Efficient lubricating oil demulsifier and production method thereof

A production method and technology for lubricating oil, applied in the field of lubricating oil, can solve problems such as equipment failure, deterioration of anti-oxidation performance, deterioration of oil quality, etc., and achieve the effects of good air release value, excellent anti-foaming property, and easy reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

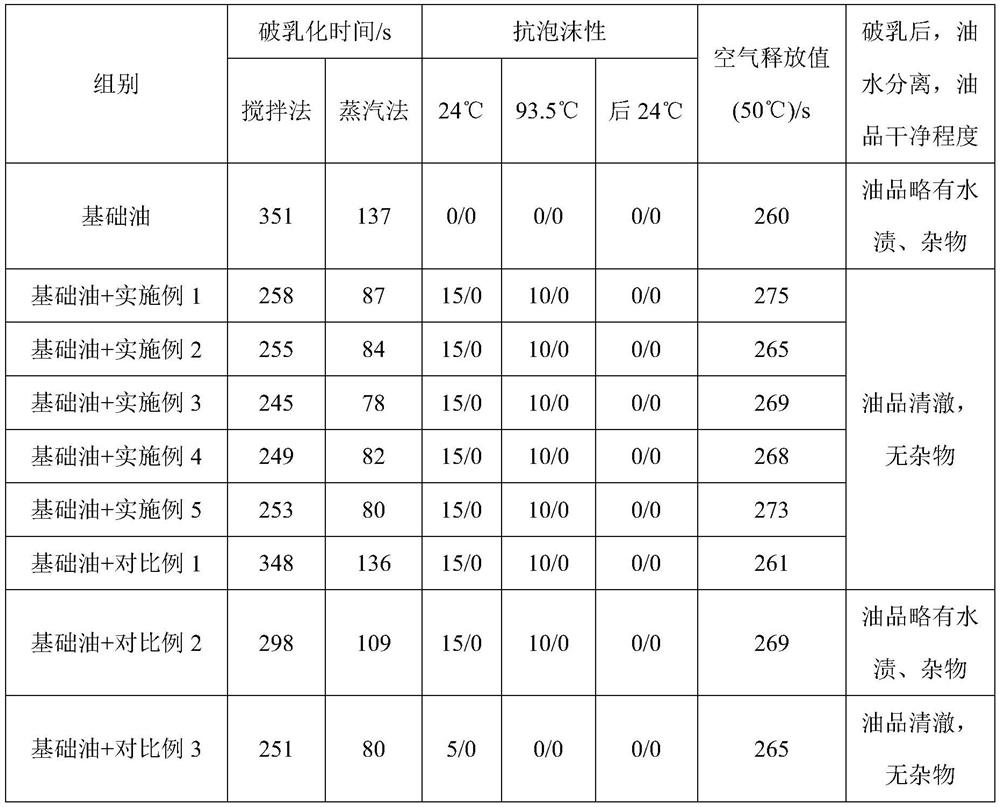

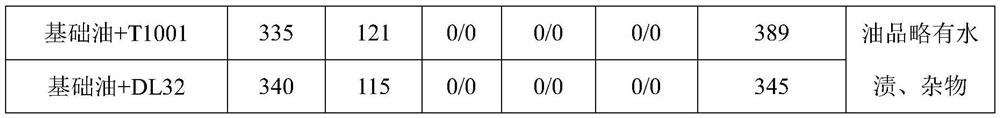

Examples

Embodiment 1

[0030] A high-efficiency lubricating oil demulsifier, in parts by weight, comprising the following raw materials: 5 parts of cetyl quaternary ammonium salt, 0.6 part of vegetable oil-based fatty acid methyl ester, 0.2 part of methyl silicone oil, 0.5 part of phosphoric acid ester, ethylene glycol 2 parts of phenyl ether.

[0031] A production method of an efficient lubricating oil demulsifier, comprising the following steps:

[0032] S1, the preparation of vegetable oil-based fatty acid methyl ester

[0033] In a four-neck flask equipped with a stirrer and a reflux condensing device, add soybean oil and methanol at a molar ratio of 1:4, stir rapidly and first raise the temperature to 60°C, then add CH 3 ONa was used as a catalyst, and the reaction temperature was controlled to reach 64°C, and the reaction time was 5 hours; excess methanol was evaporated under reduced pressure, and the glycerol in the lower layer was separated, and the methyl ester layer was washed with warm w...

Embodiment 2

[0036] A high-efficiency lubricating oil demulsifier, in parts by weight, comprising the following raw materials: 3 parts of cetyl quaternary ammonium salt, 0.4 part of vegetable oil-based fatty acid methyl ester, 0.1 part of methyl silicone oil, 0.2 part of phosphate ester, ethylene glycol 1 part of phenyl ether.

[0037] A production method of an efficient lubricating oil demulsifier, comprising the following steps:

[0038] S1, the preparation of vegetable oil-based fatty acid methyl ester

[0039] In a four-neck flask equipped with a stirrer and a reflux condensing device, add soybean oil and methanol at a molar ratio of 1:4, stir rapidly and first raise the temperature to 60°C, then add CH 3ONa was used as a catalyst, and the reaction temperature was controlled to reach 64°C, and the reaction time was 5 hours; excess methanol was evaporated under reduced pressure, and the glycerol in the lower layer was separated, and the methyl ester layer was washed with warm water at ...

Embodiment 3

[0042] A high-efficiency lubricating oil demulsifier, in parts by weight, comprising the following raw materials: 4 parts of cetyl quaternary ammonium salt, 0.5 part of vegetable oil-based fatty acid methyl ester, 0.15 part of methyl silicone oil, 0.4 part of phosphoric acid ester, ethylene glycol 1.5 parts of phenyl ether.

[0043] A production method of an efficient lubricating oil demulsifier, comprising the following steps:

[0044] S1, the preparation of vegetable oil-based fatty acid methyl ester

[0045] In a four-necked flask equipped with a stirrer and a reflux condensing device, add corn oil and methanol at a molar ratio of 1:4, stir rapidly and first raise the temperature to 60°C, then add CH 3 ONa was used as a catalyst, and the reaction temperature was controlled to reach 64°C, and the reaction time was 5 hours; excess methanol was evaporated under reduced pressure, and the glycerol in the lower layer was separated, and the methyl ester layer was washed with warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com