Hydrophilic oleophobic polymer and preparation method thereof, and application thereof in humidity response oil and water separating membrane

An oil-water separation membrane, hydrophilic and oleophobic technology, used in semi-permeable membrane separation, chemical instruments and methods, osmotic/dialysis water/sewage treatment, etc. Inexpensive, easy to clean and reuse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: FPVA / SiO 2 Preparation of / GA composite stainless steel wire mesh oil-water separation mesh

[0039] (1) Put a piece of 15×15mm 2 The 300-mesh stainless steel wire mesh was immersed in distilled water, ethanol or acetone, and distilled water in order, respectively, and ultrasonically cleaned at 150W and 40KHz for 8min, and hung up to dry at room temperature;

[0040] (2) Dissolve polyvinyl alcohol (Sinopharm AH26) in hot water above 95°C, prepare a 5% solution, cool, and mix trifluoroacetic acid (Wuhan Defu Economic Development Co., Ltd.) The functional group molar ratio is 1:1, and the esterification reaction is carried out, and the fluorine-containing segment is grafted to obtain the first type of hydrophilic and oleophobic polymer.

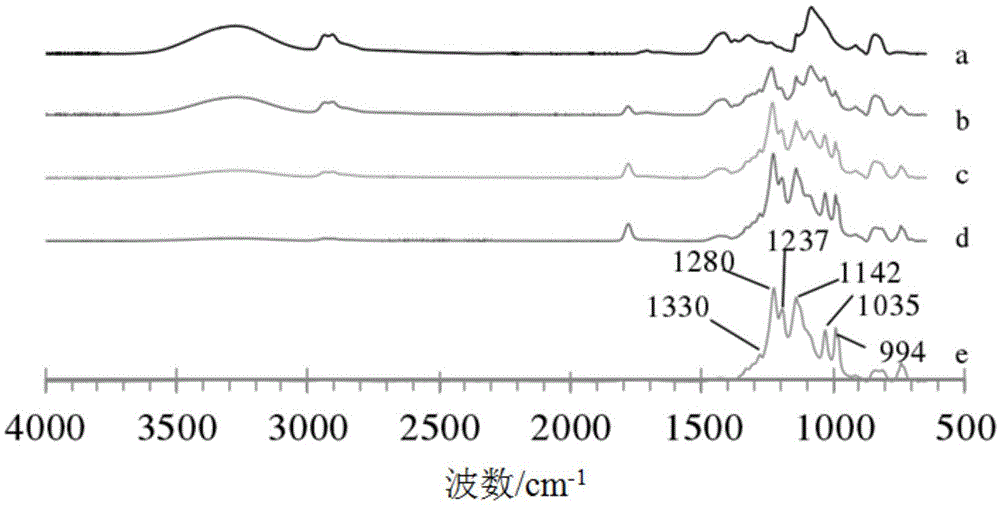

[0041] Using Perkin‐Elmerspectrum‐2000 Fourier Transform Infrared Spectrometer to measure the structural changes during the synthesis of new hydrophilic and oleophobic polymers, the infrared spectrum is shown in figure 2 s...

Embodiment 2

[0048] Example 2: FPVA / SiO 2 Preparation of / EA copper wire mesh oil-water separation mesh

[0049] (1) Put a piece of 15×15mm 2 The 100-mesh copper wire mesh was immersed in distilled water, ethanol, and distilled water in order, respectively, cleaned at 100W and 20KHz for 10min, and hung up to dry at room temperature;

[0050] (2) Dissolve polyvinyl alcohol (Sinopec 1799) in hot water above 95°C, prepare a 5% solution, cool, and react polyvinyl alcohol with monochloroacetic carboxyethylation to convert all hydroxyl groups For the carboxyethyl group, mix perfluorotriethylamine (Wuhan Defu Economic Development Co., Ltd.) and carboxyethylated polyvinyl alcohol according to the functional group molar ratio of 1:1, carry out neutralization reaction, and graft the fluorine-containing segment, Obtain the second kind of hydrophilic and oleophobic polymer, adopt Perkin‐Elmerspectrum‐2000 Fourier Transform Infrared Spectrometer to measure the structural changes in the synthesis proc...

Embodiment 3

[0057] Example 3: FPVA / SiO 2 Preparation of / GA composite stainless steel wire mesh oil-water separation mesh

[0058] (1) Put a piece of 15×15mm 2 The 200-mesh aluminum wire mesh was immersed in distilled water, ethanol or acetone, and distilled water in order, respectively, and ultrasonically cleaned at 150W and 40KHz for 10min, and hung up to dry at room temperature;

[0059] (2) Dissolve polyvinyl alcohol in hot water above 95°C, prepare a 5% solution, cool, and react polyvinyl alcohol (Sinopec 2499) with monochloroacetic acid carboxyethylation to convert all the hydroxyl groups For the carboxyethyl group, mix perfluorotributylamine (Wuhan Defu Economic Development Co., Ltd.) and carboxyethylated polyvinyl alcohol according to the functional group molar ratio of 1:4, carry out neutralization reaction, and graft the fluorine-containing segment, Obtain the second kind of hydrophilic and oleophobic polymer, adopt Perkin‐Elmerspectrum‐2000 Fourier Transform Infrared Spectrom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com