Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183results about How to "Meet cleanliness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel cleaner and stainless steel cleaning method

The invention belongs to the field of surface treatment, and relates to a stainless steel cleaner. The cleaner comprises a nonionic surfactant, an anionic surfactant, a complexing agent, a degreasing agent and deionized water, wherein the degreasing agent is one of amide, and a mixture of amide and hydramine. An environmentally-friendly cleaner comprising the amide or the hydramine, a composite surfactant and the like removes grease under the alkalescent condition, and has good cleaning effect due to the permeation effect of the composite surfactant on the grease and an oxide layer. The invention also relates to a stainless steel cleaning method. The stainless steel cleaner and the stainless steel cleaning method are widely applied to the treatment of various stainless steel surfaces.

Owner:BYD CO LTD

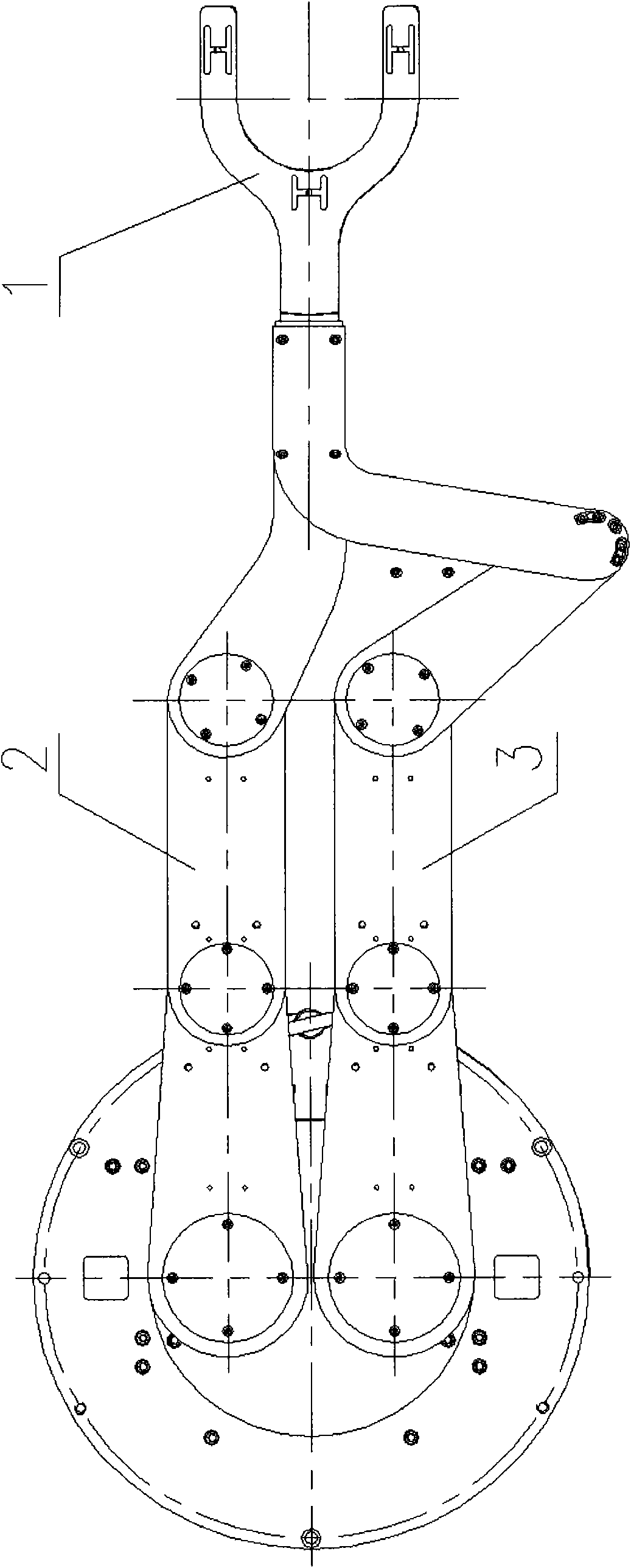

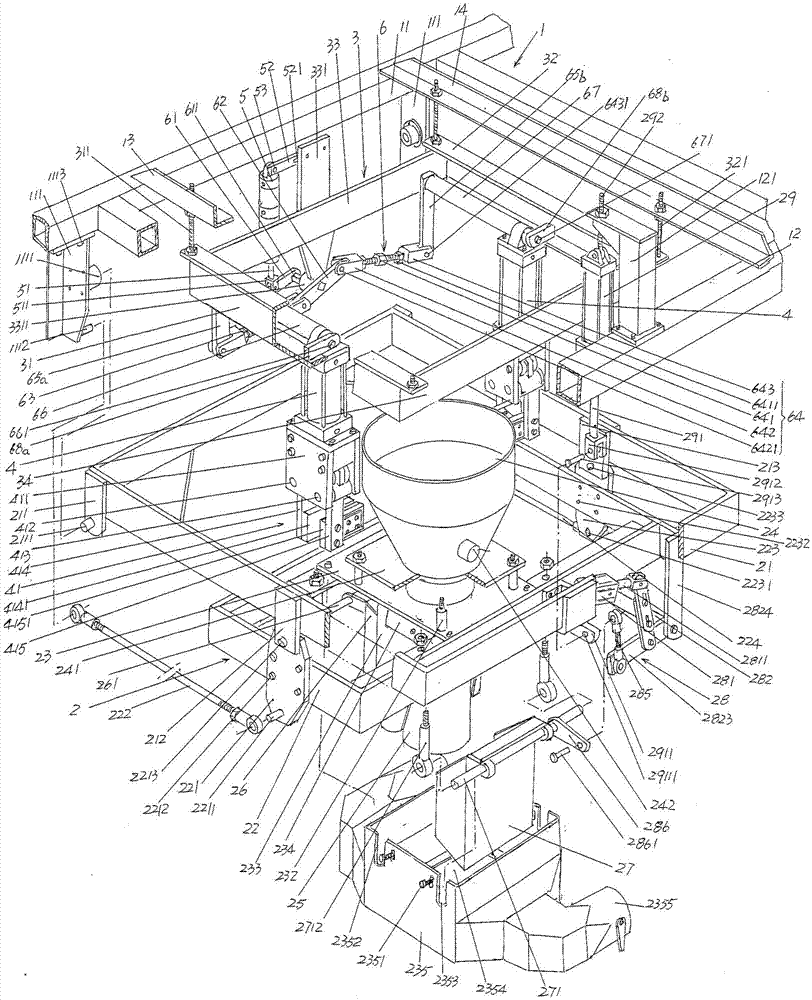

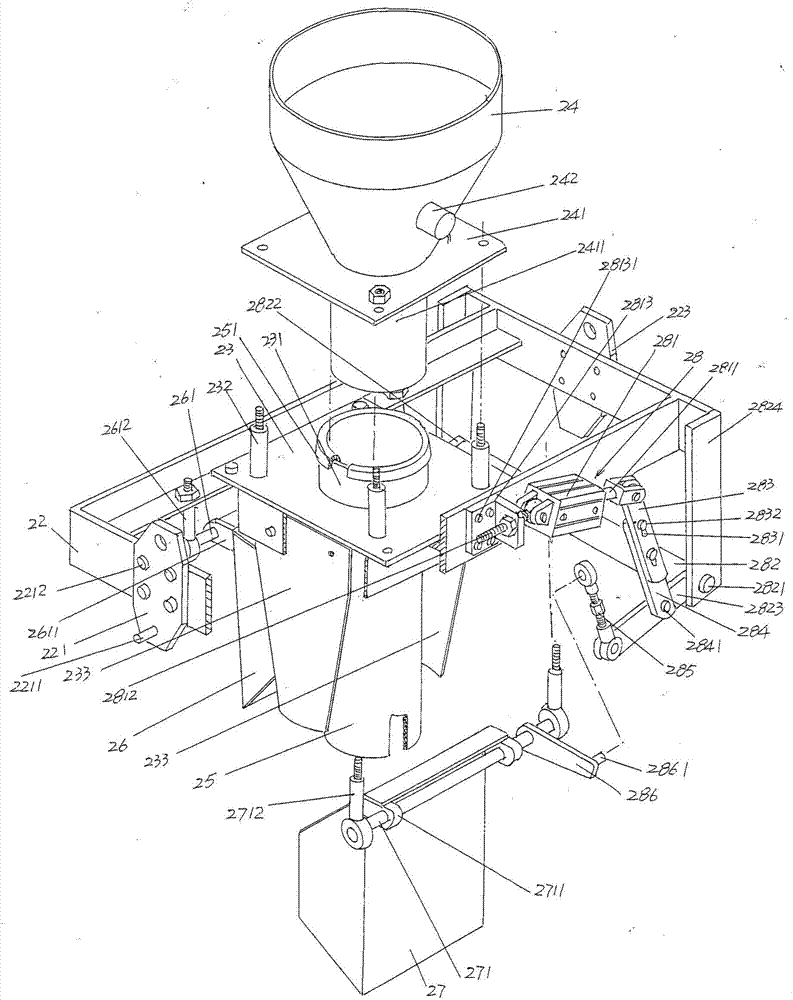

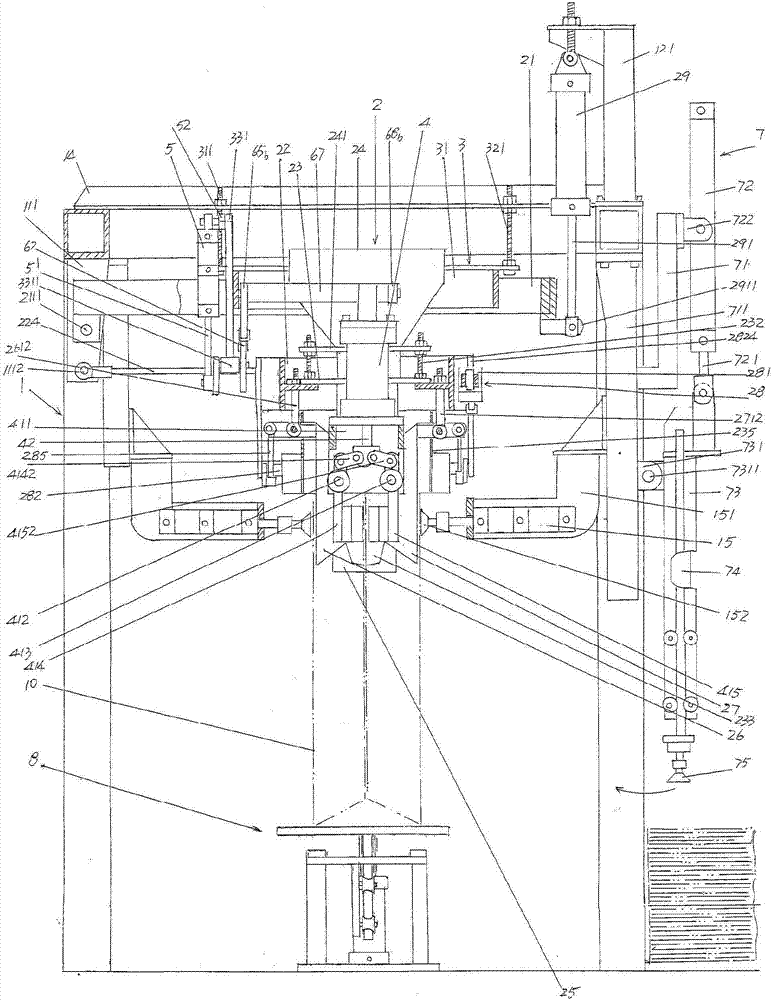

Double-arm transmission robot applied to high-cleanliness environment

InactiveCN101908497AHigh efficiency requirementsMeet cleanliness requirementsProgramme-controlled manipulatorConveyor partsSpatial structureMechanical engineering

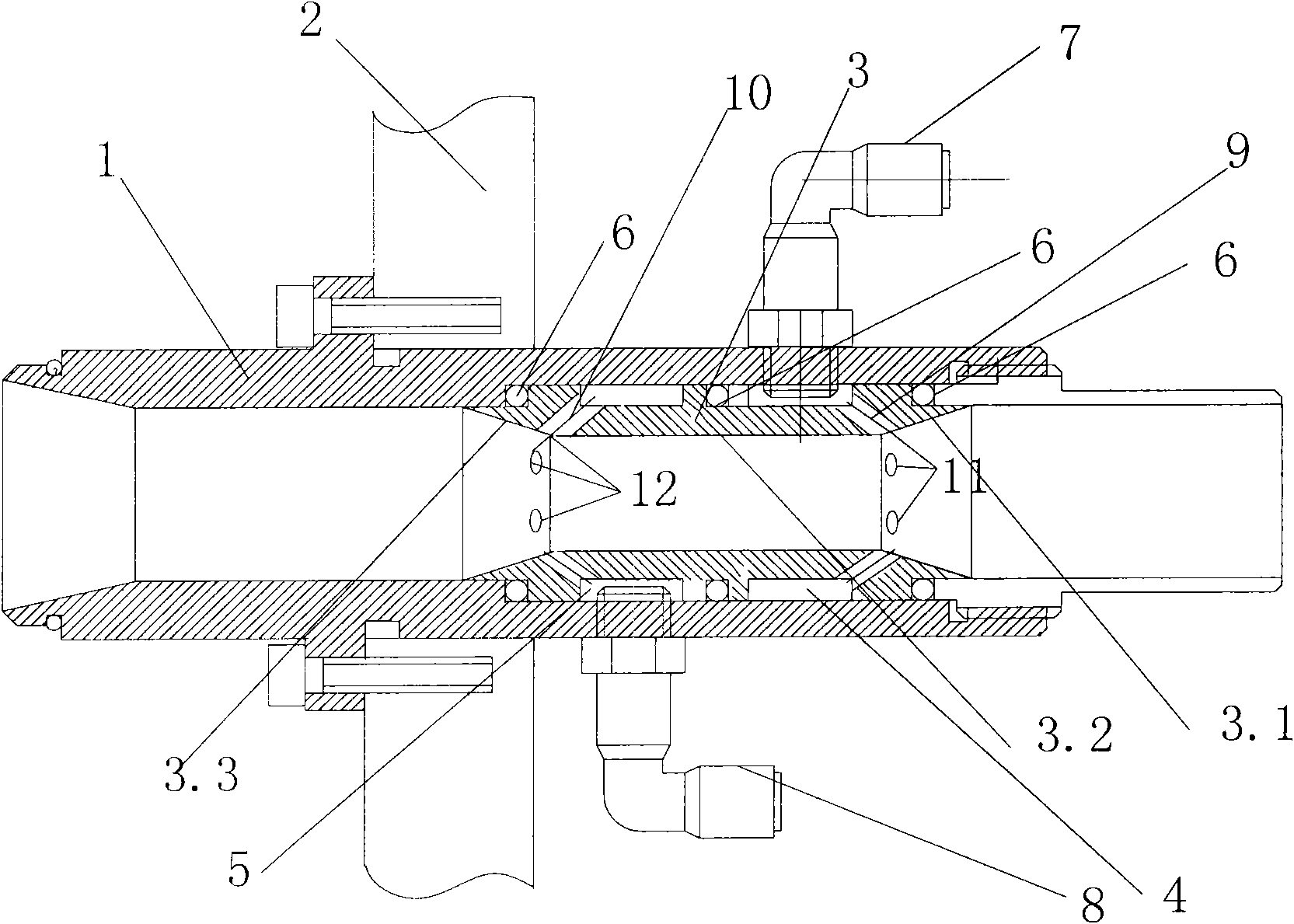

The invention relates to a double-arm transmission robot applied to a clean environment, which is used for the transmission and high-precision positioning placement of a large-diameter semiconductor silicon wafer in a high-cleanliness environment. The double-arm transmission robot is in the structural form of R-theta type and has the working principle of a space structure based on a cylindrical coordinate system and the characteristic of independent control of all motion shafts. The double-arm transmission robot mainly comprises an R-axis left arm mechanism, an R-axis right arm mechanism, a T-axis rotating mechanism, a Z-axis lifting mechanism, and the like and seals the pollution of a drive mechanism on an external environment by adopting a special seal device so as to be suitable for the high-cleanliness production environment requirement.

