Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Avoid low process precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

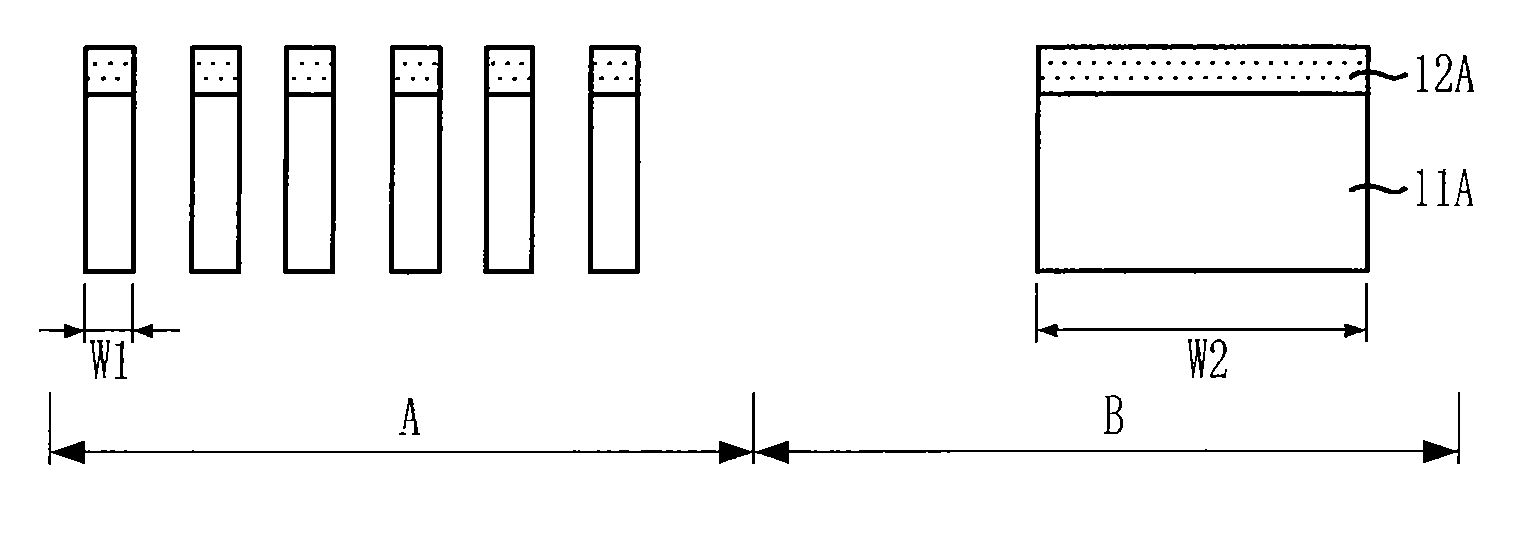

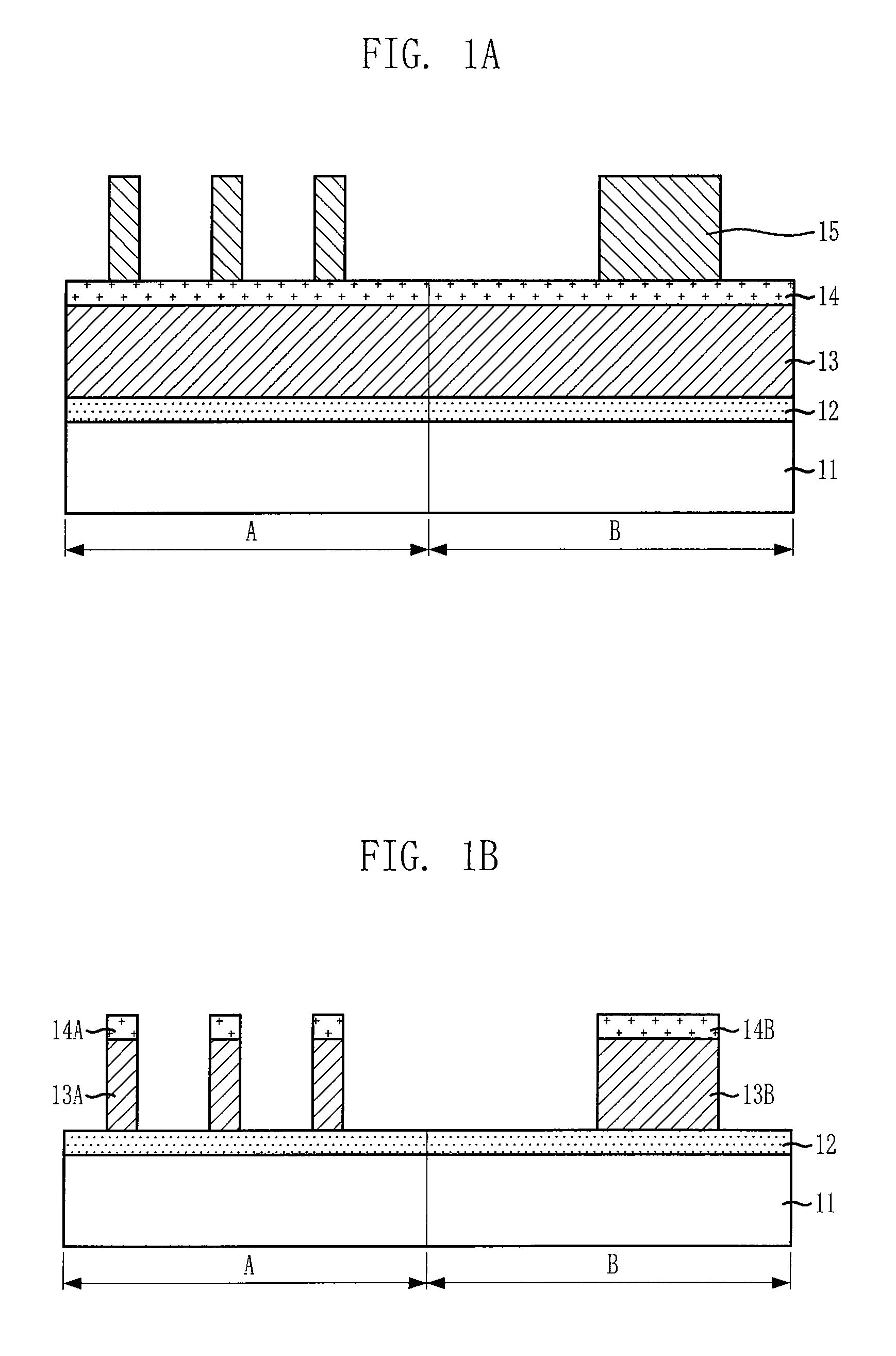

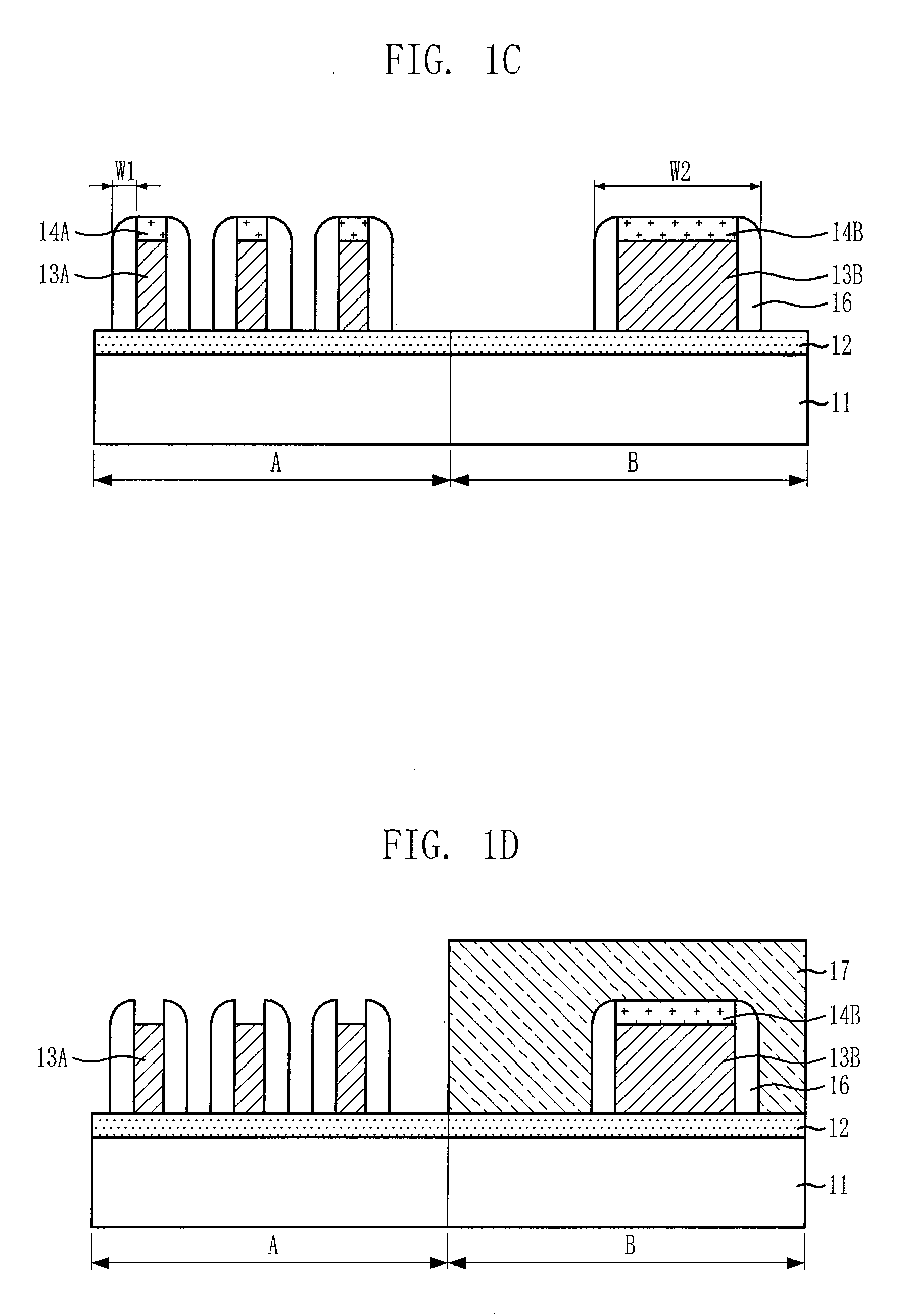

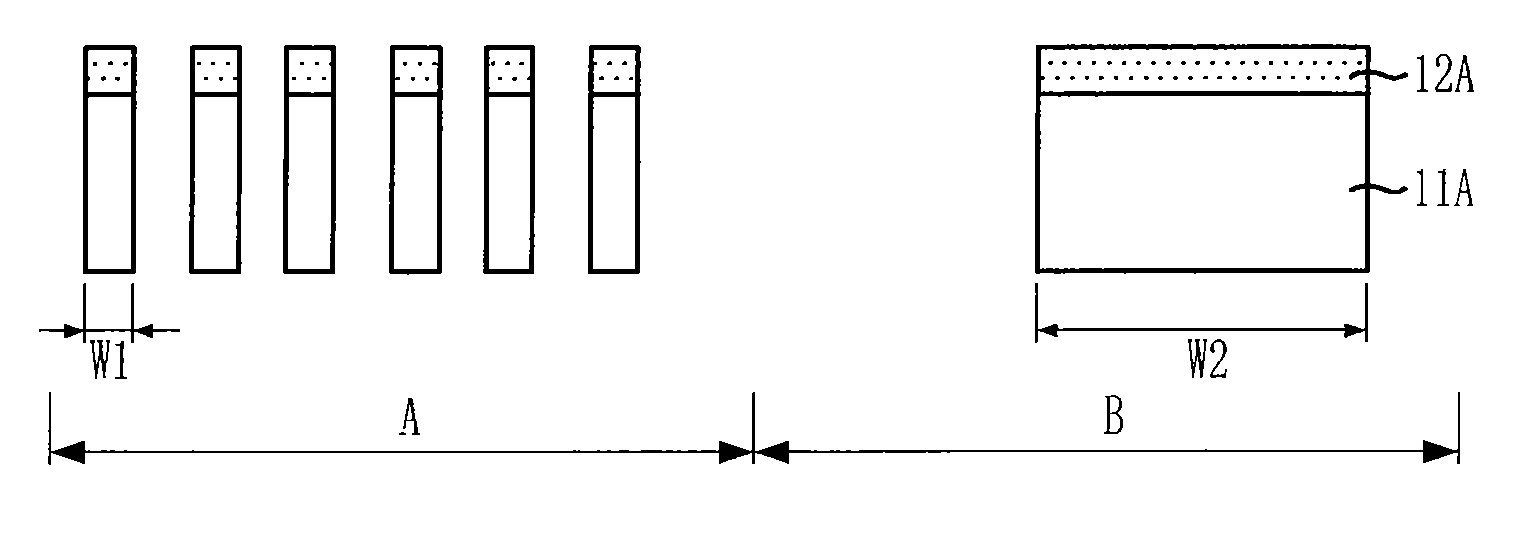

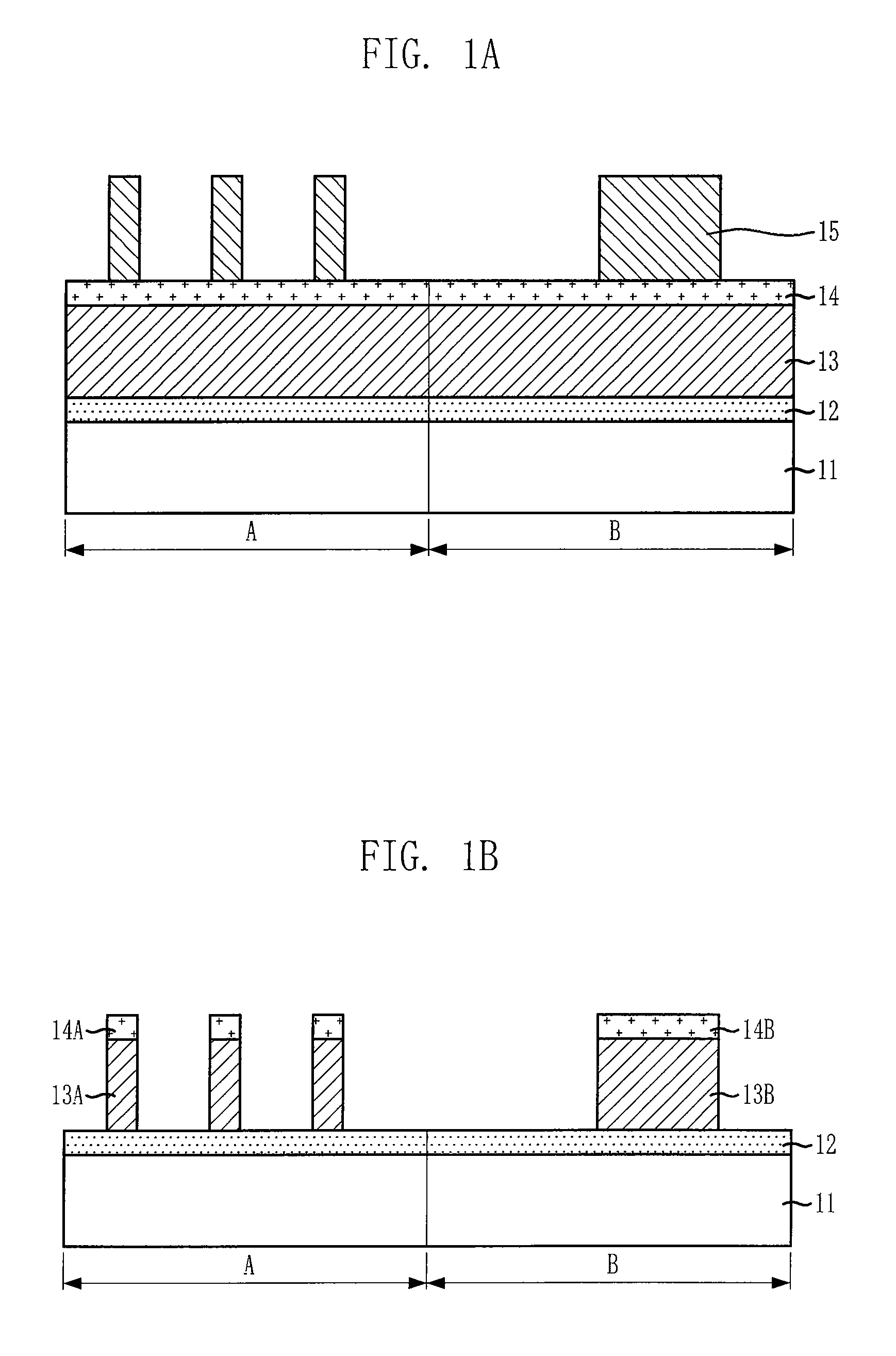

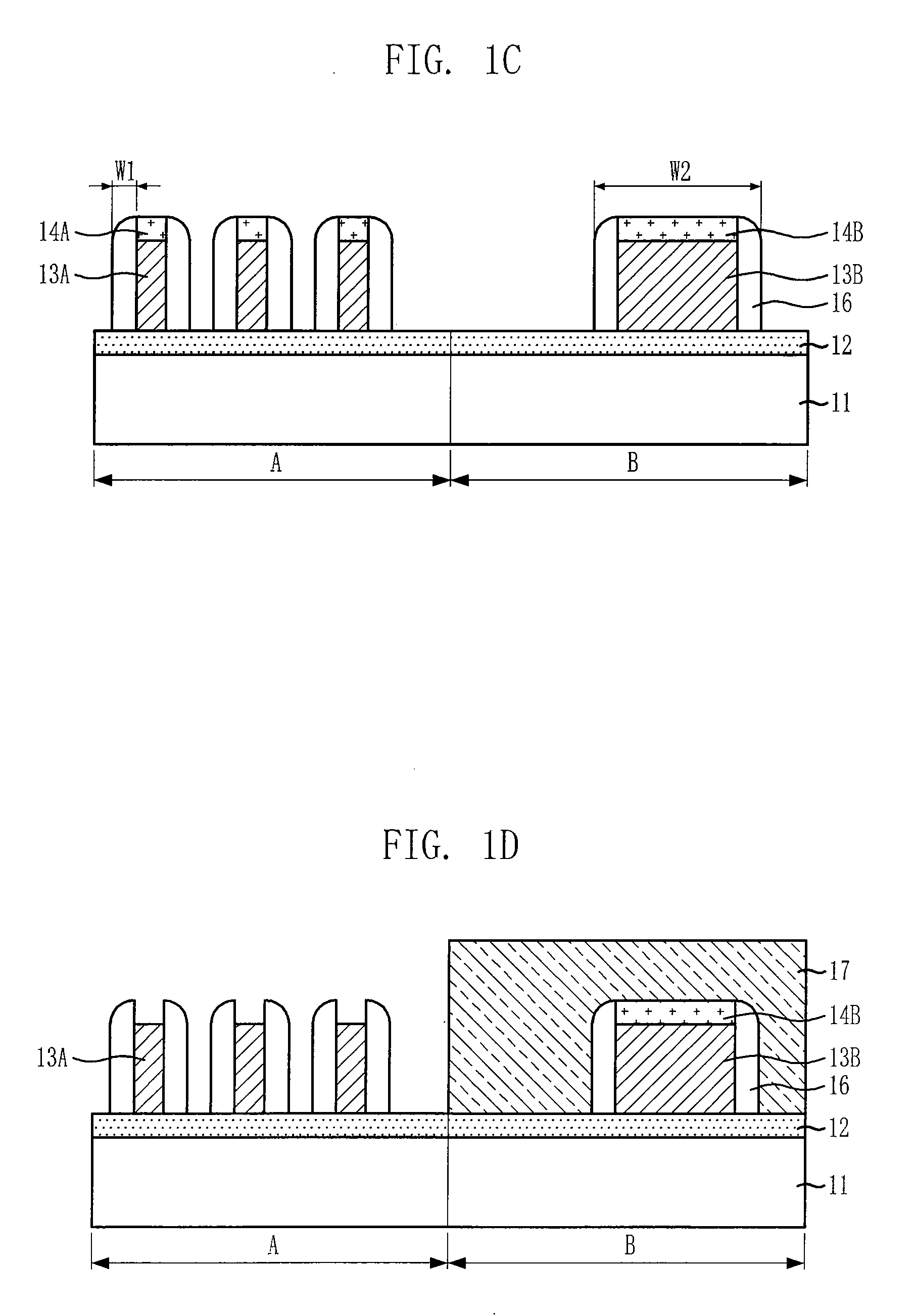

Method for forming pattern in semiconductor device

InactiveUS20090117739A1Avoid low process precisionSimple processSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSemiconductor

A method for forming a pattern in a semiconductor device includes forming an etch-target layer over a substrate, wherein the substrate includes a first region having a smaller pattern than the first region, forming a sacrificial layer and a passivation layer over the etch-target layer, etching the passivation layer and the sacrificial layer to form stack structures including a sacrificial pattern and a passivation pattern, forming spacers over sidewalls of the stack structures, forming a mask pattern covering the second region, removing a portion of the passivation pattern in the first region exposed by the mask pattern to expose a portion of the sacrificial pattern in the first region, removing the exposed portion of the sacrificial pattern in the first region, and etching the etch-target layer to form an etch-target pattern using the spacers in the first and second regions and the stack structure formed between the spacers in the second region.

