer, each component ofthe engine is subjected to dual corrosion, the engine coating is peeled off, and ternary noble metals are peeled off are effectively solved; the engine carbon deposit cleansing agent is friendly to environment and the engine; and the carbon deposit removing effect is good, and the effect of instantly peeling the carbon deposit off can be achieved.

Owner:广州市泰戈尔生物科技有限公司

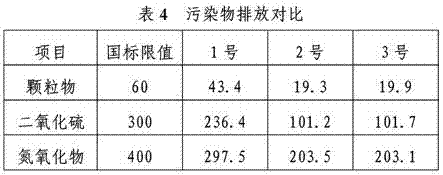

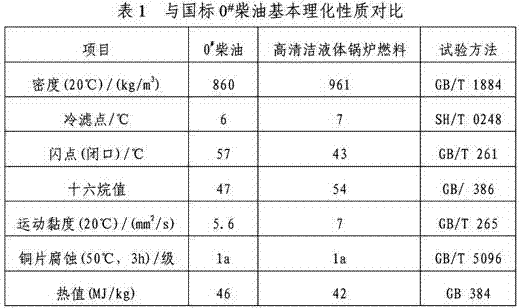

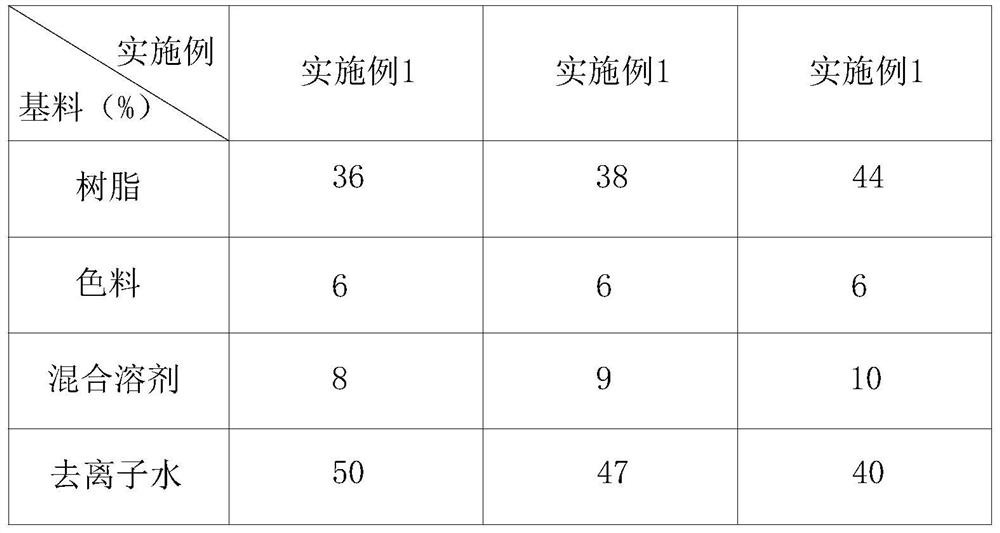

High-cleanness liquid boiler fuel

InactiveCN106947549AEmission reductionHigh calorific valueLiquid carbonaceous fuelsEthylene glycol monophenyl etherAlkylphenol

The invention relates to high-cleanness liquid boiler fuel. The fuel is prepared by blending following raw materials by volume: 60-80% of polymethoxymethylal, 13-29.5% of heavy naphtha, 5-10% of fatty acid methyl ester and 0.5-2% of an additive. The additive includes, by mass, 10-20% of alkylphenol barium, 10-20% of 2,6-bis(1,1-dimethylethyl)-4-methylphenol, 50-75% of nitropropane, 2.5-5% of ethylene glycol monophenyl ether, 1.25-2.5% of trimethyl borate and 1.25-2.5% of N,N'-bis(salicylidene)-1,2-propanediamine. The calorific value of the fuel is substantially equivalent to the calorific value of Chinese national standard 0# diesel oil, consumption amounts of the fuel and the diesel oil are at the same level, but SO2 in combustion emission of the fuel is reduced by about 60% than that of the diesel oil, NOx in combustion emission of the fuel is reduced by 30% or above than that of the diesel oil, and particles in combustion emission of the fuel are reduced by about 50% or above than those of diesel oil, and therefore cleanness of the fuel is significantly improved.

Owner:TAIYUAN NORMAL UNIV

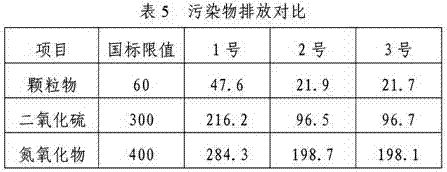

Cathode electrophoretic coating and preparation method thereof

InactiveCN113817373AImprove heat resistanceReduce surface tensionPolyurea/polyurethane coatingsPaints for electrolytic applicationsEthylene glycol monophenyl etherEpoxy

The invention provides a cathode electrophoretic coating and a preparation method thereof, and belongs to the technical field of electrophoretic coatings. The cathode electrophoretic coating is prepared from the following raw materials in percentage by mass: 35-45% of resin, 5-6% of a pigment, 7-10% of a mixed solvent and 40-55% of deionized water, the resin is a mixture of acrylic resin, epoxy resin and polyurethane, and the mixing ratio of the acrylic resin to the epoxy resin to the polyurethane is 1: 1: 1. The pigment is a mixture of an organic solvent, a container color pigment, an extender pigment and an antirust pigment, the organic solvent is specifically ethylene glycol monophenyl ether, is colorless transparent liquid and is used for improving the smoothness and corrosion resistance of the coating, the extender pigment is orthosilicate and is of a flaky particle structure, and the opacity to ultraviolet rays can enhance the crack resistance and durability of the electrophoretic paint film. When the electrophoretic coating is prepared, the finishing property, wear resistance, crack resistance and heat resistance of the electrophoretic coating can be improved, and meanwhile, the adhesive force of the electrophoretic coating and a workpiece can be increased.

Owner:枣阳市旺前电泳涂料有限公司

Ultraviolet-resistant paint and preparation method thereof

InactiveCN105462373APoor resolutionSolve functionRadiation-absorbing paintsEthylene glycol monophenyl etherAntioxidant

The invention discloses an ultraviolet-resistant paint which is prepared from the following raw materials in parts by weight: 0.75-2.15 parts of anti-aging agent, 1.2-2.3 parts of ethylene glycol monophenyl ether, 4-6.7 parts of triethanolamine oleate saponin, 0.23-0.76 part of antioxidant, 0.12-0.25 part of nekal formaldehyde condensate, 3.5-5.5 parts of 2,6-tert-butyl-4-methylphenol, 4-7.5 parts of sodium petroleum sulfonate and 2.45-4.36 parts of palm oil sodium fatty acid methyl ester sulfonate. The ultraviolet-resistant paint solves the technical problems of poor effects and single function when the existing like products are used in polarized lenses. When being coated on sunglasses and goggles, the prepared paint has the multiple functions of increasing hardness, resisting ultraviolet rays, eliminating glare, preventing vapor and absorbing infrared rays. The paint is suitable for polaroid substrates of sunglasses, goggles and the like, solves the actual demands, and is convenient for popularization and use.