Owner:HARBIN INST OF TECH

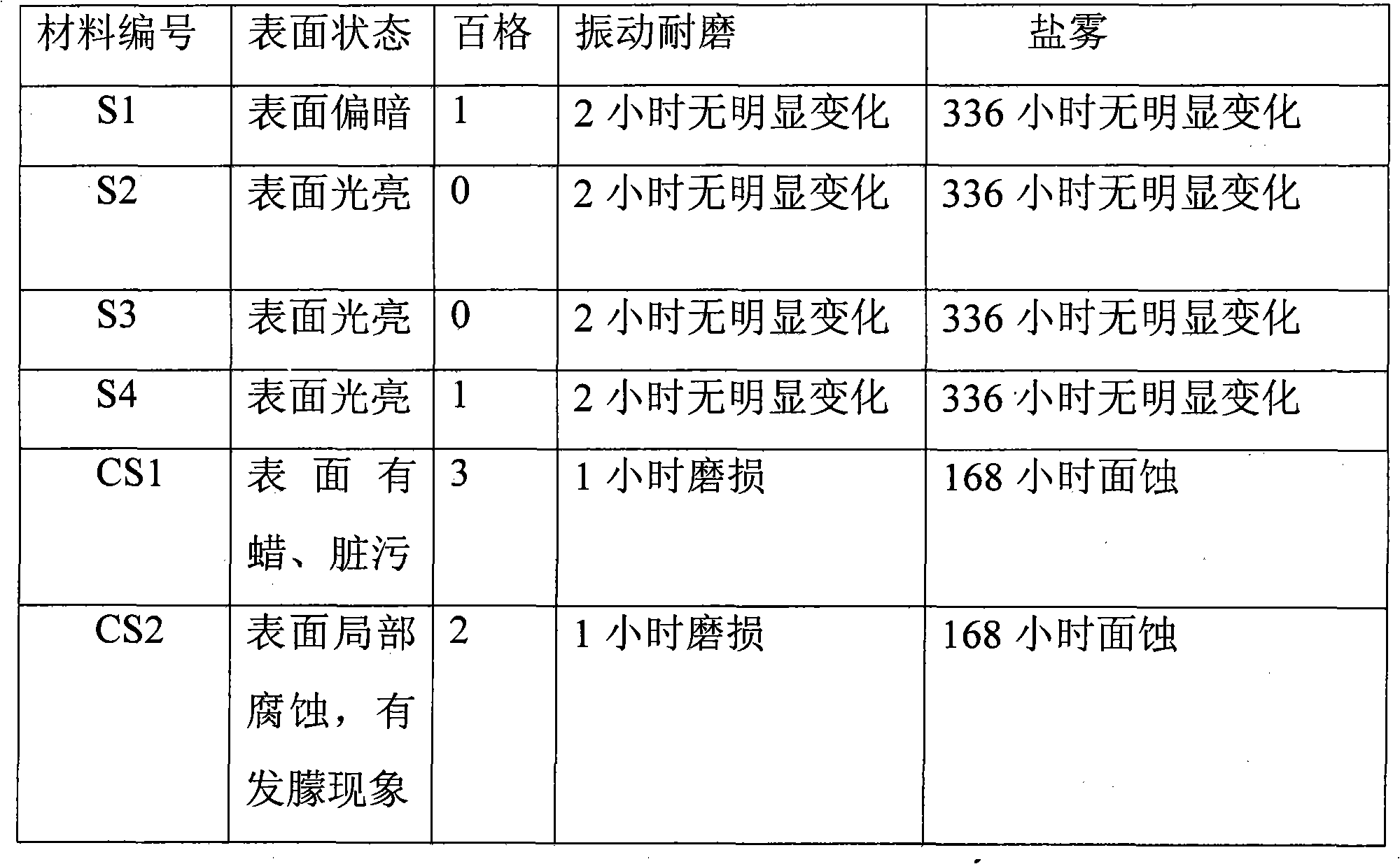

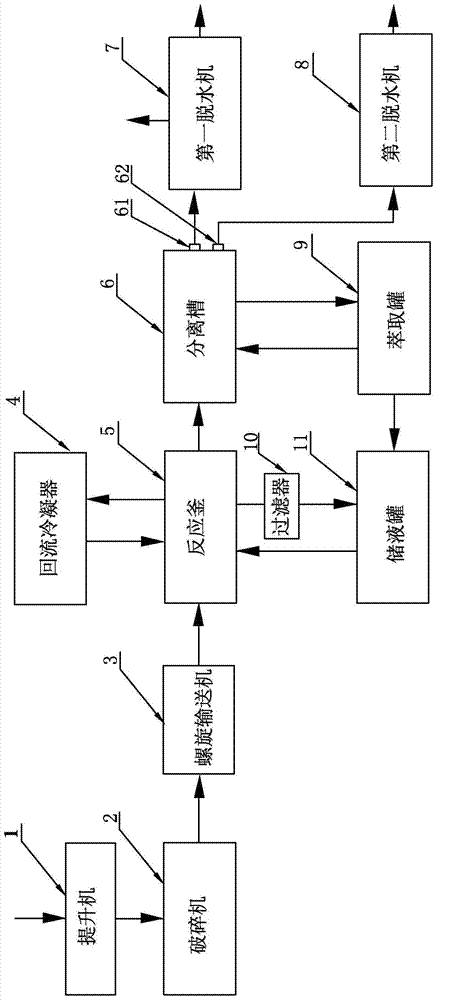

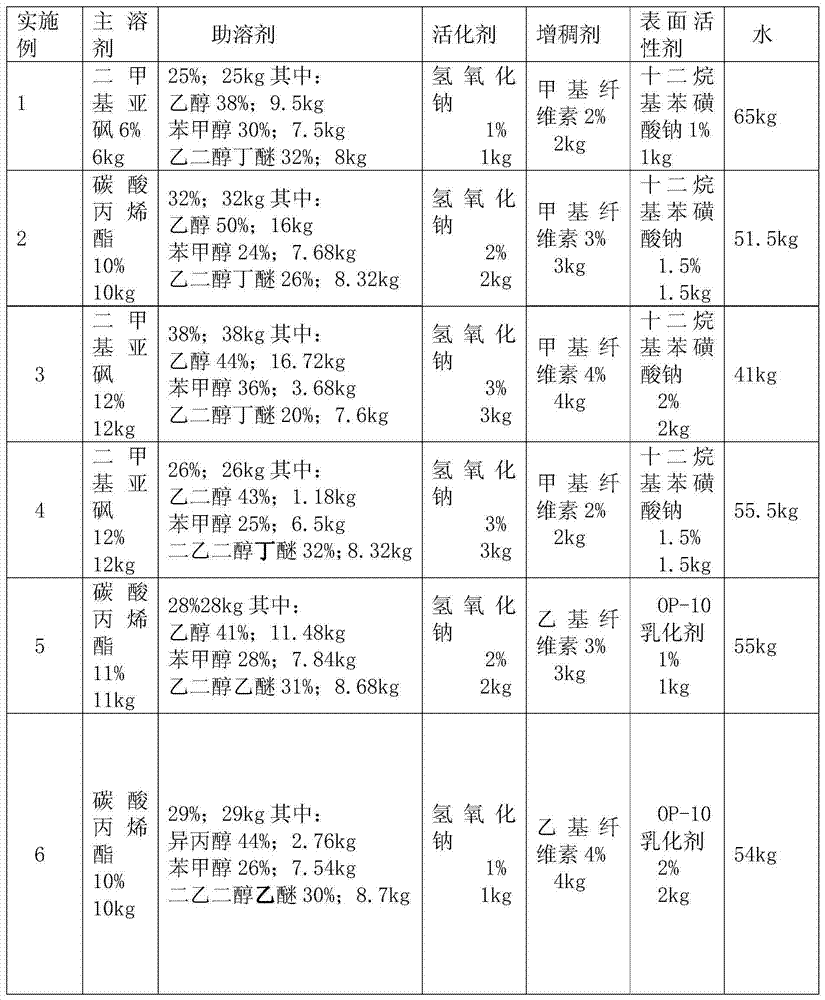

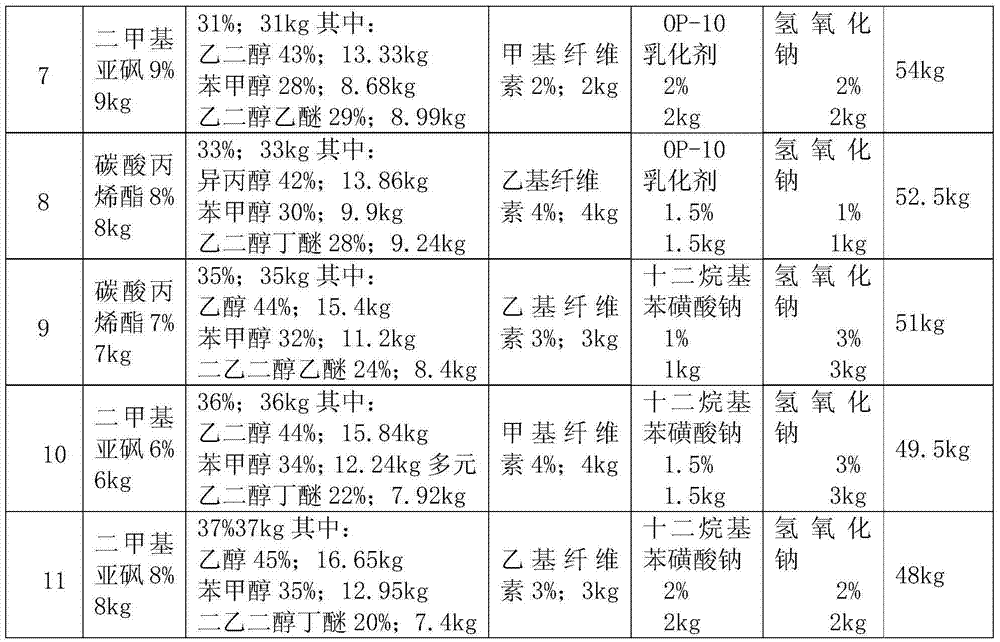

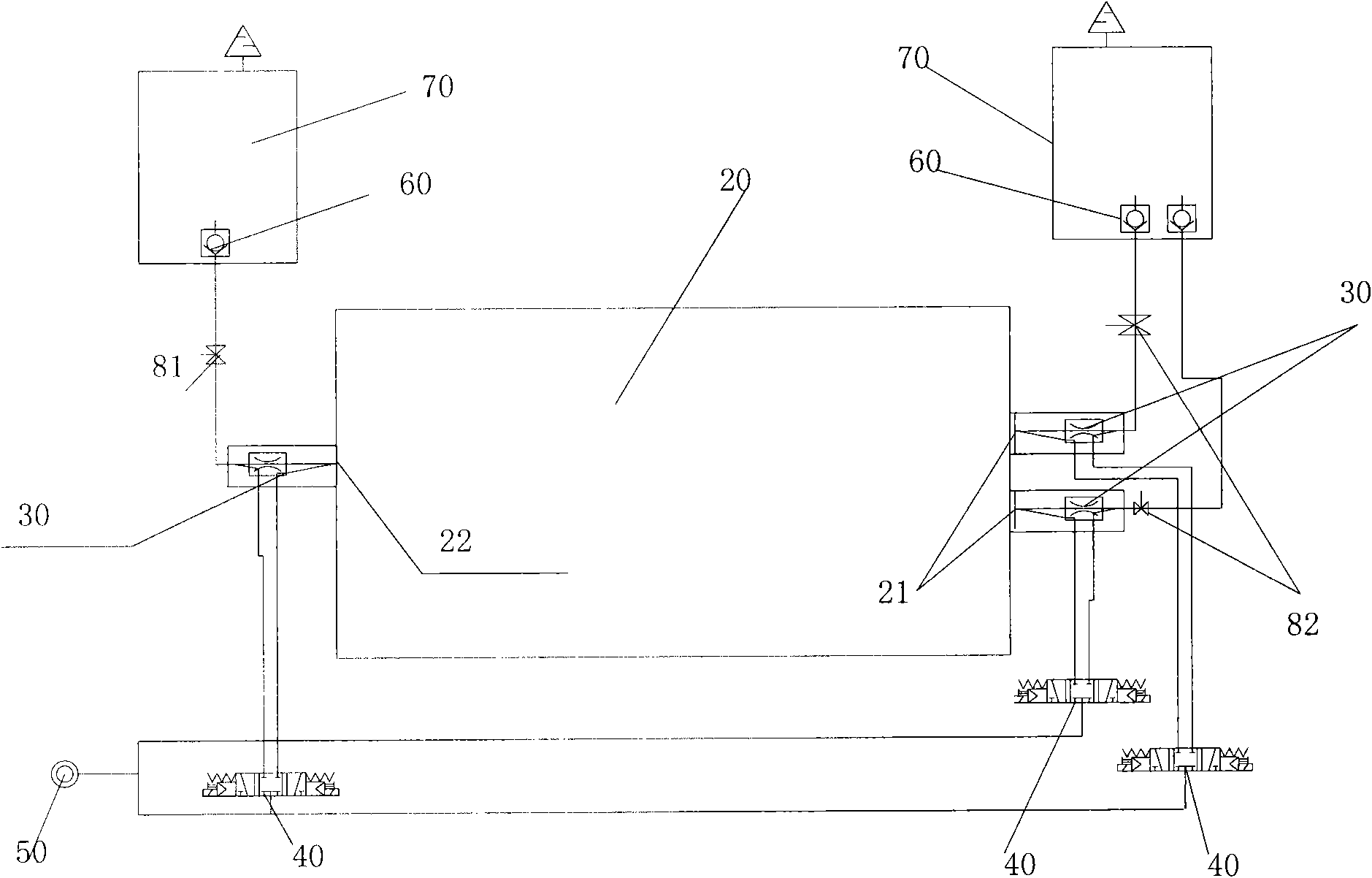

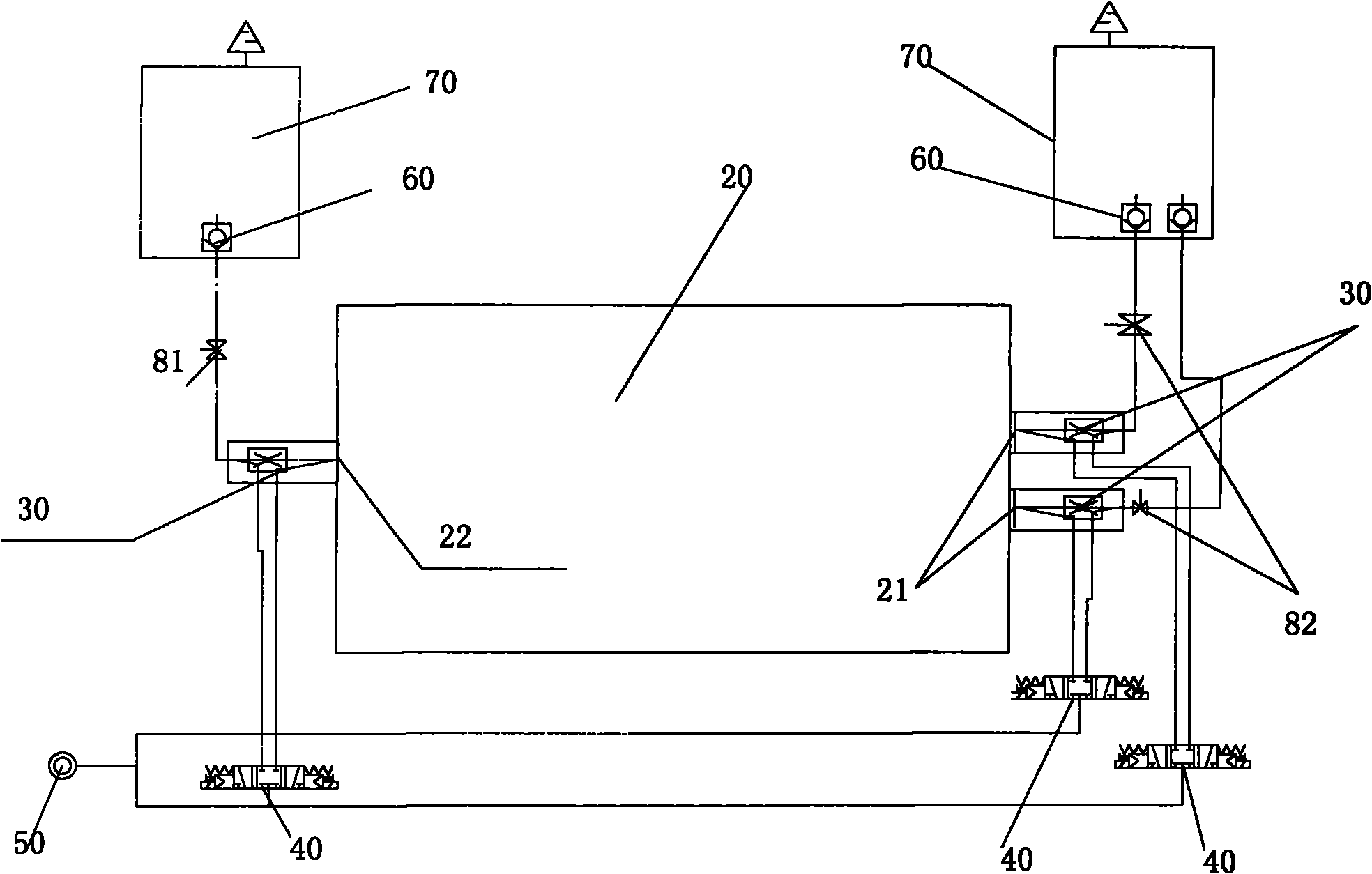

Plastic adhesion layer cleaning agent as well as plastic cleaning process and equipment adopting same

The invention relates to a plastic adhesion layer cleaning agent as well as a plastic cleaning process and equipment adopting the same. The cleaning agent comprises the following components in percentage by mass: 6-12 percent of a master solvent, 25-38 percent of a cosolvent, 1-3 percent of an activating agent, 2-4 percent of a thickener, 1-2 percent of a surfactant and the balance of water, wherein the master solvent is dimethyl sulfoxide or propylene carbonate; the cosolvent comprises the following components in percentage by mass: 38-50 percent of monohydric alcohol or polyhydric alcohol, 24-36 percent of phenylcarbinol and 20-32 percent of polyhydric alcohol ether. The cleaning process comprises the following steps: crushing plastic to form plastic fragments; putting the plastic fragments and the cleaning agent into a reaction kettle according to a mass ratio of 1: 2; heating to 65-75 DEG C in a sealed manner and stirring for 20-40 minutes; leading the cleaning agent out for recycling; separating and dehydrating the plastic fragments and stripped substances of the adhesion layer to obtain a recycled plastic finished-product; and periodically extracting liquid in a separating tank and recovering the cleaning agent. The equipment comprises the reaction kettle, the separating tank, an extracting pot, a liquid storage pot and a reflux condenser.

Owner:天津市生态环境科学研究院

Airflow blow and suction vibration cleaning method and device of engine cylinder cover

ActiveCN101865029AGet over stuckOvercoming the Difficulty of Depositing in Narrow Cavity BendsMachines/enginesEngine componentsEngineeringContract type

The invention relates to airflow blow and suction vibration cleaning method and device of an engine cylinder cover. The device comprises a Venturi tube. Air outlet pipelines are arranged in the expanding section and / or shrinkage section of the Venturi tube; the air outlet pipelines are communicated with an intake pipe; and the air outlets of the air outlet pipelines face the media flowing direction of the Venturi tube. By utilizing the device, two-direction alternate blow and suction cleaning is realized on box parts, such as the engine cylinder cover and the like, the problem that aluminium skimming jam and deposit at contracted type cavity bends, caused by the unidirectional characteristic of the traditional cleaning process, is solved, the cleaning problem of the aluminium skimmings iseffectively solved, and the cleanness demand of the product is satisfied.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