Owner:SK HYNIX INC

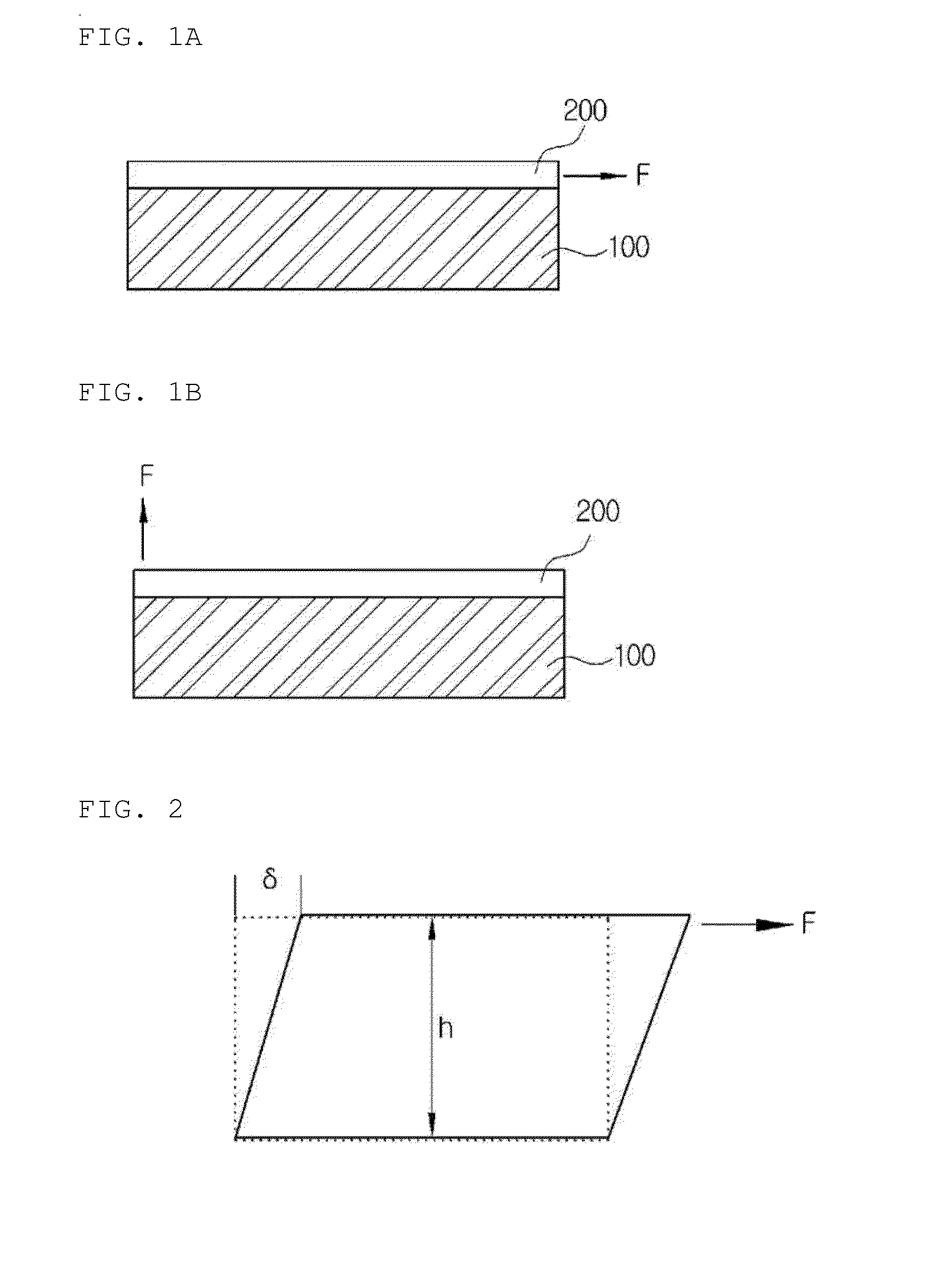

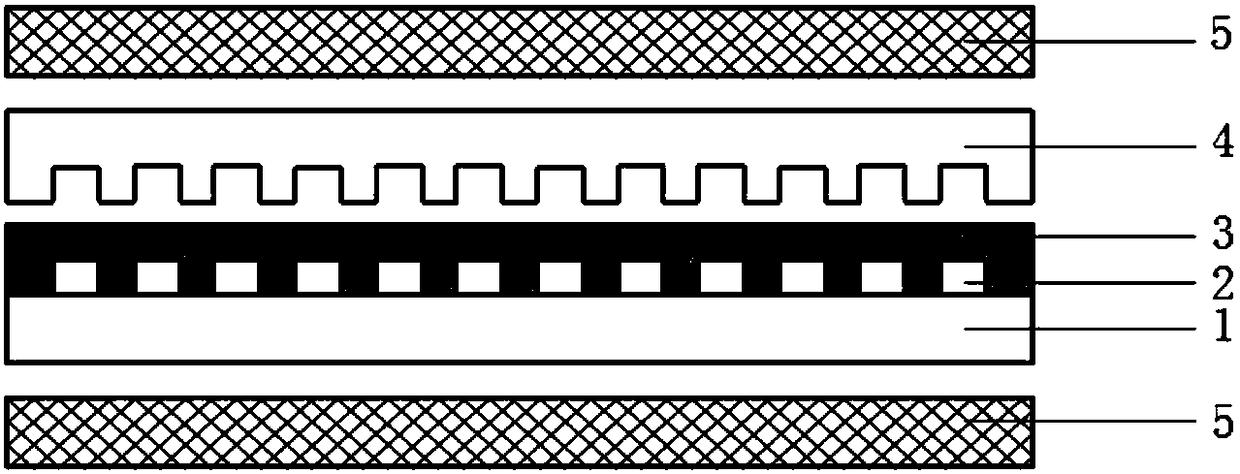

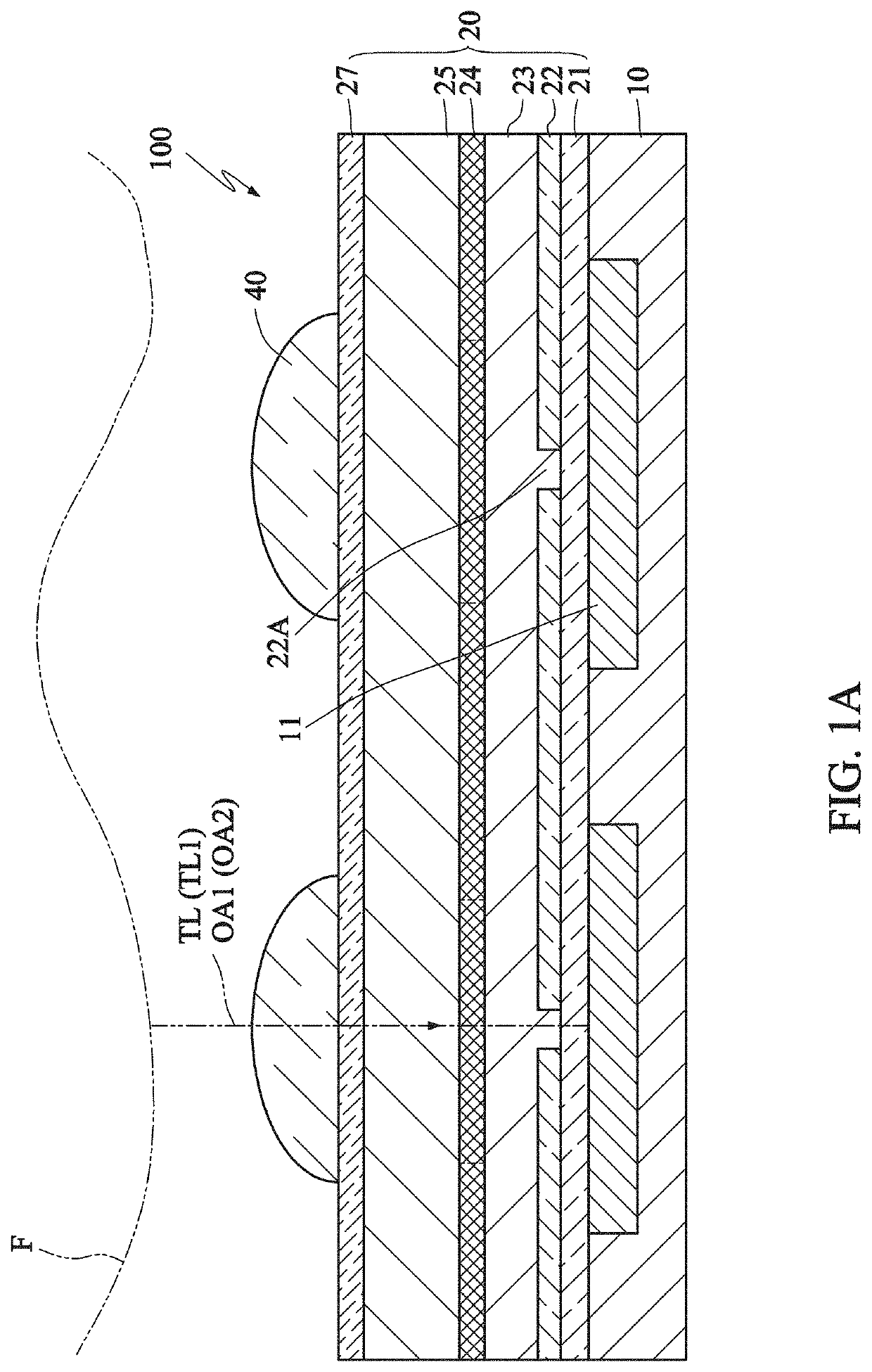

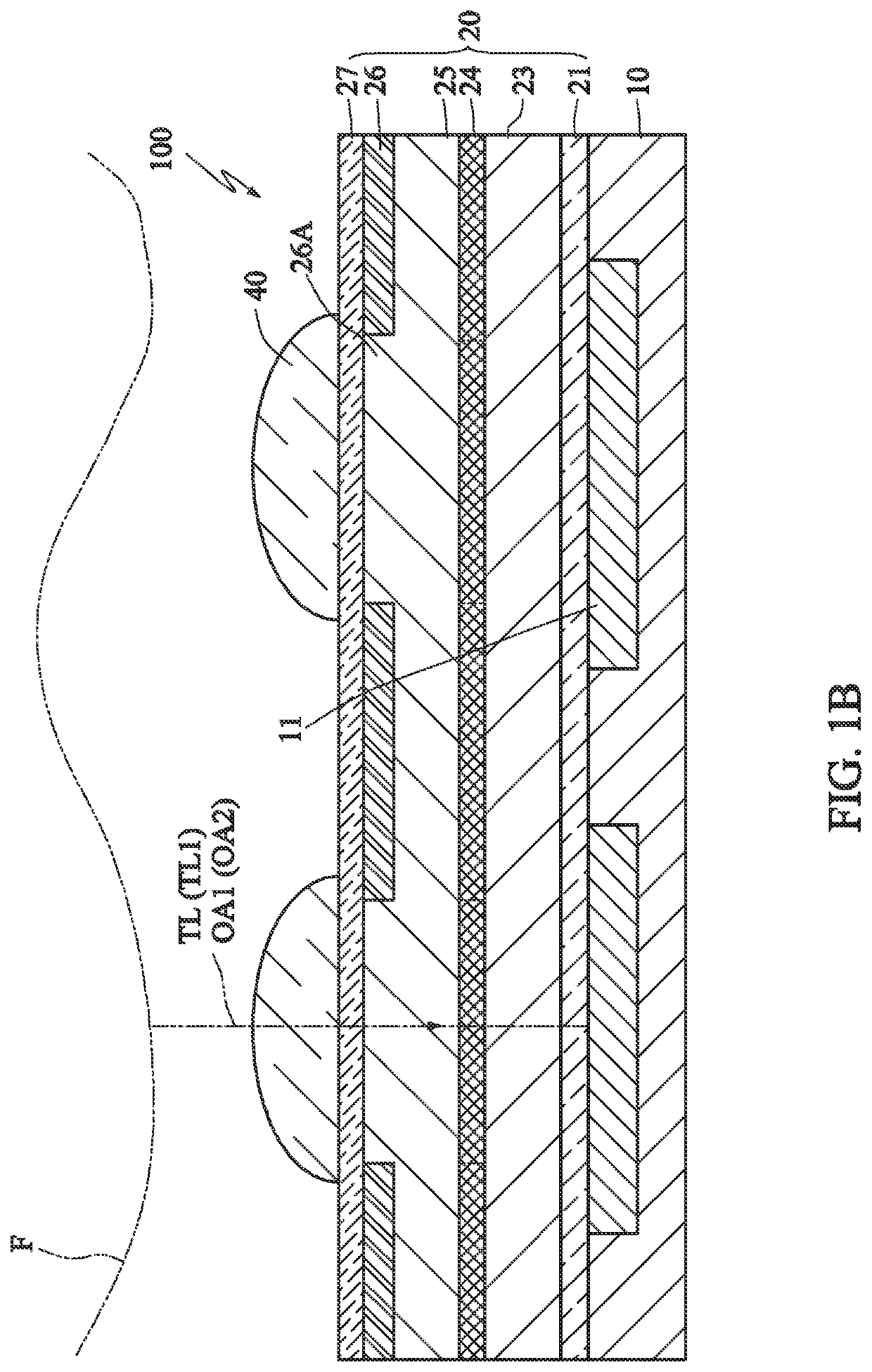

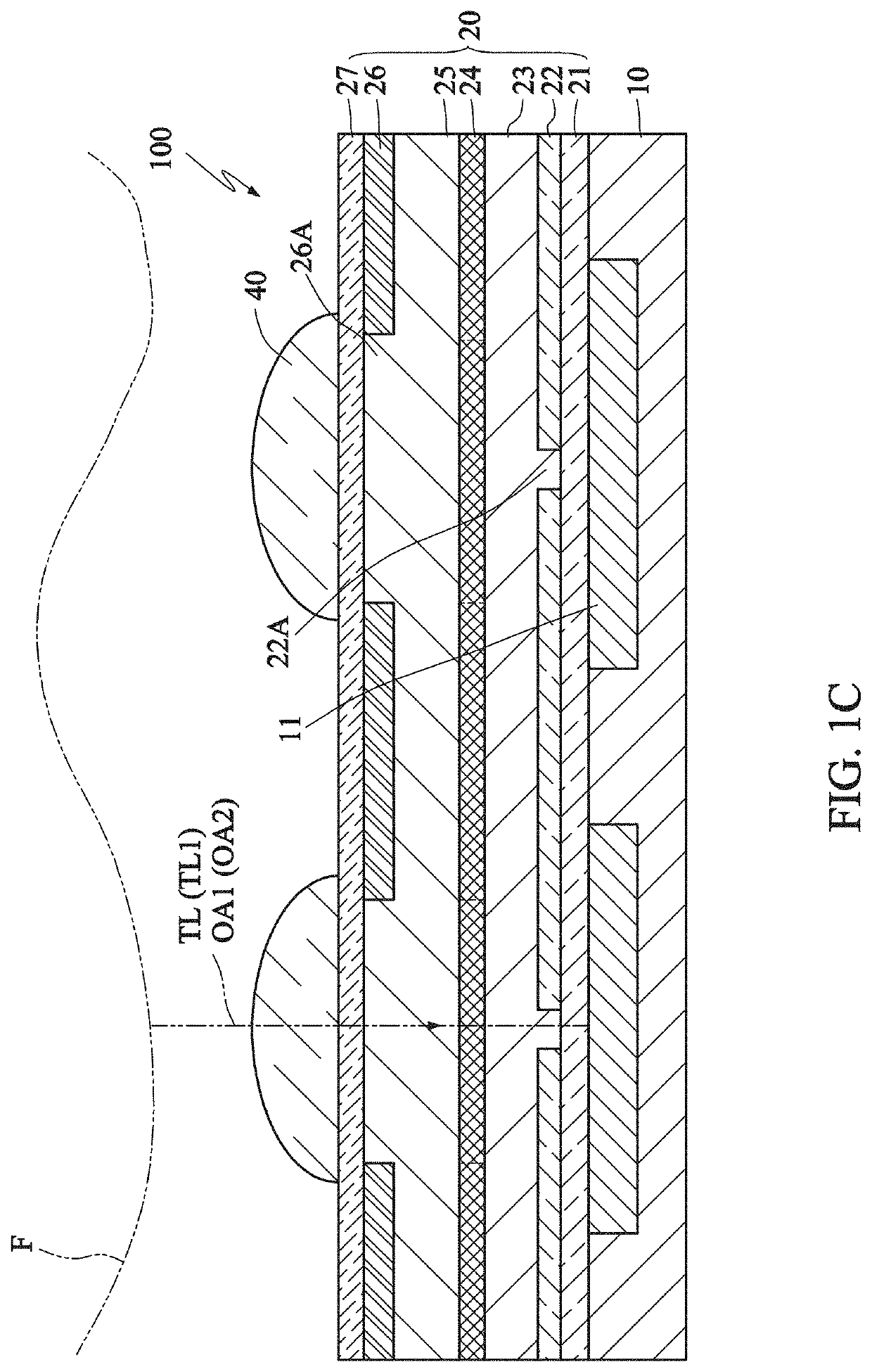

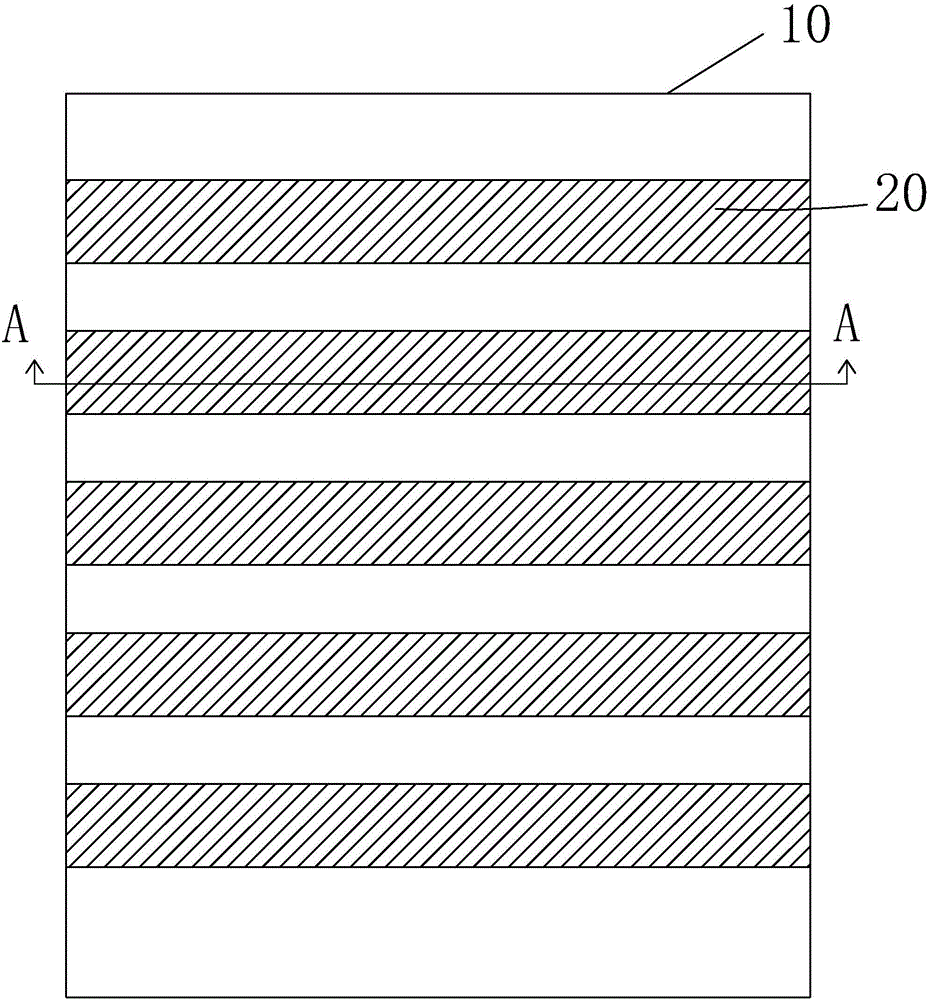

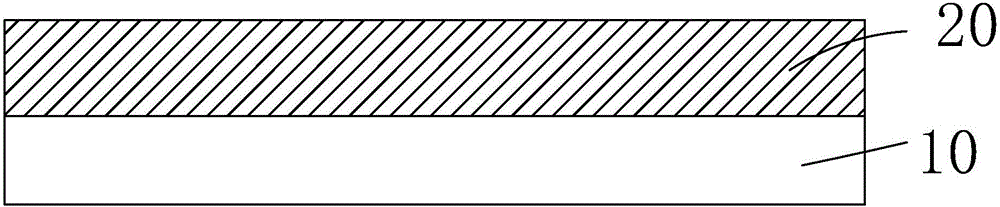

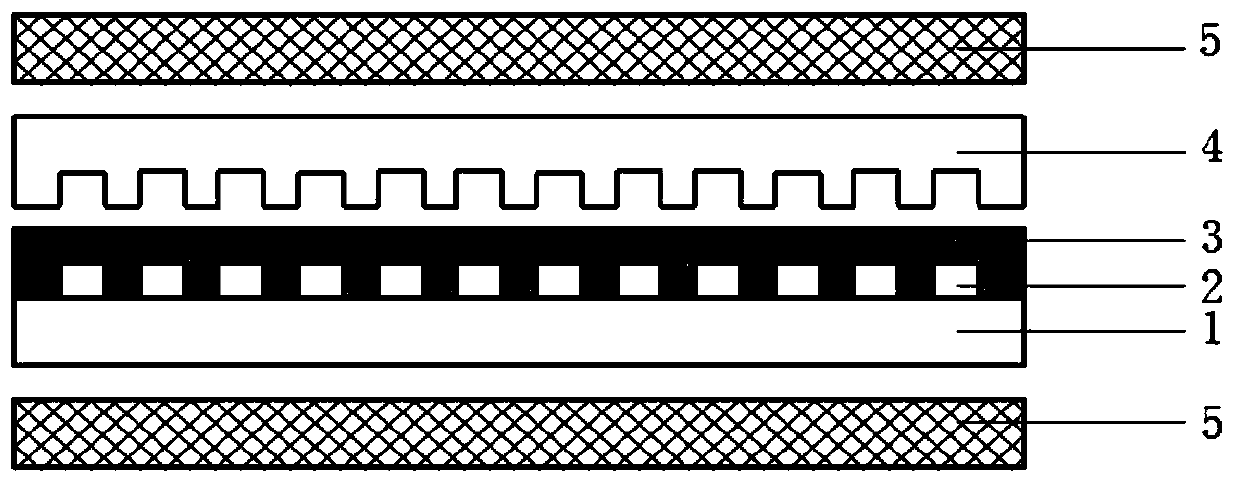

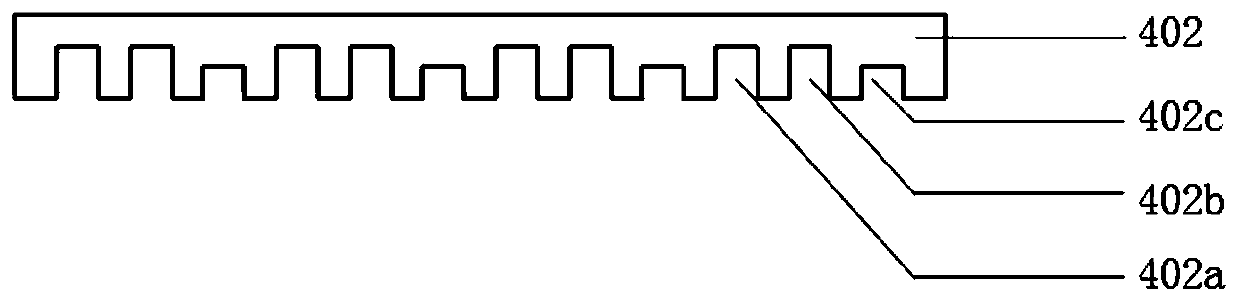

Supporting substrate for manufacturing flexible information display device, manufacturing method thereof, and flexible information display device

InactiveUS20150060870A1Low investment costIncrease equipment costLamination ancillary operationsLayered product treatmentDisplay deviceEngineering

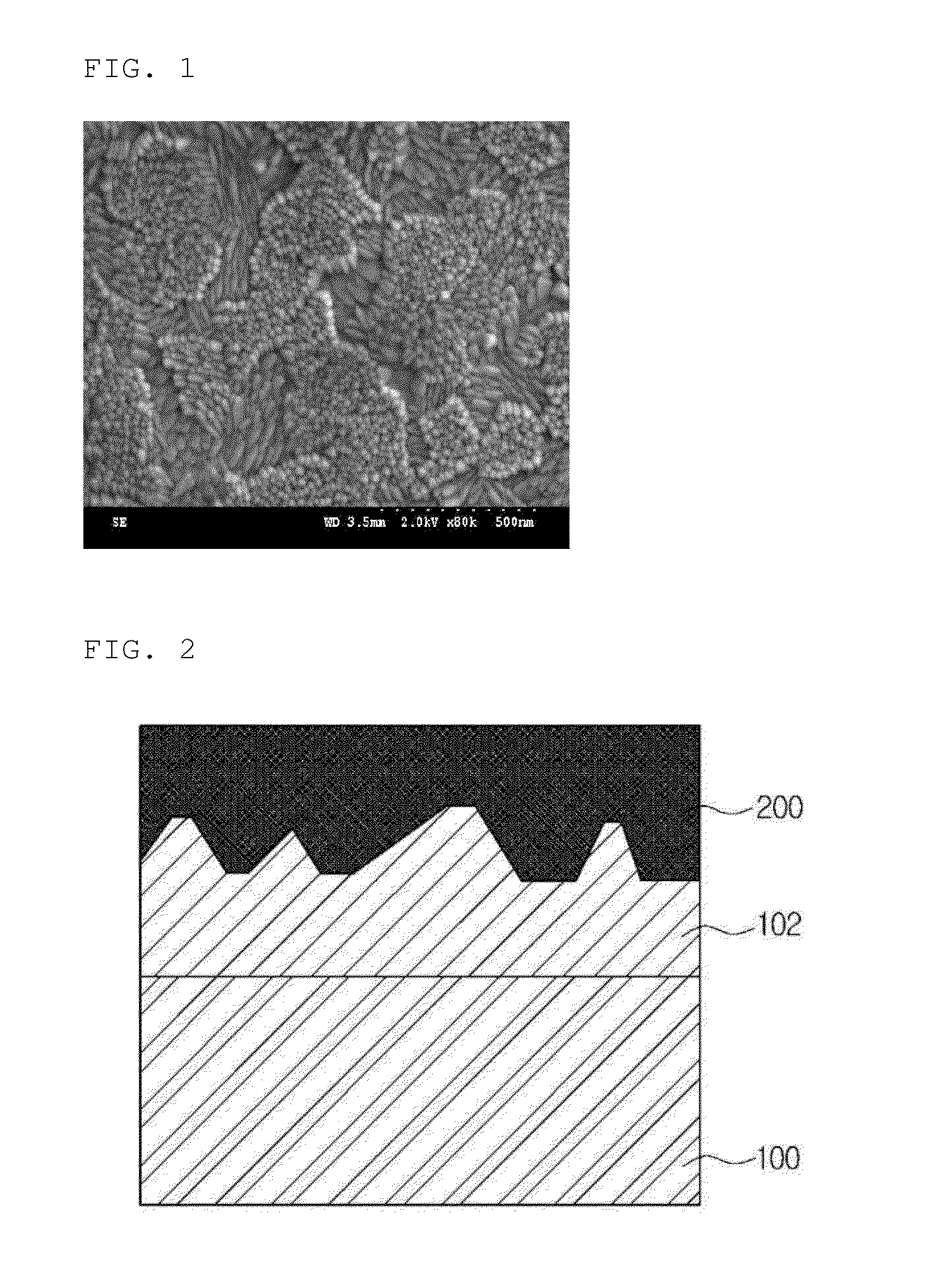

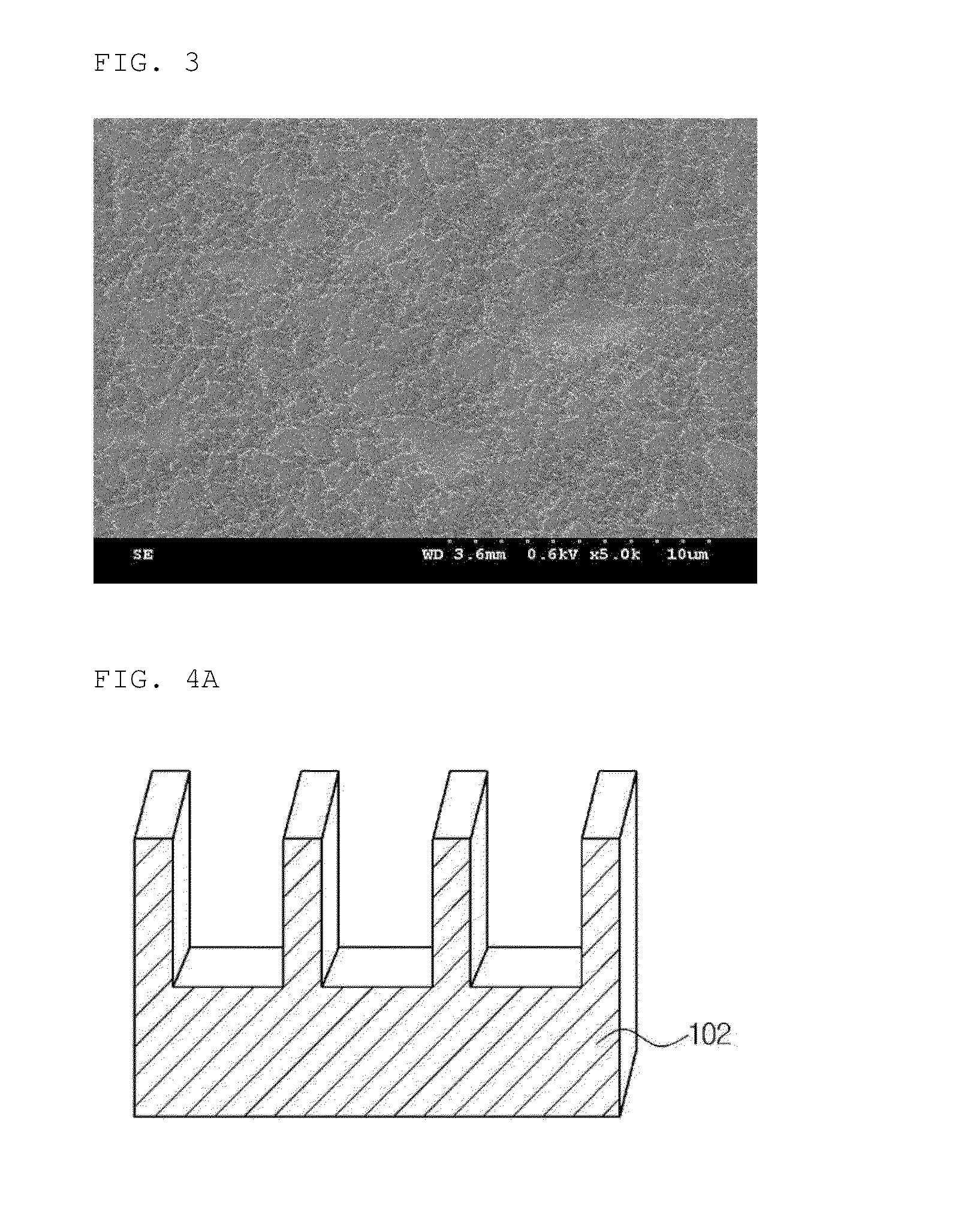

Disclosed are a supporting substrate for manufacturing a flexible information display device capable of easily separating the flexible information display device from the supporting substrate without deforming or damaging the flexible information display device, a manufacturing method thereof, and a flexible information display device manufactured thereby. The supporting substrate for manufacturing a flexible information display device includes: a coating layer formed therein with a plurality micro-protrusions formed on the supporting substrate; and a temporary bonding / debonding layer formed on the coating layer and including an adhesive material mechanically interlocked with and bonded to the supporting substrate through Van der Waals bonding force. The method provides a method capable of economically manufacturing the display device having a high resolution while reviewing a cost competitive force by reducing a device investment cost and improving the yield rate in the flexible flat panel information display device.

Owner:LEE KEUN SOO +2

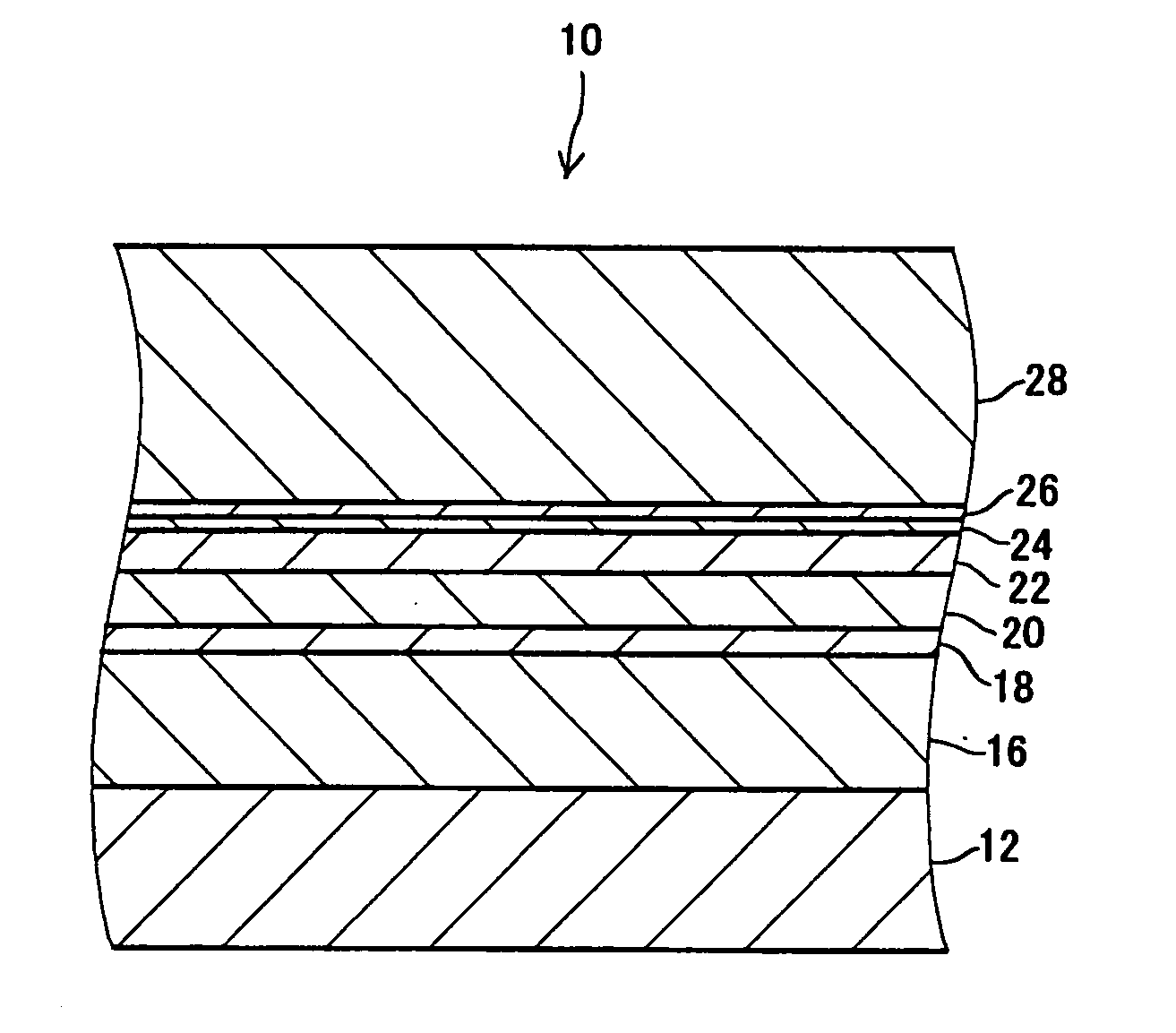

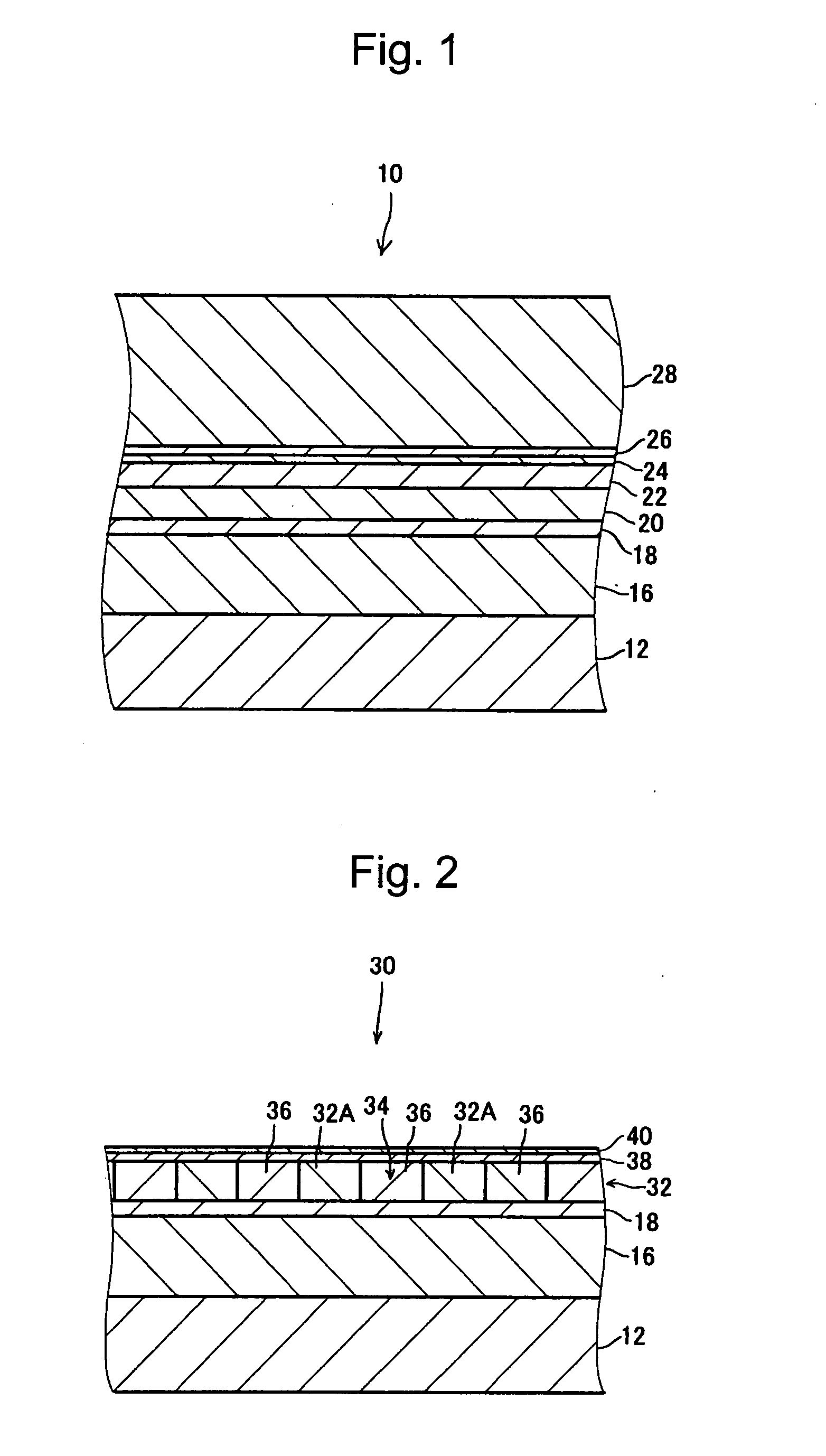

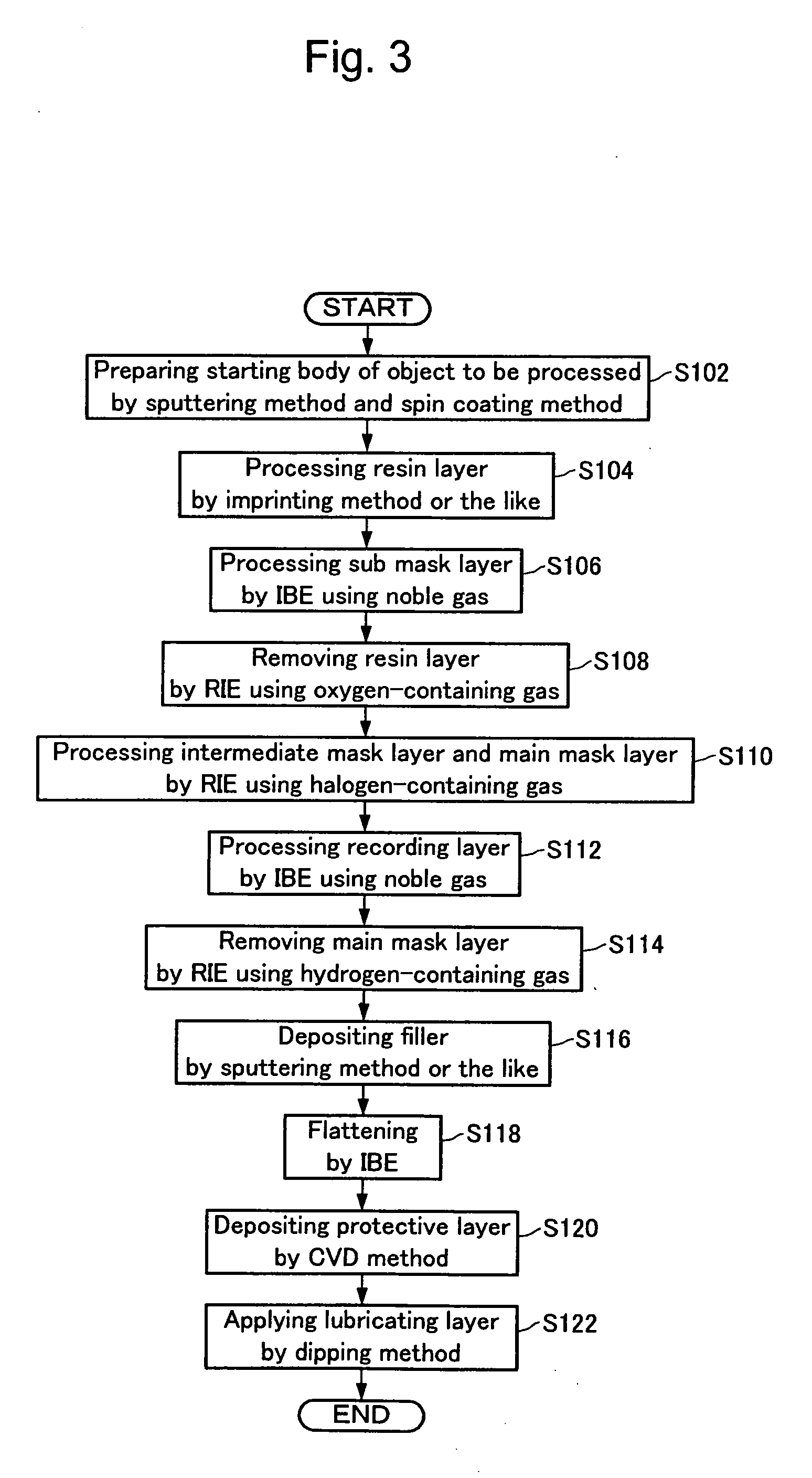

Method for manufacturing magnetic recording medium

InactiveUS20080078739A1Improve accuracyReliable removalDecorative surface effectsNanoinformaticsHalogenOptoelectronics

A method for manufacturing a magnetic recording medium with excellent production efficiency is provided in which the recording layer can be processed into a desired concavo-convex pattern with high precision and the resin layer can reliably and thoroughly be removed. A sub-mask layer having corrosion resistance against an oxygen-containing gas is provided over a main mask layer composed mainly of carbon. Furthermore, an intermediate mask layer is provided between the main mask layer and the sub-mask layer. The intermediate mask layer has corrosion resistance against the oxygen-containing gas, and its etching rate is higher for a halogen-containing gas than for the oxygen-containing gas. The resin layer removing step is conducted between the sub-mask layer processing step and the intermediate mask layer processing step (the main mask layer processing step). The resin layer removing step uses the oxygen-containing gas, and the intermediate mask layer processing step uses the halogen-containing gas.

Owner:TDK CORPARATION

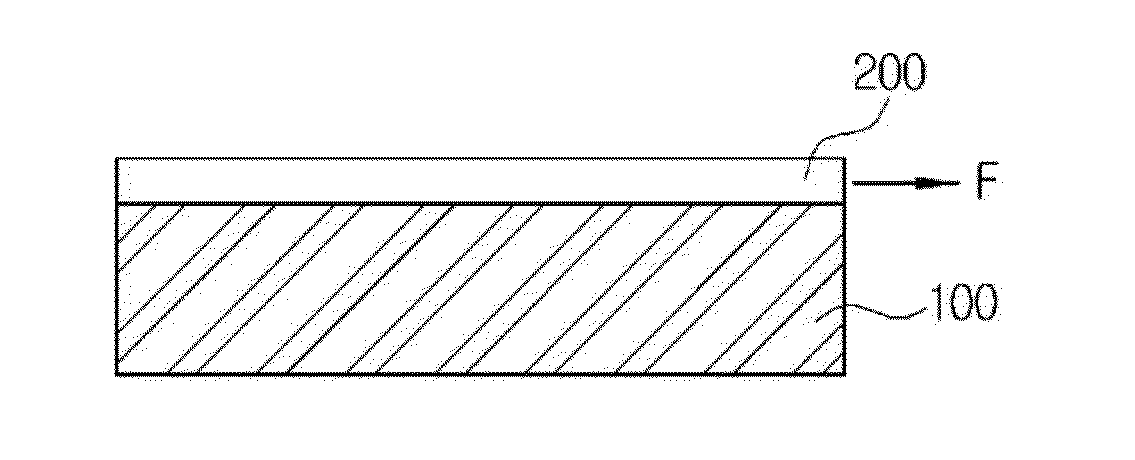

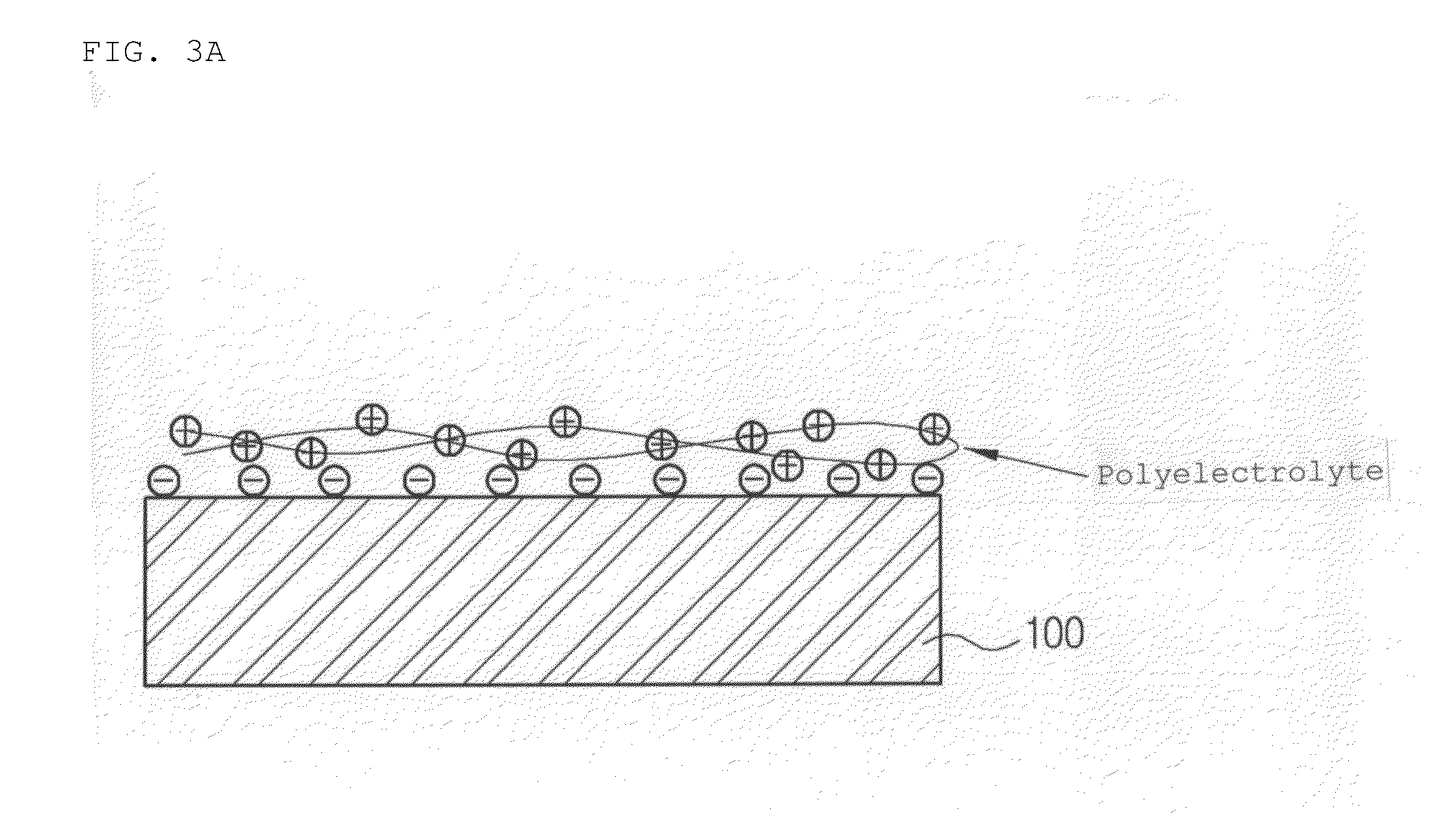

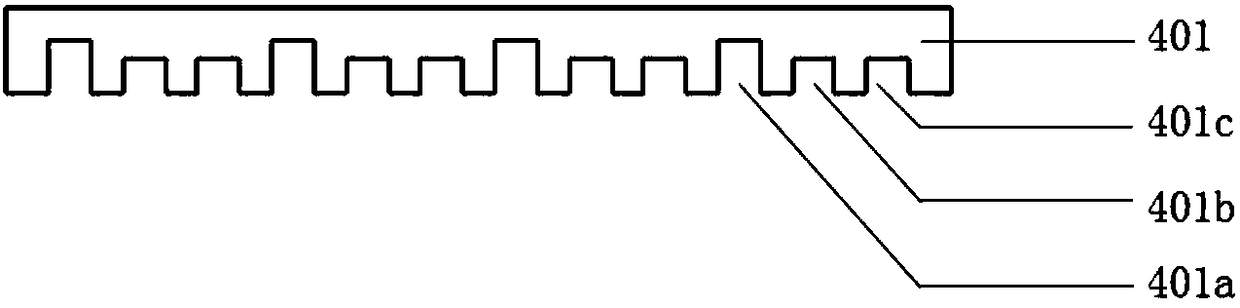

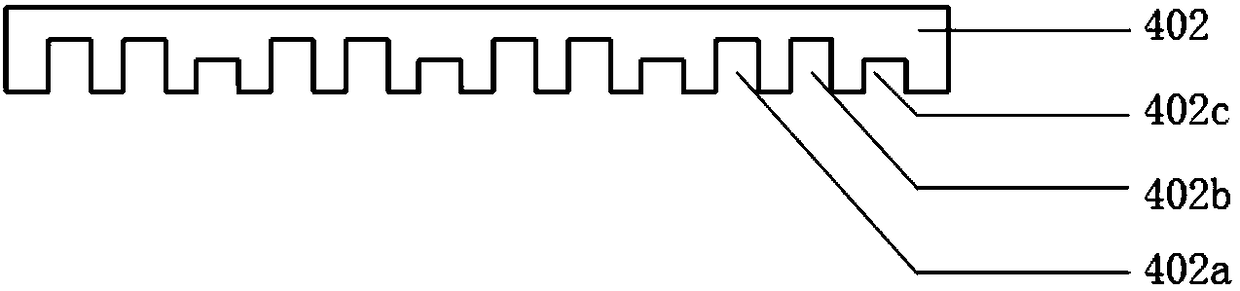

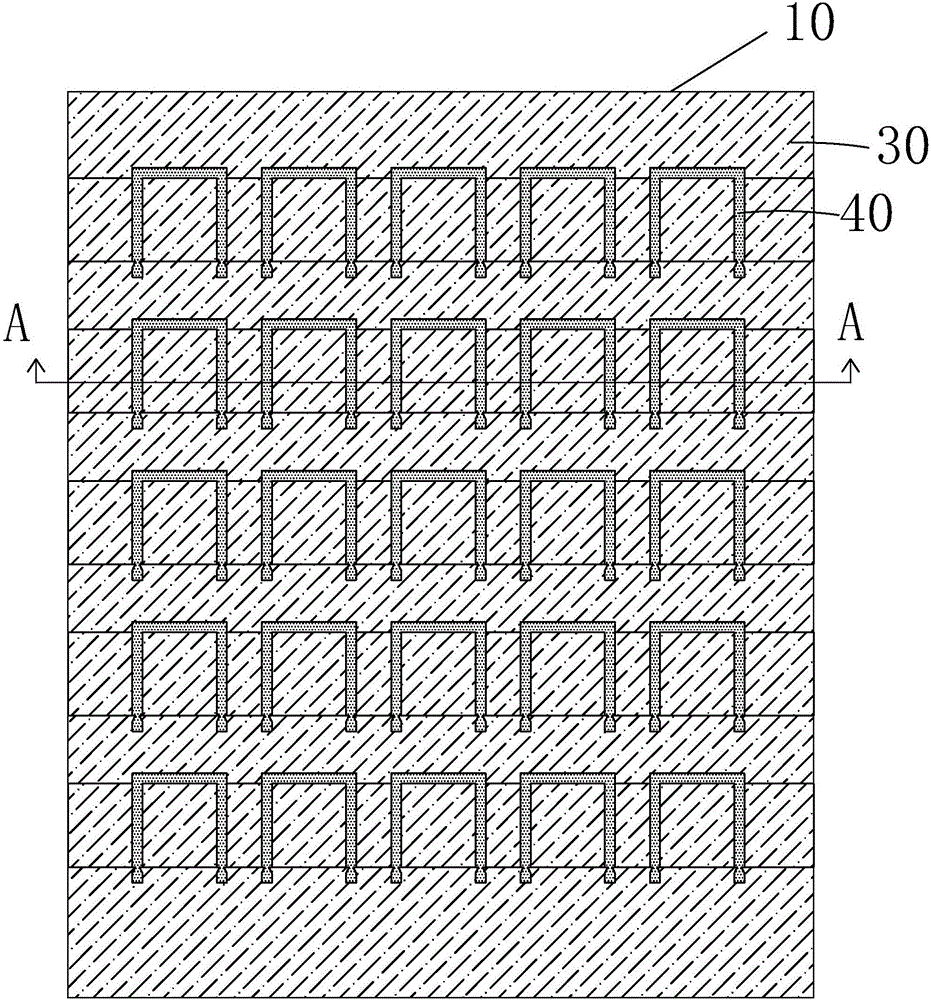

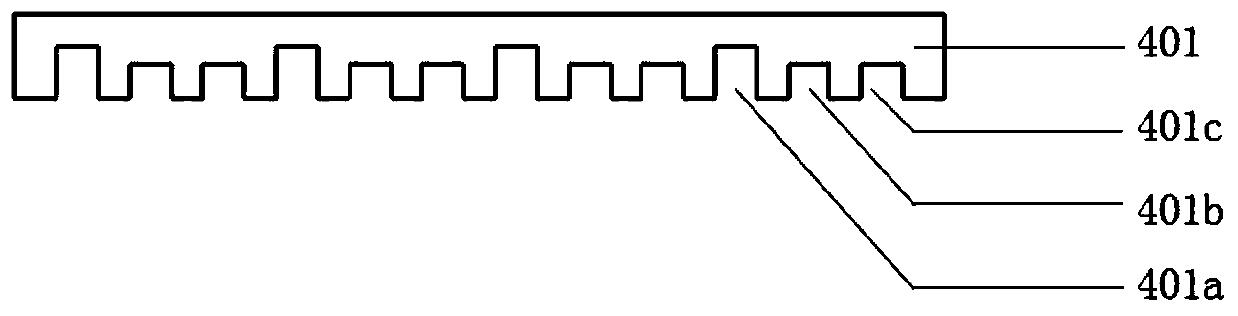

Supporting substrate for manufacturing flexible informaiton display device using temporary bonding/debonding layer, manufacturing method thereof, and flexible information display device

InactiveUS20150060869A1High resolutionAvoid low process precisionLiquid surface applicatorsElectric shock equipmentsDisplay deviceEngineering

Disclosed are a supporting substrate for manufacturing a flexible information display device using a temporary bonding / debonding layer, a manufacturing method thereof, and a flexible information display device. A supporting substrate for manufacturing a flexible information display device, the supporting substrate comprising: a temporary bonding / debonding layer having a thickness in a range of 0.1 nm to 1000 nm and comprising an adhesive material bonded to the supporting substrate through Van der Waals bonding force. Provided is a method capable of economically manufacturing the display device having a high resolution while reviewing a cost competitive force by reducing a device investment cost and improving the yield rate in the flexible flat panel information display device.