Owner:曲少春

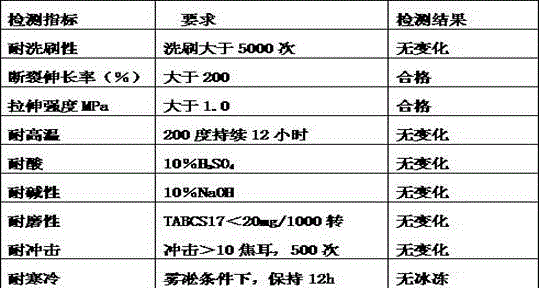

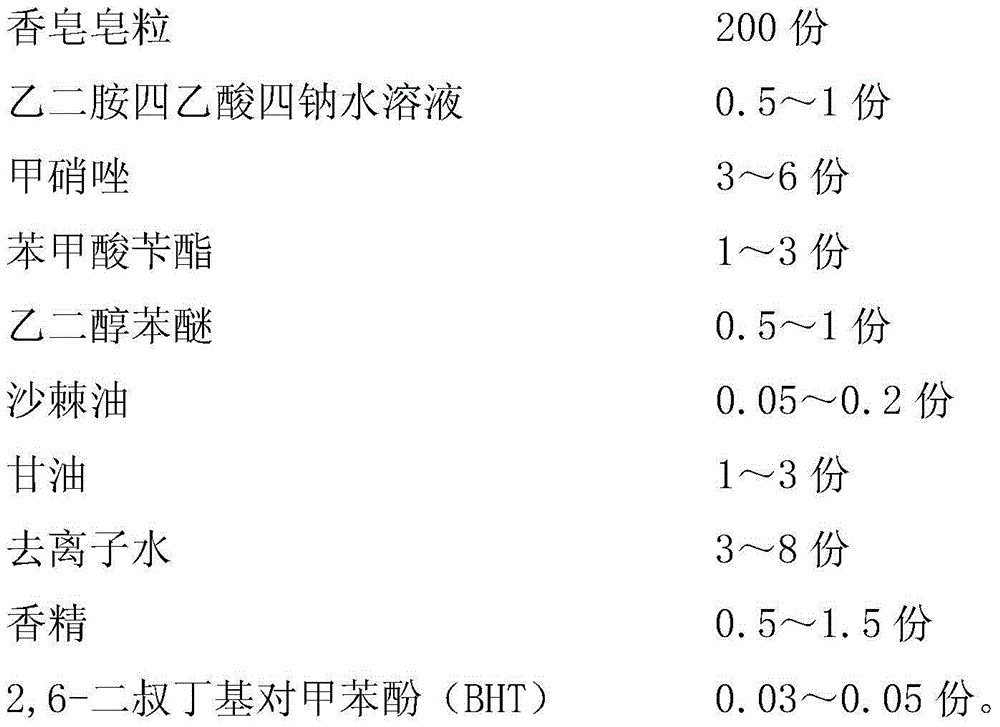

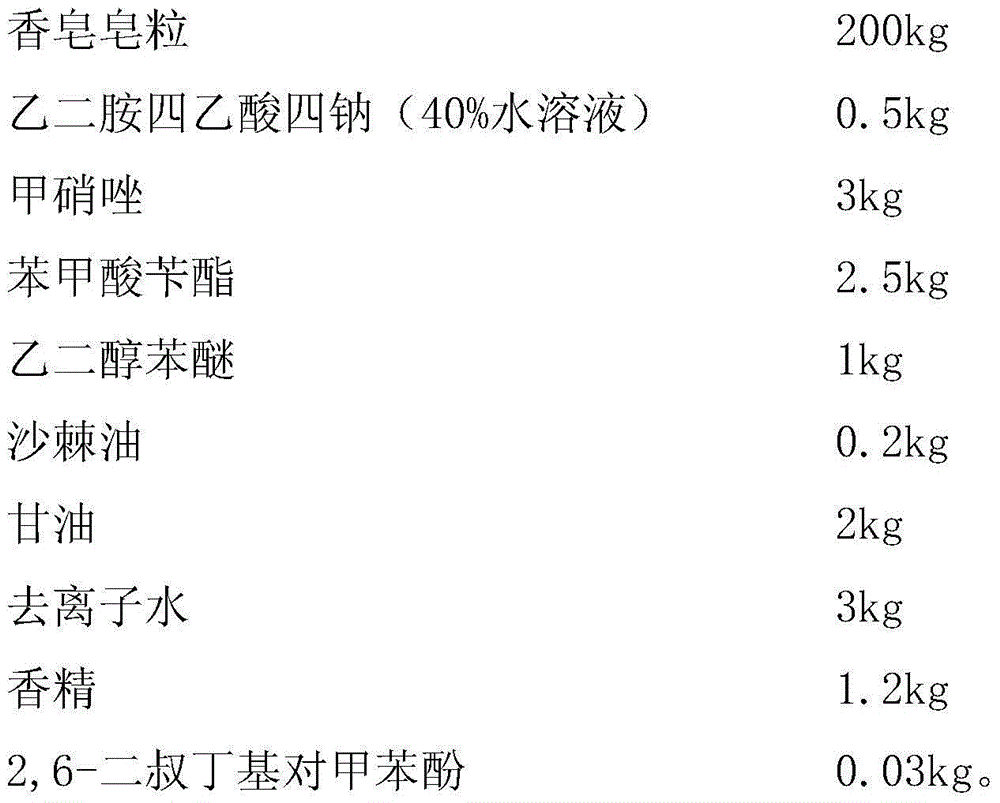

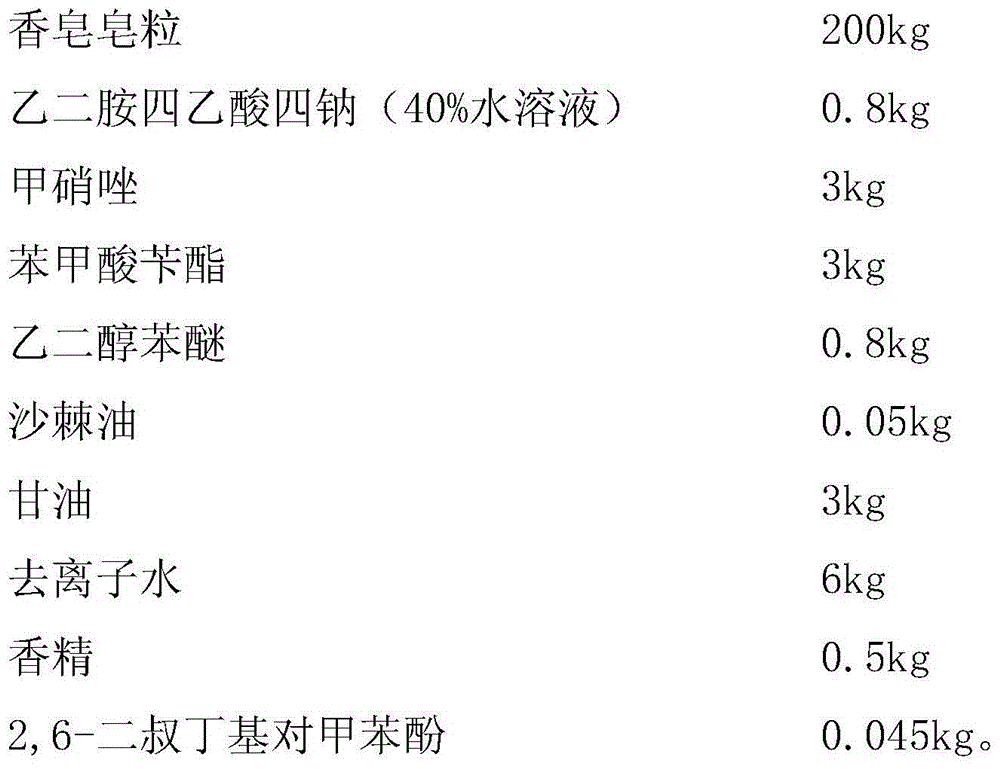

Beauty-treatment toilet medicinal soap and preparation method thereof

InactiveCN104087450AImprove repair effectStay hydratedAntibacterial agentsSoap detergents with organic compounding agentsBenzyl benzoatEthylene glycol monophenyl ether

The invention relates to a beauty-treatment toilet medicinal soap and a preparation method thereof. The beauty-treatment toilet medicinal soap is prepared from 200 parts of toilet soap grain, 0.5-1 part of tetrasodium ethylenediamine tetraacetate, 3-6 parts of metronidazole, 1-3 parts of benzyl benzoate, 0.5-1 part of ethylene glycol monophenyl ether, 0.05-0.2 part of sea buckthorn oil, 1-3 parts of glycerol, 3-8 parts of deionized water, 0.5-1.5 parts of essence and 0.03-0.05 part of BHT (butylated hydroxytoluene). The preparation method comprises the following steps: adding all the raw materials except the BHT and essence into the toilet soap grain while stirring uniformly; dissolving 2,6-di-tert-butyl-p-cresol in the essence, adding the mixture, grinding the fine mixture, extruding, and carrying out strip pressing to obtain the finished product. By reasonable material selection and scientific proportioning, the beauty-treatment toilet medicinal soap has the functions of beauty treatment, cleaning and sterilization, maximizes the synergistic effect of multiple functions, lowers the production cost and improves the product quality.

Owner:ANQING YIZHIMEI CHEM

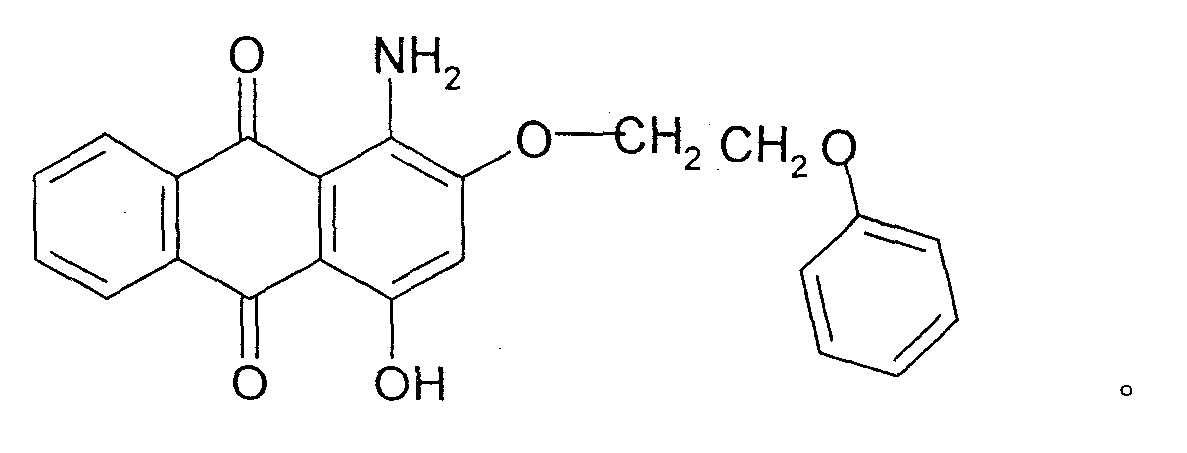

Reagent for three-classification blood cell analyzer

InactiveCN110160941AApplicable modelsImprove performanceBiological material analysisBiological particle analysisEthylene glycol monophenyl etherPolyethylene glycol

