Rustproof type special conductive printing ink and preparation method thereof

A kind of conductive ink, a special technology, applied in the direction of ink, household utensils, applications, etc., can solve the problems of large safety hazards and unsatisfactory performance, and achieve the effect of improving environmental protection, good adhesion, and fast curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

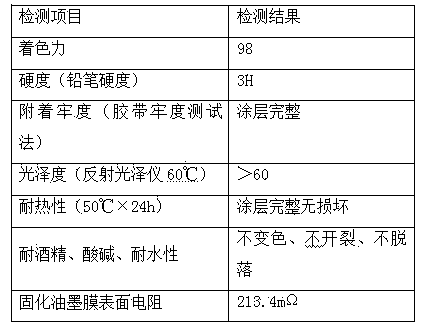

Examples

Embodiment

[0011] The ink of the present embodiment is made of the following raw materials in parts by weight: phytate 3, azone 4, 400 mesh tin oxide powder 25, ferrocene 4, epoxy acrylic resin 55, DBE solvent 16, ethanol 12, Ethylene glycol monophenyl ether 2, ethyl acetate 20, 2,5-di-tert-butyl hydroquinone 2, additive 4.

[0012] The auxiliary agent is made of the following raw materials in parts by weight: polyvinyl butyral 4, silane coupling agent KH560 2, propylenediamine phosphate 0.3, polyamide wax 3, silicone defoamer 2, diethylene glycol ether Acetate 15, nano-starch 6, the preparation method is: first mix the nano-starch and silane coupling agent KH560, grind and disperse for 30 minutes to obtain surface-modified nano-starch for later use, and then mix other remaining materials, stir for 40 minutes, and mix the mixed solution Heat to 60-80°C, add surface-modified nano-starch, stir to disperse evenly, keep warm and ultrasonically disperse for 5 hours to obtain the product.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com