Owner:LEE KEUN SOO +2

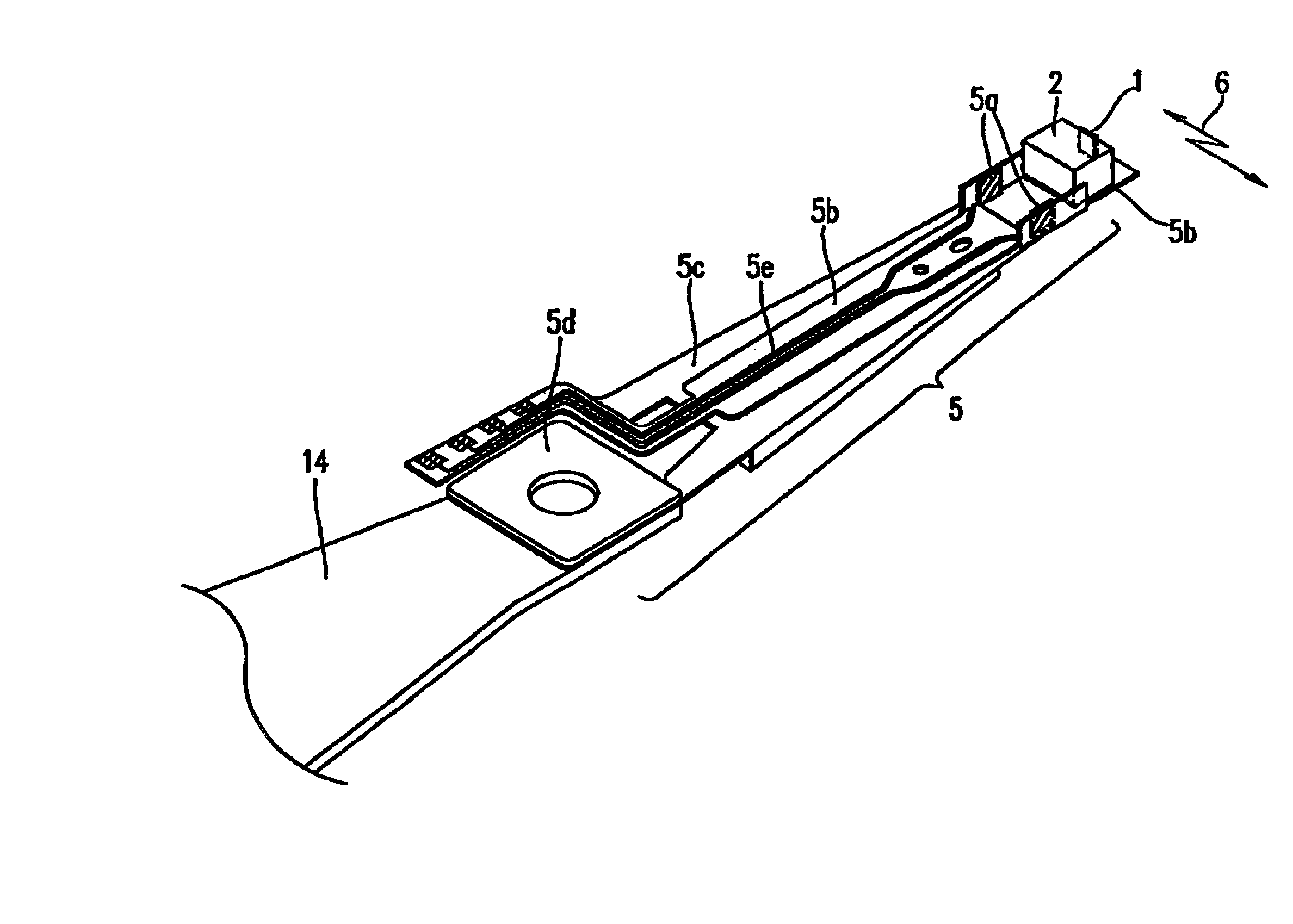

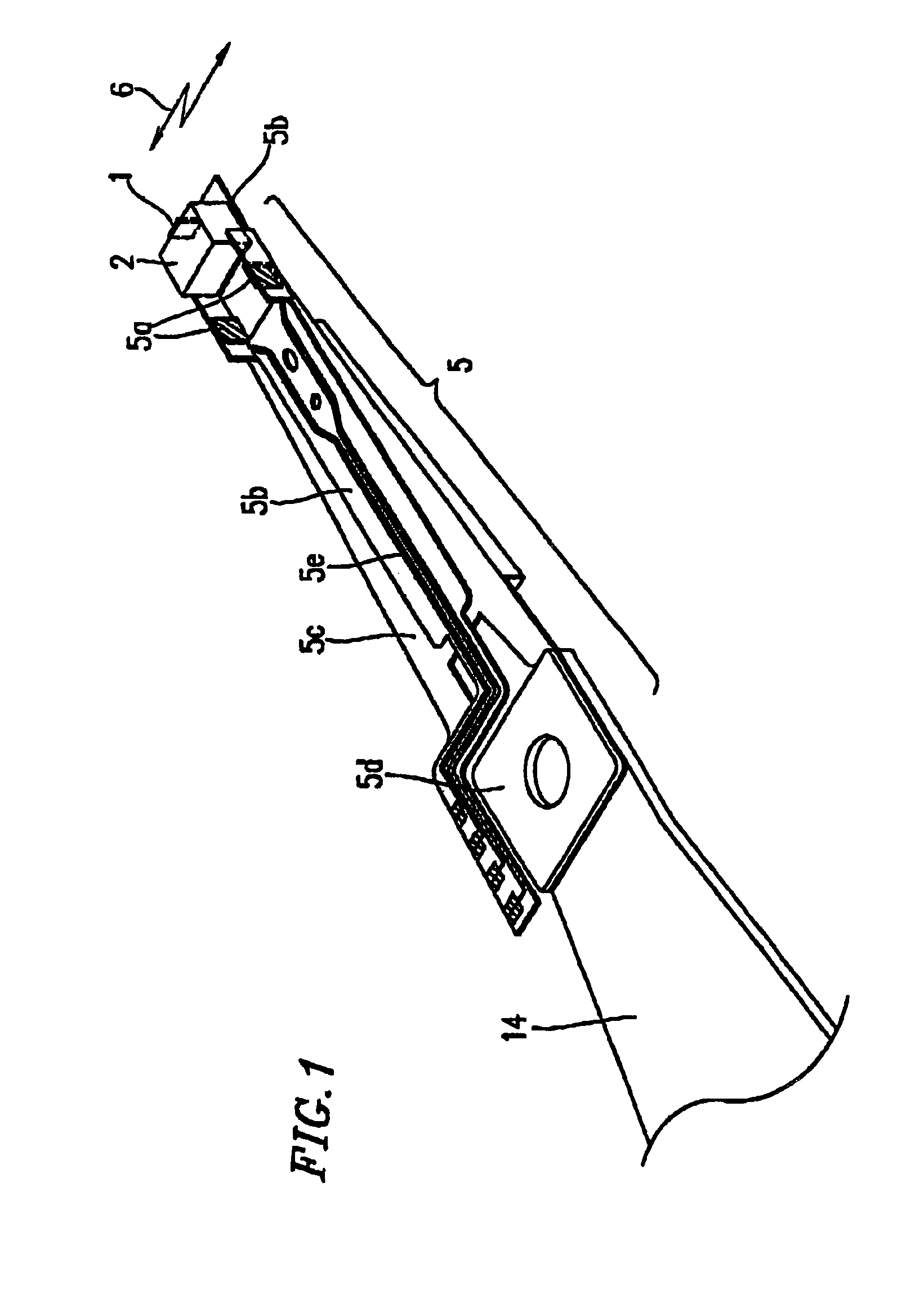

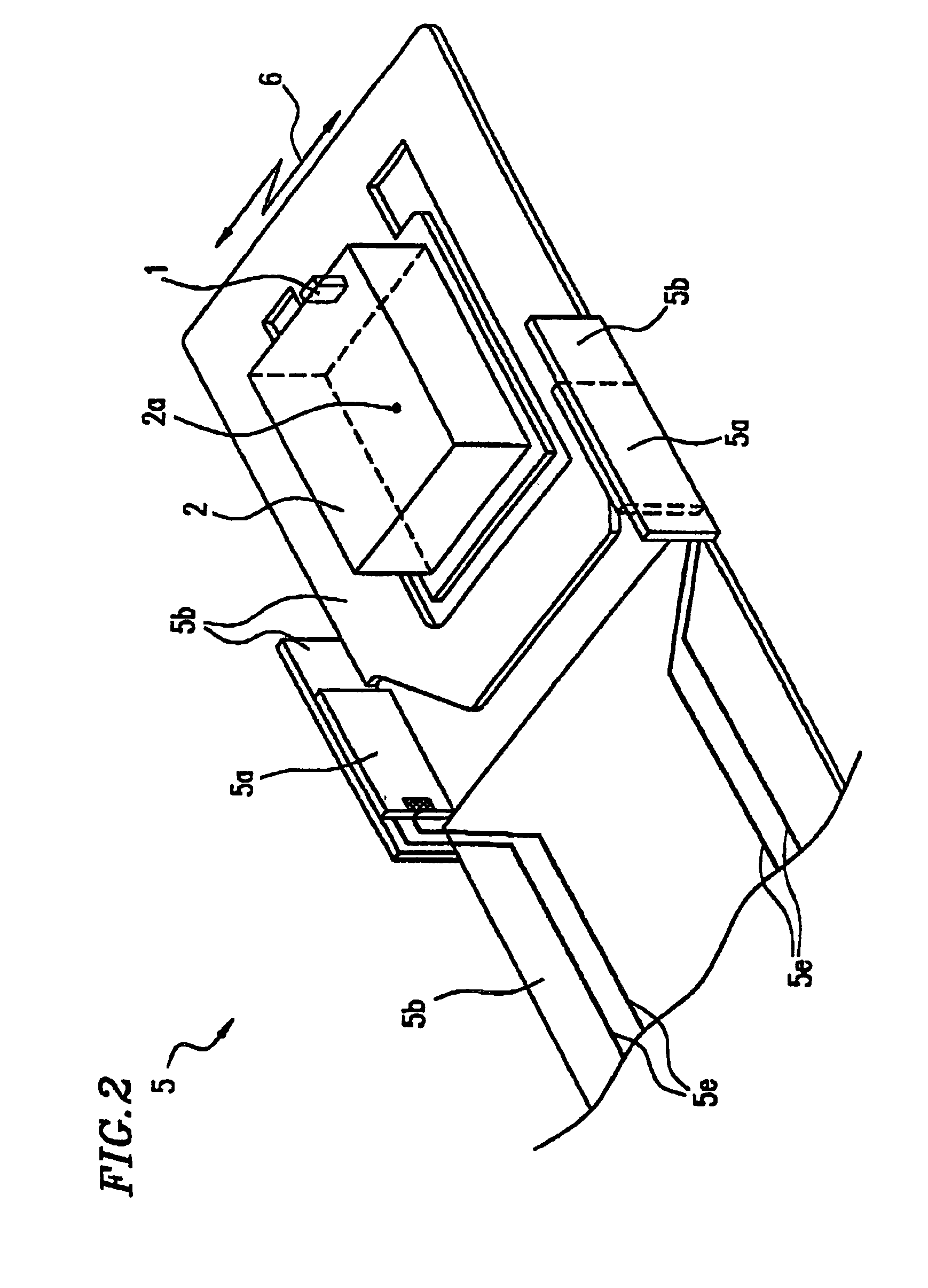

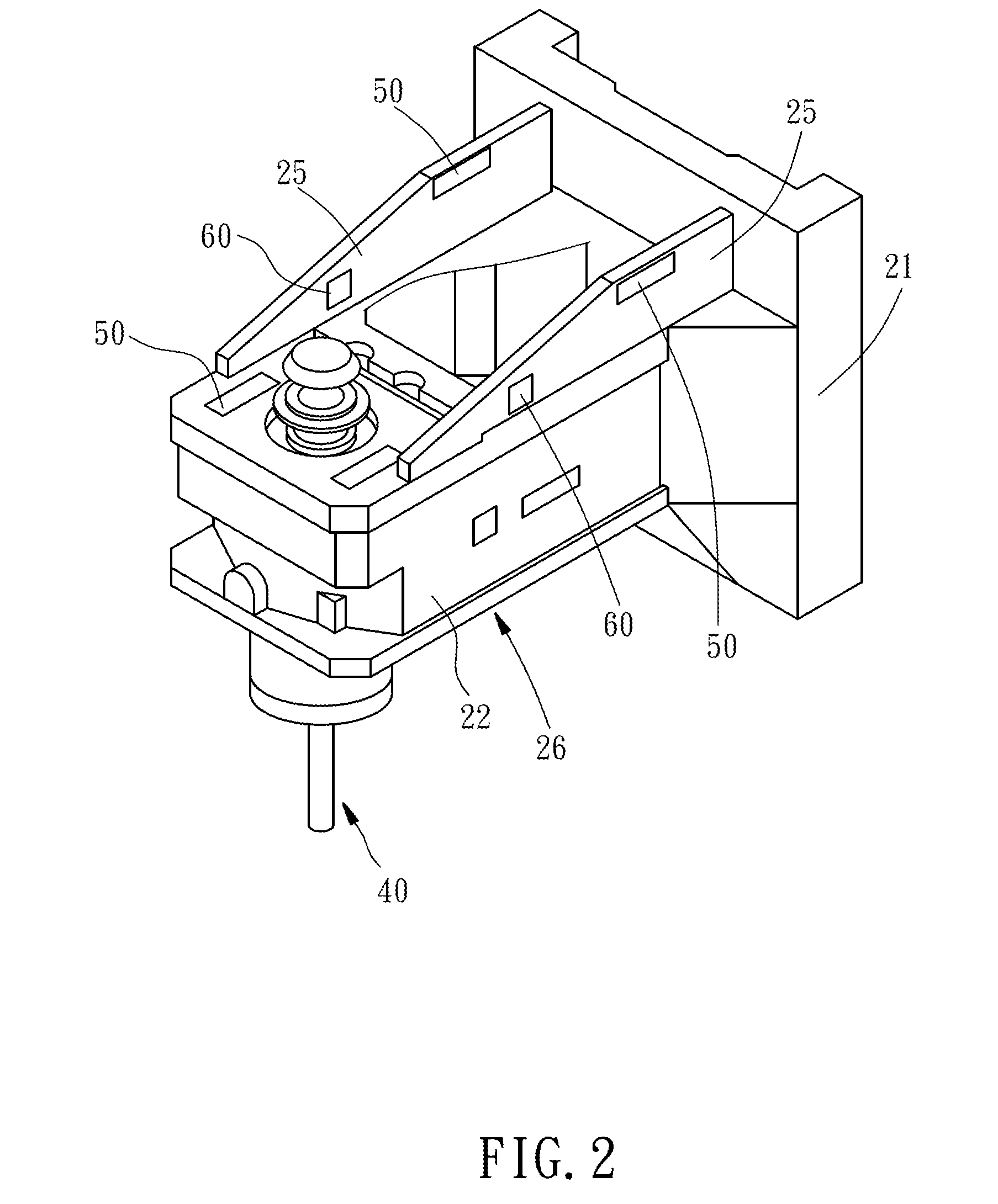

Head support mechanism, information recording/reproducing apparatus, and method of manufacturing head support mechanism

InactiveUS6943990B1Avoid low process precisionElectrical connection between head and armMagnetic discsBiomedical engineering

Owner:PANASONIC CORP

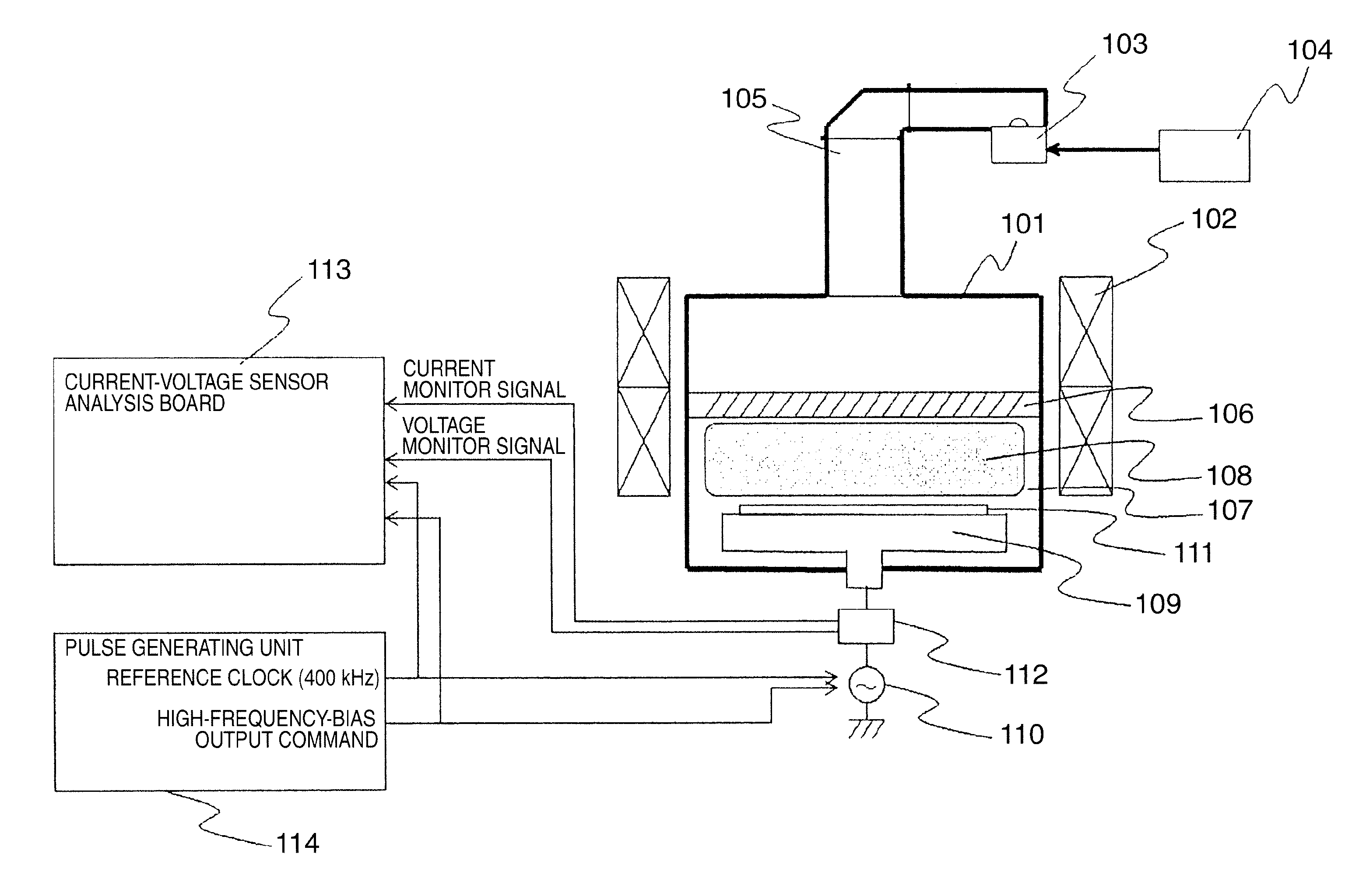

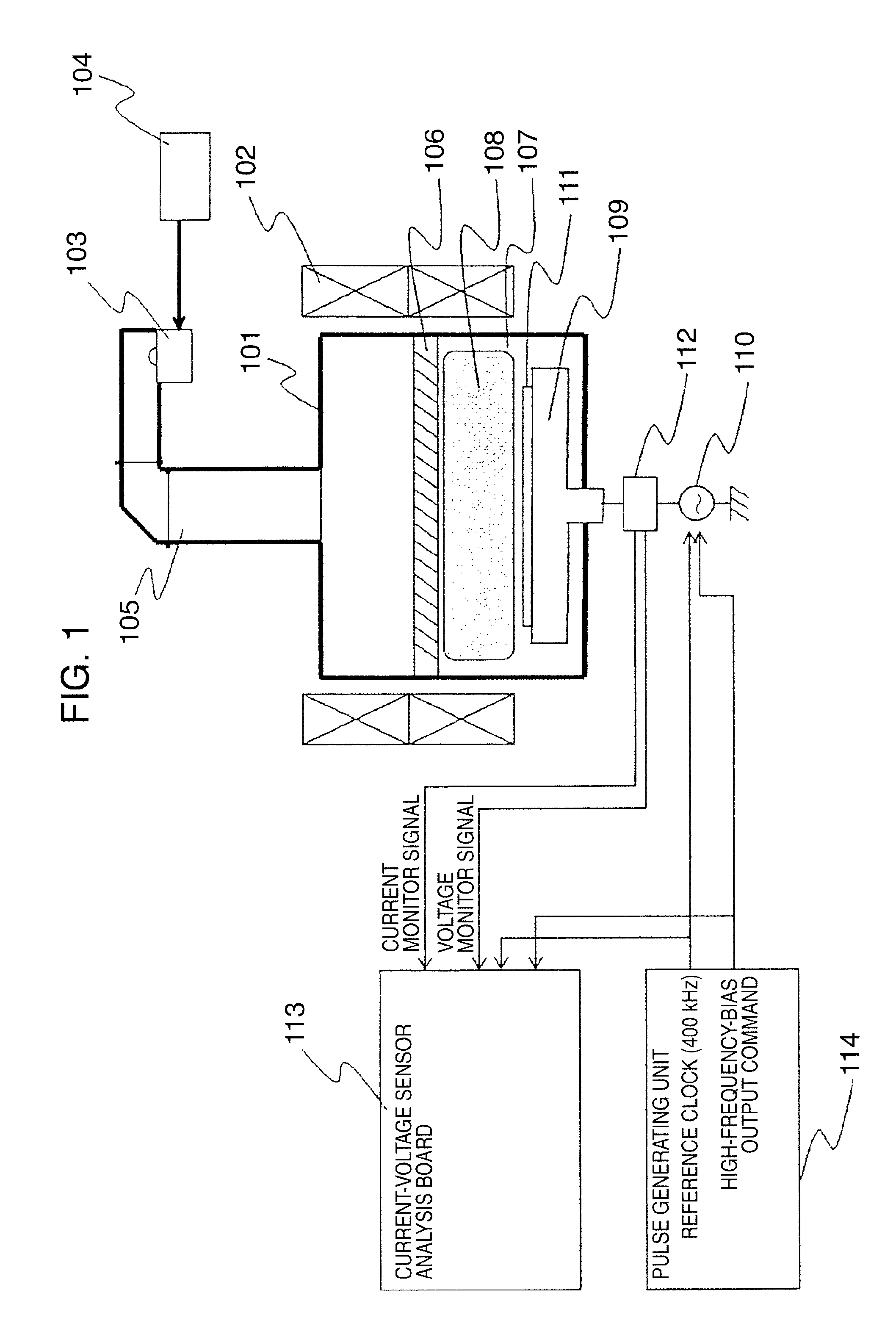

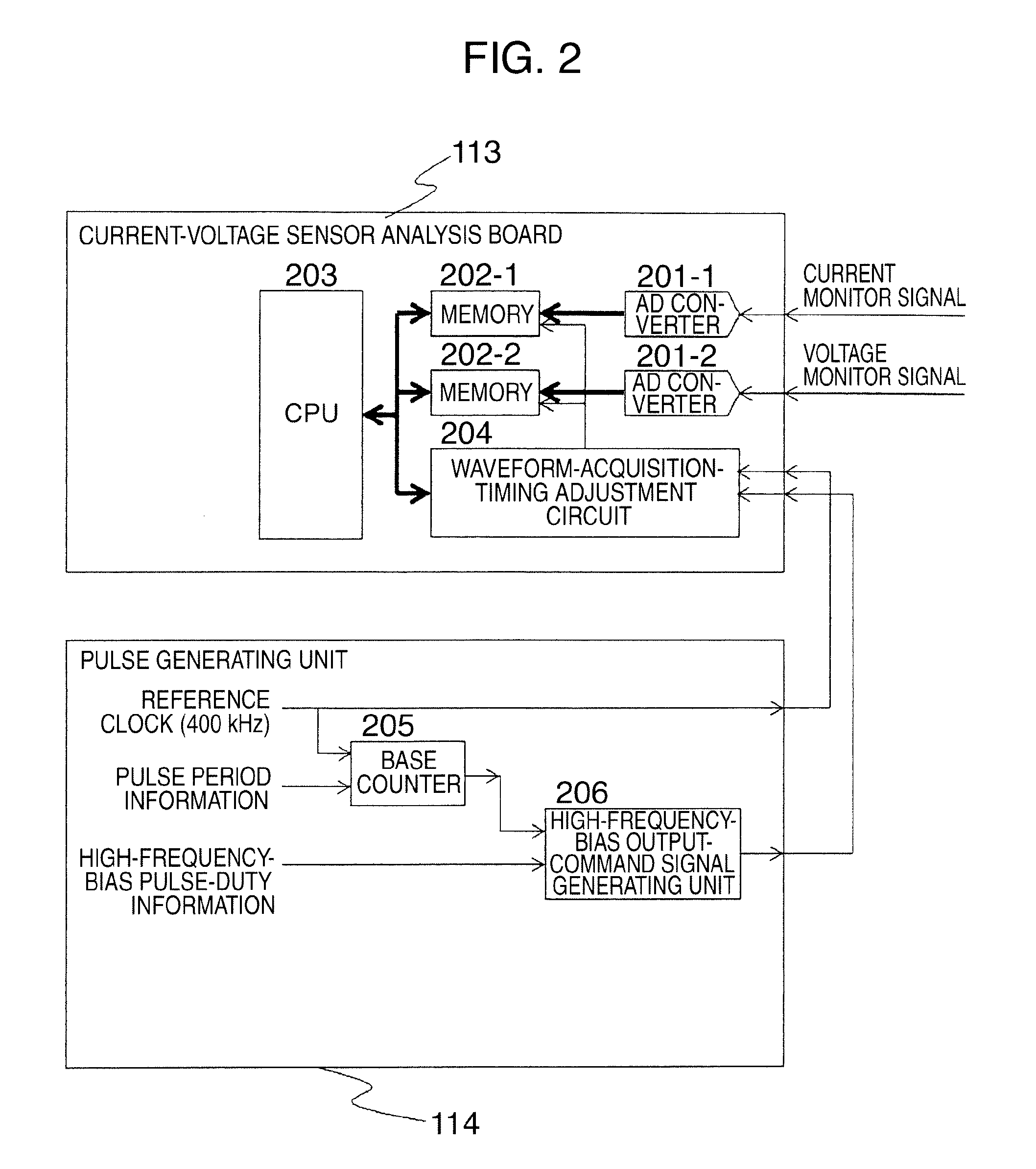

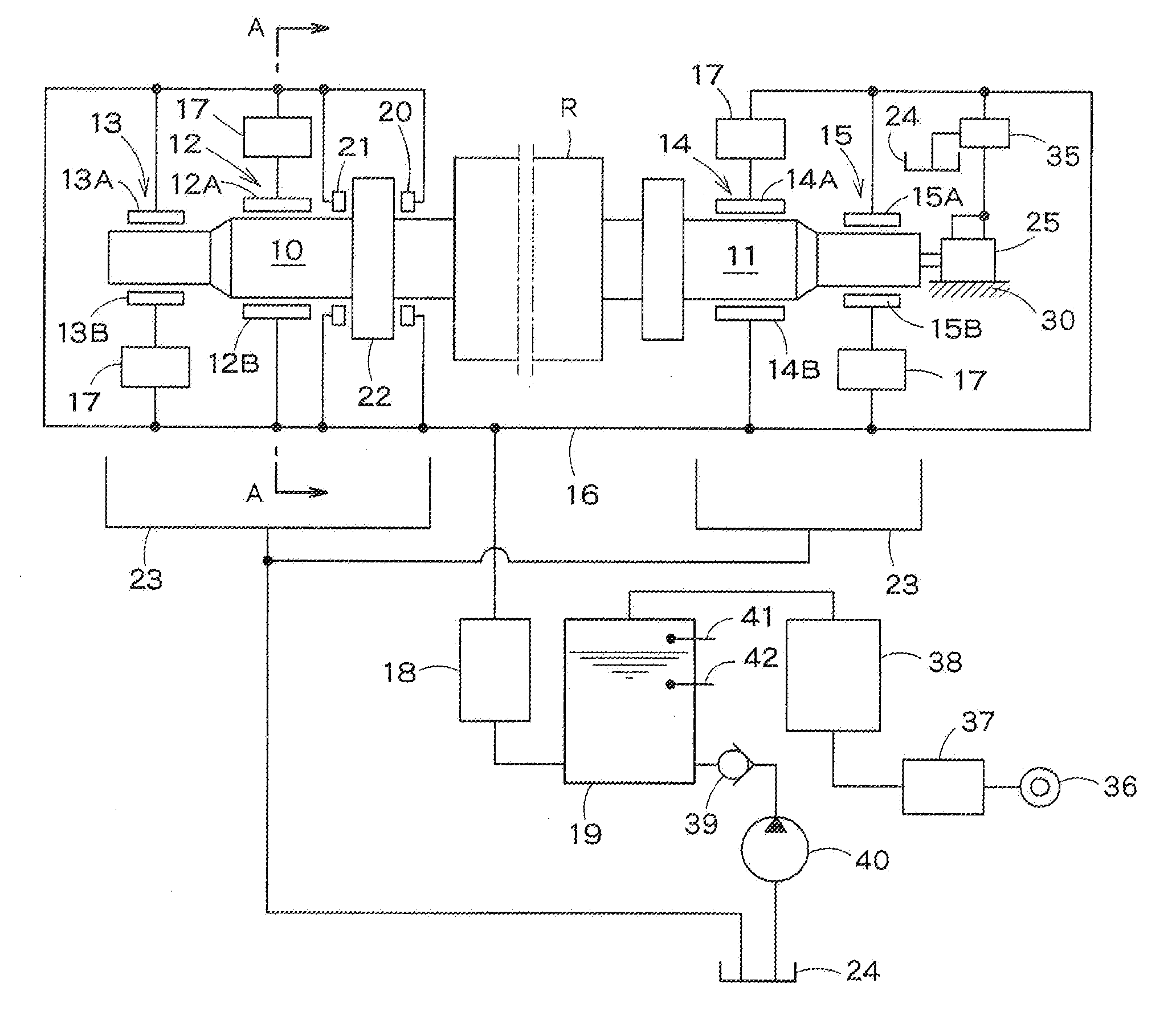

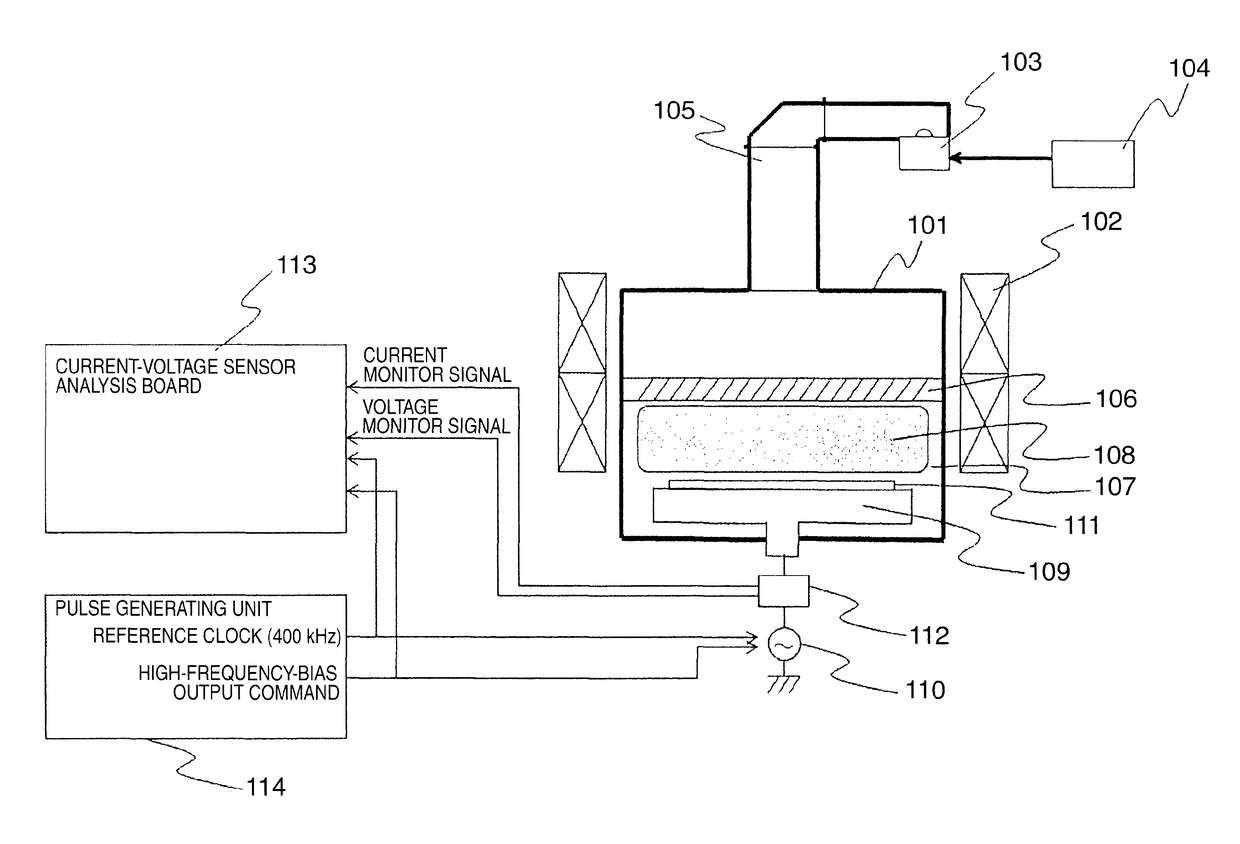

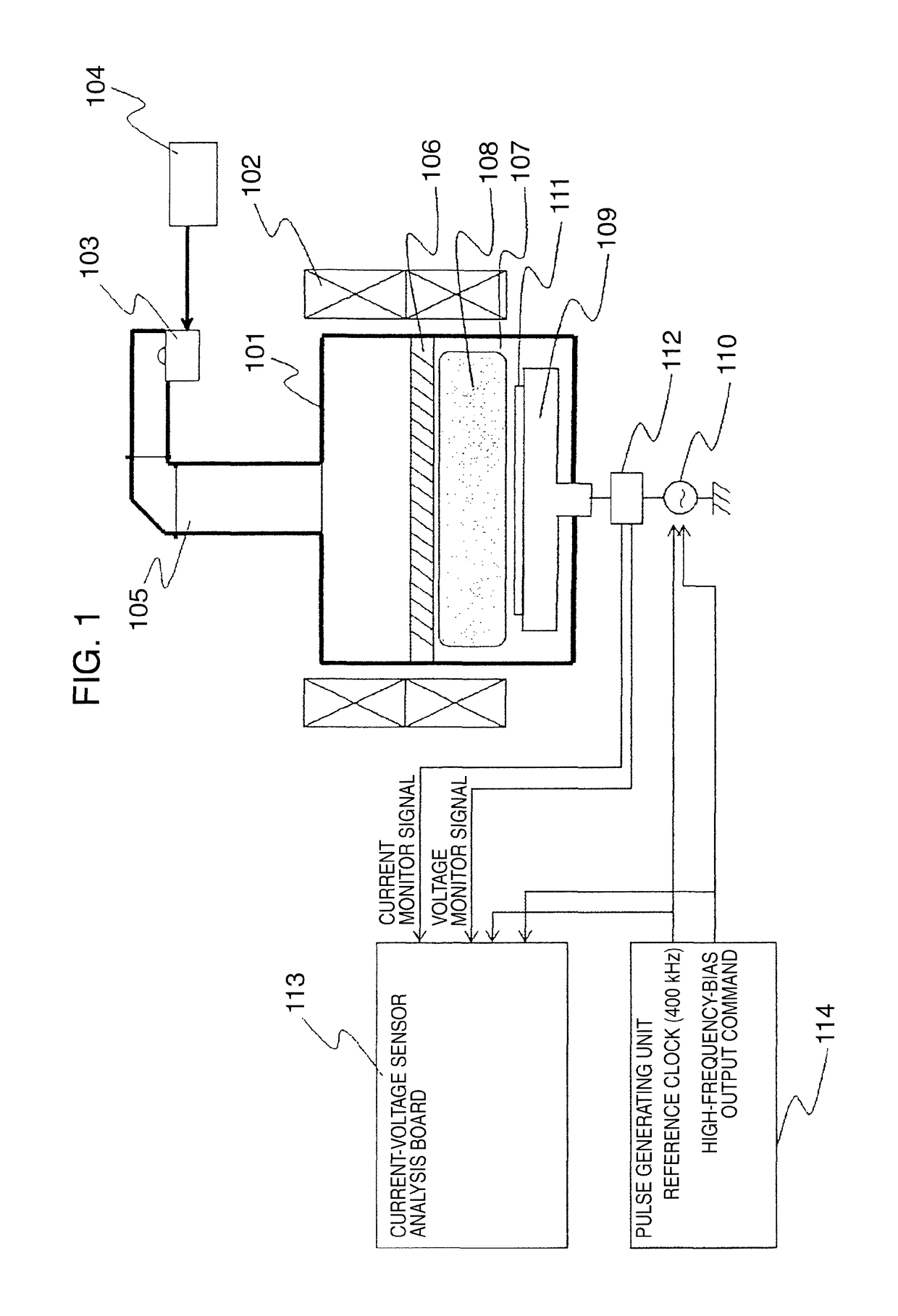

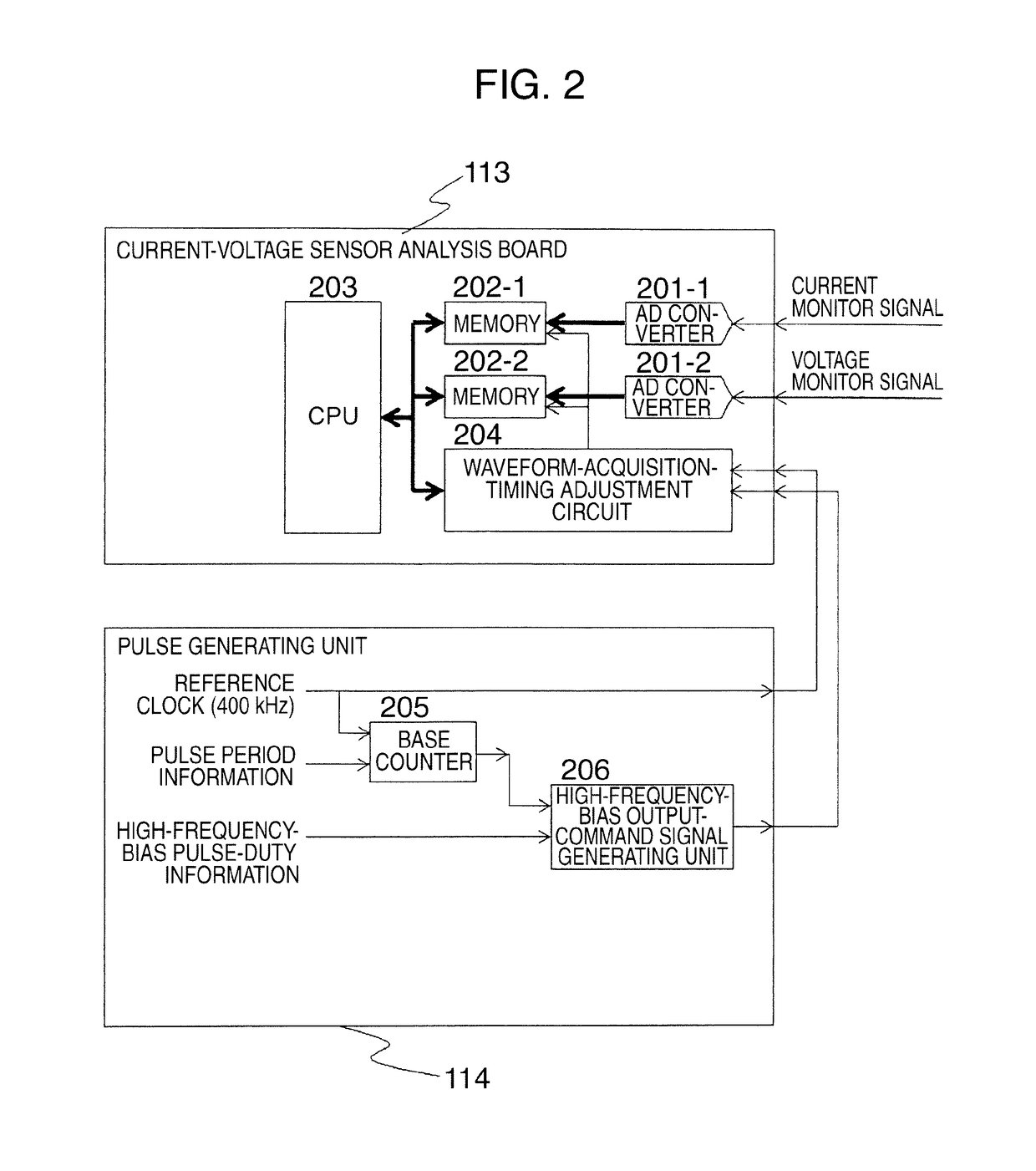

Plasma processing apparatus

ActiveUS20150279624A1Improve accuracyImprove precisionElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerEngineering

