High-cleanness liquid boiler fuel

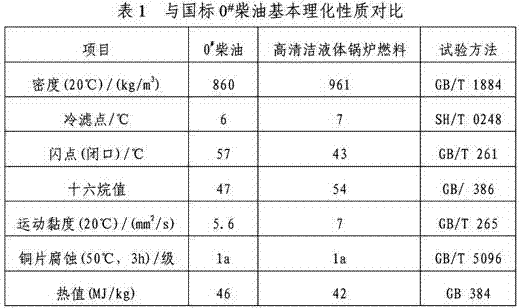

A technology for cleaning liquid and boiler fuel, applied in the field of alcohol ether fuel, can solve the problems of high ignition temperature, low calorific value, strong metal corrosion, etc., and achieve the effects of good applicability, clean emission and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 10kg of barium alkylphenol, 10kg of di-tert-butyl-p-cresol, 70kg of nitropropane, 2.5kg of ethylene glycol monophenyl ether, 1.25kg of trimethyl borate, N,N'-disalicylidene-1, 2. Add 1.25kg of propylenediamine into the mixing tank and stir well to obtain 100kg of additives.

[0033] Measure 600 liters of polymethoxymethylal, 295 liters of heavy naphtha, and 100 liters of fatty acid methyl ester, mix them evenly, add 5 liters of the above additives, and prepare 1000 liters of clean liquid boiler fuel.

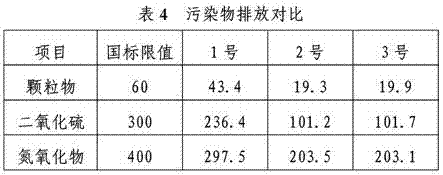

[0034] Combustion tests were carried out on three 0.7MW atmospheric pressure hot water boilers with three different fuels, and the combustion performance was tested. Among them, No. 1 is the national standard 0 # Diesel oil; No. 2 (additive) is the high-clean liquid boiler fuel prepared by the present embodiment; No. 3 (no additive) except that no auxiliary agent is added, other ingredients and consumption are the same as No. 2.

[0035] 1. Fuel consumption.

[0...

Embodiment 2

[0046] Weigh 20kg of barium alkylphenol, 20kg of di-tert-butyl p-cresol, 50kg of nitropropane, 5kg of ethylene glycol monophenyl ether, 2.5kg of trimethyl borate, N,N'-disalicylidene-1,2 Add 2.5kg of propylenediamine into the mixing tank and stir well to obtain 100kg of additives.

[0047] Measure 800 liters of polymethoxymethylal, 130 liters of heavy naphtha, and 50 liters of fatty acid methyl ester, mix them evenly, add 20 liters of the above additives, and prepare 1000 liters of clean liquid boiler fuel.

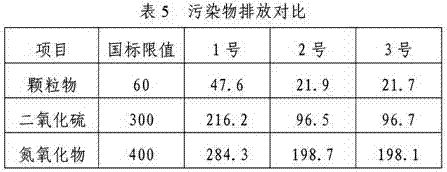

[0048] Combustion tests were carried out on three 0.7MW atmospheric pressure hot water boilers with three different fuels, and the combustion performance was tested. Among them, No. 1 is the national standard 0 # Diesel oil; No. 2 (additive) is the high-clean liquid boiler fuel prepared by the present embodiment; No. 3 (no additive) except that no auxiliary agent is added, other ingredients and consumption are the same as No. 2.

[0049] 1. Fuel consumption.

[0050] The...

Embodiment 3

[0055] Weigh 10kg of barium alkylphenol, 10kg of di-tert-butyl-p-cresol, 70kg of nitropropane, 2.5kg of ethylene glycol monophenyl ether, 1.25kg of trimethyl borate, N,N'-disalicylidene-1, 2. Add 1.25kg of propylenediamine into the mixing tank and stir well to obtain 100kg of additives.

[0056] Measure 700 liters of polymethoxymethylal, 185 liters of heavy naphtha, and 100 liters of fatty acid methyl ester, mix them evenly, add 15 liters of the above additives, and prepare 1000 liters of clean liquid boiler fuel.

[0057] Combustion tests were carried out on three 0.7MW atmospheric pressure hot water boilers with three different fuels, and the combustion performance was tested. Among them, No. 1 is the national standard 0 # Diesel oil; No. 2 (additive) is the high-clean liquid boiler fuel prepared by the present embodiment; No. 3 (no additive) except that no auxiliary agent is added, other ingredients and consumption are the same as No. 2.

[0058] 1. Fuel consumption.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com