L molecular sieve-containing catalytic gasoline selective hydrodesulfurization modification catalyst

A technology for catalytic cracking gasoline and hydrodesulfurization, which is used in molecular sieve catalysts, physical/chemical process catalysts, petroleum industry and other directions, can solve the problems of poor comprehensive performance of catalytic cracking gasoline upgrading catalysts, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

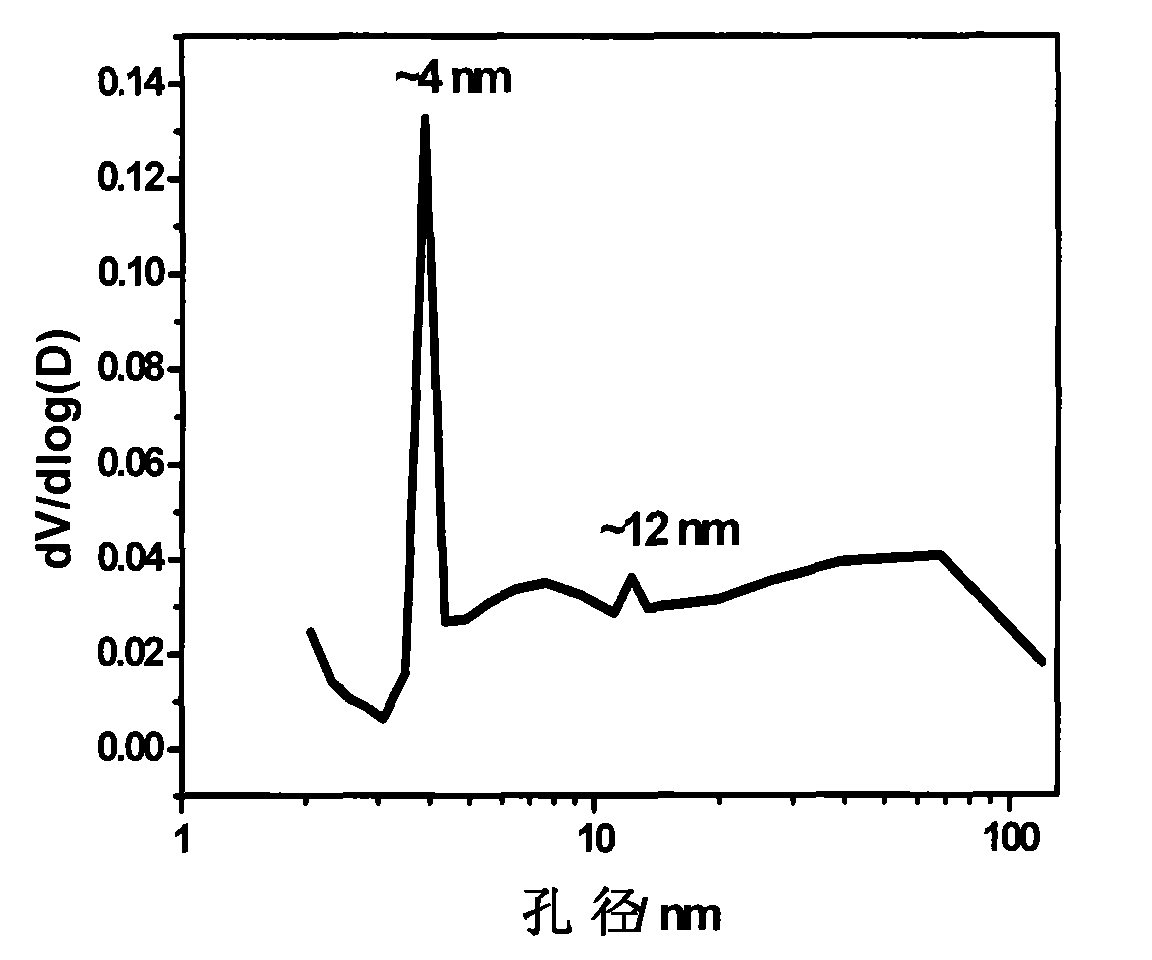

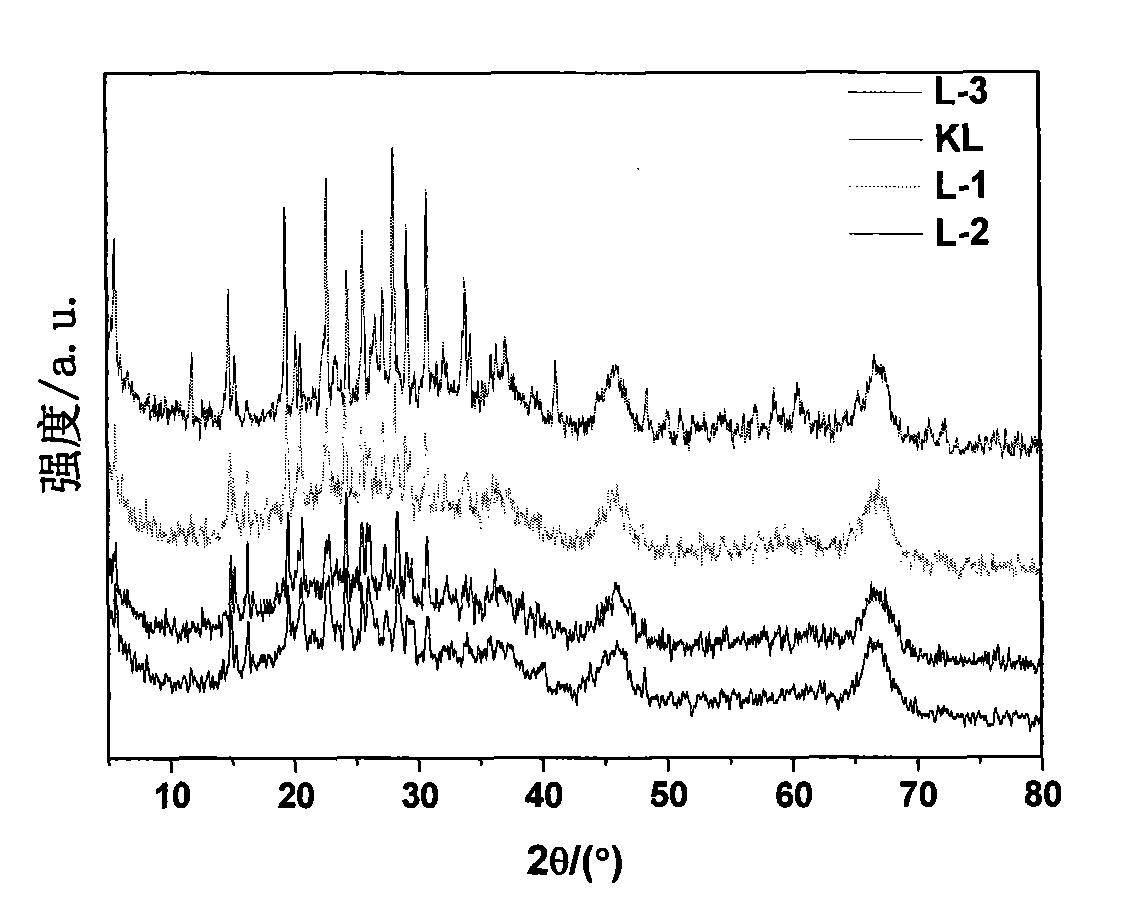

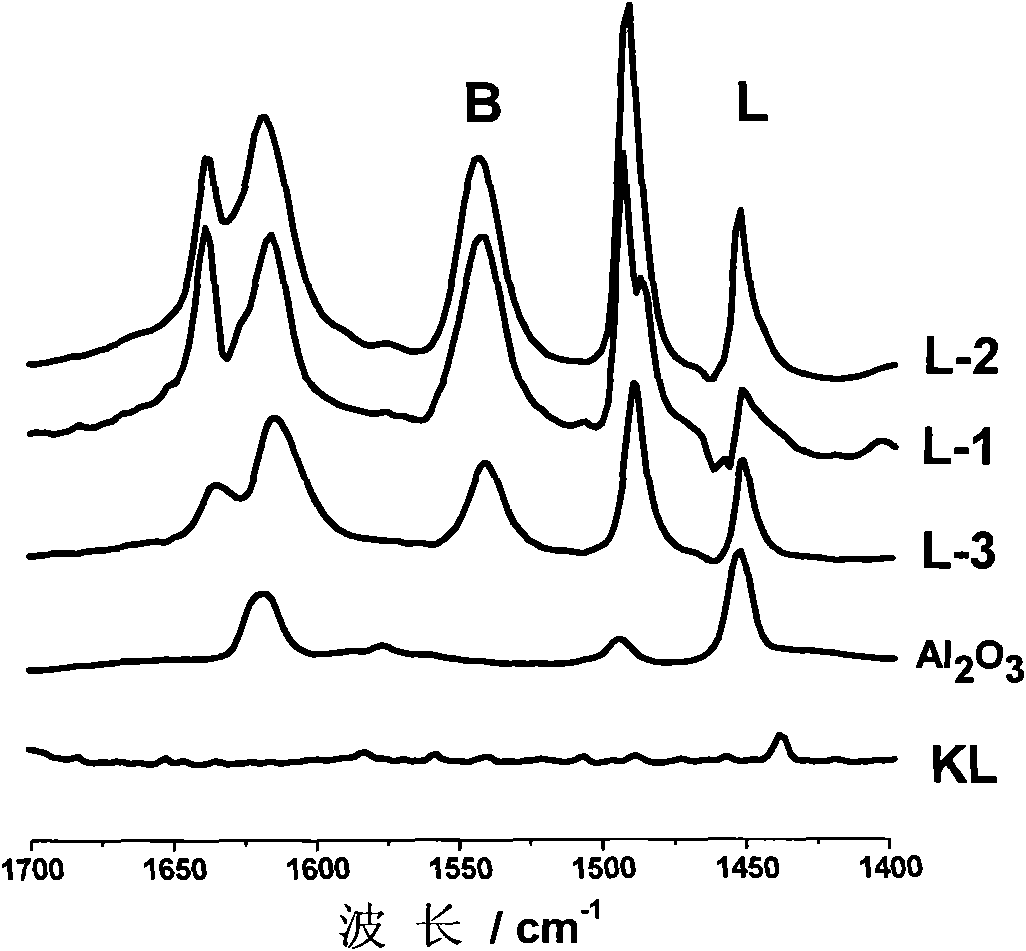

[0035] 6g of synthesized KL powder (skeleton SiO 2 / Al 2 o 3 =6~7, relative crystallinity 93%) after drying at 110 ℃ for 2 hours and cooling, after mixing with 25.9g of