The plasma processing apparatus includes: a processing chamber disposed inside a vacuum vessel; a first high-frequency power supply outputting a first high-frequency power for supplying an electric field to generate a plasma for use in processing a sample to be processed inside the processing chamber; a sample stage disposed inside the processing chamber with the sample placed on an upper surface thereof; a second high-frequency power supply intermittently outputting a second high-frequency power for generating a bias potential to an electrode disposed inside the sample stage and capable of variably adjusting the output time; and a function to adjust operation of the plasma processing apparatus using a result of detection of a temporal change in waveform of current or voltage in a transient state of the second high-frequency power in synchronism with start of the intermittent output of the second high-frequency power.

Owner:HITACHI HIGH-TECH CORP

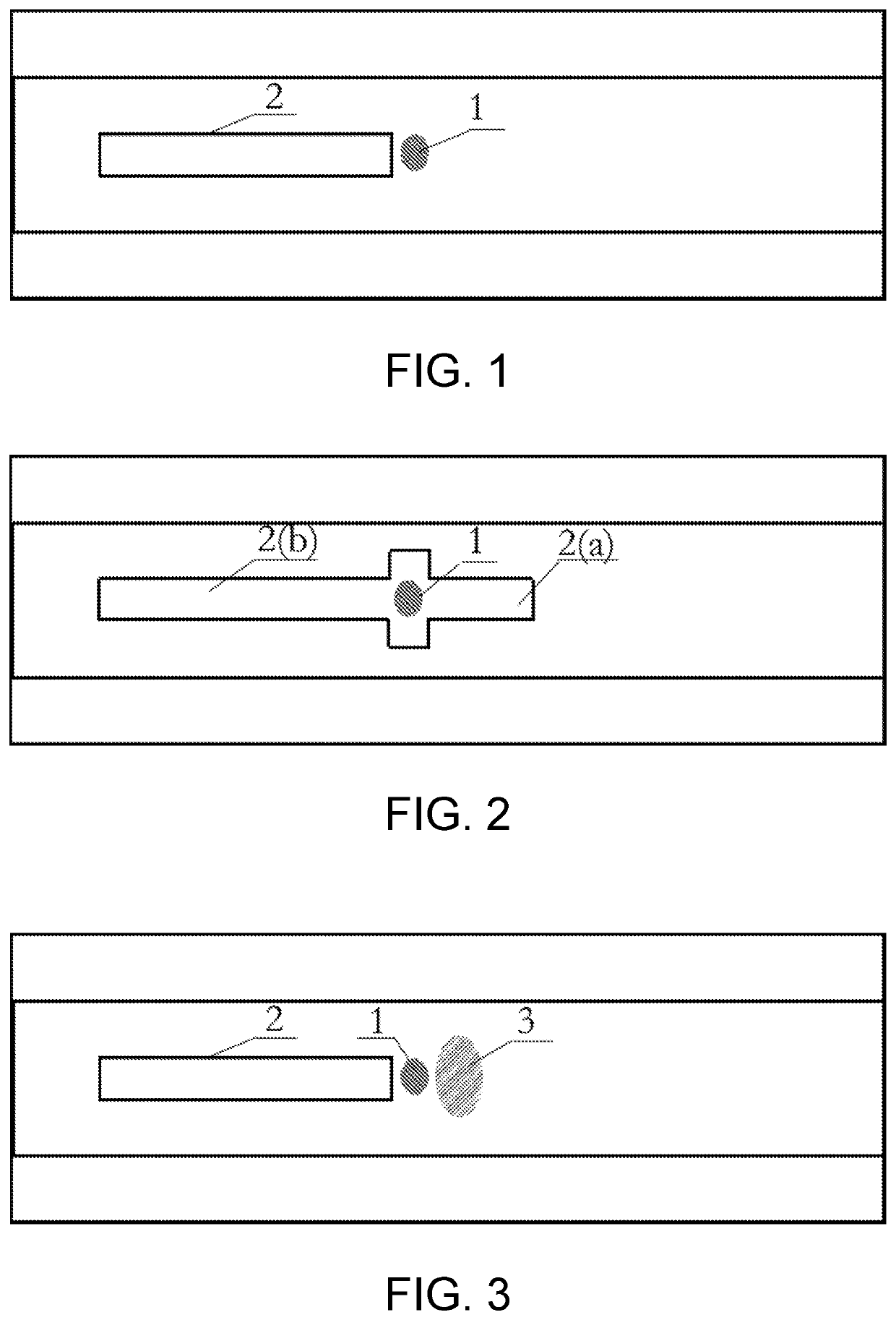

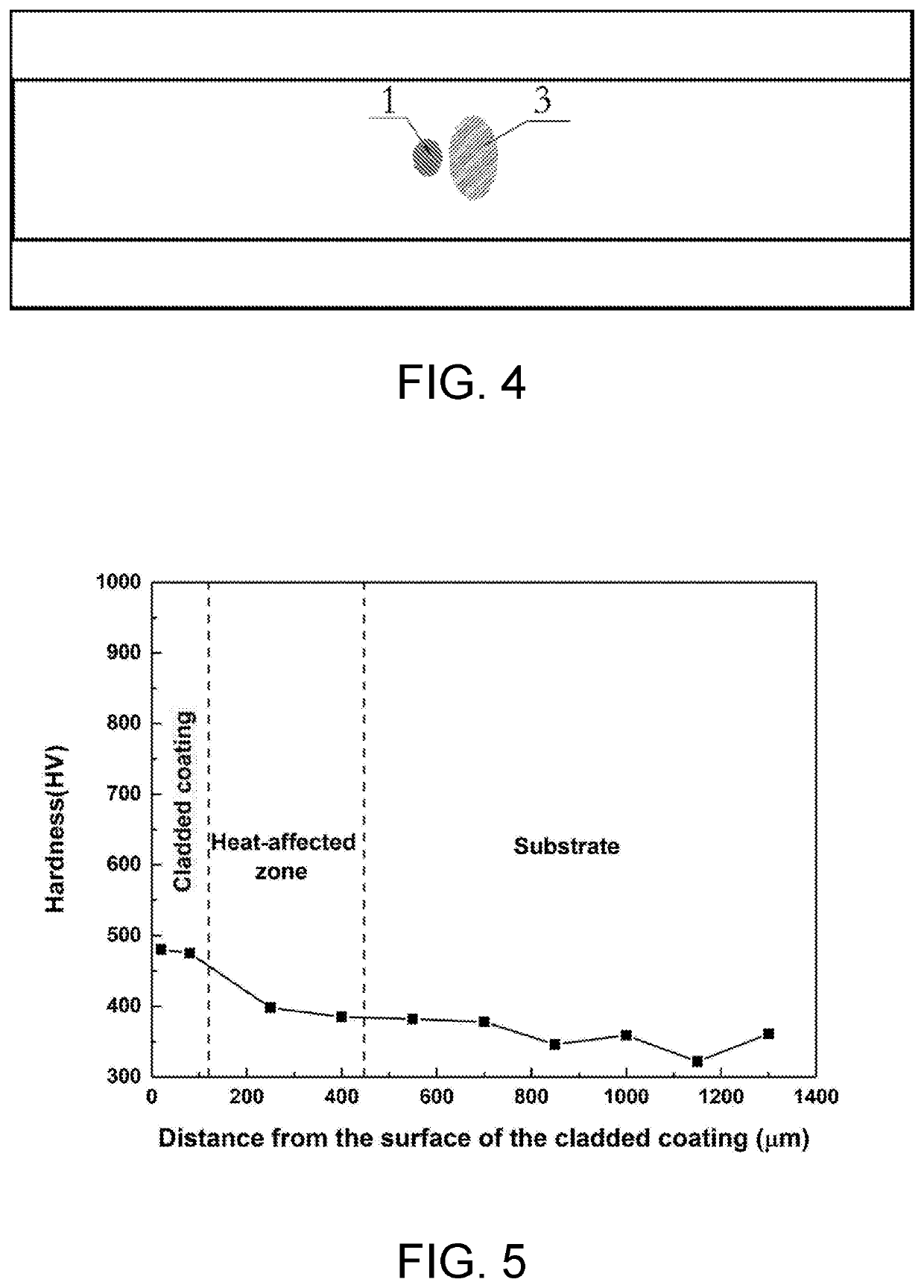

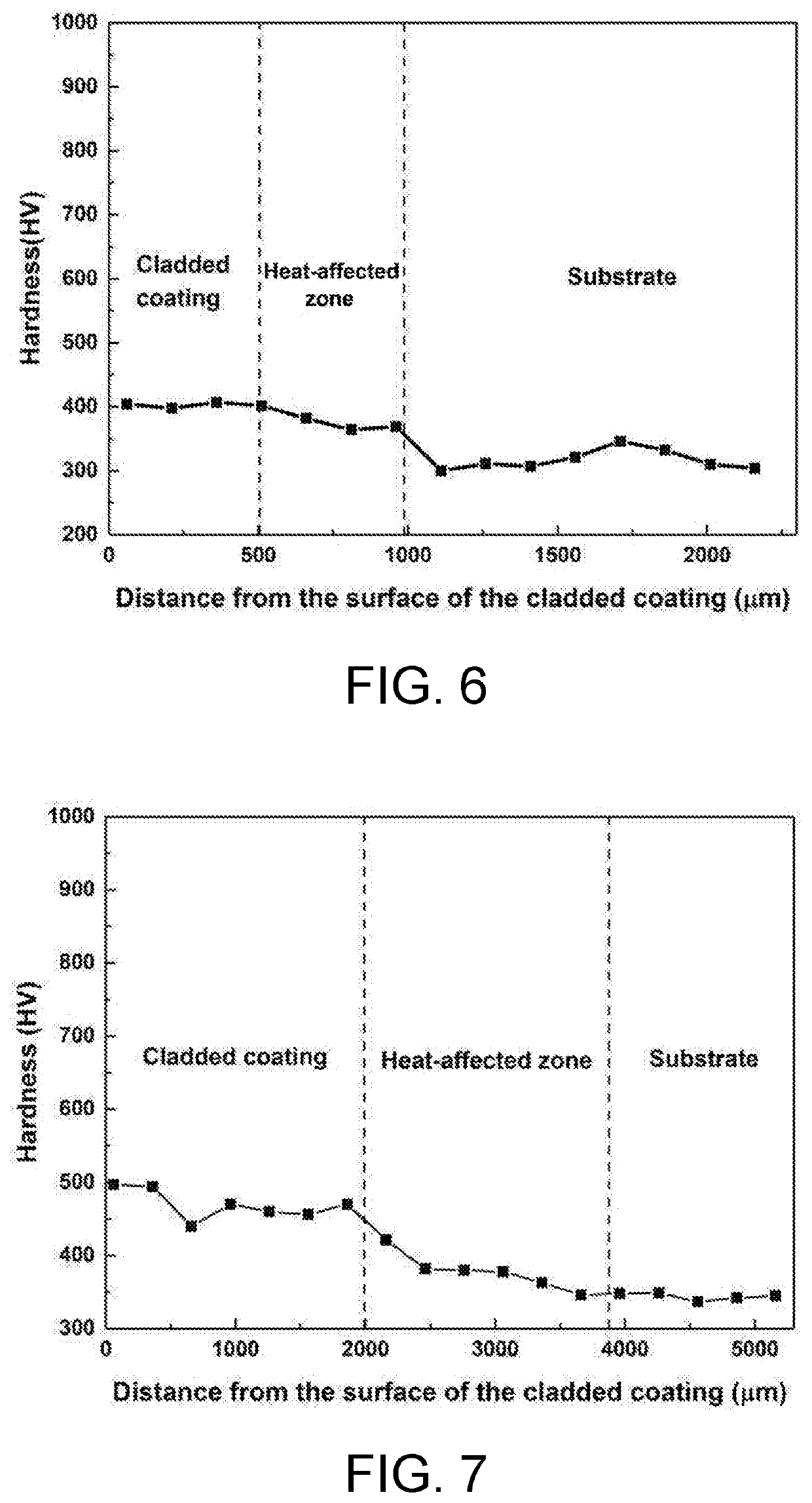

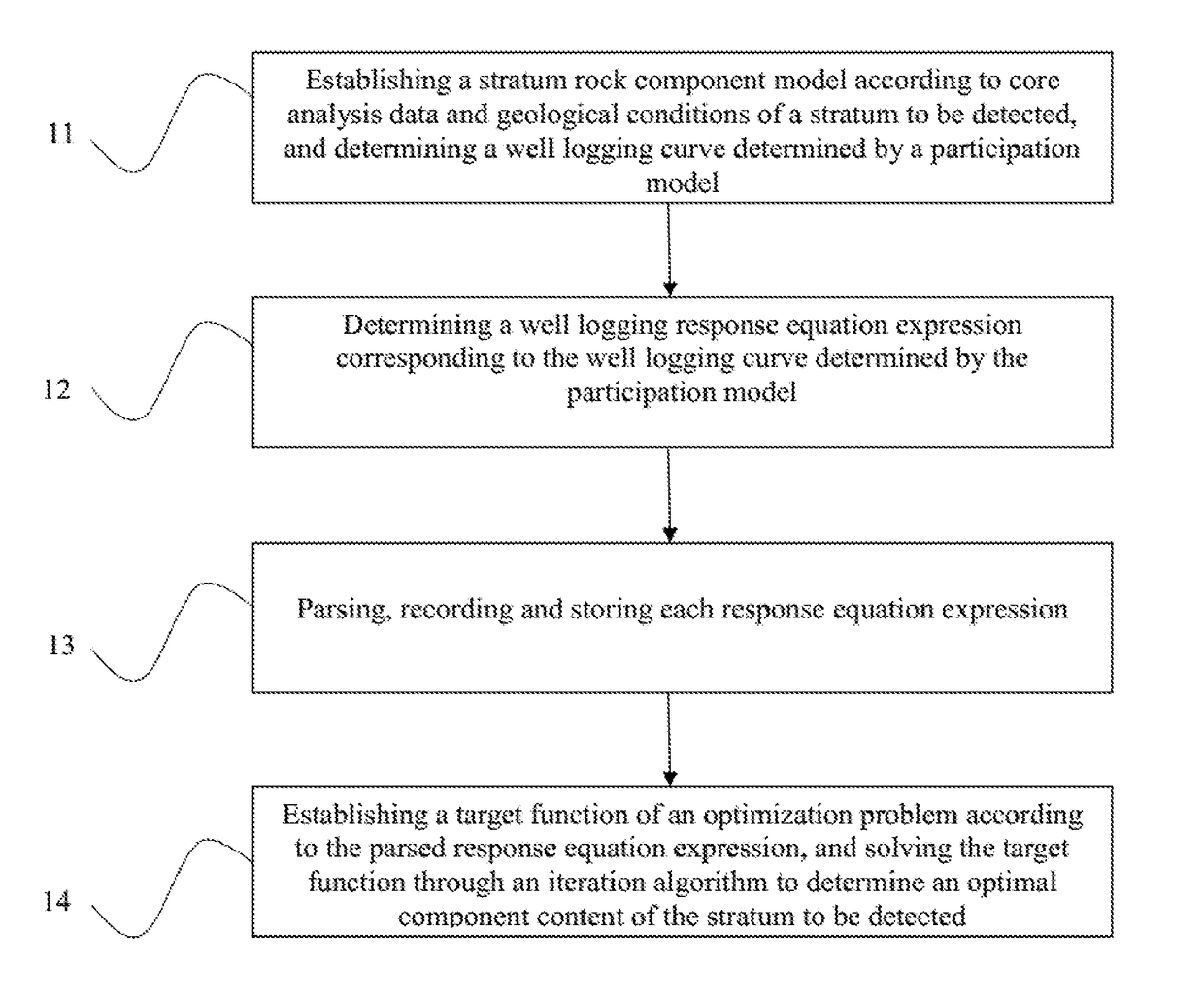

Method for reinforcing rail by laser and auxiliary heat source efficient hybrid cladding

PendingUS20200199698A1Reduce cooling rateReduce gradientFurnace typesMetallic material coating processesMartensite transformationHeat-affected zone

The disclosure discloses a method for reinforcing a rail by laser and auxiliary heat source efficient hybrid cladding. The laser and the auxiliary heat source simultaneously apply on a region to be cladded of a rail surface. The laser serves as a main heat source to enable simultaneous and rapid fusion of an added metal powder and partial substrate material in the rail surface to form a molten pool. The auxiliary heat source moves with the laser heat source in the same direction at the same speed, and performs synchronous preheating and / or post-heating on the laser molten pool, the heat-affected zone and the surface layer of the rail substrate to reduce the temperature gradient, thereby reducing the cooling rate, and avoiding martensite transformation and cracking in the heat-affected zone.

Owner:WUHAN HIVALUE INTELASER LTD +2

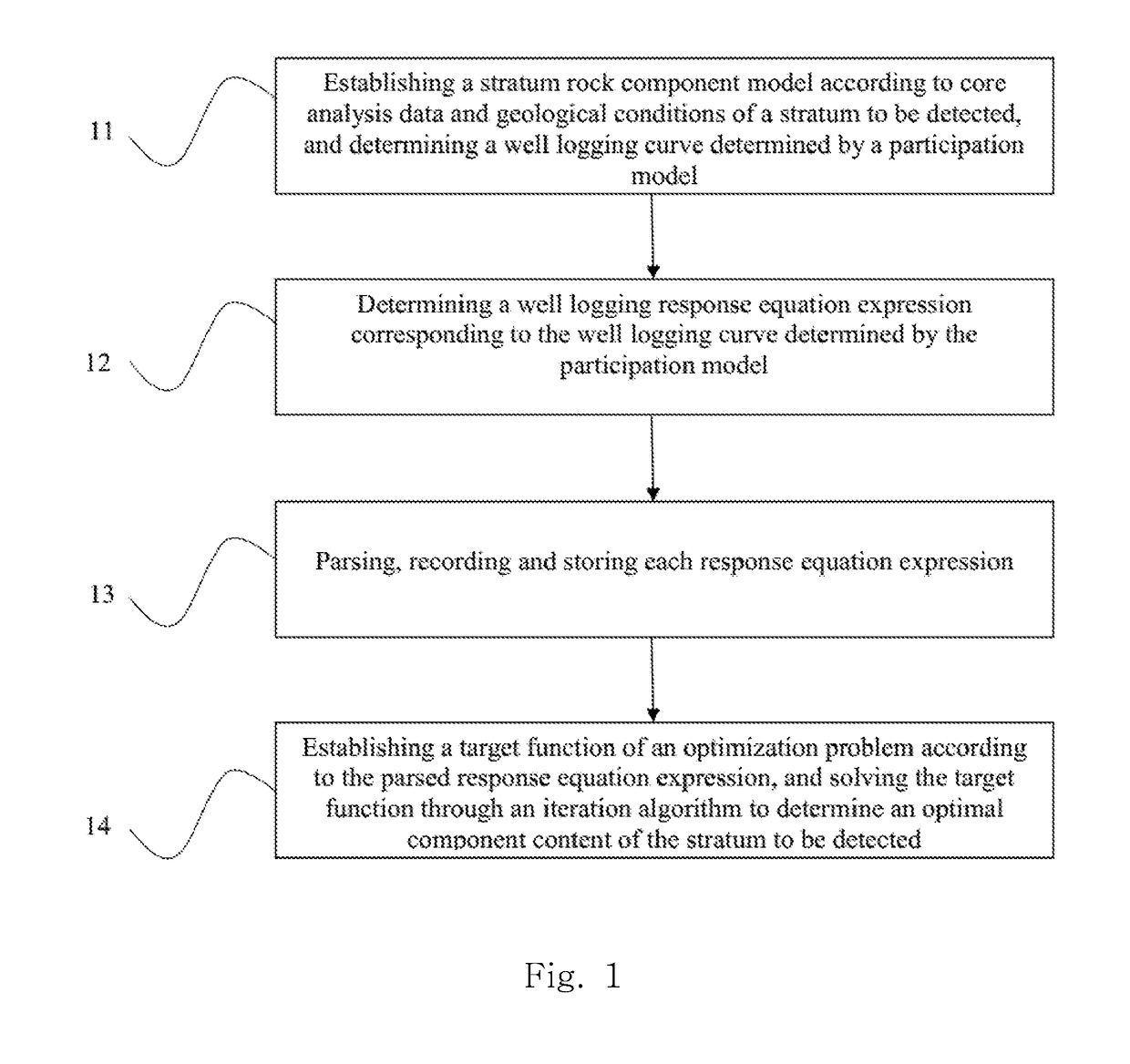

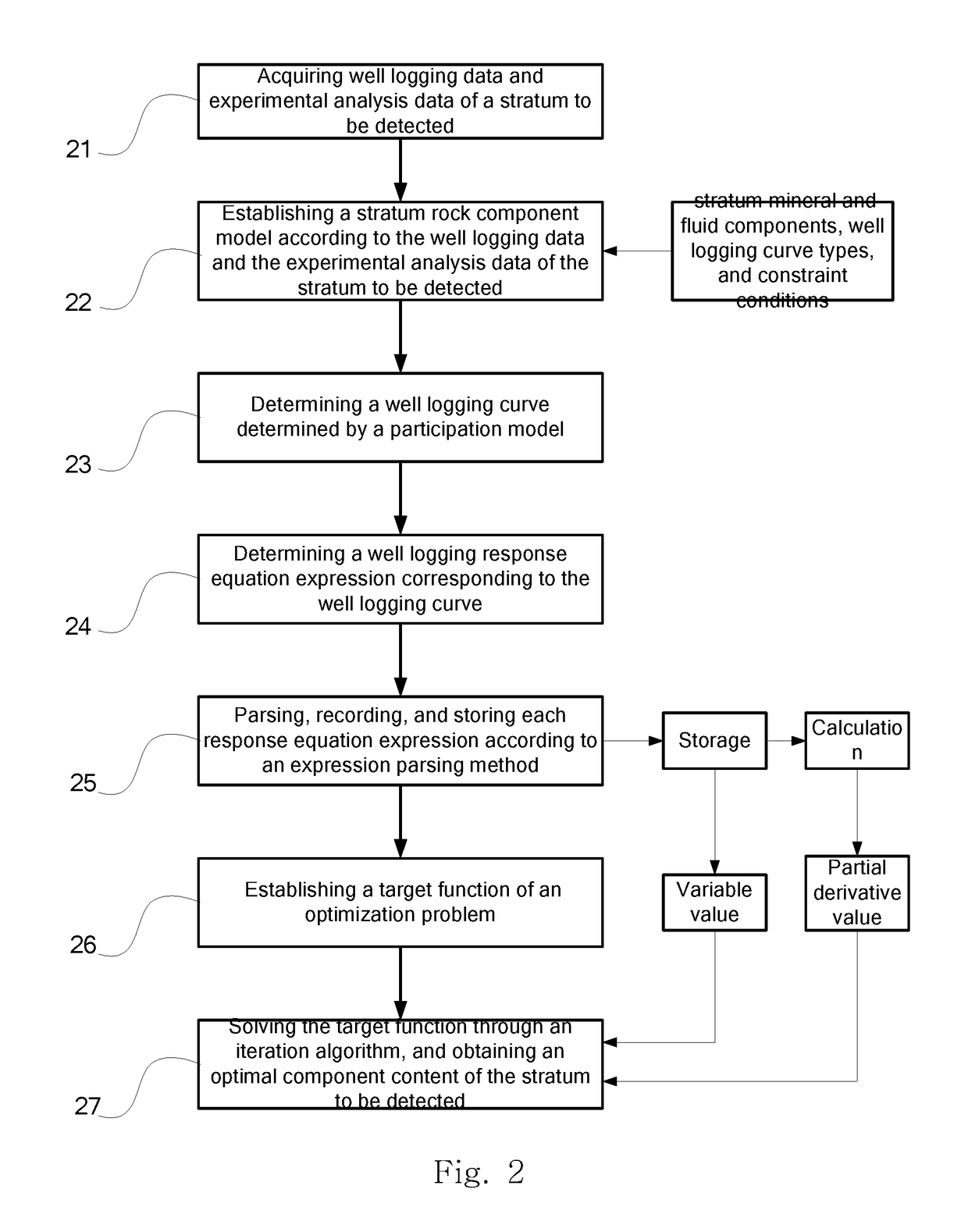

Stratum component optimization determination method and device

ActiveUS20180246999A1Avoid low process precisionImprove responseData processing applicationsDesign optimisation/simulationAnalysis dataOptimization problem

The present invention provides a stratum component optimization determination method and device, which fall within the technical field of oil-gas exploration well logging. The method comprises: establishing a stratum rock component model according to core analysis data and geological conditions of a stratum to be detected, and determining a well logging curve determined by a participation model; determining a well logging response equation expression corresponding to the well logging curve determined by the participation model; parsing, recording and storing the well logging response equation expression, establishing a target function of an optimization problem, and solving the target function through an iteration algorithm to determine an optimal component content of the stratum to be detected. By establishing the stratum rock component model, determining corresponding well logging response equation, and parsing through an expression parsing method and recording and storing the well logging response equation expression, and then, establishing the target function of the optimization problem, and obtaining the optimal component content of the stratum to be detected through the iteration algorithm, the present invention can not only optimizes the self-defined well logging response equation expression of the user, but achieves a high processing precision.

