Carbon deposit cleansing agent of engine and preparation method of carbon deposit cleansing agent

A carbon deposit cleaning agent and engine technology, applied in the field of engine cleaning agents, can solve the problems of dry metal surface, rapid diffusion of anionic surfactants, and excessive engine emissions, so as to achieve no corrosion of the overall metal, good instant cleaning effect, and dissolving effect. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

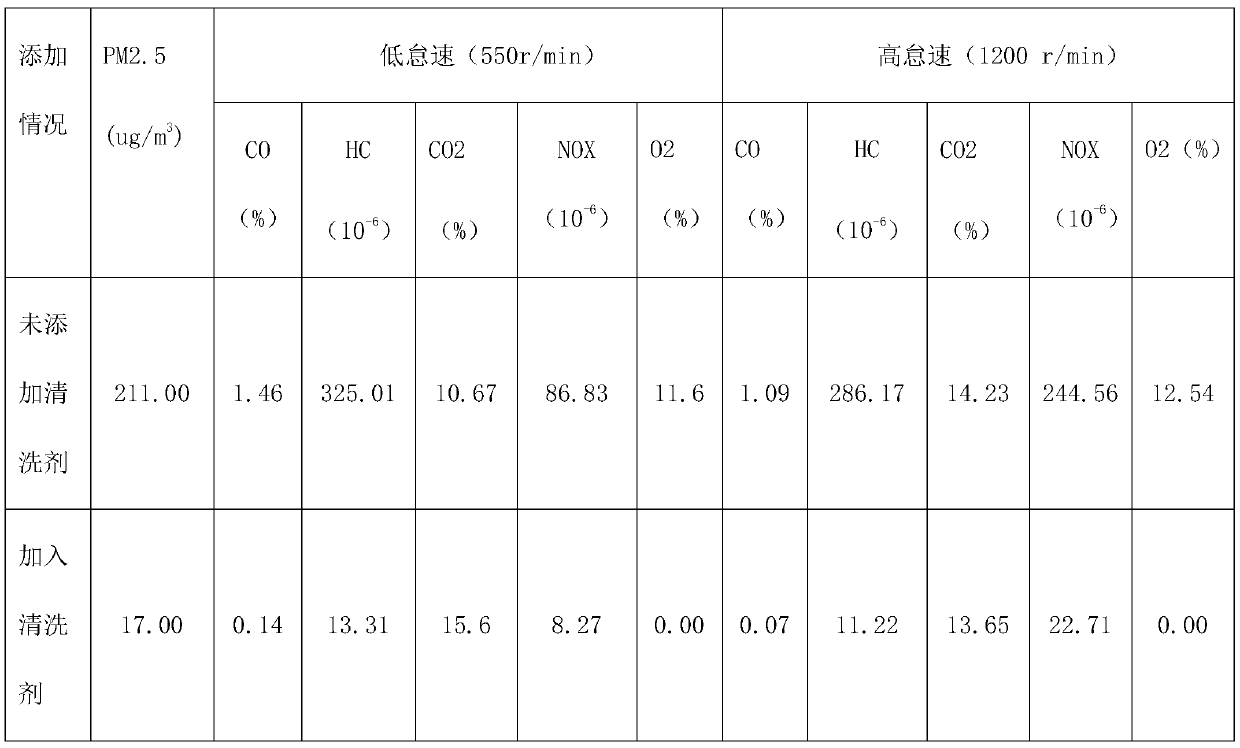

Embodiment 1

[0039] A car engine carbon deposit cleaning agent, comprising the following raw materials in parts by weight: 28 parts of diethylene glycol ether acetate, 28 parts of diethylene glycol monophenyl ether, 28 parts of methyl pyrrolidone, 2 parts of lactic acid solution, long-chain carboxylic acid Ester polyoxyethylene-18 3 parts, isothiazolinone 3 parts by weight, ammonia solution 9 parts.

[0040] The concentration of the lactic acid solution is 0.58, and the concentration of the ammonia solution is 0.37.