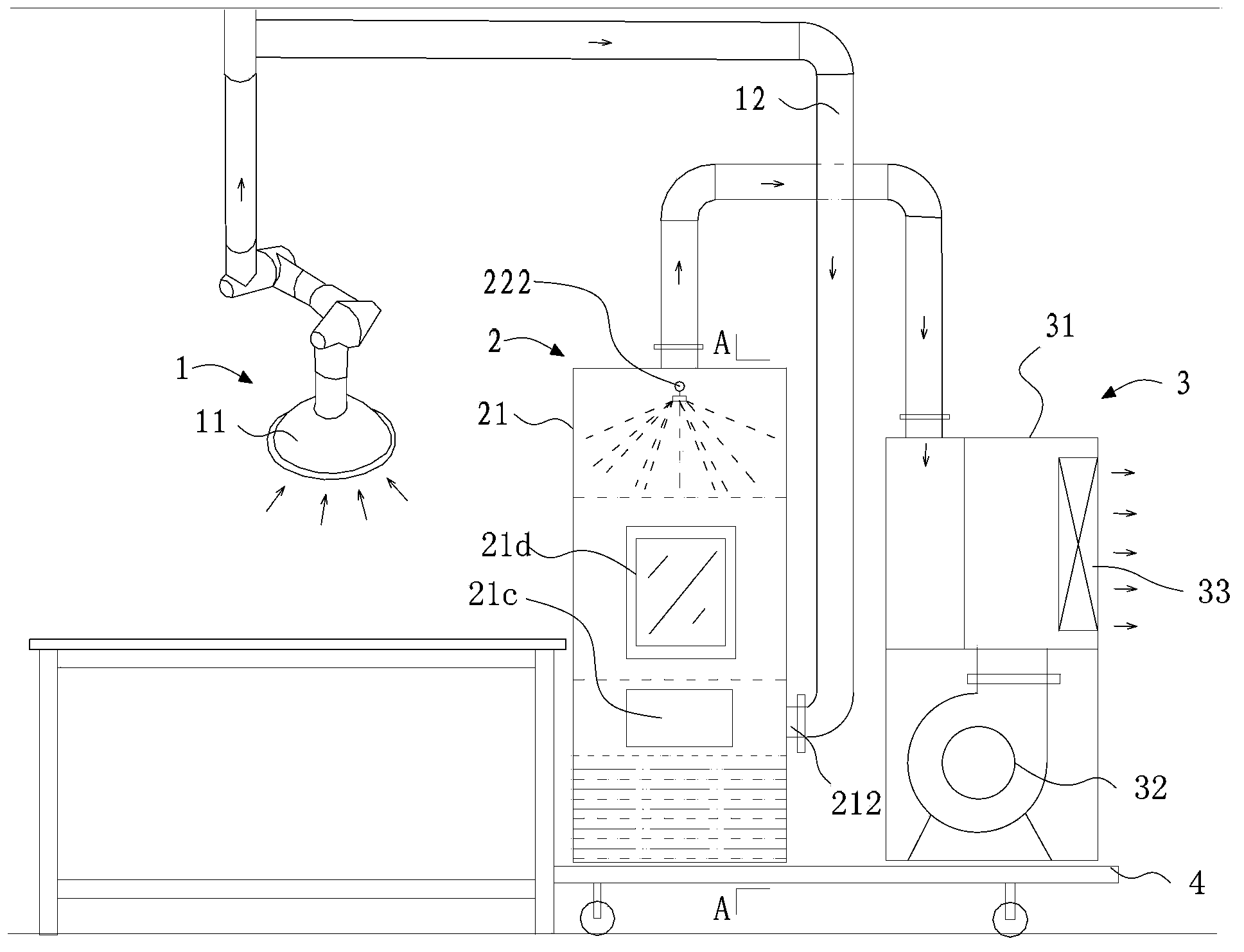

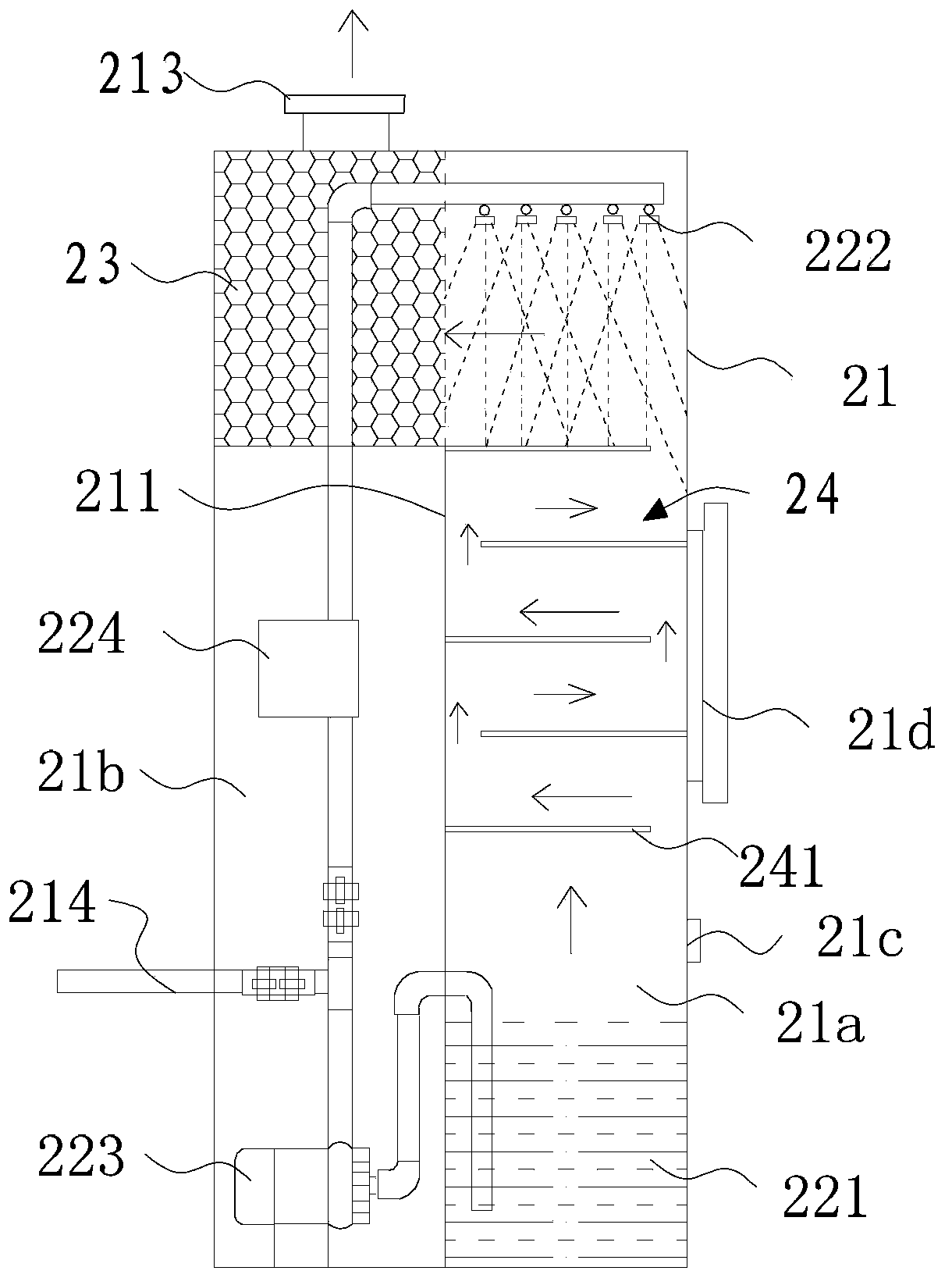

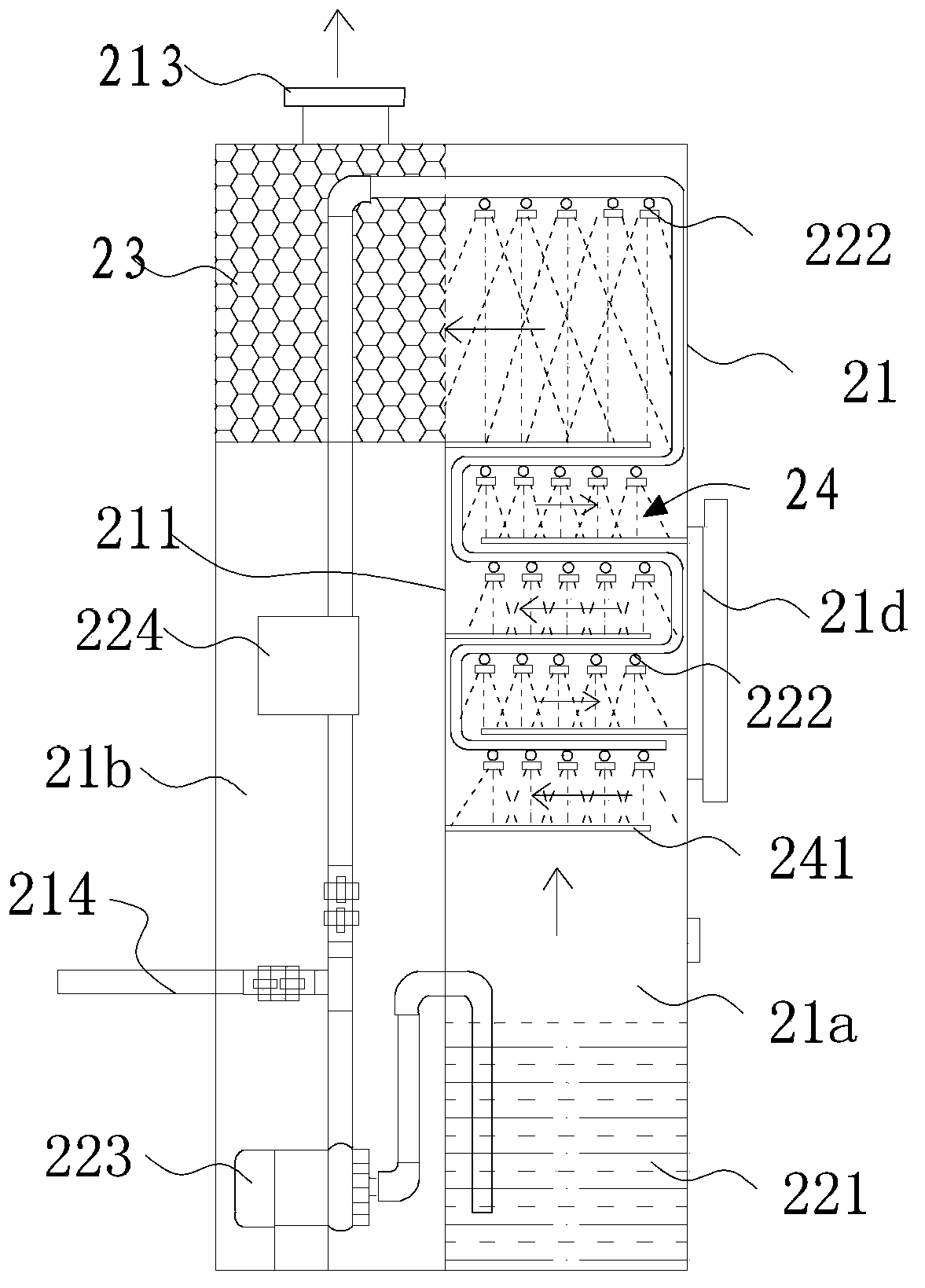

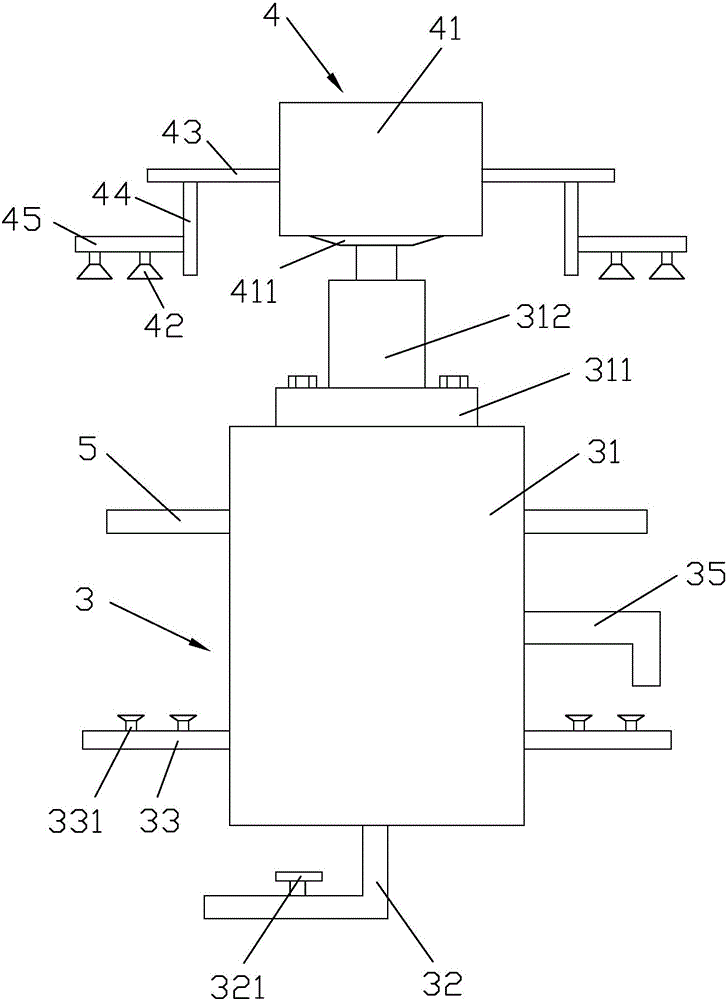

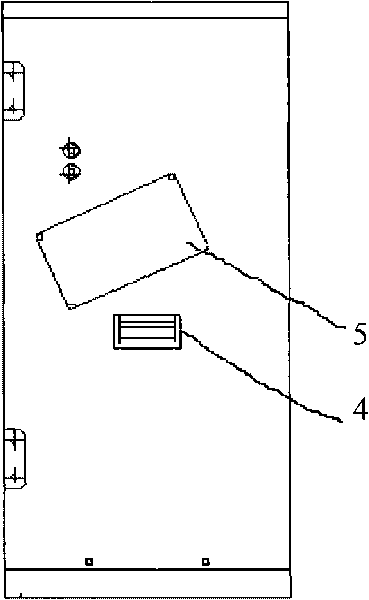

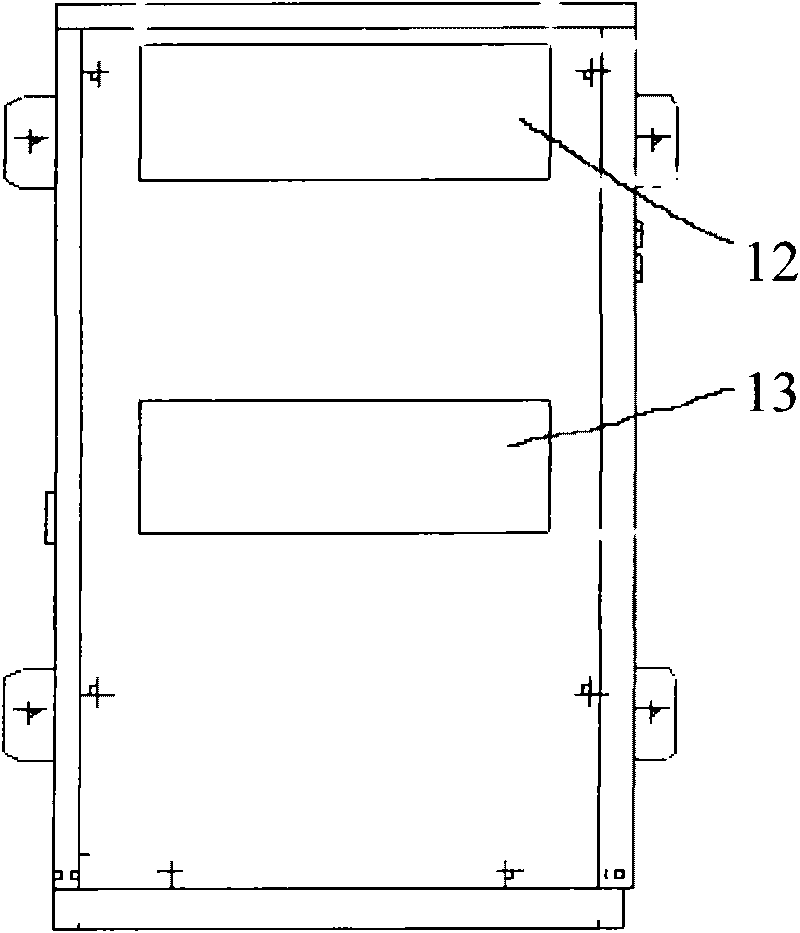

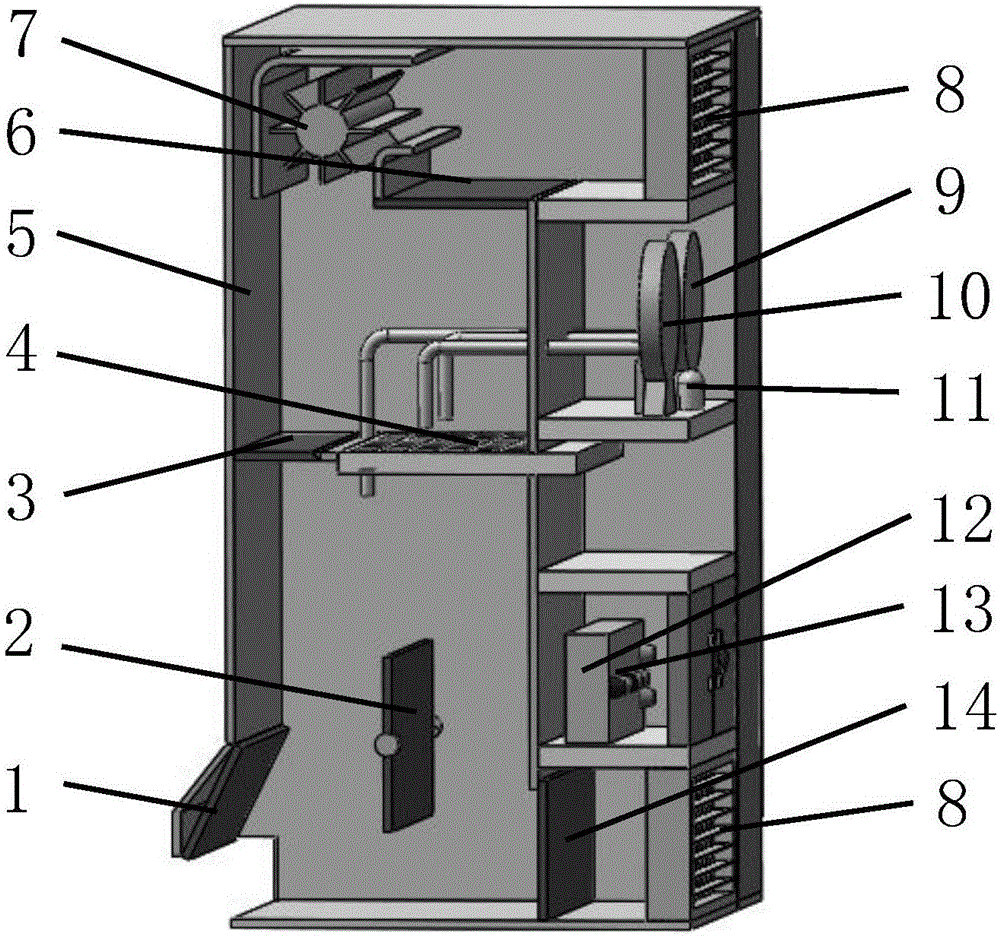

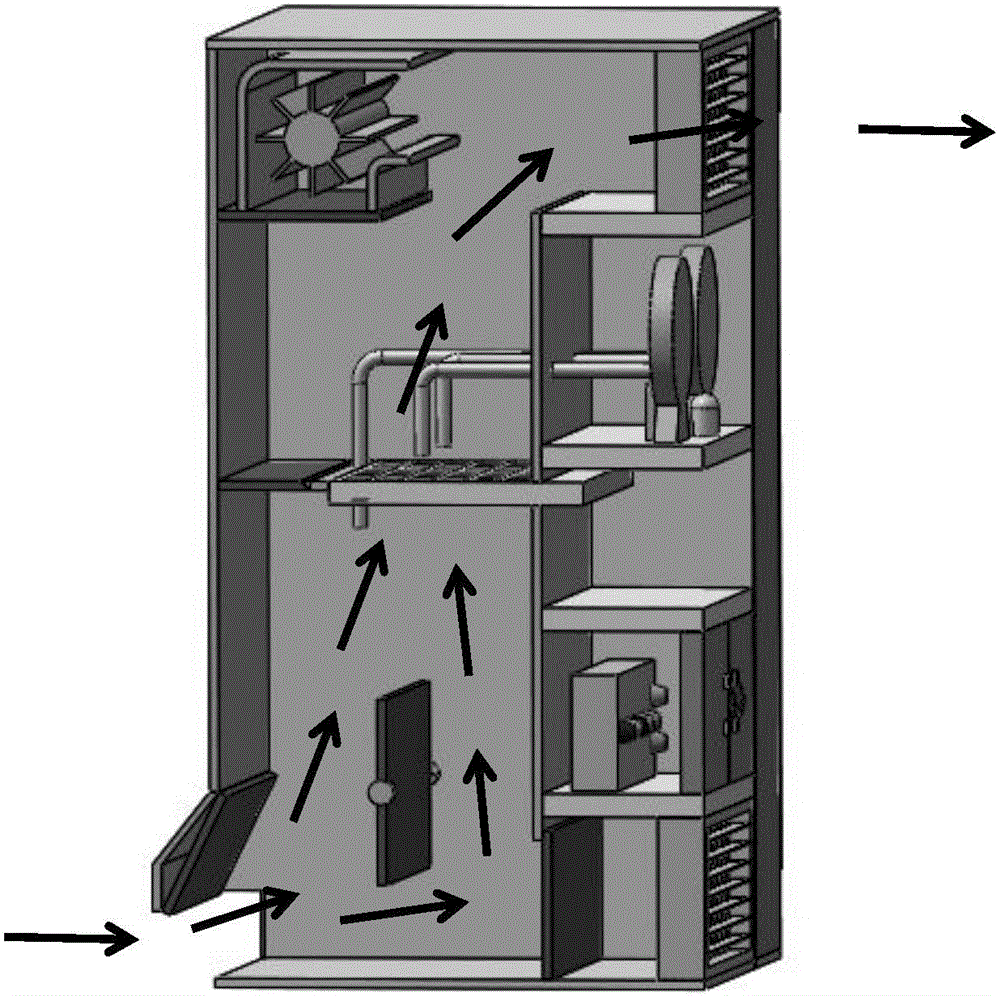

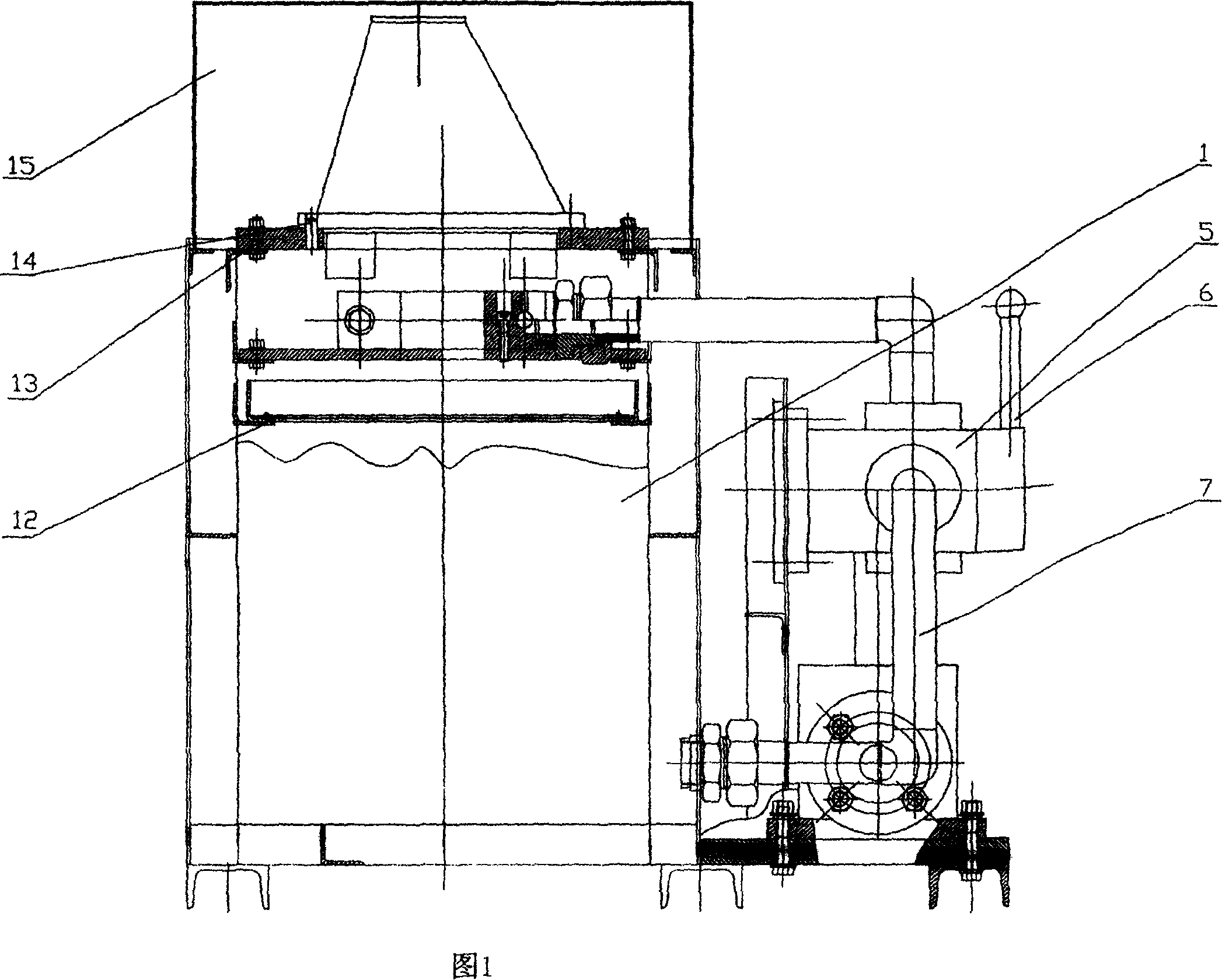

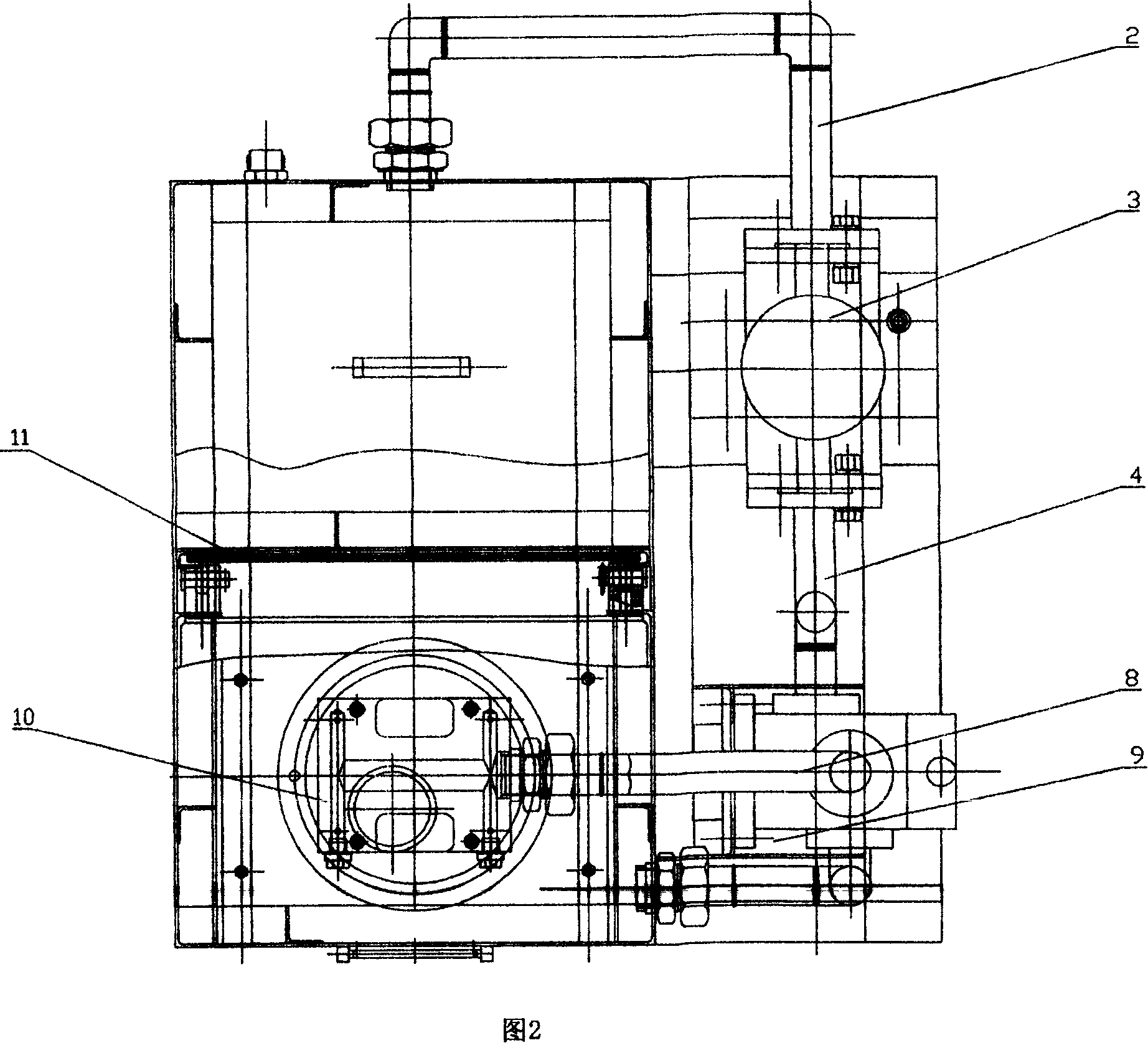

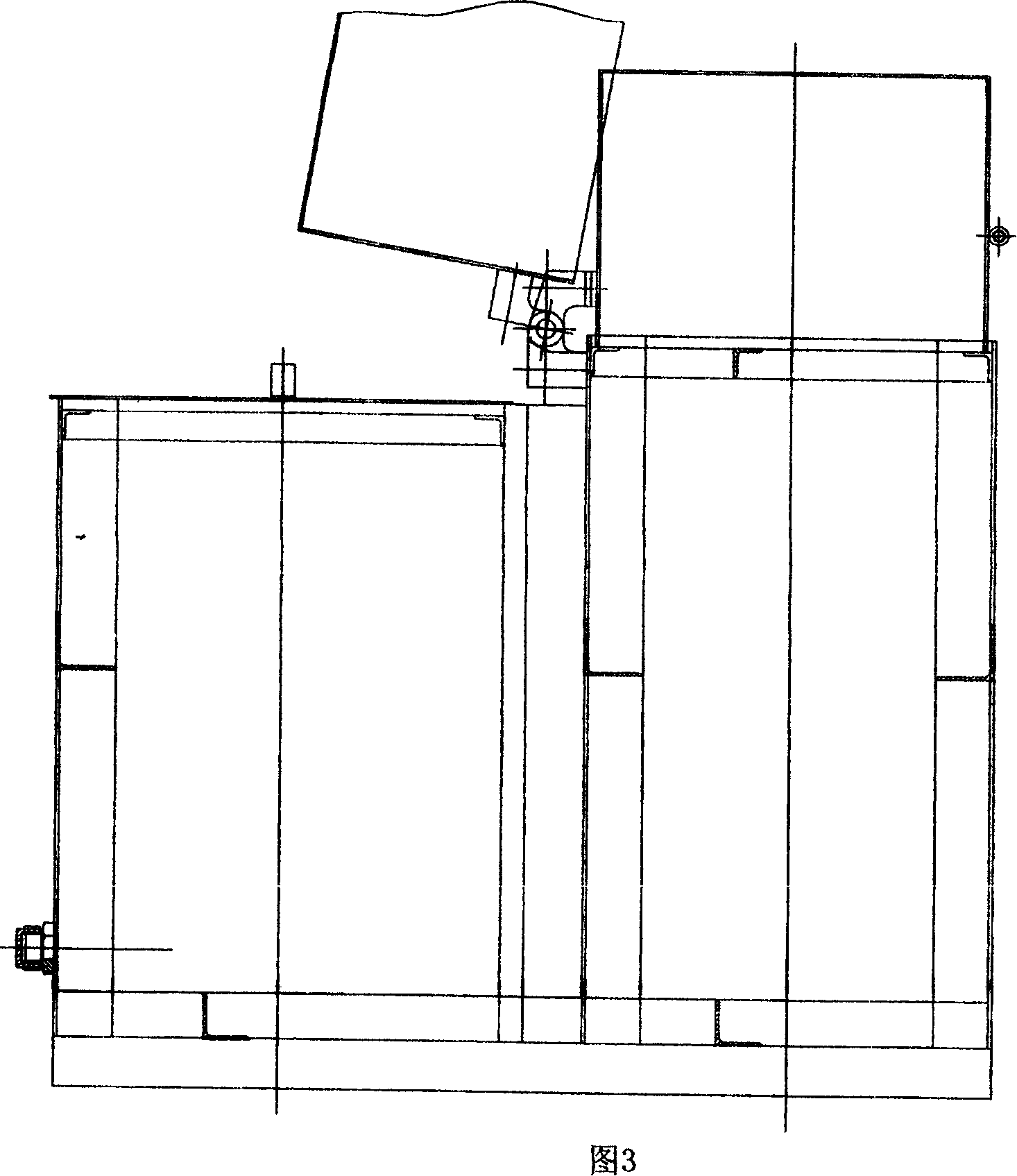

Waste gas and dust treating device

InactiveCN103505969ASimple structureMeet cleanliness requirementsUsing liquid separation agentAfter treatmentEmission standard

The invention provides a waste gas and dust treating device. The waste gas and dust treating device comprises a gas collecting device, a purification treatment device and a discharging device, wherein the gas collecting device is used for collecting waste gas and dust; the purification treatment device for purifying waste gas and dust collected by the gas collecting device is communicated with the gas collecting device and comprises a spraying device for spraying a washing liquid for washing the waste gas and the dust collected by a dust collecting device and a defogging device for dewatering and defogging gas which is obtained after the washing liquid sprayed by the spraying device is treated; the discharging device is used for discharging the gas treated by the purification treatment device and is communicated with the purification treatment device. The waste gas and dust treating device is simple in structure, and capable of effectively treating waste gas and dust and enabling the waste gas and the dust to achieve emission standards, thereby reducing pollution to workshop environment as well as harms to human bodies; the gas discharged after treatment of the waste gas and dust treating device can meet the cleaness requirement of the workshop environment and can be directly discharged into the workshop environment, so that both the cleaness requirement and the sealing requirement of the workshop environment are met.

