Water-based flame-retardant damping paint

A damping coating and damping filler technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of long drying time, poor low-temperature damping performance, and poor flame-retardant performance of coatings, and achieve widening high damping temperature range and excellent damping performance. , enhance the effect of polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

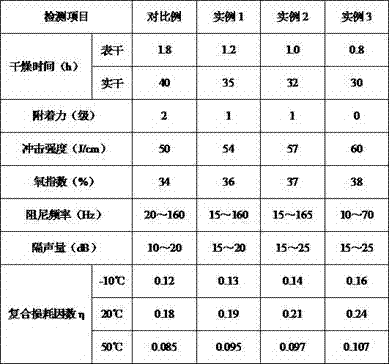

example 1

[0024] In terms of parts by weight, 30 parts of mica, 20 parts of bentonite, 20 parts of calcium silicate, 5 parts of titanium dioxide and 8 parts of talcum powder were respectively selected, mixed and added to a ball milling tank for ball milling for 2 hours. After ball milling, 300-mesh sieve was collected. To obtain the mixed powder, add the mixed powder into water according to the mass ratio of 1:5, stir and mix for 10 minutes, then add 5% cetyltrimethylammonium bromide of the mixed powder mass, ultrasonically disperse for 10 minutes under the condition of 10KHz, and obtain a suspension after dispersion Liquid, add suspension quality 3% castor oil and suspension quality 5% dimethylmethanol to the suspension, after stirring for 5min, let it stand for 2h, put it into the centrifuge after standing, and centrifuge at 2000r / min speed, Collect the precipitate and put it in an oven, dry it at 60°C for 4 hours, collect the dry powder, which is the damping filler, and select 5 parts...

example 2

[0026]In terms of parts by weight, respectively select 40 parts of mica, 30 parts of bentonite, 25 parts of calcium silicate, 8 parts of titanium dioxide and 10 parts of talcum powder, mix them and put them into a ball mill tank for ball milling for 2 hours. After ball milling, pass through a 310-mesh sieve to collect To obtain a mixed powder, add the mixed powder into water according to the mass ratio of 1:5, stir and mix for 13 minutes, then add 8% cetyltrimethylammonium bromide of the mixed powder mass, ultrasonically disperse for 13 minutes under the condition of 15KHz, and obtain a suspension after dispersion liquid, add suspension quality 4% castor oil and suspension quality 6% dimethyl methanol to the suspension, stir for 8min and then let it stand for 2h, then add it into a centrifuge after standing, and centrifuge at a speed of 2250r / min. Collect the precipitate and put it in an oven, dry it at 70°C for 5 hours, and collect the dry powder, which is the damping filler. ...

example 3

[0028] In terms of parts by weight, 50 parts of mica, 40 parts of bentonite, 30 parts of calcium silicate, 10 parts of titanium dioxide and 12 parts of talcum powder were respectively selected, mixed and added to a ball mill tank for ball milling for 3 hours. After ball milling, they were passed through a 320-mesh sieve to collect To obtain a mixed powder, add the mixed powder into water according to the mass ratio of 1:5, stir and mix for 15 minutes, then add 10% cetyltrimethylammonium bromide of the mixed powder mass, ultrasonically disperse for 15 minutes under the condition of 20KHz, and obtain a suspension after dispersion Liquid, add suspension quality 5% castor oil and suspension quality 7% dimethylmethanol to the suspension, after stirring for 10min, let it stand for 3h, put it into a centrifuge after standing, and centrifuge at a speed of 2500r / min, Collect the precipitate and put it in an oven, dry it at 80°C for 6 hours, collect the dry powder, which is the damping f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com