[0041] The preparation method of this cleaning agent is:

[0042] Step S1: add diethylene glycol ether acetate into the reaction tank and stir, the stirring speed is 200r / min, and the stirring time is 5mins;

[0043] Step S2: Add diethylene glycol monophenyl ether, and stir at a stirring speed of 200r / min for 5mins;

[0044] Step S3: Add methylpyrrolidone and stir at a stirring speed of 200r / min for 5mins;

[0045] Step S4: adding lactic acid solution, stirring at a stirri...

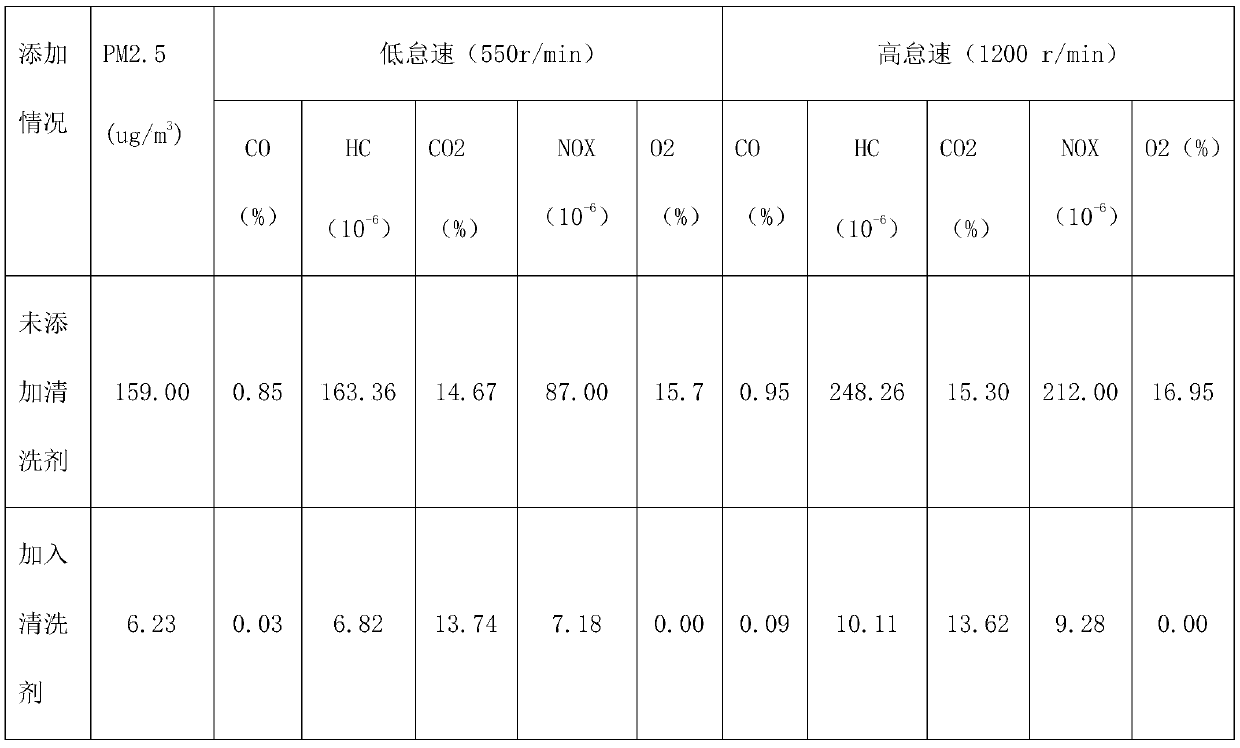

Embodiment 2

[0063] A car engine carbon deposit cleaning agent, comprising the following raw materials in parts by weight: 28 parts of diethylene glycol ether acetate, 29 parts of diethylene glycol monophenyl ether, 30 parts of methyl pyrrolidone, 2.5 parts of lactic acid solution, long-chain carboxylic acid Ester polyoxyethylene-18 3 parts, isothiazolinone 3.5 parts by weight, sodium hydroxide solution 4 parts.

[0064] The concentration of the lactic acid solution is 0.64, and the concentration of the sodium hydroxide solution is 0.42.