The invention relates to a reagent for a three-classification blood cell analyzer. The reagent comprises a diluent, a hemolytic agent and a cleaning liquid. The diluent is composed of sodium chloride,disodium hydrogen phosphate, monopotassium phosphate, potassium chloride, EDTA-2Na, ethylene glycol monophenyl ether and water; the hemolytic agent consists of disodium hydrogen phosphate, monopotassium phosphate, cetyl trimethyl ammonium bromide, polyethylene glycol octylphenol ether, sodium nitrite and water; and the cleaning fluid consists of sodium chloride, sodium sulfate, an antibacterial agent and a surfactant. The prepared regent for the three-classification blood cell analyzer is low in cost and high in stability, can be universal in multiple models, is reliable in performance and meets the clinical requirements.

Owner:INST OF BASIC MEDICINE OF SAMS

Technique for synthesizing improved disperse red 191

InactiveCN101245194AAmino-hydroxy-anthraquinone dyesEthylene glycol monophenyl etherPotassium hydroxide

The invention relates to a synthesis technique improvement of disperse red 191 which takes the disperse red 60 and hexanediol monobenzyl ether of hydioquinone as raw materials, uses potassium carbonate or potassium hydroxide as an acid binding agent and uses an emulsifier of OP series as a catalyst; after the raw materials are condensed at high temperature to the terminal, the product can be segregated by methanol (or ethanol) when the temperature is cooled, and at last the product is filtrated and separated. The mother liquid is rectified to recycle the methanol (or ethanol), phenol and hexanediol monobenzyl ether of hydioquinone, and the technique improves the product quality.