Owner:PETROCHINA CO LTD

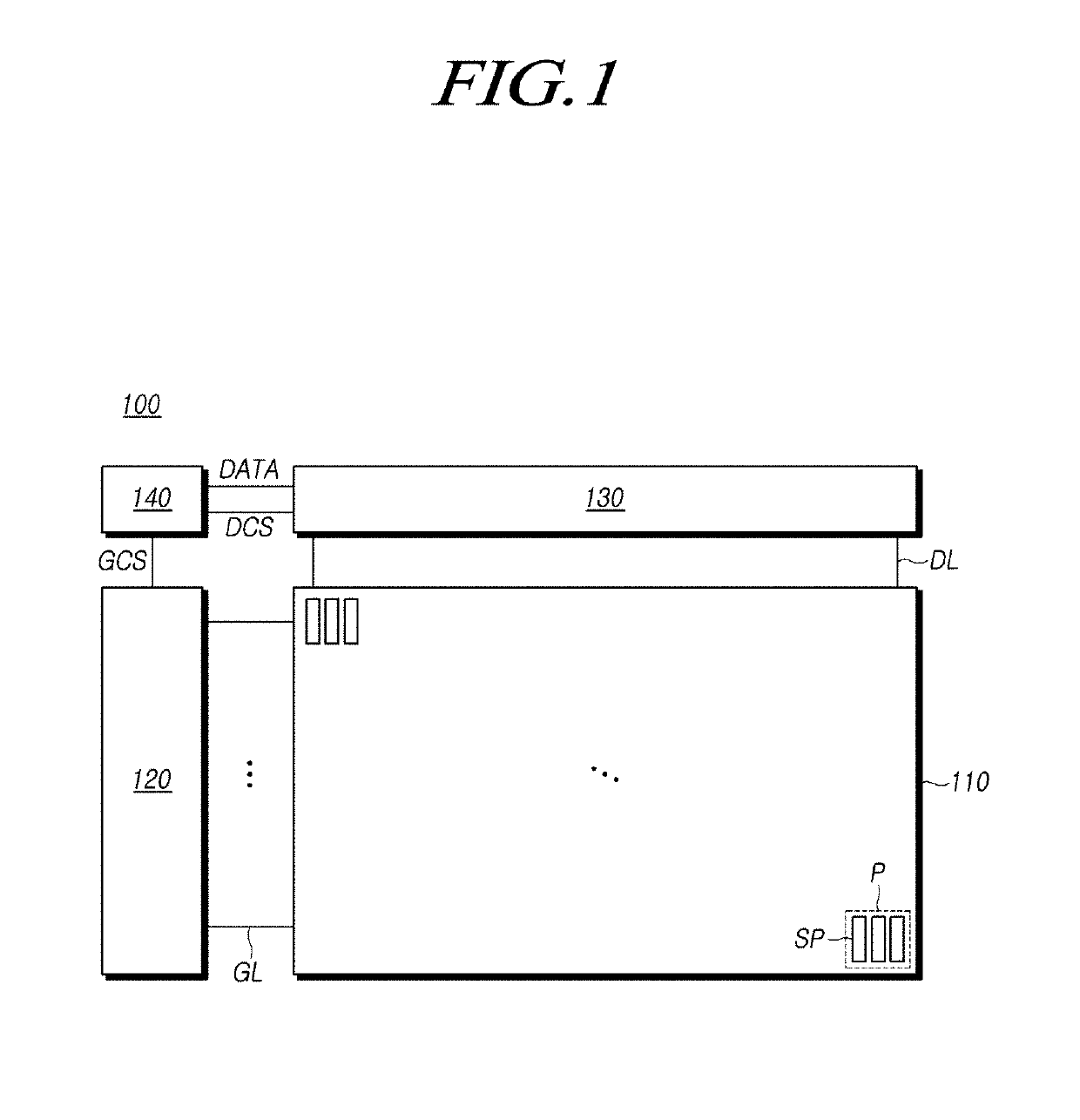

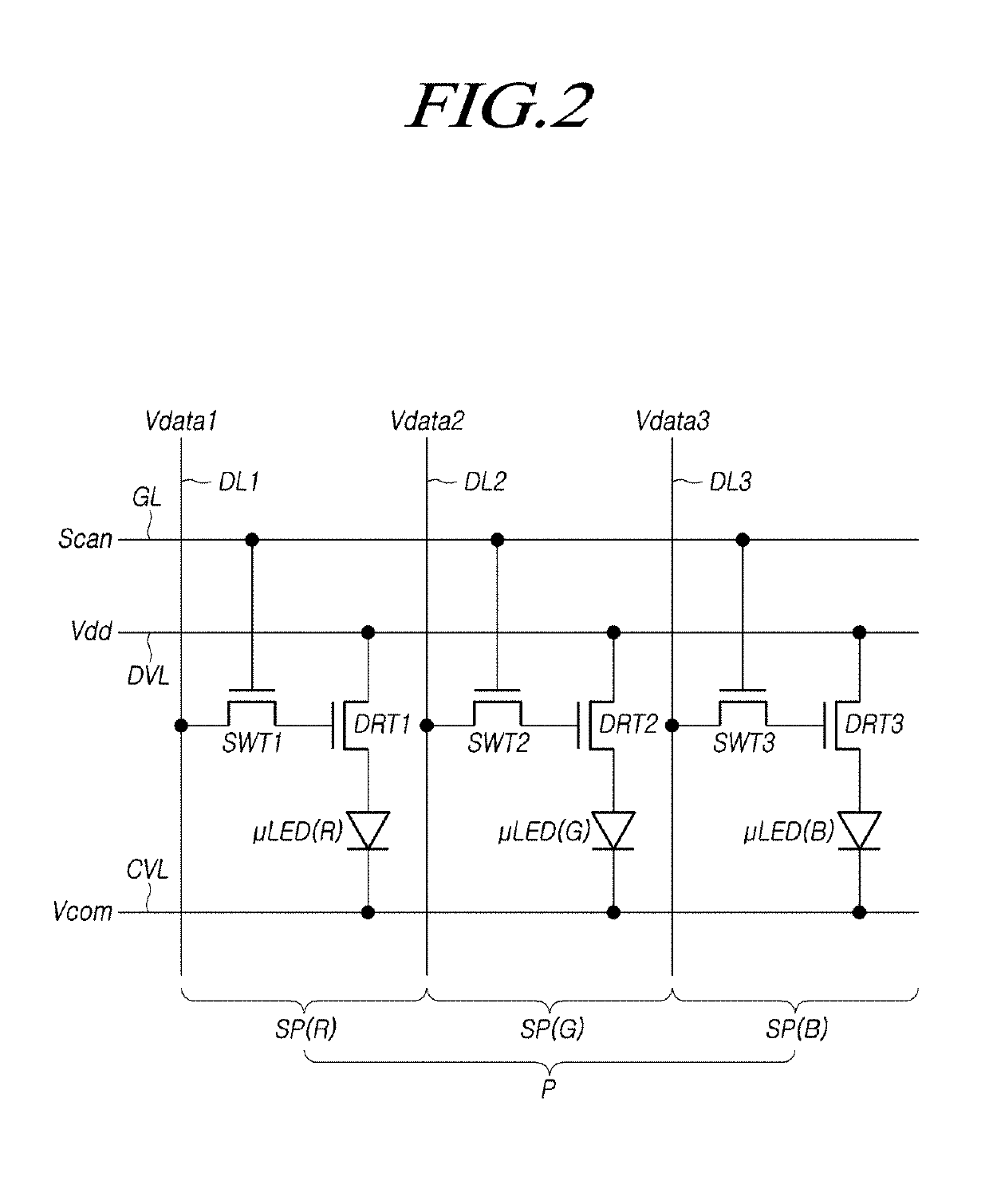

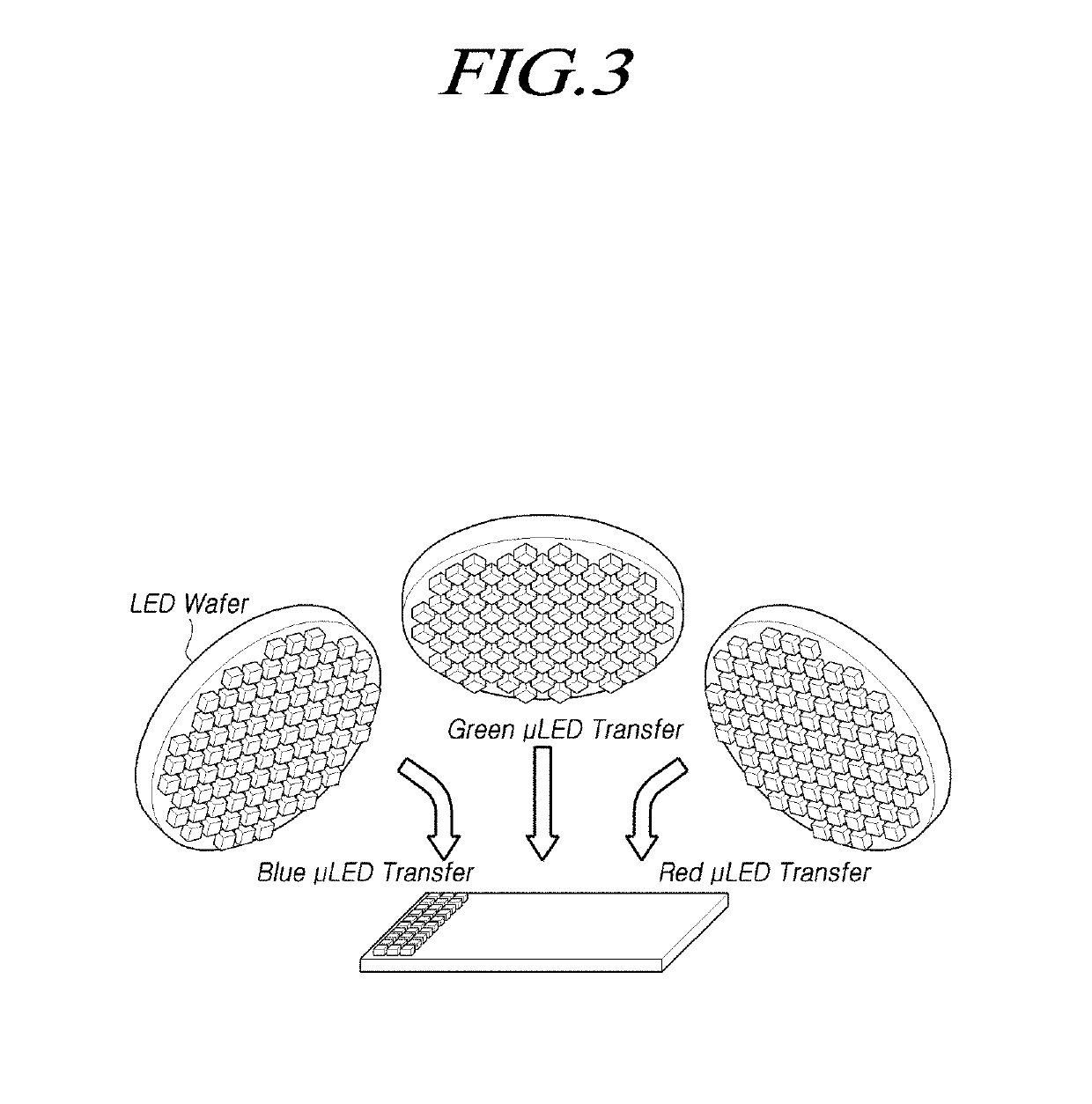

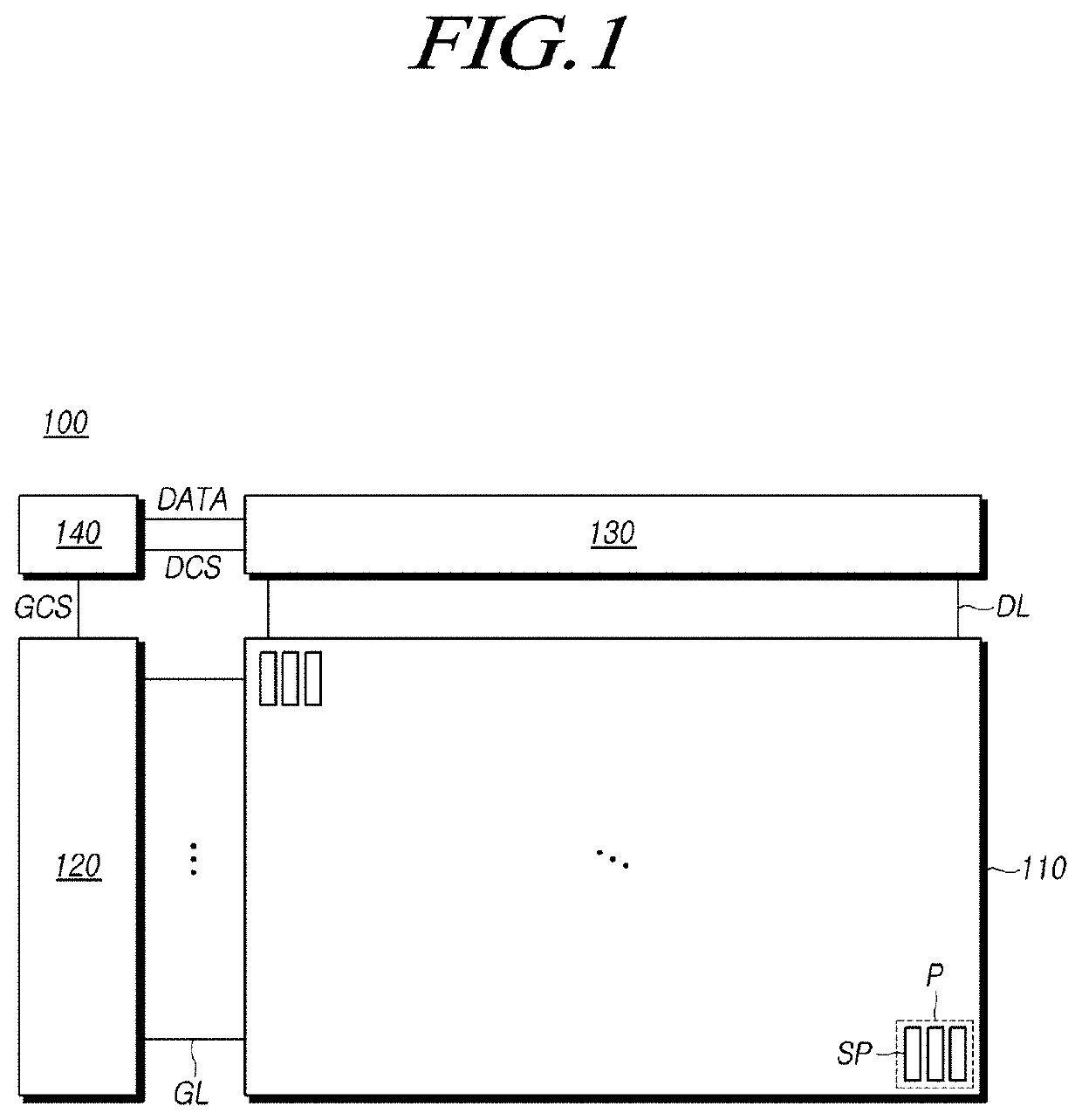

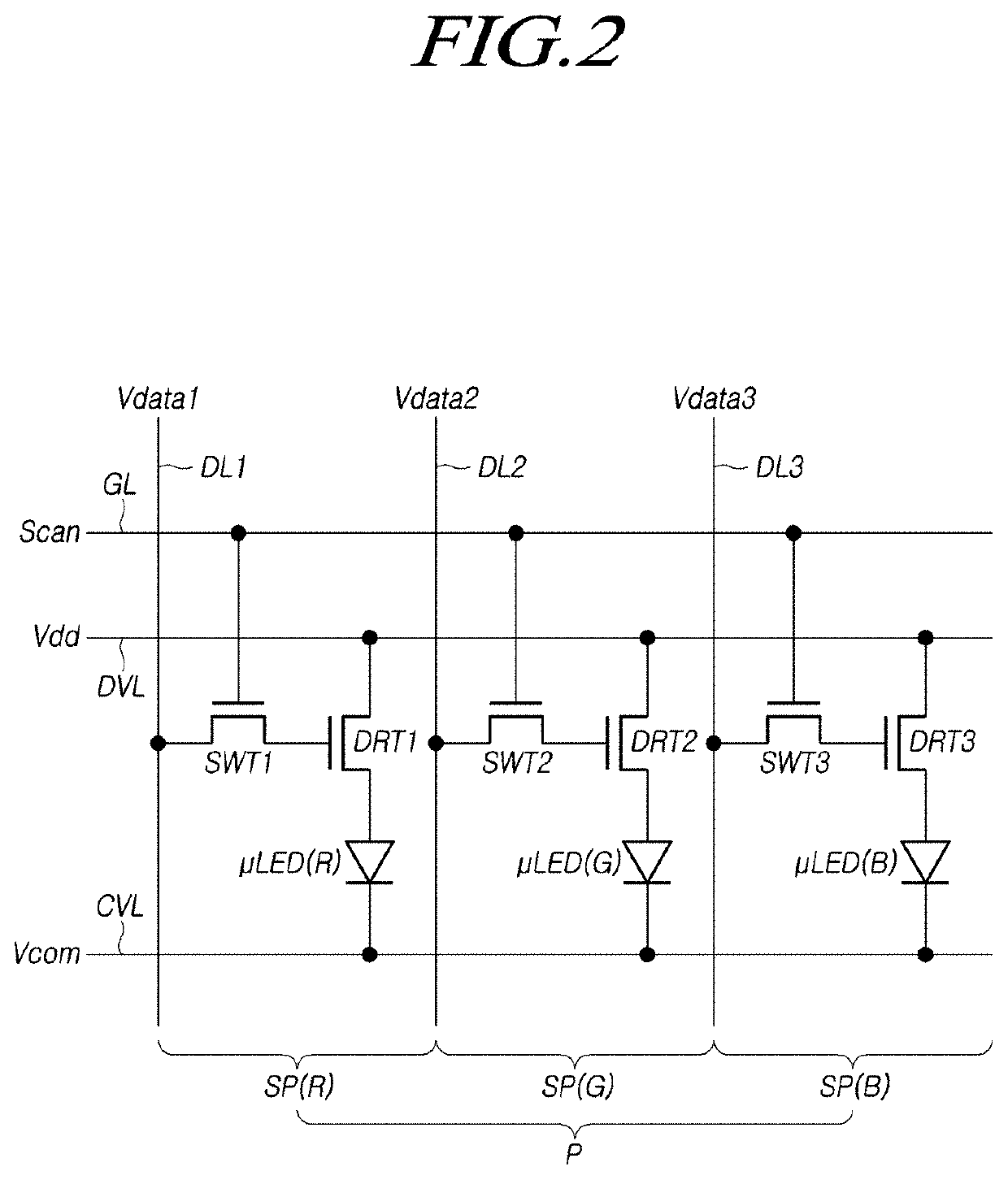

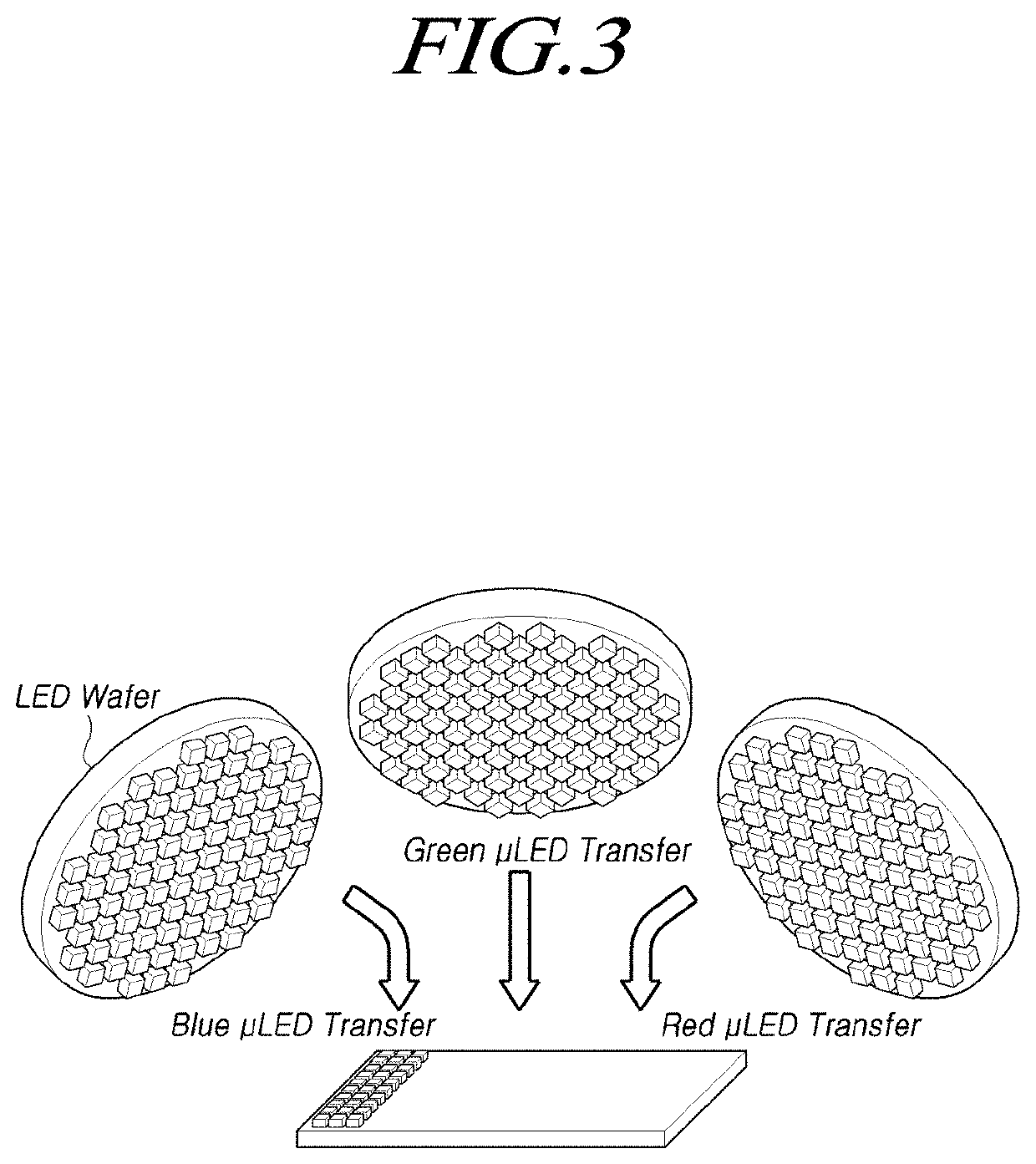

Light-emitting diode chip and micro display device

ActiveUS20190189679A1Easy to implementReduce the number of processesStatic indicating devicesSolid-state devicesEngineeringDisplay device

A light-emitting diode (LED) chip and a display device having the same are provided. A green LED is regrown on a blue LED to produce blue and green light, and a red phosphor is disposed on the blue or green LED to produce red light. Red light, green light, and blue light are to be produced using a single LED chip. The single LED chip forms three subpixels therein so as to facilitate a transfer process of the LED chip to a display panel. The LED chip is configured based on the blue, green, and blue LEDs so as to facilitate the fabrication and driving of the LED chip.

Owner:LG DISPLAY CO LTD

Fabrication method of full-color micro display device

ActiveCN108447965ARealize full color displayReduce difficultyIdentification meansSemiconductor devicesDisplay deviceEngineering

The invention relates to a fabrication method of a full-color micro display device. Single-color blue Micro LED microchips are only needed to be transferred onto a substrate by combining a nanoimprinting technology, red or green fluorescent material resin glue layers accurately cover the corresponding blue Micro LED microchips according to special arrangement by a patterning imprinting template which is prepared in advance, the red or green fluorescent material resin glue layers are simulated by the Micro LED microchips, the Micro LED microchips which are not coated with the fluorescent material resin glue layer are simulated, red, green and blue pixel points particularly arranged on surfaces of the microchips are obtained, namely, the full-color display of the Micro LED microchips can beachieved.

Owner:GUANGDONG POLY OPTOELECTRONICS

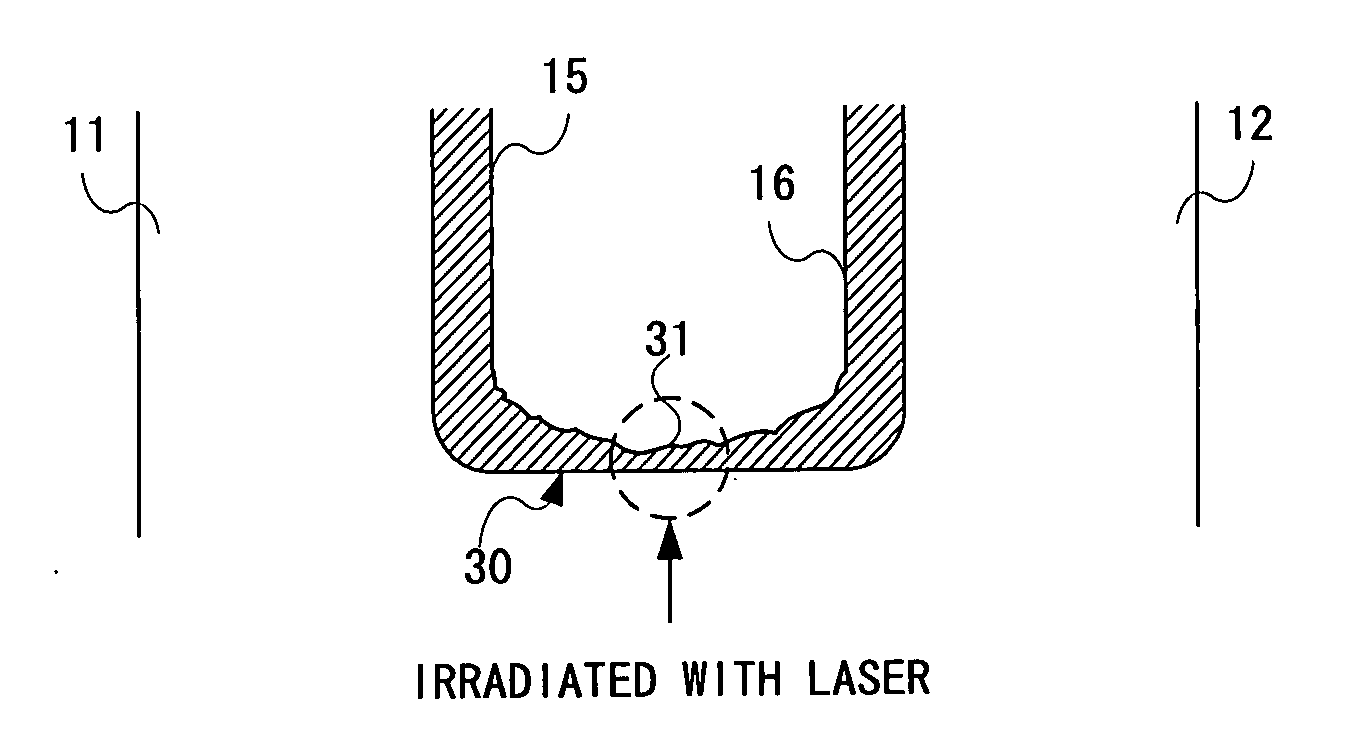

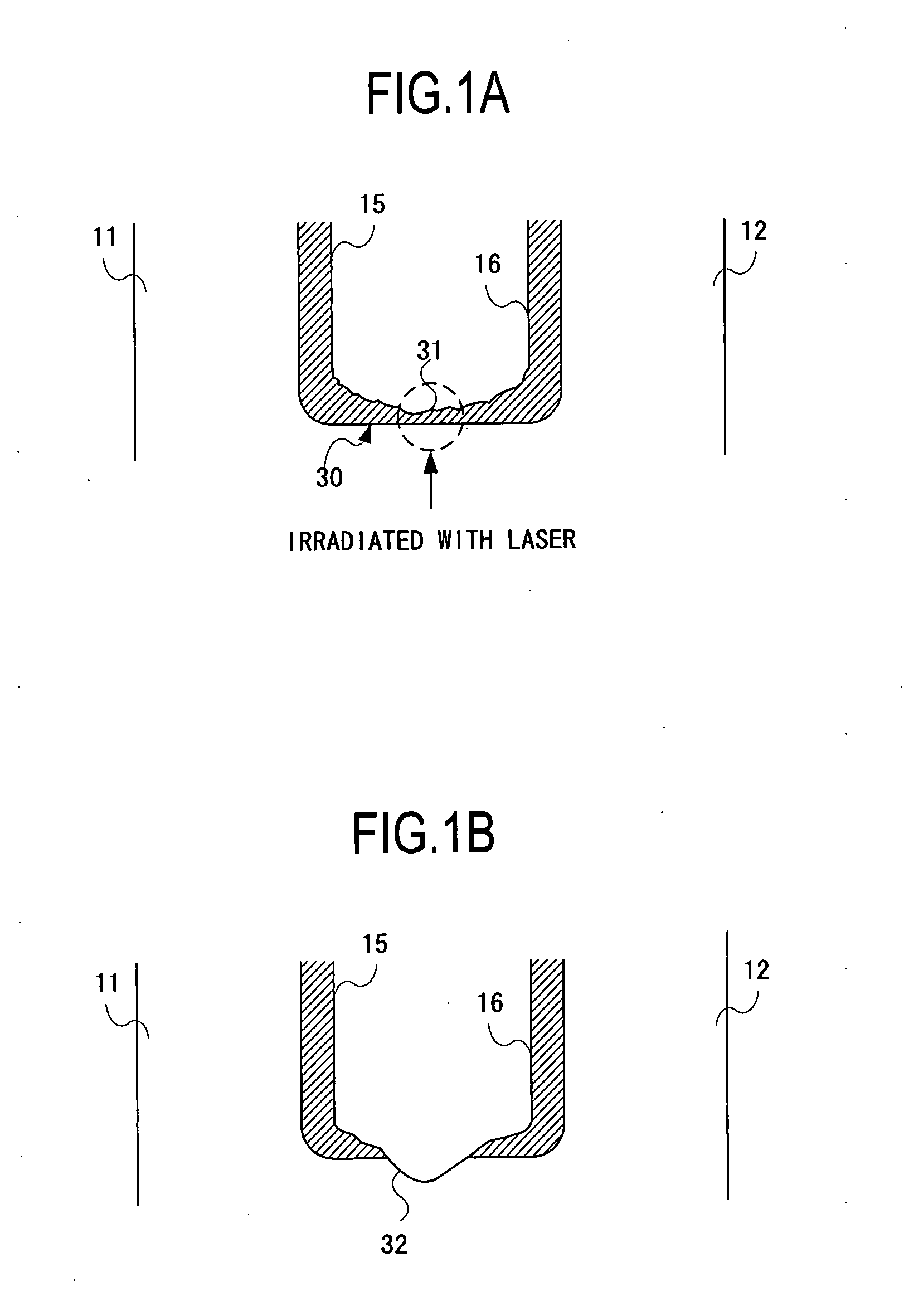

Manufacturing method of tuning-fork type quartz crystal resonator

InactiveUS20080088384A1Increase productionAvoid low process precisionPiezoelectric/electrostriction/magnetostriction machinesRadiation applicationsQuartz crystal resonatorEtching

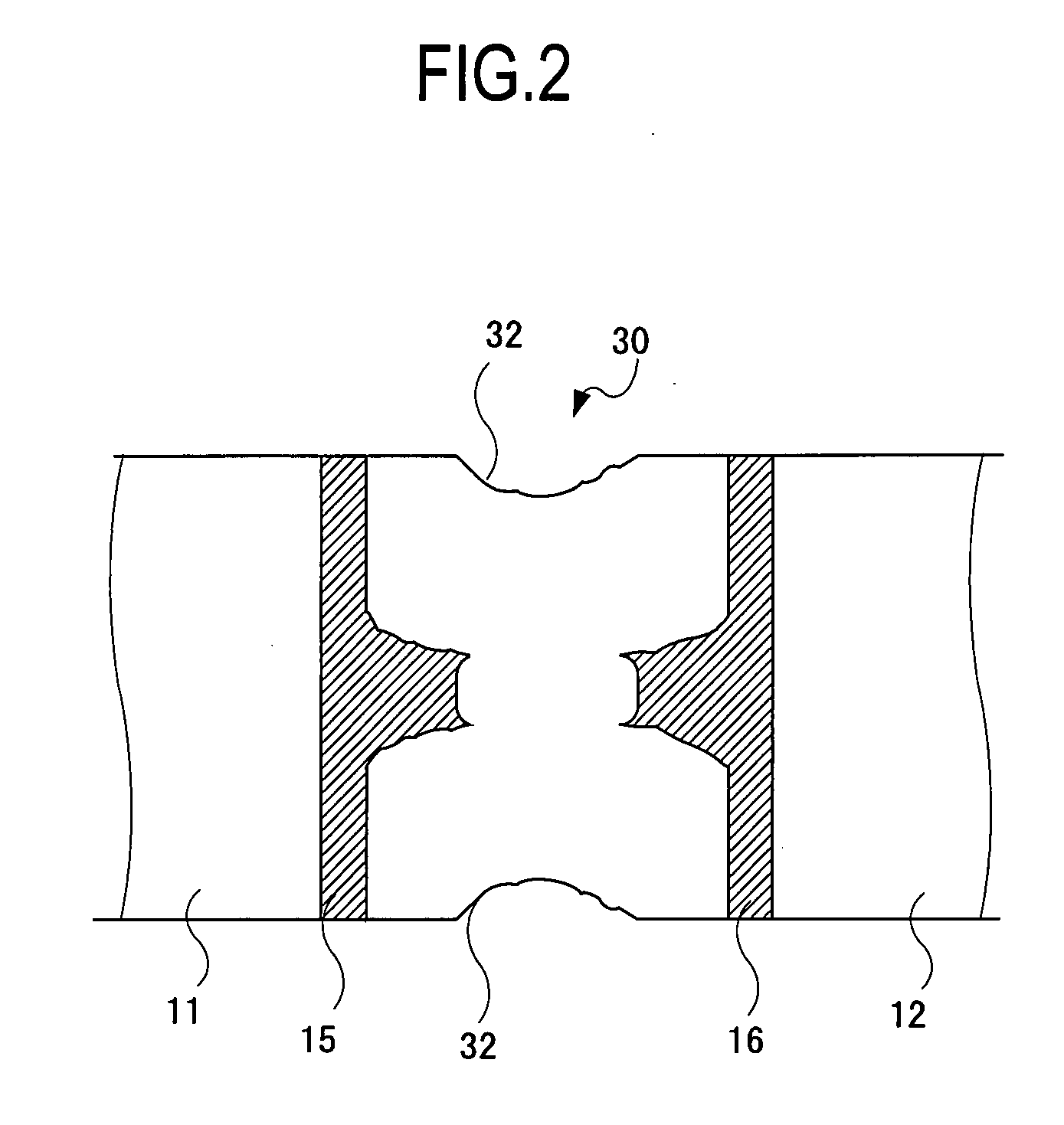

There is disclosed a manufacturing method of a tuning-fork type quartz crystal resonator, in which a simple step can just be added to the existing manufacturing process to prevent generation of short-circuit at a crotch portion and largely improve yield. On a quartz crystal wafer, a metal film is formed on a quartz crystal substrate processed into a tuning-fork form by evaporation or sputtering, the metal film is patterned into desired electrode and wiring line shapes by photolithography / etching, and then a crotch portion 30 is irradiated with laser from a direction substantially vertical to a wafer surface to remove a non-etched metal film portion in the manufacturing method of the tuning-fork type quartz crystal resonator.

