A kind of environment-friendly high-temperature leveling agent and preparation method thereof

It is a high-temperature leveling agent and an environmentally friendly technology, which can be used in dyeing, textiles and papermaking. It can solve the problems of environmental protection, poor leveling and dyeing penetration, and unsatisfactory leveling effects. Dyeability, the effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

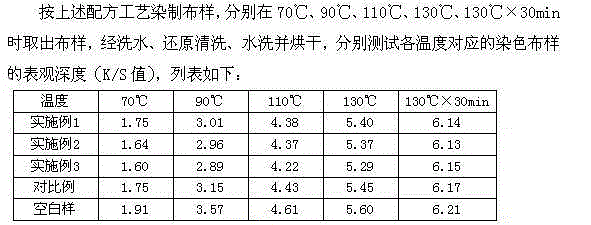

Embodiment 1

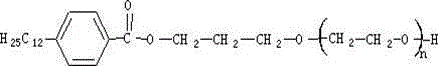

[0024] (1) Using concentrated sulfuric acid as a catalyst, add dodecylbenzoic acid dropwise to the propylene glycol solution, and carry out esterification reaction for 3 hours at a temperature of 130°C and a vacuum of -0.07MPa to obtain propylene glycol dodecylbenzoate Ester, wherein, the mass ratio of dodecylbenzoic acid and propylene glycol is 145:38, and the add-on of described concentrated sulfuric acid is 3% of dodecylbenzoic acid and propylene glycol gross mass;

[0025] (2) Combine the propylene glycol monododecylbenzoate and polyethylene glycol (PEG-800) obtained in step (1) under the action of antimony trioxide as a catalyst, under the conditions of temperature 200°C and vacuum degree -0.07MPa The condensation reaction was carried out for 3h to obtain propylene glycol dodecylbenzoate polyoxyethylene ether, wherein the mass ratio of propylene glycol monododecylbenzoate to polyethylene glycol was 1:2.8, and the trioxidized The addition of diantimony catalyst is 1% of th...

Embodiment 2

[0028] (1) Using concentrated sulfuric acid as a catalyst, add dodecylbenzoic acid dropwise to the propylene glycol solution, and perform esterification reaction for 3.5 hours at a temperature of 135°C and a vacuum of -0.085MPa to obtain propylene glycol dodecylbenzoate Monoester, wherein, the mass ratio of dodecylbenzoic acid and propylene glycol is 145:46, and the add-on of described concentrated sulfuric acid is 4% of dodecylbenzoic acid and propylene glycol gross mass;

[0029] (2) Condensate the propylene glycol monoester dodecylbenzoate and polyethylene glycol obtained in step (1) under the action of the catalyst antimony trioxide at a temperature of 210°C and a vacuum of -0.085MPa for 3.5 h, to obtain propylene glycol dodecylbenzoate polyoxyethylene ether, wherein the mass ratio of propylene glycol dodecylbenzoate to polyethylene glycol is 1:3.3, and the antimony trioxide catalyst is added The amount is 1.2% of the total mass of propylene glycol monododecylbenzoate and ...

Embodiment 3

[0032] (1) Using concentrated sulfuric acid as a catalyst, add dodecylbenzoic acid dropwise to the propylene glycol solution, and carry out esterification reaction for 4 hours at a temperature of 140°C and a vacuum of -0.1MPa to obtain propylene glycol dodecylbenzoate Esters, wherein the mass ratio of dodecylbenzoic acid and propylene glycol is 145:57, and the addition of the concentrated sulfuric acid is 5% of the total mass of dodecylbenzoic acid and propylene glycol;

[0033] (2) Condensate the propylene glycol monoester dodecylbenzoate and polyethylene glycol obtained in step (1) under the action of antimony trioxide catalyst at a temperature of 220°C and a vacuum of -0.1MPa for 4 hours , to obtain propylene glycol dodecylbenzoate polyoxyethylene ether, wherein the mass ratio of propylene glycol dodecylbenzoate to polyethylene glycol is 1:3.8, and the addition amount of the antimony trioxide catalyst 1.5% of the total mass of propylene glycol dodecylbenzoate and polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com