Ultraviolet-resistant paint and preparation method thereof

An anti-ultraviolet and coating technology, applied in the field of anti-ultraviolet coating and its preparation, can solve the problems of poor polarizing lens effect and single function, and achieve the effect of being easy to popularize and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

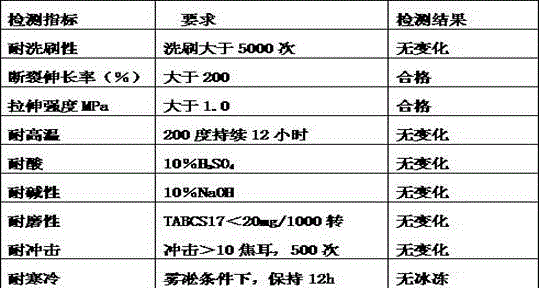

Image

Examples

Embodiment 1

[0019] The invention is an anti-ultraviolet coating, which is made of the following raw materials in parts by weight: 0.75 parts of octylated diphenylamine, 1.2 parts of ethylene glycol phenyl ether, 4 parts of oleic acid triethanolamine saponin, antioxidant 0.23 parts, 0.12 parts of sodium dibutylnaphthalene sulfonate formaldehyde condensate, 3.5 parts of 2,6-tertiary butyl-4-methylphenol, 4 parts of sodium petroleum sulfonate, 2.45 parts of sodium palm oil fatty acid methyl ester sulfonate . The antioxidant is dibutyl hydroxytoluene.

[0020] The above-mentioned preparation method for the anti-ultraviolet coating comprises the following steps:

[0021] 1) Weigh the anti-aging agent and ethylene glycol phenyl ether according to the above formula, add oleic acid triethanolamine saponin and antioxidant, put them together in a reaction kettle, heat to 50°C, keep warm and stir for 1 hour, then let stand for 2 hours ;

[0022] 2) Add the formulated amount of sodium dibutylnapht...

Embodiment 2

[0026] The present invention is an anti-ultraviolet coating, which is made of the following raw materials in parts by weight: 2.15 parts of octylated diphenylamine, 2.3 parts of ethylene glycol phenyl ether, 6.7 parts of oleic acid triethanolamine saponin, antioxidant 0.76 parts, 0.25 parts of sodium dibutylnaphthalene sulfonate formaldehyde condensate, 5.5 parts of 2,6-tertiary butyl-4-methylphenol, 7.5 parts of sodium petroleum sulfonate, 4.36 parts of sodium palm oil fatty acid methyl ester sulfonate . The antioxidant is dibutyl hydroxytoluene.

[0027] The preparation method of above-mentioned anti-ultraviolet coating comprises the following steps:

[0028] 1) Weigh the anti-aging agent and ethylene glycol phenyl ether according to the above formula, add oleic acid triethanolamine saponin and antioxidant, put them together in a reaction kettle, heat to 55°C, keep warm and stir for 1.5 hours, then let stand for 2.5 hours ;

[0029] 2) Add the formulated amount of sodium ...

Embodiment 3

[0034] The invention is an anti-ultraviolet coating, which is made of the following raw materials in parts by weight: 1.15 parts of anti-aging agent, octylated diphenylamine, 1.8 parts of ethylene glycol phenyl ether, 5.7 parts of oleic acid triethanolamine saponin, antioxidant 0.46 parts, 0.18 parts of sodium dibutylnaphthalene sulfonate formaldehyde condensate, 4.6 parts of 2,6-tertiary butyl-4-methylphenol, 5.5 parts of sodium petroleum sulfonate, 3.05 parts of sodium palm oil fatty acid methyl ester sulfonate . The antioxidant is dibutyl hydroxytoluene.

[0035] The preparation method of above-mentioned anti-ultraviolet coating comprises the following steps:

[0036] 1) Weigh the anti-aging agent and ethylene glycol phenyl ether according to the above formula, add oleic acid triethanolamine saponin and antioxidant, put them together in a reaction kettle, heat to 60°C, keep warm and stir for 2 hours, then let stand for 3 hours ;

[0037] 2) Add the formulated amount of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com