Synchronous construction method for TPZ red core molecular level bonding waterproof coiled material

A waterproof membrane and simultaneous construction technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, and roofs using flexible materials, etc., can solve the problems of long waterproof construction period, loss of strength, and failure of wet laying and sealing To achieve the effect of saving the direct cost of the project, prolonging the life of the building, and eliminating water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Simultaneous construction of basement floor waterproofing:

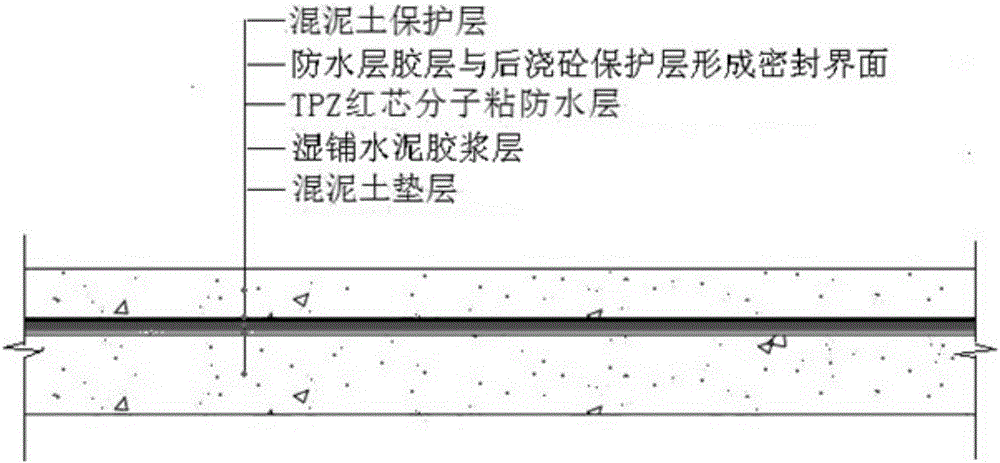

[0081] Such as figure 1 As shown, the synchronous construction of the TPZ red core molecular adhesive waterproofing membrane and the underground engineering floor cushion concrete is a schematic diagram of each layer from top to bottom:

[0082] (1) Concrete protective layer;

[0083] (2) TPZ red core molecular adhesive waterproof membrane layer;

[0084] (3) wet cement mortar layer;

[0085] (4) Concrete cushion.

[0086] The simultaneous construction of the basement floor cushion concrete of the TPZ red core molecular adhesive waterproof membrane includes the following steps:

[0087] (1) For the construction of waterproof base concrete cushion, the surface needs to be leveled and calendered once, and the thickness of the cushion is 100-150mm;

[0088] (2) After 4 hours, when the concrete surface can withstand a pressure above 10KPa, remove the isolation film on the lower surface of the TPZ red core mol...

Embodiment 2

[0097] Simultaneous construction of basement roof waterproofing:

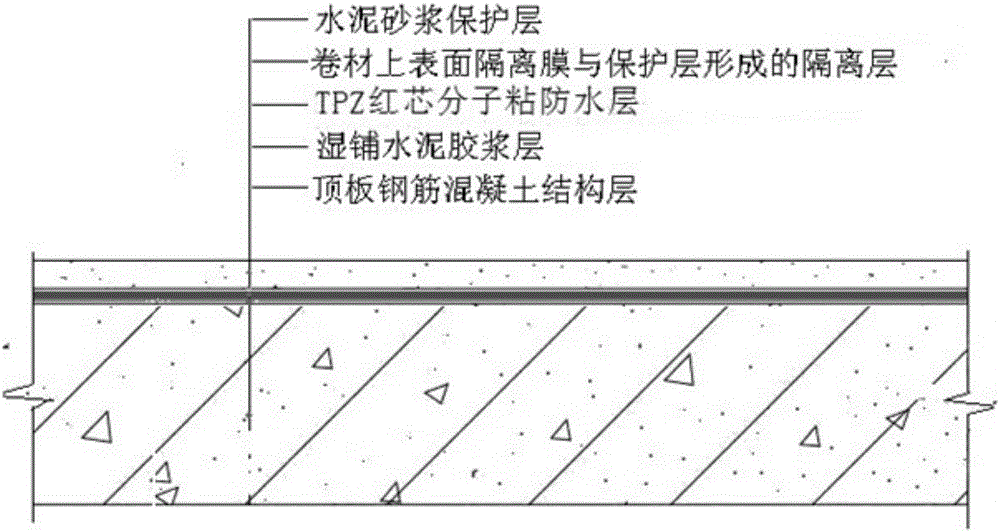

[0098] Such as figure 2 As shown, the synchronous construction of the TPZ red core molecular adhesive waterproofing membrane and the roof structure concrete of the underground project shows the schematic diagrams of each layer from top to bottom:

[0099] (1) Concrete protective layer;

[0100] (2) TPZ red core molecular adhesive waterproof membrane layer;

[0101] (3) wet cement mortar layer;

[0102] (4) Roof structure concrete.

[0103] The simultaneous construction of the underground roof structure concrete of the TPZ red core molecular adhesive waterproof membrane includes the following steps:

[0104] (1) Concrete construction of the basement roof structure, the surface needs to be leveled and calendered once, and the thickness of the roof concrete is 150-400mm;

[0105] (2) After 3 hours, when the concrete surface can withstand a pressure above 10KPa, remove the isolation film on the lower surface ...

Embodiment 3

[0113] Such as image 3 As shown, the synchronous construction of the TPZ red core molecular adhesive waterproof membrane and the roof structure concrete structure schematic diagrams of each layer from top to bottom are:

[0114] (1) Cement mortar protective layer;

[0115] (2) TPZ red core molecular adhesive waterproof membrane layer;

[0116] (3) wet cement mortar layer;

[0117] (4) Roof concrete structure layer.

[0118] The simultaneous construction of the underground roof structure concrete of the TPZ red core molecular adhesive waterproof membrane includes the following steps:

[0119] (1) For the concrete construction of the roof structure, the surface needs to be leveled and calendered once, and the thickness of the roof structure plate is 120-300mm;

[0120] (2) After 3 hours, when the concrete surface can withstand a pressure above 10KPa, remove the isolation film on the lower surface of the TPZ red core molecular sticky waterproof membrane, and use cement morta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com