Kitchen detergent composition

A cleaning agent and kitchen technology, applied in the directions of detergent compositions, surface-active detergent compositions, organic non-surface-active detergent compositions, etc., can solve the problem of difficulty in finding, rising sales prices of finished products, hindering consumers' desire to buy, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

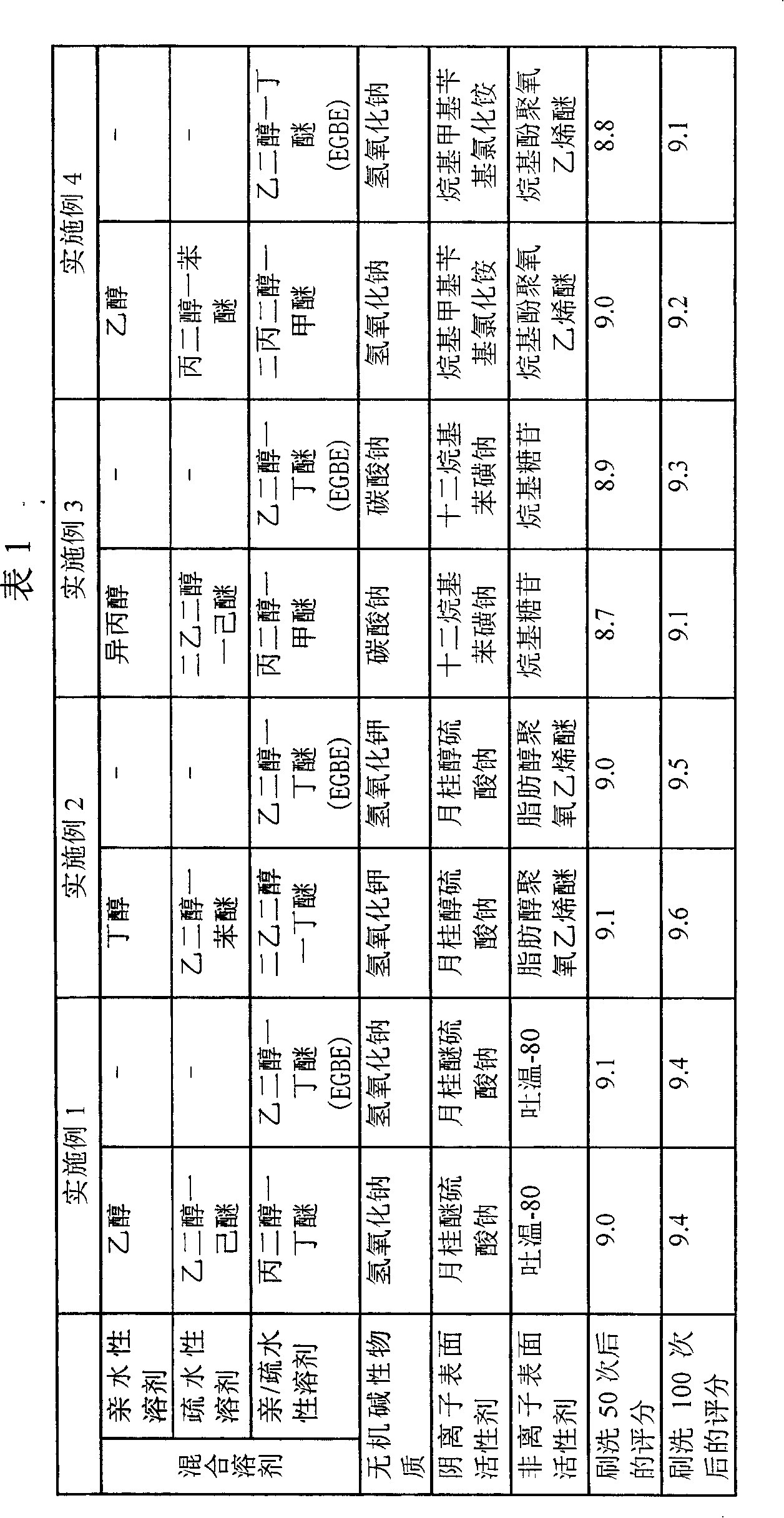

Examples

Embodiment 1

[0040] Preliminary Example 1 Test Preparation of Kitchen Grease

[0041] The composition of the test kitchen grease is as follows:

[0042] Vegetable Oil: 48%

[0043] Jam: 32%

[0044] Lard: 16%

[0045] Pigment: 4%

[0046] The preparation of test kitchen grease is as follows:

[0047] Weigh 24g vegetable oil, 16g jam and 8g lard respectively, and put them into clean containers. Heat, shaking, until the above substances are completely melted. Add 2g of pigment powder to the melt, shake or stir until uniform. The resulting mixture was naturally cooled to room temperature to obtain kitchen grease for testing.

Embodiment 2

[0048] Preliminary Example 2 Preparation of scaled stained panels for testing

[0049] Weigh 0.5-1.0 g of the test kitchen grease prepared in Preliminary Example 1, and apply it to a 15×15 cm square white ceramic tile. Alternatively, weigh 4.0-5.0 g of kitchen grease for testing, and apply it to a 30×30 cm square white ceramic tile. Use a sponge to wipe the grease on the white tiles repeatedly until it is even. Then, put the white tiles coated with grease flat in an oven (maintain a constant temperature of 145°C) and bake for 3 hours. After the baking, the tiles were naturally cooled to room temperature to obtain a stained smear for testing.

Embodiment 3

[0050] The evaluation of preliminary embodiment 3 cleaning agent cleaning effect

[0051] Place and fix the smudged stained plate for the test obtained in Preliminary Example 2 on the cleaning brush washing machine, so that the side coated with oily dirt faces the position of the brush head. Weigh 1.0g of detergent, and use a pipette to evenly drop it onto the sponge. Fix the sponge dripped with detergent to the position of the brush head of the cleaning washing machine, so that the side of the sponge dripped with detergent is opposite to the side coated with grease on the stained stained plate for testing. Turn on the power of cleaning detergent, set the number of moving cycles (50, 100...). After brushing, visually observe the remaining oil stains on the stained plate, and give a score between 1 and 10 points. Record this score in the table.

[0052] Example 1

[0053] Mix 5g of ethylene glycol monohexyl ether, 3g of ethanol and 12g of propylene glycol monobutyl ether to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com