Owner:NIHON DEMPA KOGYO CO LTD

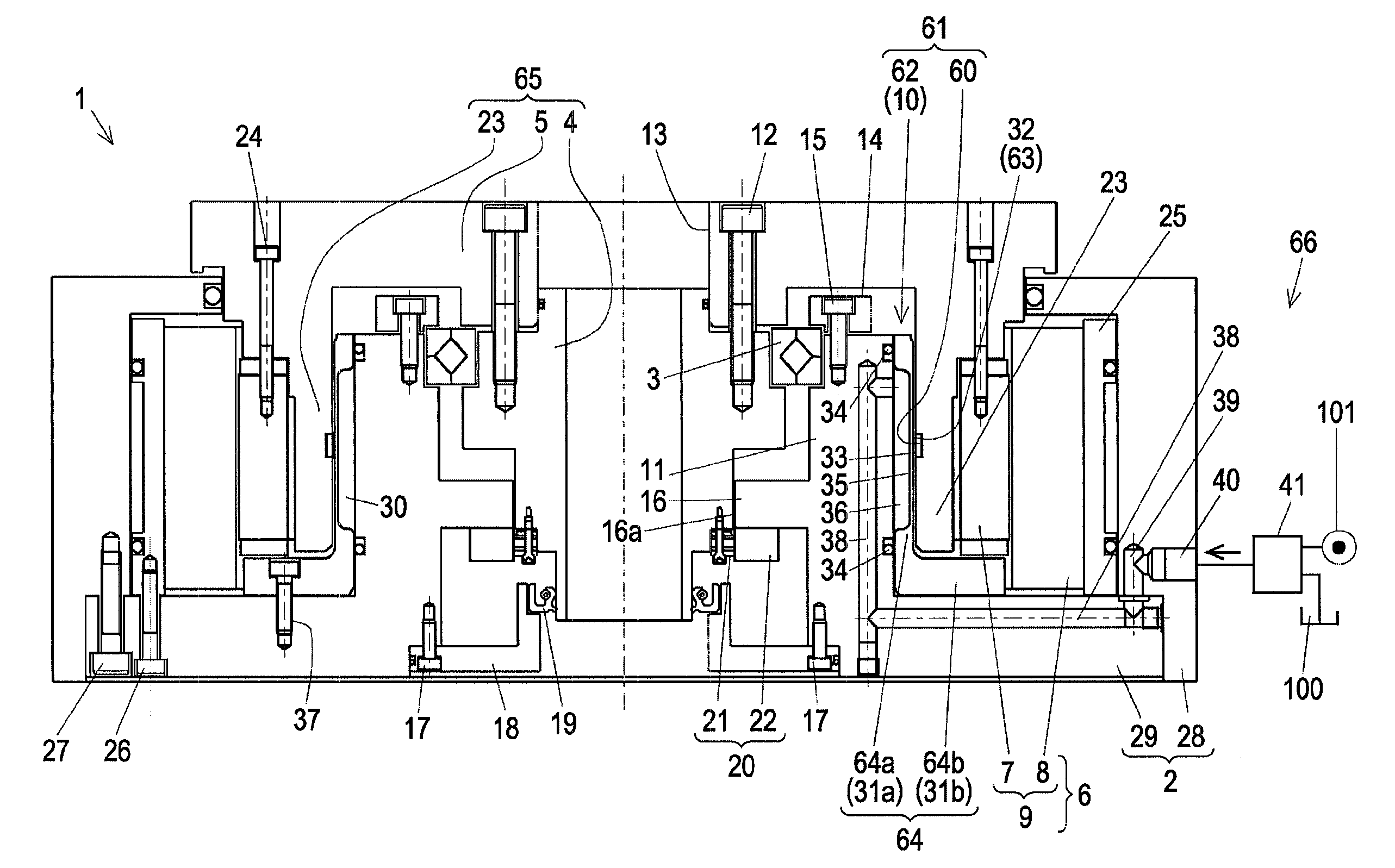

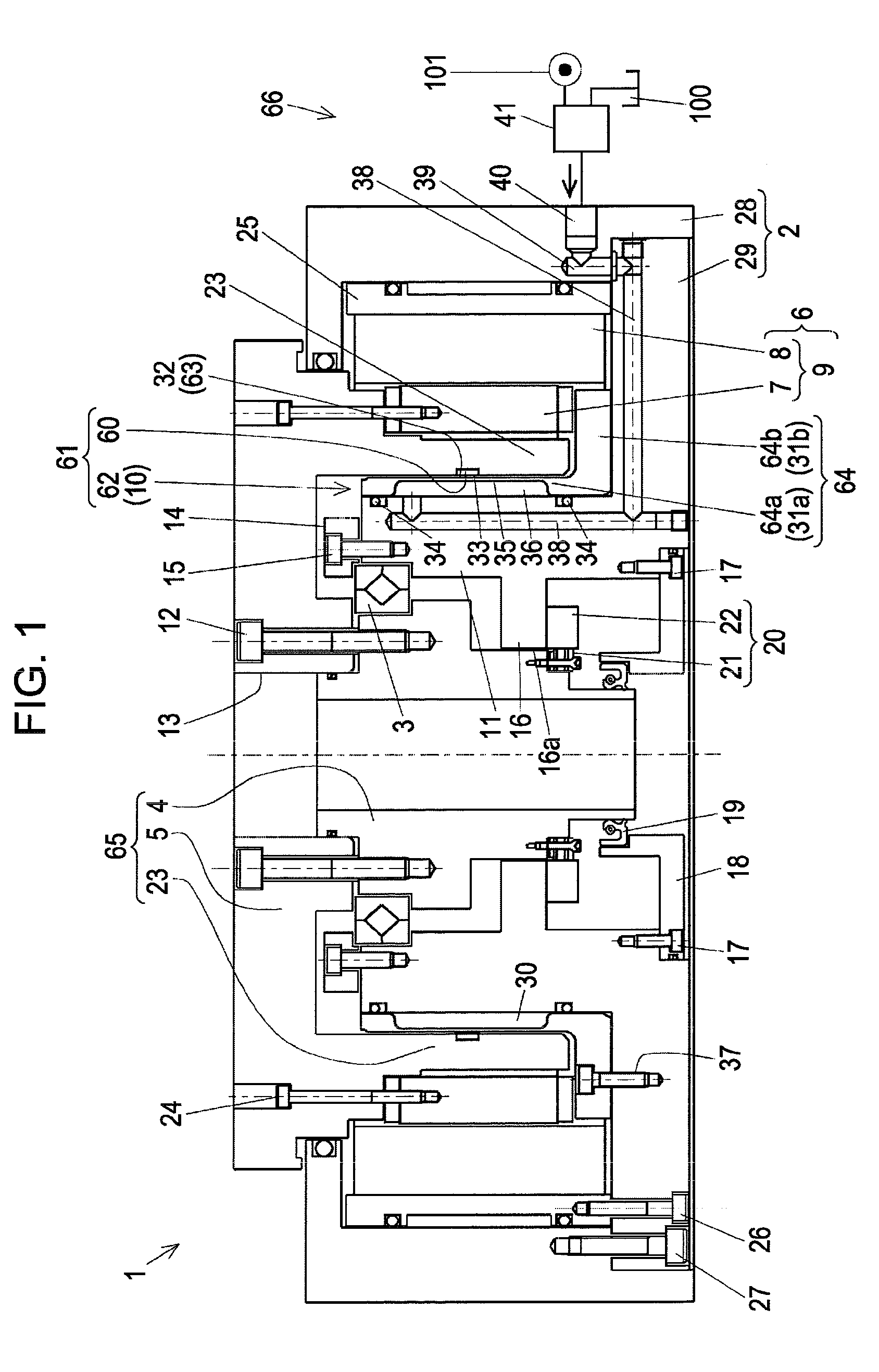

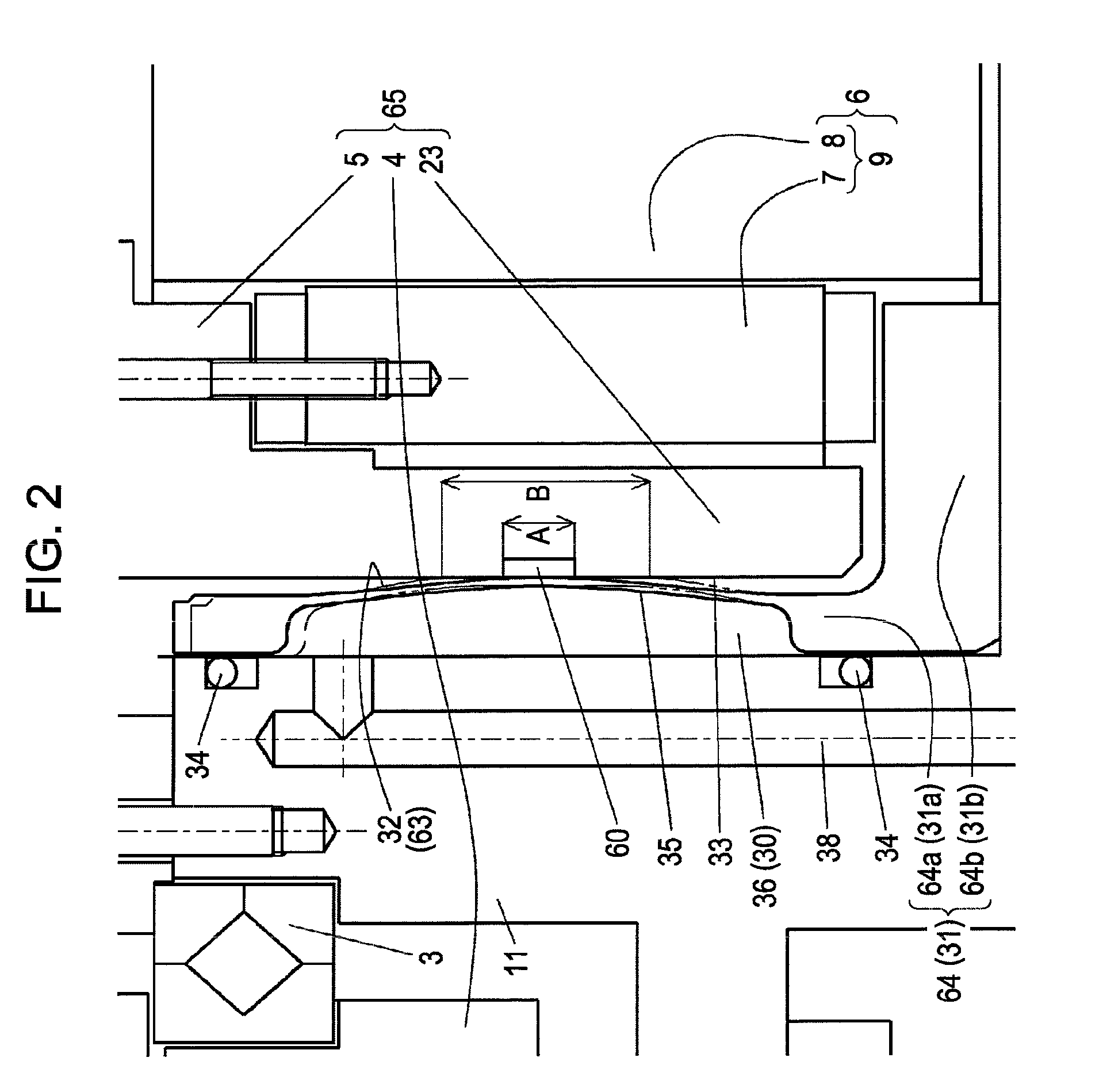

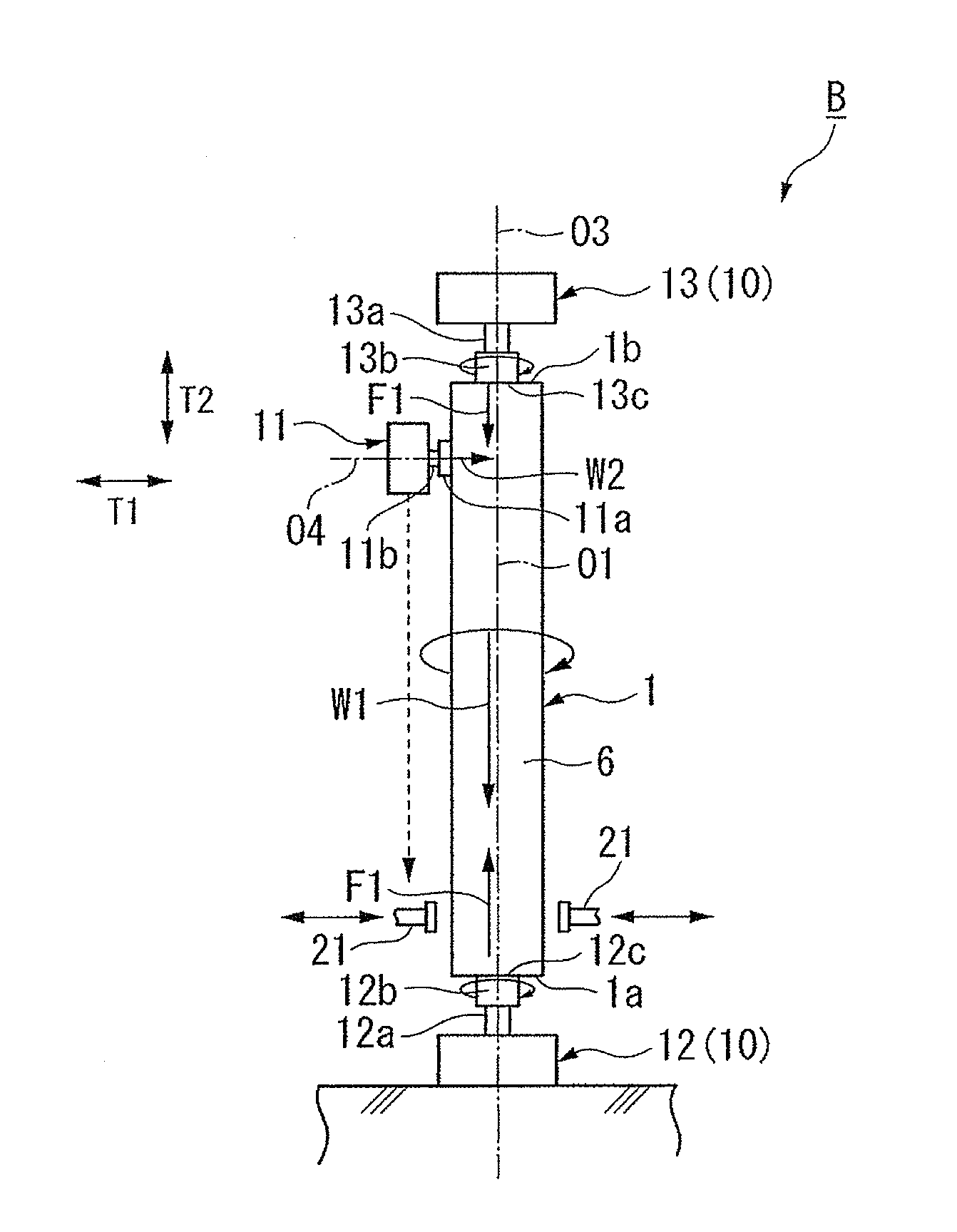

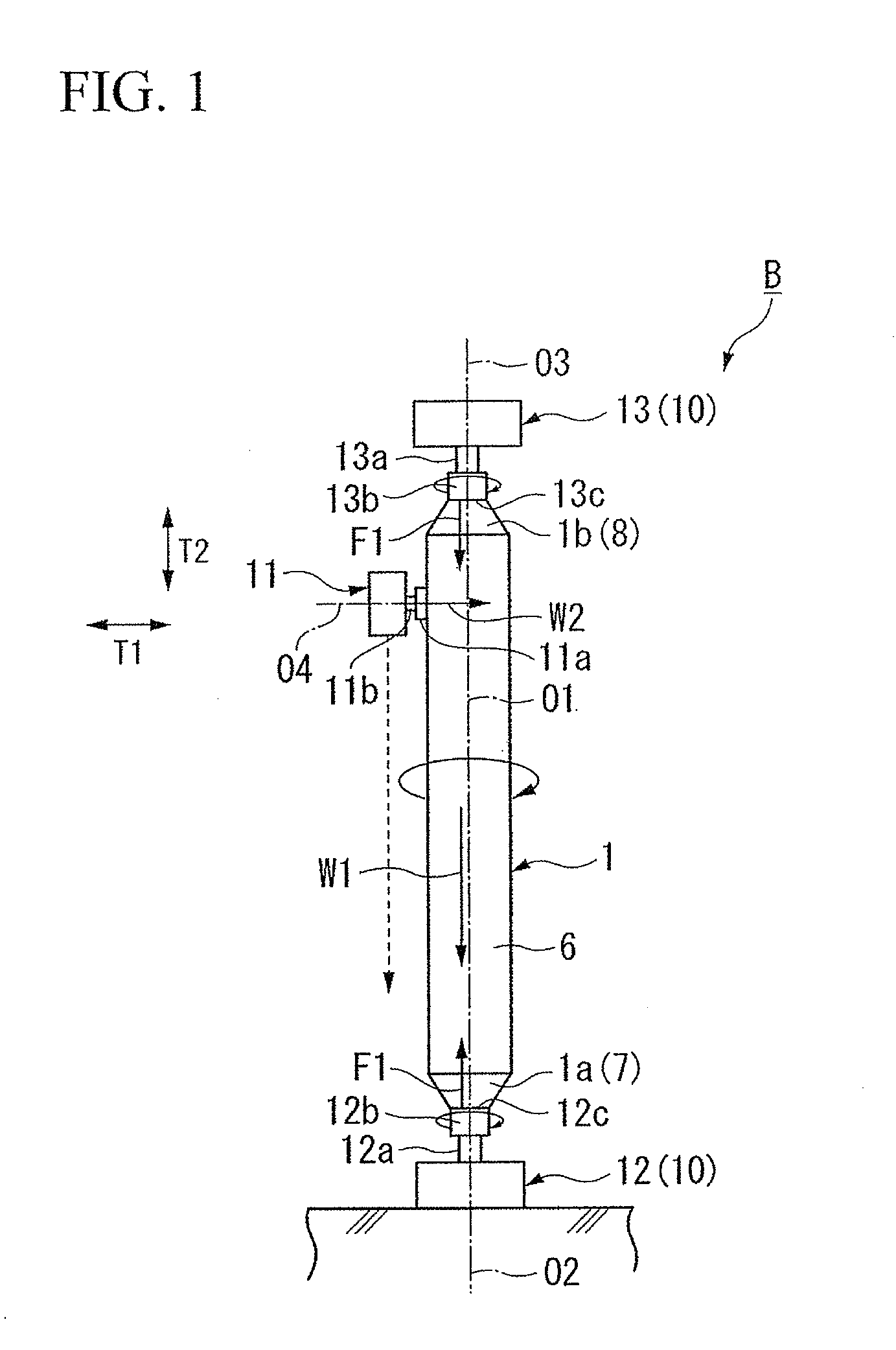

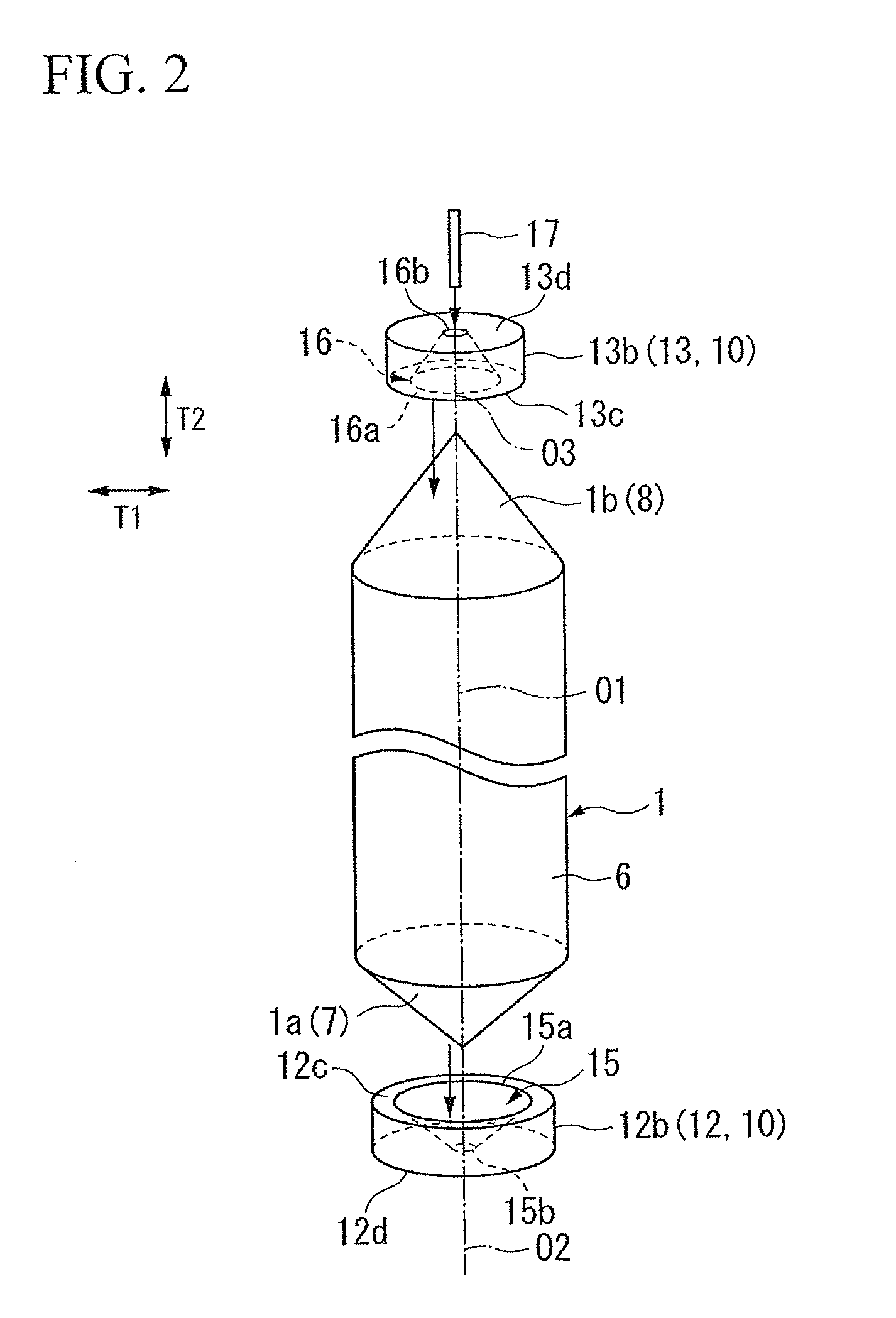

Rotation-resistance device for main shaft drive of machine tool

InactiveUS20110023655A1Uniform and stableAvoid low process precisionFluid actuated brakesPrecision positioning equipmentEngineeringMachine tool

When a finishing operation is performed while rotating a workpiece at a main shaft drive of a machine tool, pulsation occurring in a rotation of the main shaft drive is restricted and the rigidity of a main shaft is increased without increasing the size of a bearing. A rotation-resistance device of a main shaft drive in a machine tool has the following structure in the main shaft drive including a main shaft 4, a rotating body 65, and a driving device 6, the main shaft 4 being supported so as to be rotatable with respect to a frame body 2, the rotating body 65 being secured to an end of the main shaft 4, the driving device 6 rotationally driving the rotating body (65). The rotation-resistance device includes a damping device (10) including a damping member, which is provided at the frame body 2 or the rotating body 65 and which includes a resiliently deformable damping section, a pressing-force applying device 66, which applies a pressing force to the damping member by operating fluid, and a damping surface 32, provided at a side of the frame body 2. The damping device 10 causes the pressing force to act upon the damping section to flex the damping section, so that the damping surface 32 and a sliding surface 33 are pressed against each other, and a rotation resistance that allows rotation is applied to the rotating body 65. A low-friction coefficient member 60 is secured to at least one of the damping surface 32 and the sliding surface 33.

Owner:TSUDAKOMA KOGYO KK

Integrated optical sensor and method of manufacturing the same

PendingUS20220293657A1Avoid low process precisionReduce manufacturing costSolid-state devicesPrint image acquisitionOptical ModuleDielectric layer

An integrated optical sensor includes a substrate, an optical module layer and micro lenses. The substrate has sensing pixels. The optical module layer is disposed on the substrate. The micro lenses are disposed on the optical module layer. A thickness of the optical module layer defines a focal length of the micro lenses, and the sensing pixels sense object light of an object, which is focused by the micro lenses and optically processed by the optical module layer. The optical module layer includes a metal light shielding layer and an inter-metal dielectric layer disposed above the metal light shielding layer. The object light reaches the sensing pixels through apertures of the metal light shielding layer. A method of manufacturing the integrated optical sensor is also provided.

Owner:EGIS TECH

Cylindrical grinder and cylindrical grinding method of ingot

ActiveUS8376809B2Precise positioningAvoid position deviationRevolution surface grinding machinesGrinding work supportsSingle crystalCylindrical grinder

A cylindrical grinder is disclosed that includes a support unit including an upper support device and a lower support device, in which an ingot of silicon single crystal is interposed in a direction of axis line between the upper support device and the lower support device and is clampingly held to be rotated around the axis line, and a grinding unit that relatively moves along the direction of axis line of the ingot to traverse grind an outer circumference of the ingot. The upper support device is placed at an upper position and the lower support device is placed at a lower position, so that the support unit clampingly holds the ingot in a state in which the direction of the axis line of the ingot is disposed along a vertical direction.

Owner:SUMCO CORP

Machine tool capable of reducing thermal error

InactiveUS20170001277A1Minimized thermal deformationAvoid low process precisionMaintainance and safety accessoriesElectricityThermal deformation

A machine tool includes a table, a main shaft, and an electric heating piece. The table includes an upright post and a main shaft support element connected to the upright post. The main shaft is rotatably disposed at the main shaft support element of the table. The electric heating piece is disposed at the main shaft support element of the table and positioned on a side of the main shaft, wherein the side of the main shaft manifests a lower thermal deformation level. The regulation of the electric heating piece minimizes the nonlinear thermal deformation of the main shaft, thereby enhancing processing precision.

Owner:NATIONAL CHUNG HSING UNIVERSITY

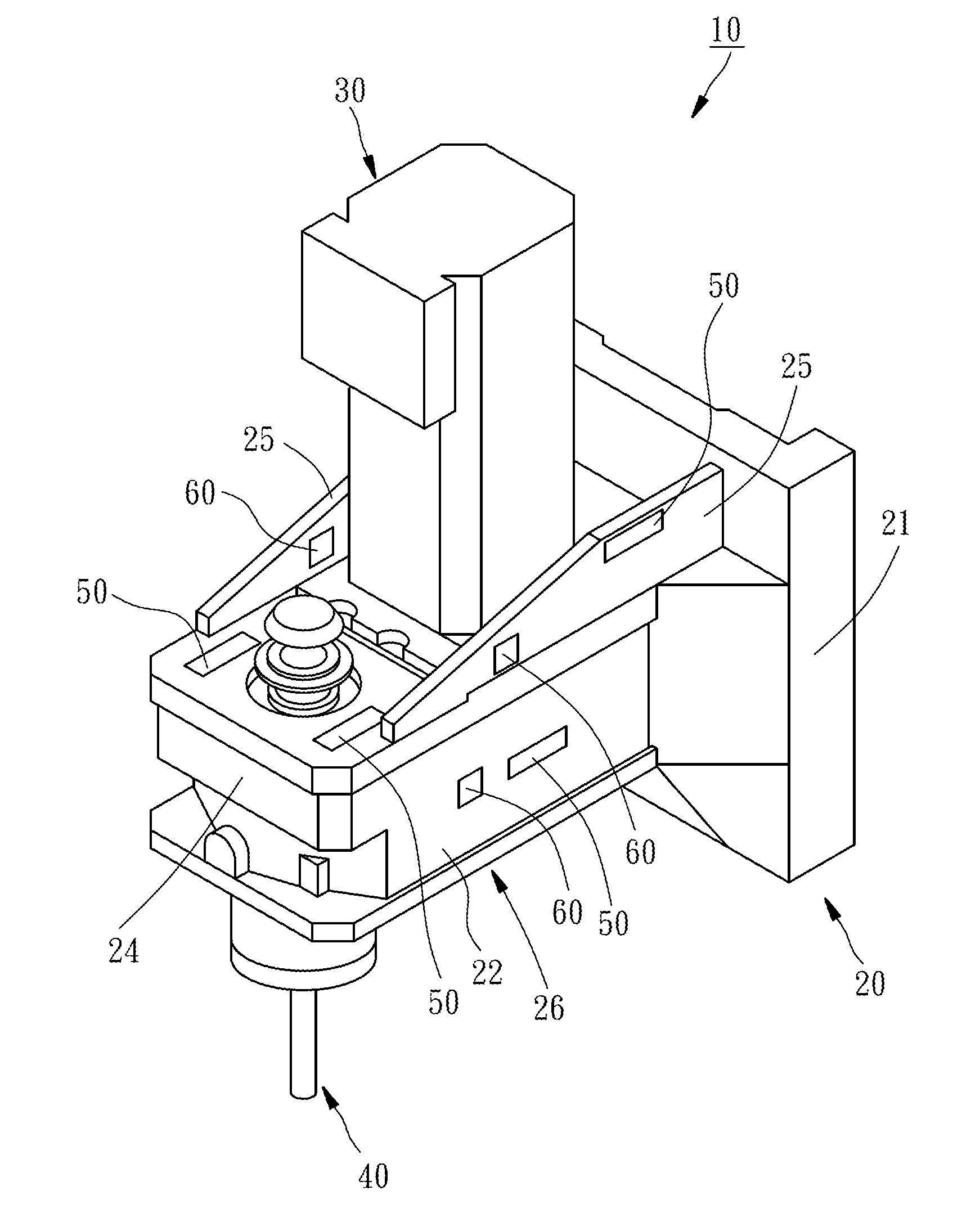

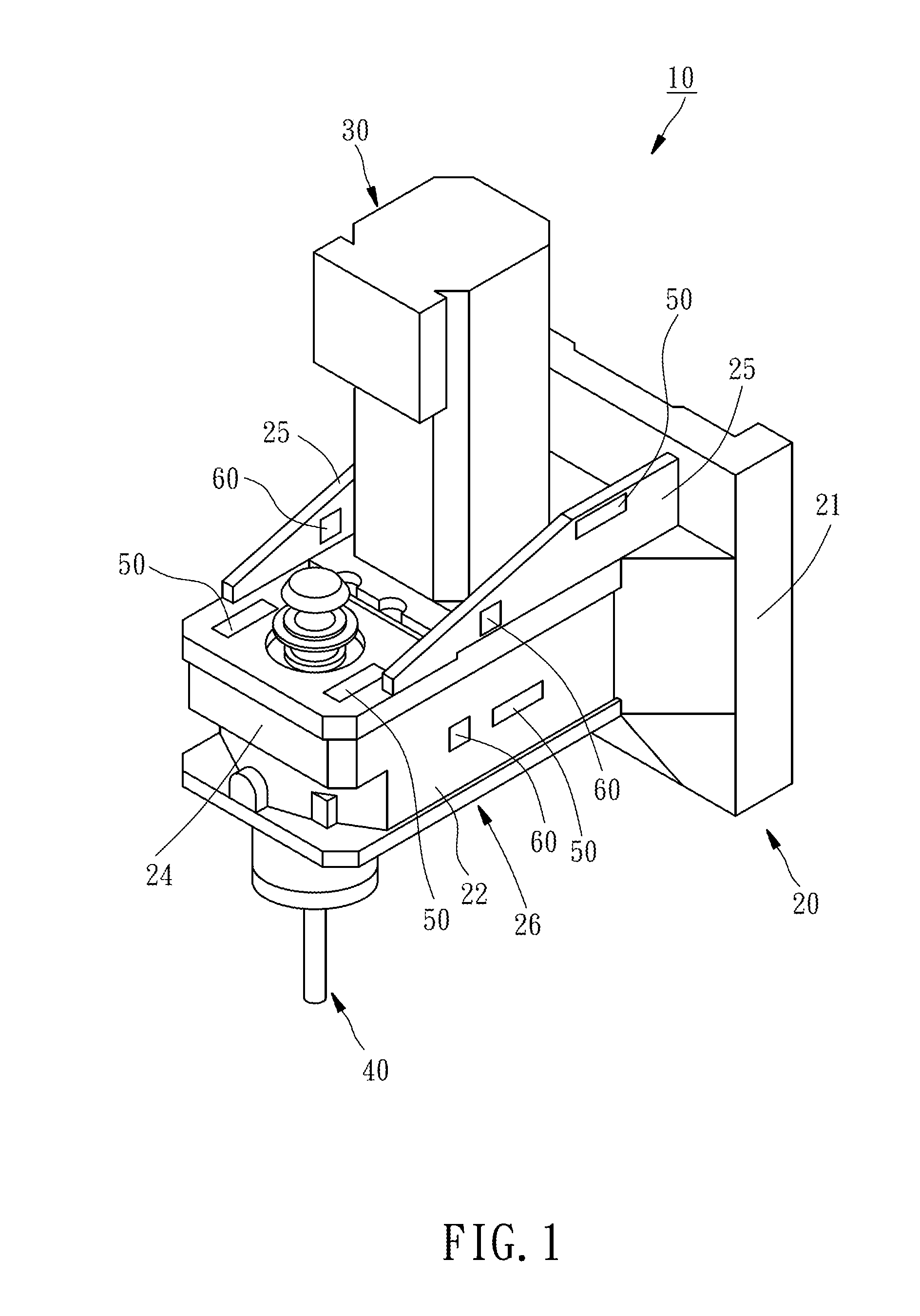

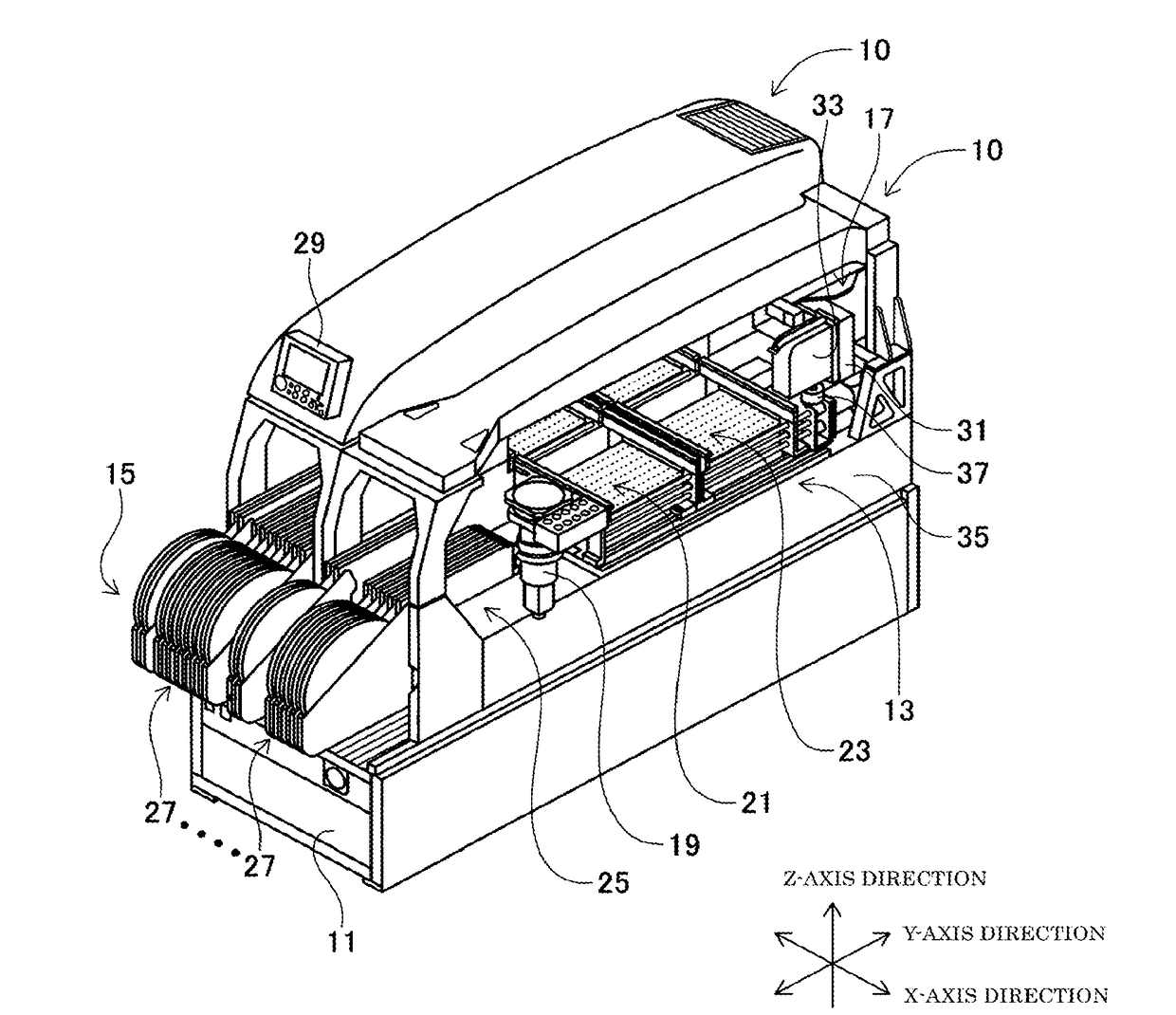

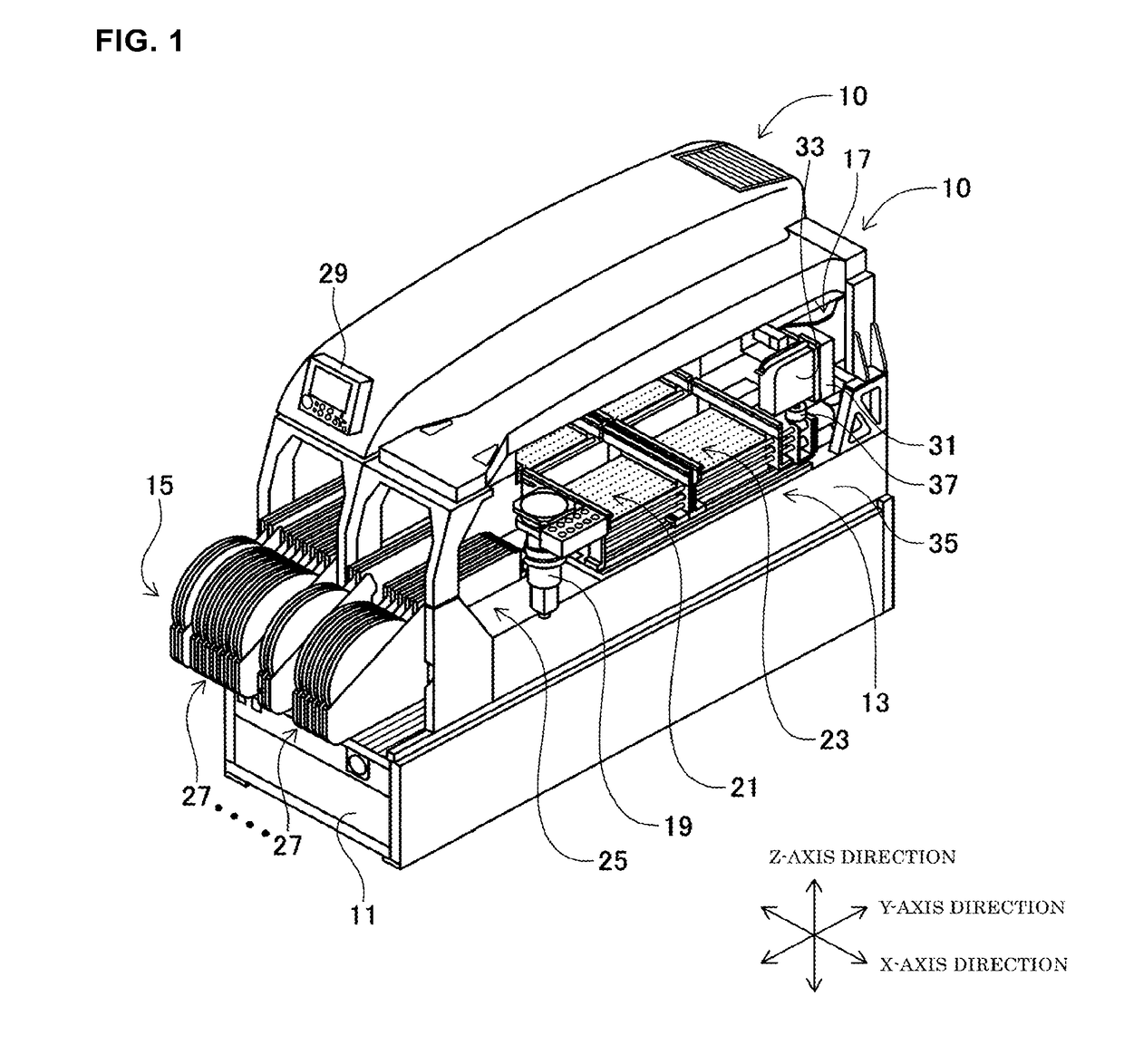

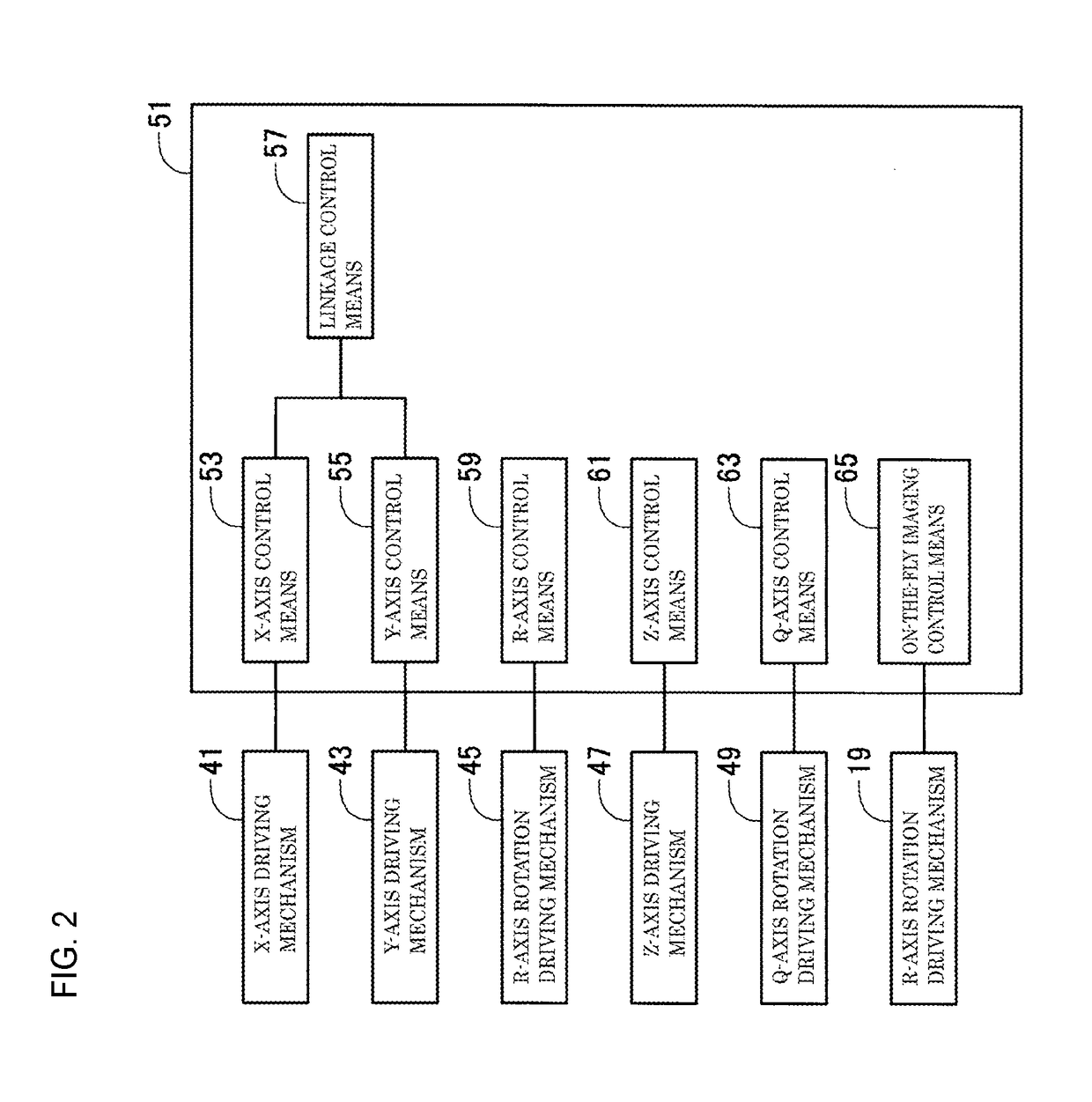

Component mounting device

ActiveUS20170142875A1Reduce waiting timeReduce the time required for installationElectrical componentsElectrical and Electronics engineering

Owner:FUJI MASCH MFG CO LTD

Method for forming pattern in semiconductor device

InactiveUS7994056B2Avoid low process precisionSimple processDecorative surface effectsSolid-state devicesSemiconductorSemiconductor device

A method for forming a pattern in a semiconductor device includes forming an etch-target layer over a substrate, wherein the substrate includes a first region having a smaller pattern than the first region, forming a sacrificial layer and a passivation layer over the etch-target layer, etching the passivation layer and the sacrificial layer to form stack structures including a sacrificial pattern and a passivation pattern, forming spacers over sidewalls of the stack structures, forming a mask pattern covering the second region, removing a portion of the passivation pattern in the first region exposed by the mask pattern to expose a portion of the sacrificial pattern in the first region, removing the exposed portion of the sacrificial pattern in the first region, and etching the etch-target layer to form an etch-target pattern using the spacers in the first and second regions and the stack structure formed between the spacers in the second region.

