Production process of disinfection mould-proof liquid

A production process and anti-mildew technology, applied in the direction of disinfectants, biocides, biocides, etc., can solve the problems of unsuitable technology, high product sales price, uneven quality, etc., to achieve rich resources, wide application range, and no skin irritation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

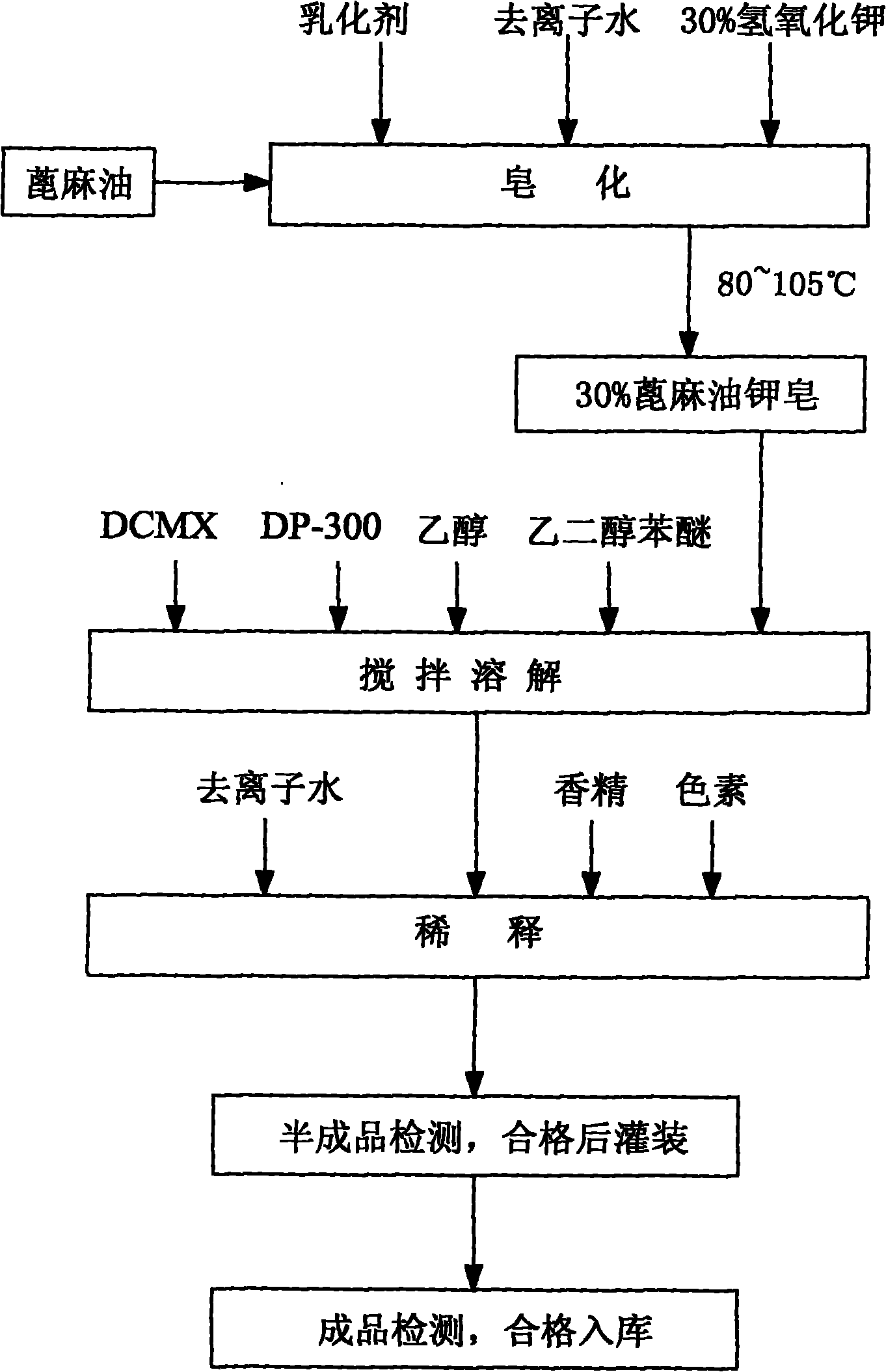

[0014] Such as figure 1 Shown, the production technology of a kind of disinfection antimold liquid described in the present embodiment comprises the following steps:

[0015] (1) castor oil saponification, at first, take by weighing following weight (gram) raw material: castor oil 27.2, emulsifier, deionized water 50.7, 30% potassium hydroxide 19.3; then, drop into described emulsifier in described castor oil Play emulsification induction reaction, in order to accelerate emulsification, add 24 grams of deionized water, the reaction temperature is 80~105 ℃; Afterwards, add described 30% potassium hydroxide while stirring; Start to react slowly, then react to accelerate and produce a large amount of foam, Add the remaining 26.7 grams of deionized water in batches, cool and eliminate foam, so that the reaction tends to be stable, and the reaction is very slow at the end. In an alkaline state, the pH is 10-11 and the reaction is completed after one hour. Potassium castor oil soap...

Embodiment 2

[0019] A kind of production technology of disinfection antimold liquid described in the present embodiment comprises the following steps:

[0020] (1) castor oil saponification, this step is with embodiment 1;

[0021] (2) Disinfectant anti-mold liquid preparation, at first, take the following weight (gram) raw material: DCMX 15, DP-3001, ethanol 9, ethylene glycol phenyl ether 4, 30% castor oil potassium soap 30, deionized water 40.65, Pigment 0.05, essence 0.3; then, in the DCMX, put into the DP-300 and ethanol in sequence, and then put into the ethylene glycol phenyl ether after stirring and dissolving, put into the 30% castor oil potassium soap after stirring evenly and Mix evenly to become transparent; finally, add the deionized water, pigment and essence to dilute to obtain the semi-finished product of disinfectant and anti-mildew liquid;

[0022] (3) This step is the same as in Example 1.

Embodiment 3

[0024] A kind of production technology of disinfection antimold liquid described in the present embodiment comprises the following steps:

[0025] (1) castor oil saponification, this step is with embodiment 1;

[0026] (2) Disinfectant anti-mold liquid preparation, at first, take the following weight (gram) raw material: DCMX 30, DP-3000.5, ethanol 3, ethylene glycol phenyl ether 1, 30% castor oil potassium soap 20, deionized water 45.15, Pigment 0.05, essence 0.3; then, in the DCMX, put into the DP-300 and ethanol in sequence, and then put into the ethylene glycol phenyl ether after stirring and dissolving, put into the 30% castor oil potassium soap after stirring evenly and Mix evenly to become transparent; finally, add the deionized water, pigment and essence to dilute to obtain the semi-finished product of disinfectant and anti-mildew liquid;

[0027] (3) This step is the same as in Example 1.

[0028] In the above-mentioned preparation method, the emulsifier is C 12 -C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com