Owner:亚邦化工集团有限公司

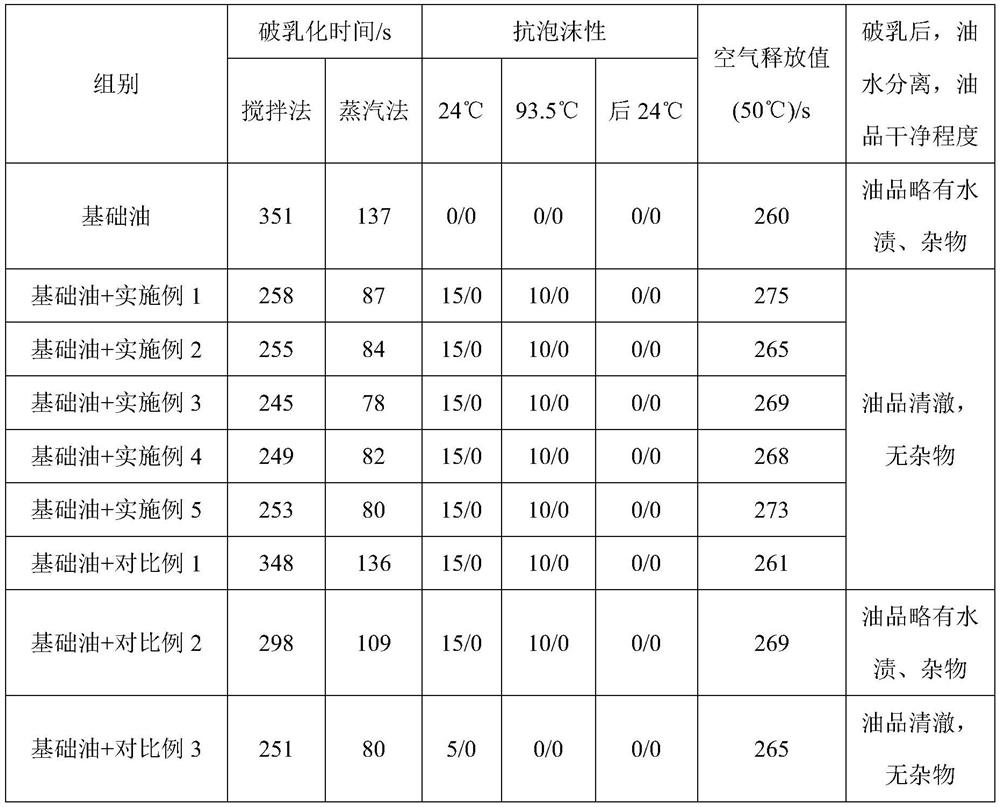

Efficient lubricating oil demulsifier and production method thereof

ActiveCN112877112ARapid demulsificationGood effectAdditivesBio-feedstockEthylene glycol monophenyl etherPhosphoric Acid Esters

The invention discloses an efficient lubricating oil demulsifier. The efficient lubricating oil demulsifier comprises the following raw materials in parts by weight: 3 to 5 parts of a cationic demulsifier, 0.4 to 0.6 part of vegetable oil-based fatty acid methyl ester, 0.1 to 0.2 part of methyl silicone oil, 0.2 to 0.5 part of phosphate and 1 to 2 parts of ethylene glycol phenyl ether. The efficient lubricating oil demulsifier is obtained by fully mixing the cationic demulsifier, the plant oil-based fatty acid methyl ester, the methyl silicone oil, the phosphate and the ethylene glycol monophenyl ether. The demulsifier disclosed by the invention is obvious in demulsification effect and easy to produce and prepare.

Owner:哈尔滨克什顿润滑油有限公司

Ceramic tile seam detergent

InactiveCN104087431AThorough descalingCompletely anti-pollutionNon-ionic surface-active compoundsOrganic detergent compounding agentsEthylene glycol monophenyl etherCarbamate

The invention discloses a ceramic tile seam detergent which is prepared from the following raw materials: 3-4 parts of nonylphenol polyethenoxy ether, 2-4 parts of alkylphenol polyoxyethylene, 3-5 parts of castor oil polyethenoxy ether, 1-3 parts of Turkey red oil, 1-2 parts of p-toluenesulfonic acid, 2-5 parts of potassium permanganate, 3-5 parts of 4-aminobenzenesulfonic acid, 2-6 parts of tartaric acid, 3-5 parts of ethylene glycol monophenyl ether, 5-8 parts of 1,2-propanediol, 2-5 parts of thermosetting phenol aldehyde resin, 3-6 parts of polypropylene, 5-8 parts of amino resin, 5-10 parts of polycarbamate, 5-10 butyl acrylate, 3-5 parts of sodium carboxymethyl cellulose, 6-8 parts of sodium hexametaphosphate, 8-10 parts of paraffin emulsifier and 120-150 parts of deionized water. The ceramic tile seam detergent can thoroughly remove scales and resist stains and molds, and can not corrode the ceramic tile seam material; and after being applied to the ceramic tile seam, the ceramic tile seam detergent can remove dust and other oxides, can not leave wash marking after volatilization, is bright, can form a protective film on the surface, has the advantages of dirt resistance and low cost, and is convenient to use.

