Low-noise modular air purification system

An air purification system and low-noise module technology, applied in air-conditioning systems, noise suppression, space heating and ventilation, etc., can solve problems such as increased cost, low oxygen content temperature, air blockage, etc., to simplify installation costs , the space requirements are low, the effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

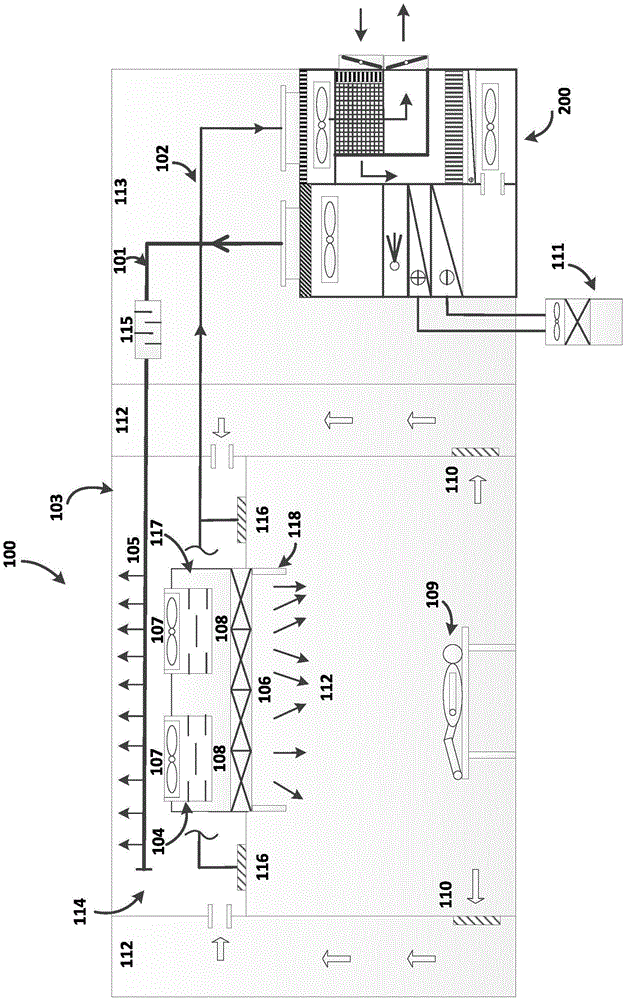

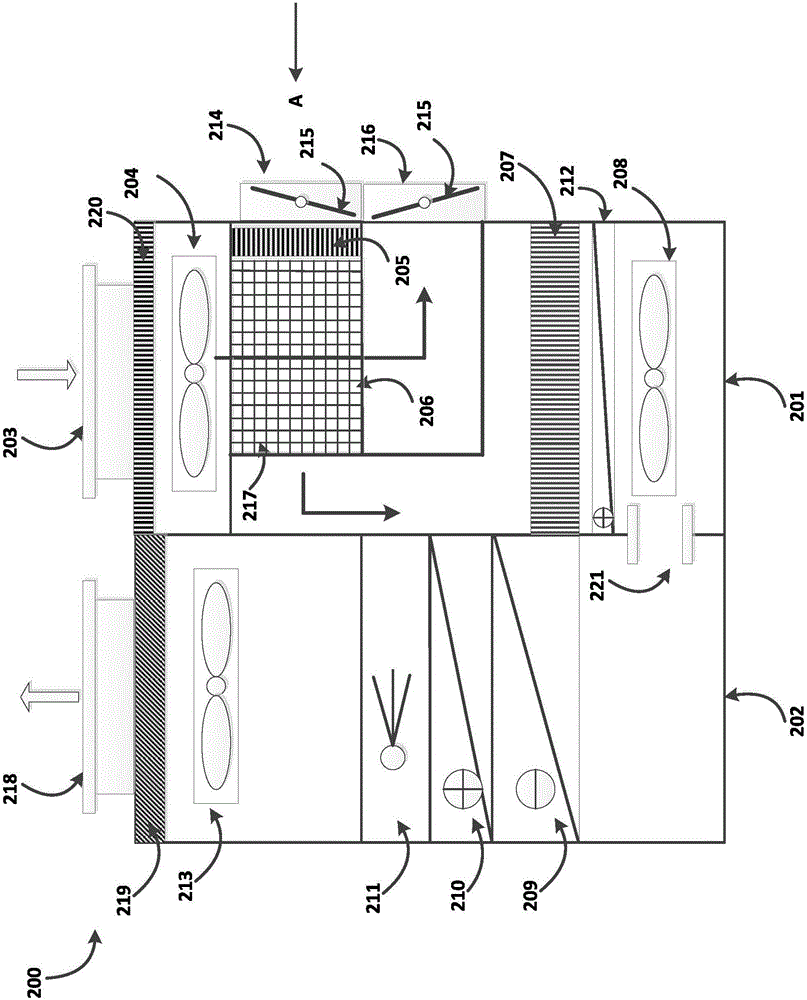

[0064] figure 1 A schematic diagram of a low-noise modular air purification system 100 according to the present invention is shown. It should be noted that components in the various figures may be shown exaggerated for the purpose of illustration and are not necessarily true to scale. In the various figures, identical or functionally identical components are assigned the same reference symbols.

[0065] like figure 1 As shown, the air purification system 100 is a highly integrated and modular structure, which mainly includes two modules: medical exhaust and fresh air integrated cabinet 200 (including its digital variable capacity direct expansion air cooling unit 111), return air treatment and air supply Smallpox 103.

[0066]The medical exhaust and fresh air integrated cabinet 200 is preferably arranged in the dirt channel 113 of the medical room. Due to its compact shape, it can be arranged in the corner of the dirt channel 113 without affecting normal traffic, thereby sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com