Owner:BEIJING SKYWING TECH CO LTD

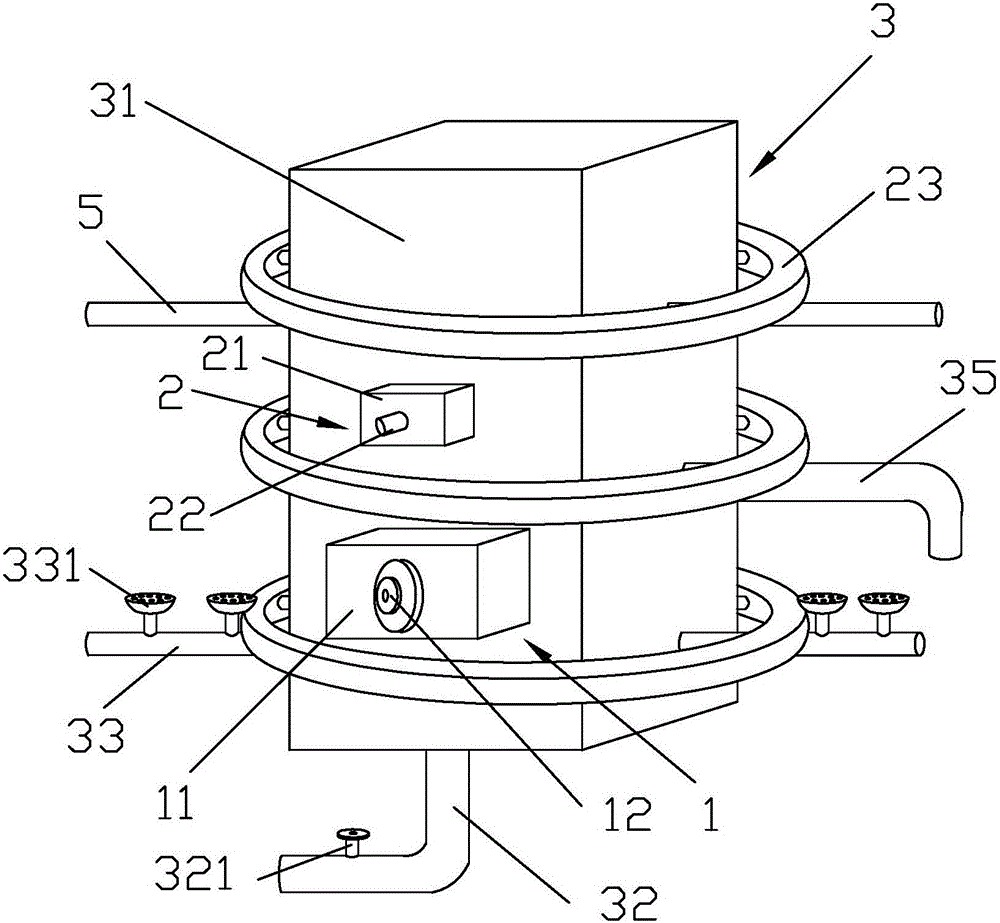

System and method for landscape fishpond purification treatment

ActiveCN106082533AExpand the range of suctionImprove water quality treatment effectWater cleaningTreatment using aerobic processesWater qualityEnvironmental engineering

The invention mainly discloses a system and method for landscape fishpond purification treatment. According to the technical scheme, the system comprises a water quality monitoring device, a water purification device and a water surface decontamination device, the water purification device comprises a shell, a water inlet pipe, an aerator pipe, a blowdown pipe and a water outlet pipe, a filtering area, an active mud area and a sterilization area are arranged in the shell from inside to outside in sequence in a nested mode, and both the water inlet pipe and the blowdown pipe are connected with the filtering area; the water outlet pipe is connected with the sterilization area, the two ends of the aerator pipe are located outside the active mud area and the shell respectively, and the water surface decontamination device comprises a collection box, a stain adsorption head and a stain adsorption pipe. The method comprises the steps of 1, installing the water purification device; 2, installing the water surface decontamination device; 3; conducting water quality detection; 4, conducting water purification; 5, conducting water surface purification; 6, conducting detection again; 7, cleaning the devices. The system is reliable in performance, water purification can be conducted automatically, water quality purification efficiency is high, treatment time and period are short, and normal operation of a fishpond system is guaranteed.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