[0065] The preparation method of this cleaning agent is:

[0066] Step S1: add diethylene glycol ether acetate into the reaction tank and stir, the stirring speed is 250r / min, and the stirring time is 5mins;

[0067] Step S2: Add diethylene glycol monophenyl ether, and stir at a stirring speed of 250r / min for 5mins;

[0068] Step S3: Add methylpyrrolidone and stir at a stirring speed of 250r / min for 5mins;

[0069] Step S4: adding lactic acid solution...

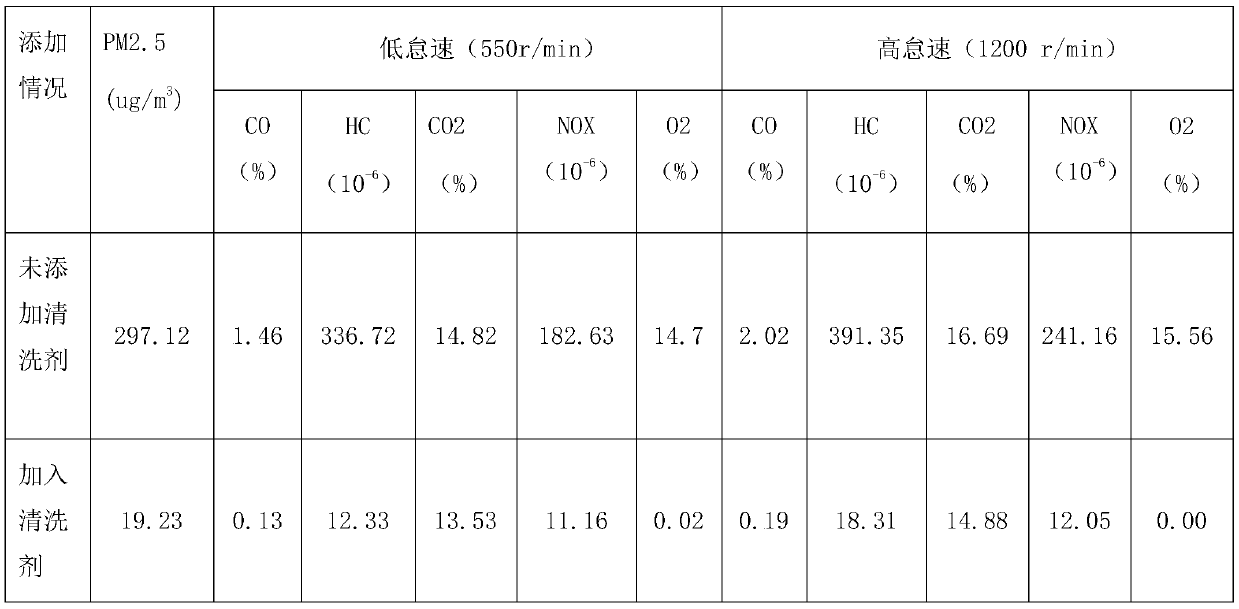

Embodiment 3

[0087] A car engine carbon deposit cleaning agent, comprising the following raw materials in parts by weight: 29 parts of diethylene glycol ether acetate, 29 parts of diethylene glycol monophenyl ether, 29 parts of methylpyrrolidone, 3 parts of lactic acid solution, long-chain carboxyl Ester polyoxyethylene-18 3 parts, isothiazolinone 3 parts by weight, potassium hydroxide solution 4 parts.

[0088] The concentration of the lactic acid solution is 0.72, and the concentration of the potassium hydroxide solution is 0.46.

[0089] The preparation method of this cleaning agent is:

[0090] Step S1: adding diethylene glycol ether acetate into the reaction tank and stirring, the stirring speed is 280r / min, and the stirring time is 5mins;

[0091] Step S2: Add diethylene glycol monophenyl ether, and stir at a stirring speed of 280r / min for 5mins;

[0092] Step S3: Add methylpyrrolidone and stir at a stirring speed of 280r / min for 5mins;

[0093] Step S4: adding lactic acid solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com