Owner:谢伟杰

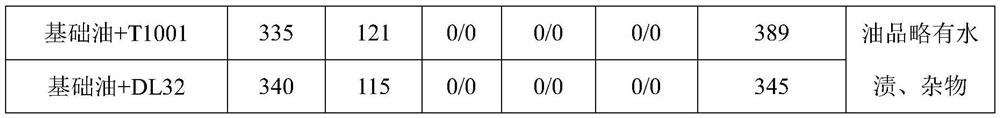

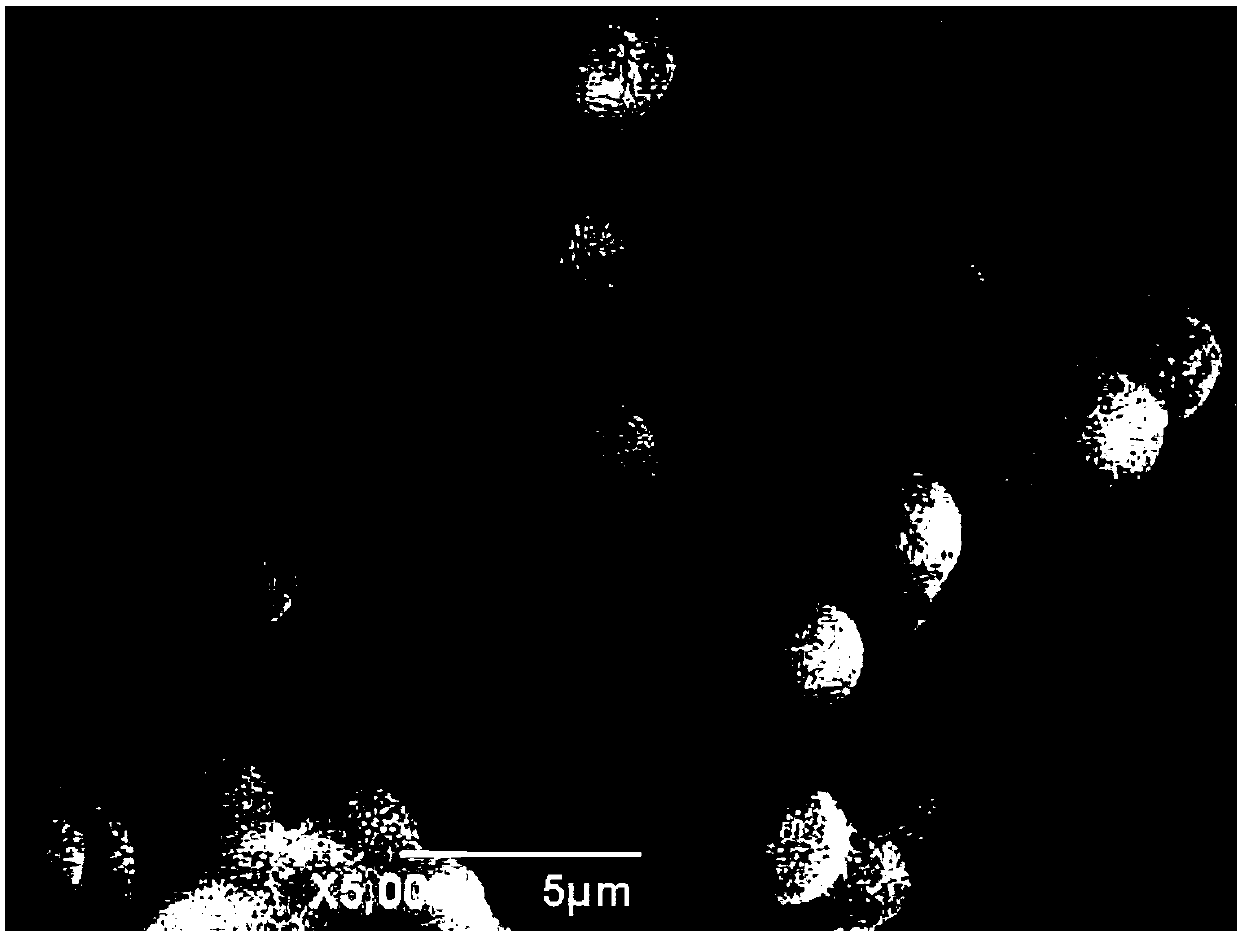

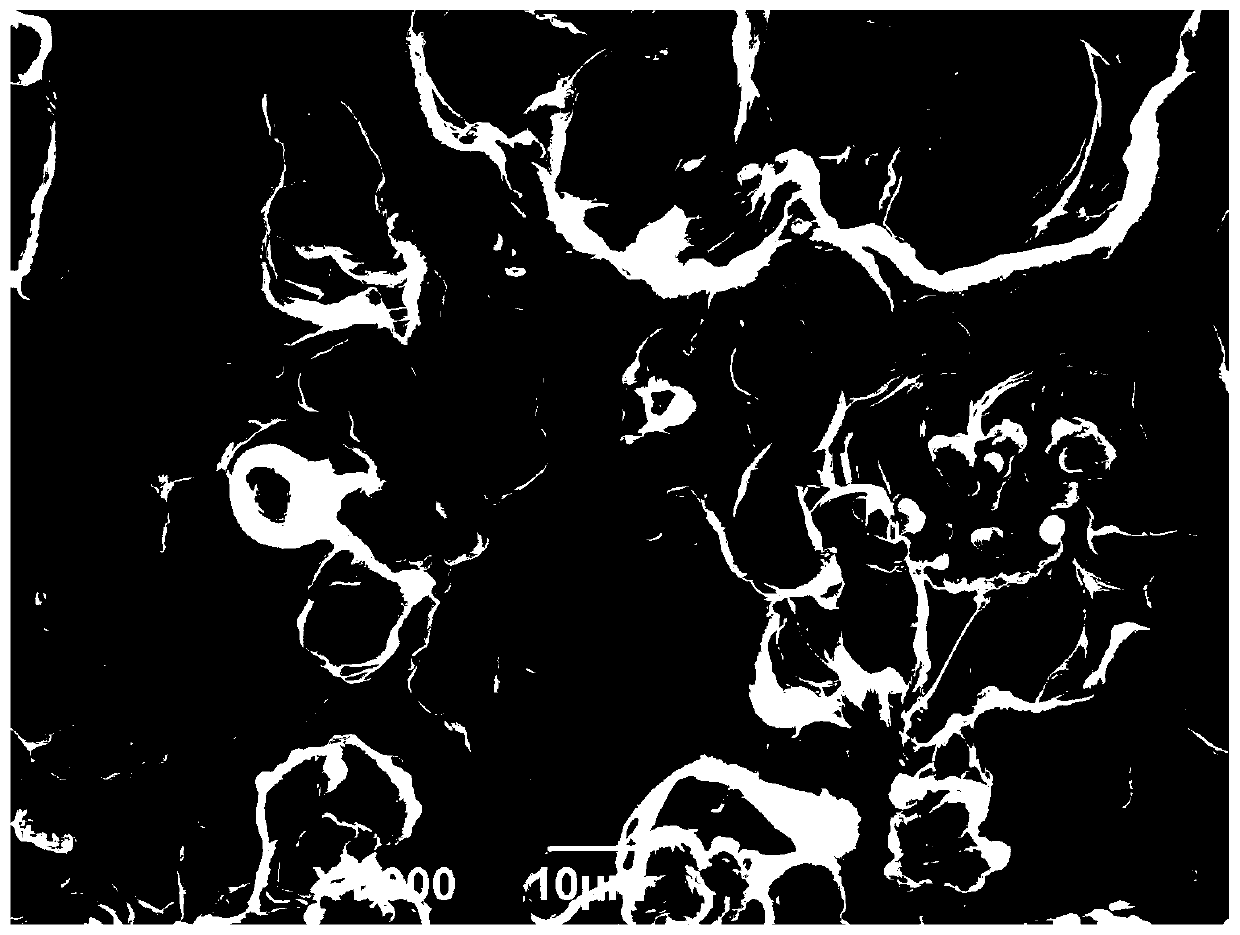

Preparation method of injection molding machine screw cleaning material

The invention discloses a preparation method of an injection molding machine screw cleaning material. The screw cleaning material is obtained by performing melt blending on a microcapsule additives and PP matrix resin according to a certain ratio and performing extrusion granulation. The microcapsule additive takes urea-formaldehyde resin as a wall material, takes a butyl phthalate, ethylene glycol monophenyl ether and n-octanol mixture as a core emulsion, and are microcapsules which are prepared under certain conditions and have a particle size of 2-3 [mu]m. The screw cleaning material has low melting energy consumption, low melt viscosity, minimal adhesive force to a barrel and a screw, good compatibility with other polymer materials, and can dissolve decomposed carbon deposited in a screw groove. Compared with commercially available professional screw cleaning materials, the screw cleaning material developed by the present invention has lower cost. Therefore, the screw cleaning material can meet the market requirements for screw cleaning material performance and price, and has market promotion and application prospects.