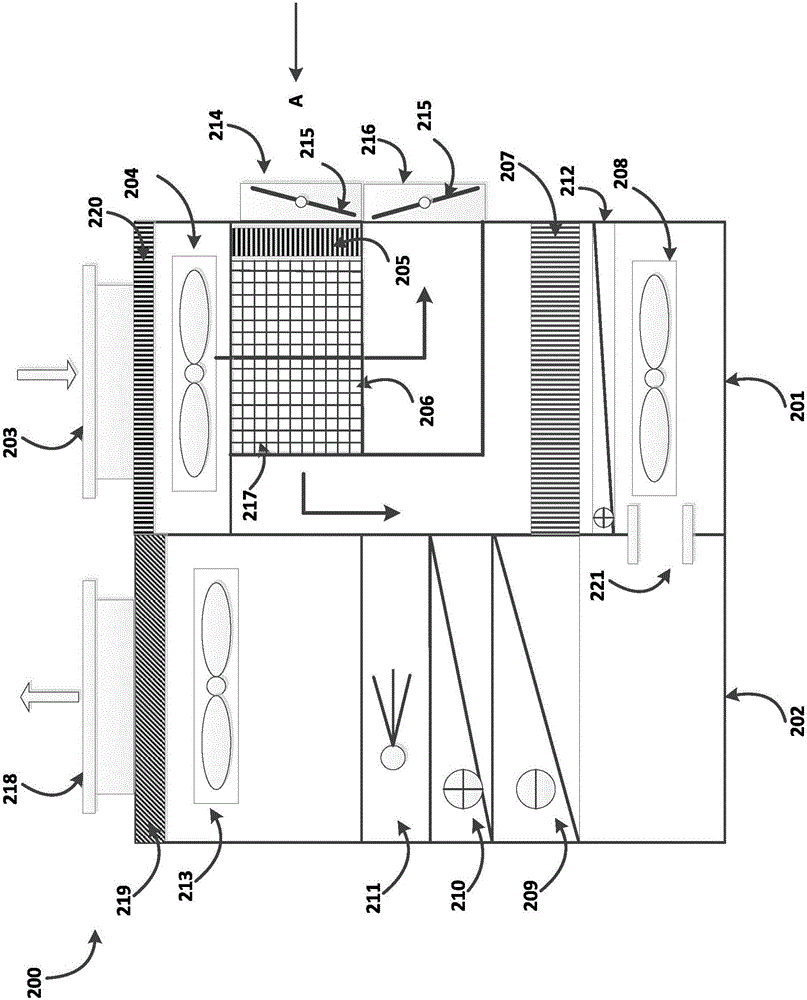

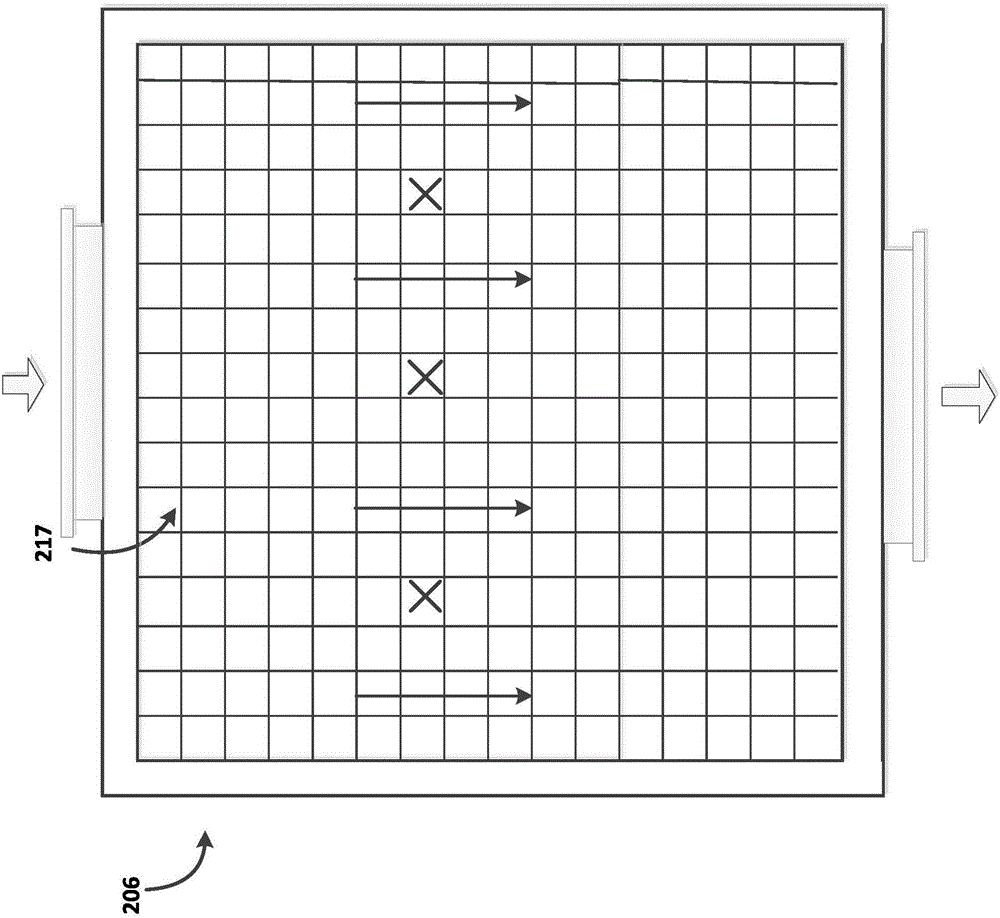

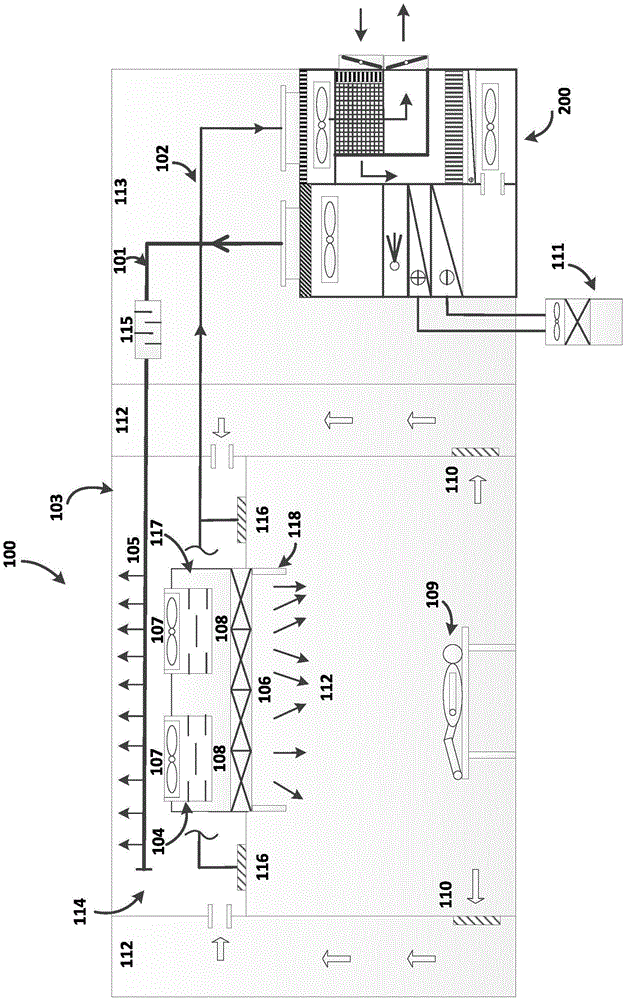

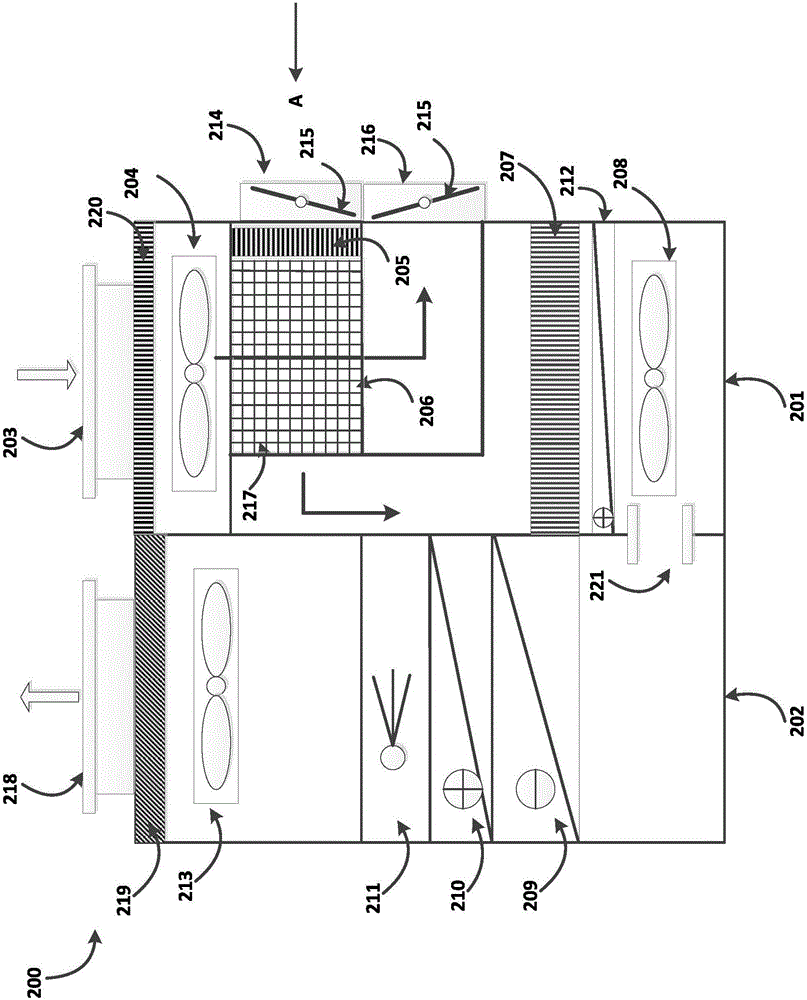

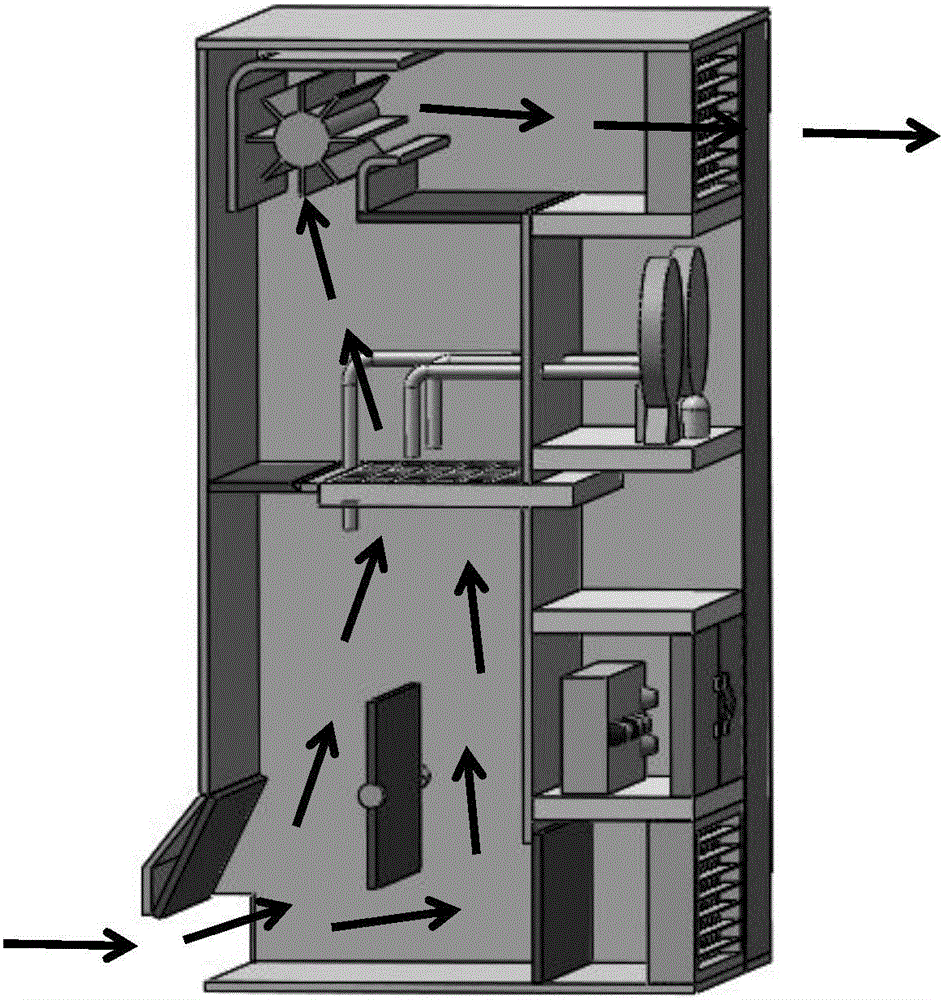

Modular working-condition-variable medical air purifying system

PendingCN106288064AQuick and easy to completeEfficient captureEnergy recovery in ventilation and heatingMechanical apparatusFresh airAir cleaning

The invention relates to a modular working-condition-variable medical air purifying system which comprises a medical air exhaust and fresh air integrated cabinet, a uniform air mixing and air supplying ceiling and a return air treater. The medical air exhaust and fresh air integrated cabinet is used for treating and outputting input fresh air and to-be-exhausted air, the uniform air mixing and air supplying ceiling is used for uniformly mixing, filtering and outputting introduced fresh air in a form of weak turbulence, and the return air treater is used for purifying, filtering and outputting return air. By utilizing the air purifying system postoperative infection rate can be lowered obviously, energy consumption can be lowered greatly, and building cost, building period and space requirements (needlessness of special machine room, few valves and short air pipe) of an operation room can be lowered remarkably at the same time. In addition, the invention further relates to the corresponding operation room.

Owner:殷晓冬

Low-noise modular air purification system

InactiveCN106678966AHighly integratedShort noiseMechanical apparatusLighting and heating apparatusLow noiseAir volume

The invention relates to a low-noise modular air purification system. The low-noise modular air purification system comprises a medical exhaust air and fresh air integrated cabinet, a return air processing and air supply ceiling and return air ports, wherein the medical exhaust air and fresh air integrated cabinet is used for feeding fresh air and to-be-exhausted air and exhausting the fresh air and the to-be-exhausted air after processing; the return air processing and air supply ceiling is used for evenly mixing, purifying and filtering the introduced fresh air and return air and exhausting the mixed air in a light turbulence mode; and a medical room and a return air channel communicate through the air return ports so that the return air can be introduced into the return air processing and air supply ceiling. The low-noise modular air purification system can remarkably decrease the rate of postoperative infection and greatly reduce energy consumption; meanwhile, through highly integrated equipment and the modular installation mode, the construction cost and complexity are remarkably reduced, so that the construction cost of operating rooms is remarkably reduced, and the construction period of operating rooms is remarkably shortened; due to the facts that no special machine room or return air pipeline is required and the number of valves is small, the space requirements are reduced remarkably; and besides, noise can be remarkably lowered on the premise that sufficient air volume is ensured.

Owner:殷晓冬

Cleaning process of hydraulic parts

InactiveCN102580951AAvoid it happening againMeet cleanliness requirementsCleaning using liquidsMegasonic cleaningMechanical engineering

The invention provides a cleaning process of hydraulic parts, which includes steps: a, spraying for cleaning, namely placing workpiece in a rotary spraying cleaner, and rotatably spraying purified water to clean the surfaces and the inner surfaces of the workpieces; b, immersing for cleaning, namely immersing the workpieces sprayed at the step a in aqueous cleaning liquid; c, powerful rotary turbulent cleaning, namely placing the workpieces immersed at the step b in the rotary spraying cleaner to quickly spray aqueous cleaning liquid to inner holes and inner cavities of the workpieces so as to achieve liquid surface oscillation for repeated cleaning; d, ultrasonic cleaning, namely placing the workpieces subjected to powerful rotary turbulent cleaning at the step c into an ultrasonic cleaner to clean the workpieces with the aqueous cleaning liquid; e, rinsing, namely using antirusting agent contained aqueous cleaning liquid to rinse the workpieces subjected to ultrasonic cleaning at the step d; f, hot air for drying, namely subjecting the workpieces rinsed at the step e to rotary hot air drying; and g, vacuum drying, namely subjecting the workpieces subjected to hot air drying at the step f to vacuum drying at the pressure of 8-10mbar for 3-5 minutes.

Owner:SHANDONG CHANGLIN MACHINERY GRP

Natural cooling intelligent fan set and using method thereof

InactiveCN101749824AReduce power consumptionAchieve energy saving effectMechanical apparatusSpace heating and ventilation safety systemsTemperature controlFree cooling

The invention relates to a natural cooling intelligent fan set, which has two integrated and split-type structures. The difference between the two structures is whether an air outlet is separated from a set host. The natural cooling intelligent fan set comprises the set host, a controller and a manual operation device. One side of the set host is provided with the controller and the manual operation device. The inside of the set host is provided with an EC centrifugal fan, a temperature sensor, a humidity sensor, a fan switch control device, a temperature control device and a monitor. The natural cooling intelligent fan set is also provided with an air supply outlet and the air outlet. A method for the natural cooling intelligent fan set comprises that when signals acquired by the temperature sensor and the humidity sensor meet requirements, an air-conditioning system is closed, and the EC centrifugal fan is started; and the outdoor low-temperature air is introduced in the room by the air supply outlet, and at the same time the hot air is exhausted from a base station by the air outlet. The invention has the advantages that the natural cooling intelligent fan set realizes temperature reduction by introducing the outdoor low-temperature air into the room to achieve the aim of energy saving and emission reduction; and the natural cooling intelligent fan set has simple system structure, convenient implementation and low cost, is suitable for the society development demand and is beneficial for popularization of the product.

Owner:AIRSYS REFRIGERATION ENG TECH BEIJING

Building haze prevention ventilation purifier

ActiveCN106765836AMeet individual needsAvoid excessive ventilationMechanical apparatusSpace heating and ventilation safety systemsAir volumeIndoor air quality

The invention discloses a building haze prevention ventilation purifier. According to the ventilation purifier, the open degree of an air inlet is changed through rotation of an air volume adjusting plate under the action of air pressure, and thus the air inlet volume in an adjusting chamber is fed back. The adjusting plate conducts vertical position adjustment through a gear connection rod mechanism so as to change the area, impacted by air pressure, of the adjusting plate, and the needs for ventilation quantity in different seasons are met. A filter in the building haze prevention ventilation purifier is provided with an ash deposition indicating device and a scrap reminding device. The ash deposition indicating device can display the front and back differential pressure of the filter under real-time air speed so as to reflect the ash deposition degree of the filter. According to the scrap reminding device, when the filter is in a scrap state, a differential pressure linkage pointer makes contact with an air speed linkage pointer, a circuit is turned on, and an indicator light is on to remind a user of replacement of a filter screen. When the cleanliness of outdoor air is high, the ventilator bypasses the filter, the service life of the filter can be prolonged, and ventilation energy consumption is reduced. Through the building haze prevention ventilation purifier, indoor air quality of a building is effectively improved with small cost.

Owner:DALIAN UNIV OF TECH

Weak turbulence air purification system capable of regulating cleanliness

PendingCN107883436AReduce the risk of infectionSave electricityMechanical apparatusLighting and heating apparatusAuto regulationAir volume

The invention relates to a weak turbulence air purification system capable of regulating cleanliness. The system is provided with one or more fresh air units, a blowing ceiling, a return air processorand a central controller, wherein the one or more fresh air units is provided with a fan, a fresh air filter layer, a dehumidifying device and an air conditioning device; the blowing ceiling is provided with a filter module which is configured to diffuse input fresh air and return air, so that the fresh air and return air enter a medical room in a form of weak turbulence; the return air processorcomprises a return air filter device for purifying and filtering imported return air; and the central controller is configured to adjust the capacities, for example, blast capacity, cooling capacity,heating capacity, humidification amount and etc.) of various functional units of the air purification system manually or automatically according to the environmental requirements (for example, temperature, humidity, air speed, cleanliness, pressure difference of a filter and etc.) of the medical room (for example, operating rooms of various types). The invention also relates to a corresponding operating room capable of regulating the cleanliness.

Owner:殷晓冬

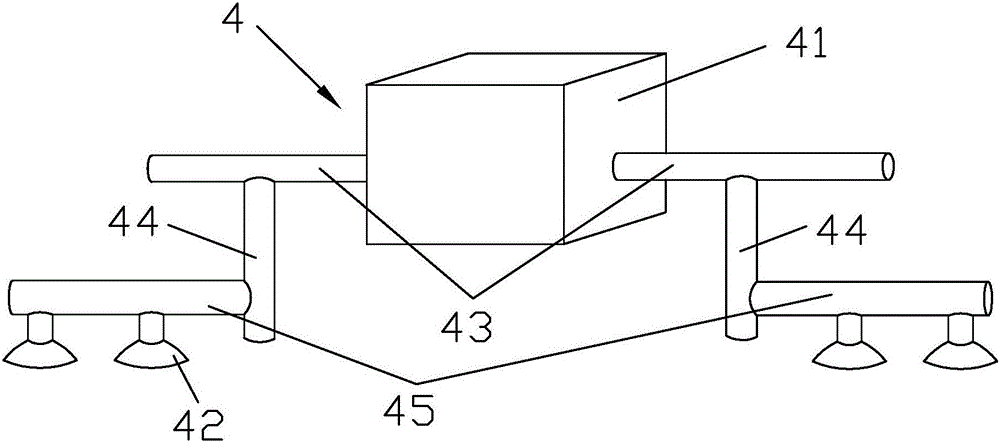

Bag clamping device for open bag automatic filling machine

ActiveCN105600017BGood for bagging and unloadingSimple structurePackagingChinese charactersEngineering

The invention provides a bag clamping device of an automatic open bag filling machine and belongs to the technical field of packaging machinery. The automatic open bag filling machine comprises a machine frame and a blanking mechanism. The bag clamping device comprises a bag clamping hanging rack, a pair of bag opening clamping-placing acting cylinders, a double-stroke acting cylinder and a clamping-placing acting cylinder linkage mechanism, wherein the bag clamping hanging rack is of a Chinese character 'kou' shaped frame-like structure formed by connecting a bag clamping hanging rack front frame strip, a bag clamping hanging rack rear frame strip, a bag clamping hanging rack left frame strip and a bag clamping hanging rack right frame strip, a supporting plate is arranged at the center position of the bag clamping hanging rack left frame strip, a double-stroke acting cylinder column swing arm shaft seat is arranged at the lower end of the supporting plate, the cylinder body tail portion of the double-stroke acting cylinder is fixed to the front end of a double-stroke acting cylinder fixing strip, the rear end of the double-stroke acting cylinder fixing strip is fixed to the upper end of the supporting plate, the clamping-placing acting cylinder linkage mechanism is hinged to the tail end of a double-stroke acting cylinder column, the bag opening clamping-placing acting cylinders correspond to each other, and bag opening clamping-placing devices in the bag opening clamping-placing acting cylinders are downward. The bag clamping device facilitates bagging and blanking of the blanking mechanism and meets the clean and tidy requirements of the automatic open bag filling machine.

Owner:CHANGSHU SANHE PRECISION MACHINERY & TECH CO LTD

Blind screw hole cleaning machine

InactiveCN101020181AQuality no special requirements noNo pollution in the processMultiple way valvesCleaning using liquidsAgricultural engineeringWater pipe

The present invention belongs to the field of machinery, and is especially one kind of blind screw hole cleaning machine. The blind screw hole cleaning machine includes frame, water tank, centrifugal pump, water jetting system, etc. The water tank is connected through water inlet pipe to the water inlet of the centrifugal pump, the centrifugal pump is connected through connecting water pipe to the water inlet of a T-valve assembly, and the T-valve assembly has water outlet connected to the water jetting system, water returning port connected to the water tank, and valve core with port connected to the water outlet or the water returning port and connected to the control handle. The present invention has simple operation, no environmental pollution and high production efficiency.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

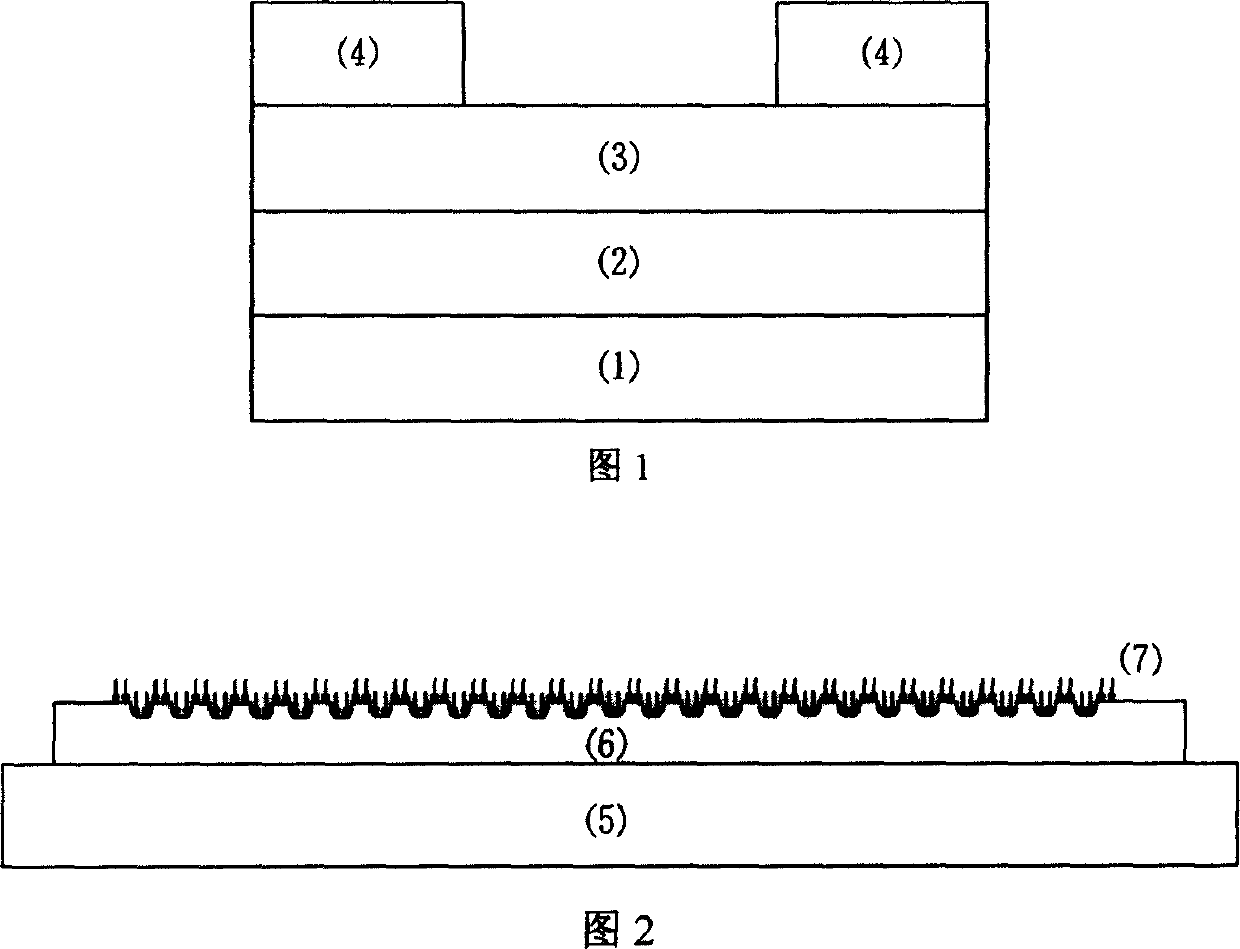

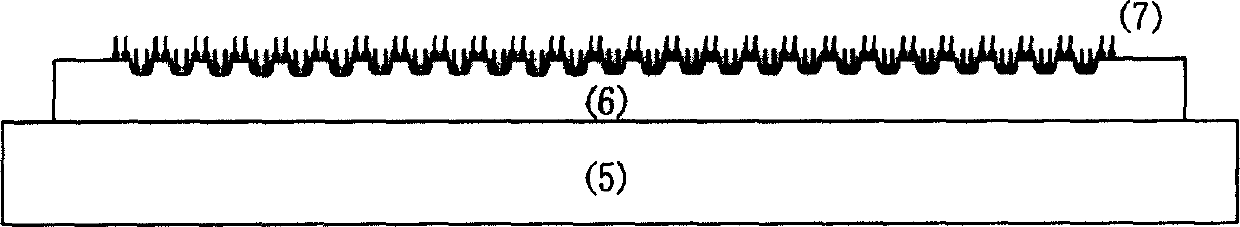

Organic field effect tube using single molecular layer as oriented transfer layer and its preparing method

InactiveCN1684286AIncreased anisotropyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMolecular arraySilanes

This invention provides an OFET device and its preparation method including an orientation transfer layer for transferring orientation efficiency, which can increase the carrier mobility of the OFET since the orientation transfer layer is the insulation one. Said one is a mono-film formed by processing the surface with silane coupler which can optimize the orientation result of the orientation layer and transfer it to the organic layer. This invention can improve molecular arrays of the organic molecular layer by transferring the orientation result to improve the carrier mobility of the OFET devices applying said orientation layer.

