A kind of preparation method of screw cleaning material of injection molding machine

A technology for screw and cleaning material of injection molding machine, which is applied in the field of polymer material research and development or maintenance of production and processing equipment, can solve the problems of low market sales volume of screw cleaning material, it is difficult to remove decomposed carbon, and the cleaning effect is not obvious. Wide applicability, low cost, low adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

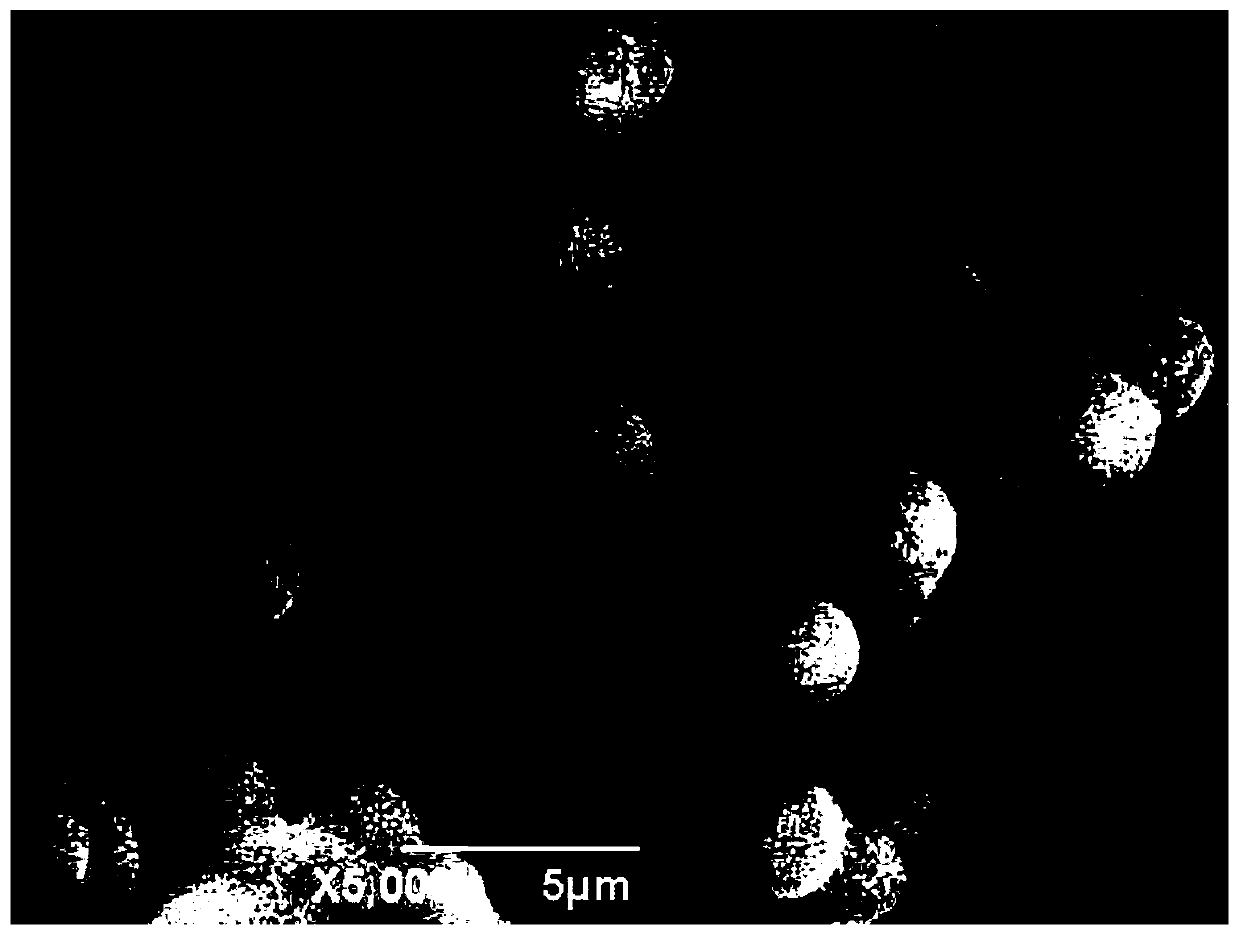

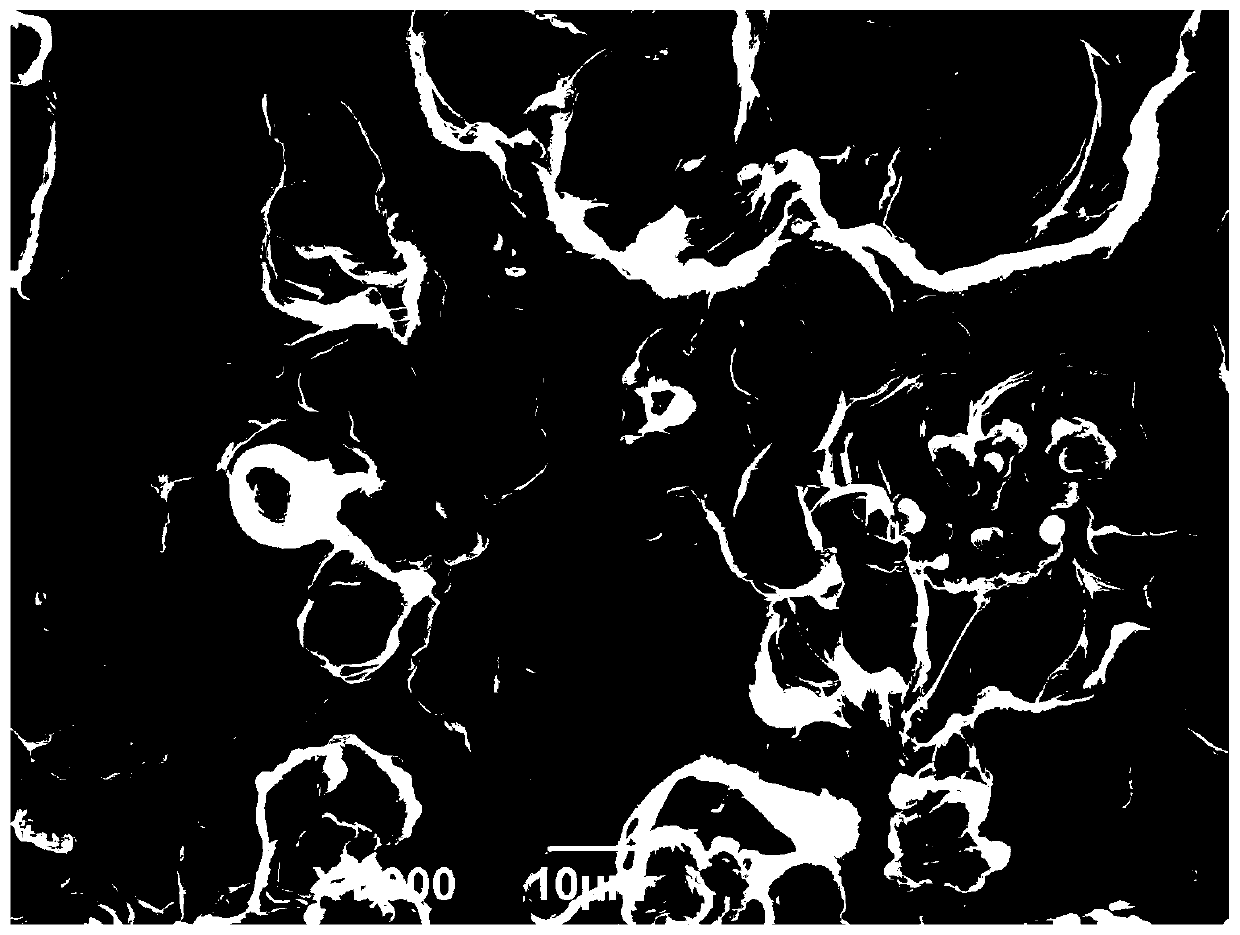

Image

Examples

Embodiment 1

[0056] The present invention comprises the following steps:

[0057] Step 1, preparing microcapsule modification aids, among the reagents or raw materials used in this step: the purity of triethanolamine, n-octanol, and melamine are analytically pure, and urea, sodium dodecylbenzenesulfonate, ortho-benzene The purity of dibutyl diformate, ethylene glycol monophenyl ether, and concentrated sulfuric acid are all chemically pure.

[0058] 101. According to the quality of each component, add 100 parts of formaldehyde solution and 40 parts of urea into a three-necked flask with a reflux device. The formaldehyde solution is an aqueous solution with a mass percentage of formaldehyde of 37%, and the purity is analytically pure; stir and mix evenly Finally, use triethanolamine to adjust the pH of the system to 8.0-9.0, and react at 70°C for 30 minutes; then adjust the system temperature to 65°C, add 18 parts of melamine, continue the reaction for 20 minutes, and cool to room temperatur...

Embodiment 2

[0063] The present invention comprises the following steps:

