Anti-corrosion and high-flux double-liquid damper

A high-flux, damper technology, applied in the direction of shock absorbers, shock absorbers, solid shock absorbers, etc., can solve the problems of unsatisfactory control effect, complicated, irreversible installation and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

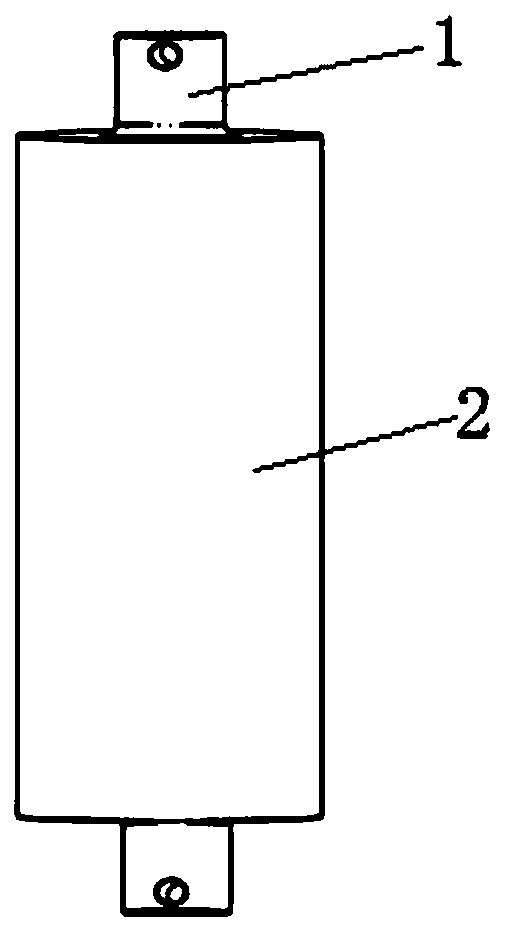

[0020] Such as Figures 1 to 5 As shown, a corrosion-resistant high-flux dual-fluid damper of the present invention includes: an outer sleeve 2 and two damping structures arranged symmetrically inside the outer sleeve 2 . The upper and lower symmetrical damping structures are connected by springs, which can better resist vibration. The damping structure includes: three magneto-rheological fluid cylinders 5 , a shear thickening fluid cylinder 3 and a stem 1 .

[0021] Such as figure 2 As shown, the shear thickening fluid cylinder 3 and the outer sleeve 2 are arranged coaxially, and the axis of the magnetorheological fluid cylinder 5 is parallel to the axis of the outer sleeve 2 . The large end of the stem 1 is arranged in the shear thickening liquid cylinder 3 , and the small end passes through the shear thickening liquid cylinder 3 and the center hole on the top of the outer sleeve 2 to protrude out of the outer sleeve 2 . The three magneto-rheological fluid cylinders 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com