Owner:FUDAN UNIV

Modified method for semi-glue die-cut product processing technique

InactiveCN101186787AAvoid secondary pollutionImprove cleanlinessFilm/foil adhesivesManufacturing technologyAdhesive

Disclosed is an improved process of the manufacture technology of semi-colloid die-cutting products. 1, in the procedure of compounding materials, a protective paper of which the size is wider than a double sticky tape via certain specification is chosen to proceed the double-faced compounding, which enables an upper layer protective paper and a lower layer protective paper of the double sticky tape to be equal in width, but to be a little bit wider than the double sticky tape via certain specification.2, the shape of the products is cut by the die-cutting of a machine from the front surface in the manner of semi-cutting, the key point is that a handle portion is enabled to be cut on the adhesive-free protective paper, the left-right position of the material should be concentrated at any time, simultaneously, the machine can automatically proceed arranging waste edges and cutting single sheet.3, finished products are produced after the machine cuts sheet, inspectors check the positions of the semi-adhesive, and the qualified products can be packed, consequently the procedure is finished. Take an ordinary semi-adhesive product for example, 40,000 times of die-cutting can be finished in eight hours, and then 40,000 products can be produced by the calculation of one product by one time. The subsequent work of boding products by hand of 40,000 products cut by the conventional technical process demands 15 persons and eight hours to accomplish. Compared with the conventional technical process, 40,000 products cut by the improved technology only demand one person and four hours to check and pack, thereby greatly saving labor resource and reducing cost.

Owner:TIANJIN NIUSIDA PACKAGE NEW TECH

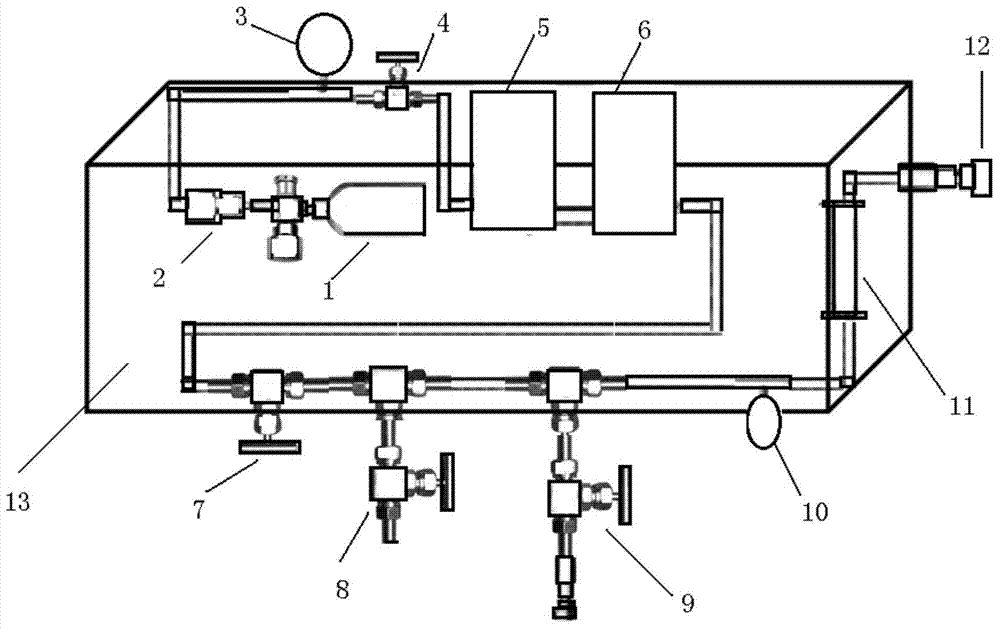

Sample pretreatment method of laser Raman natural gas analyzer and device thereof

InactiveCN104713766AResolve distortionMeet temperature requirementsPreparing sample for investigationPretreatment methodThermostat

A sample pretreatment method of a laser Raman natural gas analyzer and a device thereof belong to the technical field of petroleum and natural gas detection devices. The method comprises the following steps: opening an explosion-proof thermostat, putting a sample bottle into the thermostat, and successively connecting the sample bottle, a pressure gage, a first pressure-regulating valve, a first filter (1 micron), a second filter (0.1 micron), a second pressure-regulating valve, an unloading tee, a standard gas inlet, a pressure gage, a flowmeter and an analyzer interface; closing the thermostat, switching on a power supply of the thermostat to heat to a required temperature value, and keeping constant temperature; closing the unloading tee and a valve at the standard gas inlet, adjusting the pressure-regulating valve, carrying out gas-path purging, and connecting to the analyzer through the analyzer interface. As a natural gas sample is heated, a heavy hydrocarbon component in the sample is in a gaseous state and enters a gas path. Thus, the distortion problem of the natural gas sample due to condensation of heavy hydrocarbon is solved.

Owner:PETROCHINA CO LTD

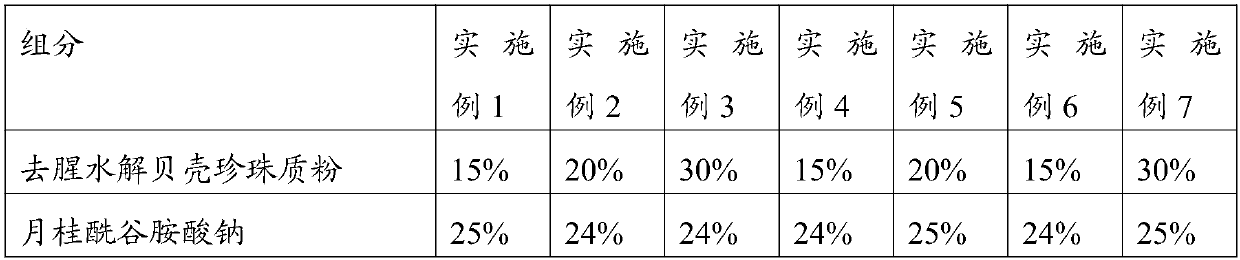

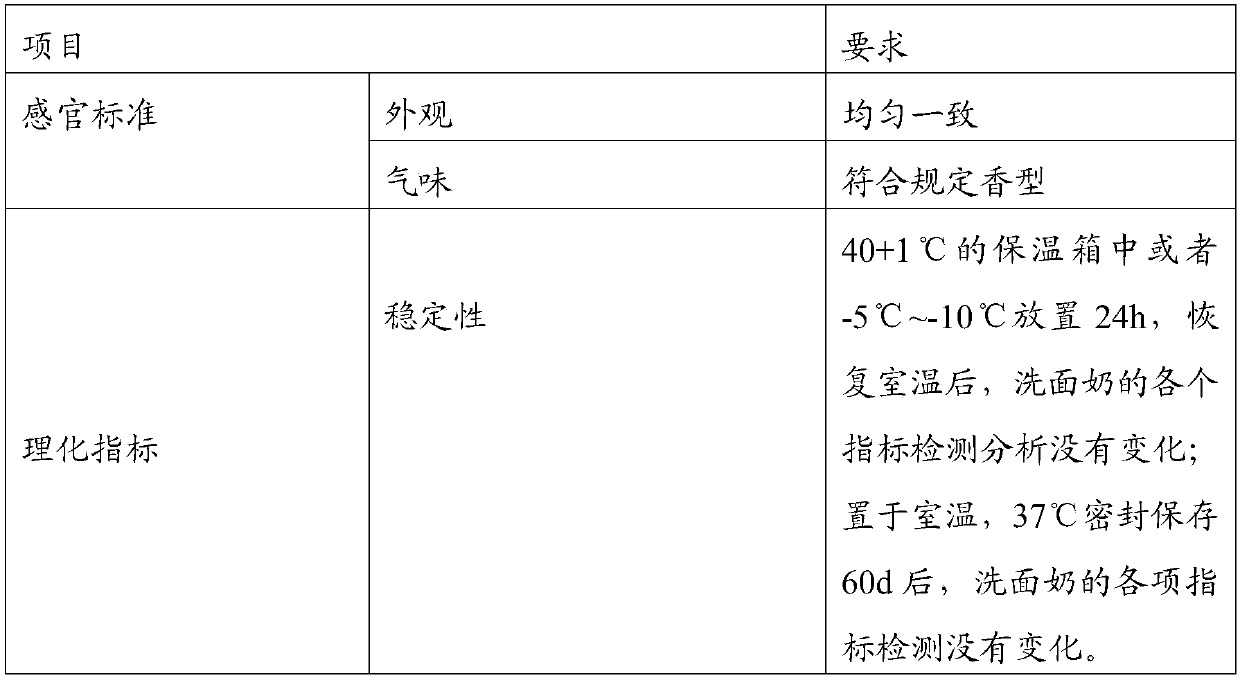

Amino acid facial cleanser based on hydrolyzed shell pearl powder and preparation method thereof

InactiveCN107638362AImprove health statusImprove moisturizingCosmetic preparationsToilet preparationsGrape seedPeppermints

The invention discloses an amino acid facial cleanser based on hydrolyzed shell pearl powder and a preparation method of the amino acid facial cleanser based on the hydrolyzed shell pearl powder. Theamino acid facial cleanser based on the hydrolyzed shell pearl powder is characterized by comprising the following components in percentage by mass: 15% to 30% of a deodorized hydrolyzed shell pearl powder, 24% to 25% of an anionic surfactant, 6% to 15% of an amino acid foaming agent, 3% to 10% of a nonionic surfactant, 1% to 5% of citric acid, 1% to 5% of pyridoxine HCL, 4% to 8% of an amino acidsurfactant, 1% to 5% of peppermint(Mentba piperita), 1% to 10% of vitamin E, 1% to 5% of vitamin B6, 4% to 10% of a grape seed or grapefruit seed extracting solution, 4% to 10% of a honeysuckle extracting solution, 2% to 5% of allantoin, 1.5% to 5% of hyaluronic acid, 1.5% to 5% of trehalose, 3% to 5% of glycerol, and the balance of deionized water. The amino acid facial cleanser based on the hydrolyzed shell pearl powder, disclosed by the invention, is rich in foam, fine and smooth, mild and non-irritating, can thoroughly remove dirt and grease in pores and is clear in skin after be used, keeps the skin moisturized, and further has the effects of whitening, inflammation resistance and the like. Furthermore, the amino acid facial cleanser based on the hydrolyzed shell pearl powder does not damage a natural protective film of the skin and has good stability.

Owner:ZHEJIANG OCEAN UNIV

Alkali aqueous cleaning agent for clearing solder paste on surface of circuit board and manufacturing method thereof

InactiveCN102021090AMeet cleanliness requirementsAvoid corrosionOrganic detergent compounding agentsNon-ionic surface-active compoundsSolventOxygen

The invention discloses an alkali aqueous cleaning agent for clearing solder paste on the surface of a circuit board, comprising the following raw materials in percent by weight: 0.5 to 10% of binary fatty acid; 1 to 30% of ethanolamine , 0.1 to 15% of diethylene glycol ethidene diamine, 0.1 to 5% of benzotriazole, 0.5 to 10% of epoxypropane epoxyethane polymer, 0.5 to 10% of isomerized alkylate epoxypropane epoxyethane polymer, 0.5 to 20% of oxygen-containing solvent and 65 to 75% of pure water. The alkali aqueous cleaning agent is low in using cost, strong in cleaning performance, capable of rapidly and thoroughly cleaning the solder paste on the surface of the circuit board, and capable of completely satisfying the surface cleanliness demands of the circuit board. The alkali aqueous cleaning agent can avoid corrosion to components of the circuit board, and can excellently protect components, welding spots, components of metal and plastic and the like. Furthermore, the alkali aqueous cleaning agent solves the problem existed in the prior art about environmental pollution, fire disaster, explosion disaster and the like, and the alkali aqueous cleaning agent is safe and reliable.

Owner:DALIAN SANDAAOKE CHEM

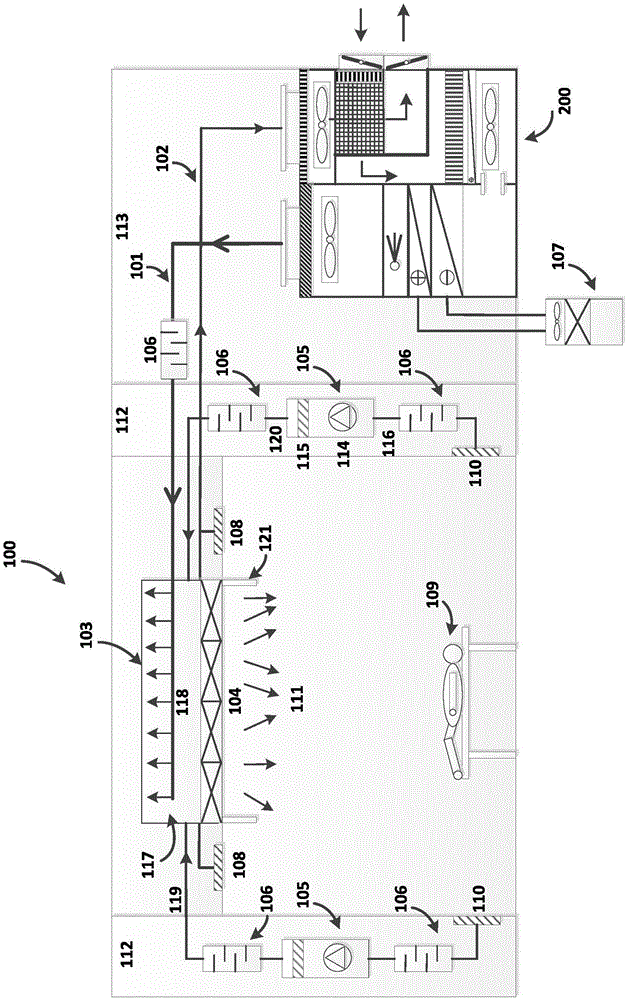

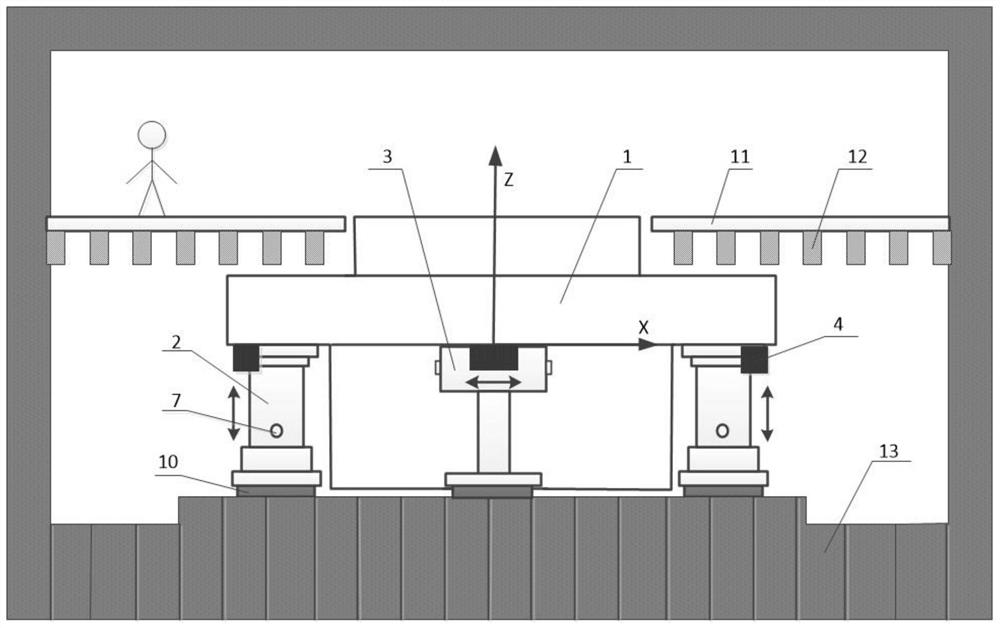

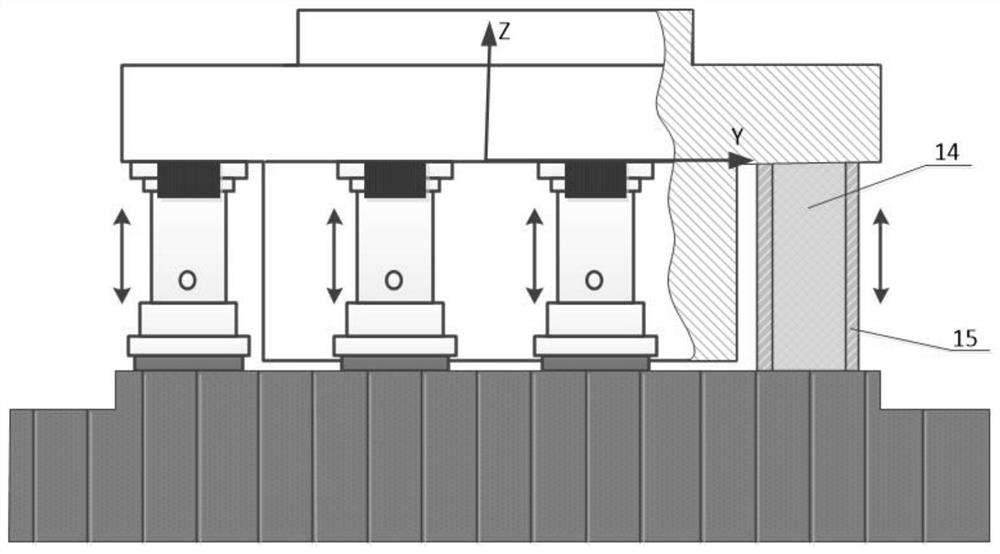

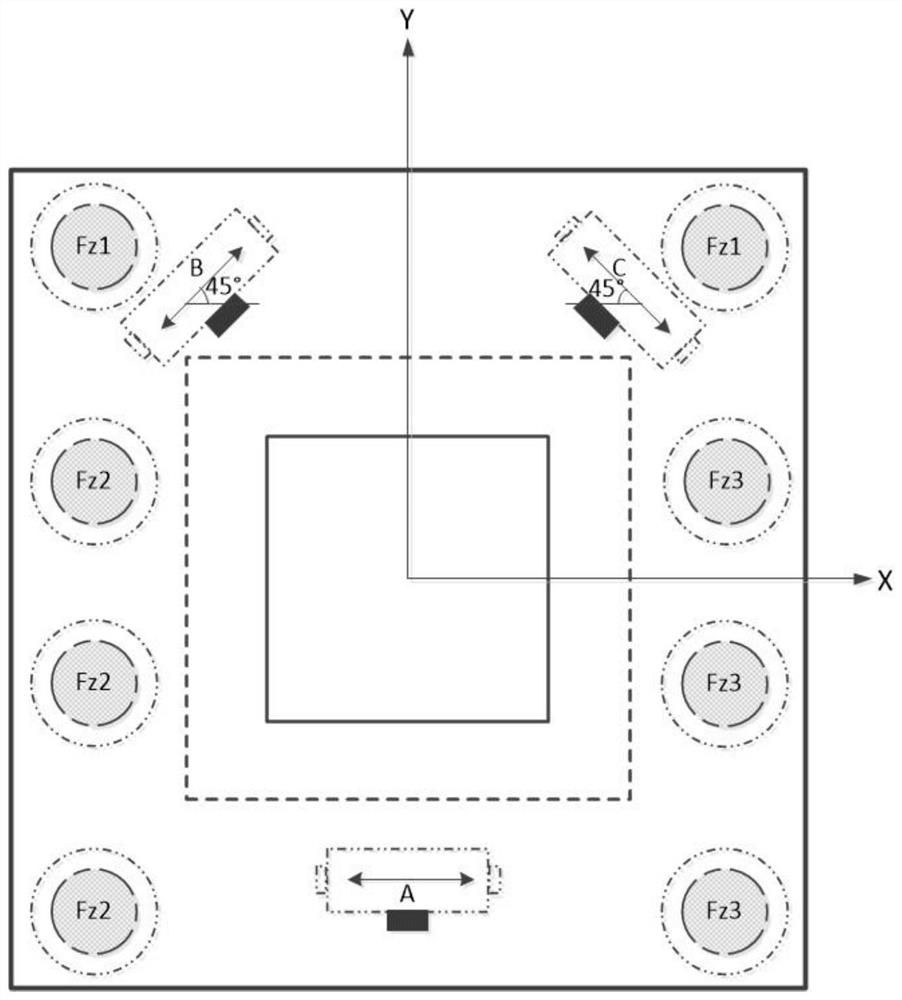

Large precise vibration isolation platform based on air springs

ActiveCN111810581ALower natural frequencyGood vibration isolationVibration suppression adjustmentsControl systemAir spring