Owner:SHAANXI SCI TECH UNIV

A kind of preparation method of screw cleaning material of injection molding machine

Owner:SHAANXI SCI TECH UNIV

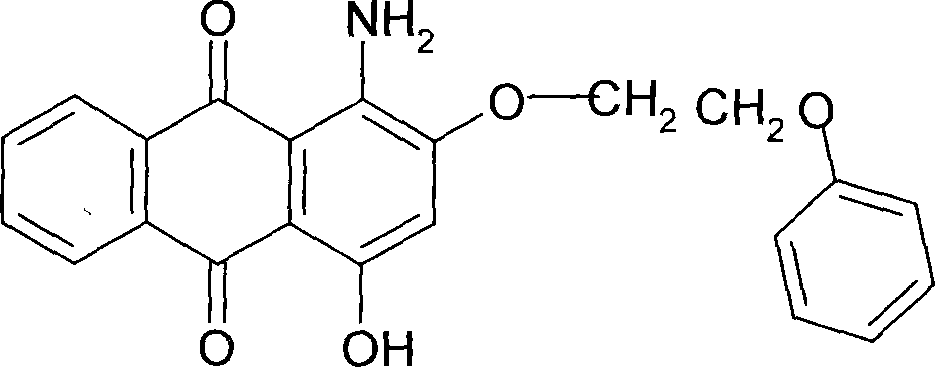

A kind of preparation method of 9,9-bis[(4-hydroxyethoxy)phenyl]fluorene

ActiveCN104030899BEasy to recycleRaw materials are cheap and easy to getOrganic chemistryOrganic compound preparationChemical synthesisEthylene glycol monophenyl ether

The invention discloses a method for preparing 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene and belongs to the technical field of chemical synthesis. The method is characterized by comprising the following steps: reacting 9-fluorenone and ethylene glycol monophenyl ether in hydrogen fluoride in the presence of a promoter to obtain 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene; at the end of the reaction, evaporating to reclaim hydrogen fluoride from the reaction system, diluting residues with alkaline liquid; extracting, washing and re-crystallizing to obtain 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene. The method has the advantages of use of low-price and easily available raw materials, high reaction yield, convenience in acid catalyst reclamation, generation of less 'three waste', environmental friendliness and the like, and has a high industrial application value.

Owner:ZHEJIANG ZHONGXIN FLUORIDE MATERIALS CO LTD

Environment-friendly polyaniline anticorrosion flame-retardant coating

InactiveCN104341951AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEthylene glycol monophenyl etherEpoxy

The invention discloses an environment-friendly polyaniline anticorrosion flame-retardant coating comprising a component A and a component B, and the weight ratio of the component A to the component B is 10:1 to 20:1. The component A is prepared from the following components: 1, 45 g of liquid epoxy resin E56; 2, 3 g of diethylene glycol dibenzoate; 3, 0.5 g of OP-10; 4, 10 g of n-amyl alcohol; 5, 3 g of ammonium persulfate; 6, 1.5 g of distilled water; 7, 1 g of a 0.4 mol / L camphorsulfonic acid aqueous solution; 8, 10 g of phenylamine; 9, 0.5 g of methyl silicone oil; and 10, 4 g of neopentyl glycol diglycidyl ether. The component B is composed of the following components: 110 g of liquid aliphatic polyamine, 30 g of polyaniline, 5 g of xanthan gum, 10 g of ethylene glycol monophenyl ether, 5 g of methylcellulose, and 5 g of turpentine silicone oil. The coating has the advantages of high polyaniline content, good corrosion resistance, no pollution, low cost and the like.

Owner:QINGDAO YIQUN PANT GRP

Heat-resistant alcohol-soluble self-adhesive paint for self-adhesive insulated winding wire and preparation method thereof

InactiveCN103694756AHigh withstand voltageGood high frequency performanceCoatingsEpoxyEthylene glycol monophenyl ether

The invention discloses heat-resistant alcohol-soluble self-adhesive paint for a self-adhesive insulated winding wire and a preparation method thereof. The heat-resistant alcohol-soluble self-adhesive paint is prepared from 10-15 parts by weight (kg) of ethyl methacrylate, 12-14 parts by weight (kg) of butyl acrylate, 4-6 parts by weight (kg) of zirconia, 7-9 parts by weight (kg) of ethylene glycol monophenyl ether, 12-15 parts by weight (kg) of nylon12, 50-55 parts by weight of isophorone, 30-35 parts by weight (kg) of benzyl alcohol, 12-15 parts by weight (kg) of E51 epoxy resin, 8-10 parts by weight (kg) of montmorillonite, 3-4 parts by weight (kg) of mercaptopolysiloxane, 3-5 parts by weight (kg) of isocyanate, 12-15 parts by weight (kg) of polyoxymethylene, 12-13 parts by weight (kg) of naphthenic oil, 3-4 parts by weight (kg) of petroleum resin, 10-12 parts by weight (kg) of dipentaerythritol hexaacrylate, 7-9 parts by weight (kg) of an assistant, 80-90 parts by weight (kg) of a mixture of m-cresol and p-cresol, and 40-50 parts by weight (kg) of xylene. The preparation method has simple processes. The outer surface of a three-layer insulated winding wire is coated with the heat-resistant alcohol-soluble self-adhesive paint so that a self-adhesive three-layer insulated winding wire is obtained. A frameless coil prepared from the self-adhesive three-layer insulated winding wire has the advantages of high voltage resistance, good high-frequency performances, good thermostability and good wear resistance.

