Mobile phone touch screen polarizer cleaning agent and preparation method and application thereof

A touch screen and cleaning agent technology, which is applied in the preparation of detergent mixture compositions, detergent compositions, cleaning methods and utensils, etc., can solve the problems of incomplete alignment of screens, insufficient qualified rate of pasting polarizers, and large consumption. , to achieve good cleaning ability, significant practical value, and reduce cleaning costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

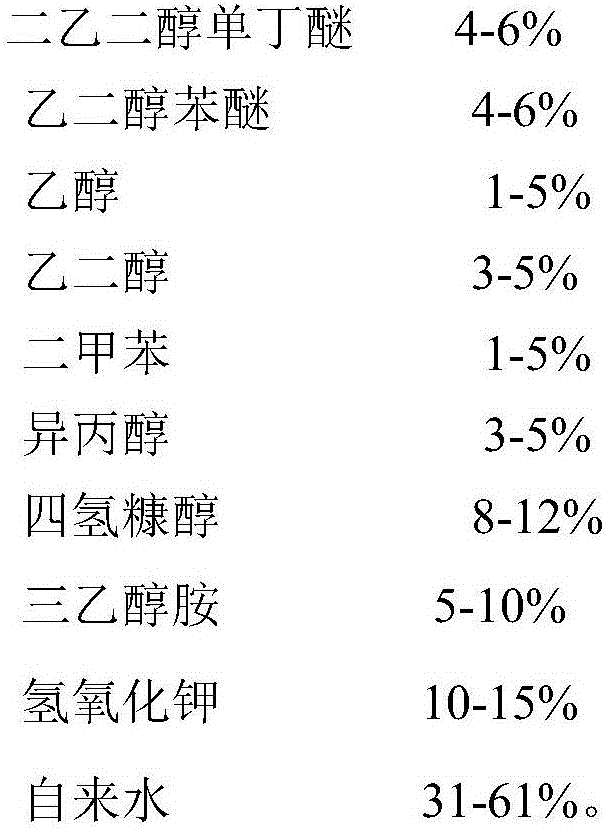

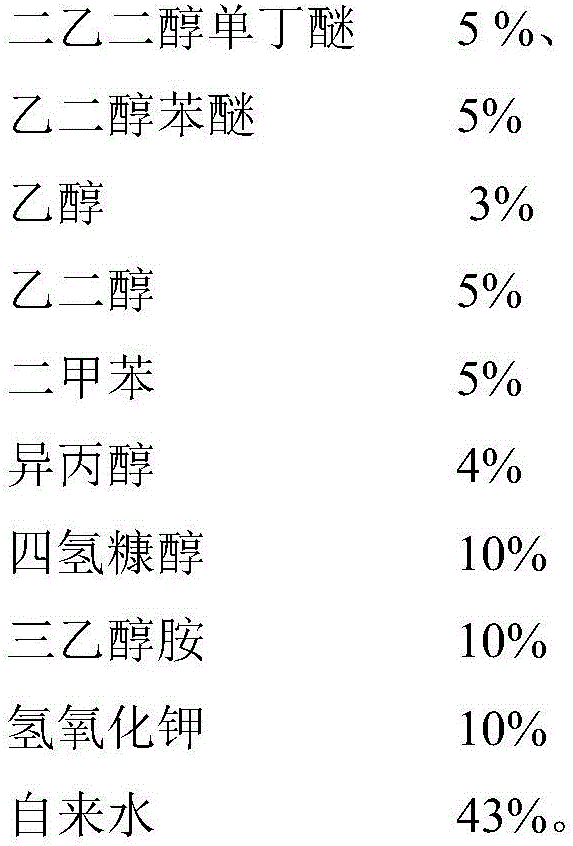

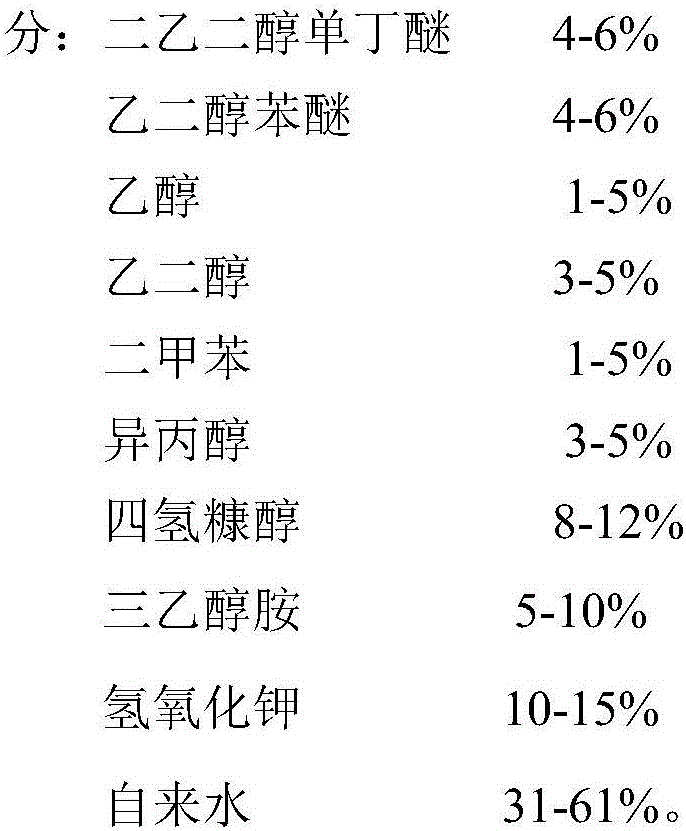

[0016] A mobile phone touch screen polarizer cleaning agent and its preparation and application, prepared from the following raw material components in terms of mass: 4% diethylene glycol monobutyl ether, 4% ethylene glycol phenyl ether, 5% ethanol, ethylene glycol Alcohol 5%, xylene 1%, isopropanol 5%, tetrahydrofurfuryl alcohol 12%, triethanolamine 5%, potassium hydroxide 15%, tap water 44%.

Embodiment 2

[0017] Example 2: A mobile phone touch screen polarizer cleaning agent and its preparation and application, prepared from the following raw material components in terms of mass: 6% diethylene glycol monobutyl ether, 6% ethylene glycol phenyl ether, 1% ethanol %, ethylene glycol 3%, xylene 1%, isopropanol 3%, tetrahydrofurfuryl alcohol 8%, triethanolamine 5%, potassium hydroxide 10%, tap water 57%.

Embodiment 3

[0018] Example 3: A mobile phone touch screen polarizer cleaning agent and its preparation and application, prepared from the following raw material components in terms of mass: 5% diethylene glycol monobutyl ether, 5% ethylene glycol phenyl ether, 3% ethanol %, ethylene glycol 5%, xylene 5%, isopropanol 4%, tetrahydrofurfuryl alcohol 10%, triethanolamine 10%, potassium hydroxide 10%, tap water 43%.

[0019] A preparation method of a mobile phone touch screen polarizer cleaning agent, specifically comprising the following steps:

[0020] (1) each raw material is weighed for subsequent use according to the required ratio;

[0021] (2) First, tap water is added to the reaction kettle, and potassium hydroxide solid is put in, and stirring is started, and the frequency converter is adjusted to 50 Hz, and after the potassium hydroxide is completely dissolved, the cooling device is turned on;

[0022] (3) When the temperature drops to room temperature, add diethylene glycol monobut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com