The invention discloses a large precise vibration isolation platform based on air springs. The large precise vibration isolation platform comprises a vibration isolation laboratory space, a load platform 1, a vertical air spring vibration isolator 2, a horizontal air spring vibration isolator 3, a high-speed electromagnetic servo valve 6, a pneumatic system and a control system. A lower panel of the load platform is supported by the vertical air spring vibration isolator and the horizontal air spring vibration isolator in a vibration isolation manner; the vertical air spring vibration isolatoris responsible for positive stiffness static load and local passive vibration isolation of the platform; the horizontal air spring vibration isolator is responsible for negative stiffness adjustmentand active vibration isolation of the platform; the inherent frequency of the vibration isolation system is reduced through positive and negative stiffness adjustment, and meanwhile, a vertical air spring and the horizontal air spring vibration isolator are combined to form active and passive composite control; feedback sensors are separately arranged on the air spring vibration isolators and areused for detecting the pressure of air cavities of the air springs and the acceleration of corresponding positions of the load platform; and the control system comprises a controller, a power unit anda servo valve.

Owner:XIAMEN UNIV

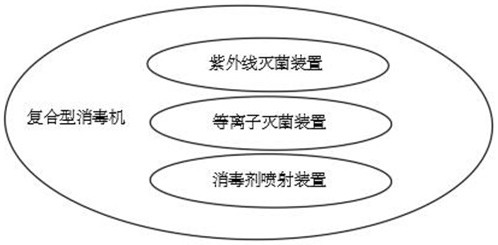

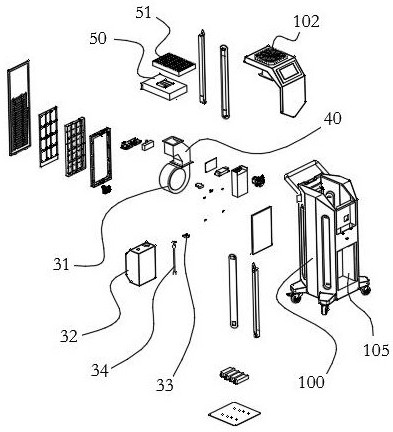

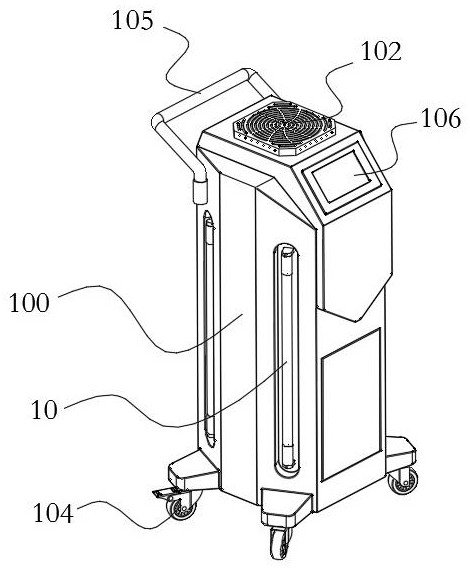

Composite disinfection machine

ActiveCN112089863AImprove sterilization effectEfficient sterilizationCombination devicesLavatory sanitoryPlasma sterilizationEnvironmental engineering

The invention discloses a composite disinfection machine which comprises a machine body. The machine body is provided with an ultraviolet disinfection device, a plasma disinfection device and a disinfectant spraying device. In the embodiment of the invention, a disinfectant solution is hydrogen peroxide, and through a three-in-one disinfection mode of ultraviolet sterilization, plasma sterilization and disinfectant spraying sterilization, the sterilization and disinfection effects are further enhanced.

Owner:湖北才风医疗科技有限公司

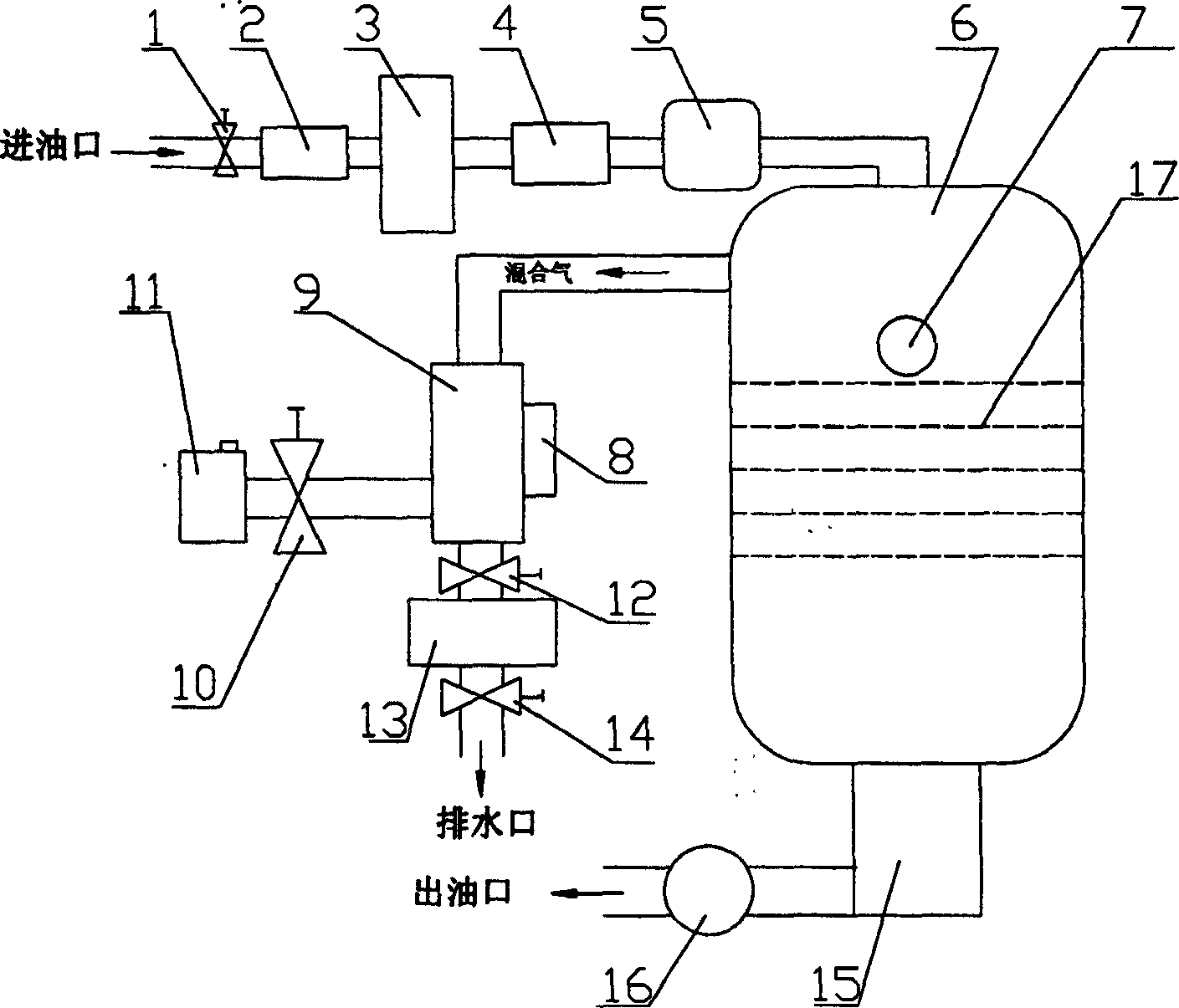

Hardening oil on-line dehydration apparatus

InactiveCN1935961AEasy to removeLarge amount of dirtFlash distillationLubricant compositionBoiling pointSurface pressure

The invention relates to quenching oil on line dewater unit. It includes oil feed control valve, backing stage filter, secondary filter, heater, anti-foaming machine, vacuum tank, pressure sensor, cooler, cooling fan, vacuum valve, vacuum pump, cistern, oil pump, and tertiary filter. The oil inlet is set oil feed control valve. The filter is set at the front and back of the heater. The anti-foaming machine is set at the front of the vacuum tank. Its upper is set cooler. Its inner is set pressure sensor. The vacuum valve is set at the front of the cooler. Its side is set cooling fan. Its lower is set cistern whose front and back are set vacuum valve. The lower of the vacuum tank is set the tertiary filter and oil pump. The unit can separate the water from the oil at vacuum by using the characteristic that the boiling point of the liquid is reduced with the lowering of the surface pressure. In addition, it has the advantages of fast impurity removing, on line running, low cost, safe, big quenching oil mass etc.

Owner:SHANGHAI JIAO TONG UNIV

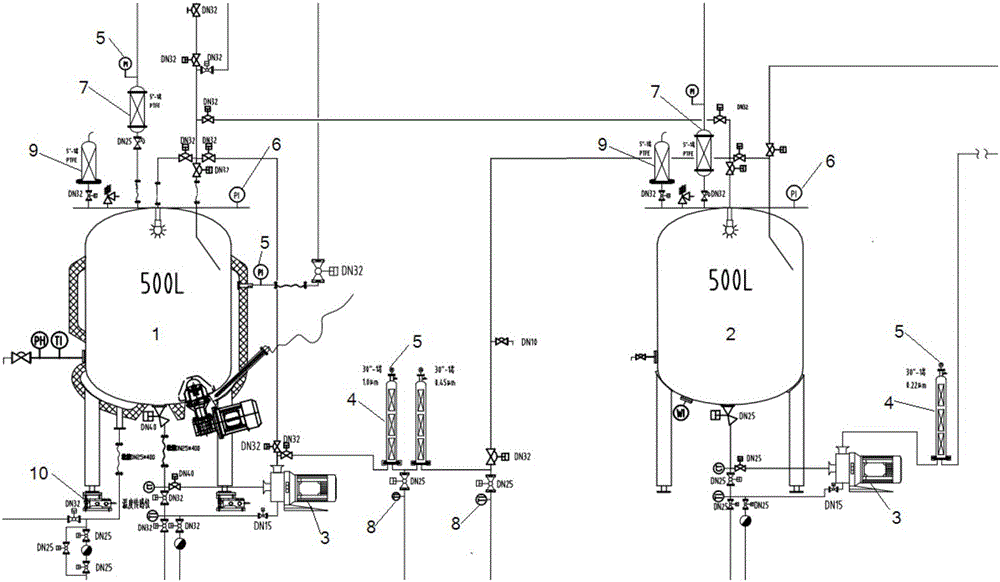

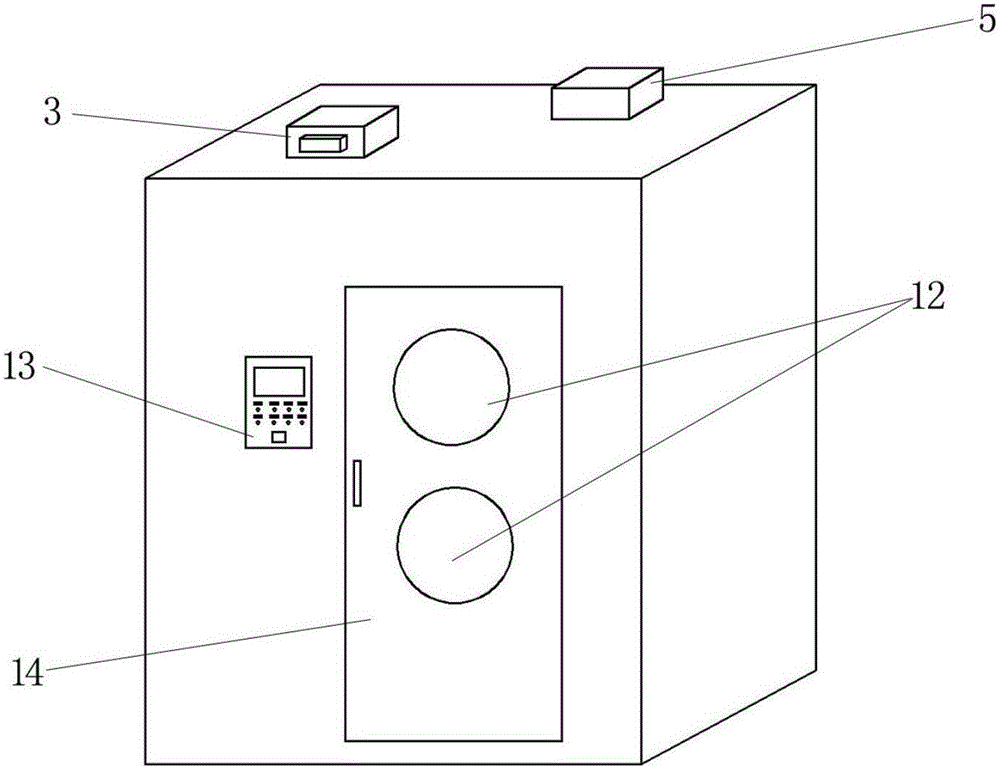

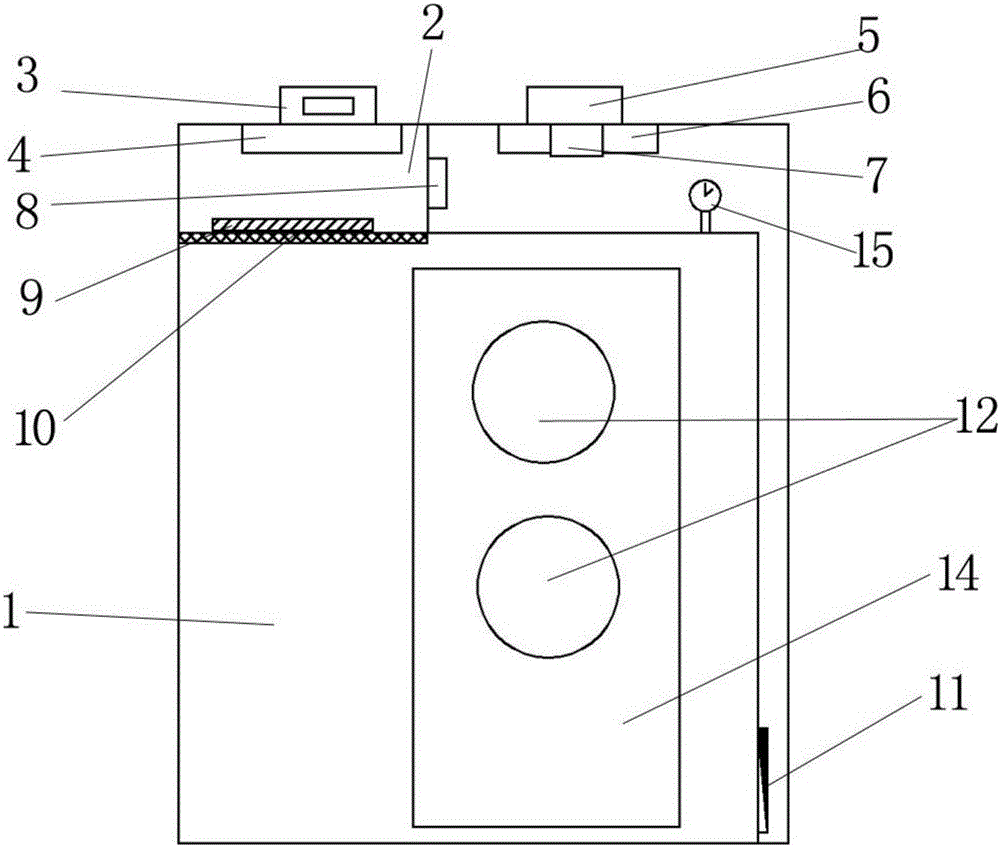

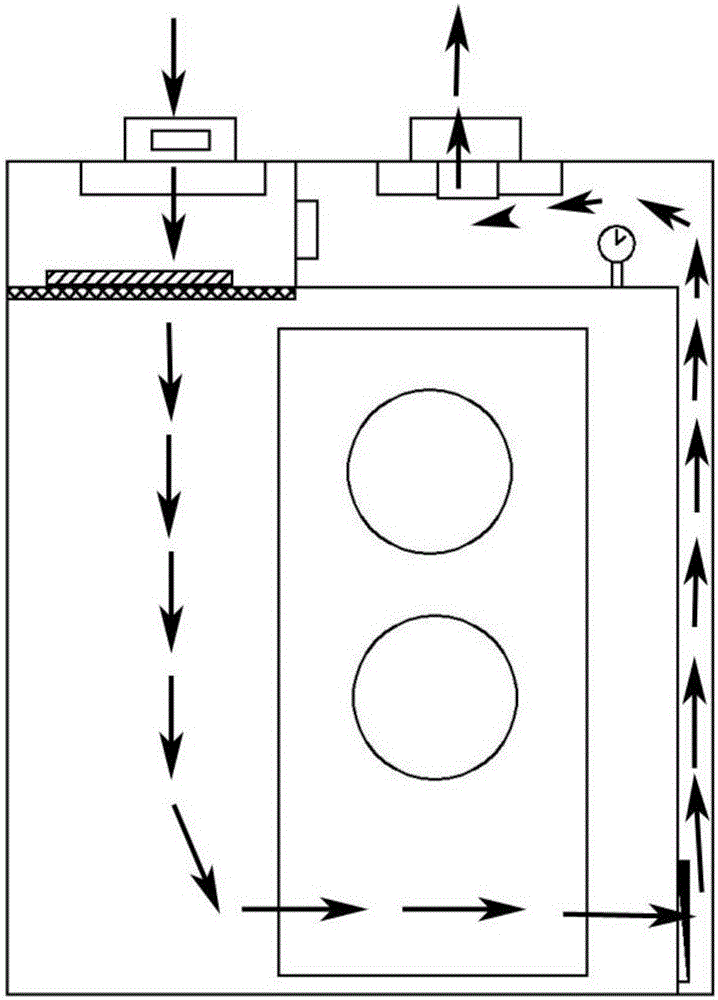

Hemodialysis agent liquid preparation and centralized supply system

InactiveCN105903402AEnhance the imageMeet cleanliness requirementsTransportation and packagingDialysis systemsSodium bicarbonateAcetic acid

The invention discloses a hemodialysis agent liquid preparation and centralized supply system comprising two sets of liquid preparation systems. More specifically, each set of liquid preparation system comprises a liquid preparation tank, a liquid preparation tank, a hygiene-grade delivery pump, a microporous membrane filter and a pipe distribution system, wherein the liquid preparation tank is connected to the liquid preparation tank. Liquid is delivered by the hygiene-grade delivery pumps, filtered by the microporous membrane filters and subsequently distributed and supplied by the pipe distribution systems. The liquid contains a concentrated liquid A and a concentrated liquid B that are mixed in a ratio of 1: 1 and then charged into a hemodialysis unit, wherein the concentrated liquid A is mainly prepared from an aqueous solution of sodium chloride, potassium chloride, calcium chloride, magnesium chloride and acetic acid, and the concentrated liquid B is mainly prepared from an aqueous solution of sodium bicarbonate or sodium bicarbonate and sodium chloride.