Owner:铜陵天河特种电磁线有限公司

A method for improving the formulation of adhesive for sizing by utilizing polyurethane and ethylene glycol phenyl ether

ActiveCN105274844BImprove sizing effectHigh affinityVegetal fibresEthylene glycol monophenyl etherYarn

The invention relates to a method for improving a formula of a binder for sizing by using ethylene glycol monophenyl ether and polyurethane and belongs to the field of textile processing. According to the method, the polyurethane and the ethylene glycol monophenyl ether are added into the formula of the binder for sizing, i.e., phosphate starch, acrylate and water, wherein the mass of the phosphate starch accounts for 3-5% the total mass of the binder for sizing, the mass of the acrylate accounts for 3-5% the total mass of the binder for sizing, the mass of the polyurethane accounts for 0.1-1% the total mass of the binder for sizing, and the mass of the ethylene glycol monophenyl ether accounts for 0.1-2% the total mass of the binder for sizing. The polyurethane and the ethylene glycol monophenyl ether are added into the binder for mixed sizing, i.e., the phosphate starch and the solid acrylate, so that the permeability of the binder for mixed sizing and the binder-for-sizing coating property of yarn surface can be obviously improved, and thus, the properties of a size film are improved.

Owner:WUHAN TEXTILE UNIV

Anti-separation and anti-corrosion environment-friendly polyaniline coating

InactiveCN104341969AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEthylene glycol monophenyl etherAniline

The invention discloses an anti-separation and anti-corrosion environment-friendly polyaniline coating comprising a component A and a component B, and the weight ratio of the component A to the component B is 10:1 to 20:1. The component A is prepared from the following components: 1, 73 g of liquid epoxy resin E44; 2, 13 g of dioctyl phthalate; 3, 2.5 g of OP-10; 4, 8 g of n-butyl alcohol; 5, 4 g of ammonium persulfate; 6, 2 g of distilled water; 7, 0.5 g of a 0.8 mol / L camphorsulfonic acid aqueous solution; 8, 6 g of phenylamine; 9, 0.8 g of methyl silicone oil; and 10, 9 g of neopentyl glycol diglycidyl ether. The component B is composed of the following components: 140 g of liquid aliphatic polyamine, 10 g of polyaniline, 10 g of quartz sand, 7 g of ethylene glycol monophenyl ether, 12 g of a talcum powder, and 3 g of ester gum. The coating has the advantages of high polyaniline content, good anti-corrosion property, no pollution, low cost and the like.

