Organic field effect tube using single molecular layer as oriented transfer layer and its preparing method

A technology of effect tube and organic field, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., and can solve problems such as inconspicuous orientation effect, inconspicuous effect, and weak optical orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

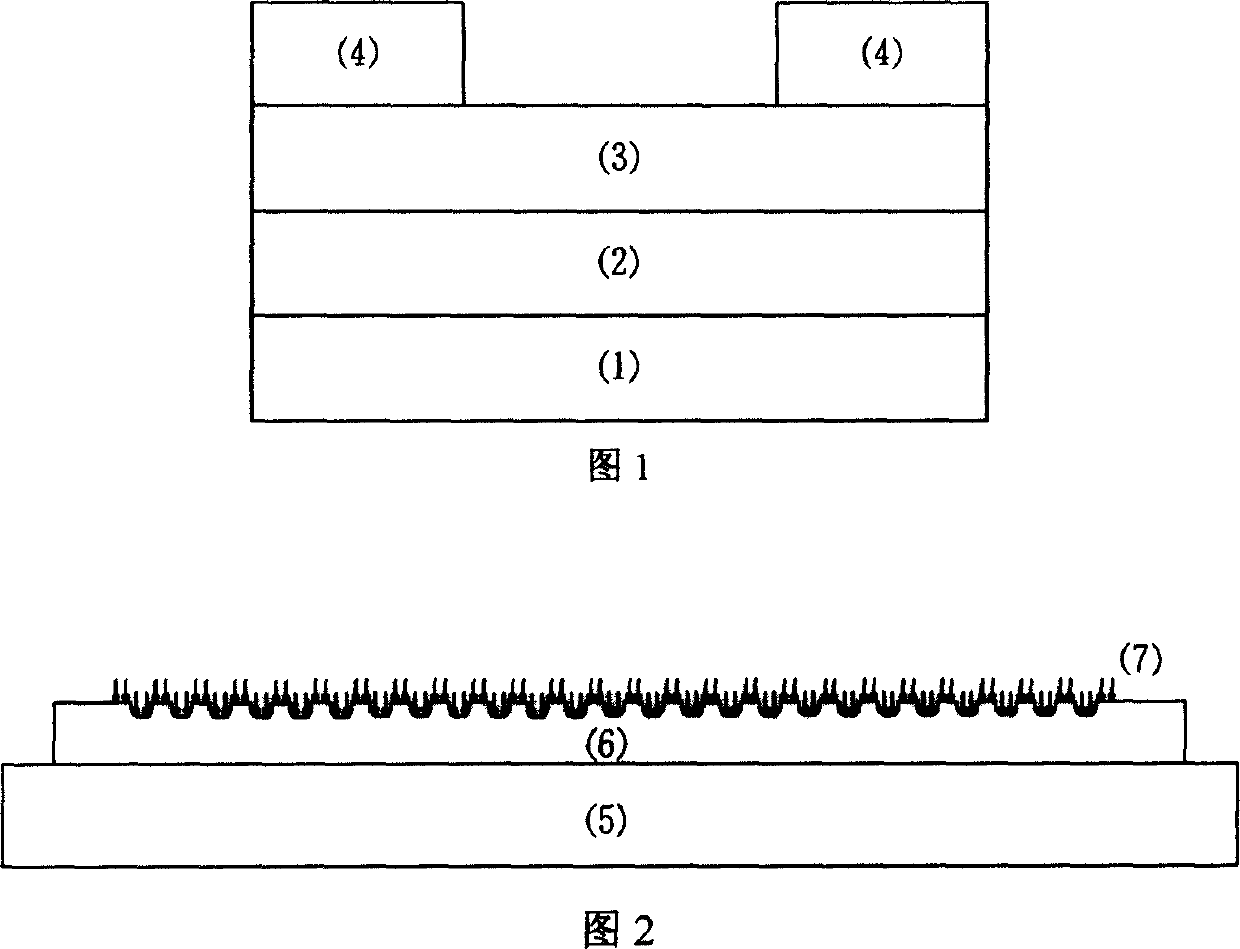

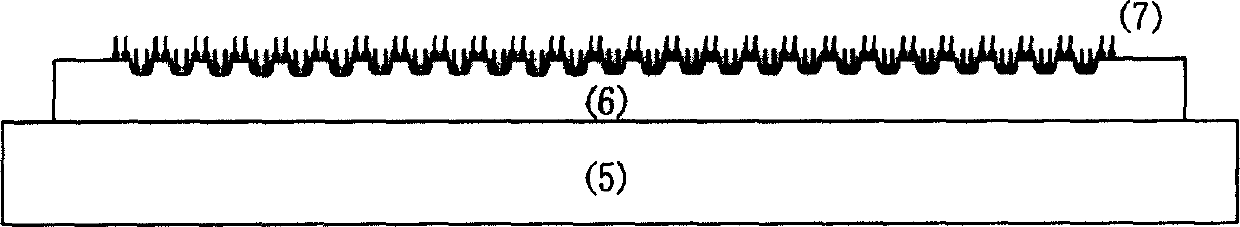

Embodiment 1

[0030] 1. First, clean the PET substrate with gate structure ITO after photolithography molding. The cleaning process is as follows: use special cleaning agent (10min), deionized water (3×10min), 50:8 isopropanol and Concentrated ammonia water mixed solution (10min), chloroform (10min), acetone (10min), and ethanol (10min) were subjected to ultrasonic treatment (treatment time in brackets), then fumigated with ethanol steam for 3 minutes, and finally UV treatment for 5 minutes;

[0031] 2. Secondly, anisotropic treatment of ITO was performed by mechanical friction. The friction material used is YA-18-R rayon flannelette provided by Yoshikawa Chemical Co. The average length of the rayon front of the flannelette is 600 μm, the average diameter is 15 μm, and the fiber density is 3200 thread / cm 2 . During mechanical friction, the drum rotates at 1500 rpm, and after 10 times of friction treatment, clean it with deionized water;

[0032] 3. Use 40g / mol concentration of NaOH soluti...

Embodiment 2

[0035] 1. First, clean the glass substrate with gate structure ITO after photolithography molding. The cleaning process is as follows: use special cleaning agent (10min), deionized water (3×10min), 50:8 isopropanol and Concentrated ammonia water mixed solution (10min), chloroform (10min), acetone (10min), and ethanol (10min) were subjected to ultrasonic treatment (treatment time in brackets), then fumigated with ethanol steam for 3 minutes, and finally UV treatment for 5 minutes;

[0036] 2. Secondly, stripes are carved on the surface of ITO by means of photolithography or laser etching to form anisotropy;

[0037] 3. Use 30g / mol concentration of NaOH solution to clean the surface of the ITO substrate for about 1 minute; then use chromic acid in chloroform solution (concentration of about 30%) to soak or ultrasonic for about 8 seconds for surface treatment; then use vinyl triethoxy Treat the surface of the substrate with base silane to form a monomolecular film;

[0038] 4. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com