Cathode electrophoretic coating and preparation method thereof

A cathodic electrophoretic paint and colorant technology, applied in the paint field, can solve the problems of scratch resistance and heat resistance paint adhesion, etc., to increase smoothness, wear resistance and crack resistance, heat resistance, and increase smoothness The effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

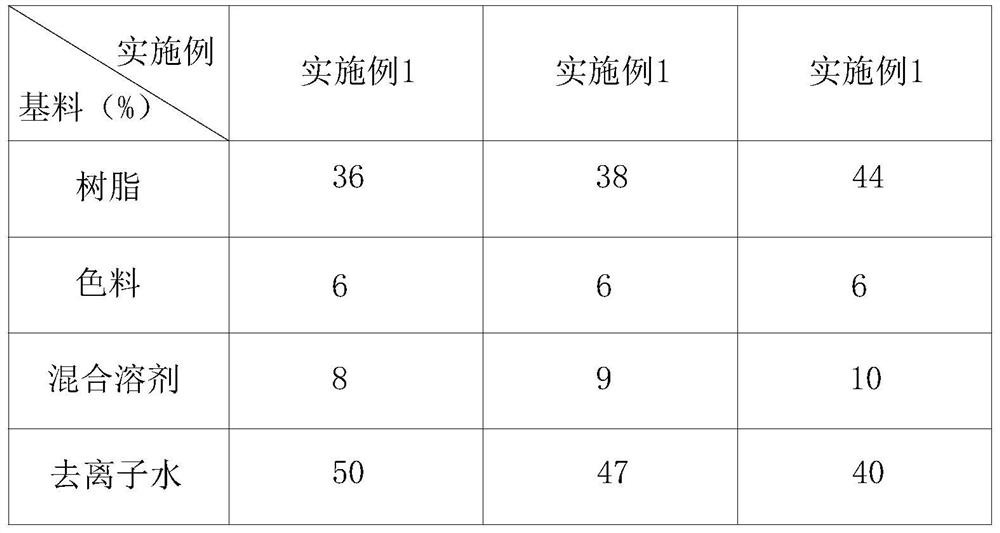

Embodiment 1

[0025] A kind of cathodic electrophoretic coating, its raw material is as follows according to mass percentage: resin 36%, pigment 6%, mixed solvent 8%, deionized water 50%, resin is the mixture of acrylic resin, epoxy resin and polyurethane, acrylic resin, ring The mixing ratio of oxygen resin and polyurethane is 1: 1: 1, the color material is a mixture of organic solvent, color pigment, body pigment and antirust pigment, the mixing ratio is 1: 1: 1: 1, and the organic solvent is specifically ethylene glycol Alcohol phenyl ether is a colorless transparent liquid used to increase the smoothness and corrosion resistance of coatings. The color pigment is specifically a mixture of carbon black and titanium dioxide. Carbon black is a light, loose and very fine black powder, and titanium dioxide is a White inert pigment, the extender pigment is orthosilicate, with a flake particle structure, its opacity to ultraviolet rays can enhance the crack resistance and durability of the elect...

Embodiment 2

[0030] A kind of cathodic electrophoretic coating, its raw material is as follows by mass percentage: resin 38%, pigment 6%, mixed solvent 9%, deionized water 40%, resin is the mixture of acrylic resin, epoxy resin and polyurethane, acrylic resin, ring The mixing ratio of oxygen resin and polyurethane is 1: 1: 1, the color material is a mixture of organic solvent, color pigment, body pigment and antirust pigment, the mixing ratio is 1: 1: 1: 1, and the organic solvent is specifically ethylene glycol Alcohol phenyl ether is a colorless transparent liquid used to increase the smoothness and corrosion resistance of coatings. The color pigment is specifically a mixture of carbon black and titanium dioxide. Carbon black is a light, loose and very fine black powder, and titanium dioxide is a White inert pigment, the extender pigment is orthosilicate, with a flake particle structure, its opacity to ultraviolet rays can enhance the crack resistance and durability of the electrophoretic...

Embodiment 3

[0037] A kind of cathodic electrophoretic coating, its raw material is as follows by mass percentage: resin 44%, pigment 6%, mixed solvent 10%, deionized water 50%, resin is the mixture of acrylic resin, epoxy resin and polyurethane, acrylic resin, ring The mixing ratio of oxygen resin and polyurethane is 1: 1: 1, the color material is a mixture of organic solvent, color pigment, body pigment and antirust pigment, the mixing ratio is 1: 1: 1: 1, and the organic solvent is specifically ethylene glycol Alcohol phenyl ether is a colorless transparent liquid used to increase the smoothness and corrosion resistance of coatings. The color pigment is specifically a mixture of carbon black and titanium dioxide. Carbon black is a light, loose and very fine black powder, and titanium dioxide is a White inert pigment, the extender pigment is orthosilicate, with a flake particle structure, its opacity to ultraviolet rays can enhance the crack resistance and durability of the electrophoreti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com