Owner:SK HYNIX INC

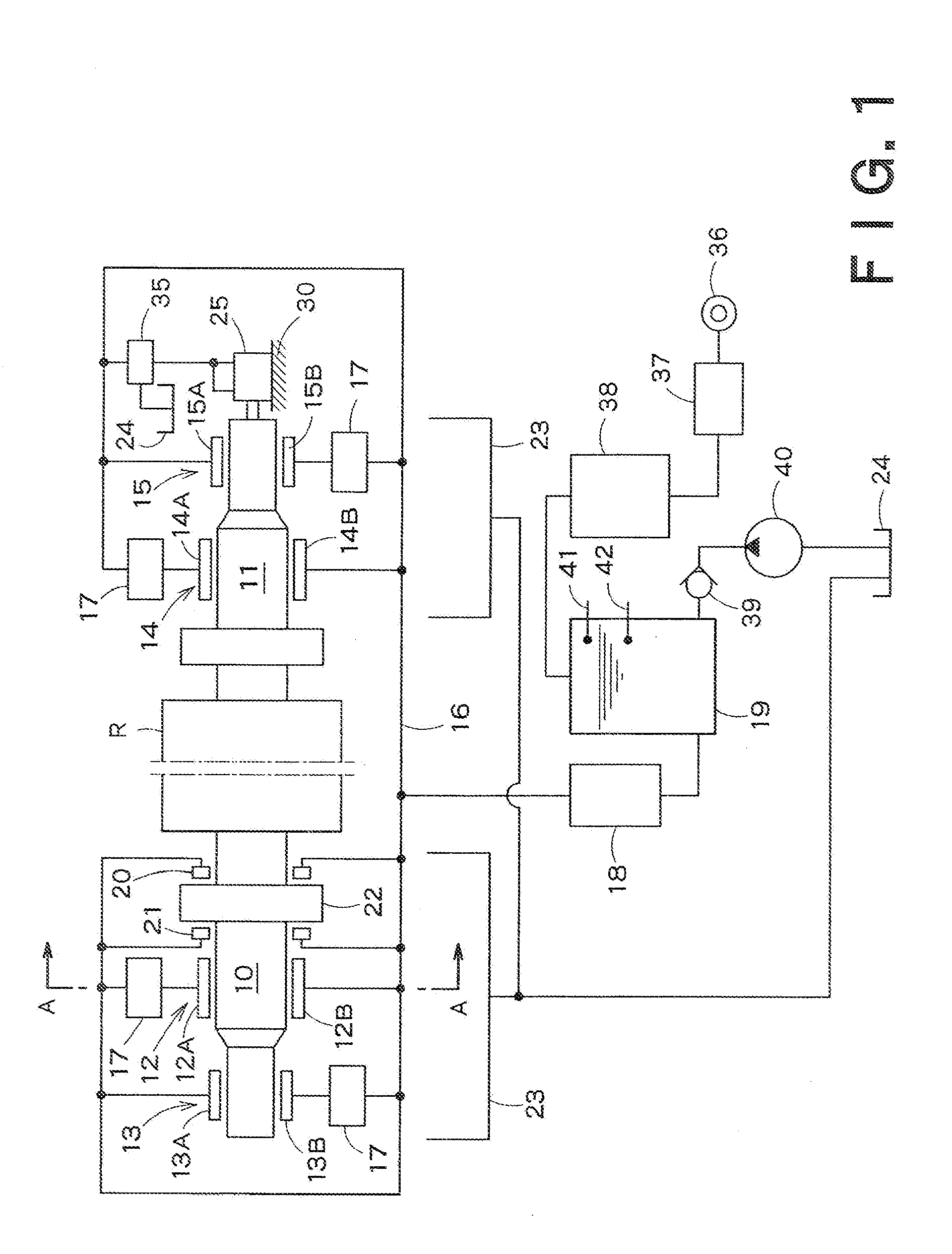

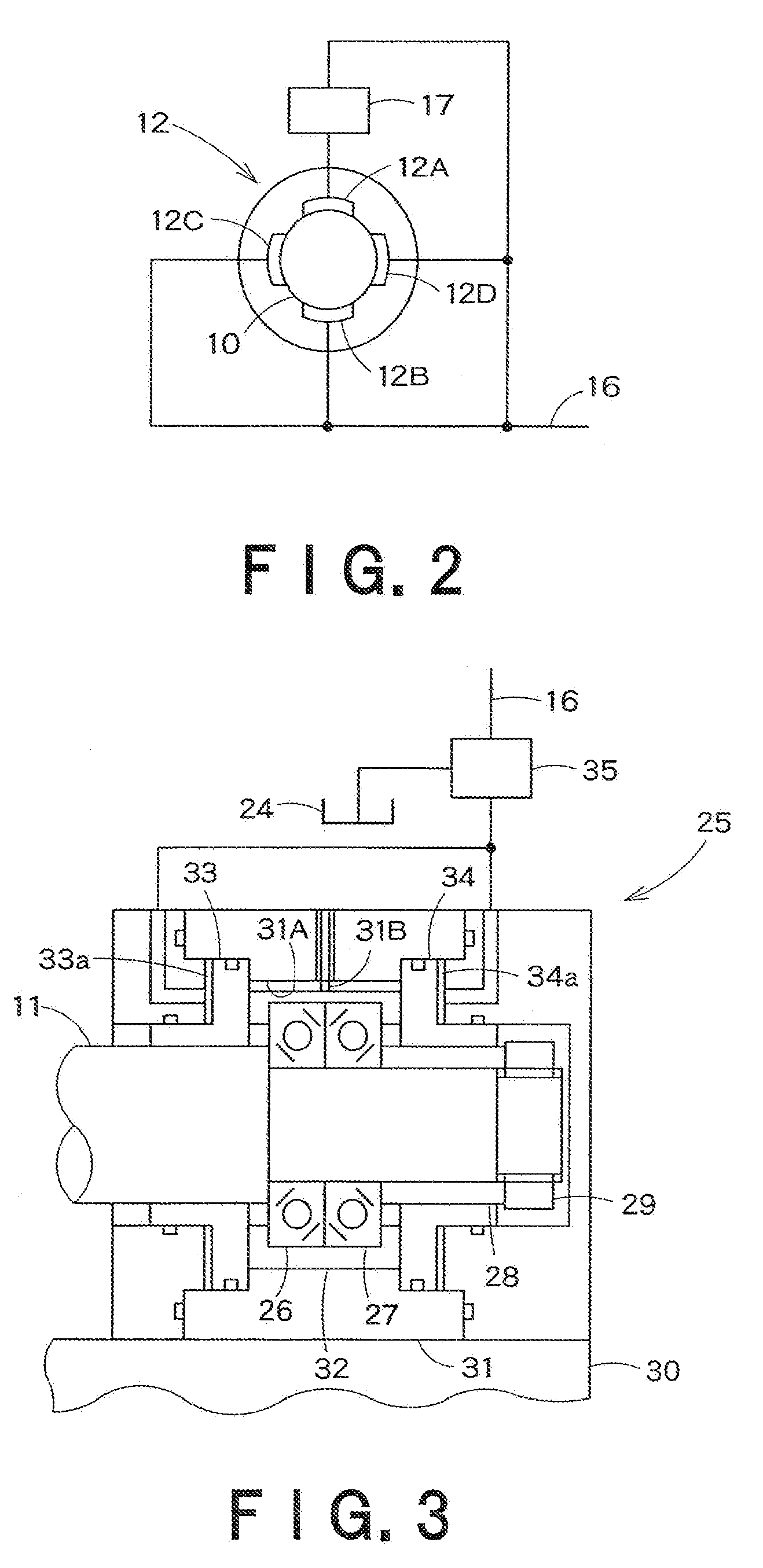

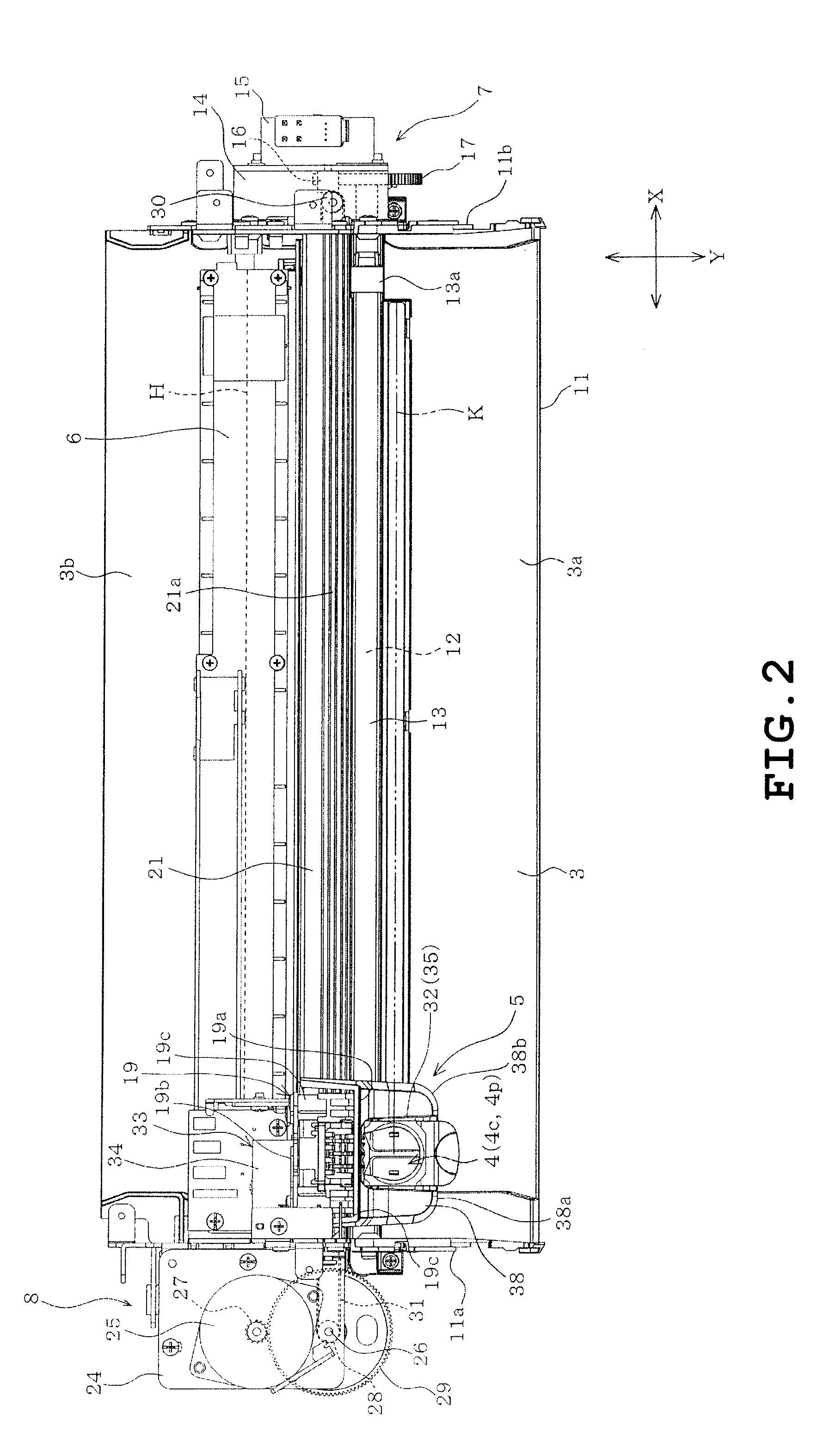

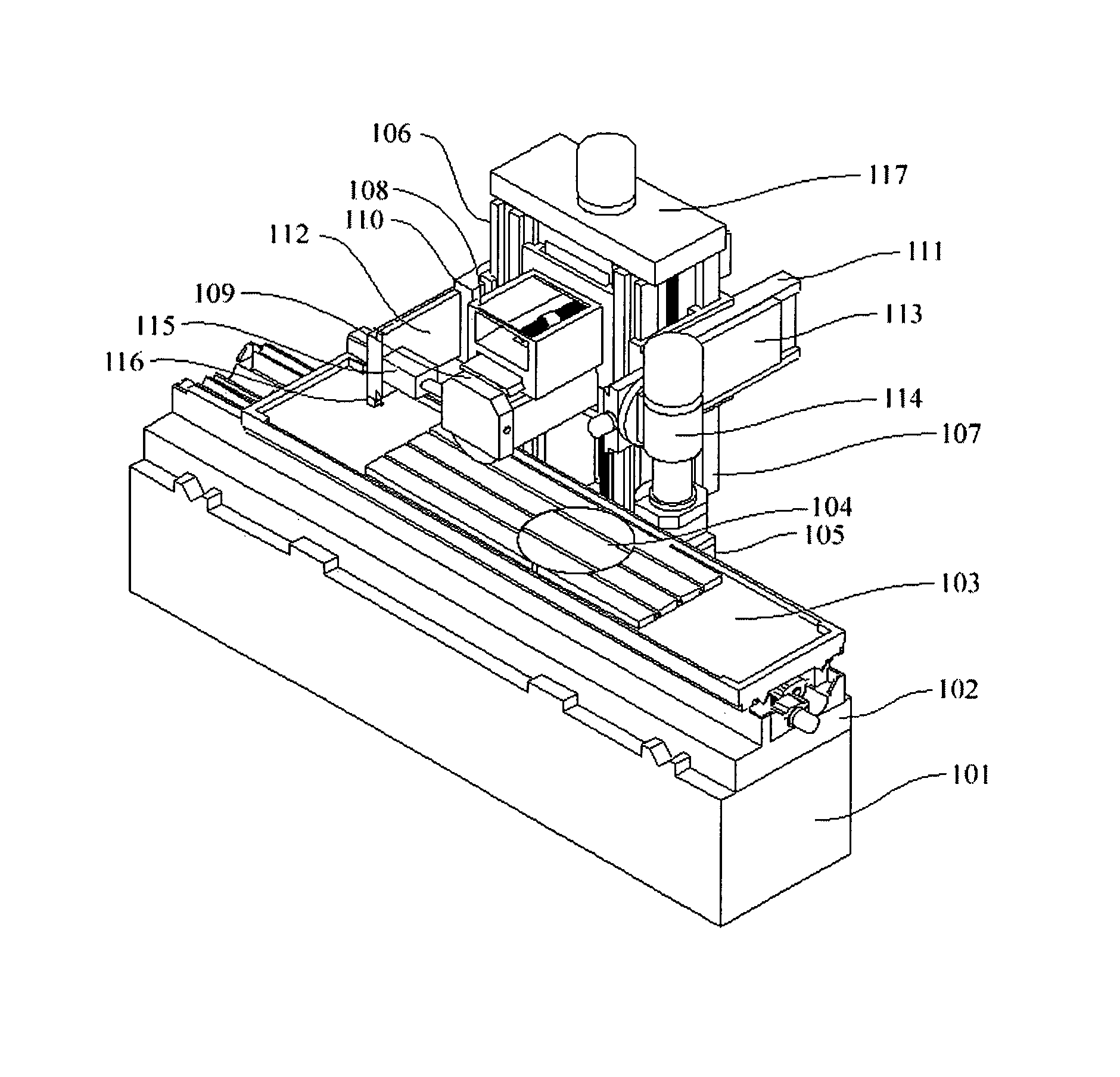

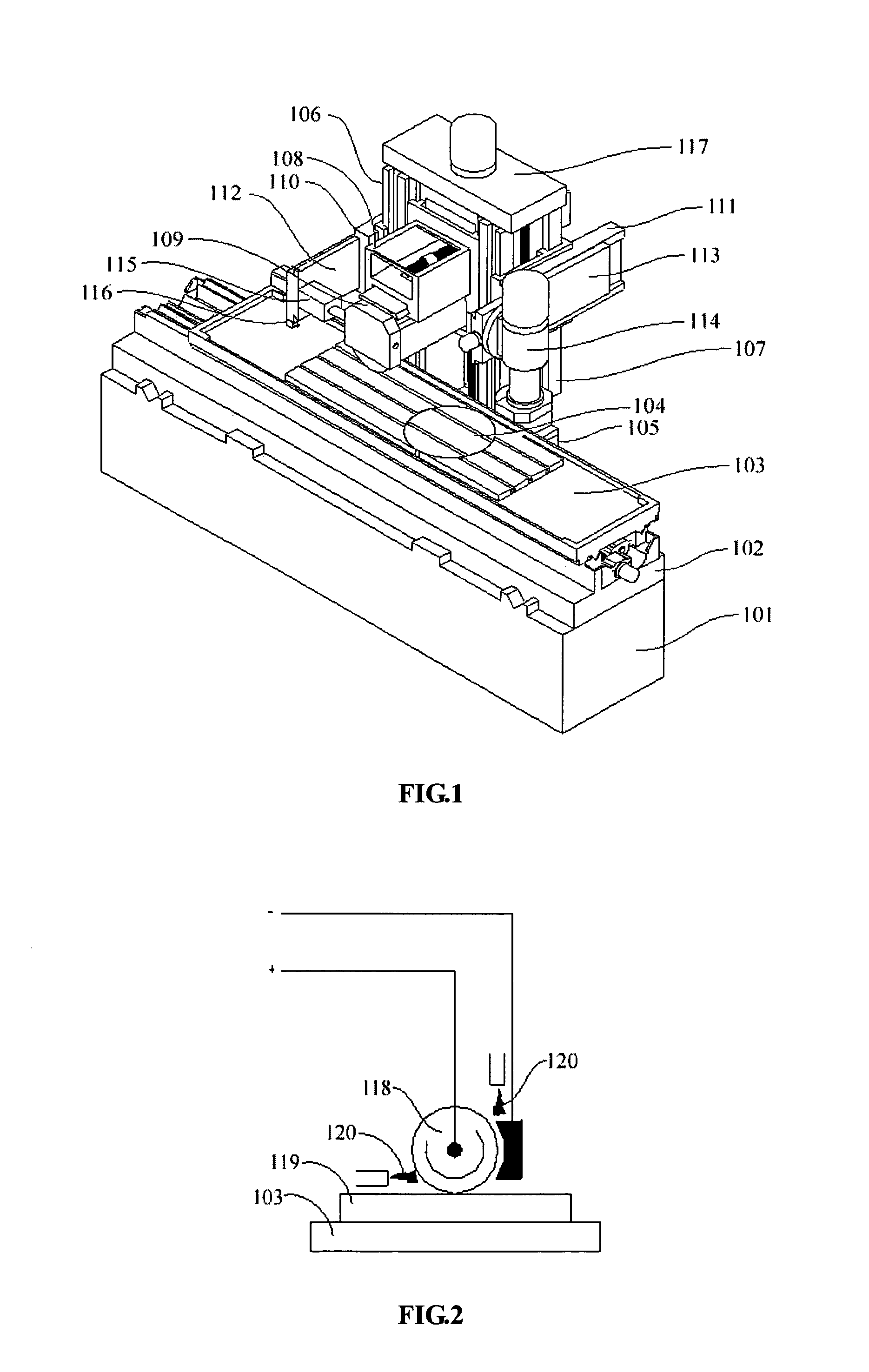

Roll machining apparatus

ActiveUS20080187266A1Easy constructionAvoid low process precisionLathesRoller bearingsRoom temperatureThrust bearing

There is provided a roll machining apparatus which can accurately support a roll by means of hydrostatic bearings while absorbing thermal expansion of the roll in the length direction e.g. due to a change in room temperature, thus enhancing the machining precision. The roll machining apparatus for machining the surface of a roll while supporting and rotating the roil in a horizontal position, includes: a first spindle to be detachably coupled to one end of the roll; a second spindle, disposed opposite to the first spindle on the same axis, to be detachably coupled to the other end of the roll; a first hydrostatic radial bearing for receiving the radial load of the first spindle and rotatably supporting the first spindle; a hydrostatic thrust bearing for receiving the thrust load of the first spindle and limiting axial movement of the first spindle, a second hydrostatic radial bearing for receiving the radial load of the second spindle and rotatably supporting the second spindle; and a floating thrust having a thrust bearing for receiving the thrust load of the second spindle, said thrust being capable of selectively limiting and permitting axial movement of the thrust bearing.

Owner:TOSHIBA MASCH CO LTD

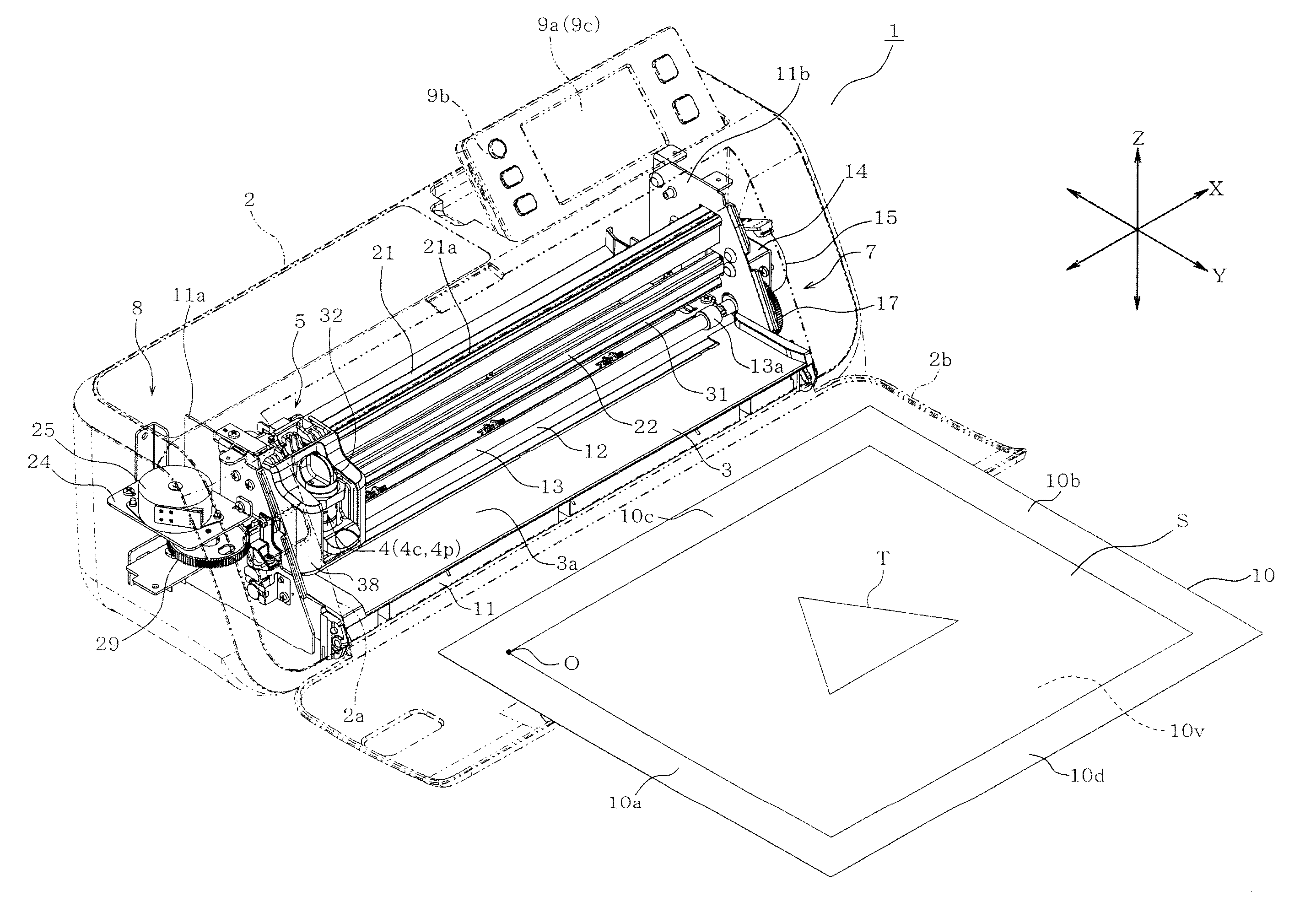

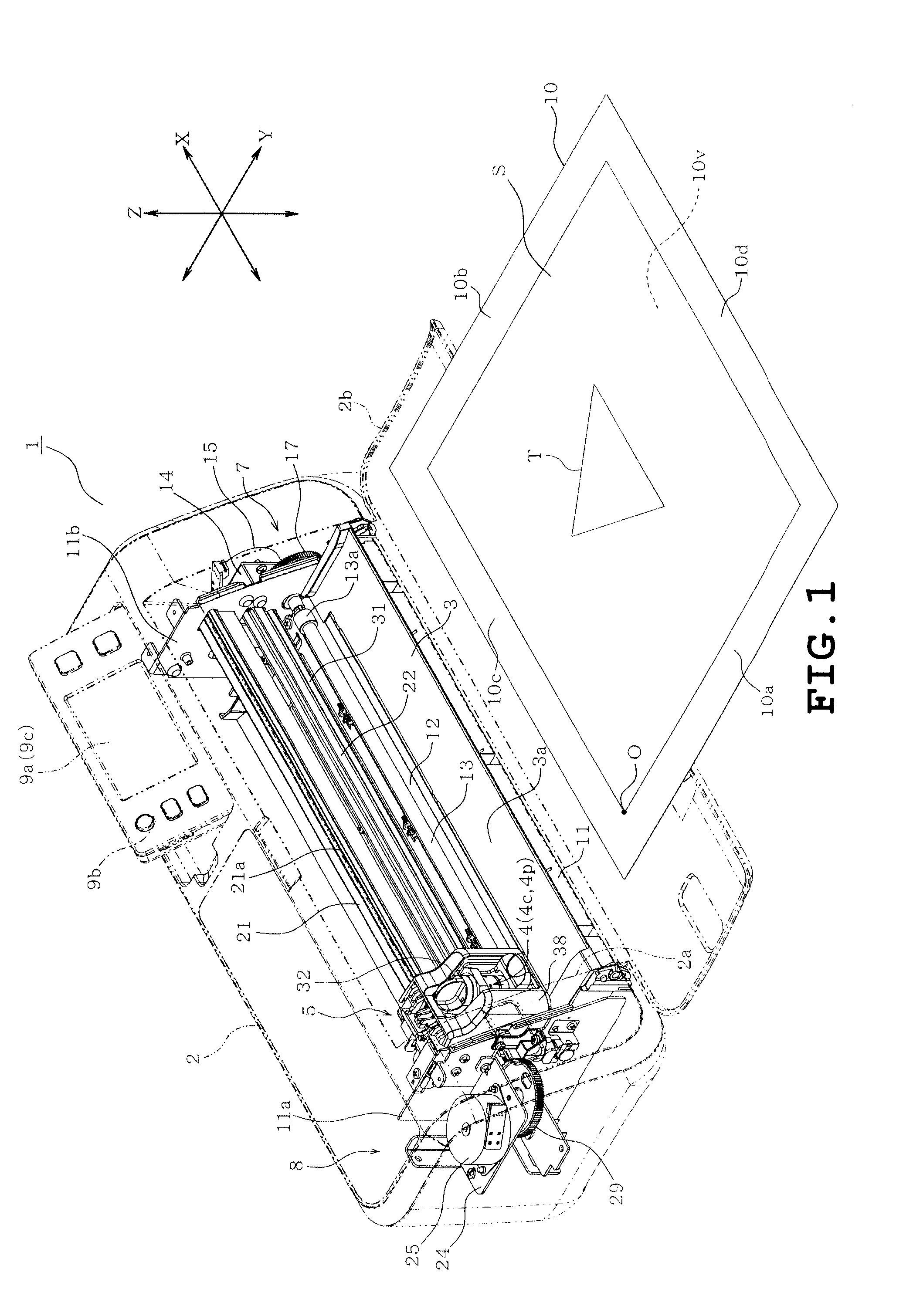

Apparatus and non-transitory computer-readable medium

ActiveUS20140290507A1Low costAvoid low process precisionMechanical working/deformationRotary pressesComputer scienceImaging data

An apparatus may include a cartridge holder configured to receive a pen or a cutter, a platen configured to receive an object, a first moving mechanism configured to move the cartridge holder, a reading unit configured to read image data from the object, a second moving mechanism configured to move the object to the reading unit, and a processor configured to instruct the apparatus to instruct the first moving mechanism to move the cartridge holder close to the platen, instruct the second moving mechanism to move the object so that the image data is read by the reading unit, extract, from the image data, a processing mark on the object, calculate a rotation angle for correcting image data, based on rotation angle, at least one of the processing mark, and correct, based on the image data and processing data.

Owner:BROTHER KOGYO KK

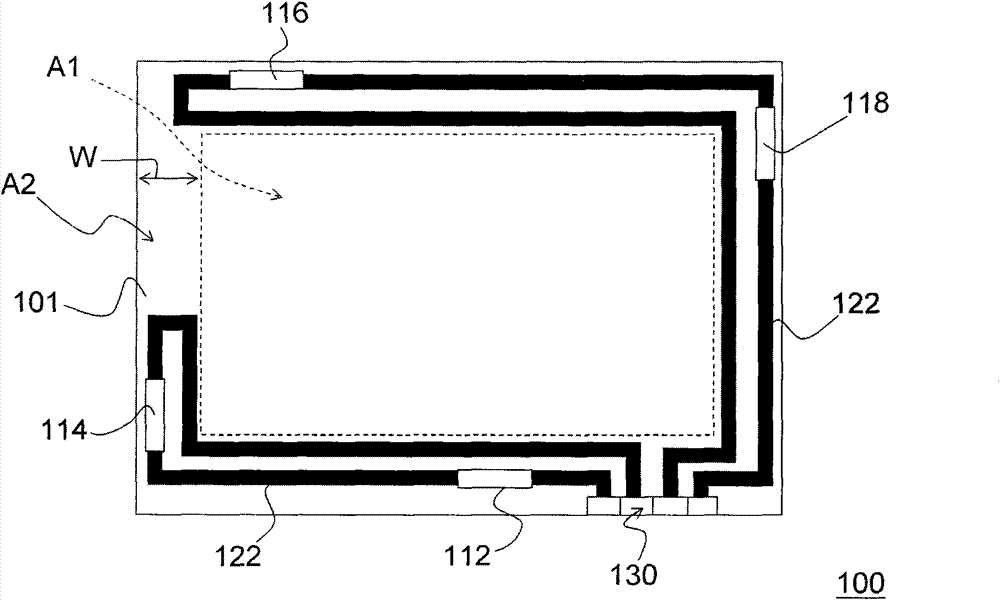

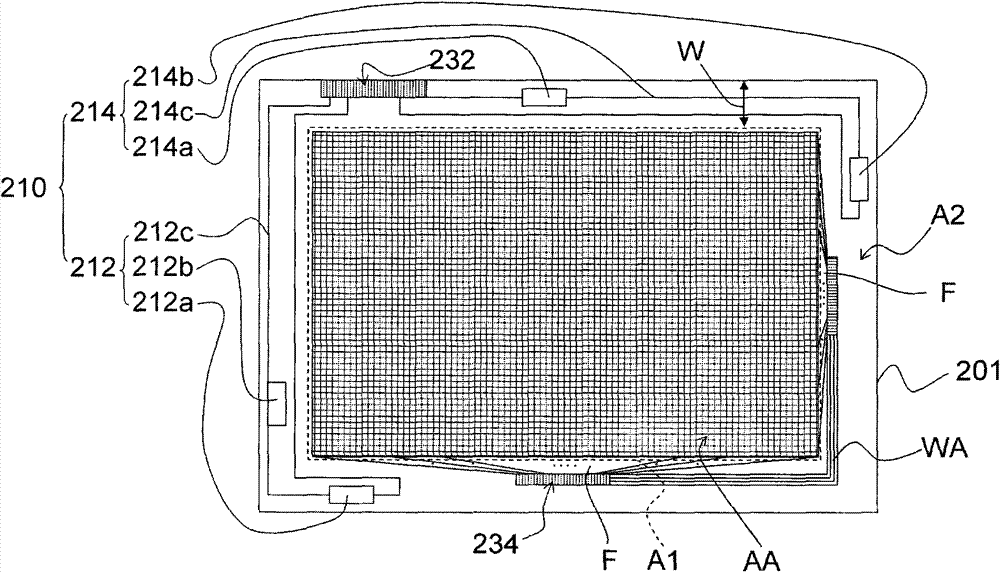

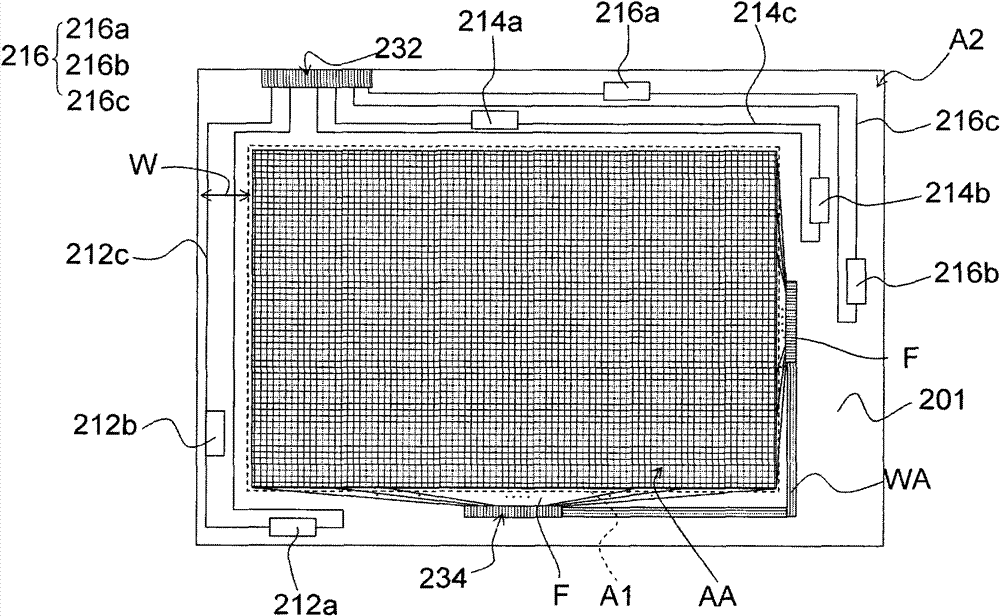

Touch-control display panel and display device

InactiveCN101673004BAvoid low process precisionLower resistanceStatic indicating devicesInput/output processes for data processingDisplay deviceMedia layer

The invention discloses a touch-control display panel and a display device. The touch-control display panel comprises a first substrate, a touch-control assembly and a display medium layer, wherein the first substrate is provided with a display area and a non-display area, and the non-display area is positioned outside the display area; the touch-control assembly is directly allocated on the first substrate and positioned in the non-display area, and the touch-control assembly at least comprises two sets of receiving assemblies; and the display medium layer is positioned in the display area. The touch-control display panel has high processing procedure precision and can reduce the resistance value and the width of the transmission wire. Since the display device is provided with the touch-control display panel, the width of the non-display area can be reduced so as to increase the size of the display screen of the product.

Owner:AU OPTRONICS CORP

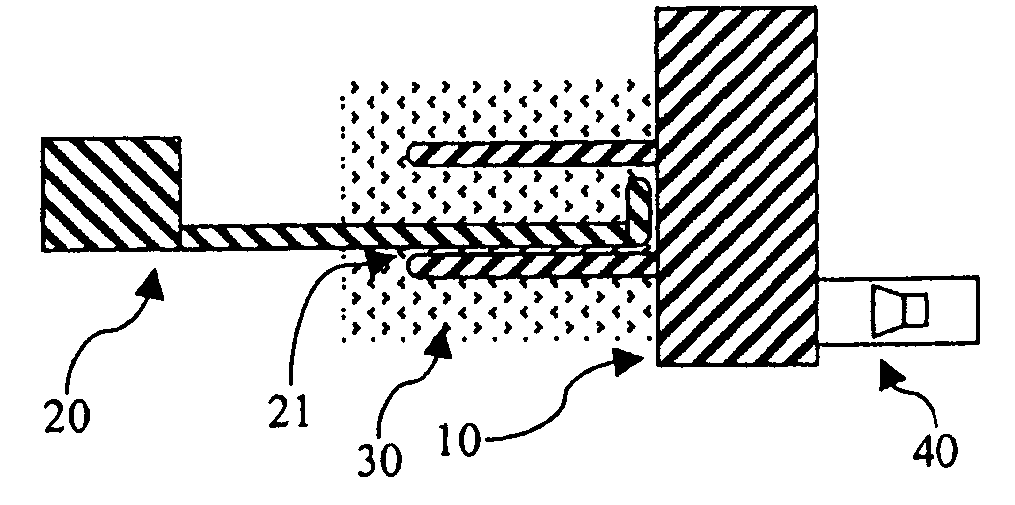

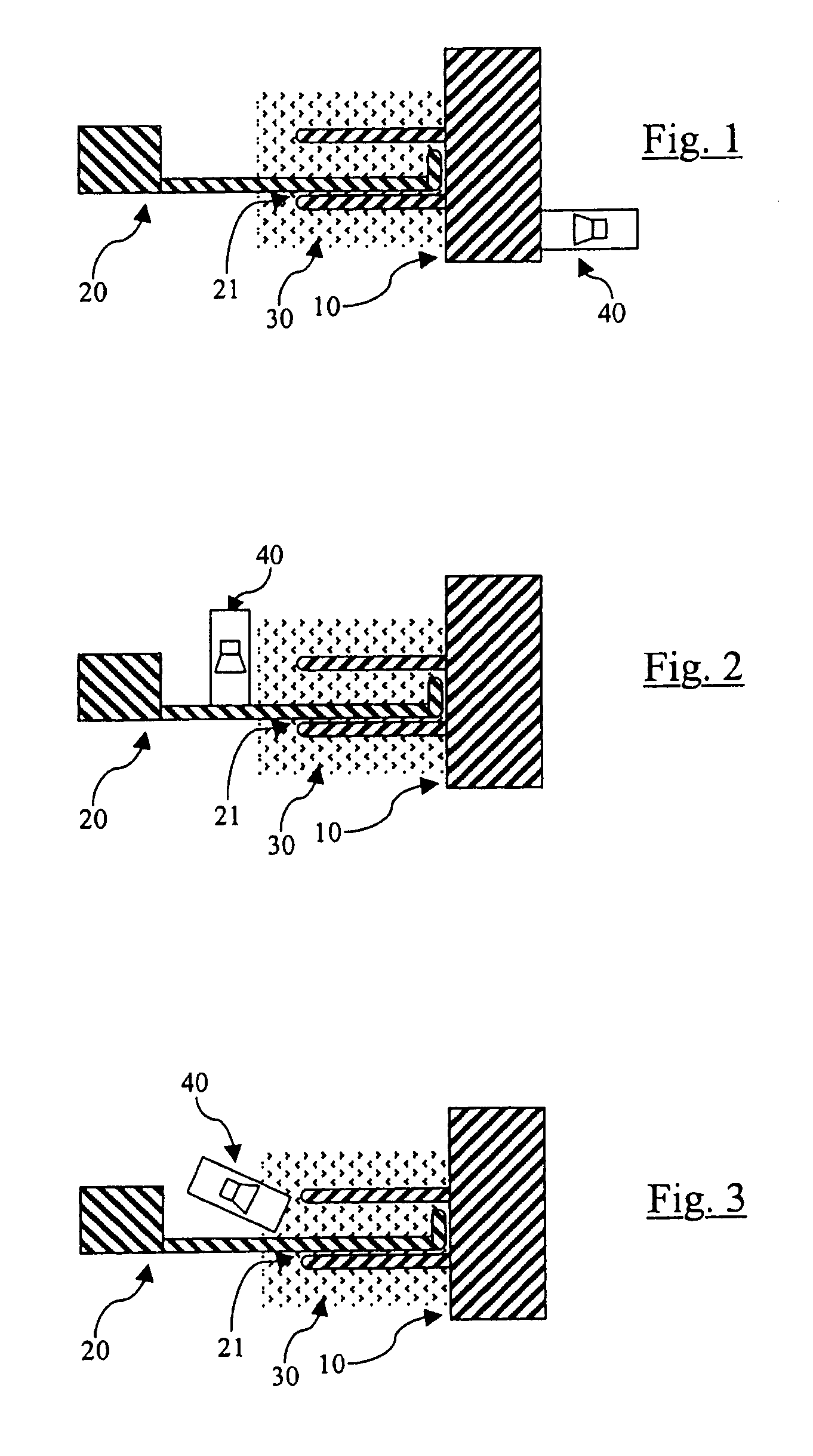

Device and method for electrochemical reduction

InactiveUS20060049055A1Avoid low process precisionAvoid developmentElectrochemical machining apparatusElectrochemistryMechanical engineering

A device for electrochemical reduction of a workpiece (10) includes a workpiece (10), an electrode (20), and an electrolyte (30), which is located between electrode (20) and workpiece (10). The electrode (20) is moved close to the workpiece (10) with a small gap dimension (21), and a processing of the workpiece (10) occurs through a flow of current between electrode (20) and workpiece (10) through the electrolyte (30). In addition, a sonotrode is positioned to introduce sound waves.