[0064] Step 1, preparing microcapsule modification aids, among the reagents or raw materials used in this step: the purity of triethanolamine, n-octanol, and melamine are analytically pure, and urea, sodium dodecylbenzenesulfonate, ortho-benzene The purity of dibutyl diformate, ethylene glycol monophenyl ether, and concentrated sulfuric acid are all chemically pure.

[0065] 101. According to the quality of each component, add 100 parts of formaldehyde solution and 50 parts of urea into a three-necked flask. The formaldehyde solution is an aqueous solution with a mass percentage of formaldehyde of 37%, and the purity is analytically pure; after mixing evenly, use three Adjust the pH of the system with ethanolamine to 8.0-9.0, and react at 80°C for 30 minutes; then adjust the temperature of the system to 60°C, add 15 parts of melamine, continue the reaction for 25 minutes, and cool to room temperature to obtain a mod...

Embodiment 3

[0071] The present invention comprises the following steps:

[0072] Step 1, preparing microcapsule modification aids, among the reagents or raw materials used in this step: the purity of triethanolamine, n-octanol, and melamine are analytically pure, and urea, sodium dodecylbenzenesulfonate, ortho-benzene The purity of dibutyl diformate, ethylene glycol monophenyl ether, and concentrated sulfuric acid are all chemically pure.

[0073] 101. According to the quality of each component, add 100 parts of formaldehyde solution and 45 parts of urea into the three-necked flask. The formaldehyde solution is an aqueous solution with a mass percentage of formaldehyde of 37%, and the purity is analytically pure; after mixing evenly, use three Adjust the pH of the system with ethanolamine to 8.0-9.0, and react at 75°C for 30 minutes; then adjust the temperature of the system to 70°C, add 20 parts of melamine, continue the reaction for 25 minutes, and cool to room temperature to obtain a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| membrane rupture temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com