Glass cloth for printed wiring board

A glass fiber cloth and glass technology, applied in the directions of printed circuits, printed circuits, printed circuit components, etc., can solve the anisotropy of dimensional change, the gap of reinforcement effect becomes larger, and the anisotropy improvement of dimensional change rate cannot be fully improved. effect, etc., to achieve the effect of less anisotropy and no warping/distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

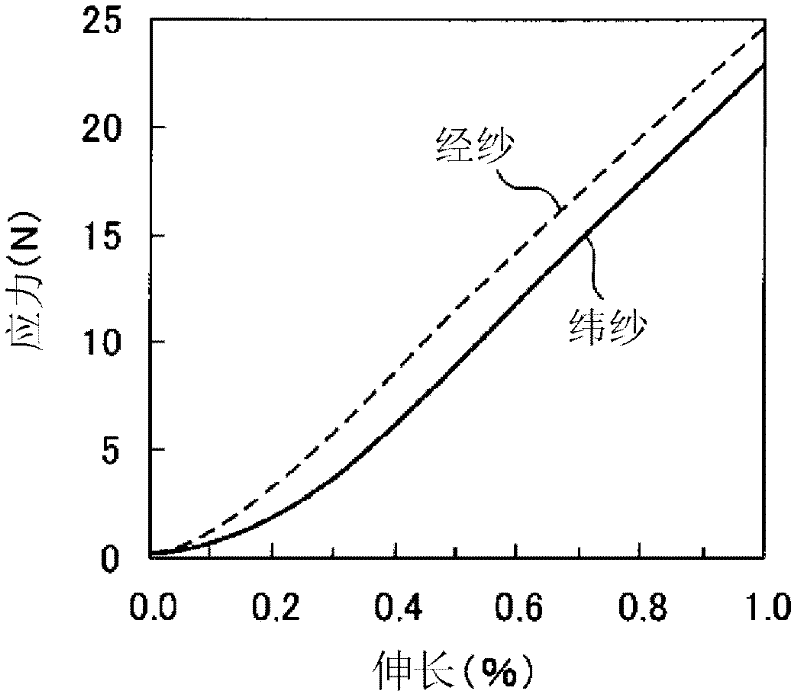

[0102] The warp uses an average single fiber diameter of 4.0 μm, the number of single fibers is 100, the number of twists is 1.0Z, and the weight per unit length is 3.4×10 -6 kg / m glass yarn, the weft yarn uses an average single fiber diameter of 4.5μm, the number of single fibers is 100, the number of twists is 1.0Z, and the weight per unit length is 4.2×10 -6 kg / m glass yarn was woven into a glass fiber cloth using an air jet loom at a weaving density of 75 warp yarns / 25mm and weft yarn 40 yarns / 25mm. The gray cloth obtained was heat-treated at 400° C. for 24 hours to desizing. Next, the glass fiber cloth was dipped in a treatment liquid using SZ6032 (manufactured by Toray Dou Corning Co., Ltd.) as a silane coupling agent, and after pressing (Japanese: relatively liquid), it was dried at 120° C. for 1 minute, and Fiber opening processing is carried out by using columnar flow to obtain a weight per unit area of 15g / m 2 1. Glass fiber cloth A with a thickness of 17 μm. Th...