Owner:QINGDAO YIQUN PANT GRP

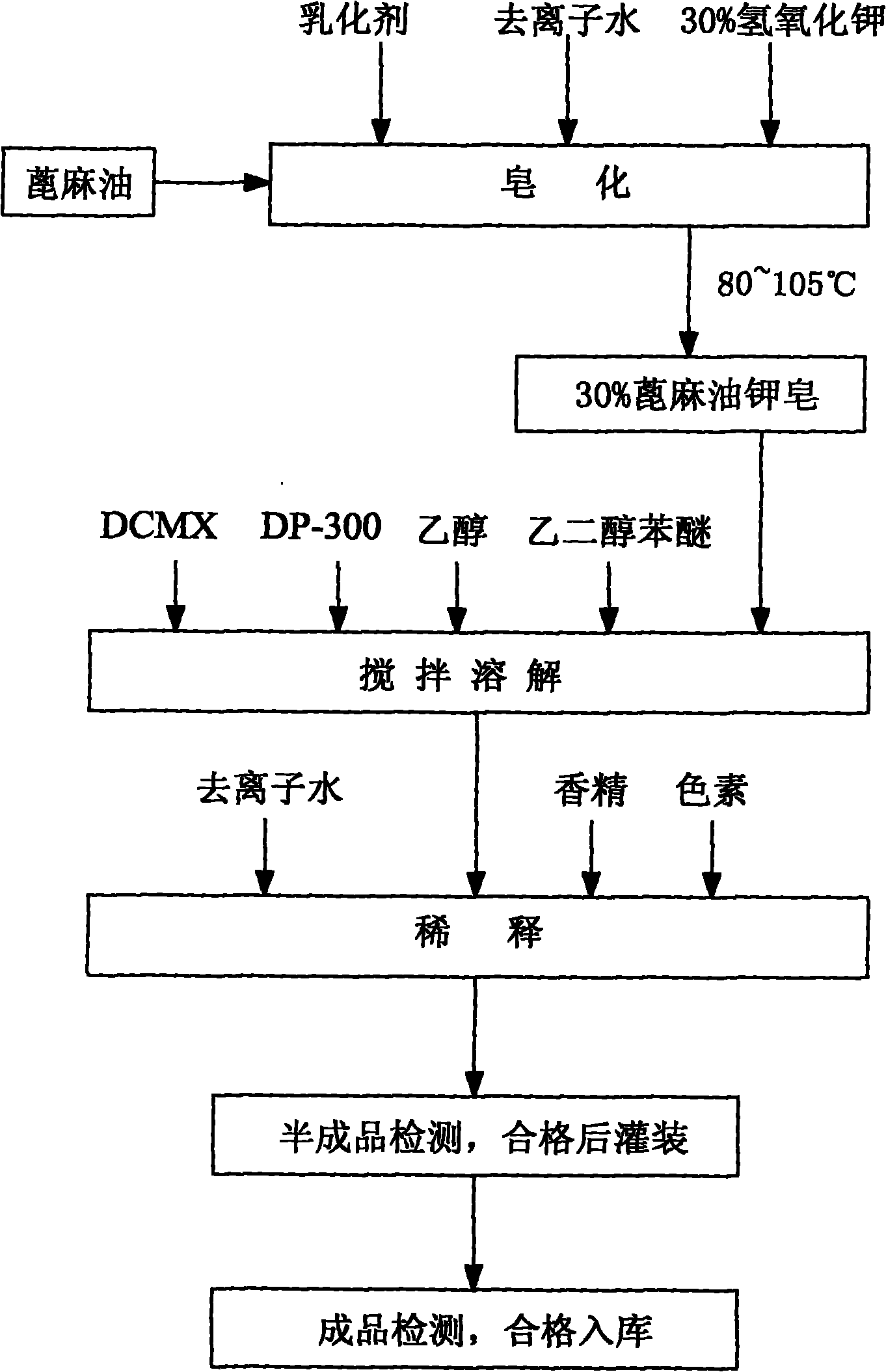

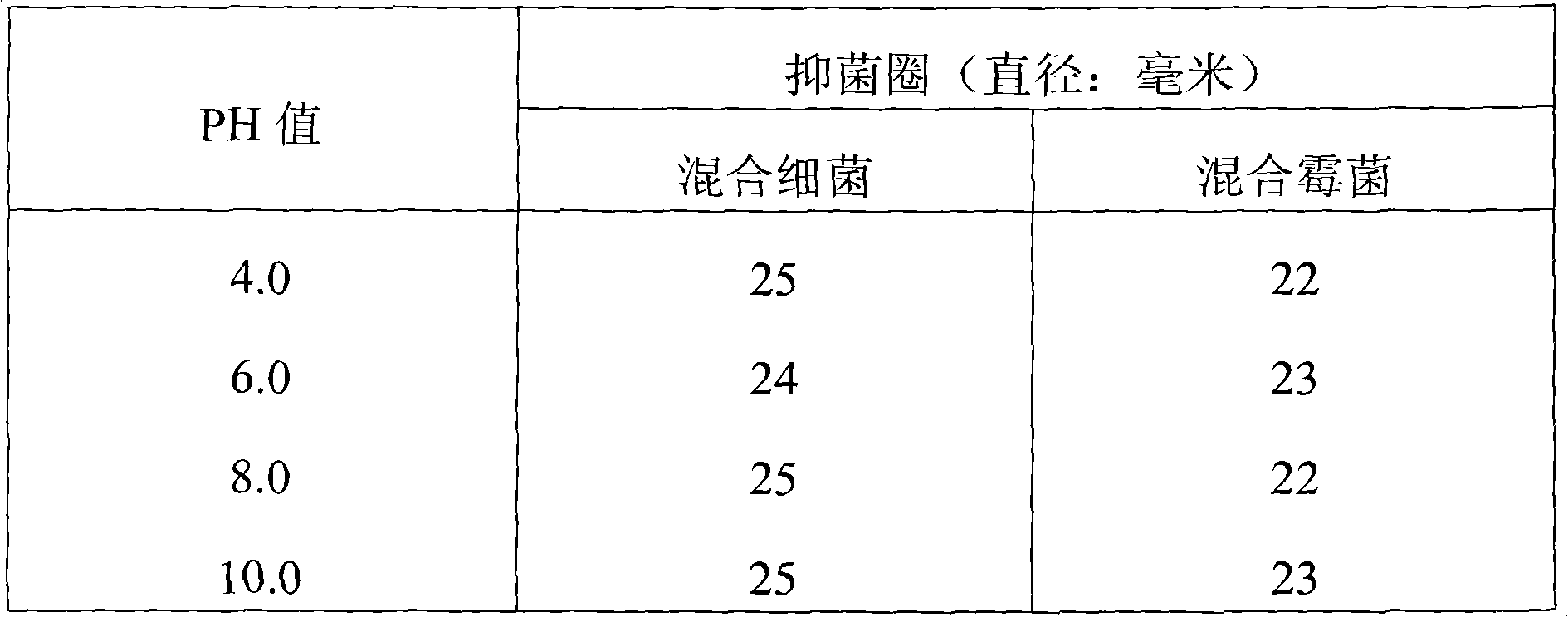

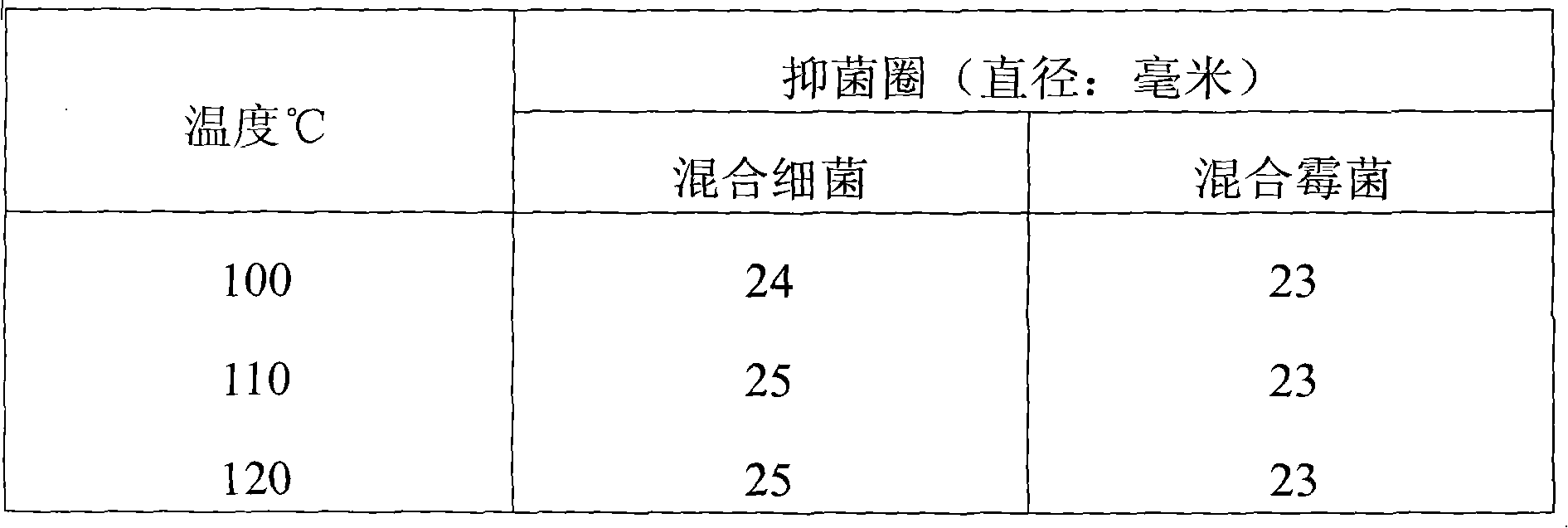

Production process of disinfection mould-proof liquid

InactiveCN101731213BInhibition of reproductionGrowth inhibitionBiocideFungicidesEthylene glycol monophenyl etherMinimum inhibitory concentration

Owner:JIANGSU HELANG BIOLOGICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene Method for preparing 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/086a5d27-4106-4340-a6a4-0927f2a5be7f/BDA0000516977770000011.PNG)

![Method for preparing 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene Method for preparing 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/086a5d27-4106-4340-a6a4-0927f2a5be7f/BDA0000516977770000012.PNG)

![Method for preparing 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene Method for preparing 9,9-bis[(4-hydroxy oxyethyl) phenyl] fluorene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/086a5d27-4106-4340-a6a4-0927f2a5be7f/BDA0000516977770000021.PNG)

![A kind of preparation method of 9,9-bis[(4-hydroxyethoxy)phenyl]fluorene A kind of preparation method of 9,9-bis[(4-hydroxyethoxy)phenyl]fluorene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/136bcc2f-ff31-4af0-baac-ff45a7909f13/BDA0000516977770000011.PNG)

![A kind of preparation method of 9,9-bis[(4-hydroxyethoxy)phenyl]fluorene A kind of preparation method of 9,9-bis[(4-hydroxyethoxy)phenyl]fluorene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/136bcc2f-ff31-4af0-baac-ff45a7909f13/BDA0000516977770000012.PNG)

![A kind of preparation method of 9,9-bis[(4-hydroxyethoxy)phenyl]fluorene A kind of preparation method of 9,9-bis[(4-hydroxyethoxy)phenyl]fluorene](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/136bcc2f-ff31-4af0-baac-ff45a7909f13/BDA0000516977770000021.PNG)