pseudo-boehmite dry base powder and 1g of turnip powder, add dropwise 1g of concentrated nitric acid, 0.4g of phosphoric acid and Appropriate amount of water; after fully back-mixing in the extruder, extrude into a cylindrical shape with a diameter of 1.5mm; then dry at 110°C for 4 hours; then roast at 550°C for 4 hours to obtain γ-Al 2 o 3 -L molecular sieve composite carrier, the prepared composite carrier is denoted as S8. Dissolve 9g of ammonium molybdate in 40g of water to impregnate the composite carrier, then ultrasonically disperse it for 20 minutes, stir for 5 minutes, dry at 110°C for 4h, roast at 550°C for 4 hours, and cool to room temperature; then use 0.6g of nitric acid Cobalt and 0.1g of nickel nitrate were dissolved in 40g of water, and the molybdenum-loaded composite carrier was co-impregna...

Embodiment 2

[0037] KL molecular sieves were subjected to ammonium exchange to obtain L-1 zeolite with an alkalinity lower than KL, and the 6 g of KL powder in Example 1 was replaced with 6 g of L-1 zeolite, and the following preparation was the same as in Example 1. The prepared composite carrier is denoted as S9, and the corresponding catalyst is denoted as Cat9.

Embodiment 3

[0039] The L-1 zeolite in Example 2 is carried out ammonium exchange again to obtain the L-2 zeolite whose basicity is lower than L-1, and the KL former powder of 6g in Example 1 is replaced with the L-2 zeolite of 6g, and the following preparation With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com