Owner:MTU AERO ENGINES GMBH

Production method of LTPS array substrate

ActiveCN106711157AReduce the numberReduce displacement errorSolid-state devicesSemiconductor/solid-state device manufacturingMetal stripsOptoelectronics

The invention provides a production method of an LTPS array substrate. According to the method, one photomask is used for respectively patterning a light shielding metal layer and photoresist for performing N type heavy doping, thus forming a plurality of parallel spaced light shielding metal strips, and a plurality of photoresist strips overlapped one by one with the light shielding metal strips. By the production method, the number of photomasks required by production of the LTPS array substrate is reduced, the production cost is lowered, the displacement errors among membranous layers are reduced, the manufacture procedure precision is elevated, and the product quality is guaranteed.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

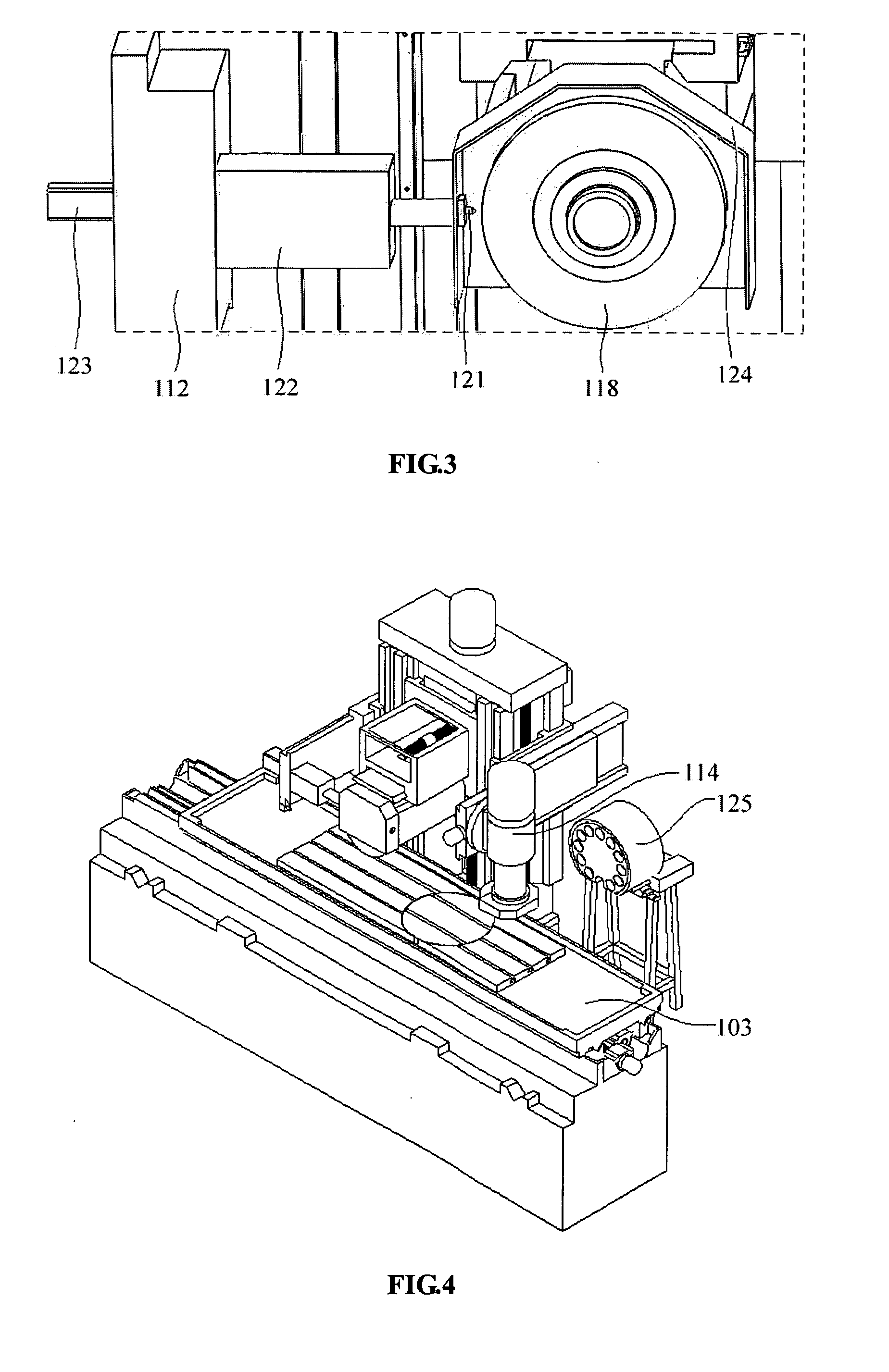

Multi-carriage dual-spindle symmetrical grinding processing center

ActiveUS9272385B2Increase capacityImprove efficiencyGrinding feed controlAbrasive surface conditioning devicesEngineeringGrinding wheel

A multi-carriage dual-spindle symmetrical grinding processing center, wherein: A work table with a rotary table therein is positioned on a first carriage which is attached to a front base; first and second upright posts are positioned in a gantry form on a back base; a horizontal grinding head is connected to a second carriage between the upright posts; a third left carriage and a third right carriage are slidingly connected to the first and second upright posts, respectively, and a left slider and a right slider are connected to the third left carriage and the third right carriage, respectively; a vertical grinding head is installed at the front end of the right slider; an automatic tool changing device is equipped with the vertical grinding head, and a grinding wheel profile dressing device can be installed on the second carriage and on the left slider.

Owner:XIANGTAN SANFENG CNC MACHINE TOOL

Light-emitting diode chip and micro display device

ActiveUS10566381B2Improve processing efficiencySimplified driver circuitStatic indicating devicesSolid-state devicesDisplay deviceGreen-light

Owner:LG DISPLAY CO LTD

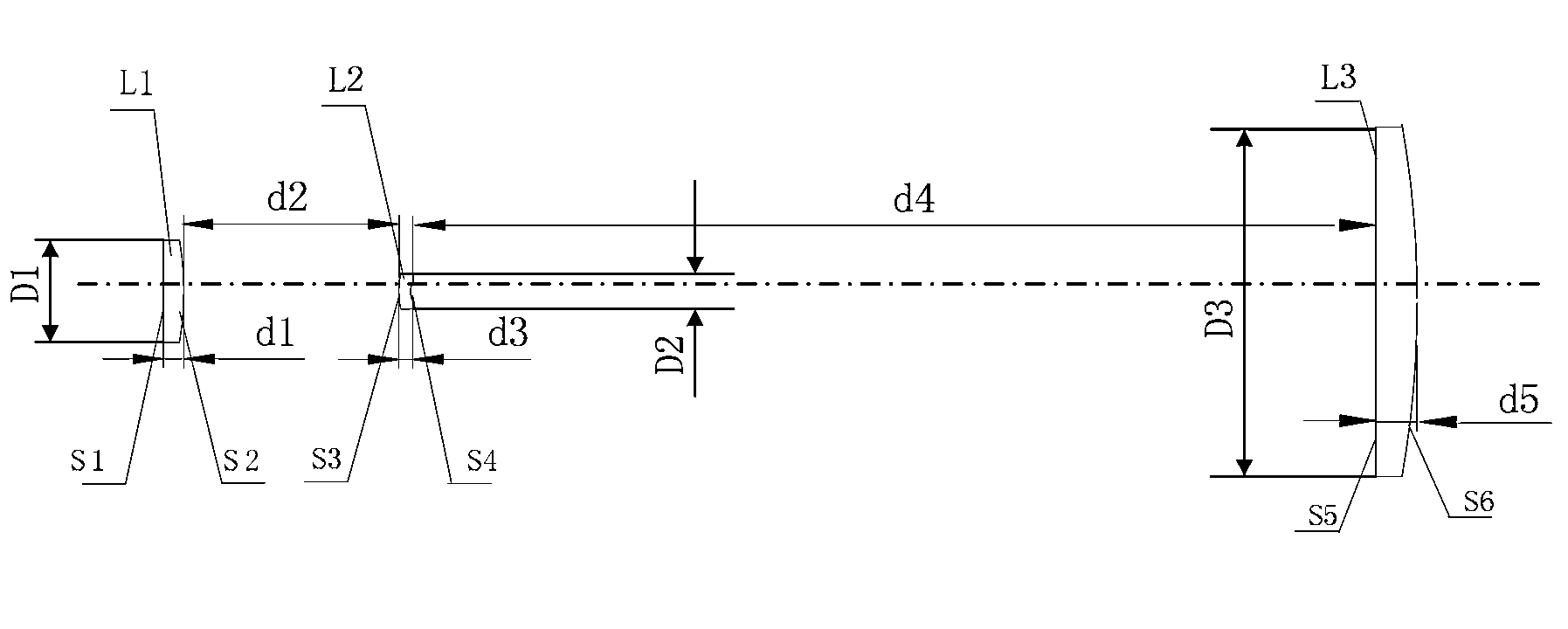

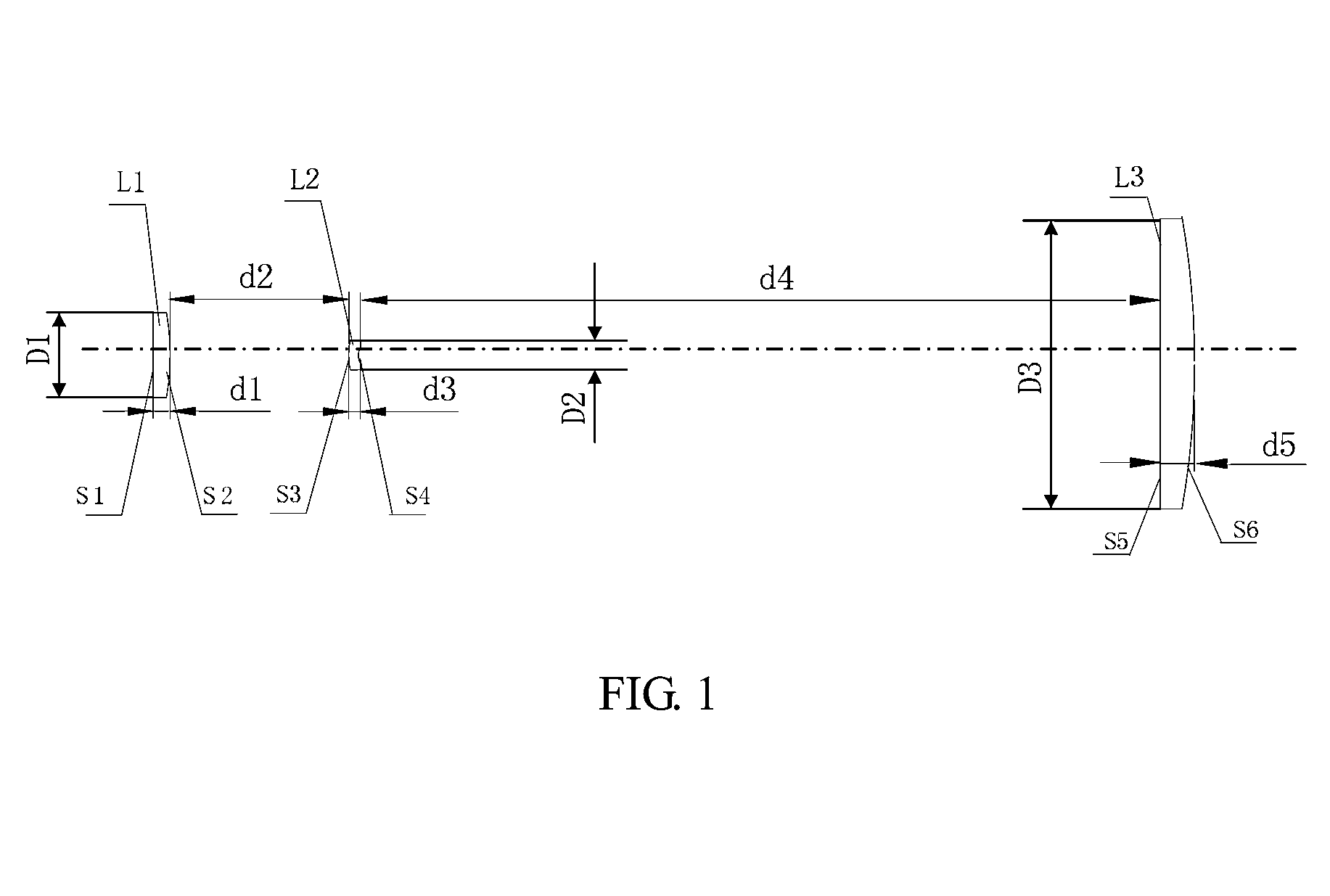

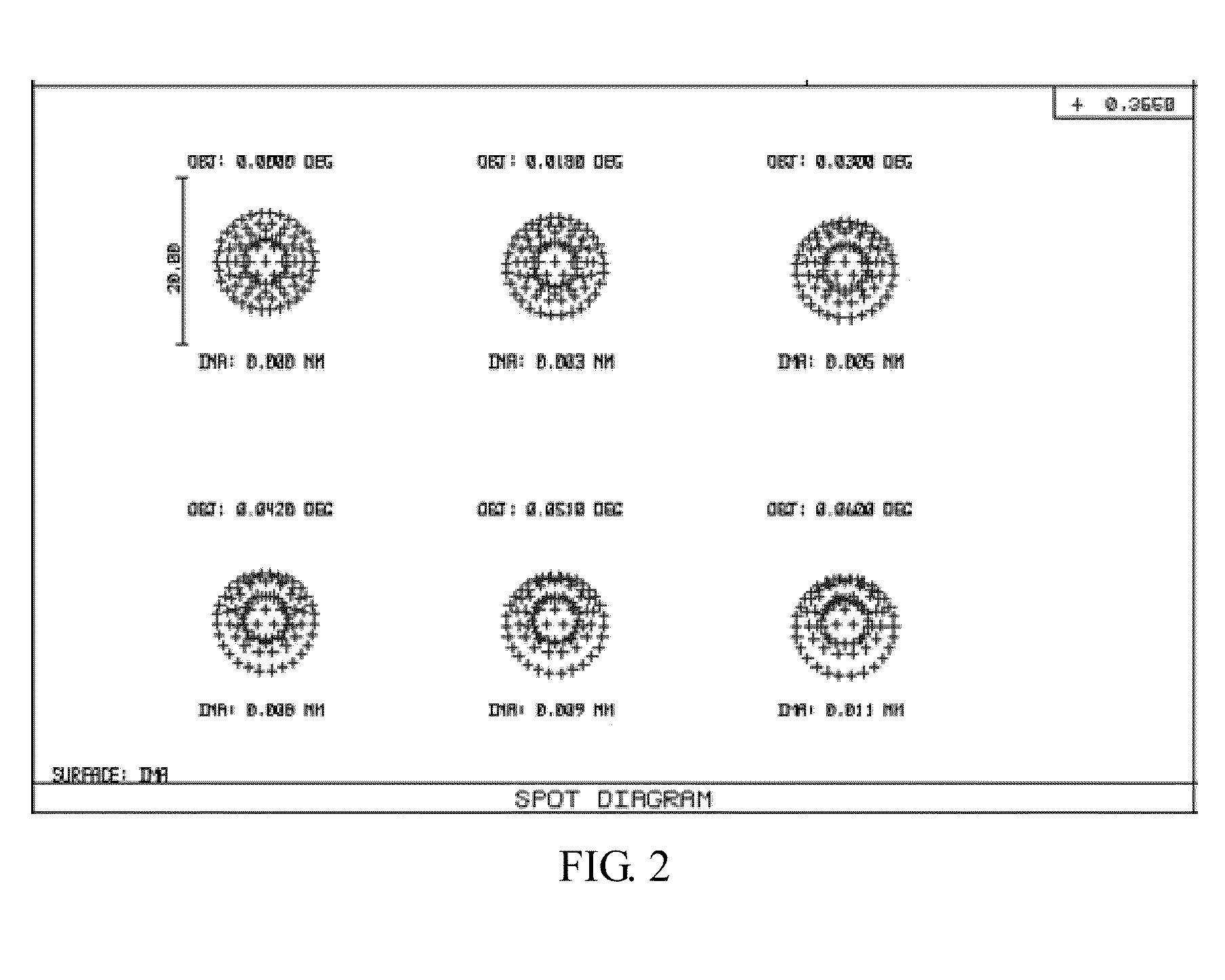

Ultraviolet laser zoom beam expanding system and laser processing equipment

An ultraviolet laser zoom beam expanding system, applied to the field of laser processing, includes a first lens, a second lens, and a third lens (L1, L2, L3). The first lens and the third lens (L1, L3) are plane-convex plus lenses, and the second lens (L2) is a convex-concave minus lens. The first lens, the second lens and the third lens (L1, L2, L3) respectively comprise a first surface and a second surface (S1, S2), a third surface and a fourth surface (S3, S4) as well as a fifth surface and a sixth surface (S5, S6). The radiuses of curvature of the first to sixth surfaces (S1, S2, S3, S4, S5, S6) are ∞, −30, 10, 2.2, ∞, −81. The center thickness of the first to third lenses (L1, L2, L3) is 2, 1, 4. The outer diameters of the first to third lenses (L1, L2, L3) are 10, 3, 34. Proportions of the refractive indexes to the abbe numbers of the first to third lenses (L1, L2, L3) are 1.57:41, 1.48:68, and 1.57:41. An interval (d2) between the second surface and the third surface (S2, S3) is 6-37. An interval (d4) between the fourth surface and the fifth surface (S4, S5) is 114-125, a unit is mm, and a tolerance is 5%. The system may perform beam expanding on entering light by 2-16 times, which may be adaptable to laser devices with different emergent diameters and divergence angles, and improve efficiency and accuracy of laser processing.

Owner:HANS LASER TECH IND GRP CO LTD

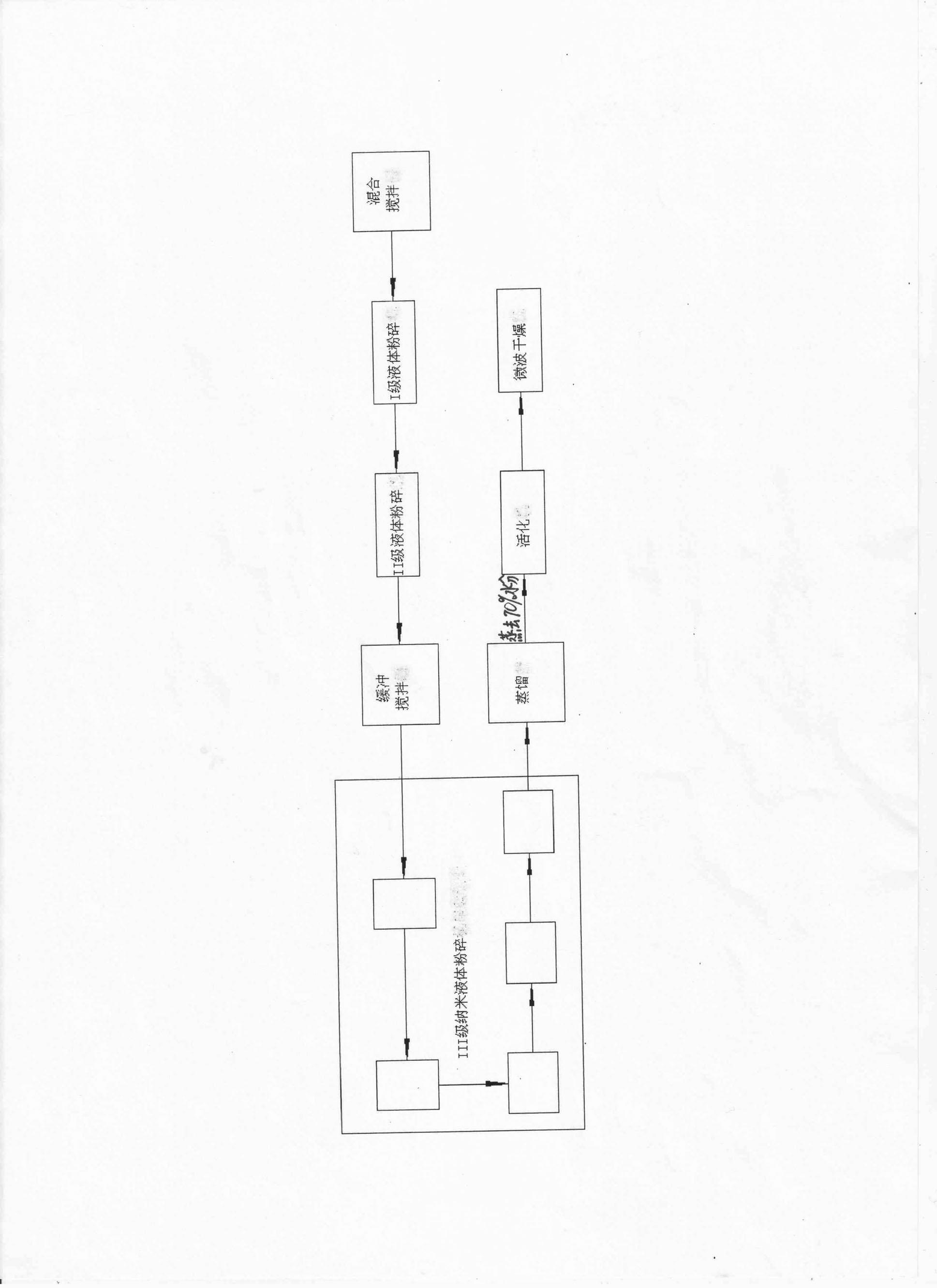

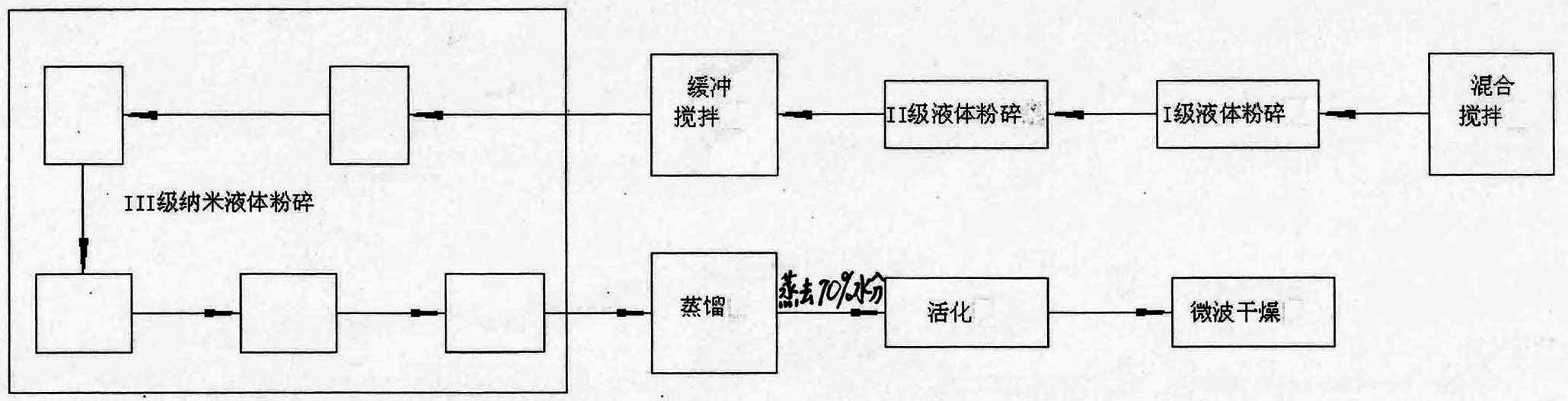

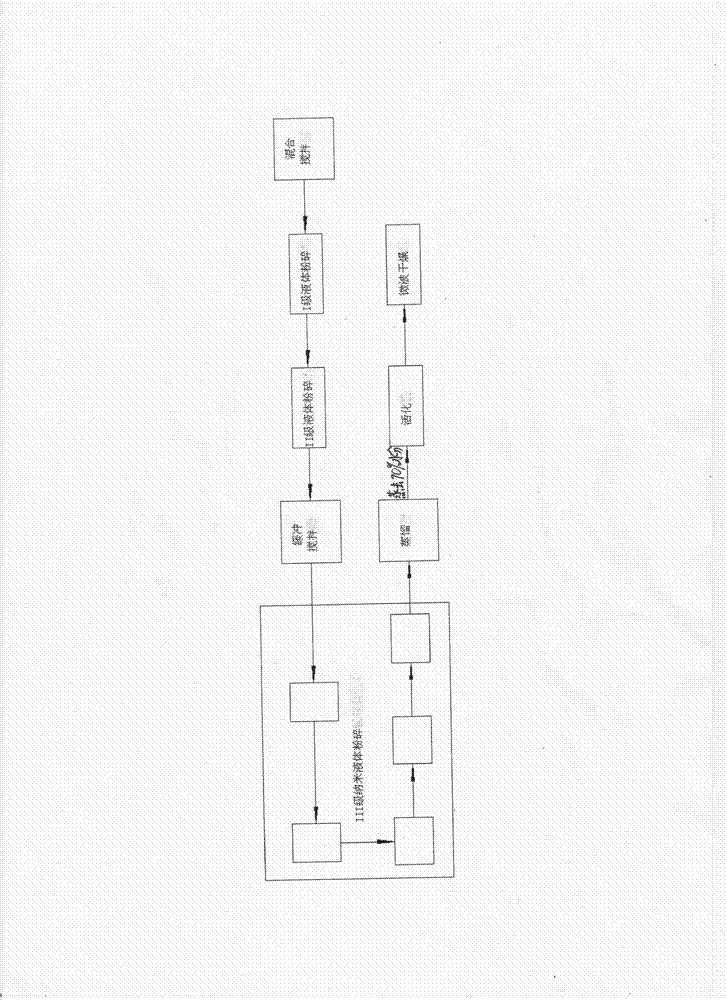

Process for wetly crushing and processing thick carbon black after pyrolysis of waste rubber

ActiveCN102240660AEliminate secondary pollutionSimple processSolid waste disposalGrain treatmentsDistillationWaste rubber

The invention discloses a process for wetly crushing and processing thick carbon black after pyrolysis of waste rubber, comprising the following steps that: industrial thick carbon black and water are filled in a mixed stirring tank and then enter a first-stage liquid crusher and a second-stage liquid crusher respectively; liquid carbon subjected to of the second-stage liquid crushing process enters a buffer stirring tank and then enters a third-stage liquid nano fine crushing system; the liquid carbon subjected to of the third-stage liquid crushing enters a distillation kettle; slurry, 70% of water content of which is evaporated, enters an activation level machine; activated granular wet carbon black enters a microwave dryer so as to be heated and dried in a microwave way; and after being dried, the carbon black is packaged for future use. The invention has the advantages of being simple in process and convenient for operation. The equipment used is the equipment in the prior art andonly needs to be assembled together. The process has high processing precision without leakage. Compared with the carbon black crushed dryly, the carbon black is finer and has higher additional value. By means of the process, the working environment is improved; the secondary pollution of the environment is thoroughly eliminated; the current industrial carbon black can be replaced by the processed fine regenerative carbon black; and resource and energy can be saved.

Owner:瑞新环境科技民权县有限公司

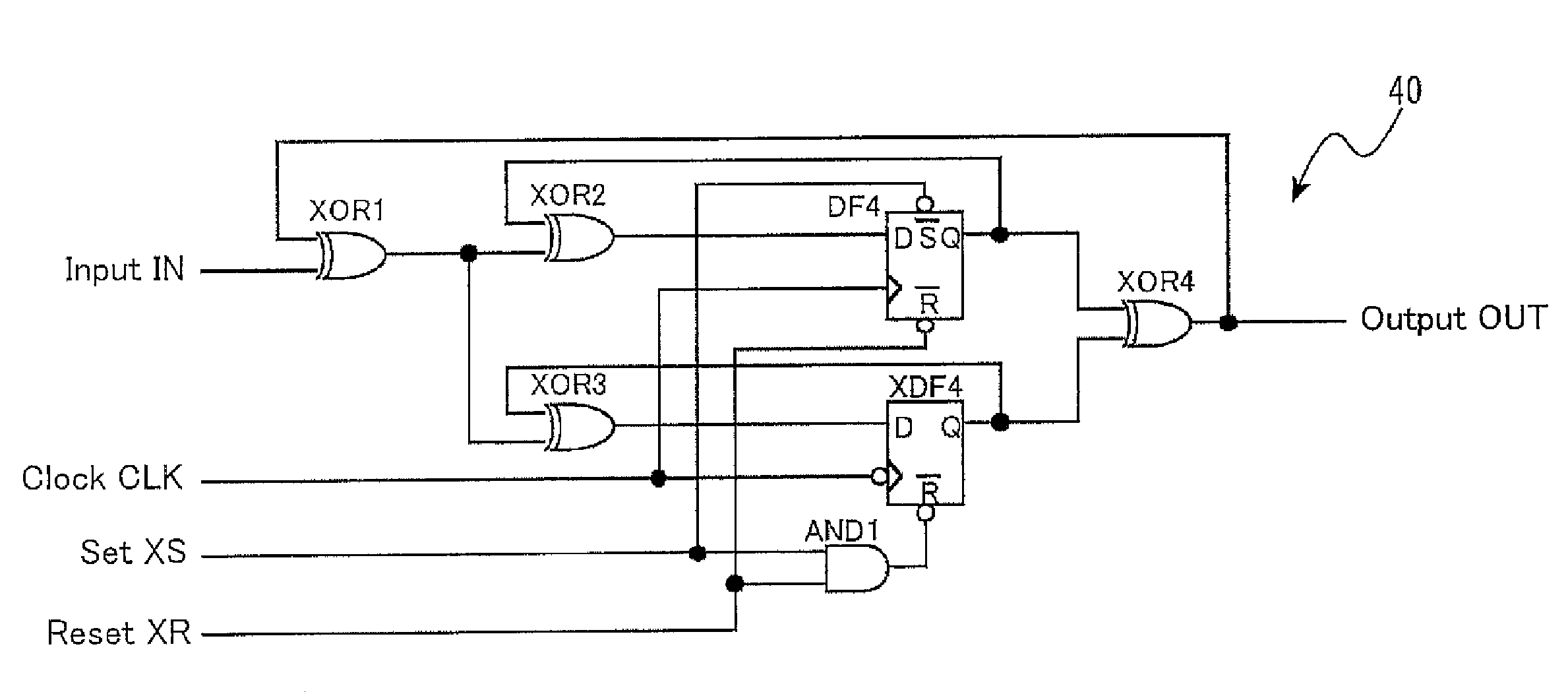

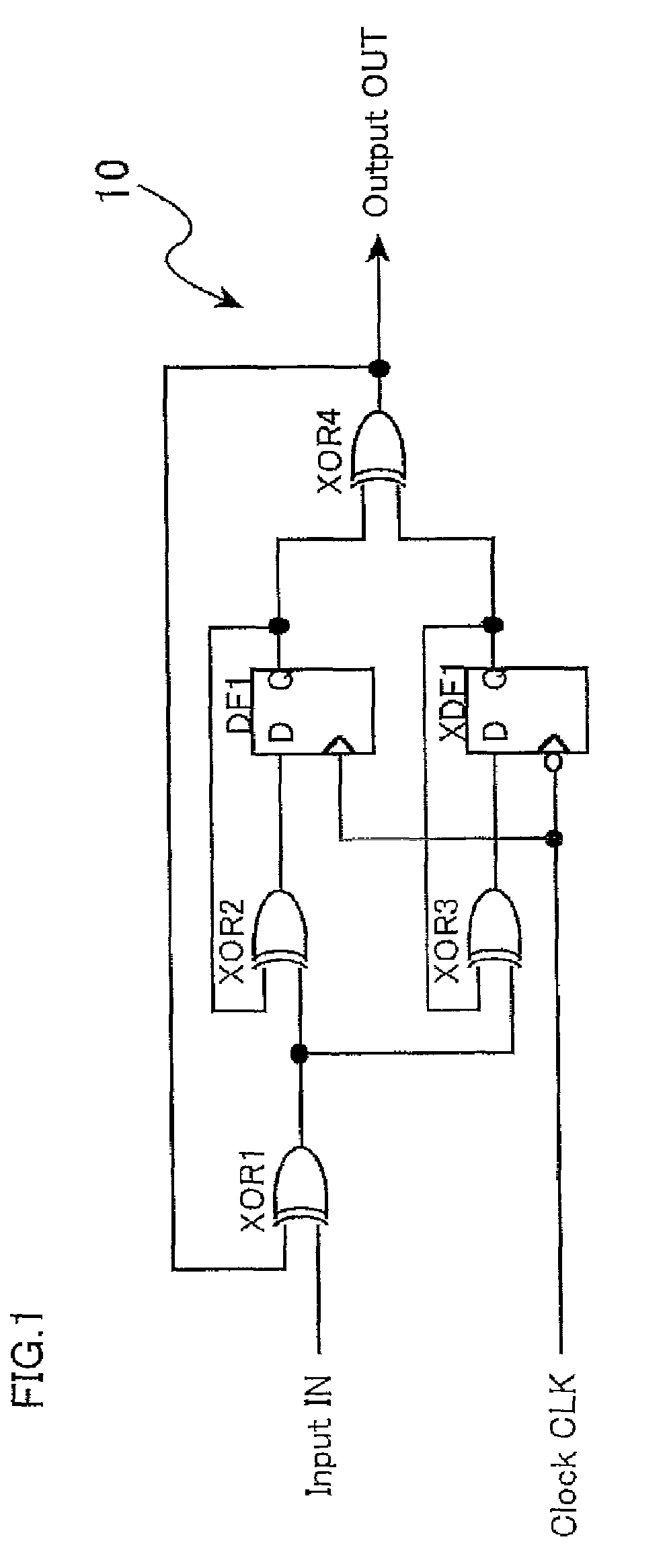

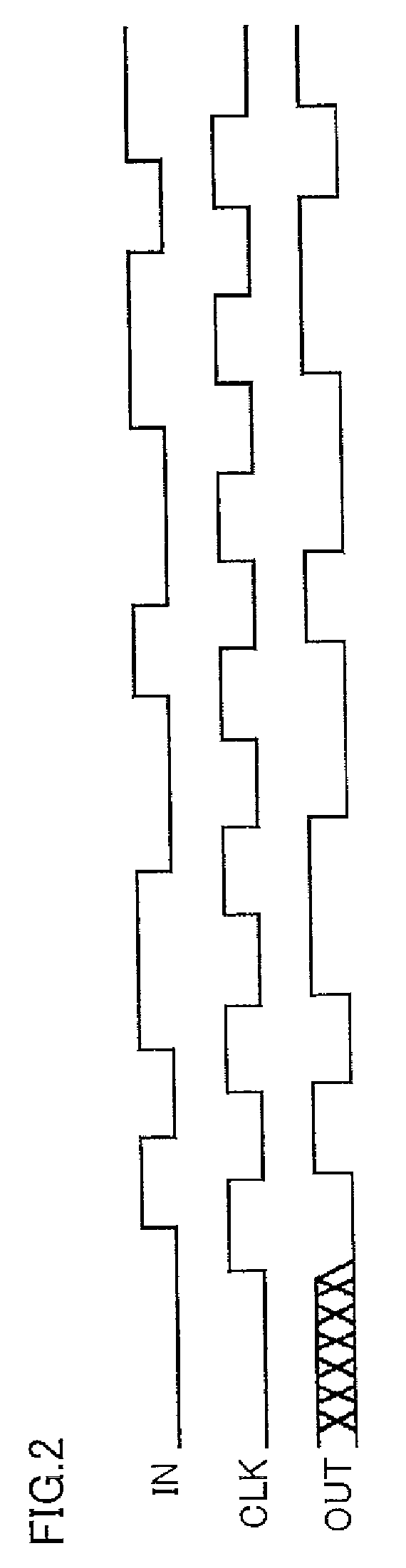

Data holding circuit and signal processing circuit

ActiveUS7622978B2Remove noiseAvoid low process precisionElectric pulse generatorSignal processing circuitsExclusive or

A data holding circuit is capable of latching an input signal at both a rising edge and a falling edge of a clock signal. Several flip-flops and exclusive OR circuits cooperate to achieve this function.

Owner:SHENZHEN TOREY MICROELECTRONIC TECH CO LTD

Process for wetly crushing and processing thick carbon black after pyrolysis of waste rubber

ActiveCN102240660BEliminate secondary pollutionSimple processSolid waste disposalGrain treatmentsDistillationWaste rubber

The invention discloses a process for wetly crushing and processing thick carbon black after pyrolysis of waste rubber, comprising the following steps that: industrial thick carbon black and water are filled in a mixed stirring tank and then enter a first-stage liquid crusher and a second-stage liquid crusher respectively; liquid carbon subjected to of the second-stage liquid crushing process enters a buffer stirring tank and then enters a third-stage liquid nano fine crushing system; the liquid carbon subjected to of the third-stage liquid crushing enters a distillation kettle; slurry, 70% of water content of which is evaporated, enters an activation level machine; activated granular wet carbon black enters a microwave dryer so as to be heated and dried in a microwave way; and after being dried, the carbon black is packaged for future use. The invention has the advantages of being simple in process and convenient for operation. The equipment used is the equipment in the prior art andonly needs to be assembled together. The process has high processing precision without leakage. Compared with the carbon black crushed dryly, the carbon black is finer and has higher additional value. By means of the process, the working environment is improved; the secondary pollution of the environment is thoroughly eliminated; the current industrial carbon black can be replaced by the processed fine regenerative carbon black; and resource and energy can be saved.

Owner:瑞新环境科技民权县有限公司

Plasma processing apparatus

ActiveUS10037868B2Avoid low process precisionIncrease productionElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerEngineering

Owner:HITACHI HIGH-TECH CORP

A kind of preparation method of full-color microdisplay device

ActiveCN108447965BRealize full color displayReduce difficultyIdentification meansSemiconductor devicesDisplay deviceEngineering

The invention relates to a fabrication method of a full-color micro display device. Single-color blue Micro LED microchips are only needed to be transferred onto a substrate by combining a nanoimprinting technology, red or green fluorescent material resin glue layers accurately cover the corresponding blue Micro LED microchips according to special arrangement by a patterning imprinting template which is prepared in advance, the red or green fluorescent material resin glue layers are simulated by the Micro LED microchips, the Micro LED microchips which are not coated with the fluorescent material resin glue layer are simulated, red, green and blue pixel points particularly arranged on surfaces of the microchips are obtained, namely, the full-color display of the Micro LED microchips can beachieved.

Owner:GUANGDONG POLY OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com