Owner:JIANGSU TONGXIE MACHINERY EQUIP CO LTD

People stream/material stream sterile airlock chamber

ActiveCN105909000ASimple structureWith ozone disinfection functionSpecial buildingSmall buildingsFresh airEngineering

The invention discloses a people stream / material stream sterile airlock chamber. The people stream / material stream sterile airlock chamber comprises an outer box and an inner box. The inner box is arranged in the outer box. Gaps exist between the top walls of the inner box and the outer box as well as between the right walls of the inner box and the outer box. A plenum chamber is arranged at the top of the inner box. The width of the plenum chamber is smaller than the width of the inner box. A fresh air electric valve and a fresh air fan are arranged on the top wall of the plenum chamber. The wall, making contact with the inner box, of the plenum chamber serves as a flow equalizing plate. A high-efficiency filter is arranged on the upper surface of the flow equalizing plate. A circulating fan is arranged on the right wall of the plenum chamber. An exhaust electric valve, an exhaust fan and an ozone machine are arranged on the top wall of the outer box. The exhaust electric valve, the exhaust fan and the ozone machine are located outside the plenum chamber. An air return port is formed in the bottom of the right wall of the inner box. According to the airlock chamber, two different clean areas can be effectively isolated, so that cross contamination is prevented; and in addition, thorough sterilization and dust removal can be achieved, and the requirement of a higher-cleanliness-grade pharmaceutical preparation technological process for the cleanliness is met.

Owner:SICHUAN CHUANJING CLEAN TECH HLDG

Hydraulic part cleaning process

InactiveCN110575994ADry thoroughlyAvoid it happening againDrying gas arrangementsCleaning using toolsKeroseneEngineering

The invention belongs to the field of hydraulic part processing, and particularly relates to a hydraulic component cleaning process. For solving the problem that due to the fact that the outer surface, the inner surface and an inner flow groove of a hydraulic part cannot be cleaned in an existing cleaning process, contaminants inherent in the interior of the hydraulic part will fall out of the adhered surface into oil to make a system to be subjected to additional pollution, the process comprises the following steps of S1, surface pretreatment, specifically, placing a workpiece on a workbench,removing burrs and rust spots on all channels, grooves, chamfers and other parts of the workpiece through tools such as a file, a steel wire brush and the like, cleaning the workpiece by using an airgun, blowing the inner surface, the outer surface and the inner flow groove of the workpiece through compressed air to remove dust and particles on the surfaces and the inner flow groove of the workpiece; and S2, kerosene cleaning, specifically, placing the workpiece in S1 in a kerosene washer. The cleaning process has the beneficial effects that the cleaning effect is good, the inner surface, the outer surface and the inner flow groove of the hydraulic part can be cleaned, and the contaminants in the hydraulic part can be thoroughly cleaned away.

Owner:江苏康达顺精密汽车附件制造有限公司

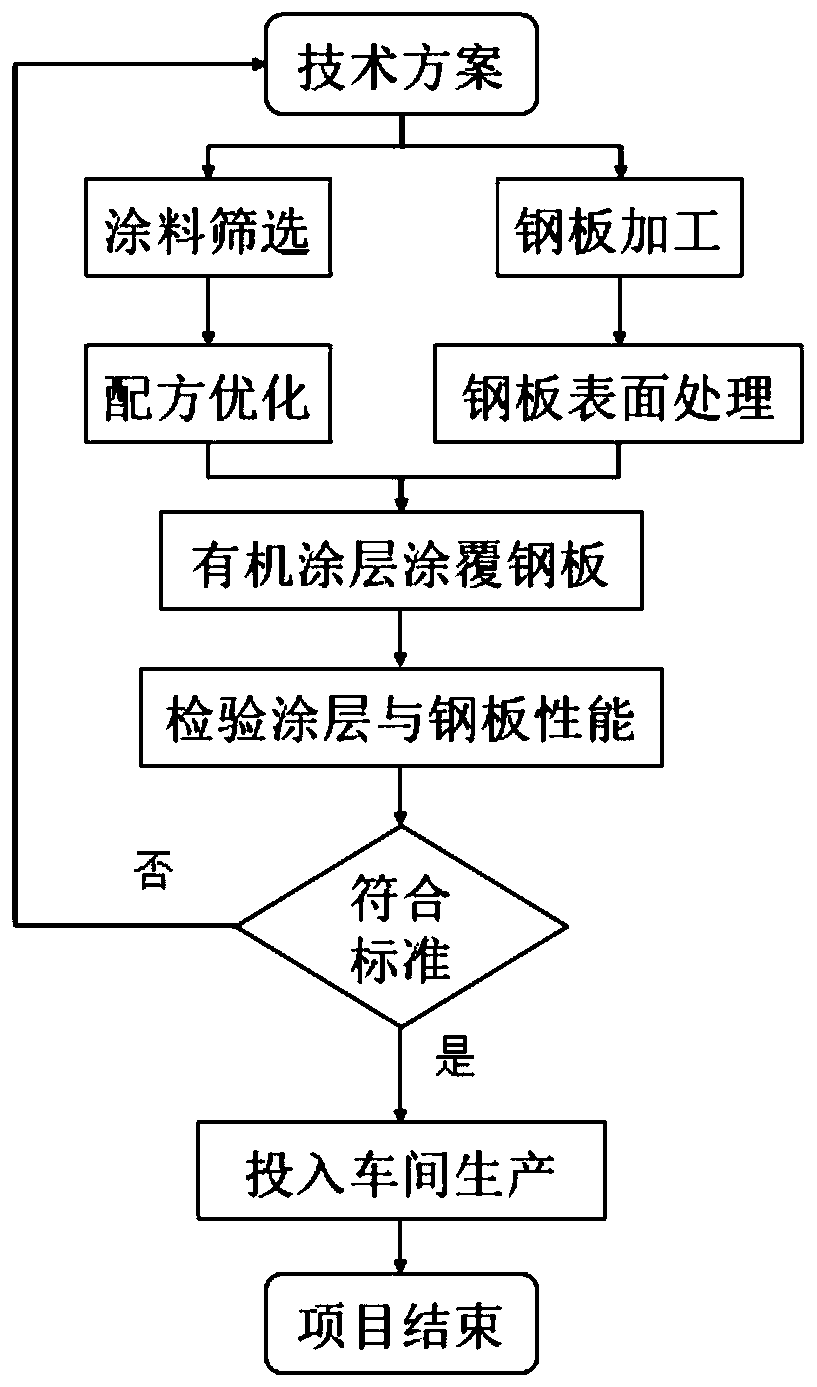

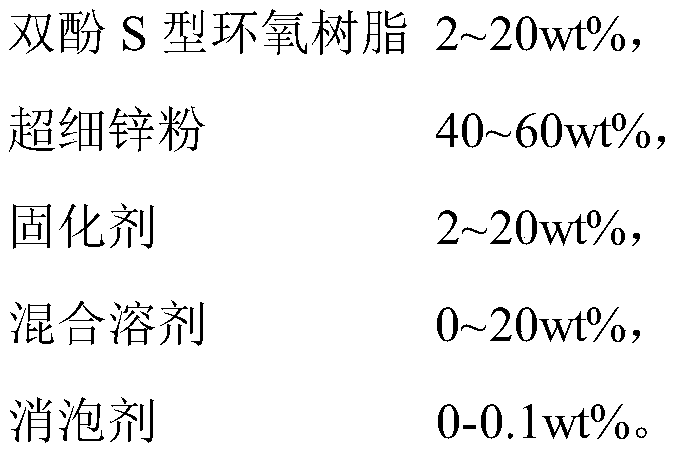

Organic coated steel sheet, manufacturing method and application thereof

ActiveCN110669415AImprove conductivityGood flexibilityPretreated surfacesAnti-corrosive paintsFirming agentBisphenol AF

The invention discloses an organic coated steel plate, a manufacturing method and application thereof. The organic coated steel plate is composed of a steel plate, primer and finish paint. The epoxy zinc-rich primer is composed of bisphenol S epoxy resin, superfine zinc powder, a mixed solvent, a curing agent and a defoaming agent. The epoxy-polyurethane composite finish paint is composed of epoxyresin, polyurethane powder, a mixed solvent, a curing agent and other components. And the epoxy resin is bisphenol S type epoxy resin, bisphenol A type epoxy resin or bisphenol AF type epoxy resin; and the other components can be one or more of titanium dioxide, talcum powder, mica iron oxide, medium chrome yellow and zinc phosphate. The preparation method of the organic coated steel plate includes: firstly carrying out surface treatment on the steel plate, then coating the steel plate with the primer, performing high-temperature curing at 100-280DEG C for 0.1-0.5h, then coating the steel plate with the finish paint, and conducting high-temperature curing. The obtained organic coated steel plate has the characteristics of good toughness, high strength, good paint film adhesiveness, friction resistance and long service life, and is particularly suitable for manufacturing bolt connection tanks.

Owner:BEIJING YINGHERUI ENVIRONMENTAL ENG

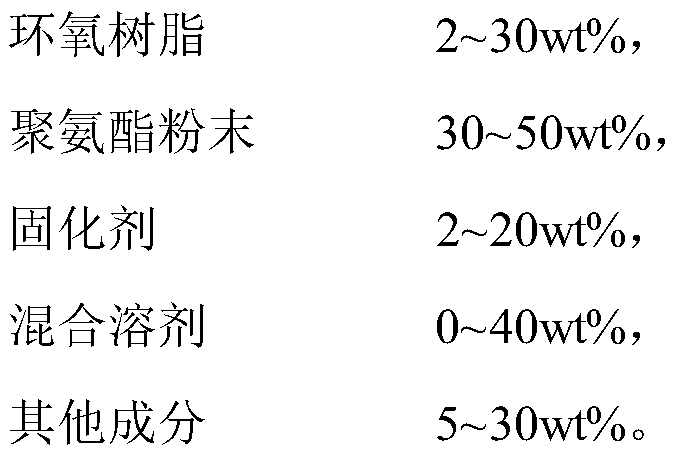

Installing construction method for semiconductor manufacture procedure gas conveying pipelines

ActiveCN104455722AQuick disassemblyGuaranteed stabilityPipe laying and repairShielding gasMass spectrometry

The invention discloses an installing construction method for semiconductor manufacture procedure gas conveying pipelines. The installing construction method includes the following steps that (1), a clean region is preset on a construction site, and a clean space is constructed; (2), all apparatuses used for construction are retested and sealed to prevent contamination; (3), the pipeline is cleanly machined in a sealed mode unit by unit in the clean space, and pipe orifices are sealed immediately after machining is completed; (4), the conveying pipeline is installed, protective gas is continuously injected in the pipeline in the installing process and at the operation intervals; (5), the tail gas pipeline is installed according to the structure of a plasma and washing processing system; (6), a gas device is installed, and the pipelines are connected with the gas device in a radial face seal connecting mode; (7), an electrostatic grounding system and an outdoor anti-thunder electric induction grounding system are installed; (8), pressure detection, helium mass spectrum leakage detection, moisture detection, cleanliness detection and oxygen detection are carried out until all results are qualified; (9), a tail gas treatment test is carried out until a test result is qualified.

Owner:成都建工第三建筑工程有限公司 +1

Texturing and cleaning method of heterojunction battery

InactiveCN110943144AAdded cleaning stepsAchieving thorough cleanlinessFinal product manufactureSemiconductor/solid-state device manufacturingProcess engineeringEnvironmental engineering

The invention discloses a texturing and cleaning method of a heterojunction battery. The method comprises the following steps: pre-cleaning an original silicon wafer by adopting SC1; carrying out rough polishing and damage removal treatment on the silicon wafer; cleaning with an ozone system solution; texturing the silicon wafer; adopting an SC1 or ozone system solution for cleaning; corroding thesilicon wafer, and carrying out smooth rounding treatment; adopting an SC2 or ozone system solution for cleaning; drying the solution ; and adding an HF acid pickling process before the SC1 or ozonesystem solution cleaning process, the smoothing and rounding process, the SC2 or ozone system solution cleaning process and the drying process. The surface of the silicon wafer is ensured to be completely clean, a better surface appearance is obtained, and the performance of an HJT battery is improved to a great extent.

Owner:JINENG CLEAN ENERGY TECH LTD

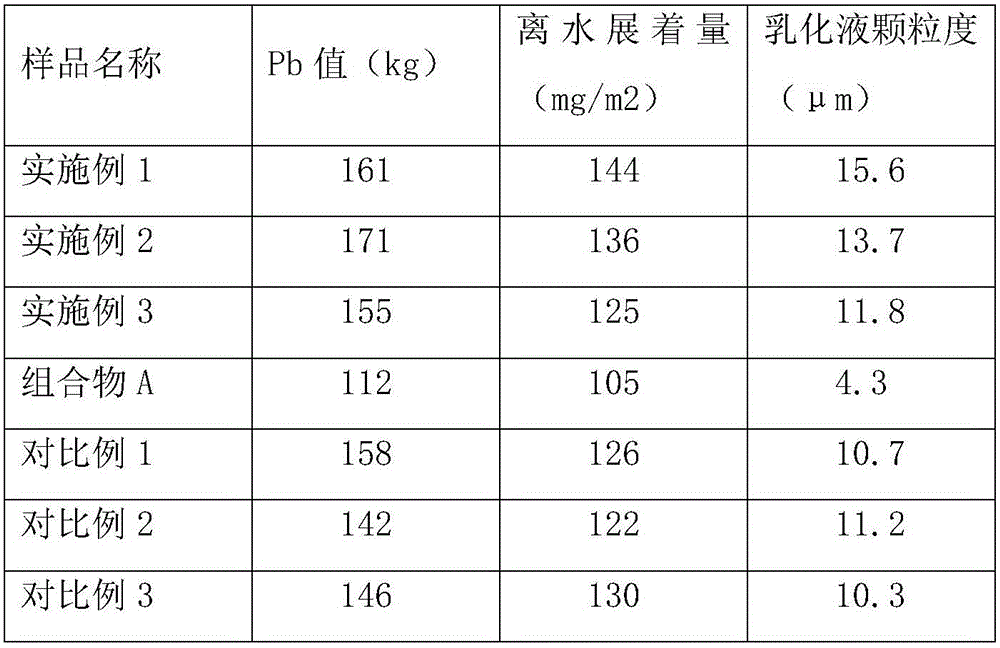

Continuous-rolling silicon steel high-detergency rolling oil and preparation method thereof

ActiveCN106833845APrevent agingInhibition of polymerizationLubricant compositionAntioxidantSURFACTANT BLEND

The invention provides continuous-rolling silicon steel high-detergency rolling oil and a preparation method thereof. The composition comprises the following components in percentage by weight: 50 to 60 percent of synthetic ester, 35 to 45 percent of refined fat, 0.5 to 3.0 percent of an antioxidant, 1.0 to 5.0 percent of an antirust agent, 1.0 to 8.0 percent of an extreme pressure antiwear additive, 1.0 to 5.0 percent of a detergent dispersant and 1.0 to 3.0 percent of a surfactant. The continuous-rolling silicon steel high-detergency rolling oil has high detergency while guaranteeing lubricating property and antirust property, and can obviously improve the detergency of a rolling mill.

Owner:SHANGHAI PARKER CHEM IND

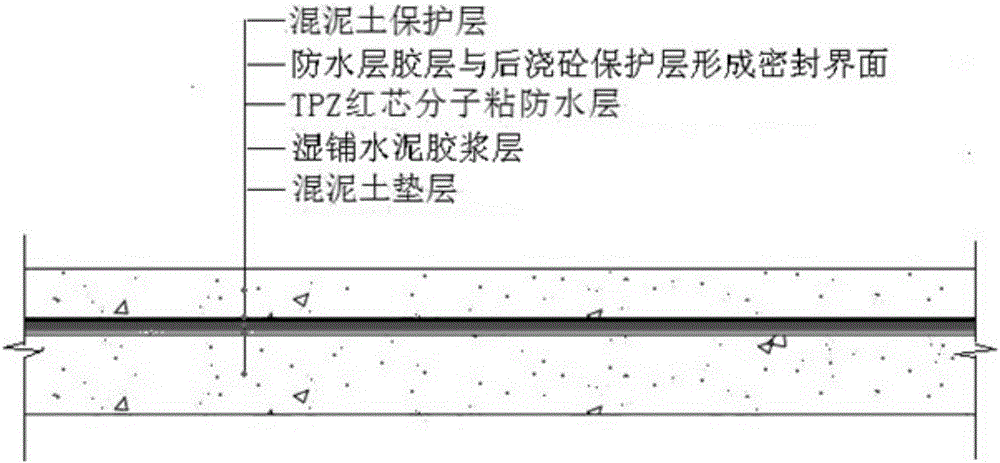

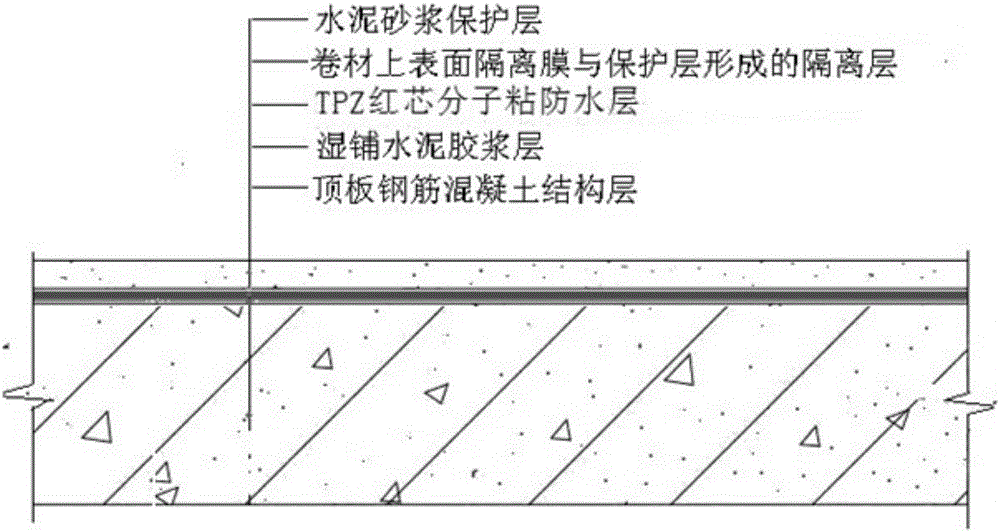

Synchronous construction method for TPZ red core molecular level bonding waterproof coiled material

InactiveCN105952070AReduced risk of breakageLow costNon-macromolecular adhesive additivesRoof covering using flexible materialsMolecular levelCement mortar

The invention discloses a synchronous construction method for TPZ red core molecular level bonding waterproof coiled material. According to the synchronous construction method, TPZ red core molecular level bonding waterproof coiled material is constructed together with concrete / cement mortar base layer, wherein the method comprises following steps: base layer concrete construction; after 2-4 hours of the concrete construction, waterproof coiled material is wetly paved; after 24-48 hours of the wet paving of the waterproof coiled material, concrete protective layer construction is performed. The synchronous construction method is safer in water resistance, higher in construction efficiency, and simpler in waterproof structure arrangement.

Owner:LIAONING DAYU WATERPROOF TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com