Embodiment 2

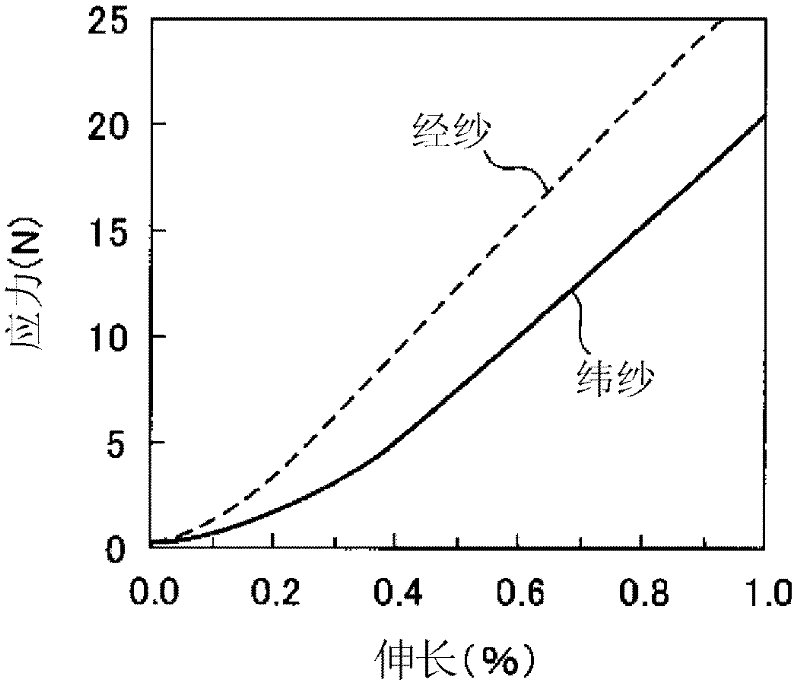

[0107] Except that the weaving density of the weft yarn is 48 / 25mm, utilize the same method as Example 1 to carry out the weaving of glass fiber cloth and the subsequent processing to obtain a weight per unit area of 18g / m 2 1. Glass fiber cloth B with a thickness of 18 μm. The elongation of the warp direction and the elongation of the weft direction of the glass fiber cloth B are respectively 0.20% and 0.24% when the load is 5N, and the elongation of the weft direction and the elongation of the warp direction (weft / warp ) ratio is 1.20, and the isotropy of the glass fiber cloth B is excellent.

[0108] Next, the production of the substrate B and the measurement of the dimensional change rate were carried out by the same method as in Example 1. The dimensional change rate of the substrate B is -0.014% in the warp direction and -0.035% in the weft direction, and the dimensional change rate of the substrate B and the anisotropy in the warp direction and weft direction are all...

Embodiment 3

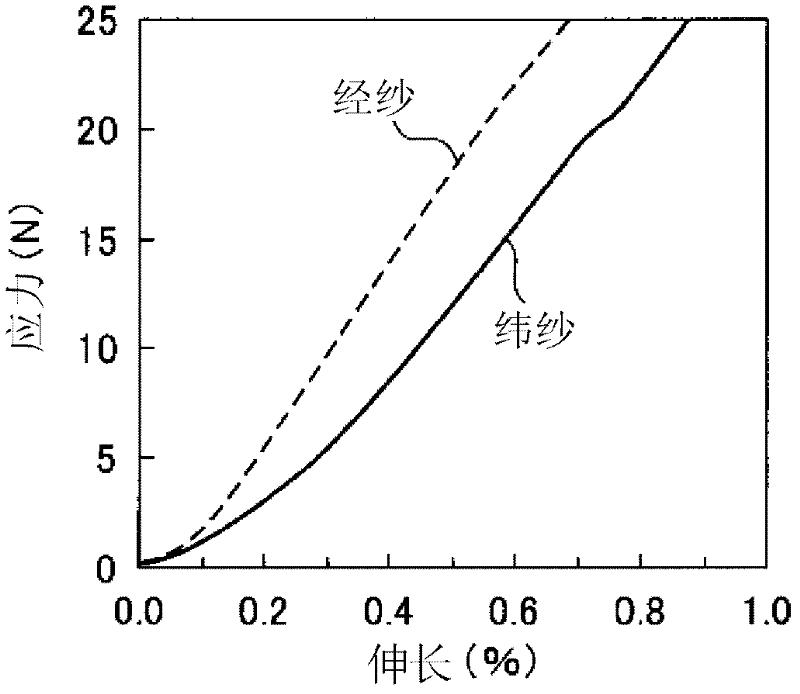

[0110] Except making the weaving density of weft yarn be 60 / 25mm, utilize the same method as embodiment 1 to carry out the weaving of glass fiber cloth and the processing afterwards, obtain unit area weight 20g / m 2 , Glass fiber cloth C with a thickness of 19 μm. The elongation of the warp direction and the elongation of the weft direction of the glass fiber cloth C are respectively 0.21% and 0.22% when the load is 5N, and the elongation of the weft direction and the elongation of the warp direction (weft / warp ) ratio is 1.09, and the isotropy of the glass fiber cloth C is excellent.

[0111] Next, the production of the substrate C and the measurement of the dimensional change rate were carried out by the same method as in Example 1. The dimensional change rate of the substrate C is -0.016% in the warp direction and -0.031% in the weft direction, and the dimensional change rate of the substrate C and the anisotropy in the warp direction and the weft direction are small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com